Inspection of PN, CO2, and Regulated Gaseous Emissions Characteristics from a GDI Vehicle under Various Real-World Vehicle Test Modes

Abstract

1. Introduction

2. Experimental Details

2.1. Test Vehicle and Fuel

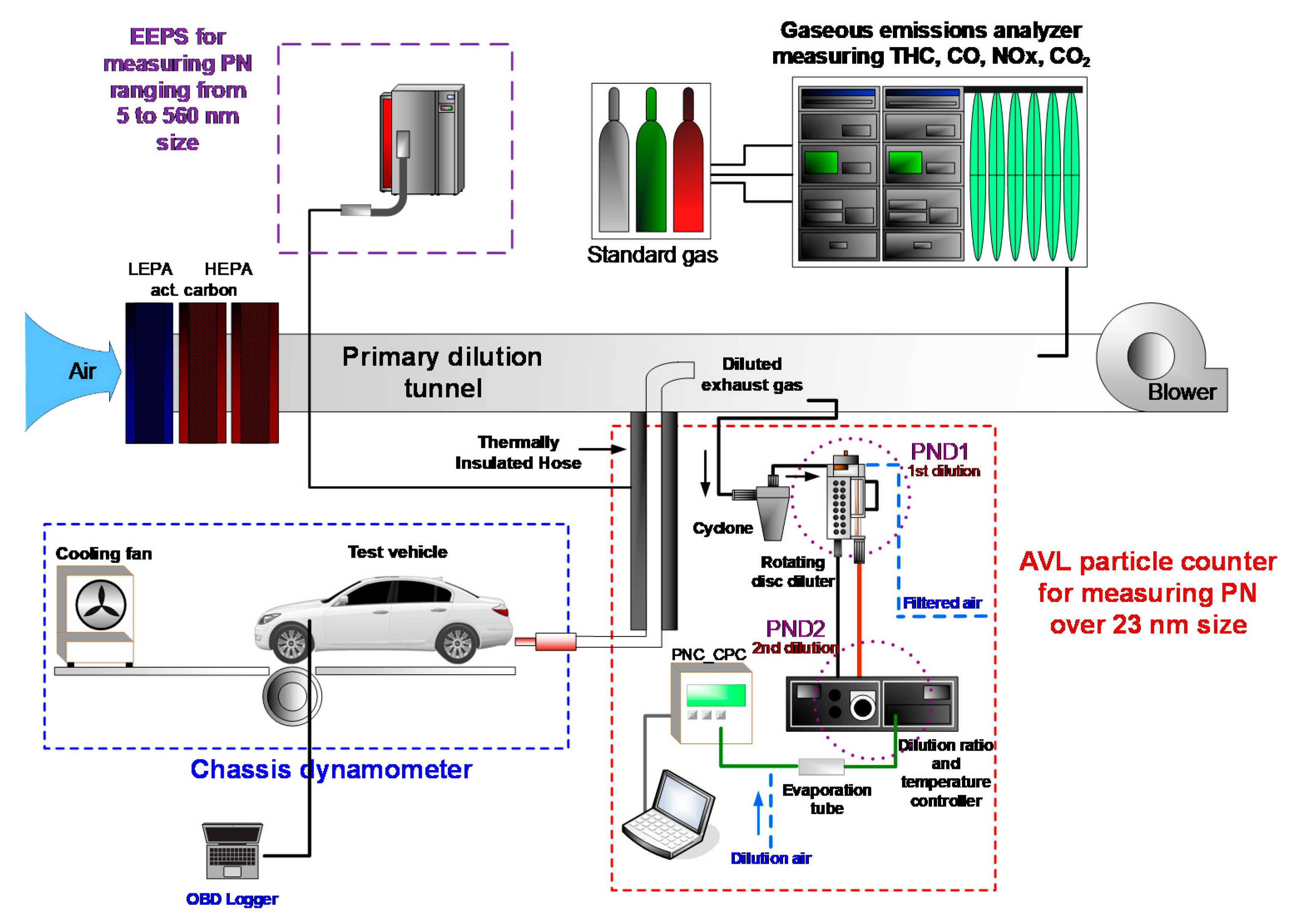

2.2. Experimental Apparatus

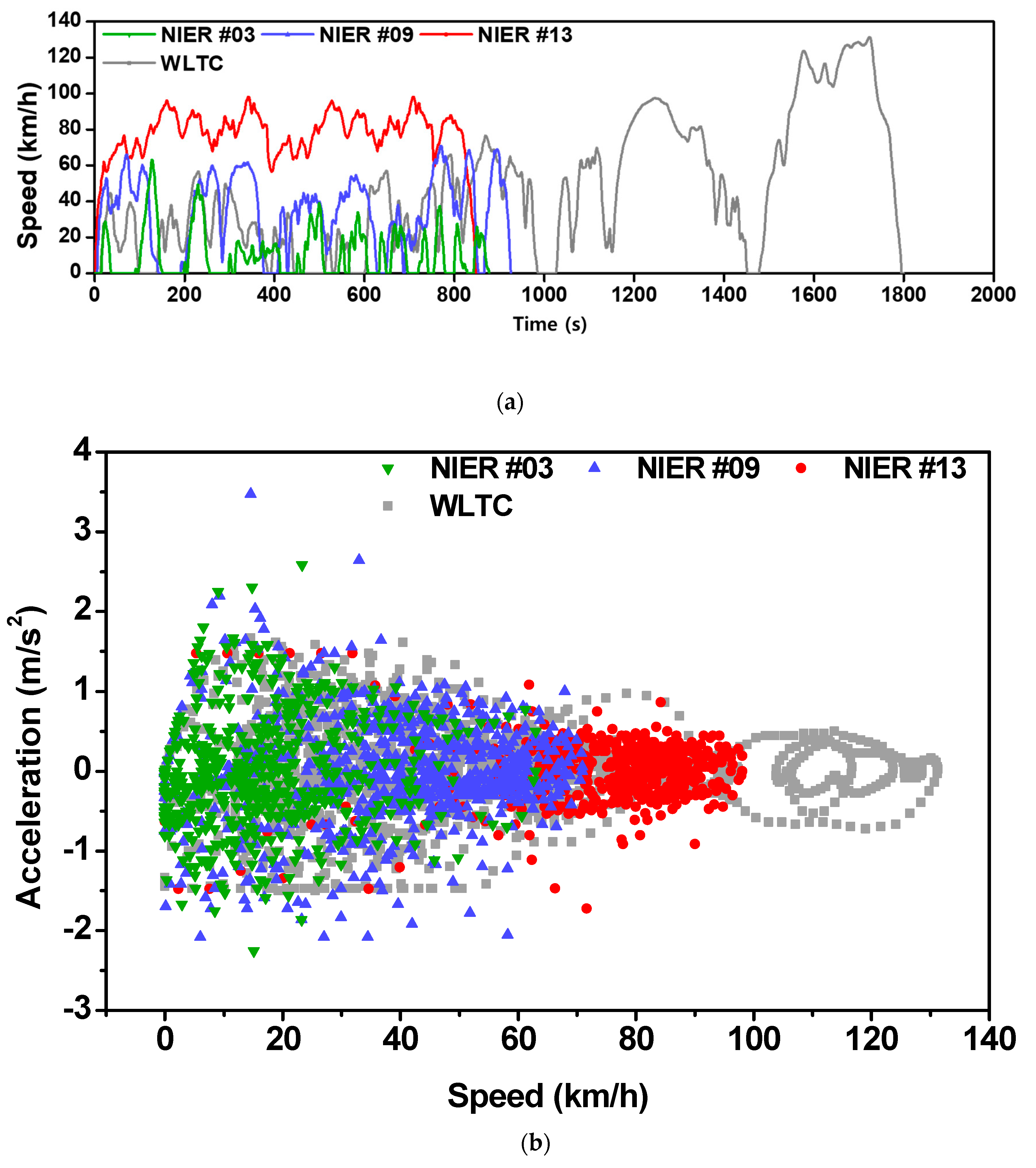

2.3. Test Cycles and Conditions

3. Results and Discussions

3.1. Engine Operating Parameters and Regulated Gaseous Emissions

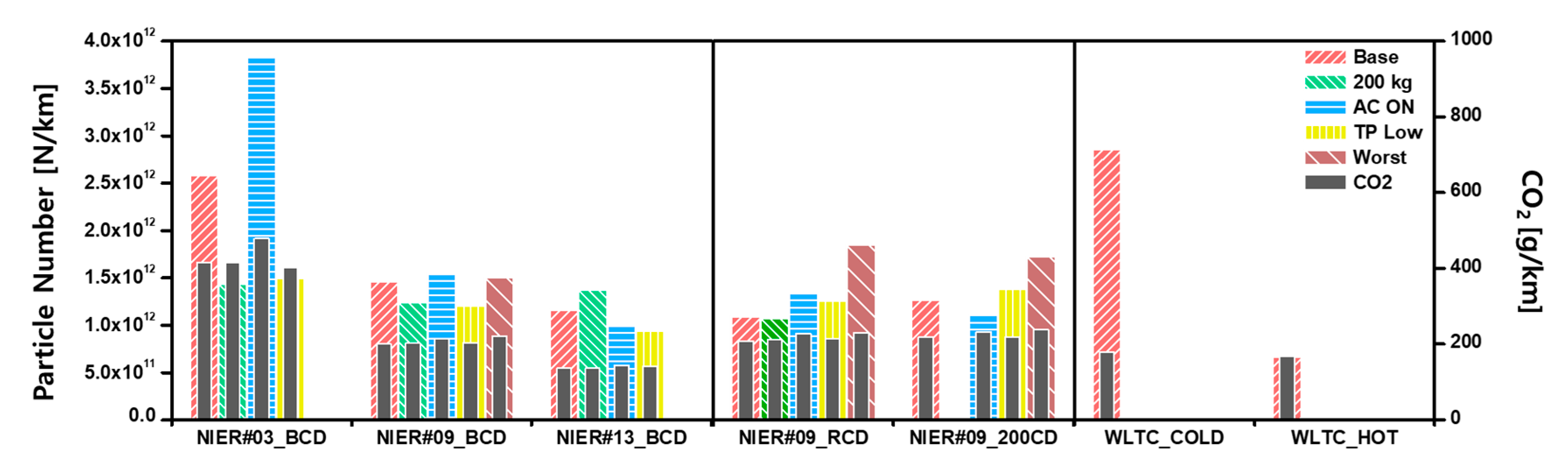

3.2. CO2 and PN Emission Results

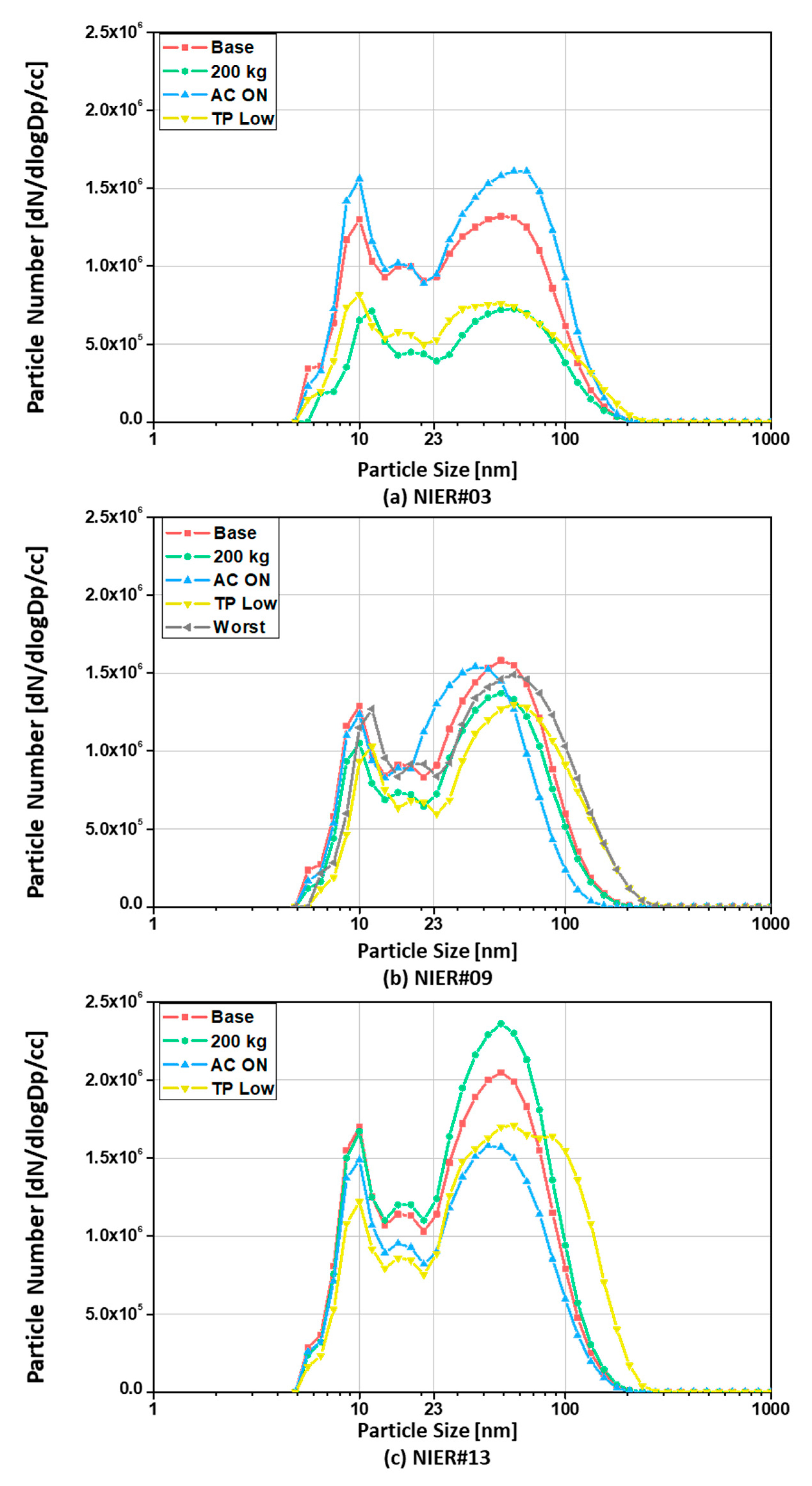

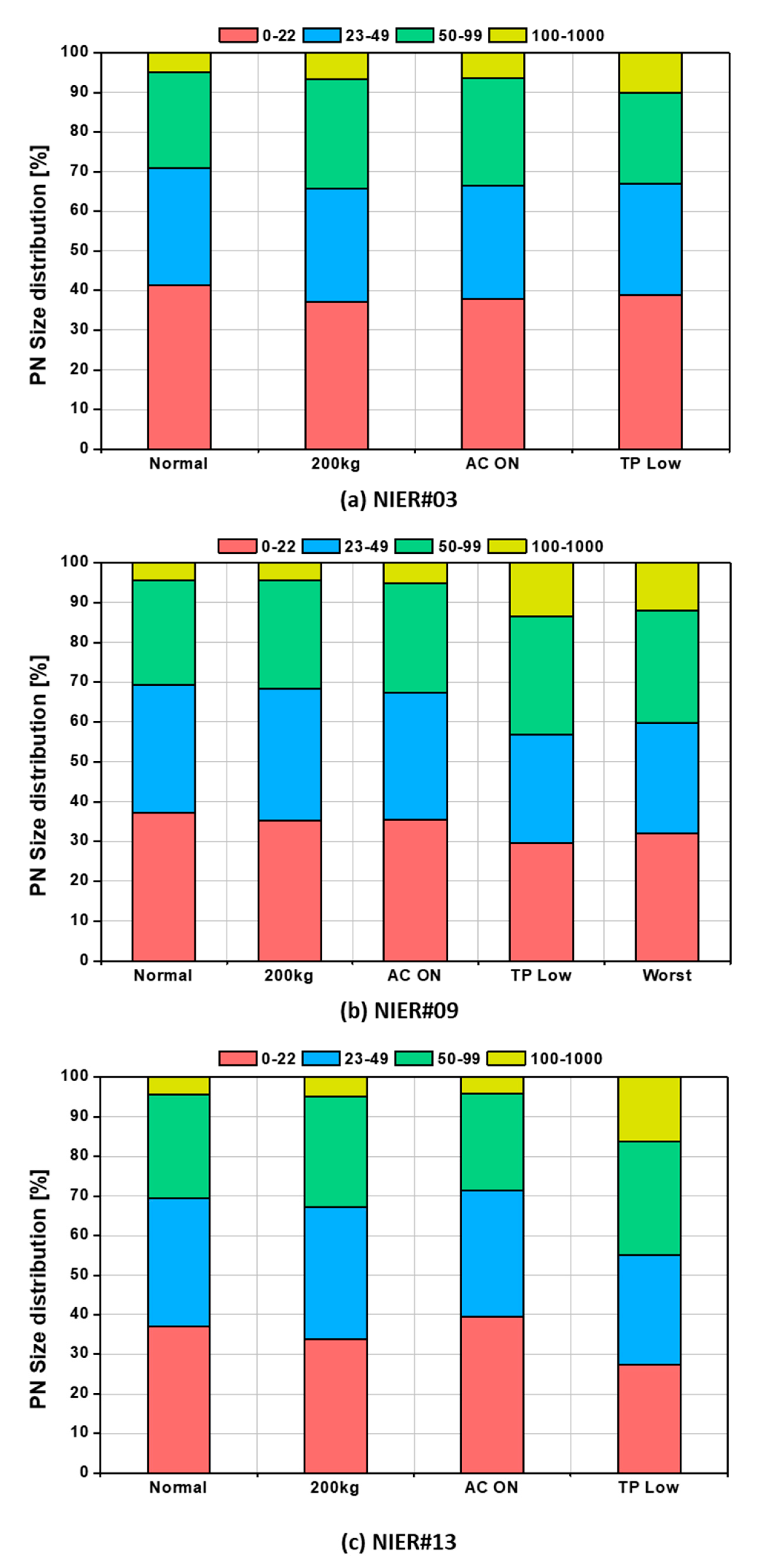

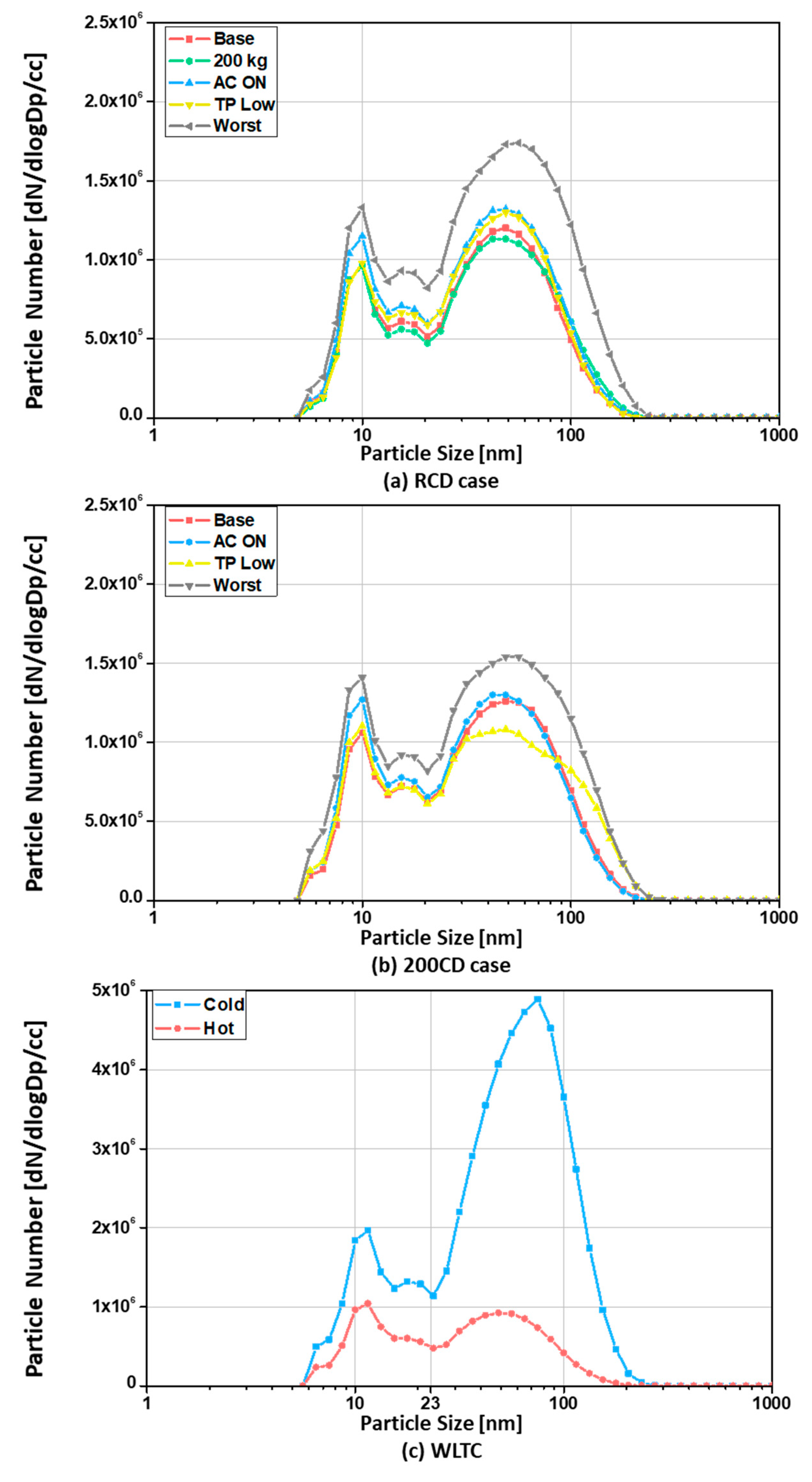

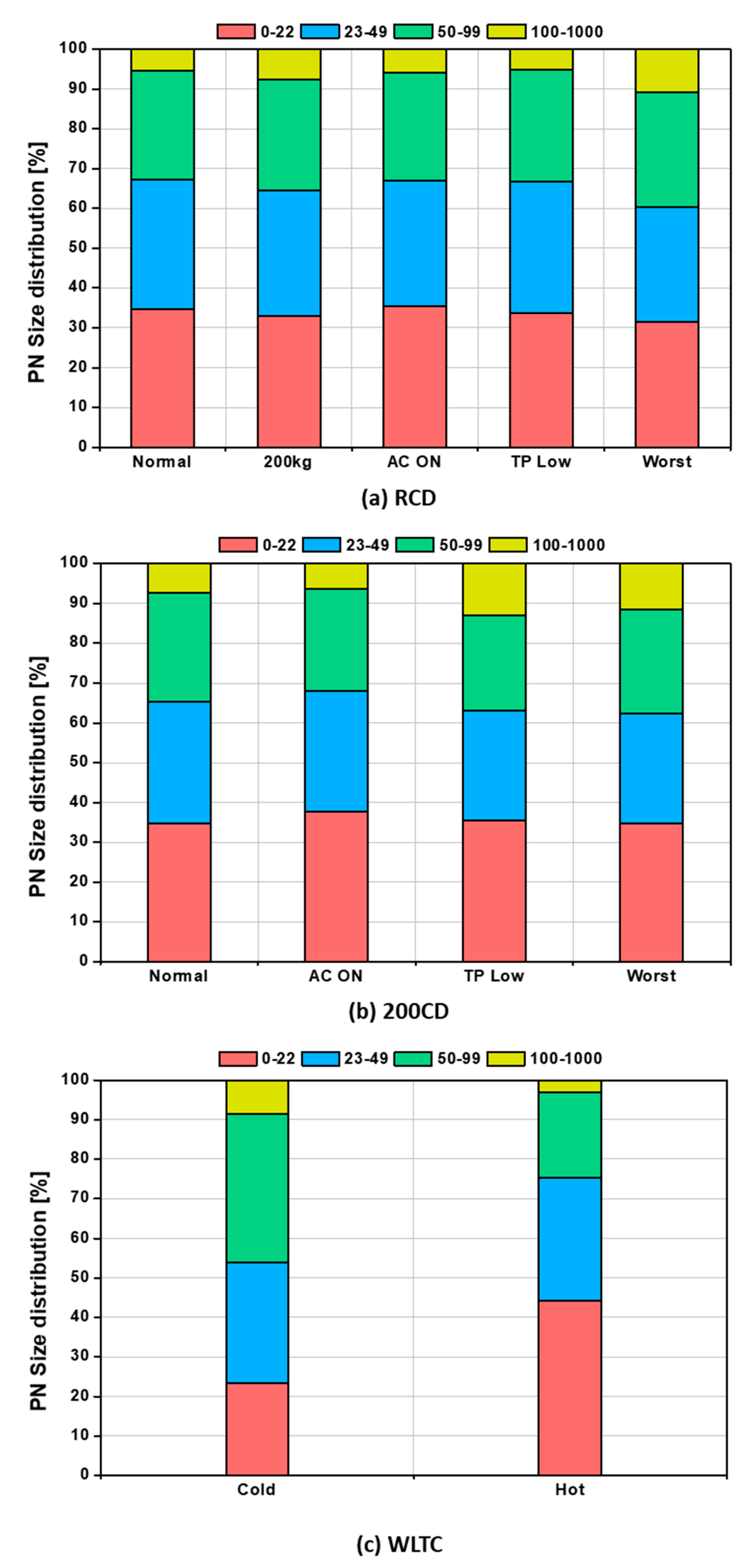

3.3. Size-Resolved PN Concentration

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nesbit, M.; Fergusson, M.; Colsa, A.; Ohlendorf, J.; Hayes, C.; Paquel, K.; Schweitzer, J.