An Integrated HBIM Simulation Approach for Energy Retrofit of Historical Buildings Implemented in a Case Study of a Medieval Fortress in Italy

Abstract

1. Introduction

2. Methods

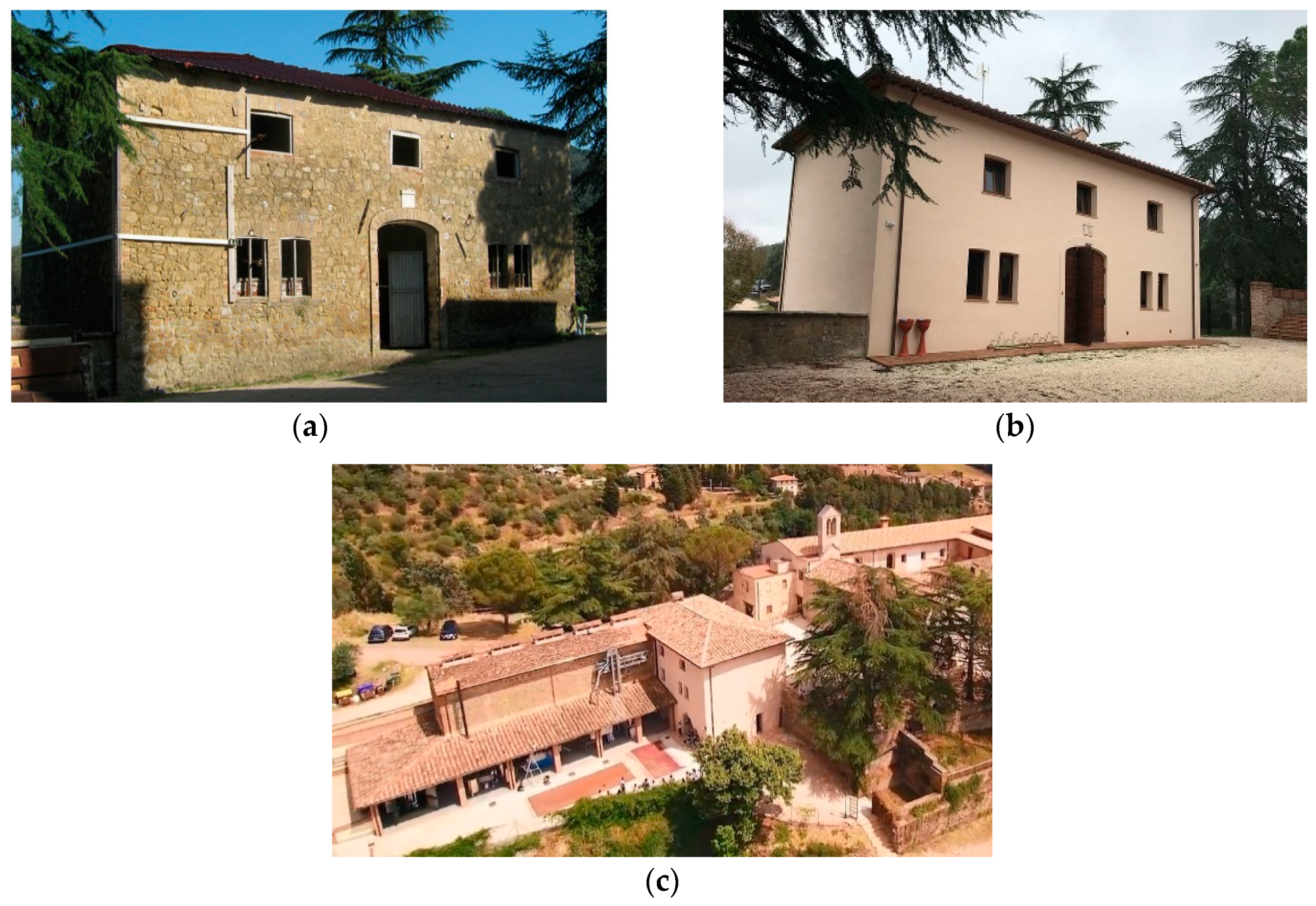

2.1. Case Study

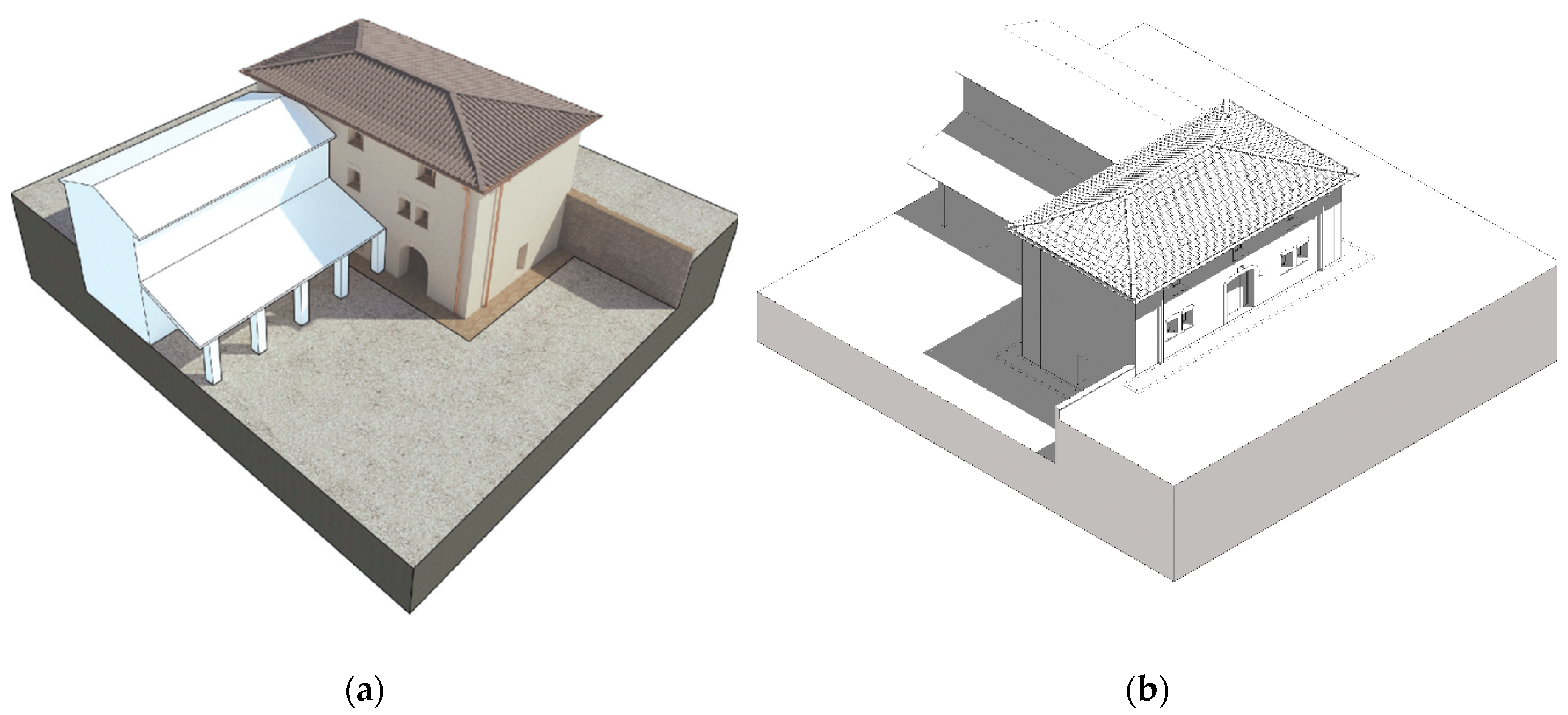

2.2. HBIM Model

- column;

- pavilion roof;

- roof clay bent tiles and tiles, that a modeled as a linear family to be arranged in lines on the roof;

- barrel vault;

- ancient wooden door;

- wooden frame with beams and joists for roof and floor.

