Direct Shear Experimental Study on the Mobilized Dilation Behavior of Granite in Alxa Candidate Area for High-Level Radioactive Waste Disposal

Abstract

1. Introduction

2. Samples and Experimental Methods

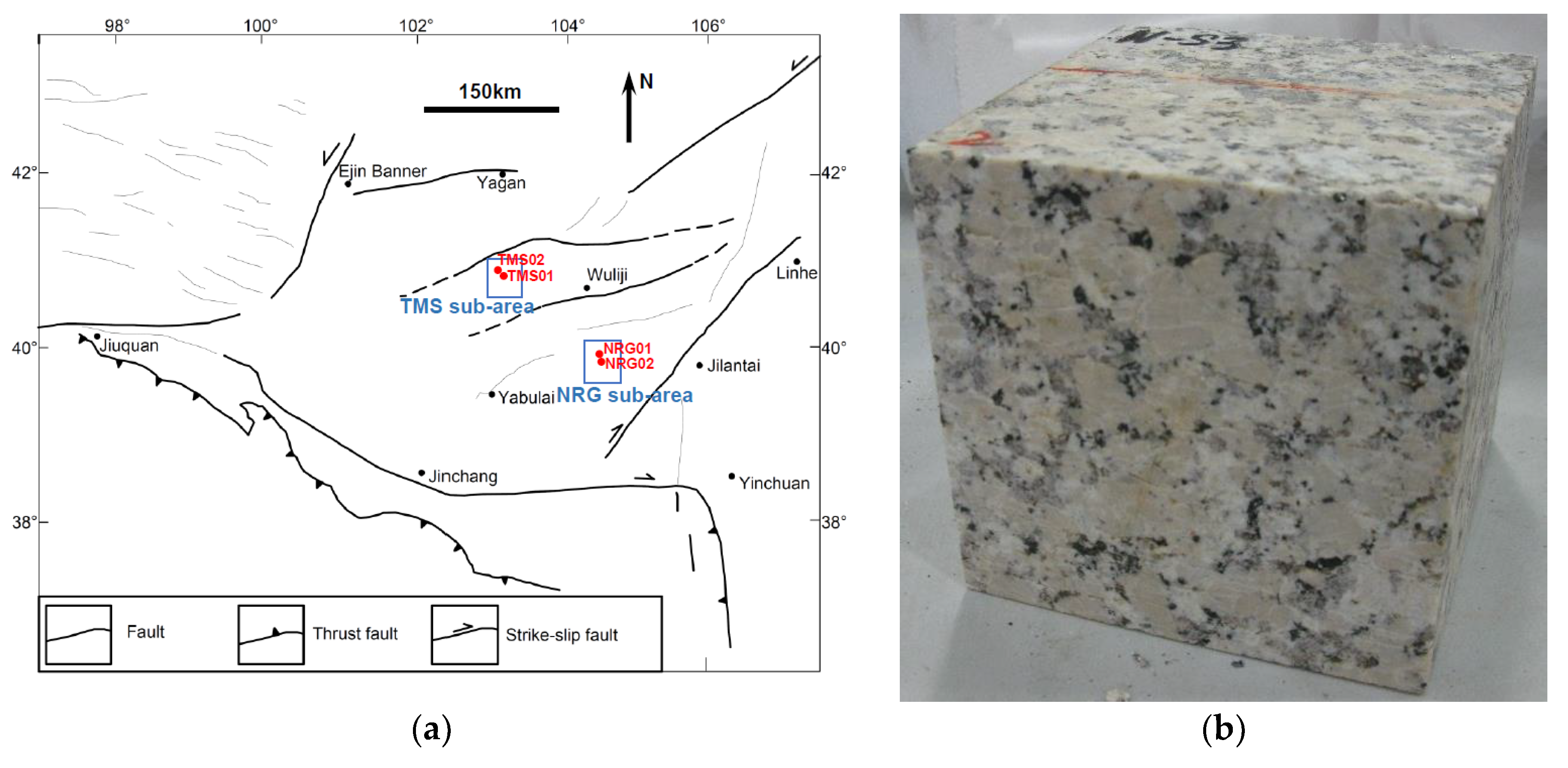

2.1. Samples

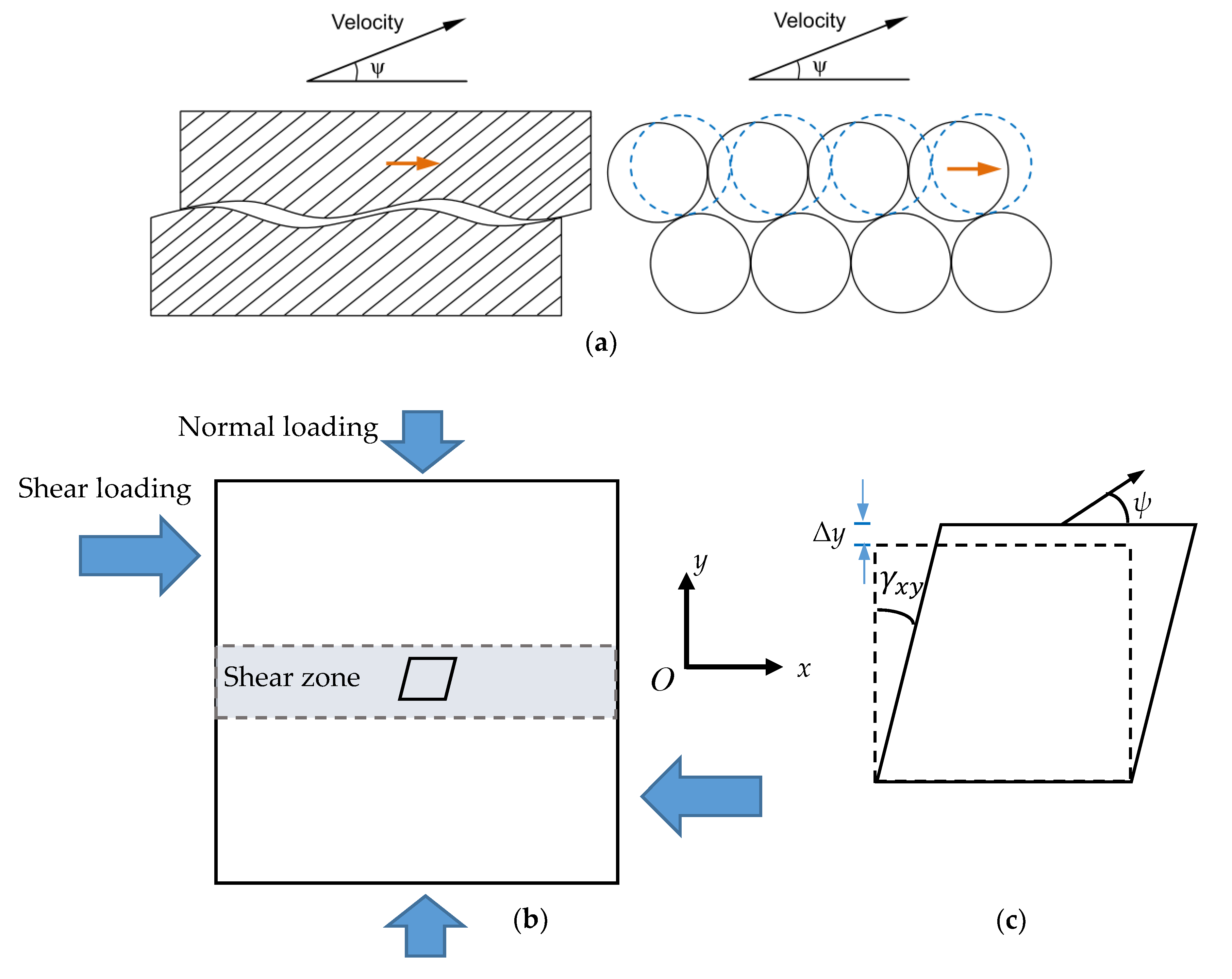

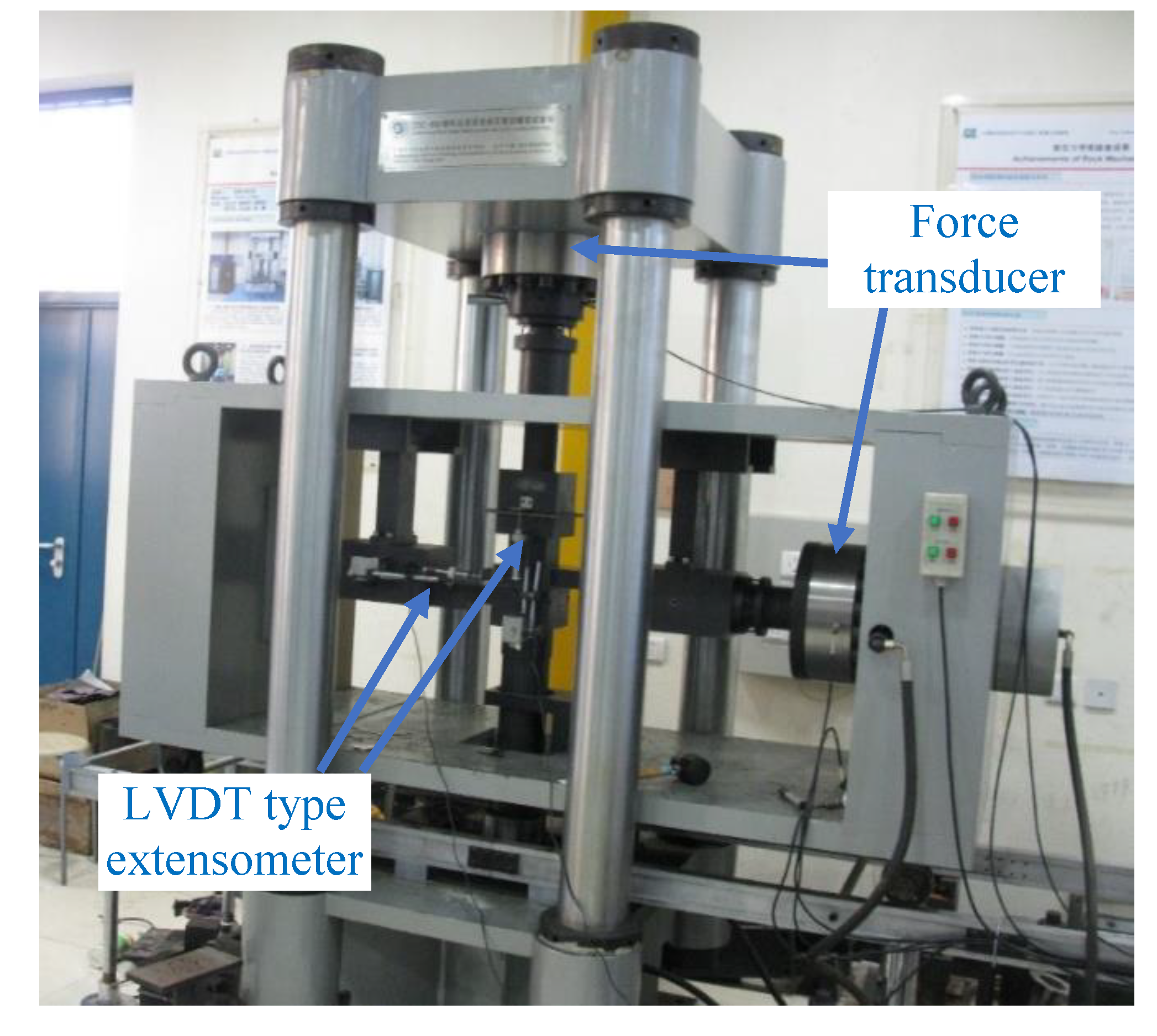

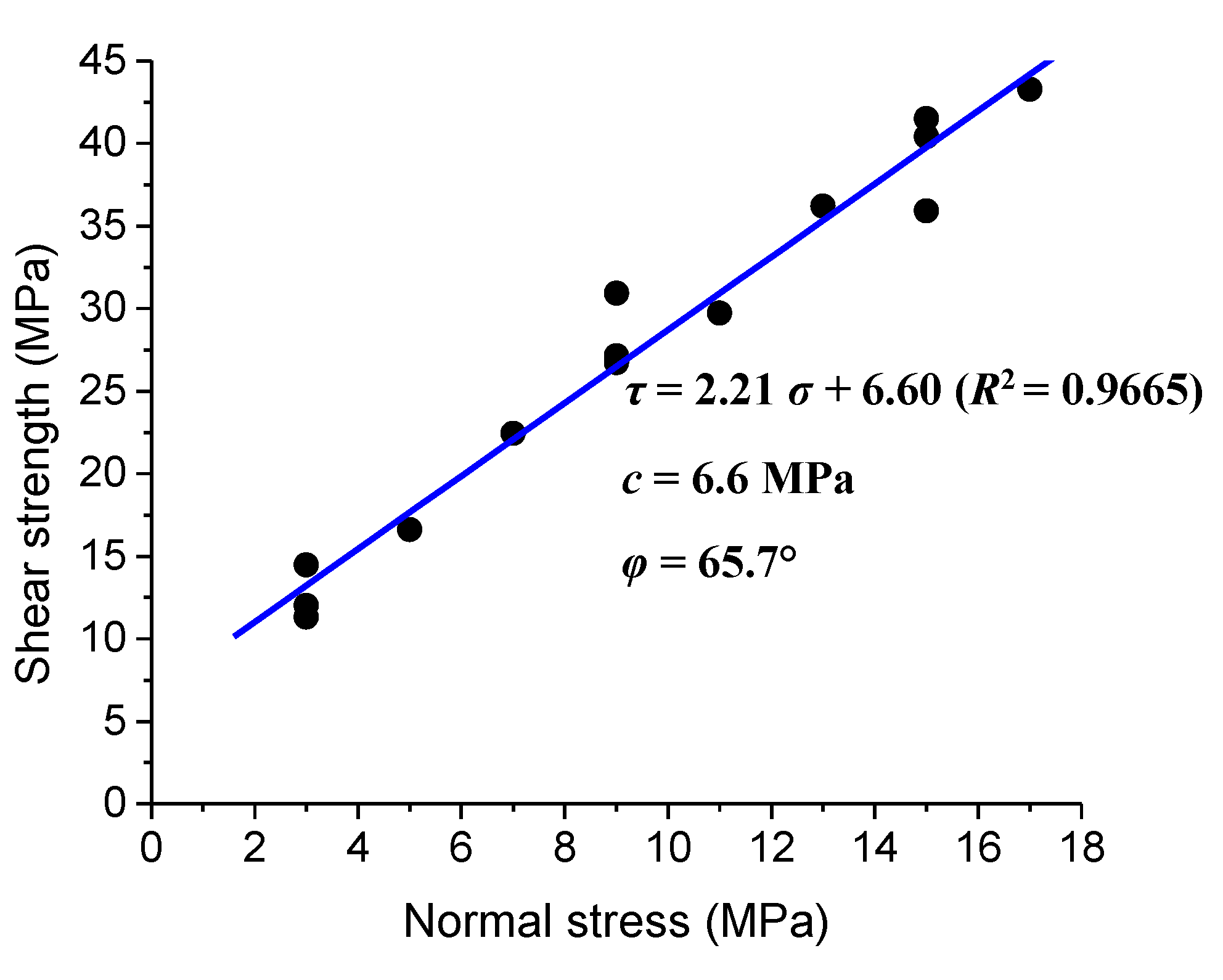

2.2. Experimental Methods

- (1)

- Each cubic granite sample is placed in the shear box. Thereafter, the normal stress is applied to the specimens to the target value. In this study, considering the loading capacity of the test machine, the normal stresses ranging from 3 to 17 MPa are applied. Actually, the results presented in the following sections show that this range of normal stresses is suitable enough to conduct a systematic analysis of the dilation behavior of these granite samples. The applied normal stress value for each specimen has been listed in Table 1.

- (2)

- When the normal stress reaches the designed value, shear stress is applied to each sample with a shear strain rate of 1.0 × 10−5 s−1. Each experiment continues until the shear stress reaches a residual value or the shearing failure of the specimen occurs.

- (3)

- During the experiment, two force transducers are installed to measure the shear and normal loads, and a pair of LVDT (linear variable differential transformer) type extensometers [36,45,63,64] are used to measure the strain values at both normal and shear directions. The data are recorded with a sampling interval of 0.02 s. With these recorded data, the shear stress‒normal strain curve and shear stress‒shear strain curve are drawn for each of the tests.

3. Experimental Results

- (1)