-P. Comparative Study on the Differences between the EU and US Legislation on Emissions in the Automotive Sector; European Parliament: Brussels, Belgium, 2016; Volume 21, Available online: Https://Www.Dieselnet.Com/Stand./Eu/Ld.Php#StdsDiaksesPada (accessed on 19 May 2020).

- Johnson, T.; Joshi, A. Review of vehicle engine efficiency and emissions. SAE Int. J. Engines 2018, 11, 1307–1330. [Google Scholar] [CrossRef]

- European Environment Agency (EEA). Air Quality in Europe—2019 Report; EEA: Copenhagen, Denmark, 2019. [Google Scholar]

- Blanco-Rodriguez, D.; Vagnoni, G.; Holderbaum, B. EU6 C-Segment Diesel vehicles, a challenging segment to meet RDE and WLTP requirements. IFAC Pap. 2016, 49, 649–656. [Google Scholar] [CrossRef]

- O’Driscoll, R.; Stettler, M.E.J.; Molden, N.; Oxley, T.; ApSimon, H.M. Real world CO2 and NOx emissions from 149 Euro 5 and 6 diesel, gasoline and hybrid passenger cars. Sci. Total Environ. 2018, 621, 282–290. [Google Scholar] [CrossRef] [PubMed]

- Park, G.; Mun, S.; Hong, H.; Chung, T.; Jung, S.; Kim, S.; Seo, S.; Kim, J.; Lee, J.; Kim, K.; et al. Characterization of emission factors concerning gasoline, LPG, and diesel vehicles via transient chassis-dynamometer tests. Appl. Sci. 2019, 9, 1573. [Google Scholar] [CrossRef]

- Moody, A.; Tate, J. In service CO2 and NOx emissions of Euro 6/VI cars, light-and heavy-dutygoods vehicles in real London driving: Taking the road into the laboratory. J. Earth Sci. Geotech. Eng. 2017, 7, 51–62. [Google Scholar]

- Mathis, U.; Mohr, M.; Forss, A. Comprehensive particle characterization of modern gasoline and diesel passenger cars at low ambient temperatures. Atmos. Environ. 2005, 39, 107–117. [Google Scholar] [CrossRef]