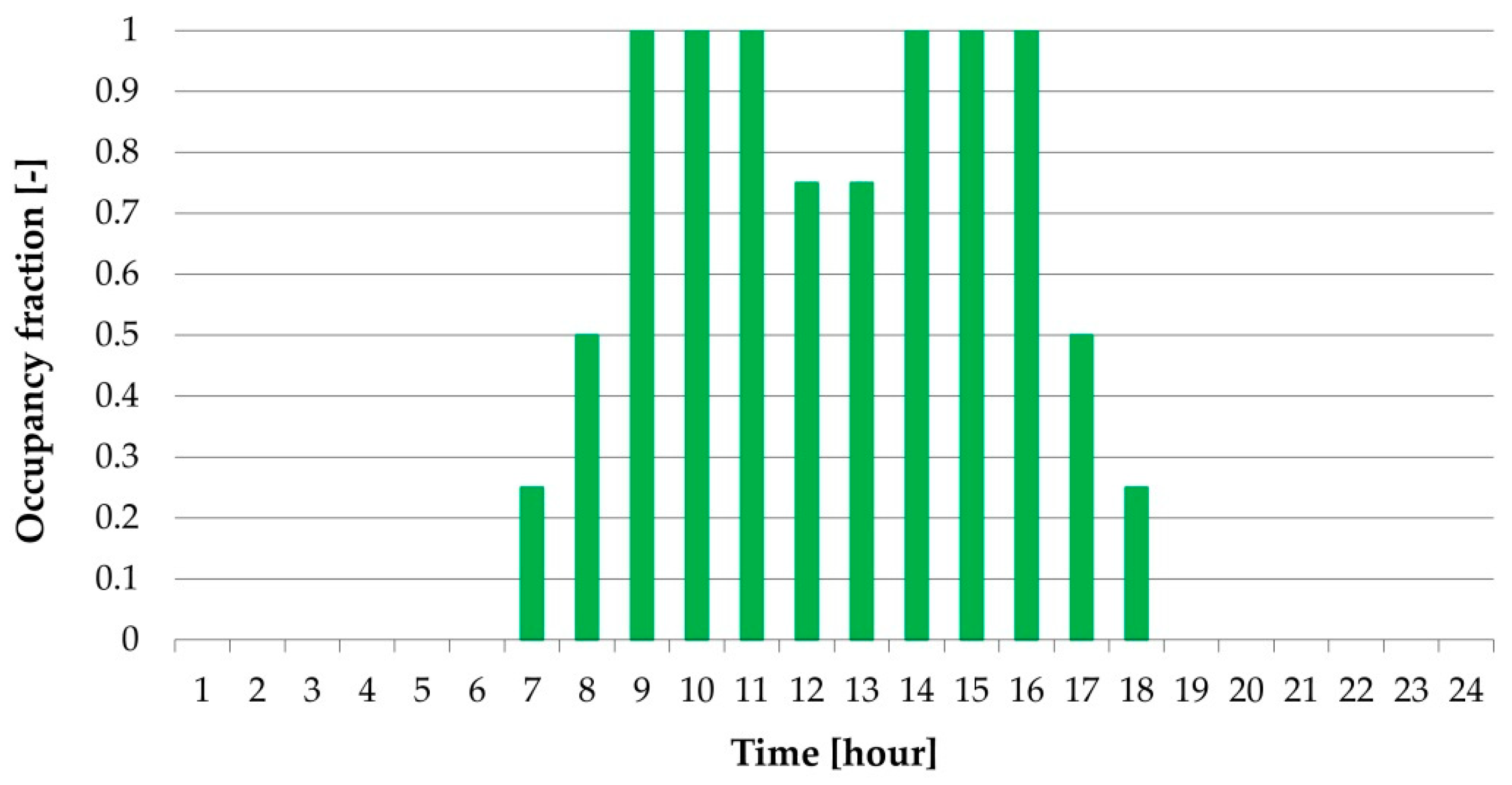

2.3. Building Thermal-Energy Model

- power density equal to 2 W/m2, representing the maximum achievable value;

- emitted radiant fraction equal to 0.10;

- schedule based on the occupancy schedule.