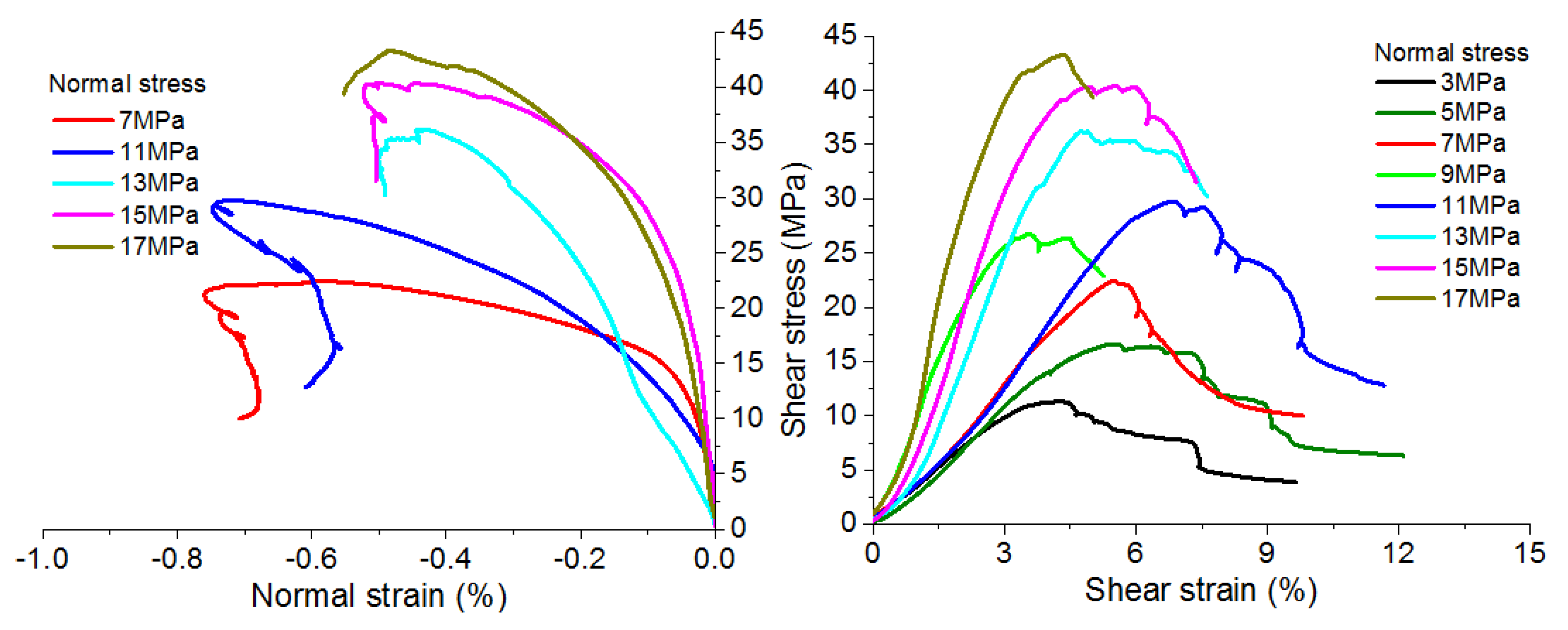

- The shear stress–shear strain curves and shear stress–normal strain curves can be divided into five different stages: (I) Crack closure stage. In this stage, the slope of the shear stress–shear strain curve keeps growing to reach a constant value, showing the closure of the pre-existing cracks inside the specimen. This process may also be mixed with the effect of seating and sample adjustment. It should be noted that the normal strain curves show a slight expansion instead of crack closure induced by compaction because the crack closure process at the normal direction has occurred during the preparation process of applying a normal load, which is prior to the shear loading, so it cannot be shown in this curve. (II) Linear elastic stage. In this stage, both the shear stress–shear strain curve and the shear stress–normal strain curve behave in an almost linear style. (III) Stable crack growth stage. Although the shear stress–shear strain curve still appears linear, the normal strain shows an apparent depart from linearity. Scattered distributed cracks begin to develop in a stable way, and the onset of crack initiation also means the beginning of dilation. (IV) Unstable crack propagation stage. Both the shear strain and normal strain increase in an apparently non-linear style, meaning that crack coalescence and the unstable crack propagation occurs. (V) Post-peak stage. The shear stress decreases with the increasing shear strain, meaning that the shear zone is forming, and the shear load cannot be maintained. The detailed division of the different stages is demonstrated in Figure 6, with a typical stress-strain curve from this group of experiments. It should be noted that the information of the cracking process has not been monitored in this study, but the above-mentioned analyses are believed to be reasonable because they are based on the features of the stress-strain curves, as well as a comparison with the stage division of conventional tri-axial compression experiments [1,35,37,38].

- (2)

- When the normal stress is relatively low (e.g., σn = 3 and 5 MPa), the shear stress drops in a gradual manner after the failure of the specimen, showing relatively ductile post-peak behavior; with increasing normal stress, the post-peak behavior turns to be more brittle. Under the normal stress σn = 13 MPa to 17 MPa, it seems that the granite samples are prone to fail before reaching the residual shear strength. It appears that the direct shear test results show a ductile–brittle transition behavior, instead of the brittle–ductile transition behavior usually found in the conventional tri-axial compression experiments [35]. This study tries to provide an explanation as follows: For the cases under lower normal stresses, the peak shear strength is lower, so the strain energy stored in the test system is also lower. Consequently, lower strain energy will be released when failure occurs; therefore, the shear stress drops in a more stable manner. On the other hand, the higher normal stress may result in higher peak shear strength, and higher strain energy will be released during the post-peak stage, leading to a more violent failure of the specimen. It should be noted that the post-peak behavior should also be closely related to the fracturing patterns under different normal stresses, which requires a more systematic research.

- (3)

- When the failure occurs, the normal strain is apparently higher under relatively lower normal stresses (e.g., σn = 7 MPa and 11 MPa) than that under higher stresses (e.g., σn = 13, 15, and 17 MPa). It is interesting to find that the normal strain may decrease during the post-failure stage. This decrease is more obvious for the samples under lower normal stresses (e.g., σn = 7 and 11 MPa). This phenomenon is related to the dilation behavior and will be discussed in detail in the next section.

