1. Introduction

The oil industry plays a central role in the modern economy and society [

1,

2]. However, intensive and extensive exploitation of oil sources often leads to environmental degradation, thus raising sustainability concerns. Despite the importance of the oil industry, the literature largely neglects the sustainability related challenges in the management of supply chains [

3].

Sustainability involves an integrated approach of economic, social and environmental dimensions of a business [

4,

5]. Since business success depends to a larger extent on efficient Supply Chain Management (SCM) [

6,

7], it is therefore critical that sustainability considerations be integrated in the management of supply chain functions [

8].

Even though Sustainable Supply Chain Management (SSCM) benefits from extensive research inputs [

9,

10,

11,

12], actual implementation has proven difficult [

13], while extensive research is required in order to fully understand its impact on supply chains [

14,

15,

16,

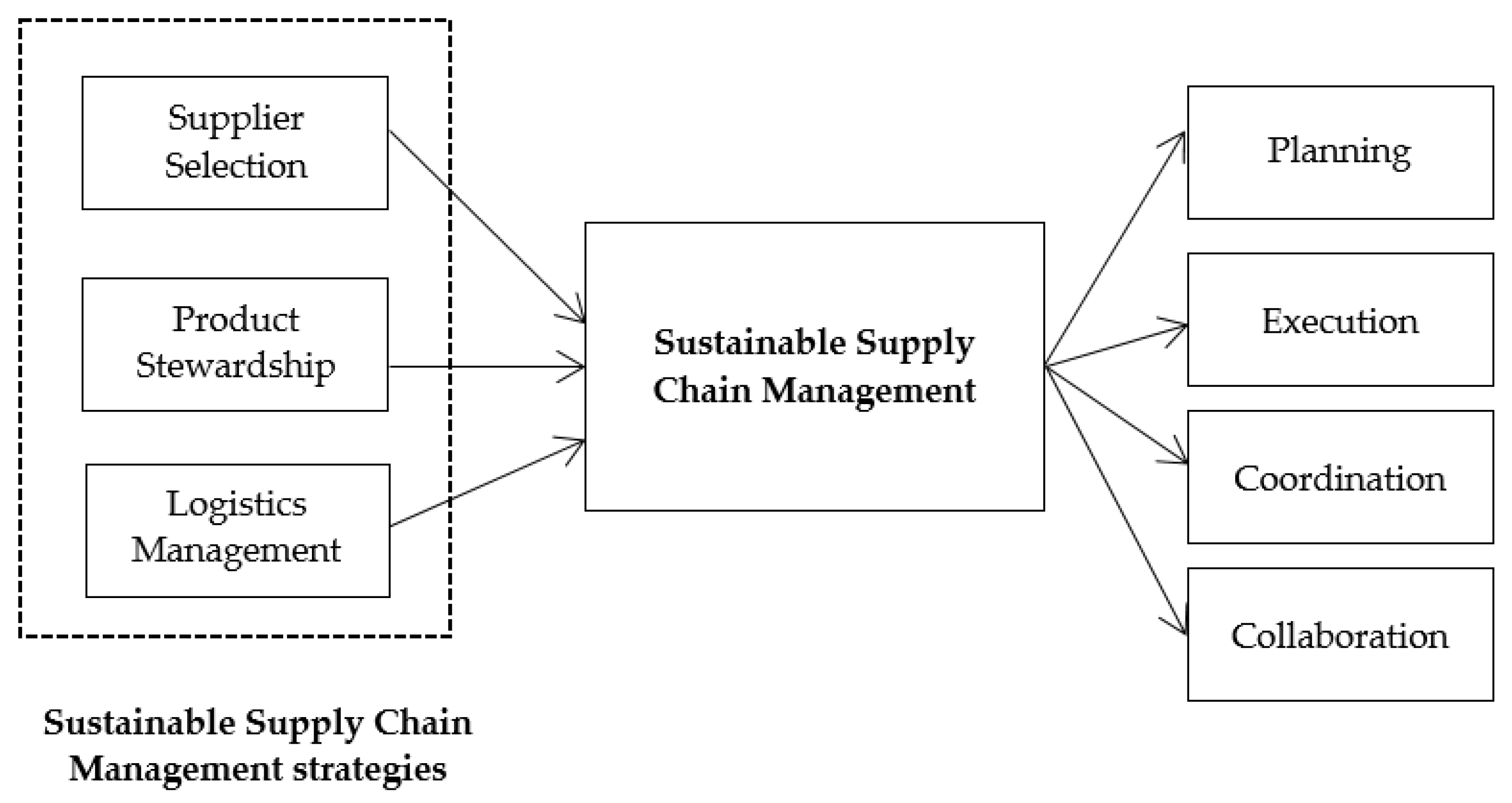

17]. This provided the rationale of this study: to analyze the possible impact induced by sustainable approach of Supply Chain Management upon Supply Chain Management functions. Since the relationships between SCM functions and SSCM strategies in the oil industry are not analysed in the literature, this contributes to literature development on the topic. Accordingly, this study aims to contribute to understanding the impact of Sustainable Supply Chain Management strategies—Supplier Selection, Product Stewardship and Logistics Management—on SCM functions—Planning, Execution, Coordination and Collaboration.

The paper is organized as follows:

Section 2 presents existing literature related to SSCM strategies and the SCM functions;

Section 3 presents the conceptual research model;

Section 4 describes the research methodology;

Section 5 details the results; and

Section 6 is dedicated to conclusions by highlighting the main findings, shortcomings and future research directions.

2. Literature Review

Sustainable Supply Chain Management represents the systemic integration of critical business processes which enables companies and their supply chains to fulfill economic, environmental and social goals [

10]. As such, companies implementing it are able to reach short term economic goals and become proactive in addressing supply chain activities long term environmental and social expectations.