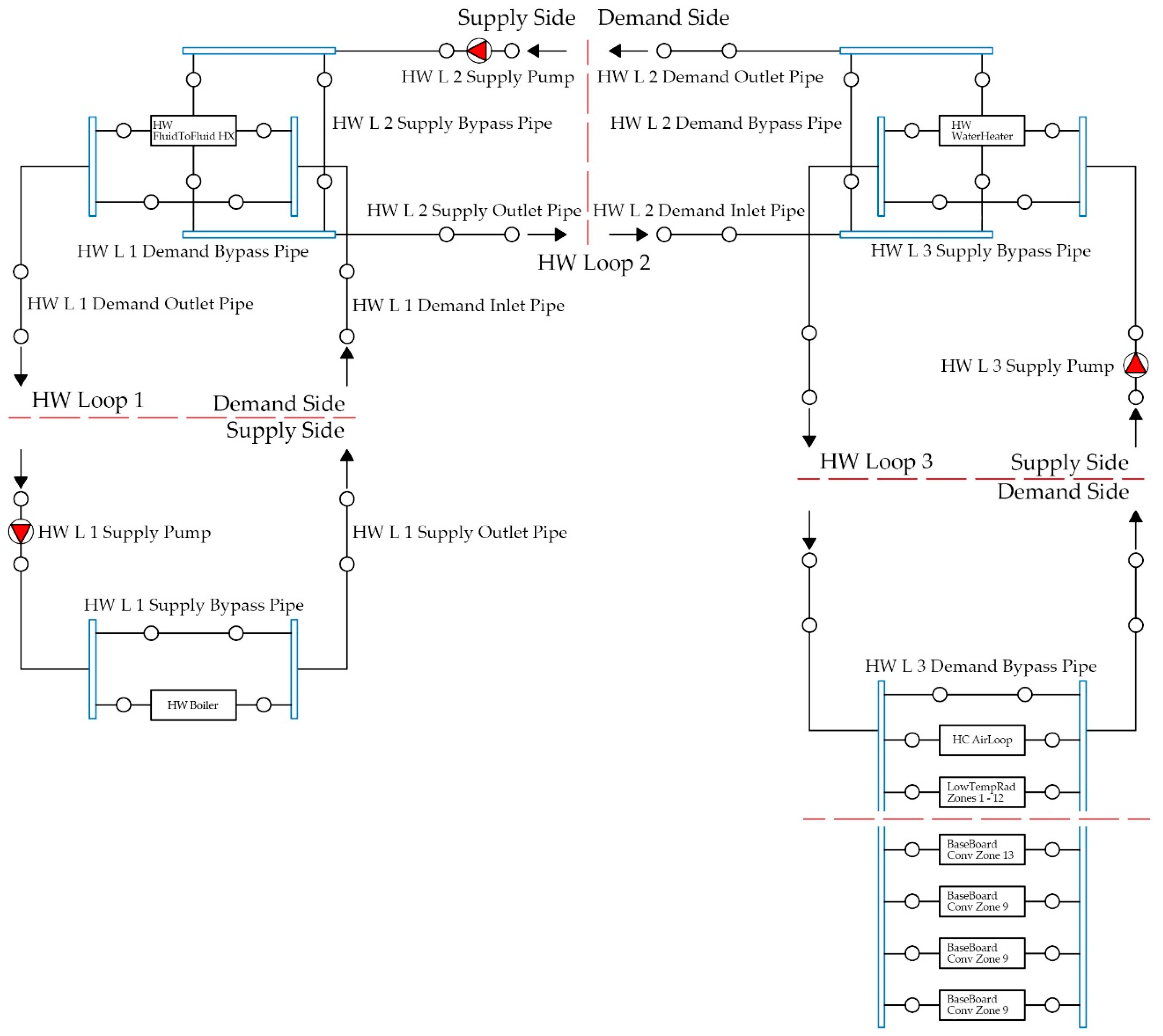

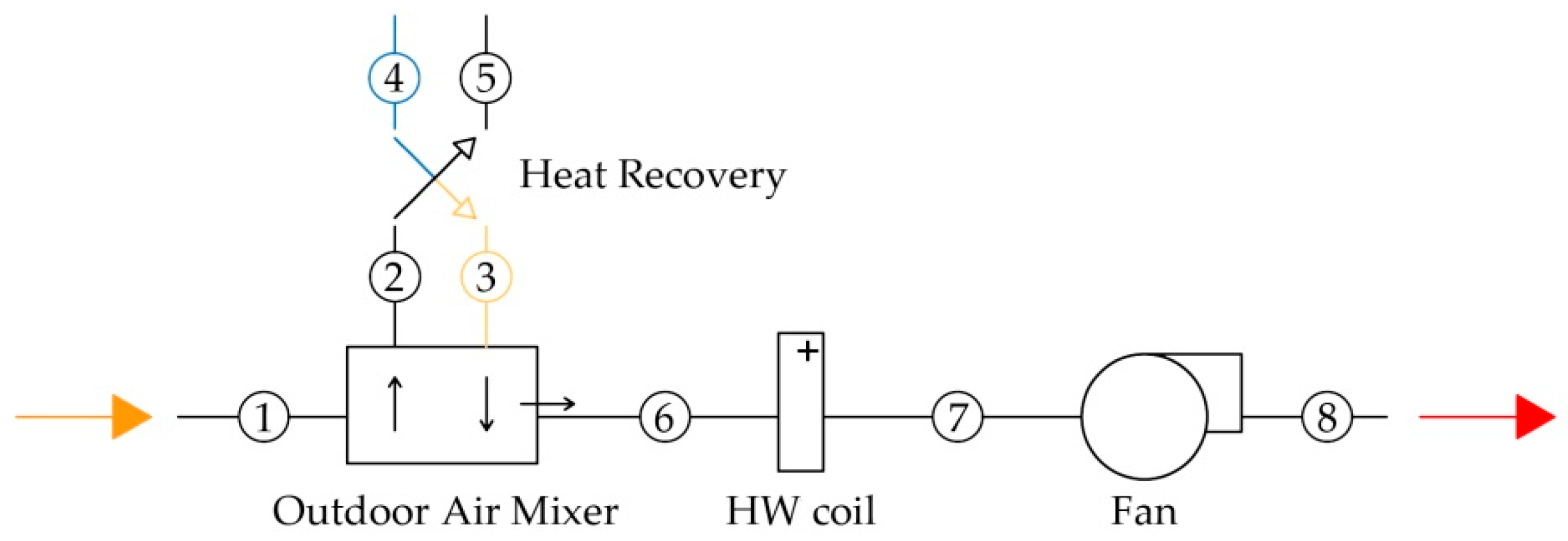

2.4. HVAC System Model

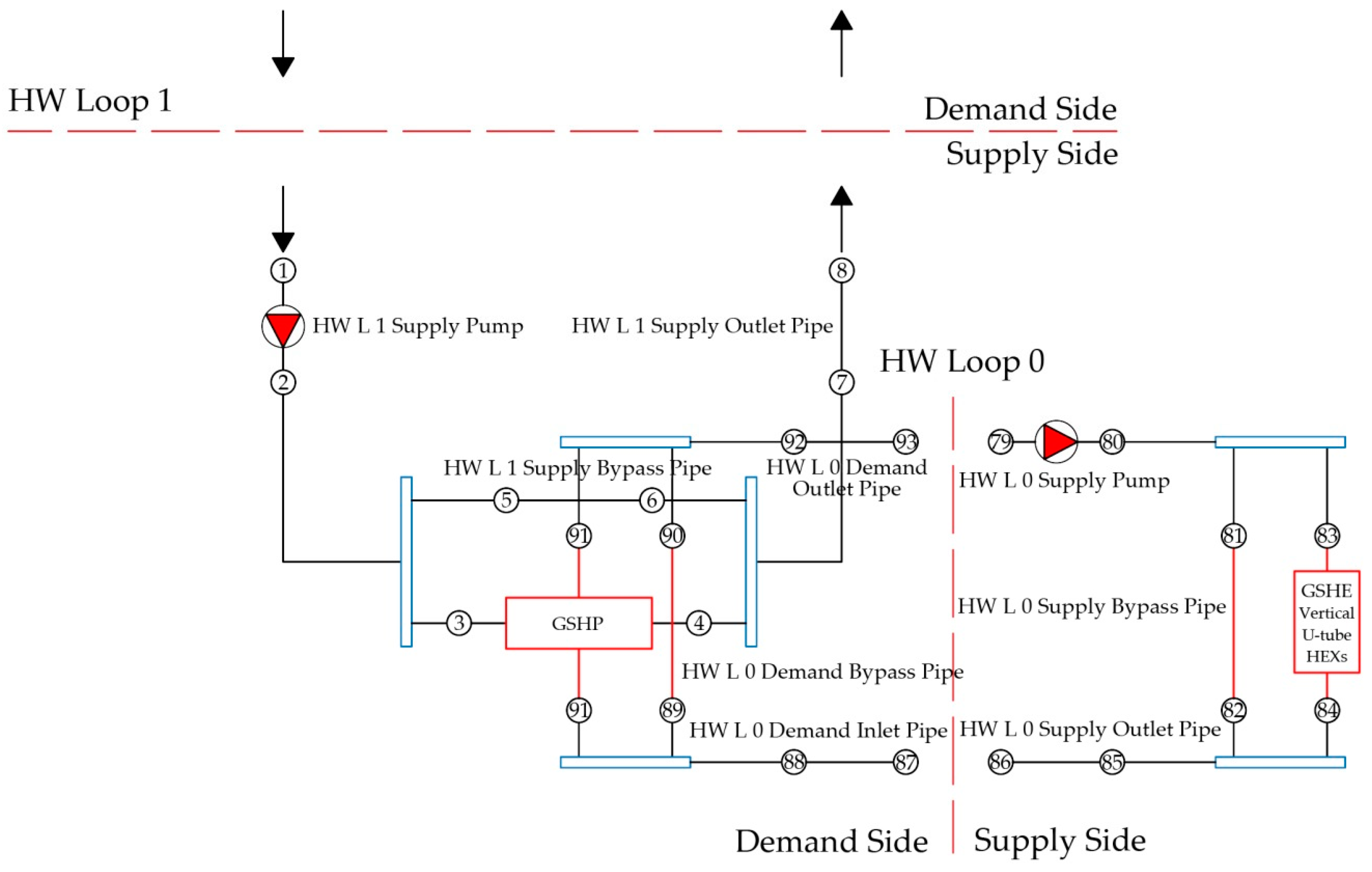

- Hot Water Loop 1: the loop on the heat generation side of the system with the gas boiler on the supply side and the plate heat exchanger on the demand side.