4. Data Analyses and Discussion

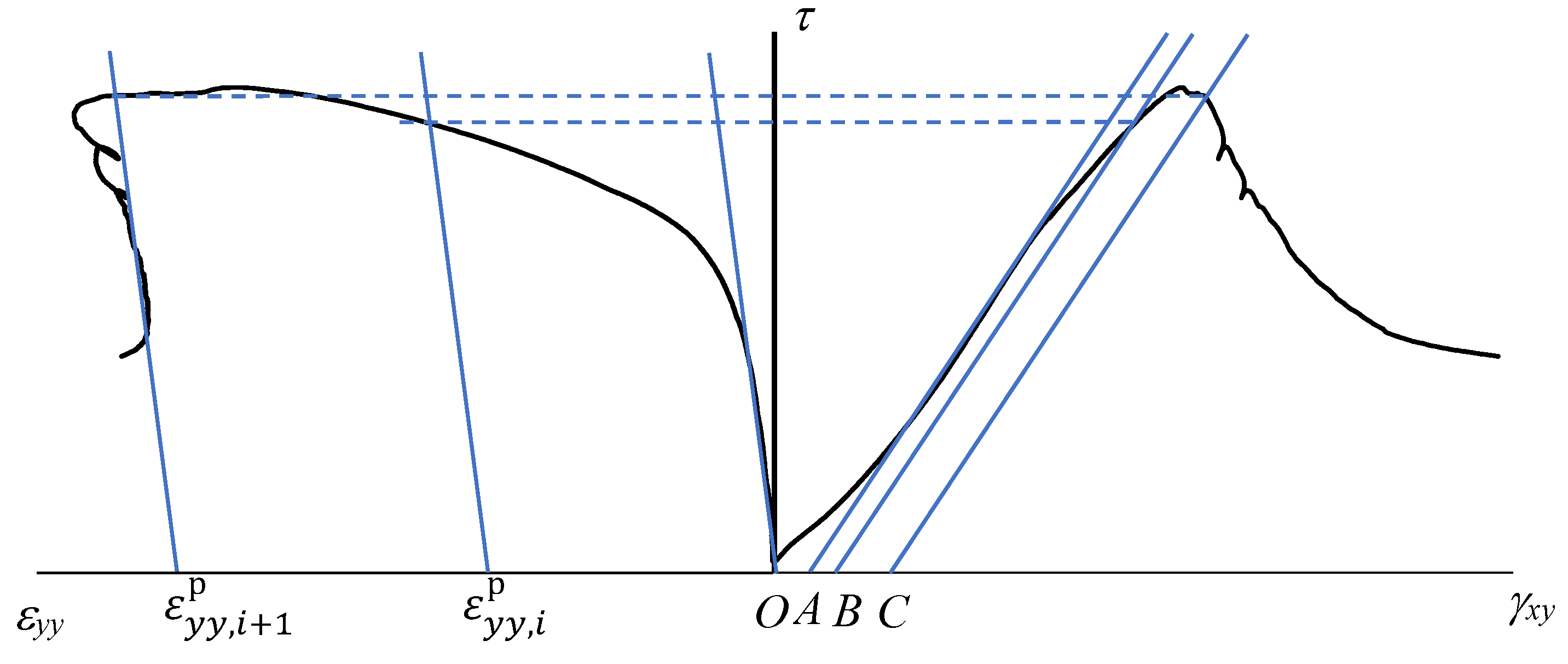

4.1. Methods

4.2. Mobilized Dilation Angle of the Granite Samples Dependent on Normal Stress and Plastic Shear Strain

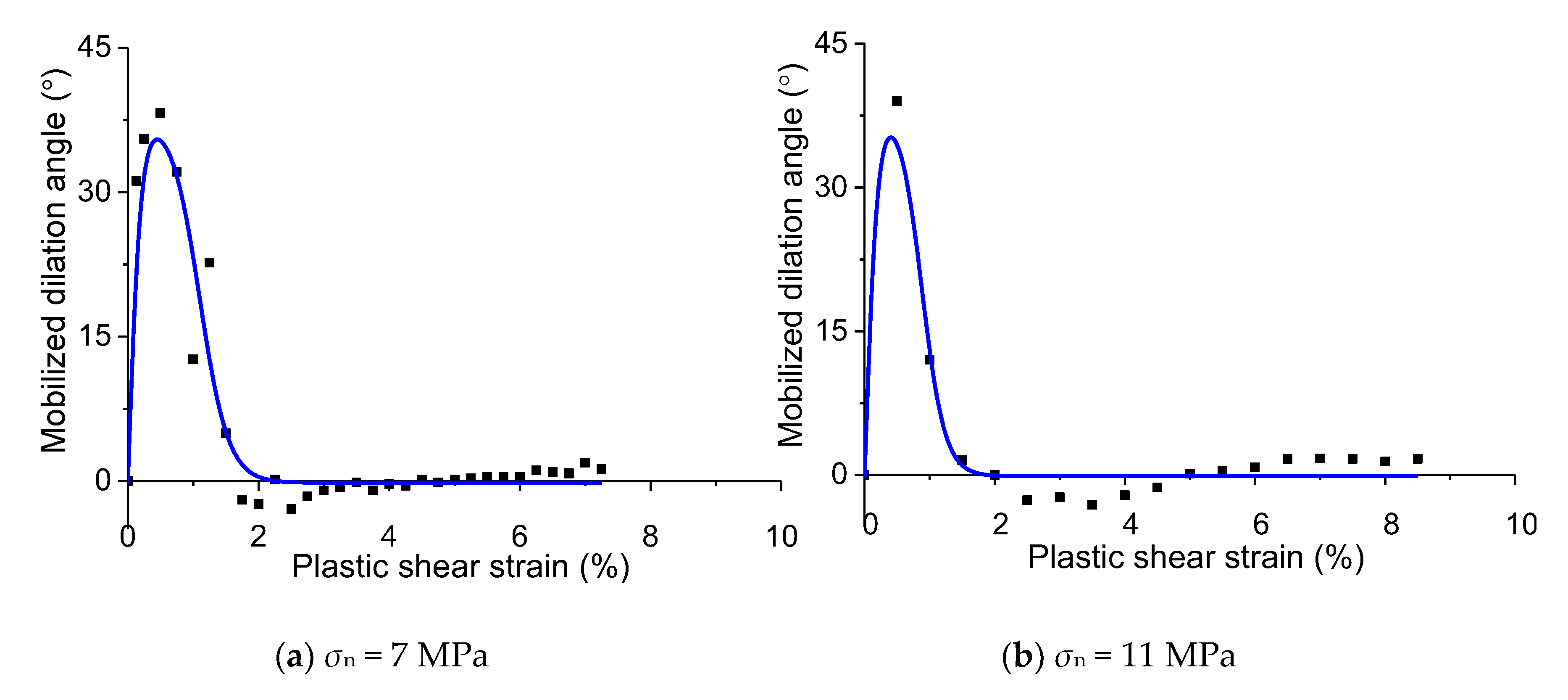