The oil industry is important in terms of sustainability because its products are widely used in economic and social activities. SSCM implementation may reduce the negative impacts of operations. Although SCM as a field reached maturity, research on SSCM in the oil industry is still in its infancy. The few existing studies on the topic focused on supply chain performance improvement through innovation strategies and open innovation programs [

18]: suppliers development through management systems able to identify and manage the environmental and social risks involved in their operations [

17]; developing a Green SCM framework to assess environmental sustainability in oil refinery operations [

19]; assessing the impacts on environment of decommissioning offshore oil platforms [

20]; challenges in integrating corporate strategic topic in SCM in oil companies and their suppliers [

21]; and close cooperation of oil companies with suppliers to improve the environmental performance of logistics operations [

22].

2.1. Sustainable Supply Chain Management Strategies

SSCM strategy was considered on two levels: first as a singular concept, regardless of various specific strategies which are employed by oil distribution companies to support SSCM. In this case, SSCM strategy was composed of all items comprising the specific strategies; second, as specific strategies—Supplier Selection, Product Stewardship and Logistics Management [

9].

a. Supplier Selection Strategy

Oil and gas distribution companies are confronted with a wide range of economic, environmental and social challenges in the management of a supply chain [

23,

24]. This is why SSCM in the oil industry has to cope with a broad variety of issues, ranging from the replacement of pollution effects, excessive energy and material consumption to biodiversity protection [

25]. Instead of managing each potential issue separately, oil companies choose to conform to norms or to apply commonly accepted standards [

26].

Oil and gas distribution companies may assess the environmental or social impact of suppliers by using codes of conduct, norms and standards and certification which authenticate the compliance [

27]. All of these constitute criteria for performance improvements along the supply chain.