- Hot Water Loop 2: the intermediate loop between the generation side and the distribution side, where the plate heat exchanger provides the necessary heat to the water storage tank.

- Hot Water Loop 3: the final side of the system between the tank and the distribution to the various terminal units (radiant floors, wall radiators, and AHU heating coil).

- Hot Water Boiler: the gas boiler, which can be characterized in terms of efficiency curves and type of fuel used, e.g., natural gas in this case.

- Fluid-to-Fluid Heat Exchanger: type of heat exchanger that models a general heat exchange from fluid to fluid, whose heat transfer rate and efficiency are described in Equations (1) and (2), respectively:where is the mass flow rate, cp is the specific heat capacity, TSupLoop,in and TDmdLoop,in are the fluid temperatures entering the heat exchanger on the supply side and on the demand side of the loop, respectively, NTU is the Number of Transfer Units [44], and Rc is the flow thermal capacity ratio [44].

- Mixed Water Thermal Tank: water heater with only water storage function and, therefore, without auxiliary heater capacity. Due to the small volume, it is not affected by stratification phenomena and simulates a well-mixed water tank. The storage energy balance equation is as follows (Equation (3)):where ρ and cp are water density and specific heat, respectively, V is the tank volume, T is the temperature of the water tank, and qnet is the net heat transfer rate to the tank water.

- Low Temperature Radiant Variable Flow: represents the radiant floor when integrated as a tailored type of internal source within floor construction layers to calculate the relative conduction transfer function (CTF).

- Water Convective Baseboard: radiators installed in service rooms, which split the thermal power emitted into radiant and convective.

- Water Heating Coil: downstream heating coil in the AHU, equipped with a water controller to vary the flow of hot water depending on the thermal load.

- Air-to-Air Sensible Heat Exchanger: sensible heat recovery for ventilation system, characterized by an efficiency equal to 0.8 in design conditions.