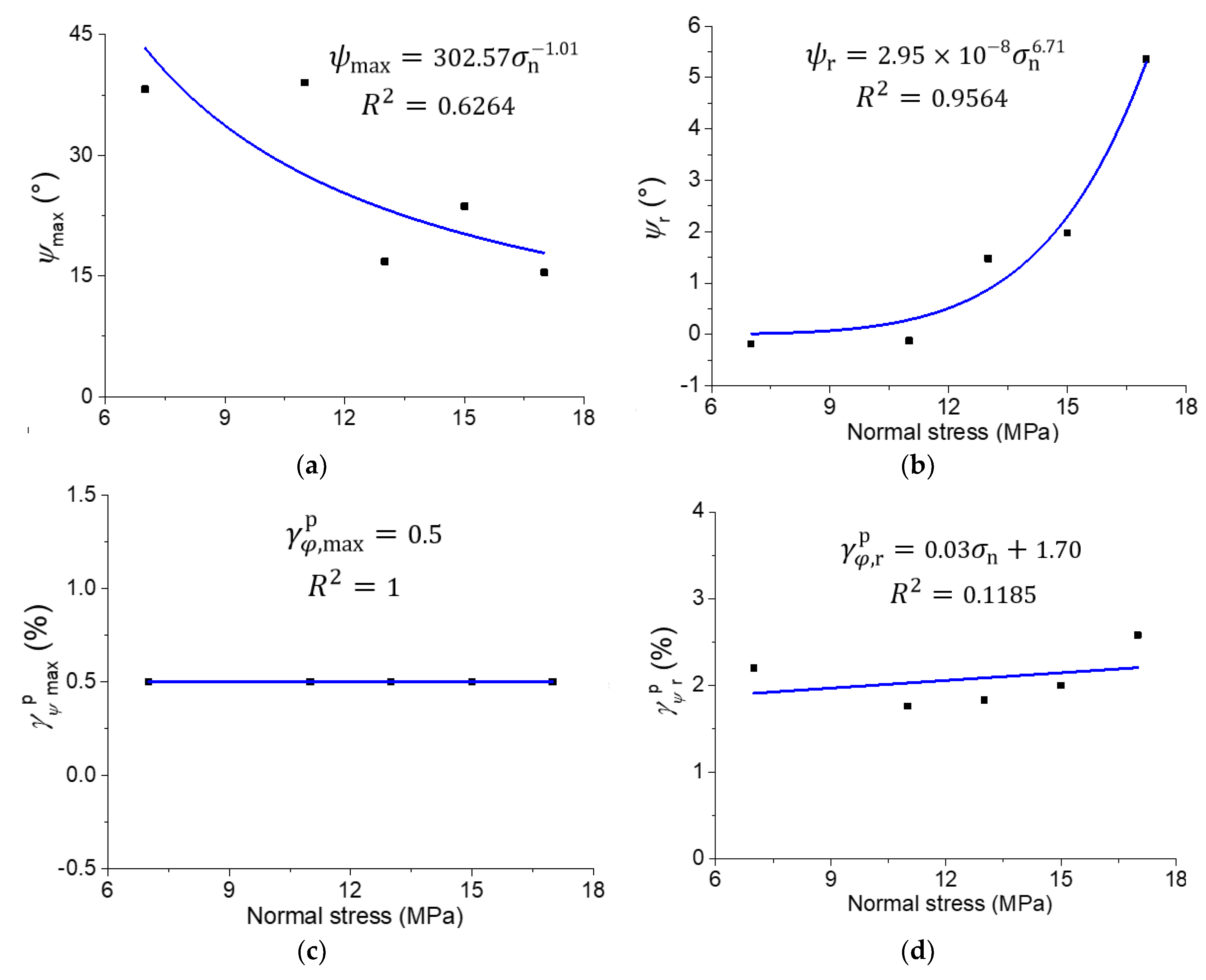

- (1)

- For all the tests under different normal stresses, the dilation angle increases significantly to the peak value firstly with the increasing plastic shear strain; thereafter, it drops to a residual value.