Since oil and gas distribution companies are governing their supply chains [

28] they also evaluate their suppliers by establishing minimum requirements and standards. Therefore, suppliers can provide self-assessments on environmental or social requirements, which may be encouraged by providing incentives [

29,

30].

b. Product Stewardship Strategy

Product Stewardship strategy includes many aspects of sustainability such as reverse logistics and closed loop supply chains [

31,

32]. Lane and Watson (2012) [

33] argue that Product Stewardship strategy is a fast expanding area that have an increasingly important role for conserving resources and is creating a differentiation advantage for a firm [

34]. Various scholars [

35,

36] finds that stewardship related to environmental management is a strategy increasingly used in relation to material responsibility. The concept of Product stewardship evolved from responsible management of hazardous wastes towards a broader focus on resource conservation. Product Stewardship approaches have changed the relationship between the societal and material worlds [

37] and new industrial sectors have arisen from these initiatives and resulted in the formation of partnerships [

38]. The ultimate goal of engaging in Product Stewardship is to minimize the environmental impacts of the products through the life cycle [

39].

c. Logistics Management

Grant et al. (2013) [

40] argue that companies have come to realize that logistics services and expertise are the key elements in providing sustainable solutions. The development towards logistics as a sustainability enhancer comes both from suppliers rethinking their offering and from companies adjusting their view about their own logistics processes, increasingly regarded as strategic levers influencing their market position [

41]. The trend towards sustainable logistics brings forward an increased level of cooperation among all actors involved in the supply chain, as they have to comply with more rigorous standards, agree on price tags and support binding regulations.

Grant et al. (2006) [

42] argue that consumers have the power to enforce change through their buying decisions. However, they will also demand more transparency, especially when paying a premium for sustainable solutions, requesting comprehensive carbon accounting, controlling and management systems, standardized CO

2 labelling, etc. Currently, this transparency is provided mostly for green products within companies and is determined by promoting international standards that provide transparency regarding CO

2 emissions. Common standards and rules that apply to all actors in the business will therefore need to be introduced [

40]. At the start, the industry will see a drive to implement accurate but feasible standards for CO

2 accounting and reporting across the sector.

2.2. Supply Chain Management Functions

A range of SCM functions exist, emphasizing different perspectives [

43]. Hassini et al. [

44] consider that the essential supply chain functions are planning and execution while other scholars [

45,

46] argue that SSCM requires a wider focus by extending towards coordination and collaboration. As a consequence, four SCM functions are considered in this paper: Planning, Execution, Coordination and Collaboration.

Developing a SSCM requires a focus on the supply chain and the active participation of supply chain members [

47,

48,

49] and involves collaboration. Efficient planning and collaboration has been found to have a positive impact for supply chains on areas like waste elimination, material recycling or energy saving [

50,

51], the development of innovative environmental improvement processes [

52,

53] and the environmental impact information on purchased materials [

54]. On the other hand, poor supply chain communication leads to insufficient information transfer [

55] and affects the goal alignment [

56], which is required for implementing environmental sustainability in supply chains [

57].

Supply chain collaboration influences supply chain sustainability through its effect on knowledge transfer and problem-solving associated with supply chain members [

58,

59]. For instance, codes of conduct are used to establish principles in supply chains and require communication to enforce those standards throughout the supply chain [

60,

61]. Hence, the communication may directly affect the social sustainability performance of the supply chain.

a. Planning

Supply chains in oil and gas distribution industry are complex, involving large numbers of suppliers and customers [

62]. Hence, the planning process is complex and requires long-term demand, capacity, network and distribution planning [

63], while purchasing, distribution and demand fulfillment usually requires a medium to short-term perspective [

64]. Adequate planning for setting up a sustainable supply chain is critical and a comprehensive long-term strategy is required [

10].

b. Execution

Execution function includes managing orders, inventories, material flows and delivery, as well as warehousing and transportation [

28]. Execution enables decisions regarding procurement, production, distribution and sales made during planning to be operationalized [

64]. Efficient execution is highly dependent on supply chain planning, but also on coordination and collaboration [

46].

c. Coordination

Coordination function involves monitoring of operations, analysis and process optimization in supply chain processes such as procurement and distribution [

65]. SCM is accomplished through supply chain processes that cut across functional boundaries [