2.5. Geothermal System Model

2.6. Model Validation

3. Results and Discussion

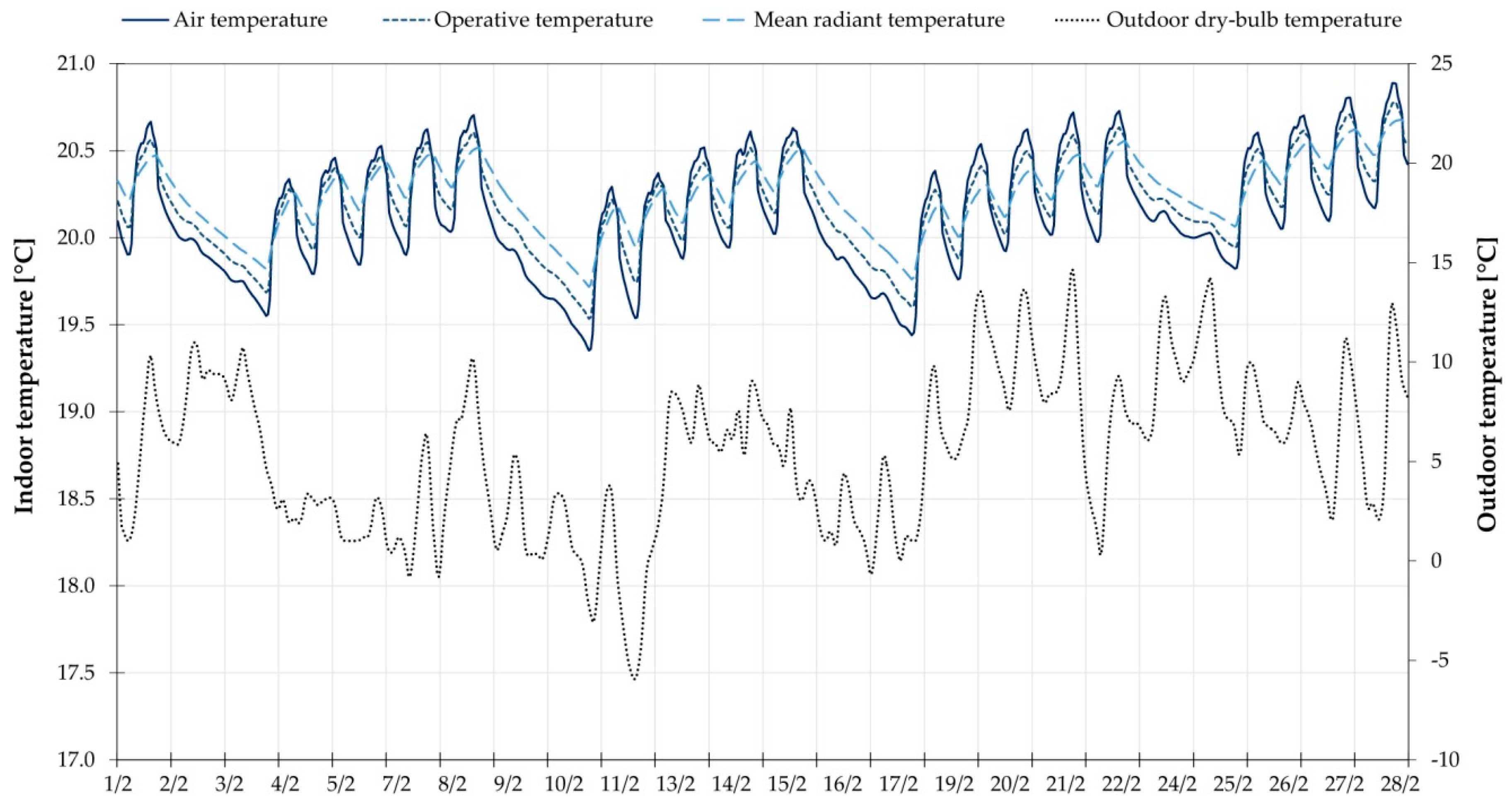

3.1. Building Envelope Performance Validation and Modelling

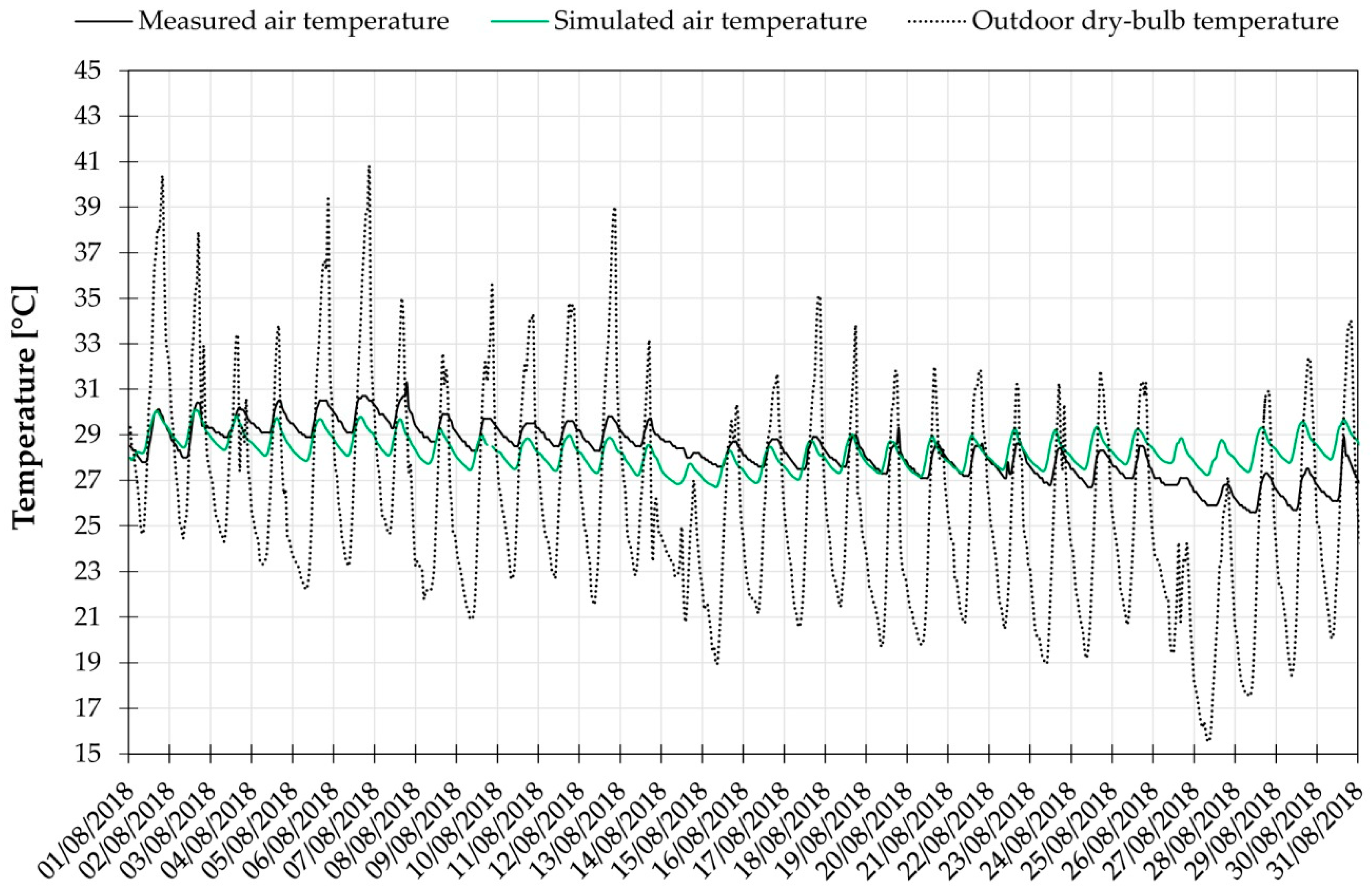

3.2. Building-System Model Validation

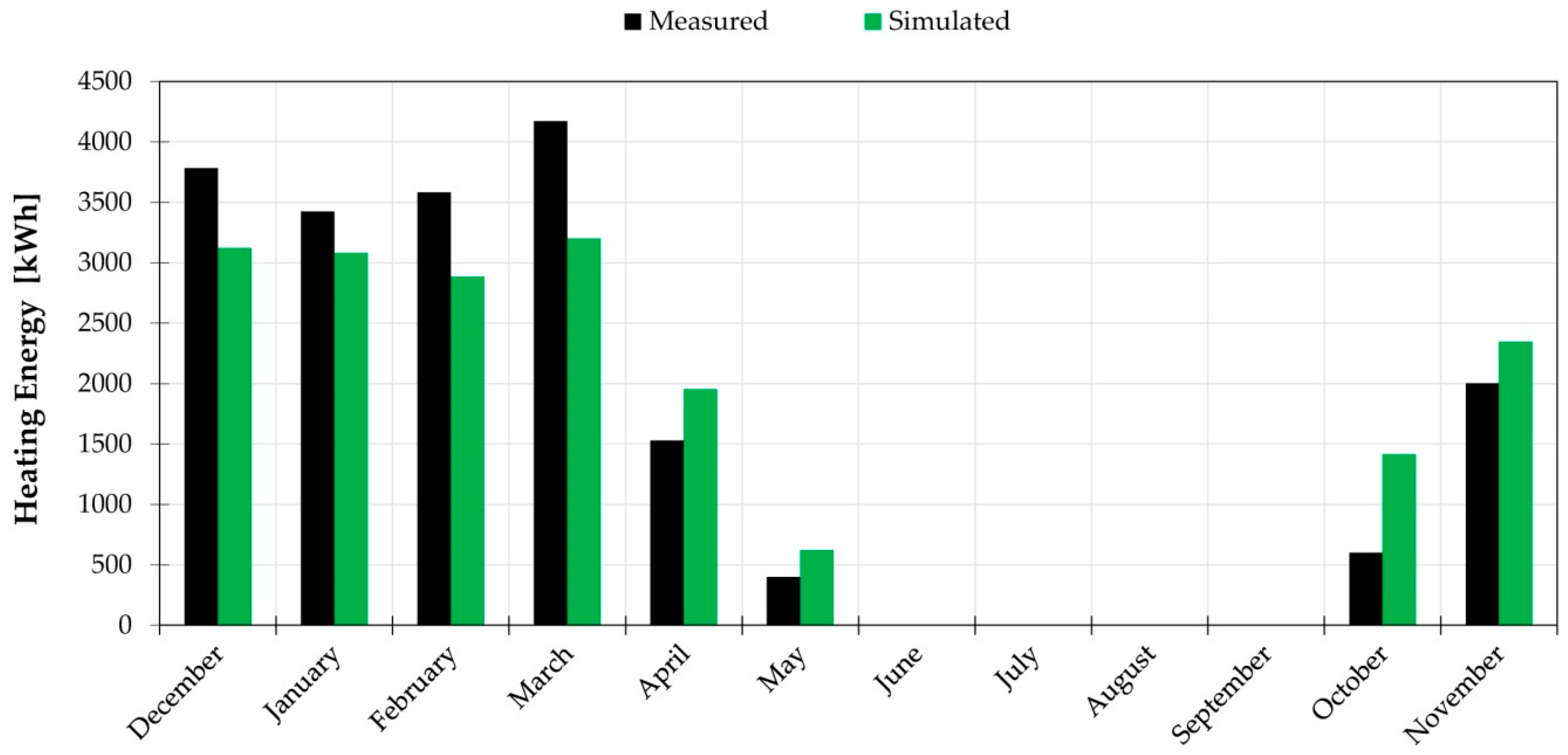

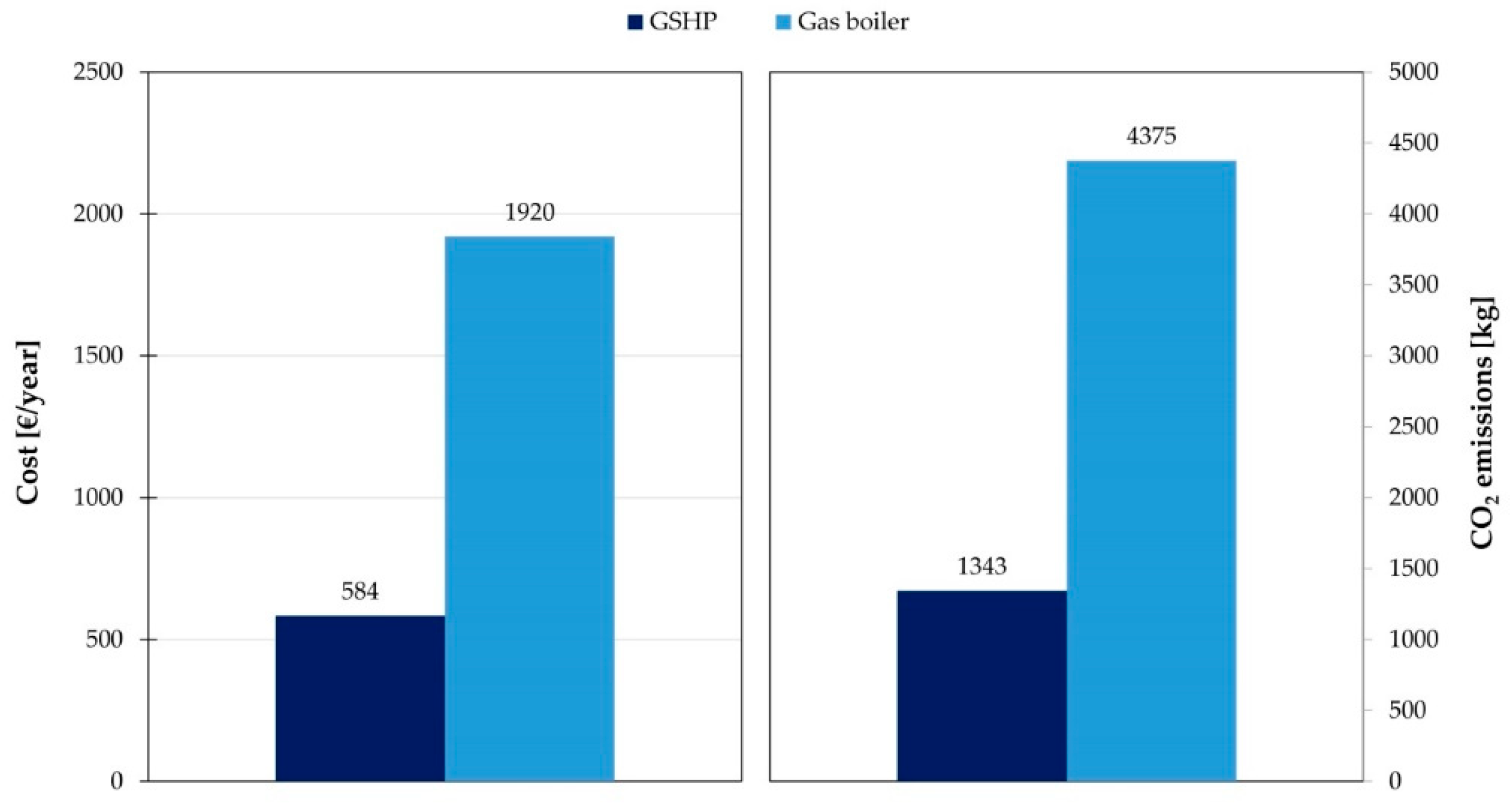

3.3. Building Energy Performance

4. Conclusions and Future Developments

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- H2020 GEOFIT Project. Available online: https://geofit-project.eu/ (accessed on 11 March 2020).

- Messervey, T.; Calderoni, M.; Font, A.; Borras, M.; Sterling, R.; Martin, D.; Lennard, Z. Introducing GEOFIT: Cost-Effective Enhanced Geothermal Systems for Energy Efficient Building Retrofitting. Proceedings 2018, 2, 557. [Google Scholar] [CrossRef]

- Romanelli, J.; Di Grazia, M.; Piselli, C.; Pisello, A.L.; Cotana, F. Environmental sustainability and Energy Efficiency in Historical Buildings: GeoFit Project Implementation in the Case Study of a medieval fortress in Perugia. In Proceedings of the Building Simulation 2019: 16th Conference of IBPSA, Rome, Italy, 2–4 September 2019; Corrado, V., Fabrizio, E., Gasparella, A., Patuzzi, F., Eds.; International Building Performance Association (IBPSA): Rome, Italy, 2019; pp. 286–292. [Google Scholar]

- Mazzola, E.; Mora, T.D.; Peron, F.; Romagnoni, P. An integrated energy and environmental audit process for historic buildings. Energies 2019, 12, 3940. [Google Scholar] [CrossRef]

- Rosso, F.; Golasi, I.; Castaldo, V.L.; Piselli, C.; Pisello, A.L.; Salata, F.; Ferrero, M.; Cotana, F.; de Lieto Vollaro, A. On the impact of innovative materials on outdoor thermal comfort of pedestrians in historical urban canyons. Renew. Energy 2018, 118, 825–839. [Google Scholar] [CrossRef]

- Pisello, A.L. Thermal-energy analysis of roof cool clay tiles for application in historic buildings and cities. Sustain. Cities Soc. 2015, 19, 271–280. [Google Scholar] [CrossRef]