- Myung, C.L.; Park, S. Exhaust nanoparticle emissions from internal combustion engines: A review. Int. J. Automot. Technol. 2011, 13, 9–22. [Google Scholar] [CrossRef]

- Kraft, D.K.M. Particle Formation and Models in Internal Combustion Engines; ComoChengCamAcUk; University of Cambridge: Cambridge, UK, 2014; pp. 1473–4273. [Google Scholar]

- Kontses, A.; Triantafyllopoulos, G.; Ntziachristos, L.; Samaras, Z. Particle number (PN) emissions from gasoline, diesel, LPG, CNG and hybrid-electric light-duty vehicles under real-world driving conditions. Atmos. Environ. 2020, 222. [Google Scholar] [CrossRef]

- Awad, O.I.; Ma, X.; Kamil, M.; Ali, O.M.; Zhang, Z.; Shuai, S. Particulate emissions from gasoline direct injection engines: A review of how current emission regulations are being met by automobile manufacturers. Sci. Total Environ. 2020, 718, 137302. [Google Scholar] [CrossRef]

- Qian, Y.; Li, Z.; Yu, L.; Wang, X.; Lu, X. Review of the state-of-the-art of particulate matter emissions from modern gasoline fueled engines. Appl. Energy 2019, 238, 1269–1298. [Google Scholar] [CrossRef]

- European Union. Commision Regulation (EU) 2017/1151; Official Journal of the European Union; European Union: Brussels, Belgium, 2017. [Google Scholar]

- Mock, P. Changes to the Motor Vehicle Type-Approval System in the European Union; International Council on Clean Transportation: Washington, DC, USA, 2018. [Google Scholar]

- Myung, C.-L.; Choi, K.; Cho, J.; Kim, K.; Baek, S.; Lim, Y.; Park, S. Evaluation of regulated, particulate, and BTEX emissions inventories from a gasoline direct injection passenger car with various ethanol blended fuels under urban and rural driving cycles in Korea. Fuel 2020, 262. [Google Scholar] [CrossRef]