66]. SSCM requires improved coordination between all supply chain stakeholders to be able to ascertain orientation toward cost or profit, or compliance with regulations [

67]. As a consequence, Coordination activities affect supply chain sustainability by developing SSCM in the organization [

68].

d. Collaboration

In the last years, a shift in academic discourse emerged towards supply chain collaboration and the importance of a cross-organisational focus [

69]. Extending collaboration across organisational boundaries is a challenging and complex endeavour [

65]. The findings emphasise the importance of developing supply chain visibility, trust, a common strategy and vision, effective change management processes as well as active relationship management [

70].

Communication may be improved by information sharing and regular updates between supply chain members and by establishing a shared vision [

71]. Internal relationship management have been associated with waste elimination and the reduction, prevention and control of pollution [

72]. External relationship management associated with stakeholders regards outside actors such as governments, NGOs or customers which assert sustainability pressure on supply chains through legal demands, regulations, and by shaping public opinion [

28] making external relationship management instrumental to SSCM.

3. The Conceptual Model

a. Supplier Selection Strategy

In this study, Supplier Selection strategy envisages items like sustainability requirements, environmental certification, code of business conduct, compliance with contract and quality standards compliance, technical capability and reputation or long term relationship (see

Table 1).

b. Product Stewardship Strategy

Product Stewardship strategy comprises, in this study, items related to safety warning compliance, supplier involvement, safety compliance, environment-friendly alternative materials or safe and ecological packaging (see

Table 2).

c. Logistics Management

Logistics Management strategy comprises items like recycle/reuse containers, use of fuel efficient vehicles, use of recyclable packaging systems, environmental-friendly transport mode, transport safety training, safety and health risks of transport mode and inspection and maintenance of vehicles (see

Table 3).

Supply Chain Management Functions

a. Planning

Planning function comprises items like commitment, long-term focus on sustainability goals, focus on SSCM goals, sustainable investments, incentives for SSCM, and research in sustainability of supply chains, transport and warehousing planning and renewability of resources (see

Table 4).

b. Execution

In this paper, Execution function comprises operational accuracy focus, customer satisfaction focus, efficiency in transportation, efficiency in warehousing, measurement and performance tracking, health and safety measures, waste and recycling management and maintenance of equipment (see

Table 5).

c. Coordination

Coordination function is described in the study using the following items: Supply chain alignment, supply chain costs focus, supply chain profits focus, compliance, contribution for local community, cost allocations for unaccounted supply chain impacts and empowerment (see

Table 6).

d. Collaboration

The following items were considered in the paper to describe Collaboration function: information sharing, process integration, attitude towards SSCM, external relationship management, internal relationship management and shared vision (see

Table 7).

The conceptual model is presented below (see

Figure 1).

4. Materials and Methods

For this study, a questionnaire was developed, based on the literature review as well as input from academia and experts from companies operating in the oil and gas distribution industry.

The survey population consisted of companies operating in oil and gas distribution industry from Romania and Republic of Moldova. Top executives were investigated, such as Chief Executive Officers, Chief Procurement Officers or Chief Financial Officers.

The questionnaire was mailed to 255 companies, for Romanian based companies from a database used for a previously published study. For Republic of Moldova the authors used contact data made available by Romanian companies which accepted to participate in the study, using snowball sampling. We received 83 answers (32.5% response rate, with 2 one-month apart reminders), out of which 79 were valid (see

Table 8), a percentage in line with other studies in the industry [

73,

74]. To reduce the bias of self-reporting, a detailed description of each item was included as appendix to the questionnaire. At the same time, the authors compared the answers from companies in Romania with those received from companies in Republic of Moldova and found no significant differences between them.

Exploratory Factor Analysis (EFA) was used to measure both SCM functions and SSCM strategies by using the principal component method. In order to determine the factors retained for analysis, the factors with eigenvalues higher than 1 were selected [

75].