- Pisello, A.L.; Petrozzi, A.; Castaldo, V.L.; Cotana, F. On an innovative integrated technique for energy refurbishment of historical buildings: Thermal-energy, economic and environmental analysis of a case study. Appl. Energy 2016, 162, 1313–1322. [Google Scholar] [CrossRef]

- Emmi, G.; Zarrella, A.; De Carli, M.; Moretto, S.; Galgaro, A.; Cultrera, M.; Di Tuccio, M.; Bernardi, A. Ground source heat pump systems in historical buildings: Two Italian case studies. Energy Procedia 2017, 133, 183–194. [Google Scholar] [CrossRef]

- Carnieletto, L.; Badenes, B.; Belliardi, M.; Bernardi, A.; Graci, S.; Emmi, G.; Urchueguía, J.F.; Zarrella, A.; DI Bella, A.; Dalla Santa, G.; et al. A European database of building energy profiles to support the design of ground source heat pumps. Energies 2019, 12, 2496. [Google Scholar] [CrossRef]

- Schibuola, L.; Tambani, C.; Zarrella, A.; Scarpa, M. Ground source heat pump performance in case of high humidity soil and yearly balanced heat transfer. Energy Convers. Manag. 2013, 76, 956–970. [Google Scholar] [CrossRef]

- Schibuola, L.; Scarpa, M. Ground source heat pumps in high humidity soils: An experimental analysis. Appl. Therm. Eng. 2016, 99, 80–91. [Google Scholar] [CrossRef]

- Moretti, E.; Bonamente, E.; Buratti, C.; Cotana, F. Development of innovative heating and cooling systems using renewable energy sources for non-residential buildings. Energies 2013, 6, 5114–5129. [Google Scholar] [CrossRef]

- Bonamente, E.; Moretti, E.; Buratti, C.; Cotana, F. Design and monitoring of an innovative geothermal system including an underground heat-storage tank. Int. J. Green Energy 2016, 13, 822–830. [Google Scholar] [CrossRef]

- Galgaro, A.; Santa, G.D.; De Carli, M.; Emmi, G.; Zarrella, A.; Mueller, J.; Bertermann, D.; Castelruiz, A.; Noye, S.; Perego, R.; et al. New tools to support the designing of efficient and reliable ground source heat exchangers: The Cheap-GSHPs databases and maps. Adv. Geosci. 2019, 49, 47–55. [Google Scholar] [CrossRef]