- (2)

- For the cases under higher normal stresses (e.g., σn = 13, 15, and 17 MPa), the dilation angles are all positive. The peak value of the dilation angle is lower than that under the lower normal stresses; however, the residual value is relatively higher.

- (3)

- When the normal stress is relatively lower (e.g., σn = 7 and 11 MPa), the maximum dilation angle is higher, and it drops in a more significant manner. The dilation angle can even drop to a negative value, meaning the behavior of “contraction” occurs. However, the absolute value of the negative dilation angle is not very high.

5. Conclusions

- (1)

- The shear stress–shear strain curves and shear stress–normal strain curves are divided into five typical stages, which are associated with the deformation and fracturing process. The typical stress thresholds were proposed to divide the different stages.

- (2)

- It is found that the increasing normal stress may reduce the maximum dilation angle. When the normal stress is lower, the negative dilation angle may occur; however, this phenomenon has not been observed in the cases under higher normal stresses.

- (3)

- An empirical model of the mobilized dilation angle dependent on normal stress and plastic shear strain is proposed based on the fitting of the data collected from the direct shear tests. This model can be used in further studies on the constitutive modeling of the host rock.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Martin, C.D. The Strength of Massive Lac du Bonnet Grantie around Underground Openings; University of Manitoba: Winnipeg, MB, Canada, 1993. [Google Scholar]

- Makurat, A.; Ahola, M.; Khair, K.; Noorishad, J.; Rosengren, L.; Rutqvist, J. The decovalex test—Case one. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1995, 32, 399–408. [Google Scholar] [CrossRef]

- Martin, C.D.; Read, R.S.; Martino, J.B. Observations of brittle failure around a circular test tunnel. Int. J. Rock Mech. Min. Sci. 1997, 34, 1065–1073. [Google Scholar] [CrossRef]

- Duevel, B.; Haimson, B. Mechanical characterization of pink lac du bonnet granite: Evidence of nonlinearity and anisotropy. Int. J. Rock Mech. Min. Sci. 1997, 34, 18. [Google Scholar] [CrossRef]

- Martin, C.D. Seventeenth canadian geotechnical colloquium: The effect of cohesion loss and stress path on brittle rock strength. Can. Geotech. J. 1997, 34, 698–725. [Google Scholar] [CrossRef]

- Hökmark, H.; Fälth, B. Thermal Dimensioning of the Deep Repository; TR-03-09; SKB, 2003; Available online: http://www.skb.se/publication/21133/TR-03-09.pdf (accessed on 13 July 2016).

- Fairhurst, C. Nuclear waste disposal and rock mechanics: Contributions of the underground research laboratory (url), pinawa, manitoba, canada. Int. J. Rock Mech. Min. Sci. 2004, 41, 1221–1227. [Google Scholar] [CrossRef]

- Martino, J.B.; Chandler, N.A. Excavation-induced damage studies at the underground research laboratory. Int. J. Rock Mech. Min. Sci. 2004, 41, 1413–1426. [Google Scholar] [CrossRef]

- Read, R.S. 20 years of excavation response studies at aecl’s underground research laboratory. Int. J. Rock Mech. Min. Sci. 2004, 41, 1251–1275. [Google Scholar] [CrossRef]

- Wanne, T.; Johansson, E.; Potyondy, D.; Saanio; Oy, R. Spö Pillar Stability Experiment: Final Coupled 3d Thermo-Mechanical Modeling: Preliminary Particle-Mechanical Modeling; R-04-03; Svensk Kärnbränslehantering AB, 2004; p. 40. Available online: http://www.skb.se/upload/publications/pdf/R-04-03.pdf (accessed on 23 December 2019).

- Wang, J. High-level radioactive waste disposal in China: Update 2010. J. Rock Mech. Geotech. Eng. 2010, 2, 1–11. [Google Scholar]

- Galamboš, M.; Rosskopfová, O.G.; Kufčáková, J.; Rajec, P. Utilization of slovak bentonites in deposition of high-level radioactive waste and spent nuclear fuel. J. Radioanal. Nucl. Chem. 2011, 288, 765–777. [Google Scholar] [CrossRef]

- Zhao, X.G.; Wang, J.; Cai, M.; Cheng, C.; Ma, L.K.; Su, R.; Zhao, F.; Li, D.J. Influence of unloading rate on the strainburst characteristics of Beishan granite under true-triaxial unloading conditions. Rock Mech. Rock Eng. 2013, 1–17. [Google Scholar] [CrossRef]

- Zhao, X.G.; Wang, J.; Cai, M.; Ma, L.K.; Zong, Z.H.; Wang, X.Y.; Su, R.; Chen, W.M.; Zhao, H.G.; Chen, Q.C.; et al. In-situ stress measurements and regional stress field assessment of the Beishan area, China. Eng. Geol. 2013, 163, 26–40. [Google Scholar] [CrossRef]

- Adamcová, R.; Suraba, V.; Krajňák, A.; Rosskopfová, O.; Galamboš, M. First shrinkage parameters of slovak bentonites considered for engineered barriers in the deep geological repository of high-level radioactive waste and spent nuclear fuel. J. Radioanal. Nucl. Chem. 2014, 302, 737–743. [Google Scholar] [CrossRef]

- Wang, J. On area-specific underground research laboratory for geological disposal of high-level radioactive waste in china. J. Rock Mech. Geotech. Eng. 2014, 6, 99–104. [Google Scholar] [CrossRef]

- Bond, A.E.; Chittenden, N.; Fedors, R.; Lang, P.; McDermott, C.; Neretnieks, I.; Pan, P.; Šembera, J.; Watanabe, N.; Yasuhara, H. Coupled THMC Modelling of a Single Fracture in Novaculite for Decovalex-2015. In Proceedings of the 1st International Conference on Discrete Fracture Network Engineering, Vancouver, BC, Canada, 19–22 October 2014. [Google Scholar]

- Chen, L.; Wang, J.; Zong, Z.; Liu, J.; Su, R.; Guo, Y.; Jin, Y.; Chen, W.; Ji, R.; Zhao, H. A new rock mass classification system QHLW for high-level radioactive waste disposal. Eng. Geol. 2015, 190, 33–51. [Google Scholar] [CrossRef]

- Hoorelbeke, J.-M.; Lagrange, M.-H.; Chabert, C. Impact of Minor Actinide Transmutation Options on Geological Disposal: The French Case; Fast Reactors and Related Fuel Cycles: Safe Technologies and Sustainable Scenarios (FR13). In Proceedings of the International Conference on Fast Reactors And Related Fuel Cycles, Paris, France, 4–7 March 2013. [Google Scholar]

- Zhao, X.G.; Cai, M.; Wang, J.; Li, P.F. Strength comparison between cylindrical and prism specimens of Beishan granite under uniaxial compression. Int. J. Rock Mech. Min. Sci. 2015, 76, 10–17. [Google Scholar] [CrossRef]