- Myung, C.-L.; Ko, A.; Lim, Y.; Kim, S.; Lee, J.; Choi, K.; Park, S. Mobile source air toxic emissions from direct injection spark ignition gasoline and LPG passenger car under various in-use vehicle driving modes in Korea. Fuel Process. Technol. 2014, 119, 19–31. [Google Scholar] [CrossRef]

- Momenimovahed, A.; Handford, D.; Checkel, M.D.; Olfert, J.S. Particle number emission factors and volatile fraction of particles emitted from on-road gasoline direct injection passenger vehicles. Atmos. Environ. 2015, 102, 105–111. [Google Scholar] [CrossRef]

- Ko, J.; Kim, K.; Chung, W.; Myung, C.-L.; Park, S. Characteristics of on-road particle number (PN) emissions from a GDI vehicle depending on a catalytic stripper (CS) and a metal-foam gasoline particulate filter (GPF). Fuel 2019, 238, 363–374. [Google Scholar] [CrossRef]

- Suarez-Bertoa, R.; Valverde, V.; Clairotte, M.; Pavlovic, J.; Giechaskiel, B.; Franco, V.; Kregar, Z.; Astorga, C. On-road emissions of passenger cars beyond the boundary conditions of the real-driving emissions test. Environ. Res. 2019, 176, 108572. [Google Scholar] [CrossRef]

- Jang, J.; Lee, J.; Choi, Y.; Park, S. Reduction of particle emissions from gasoline vehicles with direct fuel injection systems using a gasoline particulate filter. Sci. Total Environ. 2018, 644, 1418–1428. [Google Scholar] [CrossRef]

- Varella, R.; Giechaskiel, B.; Sousa, L.; Duarte, G. Comparison of portable emissions measurement systems (PEMS) with laboratory grade equipment. Appl. Sci. 2018, 8, 1633. [Google Scholar] [CrossRef]

- Khan, T.; Frey, H.C. Comparison of real-world and certification emission rates for light duty gasoline vehicles. Sci. Total Environ. 2018, 622–623, 790–800. [Google Scholar] [CrossRef]

- Huang, Y.; Surawski, N.C.; Organ, B.; Zhou, J.L.; Tang, O.H.H.; Chan, E.F.C. Fuel consumption and emissions performance under real driving: Comparison between hybrid and conventional vehicles. Sci. Total Environ. 2019, 659, 275–282. [Google Scholar] [CrossRef]

- Gallus, J.; Kirchner, U.; Vogt, R.; Benter, T. Impact of driving style and road grade on gaseous exhaust emissions of passenger vehicles measured by a Portable Emission Measurement System (PEMS). Transp. Res. Part D Transp. Environ. 2017, 52, 215–226. [Google Scholar] [CrossRef]

- Franco, V.; Sánchez, F.P.; German, J.; Mock, P. Real-World Exhaust Emissions from Modern Diesel Cars; International Council on Clean Transportation Europe: Berlin, Germany, 2014. [Google Scholar]

- Kwon, S.; Park, Y.; Park, J.; Kim, J.; Choi, K.H.; Cha, J.S. Characteristics of on-road NOx emissions from Euro 6 light-duty diesel vehicles using a portable emissions measurement system. Sci. Total Environ. 2017, 576, 70–77. [Google Scholar] [CrossRef] [PubMed]

- Fontaras, G.; Zacharof, N.-G.; Ciuffo, B. Fuel consumption and CO2 emissions from passenger cars in Europe—Laboratory versus real-world emissions. Prog. Energy Combust. Sci. 2017, 60, 97–131. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, Y.; Wu, L.; Martinet, S.; Zhang, Y.; Andre, M.; Mao, H. Real-world gaseous emission characteristics of Euro 6b light-duty gasoline- and diesel-fueled vehicles. Transp. Res. Part D Transp. Environ. 2020, 78. [Google Scholar] [CrossRef]

- Triantafyllopoulos, G.; Dimaratos, A.; Ntziachristos, L.; Bernard, Y.; Dornoff, J.; Samaras, Z. A study on the CO2 and NOx emissions performance of Euro 6 diesel vehicles under various chassis dynamometer and on-road conditions including latest regulatory provisions. Sci. Total Environ. 2019, 666, 337–346. [Google Scholar] [CrossRef]

- Weilenmann, M.F.; Vasic, A.-M.; Stettler, P.; Novak, P. Influence of mobile air-conditioning on vehicle emissions and fuel consumption: A model approach for modern gasoline cars used in Europe. Environ. Sci. Technol. 2005, 39, 9601–9610. [Google Scholar] [CrossRef]

- He, L.; Hu, J.; Zhang, S.; Wu, Y.; Zhu, R.; Zu, L.; Bao, X.; Lai, Y.; Su, S. The impact from the direct injection and multi-port fuel injection technologies for gasoline vehicles on solid particle number and black carbon emissions. Appl. Energy 2018, 226, 819–826. [Google Scholar] [CrossRef]

- Nikolian, A.; Fontaras, G.; Marotta, A.; Dilara, P. CO2 emissions for Euro 5 passenger cars over different driving and load conditions. In Proceedings of the 19th Transport and Air Pollution Conference, Thessaloniki, Greece, 16–27 November 2012. [Google Scholar]

- Sina, N.; Nasiri, S.; Karkhaneh, V. Effects of resistive loads and tire inflation pressure on tire power losses and CO2 emissions in real-world conditions. Appl. Energy 2015, 157, 974–983. [Google Scholar] [CrossRef]

- Fernandes, P.; Macedo, E.; Bahmankhah, B.; Tomas, R.F.; Bandeira, J.M.; Coelho, M.C. Are internally observable vehicle data good predictors of vehicle emissions? Transp. Res. Part D Transp. Environ. 2019, 77, 252–270. [Google Scholar] [CrossRef]

- Ramos, A.; Muñoz, J.; Andrés, F.; Armas, O. NOx emissions from diesel light duty vehicle tested under NEDC and real-word driving conditions. Transp. Res. Part D Transp. Environ. 2018, 63, 37–48. [Google Scholar] [CrossRef]