- Bobbo, S.; Fedele, L.; Curcio, M.; Bet, A.; De Carli, M.; Emmi, G.; Poletto, F.; Tarabotti, A.; Mendrinos, D.; Mezzasalma, G.; et al. Energetic and exergetic analysis of low global warming potential refrigerants as substitutes for R410A in ground source heat pumps. Energies 2019, 12, 3538. [Google Scholar] [CrossRef]

- Ferrari, F.; Sasso, D.F. Integration between GBC Historic Building® and BIM: The methodological innovation for conservation project workflow. DISEGNARECON 2016, 9, 6.1–6.5. [Google Scholar]

- Shirowzhan, S.; Sepasgozar, S.M.E.; Edwards, D.J.; Li, H.; Wang, C. BIM compatibility and its differentiation with interoperability challenges as an innovation factor. Autom. Constr. 2020, 112, 103086. [Google Scholar] [CrossRef]

- Patiño-Cambeiro, F.; Bastos, G.; Armesto, J.; Patiño-Barbeito, F. Multidisciplinary energy assessment of tertiary buildings: Automated geomatic inspection, building information modeling reconstruction and building performance simulation. Energies 2017, 10, 1032. [Google Scholar] [CrossRef]

- Najjar, M.K.; Tam, V.W.Y.; Di Gregorio, L.T.; Evangelista, A.C.J.; Hammad, A.W.A.; Haddad, A. Integrating parametric analysis with building information modeling to improve energy performance of construction projects. Energies 2019, 12, 1515. [Google Scholar] [CrossRef]

- Torregrosa-Jaime, B.; González, B.; Martínez, P.J.; Payá-Ballester, G. Analysis of the operation of an aerothermal heat pump in a residential building using building information modelling. Energies 2018, 11, 1642. [Google Scholar] [CrossRef]

- Arayici, Y.; Counsell, J.; Mahdjoubi, L.; Nagy, G.; Hawas, S.; Dewidar, K. Heritage Building Information Modelling; Routledge: London, UK, 2017; ISBN 9781317239765. [Google Scholar]

- Bruno, N.; Roncella, R. HBIM for conservation: A new proposal for information modeling. Remote Sens. 2019, 11, 1751. [Google Scholar] [CrossRef]

- Angulo-Fornos, R.; Castellano-Román, M. HBIM as support of preventive conservation actions in heritage architecture. Experience of the renaissance quadrant facade of the cathedral of seville. Appl. Sci. 2020, 10, 2428. [Google Scholar] [CrossRef]

- Brumana, R.; Oreni, D.; Barazzetti, L.; Cuca, B.; Previtali, M.; Banfi, F. Survey and scan to BIM model for the knowledge of built heritage and the management of conservation activities. In Digital Transformation of the Design, Construction and Management Processes of the Built Environment. Research for Development; Daniotti, B., Gianinetto, M., Della Torre, S., Eds.; Springer: Cham, Switzerland, 2020; pp. 391–400. [Google Scholar]

- Osello, A.; Lucibello, G.; Morgagni, F. HBIM and virtual tools: A new chance to preserve architectural heritage. Buildings 2018, 8, 12. [Google Scholar] [CrossRef]

- Martínez-Carricondo, P.; Carvajal-Ramírez, F.; Yero-Paneque, L.; Agüera-Vega, F. Combination of nadiral and oblique UAV photogrammetry and HBIM for the virtual reconstruction of cultural heritage. Case study of Cortijo del Fraile in Níjar, Almería (Spain). Build. Res. Inf. 2020, 48, 140–159. [Google Scholar] [CrossRef]

- Colucci, E.; de Ruvo, V.; Lingua, A.; Matrone, F.; Rizzo, G. HBIM-GIS integration: From IFC to cityGML standard for damaged cultural heritage in a multiscale 3D GIS. Appl. Sci. 2020, 10, 1356. [Google Scholar] [CrossRef]

- Previtali, M.; Brumana, R.; Stanga, C.; Banfi, F. An ontology-based representation of vaulted system for HBIM. Appl. Sci. 2020, 10, 1377. [Google Scholar] [CrossRef]

- Marín Miranda, M.J.; Chorro Domínguez, F.J.; Sánchez-Fernández, M.; Cortés-Pérez, J.P. HBIM. Parametric Families from Point Clouds in Heritage Elements. In Advances in Design Engineering. INGEGRAF 2019. Lecture Notes in Mechanical Engineering; Cavas-Martínez, F., Sanz-Adan, F., Morer Camo, P., Lostado Lorza, R., Santamaría Peña, J., Eds.; Springer: Cham, Switzerland, 2020; pp. 518–526. [Google Scholar]

- Palomar, I.J.; García Valldecabres, J.L.; Tzortzopoulos, P.; Pellicer, E. An online platform to unify and synchronise heritage architecture information. Autom. Constr. 2020, 110, 103008. [Google Scholar] [CrossRef]

- Bolognesi, C.; Fiorillo, F.; Aiello, D. Three renaissance vaults in Milan. Cultural heritage and digital workflows for BIM modelling. In Advances in Additive Manufacturing, Modeling Systems and 3D Prototyping. AHFE 2019. Advances in Intelligent Systems and Computing; Di Nicolantonio, M., Rossi, E., Alexander, T., Eds.; Springer: Cham, Switzerland, 2020; Volume 975, pp. 202–211. [Google Scholar]

- Gigliarelli, E.; Calcerano, F.; Calvano, M.; Ruperto, F.; Sacco, M.; Cessari, L. Integrated numerical analysis and building information modeling for cultural heritage. In Proceedings of the Building Simulation Applications, Bolzano, Italy, 8–10 February 2017; Volume 2017, pp. 105–112. [Google Scholar]

- Green Building XML (gbXML). Available online: http://www.gbxml.org/ (accessed on 2 March 2020).

- Boarin, P.; Guglielmino, D.; Pisello, A.L.; Cotana, F. Sustainability assessment of historic buildings: Lesson learnt from an Italian case study through LEED® rating system. Energy Procedia 2014, 61, 1029–1032. [Google Scholar] [CrossRef]

- Green Building Council (GBC) Historic Building (HB) Protocol. Available online: http://www.gbcitalia.org/historic-building (accessed on 2 March 2020).

- Castaldo, V.L.; Pisello, A.L.; Boarin, P.; Petrozzi, A.; Cotana, F. The experience of international sustainability protocols for retrofitting historical buildings in Italy. Buildings 2017, 7, 52. [Google Scholar] [CrossRef]

- Wing, E. Autodesk Revit 2017 for Architecture, 1st ed.; Sybex, Wiley: Hoboken, NJ, USA, 2016; pp. 1–593. [Google Scholar]

- Crawley, D.B.; Lawrie, L.K.; Winkelmann, F.C.; Buhl, W.F.; Huang, Y.J.; Pedersen, C.O.; Strand, R.K.; Liesen, R.J.; Fisher, D.E.; Witte, M.J.; et al. EnergyPlus: Creating a new-generation building energy simulation program. Energy Build. 2001, 33, 319–331. [Google Scholar] [CrossRef]

- DesignBuilder Software. Available online: https://www.designbuilder.co.uk/ (accessed on 18 March 2020).

- ASHRAE. ASHRAE Handbook—Fundamentals. In ASHRAE Handbook Online; Owen, Mark S., Ed.; ASHRAE: Atlanta, GA, USA, 2017. [Google Scholar]

- EN 15251:2007—Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics; European Committee for Standardization: Bruxelles, Belgium, 2007.