- Zhao, X.G.; Wang, J.; Qin, X.H.; Cai, M.; Su, R.; He, J.G.; Zong, Z.H.; Ma, L.K.; Ji, R.L.; Zhang, M.; et al. In-situ stress measurements and regional stress field assessment in the Xinjiang candidate area for China’s HLW disposal. Eng. Geol. 2015, 197, 42–56. [Google Scholar] [CrossRef]

- Cheng, C.; Li, X.; Li, S.; Zheng, B. Geomechanical studies on granite intrusions in Alxa area for high-level radioactive waste disposal. Sustainability 2016, 8, 1329. [Google Scholar] [CrossRef]

- Song, F.; Dong, Y.-H.; Xu, Z.-F.; Zhou, P.-P.; Wang, L.-H.; Tong, S.-Q.; Duan, R.-Q. Granite microcracks: Structure and connectivity at different depths. J. Asian Earth Sci. 2016, 124, 156–168. [Google Scholar] [CrossRef]

- Zhao, X.G.; Wang, J.; Chen, F.; Li, P.F.; Ma, L.K.; Xie, J.L.; Liu, Y.M. Experimental investigations on the thermal conductivity characteristics of Beishan granitic rocks for China’s HLW disposal. Tectonophysics 2016, 683, 124–137. [Google Scholar] [CrossRef]

- Cheng, C.; Li, X.; Li, S.; Zheng, B. Failure behavior of granite affected by confinement and water pressure and its influence on the seepage behavior by laboratory experiments. Materials 2017, 10, 798. [Google Scholar] [CrossRef]

- Marschall, P.; Giger, S.; De La Vassière, R.; Shao, H.; Leung, H.; Nussbaum, C.; Trick, T.; Lanyon, B.; Senger, R.; Lisjak, A.; et al. Hydro-mechanical evolution of the edz as transport path for radionuclides and gas: Insights from the mont terri rock laboratory (switzerland). Swiss J. Geosci. 2017, 110, 173–194. [Google Scholar] [CrossRef]

- Wang, J.; Chen, L.; Su, R.; Zhao, X. The Beishan underground research laboratory for geological disposal of high-level radioactive waste in China: Planning, site selection, site characterization and in situ tests. J. Rock Mech. Geotech. Eng. 2018, 10, 411–435. [Google Scholar] [CrossRef]

- Zhao, X.G.; Zhao, Z.; Guo, Z.; Cai, M.; Li, X.; Li, P.F.; Chen, L.; Wang, J. Influence of thermal treatment on the thermal conductivity of Beishan granite. Rock Mech. Rock Eng. 2018, 51, 2055–2074. [Google Scholar] [CrossRef]

- Zhou, J.; Lan, H.; Zhang, L.; Yang, D.; Song, J.; Wang, S. Novel grain-based model for simulation of brittle failure of Alxa porphyritic granite. Eng. Geol. 2019, 251, 100–114. [Google Scholar] [CrossRef]

- Ahlgren, S.G. The nucleation and evolution of riedel shear zones as deformation bands in porous sandstone. J. Struct. Geol. 2001, 23, 1203–1214. [Google Scholar] [CrossRef]

- Cho, N.; Martin, C.D.; Sego, D.C. Development of a shear zone in brittle rock subjected to direct shear. Int. J. Min. 2008, 45, 1335–1346. [Google Scholar]

- Précigout, J.; Stünitz, H. Evidence of phase nucleation during olivine diffusion creep: A new perspective for mantle strain localisation. Earth Planet. Sci. Lett. 2016, 455, 94–105. [Google Scholar] [CrossRef][Green Version]

- Précigout, J.; Stünitz, H.; Villeneuve, J. Excess water storage induced by viscous strain localization during high-pressure shear experiment. Sci. Rep. 2019, 9, 3463. [Google Scholar]

- Vermeer, P.A.; De Borst, R. Non-associated plasticity for soils, concrete and rock. HERON 1984, 29, 1–64. [Google Scholar]

- Zhao, X.G.; Cai, M. A mobilized dilation angle model for rocks. Int. J. Rock Mech. Min. Sci. 2010, 47, 368–384. [Google Scholar] [CrossRef]

- Walton, G.; Diederichs, M.S. A new model for the dilation of brittle rocks based on laboratory compression test data with separate treatment of dilatancy mobilization and decay. Geotech. Geol. Eng. 2015, 33, 661–679. [Google Scholar] [CrossRef]

- Diederichs, M.S.; Kaiser, P.K.; Eberhardt, E. Damage initiation and propagation in hard rock during tunnelling and the influence of near-face stress rotation. Int. J. Rock Mech. Min. Sci. 2004, 41, 785–812. [Google Scholar] [CrossRef]

- Cai, M. Practical estimates of tensile strength and Hoek-Brown strength parameter mi of brittle rocks. Rock Mech Rock Eng 2010, 43, 167–184. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E.T. Practical estimates of rock mass strength. Int. J. Rock Mech. Min. Sci. 1997, 34, 1165–1186. [Google Scholar] [CrossRef]

- Detournay, E. Elastoplastic model of a deep tunnel for a rock with variable dilatancy. Rock Mech. Rock Eng. 1986, 19, 99–108. [Google Scholar] [CrossRef]

- Alejano, L.R.; Alonso, E. Considerations of the dilatancy angle in rocks and rock masses. Int. J. Rock Mech. Min. Sci. 2005, 42, 481–507. [Google Scholar] [CrossRef]

- Yuan, S.-C.; Harrison, J. An empirical dilatancy index for the dilatant deformation of rock. Int. J. Rock Mech. Min. Sci. 2004, 4, 679–686. [Google Scholar] [CrossRef]

- Zhao, X.G.; Cai, M. Influence of plastic shear strain and confinement-dependent rock dilation on rock failure and displacement near an excavation boundary. Int. J. Rock Mech. Min. Sci. 2010, 47, 723–738. [Google Scholar] [CrossRef]

- Walton, G.; Arzúa, J.; Alejano, L.R.; Diederichs, M.S. A laboratory-testing-based study on the strength, deformability, and dilatancy of carbonate rocks at low confinement. Rock Mech. Rock Eng. 2015, 48, 941–958. [Google Scholar] [CrossRef]

- Walton, G.; Alejano, L.R.; Arzua, J.; Markley, T. Crack damage parameters and dilatancy of artificially jointed granite samples under triaxial compression. Rock Mech. Rock Eng. 2018, 51, 1637–1656. [Google Scholar] [CrossRef]

- Cresswell, A.W.; Barton, M.E. Direct shear tests on an uncemented, and a very slightly cemented, locked sand. Q. J. Eng. Geol. Hydrogeol. 2003, 36, 119–132. [Google Scholar] [CrossRef]