- Jung, S.; Lim, J.; Kwon, S.; Jeon, S.; Kim, J.; Lee, J.; Kim, S. Characterization of particulate matter from diesel passenger cars tested on chassis dynamometers. J. Environ. Sci. (China) 2017, 54, 21–32. [Google Scholar] [CrossRef]

- He, X.; Ratcliff, M.A.; Zigler, B.T. Effects of gasoline direct injection engine operating parameters on particle number emissions. Energy Fuels 2012, 26, 2014–2027. [Google Scholar] [CrossRef]

- Pei, Y.-Q.; Qin, J.; Pan, S.-Z. Experimental study on the particulate matter emission characteristics for a direct-injection gasoline engine. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2014, 228, 604–616. [Google Scholar] [CrossRef]

- Raza, M.; Chen, L.; Leach, F.; Ding, S. A review of particulate number (PN) emissions from gasoline direct injection (GDI) engines and their control techniques. Energies 2018, 11, 1417. [Google Scholar] [CrossRef]

- Cho, J.; Si, W.; Jang, W.; Jin, D.; Myung, C.-L.; Park, S. Impact of intermediate ethanol blends on particulate matter emission from a spark ignition direct injection (SIDI) engine. Appl. Energy 2015, 160, 592–602. [Google Scholar] [CrossRef]

- Wu, T.; Yao, A.; Feng, J.; Wang, H.; Li, Z.; Liu, M.; Yao, C. A reduced PM index for evaluating the effect of fuel properties on the particulate matter emissions from gasoline vehicles. Fuel 2019, 253, 691–702. [Google Scholar] [CrossRef]

- Seigneur, C. Current understanding of ultrafine particulate matter emitted from mobile sources. J. Air Waste Manag. Assoc. 2009, 59, 3–17. [Google Scholar] [CrossRef]

- Wang, X.; Grose, M.A.; Avenido, A.; Stolzenburg, M.R.; Caldow, R.; Osmondson, B.L.; Chow, J.C.; Watson, J.G. Improvement of Engine Exhaust Particle Sizer (EEPS) size distribution measurement—I. Algorithm and applications to compact-shape particles. J. Aerosol. Sci. 2016, 92, 95–108. [Google Scholar] [CrossRef]

- Chen, L.; Liang, Z.; Zhang, X.; Shuai, S. Characterizing particulate matter emissions from GDI and PFI vehicles under transient and cold start conditions. Fuel 2017, 189, 131–140. [Google Scholar] [CrossRef]

- Karjalainen, P.; Pirjola, L.; Heikkilä, J.; Lähde, T.; Tzamkiozis, T.; Ntziachristos, L.; Keskinen, J.; Rönkkö, T. Exhaust particles of modern gasoline vehicles: A laboratory and an on-road study. Atmos. Environ. 2014, 97, 262–270. [Google Scholar] [CrossRef]

- Kumar Pathak, S.; Sood, V.; Singh, Y.; Channiwala, S.A. Real world vehicle emissions: Their correlation with driving parameters. Transp. Res. Part D Transp. Environ. 2016, 44, 157–176. [Google Scholar] [CrossRef]

- Chong, H.S.; Kwon, S.; Lim, Y.; Lee, J. Real-world fuel consumption, gaseous pollutants, and CO2 emission of light-duty diesel vehicles. Sustain. Cities Soc. 2020, 53. [Google Scholar] [CrossRef]

- Choudhary, A.; Gokhale, S. On-road measurements and modelling of vehicular emissions during traffic interruption and congestion events in an urban traffic corridor. Atmos. Pollut. Res. 2019, 10, 480–492. [Google Scholar] [CrossRef]

- Ronkko, T.; Pirjola, L.; Ntziachristos, L.; Heikkila, J.; Karjalainen, P.; Hillamo, R.; Keskinen, J. Vehicle engines produce exhaust nanoparticles even when not fueled. Environ. Sci. Technol. 2014, 48, 2043–2050. [Google Scholar] [CrossRef] [PubMed]

- Kim, C.; Lee, H.; Park, Y.; Myung, C.-L.; Park, S. Study on the criteria for the determination of the road load correlation for automobiles and an analysis of key factors. Energies 2016, 9, 575. [Google Scholar] [CrossRef]

- Wang, C.; Xu, H.; Herreros, J.M.; Wang, J.; Cracknell, R. Impact of fuel and injection system on particle emissions from a GDI engine. Appl. Energy 2014, 132, 178–191. [Google Scholar] [CrossRef]

- Zhang, M.; Hong, W.; Xie, F.; Su, Y.; Liu, H.; Zhou, S. Combustion, performance and particulate matter emissions analysis of operating parameters on a GDI engine by traditional experimental investigation and Taguchi method. Energy Convers. Manag. 2018, 164, 344–352. [Google Scholar] [CrossRef]

- Tsiakmakis, S.; Ciuffo, B.; Fontaras, G.; Anagnostopoulos, K.; Arcidiacono, V.; Praksova, R.; Marotta, A. Introducing a new emissions certification procedure for european light-duty vehicles: Monte carlo simulation of the potential effect on fleet carbon dioxide emissions. Transp. Res. Rec. 2016, 2572, 66–77. [Google Scholar] [CrossRef]