- Pisello, A.L.; Piselli, C.; Cotana, F. Influence of human behavior on cool roof effect for summer cooling. Build. Environ. 2015, 88, 116–128. [Google Scholar] [CrossRef]

- U.S. Department of Energy (DoE). EnergyPlus Plant Application Guide; U.S. Department of Energy: Washington, DC, USA, 2018; Volume 99.

- U.S. Department of Energy (DoE). EnergyPlus Version 8.9.0 Engineering Reference; U.S. Department of Energy: Washington, DC, USA, 2018; Volume 1716.

- Hamilton, J.F.; Miller, J.L. A simulation program for modeling an air-conditioning system. ASHRAE Trans. 1990, 96, 213–221. [Google Scholar]

- Jin, H.; Spitler, J.D. A Parameter Estimation Based Model of Water-to-Water Heat Pumps for Use in Energy Calculation Programs. ASHRAE Trans. 2002, 108, 3–17. [Google Scholar]

- Tang, C.C. Modeling Packaged Heat Pumps in a Quasi-Steady State Energy Simulation Program. Ph.D. Thesis, Oklahoma State University, Stillwater, OK, USA, 2005. [Google Scholar]

- Fisher, D.E.; Rees, S.J. Modeling ground source heat pump systems in a building energy simulation program (Energyplus). In Proceedings of the BS2005: Building Simulation, Montréal, QC, Canada, 15–18 August 2005; pp. 311–318. [Google Scholar]

- Nelder, J.A.; Mead, R. A Simplex Method for Function Minimization. Comput. J. 1965, 7, 308–313. [Google Scholar] [CrossRef]

- Kasuda, T.; Achenboch, P.R. Earth Temperatures and Thermal Diffusivity at Selected Stations in the United States; U.S. Department of Commerce, National Bureau of Standards: Washington, DC, USA, 1965.

- U.S. Department of Energy’s (DOE). Building Technologies Office (BTO) EnergyPlus—Weather Data. Available online: https://energyplus.net/weather (accessed on 18 March 2020).

- Eskilson, P. Thermal Analysis of Heat Extraction Boreholes. Ph.D. Thesis, University of Lund, Lund, Sweden, 1987. [Google Scholar]

- Yavuzturk, C.; Spitler, J.D. A Short Time Step Response Factor Model for Vertical Ground Loop Heat Exchangers. ASHRAE Trans. 1999, 105, 475–485. [Google Scholar]

- Yavuzturk, C.; Spitler, J.D. Field Validation of a Short Time Step Model for Vertical Ground-Loop Heat Exchangers. ASHRAE Trans. 2001, 107, 617–625. [Google Scholar]

- ASHRAE. Guideline 14-2014 for Measurement of Energy, Demand, and Water Savings; ASHRAE Standards Committee: Atlanta, GA, USA, 2014. [Google Scholar]

| Material | Thickness (m) | Solar Transmittance (-) | Front Solar Reflectance (-) | Back Solar Reflectance (-) | Front Thermal Emissivity (-) | Back Thermal Emissivity (-) | Conductivity (W/m K) |

|---|---|---|---|---|---|---|---|

| External glass | 0.006 | 0.600 | 0.170 | 0.220 | 0.840 | 0.100 | 0.900 |

| Internal glass | 0.006 | 0.775 | 0.071 | 0.071 | 0.840 | 0.840 | 0.900 |

| Envelope Component | Layers | Thickness (m) | Thermal Transmittance (W/m2 K) |

|---|---|---|---|

| External wall | outdoor | 0.36 | |

| Weber cote action coating | 0.006 | ||

| Cork panel | 0.100 | ||

| Weber lime plaster | 0.013 | ||

| Stone masonry | 0.390 * | ||

| Webertherm insulating panel | 0.030 | ||

| indoor | |||

| Wall against the ground | outdoor | 0.70 | |

| Lime mortar | 0.010 | ||

| Stone masonry | 0.740 | ||

| Lime mortar | 0.013 | ||

| Cork panel | 0.040 | ||

| Webertherm insulating panel | 0.030 | ||

| indoor | |||

| Ground floor | outdoor | 0.20 | |

| Concrete slab | 0.100 | ||

| Underfloor air cavity | 0.450 | ||

| Reinforced concrete | 0.050 | ||

| LEKA screed | 0.120 | ||

| Lime mortar | 0.300 | ||

| Concrete slab | 0.050 | ||

| Insulation radiant floor | 0.040 | ||

| MR18 metal screed | 0.060 | ||

| Ceramic floor tiles | 0.014 | ||

| indoor | |||

| Sloped roof | outdoor | 0.26 | |

| Roof clay tiles | 0.030 | ||

| OSB board | 0.012 | ||

| Wood fiber insulation | 0.140 | ||

| Clay tiles | 0.040 | ||

| Wood beams | 0.120 | ||

| indoor |

| Coefficient | Value (-) |

|---|---|

| Heating Capacity Coefficient 1 (C1) | −3.33491153 |

| Heating Capacity Coefficient 2 (C2) | −0.51451946 |

| Heating Capacity Coefficient 3 (C3) | 4.51592706 |

| Heating Capacity Coefficient 4 (C4) | 0.01797107 |

| Heating Capacity Coefficient 5 (C5) | 0.15579766 |

| Heating Compressor Power Coefficient 1 (D1) | −8.93121751 |

| Heating Compressor Power Coefficient 2 (D2) | 8.57035762 |

| Heating Compressor Power Coefficient 3 (D3) | 1.29660976 |

| Heating Compressor Power Coefficient 4 (D4) | −0.21629222 |

| Heating Compressor Power Coefficient 5 (D5) | 0.03386238 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piselli, C.; Romanelli, J.; Di Grazia, M.; Gavagni, A.; Moretti, E.; Nicolini, A.; Cotana, F.; Strangis, F.; Witte, H.J.L.; Pisello, A.L. An Integrated HBIM Simulation Approach for Energy Retrofit of Historical Buildings Implemented in a Case Study of a Medieval Fortress in Italy. Energies 2020, 13, 2601. https://doi.org/10.3390/en13102601

Piselli C, Romanelli J, Di Grazia M, Gavagni A, Moretti E, Nicolini A, Cotana F, Strangis F, Witte HJL, Pisello AL. An Integrated HBIM Simulation Approach for Energy Retrofit of Historical Buildings Implemented in a Case Study of a Medieval Fortress in Italy. Energies. 2020; 13(10):2601. https://doi.org/10.3390/en13102601

Chicago/Turabian StylePiselli, Cristina, Jessica Romanelli, Matteo Di Grazia, Augusto Gavagni, Elisa Moretti, Andrea Nicolini, Franco Cotana, Francesco Strangis, Henk J. L. Witte, and Anna Laura Pisello. 2020. "An Integrated HBIM Simulation Approach for Energy Retrofit of Historical Buildings Implemented in a Case Study of a Medieval Fortress in Italy" Energies 13, no. 10: 2601. https://doi.org/10.3390/en13102601

APA StylePiselli, C., Romanelli, J., Di Grazia, M., Gavagni, A., Moretti, E., Nicolini, A., Cotana, F., Strangis, F., Witte, H. J. L., & Pisello, A. L. (2020). An Integrated HBIM Simulation Approach for Energy Retrofit of Historical Buildings Implemented in a Case Study of a Medieval Fortress in Italy. Energies, 13(10), 2601. https://doi.org/10.3390/en13102601