For the SSCM strategies items (see

Table 9), three factors were derived from the analysis. The three factors explain, respectively, 71.9% and 76.8% of the variance in their measurement items, well above the threshold of 60% [

75].

As for the SCM functions items (see

Table 10), the factor analysis reveals the presence of four factors as proposed in our framework. No items were removed.

For the reliability test, the Cronbach’s alpha values for all factors are above 0.70 (see

Table 11) [

76], with the correlations between independent variables relatively weak, an indication of low multicollinearity.

5. Analysis and Discussion

A multiple regression analysis was conducted to understand the relationship between SSCM strategies and Supply Chain Management, considered as the sum of all functions. Two control variables were used to test the regression model, namely company size and company age (see

Table 12).

The first model tests the relationship between SSCM strategies and SCM as a whole, this means considering all the functions, without control variables.

The second model tests the relationship between SSCM strategies and SCM as a whole, with control variable Size included.

The third model tests the relationship between SSCM strategies and SCM as a whole, with control variable Age included.

The fourth model tests the relationship between SSCM strategies and SCM as a whole, with all control variables included.

All models are highly significant, with around half of the variation in the SCM functions can be explained by Supplier Selection, Product Stewardship and Logistics Management strategies. Overall, Product Stewardship has the most impact, while Logistics Management has a lesser impact overall.

Another multiple regression analysis was conducted to understand the relationship between each SSCM strategy and with each SCM function, without (a) and with (b) control variables included (see

Table 13).

The models of all regression analyses, with and without control variables, are highly significant. About 35% of the variance in each SCM functions is explained by SSCM strategy.

Generally, we find Logistics Management strategy to influence more the Execution and Planning functions; Product Stewardship is more important for Planning, Coordination and Collaboration functions; overall, Execution functions seems least influenced by SSCM strategies, except Product Stewardship; Logistics Management strategy does not influence much Coordination and Collaboration.

6. Conclusions

This study seeks to understand the impact of SSCM strategies on SCM functions in companies operating in the oil and gas distribution industry. It explores the influence of three SSCM strategies—Supplier Selection, Product Stewardship and Logistics Management—on four SCM functions—Planning, Execution, Coordination and Collaboration. The main findings of our analyses are as follows.

The study proves that oil and gas companies’ sustainability strategies in supply chains definitely impacts the way SCM functions are implemented in companies, both overall, if considering SCM as being comprised of all four functions described in the study, and separately, especially in terms of Planning and Collaboration. The conclusions had to consider the fact that SCM functions are actually interconnected, while SSCM strategies are not mutually exclusive.

We found out that Supplier Selection strategy is influencing the Planning function more than others in terms of sustainability requirements, by considering the ability to meet sustainability requirements of the supply chain. Of course, these requirements may be internal or external, still they exists and has to be incorporated in oil and gas distribution companies long and medium terms strategies and policies. The focus on long term relationships gets oil and gas companies, when choosing a supplier, to consider a more comprehensive set of factors and to be more willing to invest in them. Another influence regards environmental certification, an increasing number of companies paying attention to certification, which sometimes may be compulsory of specific markets, especially in Romania as a member of European Union. Last but not least, we found out that reputation influences Planning. A corollary of the previous items, the reputation of the supplier in terms of environmental compliance may prove decisive in setting up a long-term relationship.

Supplier Selection strategy impacts upon Execution function in terms of contract and quality standards compliance. As a consequence, oil and gas distribution companies have to continuously monitor and assess their supplier commitment to contract requirements and its compliance with quality of service/product standards and regulations. Another area of interest is suppliers’ sustainable oriented technical capability—its capability to possesses equipment and technologies.

In terms of Coordination and Collaboration functions, Supplier Selection strategy gives credit to the congruence of suppliers with the industry and oil and gas company code of business conduct.