- Simoni, A.; Houlsby, G.T. The direct shear strength and dilatancy of sand–gravel mixtures. Geotech. Geol. Eng. 2006, 24, 523. [Google Scholar] [CrossRef]

- Hamidi, A.; Azini, E.; Masoudi, B. Impact of gradation on the shear strength-dilation behavior of well graded sand-gravel mixtures. Sci. Iran. 2012, 19, 393–402. [Google Scholar] [CrossRef]

- Chu, L.-M.; Yin, J.-H. Comparison of interface shear strength of soil nails measured by both direct shear box tests and pullout tests. J. Geotech. Geoenviron. Eng. 2005, 131, 1097–1107. [Google Scholar] [CrossRef]

- Bagherzadeh-Khalkhali, A.; Mirghasemi, A.A. Numerical and experimental direct shear tests for coarse-grained soils. Particuology 2009, 7, 83–91. [Google Scholar] [CrossRef]

- Lajtai, E.Z. Shear strength of weakness planes in rock. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1969, 6, 499–515. [Google Scholar] [CrossRef]

- Barton, N. A model study of rock-joint deformation. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1972, 9, 579–582. [Google Scholar] [CrossRef]

- Bandis, S. Experimental Studies of Scale Effects on Shear Strength, and Deformation of Rock Joints. Ph.D. Thesis, University of Leeds, Leeds, UK, 1980. [Google Scholar]

- Barton, N.; Bandis, S. Some effects of scale on the shear strength of joints. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1980, 17, 69–73. [Google Scholar] [CrossRef]

- Gehle, C.; Kutter, H.K. Breakage and shear behaviour of intermittent rock joints. Int. J. Rock Mech. Min. Sci. 2003, 40, 687–700. [Google Scholar] [CrossRef]

- Li, H.; Feng, H.; Liu, B. Study on strength behaviors of rock joints under different shearing deformation velocities. Chin. J. Rock Mech. Eng. 2006, 12, 11. [Google Scholar]

- Ghazvinian, A.; Nikudel, M.; Sarfarazi, V. Effect of Rock Bridge Continuity and Area on Shear Behavior of Joints. In Proceedings of the 11th Congress of the International Society for Rock Mechanics, Lisbon, Portugal, 9–13 July 2007. [Google Scholar]

- Tang, Z.; Xia, C.; Xiao, S. Constitutive model for joint shear stress-displacement and analysis of dilation. Chin. J. Rock Mech. Eng. 2011, 30, 917–925. [Google Scholar]

- Ghazvinian, A.; Sarfarazi, V.; Schubert, W.; Blumel, M. A study of the failure mechanism of planar non-persistent open joints using pfc2d. Rock Mech. Rock Eng. 2012, 45, 677–693. [Google Scholar] [CrossRef]

- Tian, H.; Chen, W.; Yang, D.; Yang, J. Experimental and numerical analysis of the shear behaviour of cemented concrete–rock joints. Rock Mech. Rock Eng. 2015, 48, 213–222. [Google Scholar] [CrossRef]

- Zheng, B.; Qi, S. A new index to describe joint roughness coefficient (JRC) under cyclic shear. Eng. Geol. 2016, 212, 72–85. [Google Scholar] [CrossRef]

- Huang, D.; Zhu, T.-T. Experimental and numerical study on the strength and hybrid fracture of sandstone under tension-shear stress. Eng. Fract. Mech. 2018, 200, 387–400. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, L.; Yang, D.; Braun, A.; Han, Z. Investigation of the quasi-brittle failure of alashan granite viewed from laboratory experiments and grain-based discrete element modeling. Materials 2017, 10, 835. [Google Scholar] [CrossRef]

- Bruning, T.; Karakus, M.; Nguyen, G.D.; Goodchild, D. Experimental study on the damage evolution of brittle rock under triaxial confinement with full circumferential strain control. Rock Mech. Rock Eng. 2018, 51, 3321–3341. [Google Scholar] [CrossRef]

| NO. | Sample Size (mm × mm × mm) | Normal Stress (MPa) |

|---|---|---|

| N-S1 | 98.91 × 99.07 × 99.05 | 5 |

| N-S2 | 99.12 × 99.16 × 99.15 | 3 |

| N-S3 | 98.87 × 98.90 × 99.06 | 7 |

| N-S4 | 99.02 × 99.33 × 99.14 | 11 |

| N-S5 | 99.01 × 99.28 × 98.83 | 9 |

| N-S6 | 99.16 × 98.97 × 99.11 | 13 |

| N-S7 | 99.26 × 98.98 × 99.07 | 15 |

| N-S8 | 99.22 × 98.88 × 99.13 | 17 |

| N-S9 | 99.03 × 99.11 × 99.09 | 15 |

| N-S10 | 99.08 × 99.13 ×98.77 | 15 |

| N-S11 | 98.83 × 98.94 × 98.94 | 9 |

| N-S12 | 98.99 × 99.07 × 98.87 | 9 |

| N-S13 | 99.22 × 99.09 × 99.18 | 3 |

| N-S14 | 99.09 × 99.08 × 99.20 | 3 |

| Normal Stress (MPa) | R2 | ||||

|---|---|---|---|---|---|

| 7 | 38.20 | −0.18 | 0.50 | 2.20 | 0.9150 |

| 11 | 39.01 | −0.12 | 0.50 | 1.76 | 0.9565 |

| 13 | 16.81 | 1.48 | 0.50 | 1.83 | 0.8517 |

| 15 | 23.66 | 1.98 | 0.50 | 2.00 | 0.9236 |

| 17 | 15.45 | 5.36 | 0.50 | 2.58 | 0.9008 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, C.; Li, X.; Xu, N.; Zheng, B. Direct Shear Experimental Study on the Mobilized Dilation Behavior of Granite in Alxa Candidate Area for High-Level Radioactive Waste Disposal. Energies 2020, 13, 122. https://doi.org/10.3390/en13010122

Cheng C, Li X, Xu N, Zheng B. Direct Shear Experimental Study on the Mobilized Dilation Behavior of Granite in Alxa Candidate Area for High-Level Radioactive Waste Disposal. Energies. 2020; 13(1):122. https://doi.org/10.3390/en13010122

Chicago/Turabian StyleCheng, Cheng, Xiao Li, Nengxiong Xu, and Bo Zheng. 2020. "Direct Shear Experimental Study on the Mobilized Dilation Behavior of Granite in Alxa Candidate Area for High-Level Radioactive Waste Disposal" Energies 13, no. 1: 122. https://doi.org/10.3390/en13010122

APA StyleCheng, C., Li, X., Xu, N., & Zheng, B. (2020). Direct Shear Experimental Study on the Mobilized Dilation Behavior of Granite in Alxa Candidate Area for High-Level Radioactive Waste Disposal. Energies, 13(1), 122. https://doi.org/10.3390/en13010122