| Specification | |

|---|---|

| Engine type | In-line 4 cylinder |

| Fuel Injection System | Stoichiometric GDI |

| Displacement (cm3) | 2359 |

| Bore × Stroke (mm) | 88 × 97 |

| Compression ratio | 11.3 |

| Max. power (ps/rpm) | 201/6300 |

| Max. torque (kgf∙m/rpm) | 25.5/4250 |

| Transmission | 6-speed automatic |

| After-treatment system | 2-brick underfloor TWC |

| Regulation category | ULEV II, PZEV |

| Unloading weight (kg) | 1465 |

| Specification | Test Result | Test Method |

|---|---|---|

| Density (kg/m3 @ 15 °C) | 721.7 | KS M ISO 12185:2003 |

| Research Octane Number | 91 | KS M 2039:2006 |

| Distillation 10% (°C) | 55.3 | ASTM D86-16a |

| Distillation 50% (°C) | 83.7 | |

| Distillation 90% (°C) | 145.6 | |

| Final boiling point (°C) | 185.8 | |

| Distillation residue (%vol.) | 1.0 | |

| DVPE (kPa @ 37.8 °C) | 54.3 | ASTM D5191-15 |

| Aromatics (%vol.) | 13.5 | KS M 2963:2008 |

| Benzene (%vol.) | 0.5 | |

| Olefins (%vol.) | 13.5 | |

| Oxygen content (%vol.) | 1.9 | |

| Sulfur content (mg/kg) | 7 | KS M 2027:2010 |

| Test Mode | NIER#03 | NIER#09 | NIER#13 | WLTP |

|---|---|---|---|---|

| Duration (s) | 878 | 926 | 849 | 1800 |

| Distance (km) | 2.63 | 8.77 | 18.24 | 23.27 |

| Avg./Max. Speed (km/h) | 10.8/63 | 34.1/71 | 77.4/98 | 46.5/131.3 |

| Avg. Acceleration (m/s2) | 0.64 | 0.53 | 0.25 | 0.41 |

| Idle Fraction (%) | 40 | 13 | 0 | 13 |

| Test Mode | Test Condition | Lambda (λ) | Fuel Pressure (bar) | Spark Timing (BTDC CA) | Engine Speed (rpm) |

|---|---|---|---|---|---|

| NIER #3 | Normal | 1.040 | 48.3 | 20.408 | 935 |

| +200 kg | 1.037 | 48.1 | 19.623 | 922 | |

| A/C | 1.038 | 51.2 | 19.394 | 940 | |

| TP Low | 1.020 | 47.3 | 19.448 | 919 | |

| NIER #9 (BCD/RCD/200CD) | Normal | 1.136/1.126/1.126 | 51.8/51.4/52.1 | 26.6/26.8/25.7 | 1250/1253/1263 |

| +200 kg | 1.128/1.100/- 1 | 51.3/51.9/- | 27.8/26.2/- | 1251/1253/- | |

| A/C | 1.094/1.110/1.127 | 53.0/53.9/54.2 | 25.9/24.6/23.3 | 1229/1252/1259 | |

| TP Low | 1.149/1.096/1.126 | 51.6/52.3/52.3 | 27.2/26.9/25.6 | 1255/1261/1269 | |

| Worst | 1.090/1.080/1.118 | 53.6/54.2/54.8 | 24.6/25.6/24.8 | 1241/1247/1266 | |

| NIER #13 | Normal | 1.238 | 59.1 | 30.3 | 1573 |

| +200 kg | 1.258 | 59.1 | 30.0 | 1572 | |

| A/C | 1.233 | 60.5 | 28.2 | 1577 | |

| TP Low | 1.269 | 59.7 | 29.1 | 1587 | |

| WLTP | Cold Start | 1.055 | 53.1 | 26.3 | 1166 |

| Hot Start | 1.087 | 50.1 | 26.5 | 1139 |

| Test Mode | Test Condition | THC (g/km) | CO (g/km) | NOx (g/km) |

|---|---|---|---|---|

| NIER #3 | Normal | 0.1195 | 0.5640 | 0.0923 |

| +200 kg | 0.0162 | 0.1789 | 0.0052 | |

| A/C | 0.1286 | 0.6834 | 0.1003 | |

| TP Low | 0.0465 | 0.2050 | 0.0276 | |

| NIER #9 (BCD/RCD/200CD) | Normal | 0.0215/0.0055/0.0223 | 0.2589/0.0858/0.2306 | 0.0437/0.0071/0.0350 |

| +200 kg | 0.0050/0.0044/- 1 | 0.0396/0.1140/- | 0.0093/0.0064/- | |

| A/C | 0.0321/0.0063/0.0292 | 0.2152/0.1336/0.2867 | 0.0367/0.0119/0.0353 | |

| TP Low | 0.0042/0.0057/0.0164 | 0.0976/0.1258/0.3091 | 0.0075/0.0076/0.0259 | |

| Worst | 0.0347/0.0095/0.0253 | 0.2991/0.1121/0.3305 | 0.0446/0.0197/0.0403 | |

| NIER #13 | Normal | 0.0051 | 0.0652 | 0.0112 |

| +200 kg | 0.0043 | 0.1085 | 0.0078 | |

| A/C | 0.0050 | 0.1576 | 0.0066 | |

| TP Low | 0.0025 | 0.0967 | 0.0070 | |

| WLTP | Cold Start | 0.1368 | 1.7062 | 0.0224 |

| Hot Start | 0.0179 | 0.0650 | 0.0197 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.; Chung, W.; Kim, M.; Kim, C.; Myung, C.-L.; Park, S. Inspection of PN, CO2, and Regulated Gaseous Emissions Characteristics from a GDI Vehicle under Various Real-World Vehicle Test Modes. Energies 2020, 13, 2581. https://doi.org/10.3390/en13102581

Kim K, Chung W, Kim M, Kim C, Myung C-L, Park S. Inspection of PN, CO2, and Regulated Gaseous Emissions Characteristics from a GDI Vehicle under Various Real-World Vehicle Test Modes. Energies. 2020; 13(10):2581. https://doi.org/10.3390/en13102581

Chicago/Turabian StyleKim, Kangjin, Wonyong Chung, Myungsoo Kim, Charyung Kim, Cha-Lee Myung, and Simsoo Park. 2020. "Inspection of PN, CO2, and Regulated Gaseous Emissions Characteristics from a GDI Vehicle under Various Real-World Vehicle Test Modes" Energies 13, no. 10: 2581. https://doi.org/10.3390/en13102581

APA StyleKim, K., Chung, W., Kim, M., Kim, C., Myung, C.-L., & Park, S. (2020). Inspection of PN, CO2, and Regulated Gaseous Emissions Characteristics from a GDI Vehicle under Various Real-World Vehicle Test Modes. Energies, 13(10), 2581. https://doi.org/10.3390/en13102581