Product Stewardship strategy determines in the Execution function the focus on safety compliance, namely the company takes into account, when choosing a supplier, its safety legislation compliance and history. For some respondents, this was, at least partially, similar with reputation, and further efforts were required to differentiate the two concepts. The suppliers’ propensity to use environment-friendly alternative materials whenever possible or to ensure that their packaging is safe and ecological proved to be less important. That was not a surprise since we do not differentiate in our study downstream or upstream suppliers. Finally, adequate information for customers and users in the form of safety warning compliance must to be considered. The oil and gas distribution companies take into account, when choosing a supplier, products that have product safety warnings complying with existing regulations. Collaboration function is influenced by Product Stewardship in terms of suppliers’ involvement in the development of new products/services or in the development of new ones.

In terms of Logistics Management strategy, it has an impact on Planning by making the oil and gas distribution companies to by encouraging suppliers to focus on recycle/reuse containers and include this focus on their plans and operational programs, and to consider use of recyclable packaging systems both for themselves and their suppliers. Again, since we do not use as a control variable the position of the company—downstream or upstream suppliers—the results were mixed.

In terms of Execution function, use of fuel efficient vehicles, to some extent even hybrid or electric vehicles may become part of their business model. As a consequence, preference for environmental-friendly transport modes has to be considered by oil and gas distribution companies, making them prone to use more fuel efficient suppliers both form corporate social responsibility reasons and to cut costs. All this may determine a need for transport safety training focus, adequate consideration of safety and health risks of transport mode and responsible inspection and maintenance of vehicles.

There are several shortcomings of the study. First, the intermingling of the SCM functions, which are hard to differentiate in actual business processes, proved to be difficult to be understood by some respondents. Second, the fact that SSCM strategies are not mutually exclusive, while in the research model they are considered independent. Third, a small sample, but this is a common occurrence for the industry since the oil and gas distribution companies are less willing to get involved.

Overall, the findings of this study can be used by companies operating in oil and gas distribution to design SSCM strategies to better address the requirements for more environmentally and socially responsible activities in their supply chains and to optimize their SCM to better cope with Sustainable Supply Chain Management requirements and expectations. Since it is one of the first studies analyzing the impact of SSCM strategies on SCM, this may provide a scientific pillar for CEOs and SSCM supervisors to better substantiate their programs.

The results open new research directions in terms of including other elements in the analysis, such as the impact of digitalization [

77,

78,

79] or innovation based strategies, like adoptive [

80] upon Sustainable Supply Chain Management.

Author Contributions

Conceptualization, M.S.F., E.G.C., A.F.C., S.I.C.; methodology, E.G.C., S.I.C.; validation, M.S.F., E.G.C., A.F.C., S.I.C.; formal analysis, M.S.F., E.G.C., A.F.C., S.I.C.; investigation, E.G.C., S.I.C.; data curation, S.I.C.; writing—original draft preparation, E.G.C., A.F.C., S.I.C.; writing—review and editing, M.S.F., E.G.C., A.F.C., S.I.C.; funding acquisition, M.S.F.

Funding

The research published in this article has been supported by the Romanian government through CERTRAN project—The Upgrade of the Research Capacity in Economics through Development of a Transdisciplinary Research Infrastructure.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ceptureanu, E.G.; Ceptureanu, S.I.; Olaru, M.; Bogdan, V.L. An exploratory study on coopetitive behavior in oil and gas distribution. Energies 2018, 11, 1234. [Google Scholar] [CrossRef]

- Ceptureanu, E.G.; Ceptureanu, S.I.; Radulescu, V.; Ionescu, S. What makes coopetition successful? An inter-organizational side analysis on Critical Success Factors in oil and gas distribution networks. Energies 2018, 11, 3447. [Google Scholar] [CrossRef]

- Hussain, R.; Assavapokee, T.; Khumawala, B. Supply chain management in the petroleum industry: Challenges and opportunities. Int. J. Glob. Logist. Supply Chain Manag. 2006, 1, 90–97. [Google Scholar]

- Ceptureanu, S.I.; Ceptureanu, E.G.; Luchian, C.E.; Luchian, I. Community based programs sustainability. A multidimensional approach. Sustainability 2018, 10, 870. [Google Scholar] [CrossRef]

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of 21st Century Business; New Society Publishers: Gabriola Island, BC, Canada; Stony Creek, CT, USA, 1998. [Google Scholar]

- Chen, I.J.; Paulraj, A. Towards a theory of supply chain management: The constructs and measurements. J. Oper. Manag. 2004, 22, 119–150. [Google Scholar] [CrossRef]

- Lambert, D.M.; Cooper, M.C. Issues in supply chain management. Ind. Mark. Manag. 2000, 29, 65–83. [Google Scholar] [CrossRef]

- Jayaraman, V.; Klassen, R.; Linton, J.D. Supply chain management in a sustainable environment. J. Oper. Manag. 2007, 25, 1071–1074. [Google Scholar] [CrossRef]

- Ahmad, W.N.K.W.; Rezaei, J.; Tavasszy, L.A.; de Brito, M.P. Commitment to and preparedness for sustainable supply chain management in the oil and gas industry. J. Environ. Manag. 2016, 180, 202–213. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Corbett, C.J.; Klassen, R.D. Extending the horizons: Environmental excellence as key to improving operations. Manuf. Serv. Oper. Manag. 2006, 8, 5–22. [Google Scholar] [CrossRef]

- Winter, M.; Knemeyer, A.M. Exploring the integration of sustainability and supply chain management: Current state and opportunities for future inquiry. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 18–38. [Google Scholar] [CrossRef]

- Wagner, B.; Svensson, G. Sustainable supply chain practices: Research propositions for the future. Int. J. Logist. Econ. Glob. 2010, 2, 176–186. [Google Scholar] [CrossRef]

- Carter, C.R.; Easton, P.L. Sustainable supply chain management: Evolution and future directions. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 46–62. [Google Scholar] [CrossRef]

- Dey, A.; LaGuardia, P.; Srinivasan, M. Building sustainability in logistics operations: A research agenda. Manag. Res. Rev. 2011, 1237–1259. [Google Scholar] [CrossRef]

- Halldórsson, Á.; Kovács, G. The sustainable agenda and energy efficiency: Logistics solutions and supply chains in times of climate change. Int. J. Phys. Distrib. Logist. Manag. 2010, 40, 5–13. [Google Scholar] [CrossRef]

- Wagner, J.; Armstrong, K. Managing environmental and social risks in international oil and gas projects: Perspectives on compliance. J. World Energy Law Bus. 2010, 3, 140–165. [Google Scholar] [CrossRef]

- Thurner, T.; Proskuryakova, L.N. Out of the cold—The rising importance of environmental management in the corporate governance of Russian oil and gas producers. Bus. Strategy Environ. 2014, 23, 318–332. [Google Scholar] [CrossRef]

- Lakhal, S.Y.; H’Mida, S.; Islam, M.R. Green supply chain parameters for a Canadian petroleum refinery company. Int. J. Environ. Technol. Manag. 2007, 7, 56–67. [Google Scholar] [CrossRef]

- Lakhal, S.Y.; Khan, M.; Islam, M.R. An “Olympic” framework for a green decommissioning of an offshore oil platform. Ocean Coast. Manag. 2009, 52, 113–123. [Google Scholar] [CrossRef]

- Midttun, A.; Dirdal, T.; Gautesen, K.; Omland, T.; Wenstøp, S. Integrating corporate social responsibility and other strategic foci in a distributed production system: A transaction cost perspective on the North Sea offshore petroleum industry. Corp. Gov. 2007, 7, 194–208. [Google Scholar] [CrossRef][Green Version]

- Tesfay, Y.Y. Environmentally friendly cost efficient and effective sea transport outsourcing strategy: The case of Statoil. Transp. Res. Part D Transp. Environ. 2014, 31, 135–147. [Google Scholar] [CrossRef]

- Cousins, P.D.; Lamming, R.C.; Bowen, F. The role of risk in environment-related supplier initiatives. Int. J. Oper. Prod. Manag. 2004, 24, 554–565. [Google Scholar] [CrossRef]

- Teuscher, P.; Grüninger, B.; Ferdinand, N. Risk management in sustainable supply chain management (SSCM): Lessons learnt from the case of GMO-free soybeans. Corp. Soc. Responsib. Environ. Manag. 2006, 13, 1–10. [Google Scholar] [CrossRef]

- Halldórsson, Á.; Kotzab, H.; Skjoett-Larsen, T. Supply chain management on the crossroad to sustainability: A blessing or a curse? Int. J. Phys. Distrib. Logist. Manag. 2009, 1, 83–94. [Google Scholar] [CrossRef]

- Beske, P.; Koplin, J.; Seuring, S. The Use of Environmental and Social Standards by German First-Tier Suppliers of the Volkswagen AG. Corp. Soc. Responsib. Environ. Manag. 2008, 15, 63–75. [Google Scholar] [CrossRef]

- Pedersen, E.R.; Andersen, M. Safeguarding corporate social responsibility (CSR) in global supply chains: How codes of conduct are managed in buyer-supplier relationships. J. Public Aff. 2006, 6, 228–240. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Peters, N. Inter-Organisational Design of Voluntary Sustainability Initiatives: Increasing the Legitimacy of Sustainability Strategies for Supply Chains; Gabler: Wiesbaden, Germany, 2010. [Google Scholar]

- Delmas, M.A.; Montiel, I. Greening the Supply Chain: When Is Customer Pressure Effective? J. Econ. Manag. Strategy 2009, 18, 171–201. [Google Scholar] [CrossRef]

- Shuaib, M.; Metta, H.; Lu, T.; Badurdeen, F.; Jawahir, I.; Goldsby, T. Design and performance evaluation of sustainable supply chains: Approach and methodologies. Adv. Sustain. Manuf. 2011, 8, 347–352. [Google Scholar]

- Jaber, M.; El Saadaany, A.; Rosen, M. A simple price-driven reverse logistics system with entropy and exergy costs. Int. J. Exergy 2011, 9, 486–502. [Google Scholar] [CrossRef]

- Lane, R.; Watson, M. Stewardship of things: The radical potential of product stewardship for re-framing responsibilities and relationships to products and materials. Geoforum 2012, 43, 1254–1265. [Google Scholar] [CrossRef]

- Bhupendra, K.V.; Sangle, S. Product Stewardship Strategy: A Study of Indian Firms. Corp. Soc. Responsib. Environ. Manag. 2018, 25, 124–134. [Google Scholar] [CrossRef]

- Lewis, H. Defining product stewardship and sustainability in the Australian packaging industry. Environ. Sci. Policy 2005, 8, 45–55. [Google Scholar] [CrossRef]

- Michealis, P. Product stewardship, waste minimization and economic efficiency: Lessons from Germany. J. Environ. Plan. Manag. 1995, 38, 231–243. [Google Scholar] [CrossRef]

- Bridge, G. Material worlds: Natural resources, resource geography and the material economy. Geogr. Compass 2009, 3, 1217–1244. [Google Scholar] [CrossRef]

- Schroeder, H. Trends in Recycling and Product Stewardship: A Case for Enterprise Information Systems. Sustain. J. Rec. 2013, 6, 320–326. [Google Scholar] [CrossRef]

- Deutz, P. Producer responsibility in a sustainable development context: Ecological modernisation or industrial ecology. Geogr. J. 2009, 175, 274–285. [Google Scholar] [CrossRef]

- Grant, D.B.; Wong, C.Y.; Trautrims, A. Sustainable Logistics and Supply Chain Management; Kogan Page Ltd.: New York, NY, USA, 2013. [Google Scholar]

- Lemoine, W.; Dagnaes, L. Globalisation strategies and business organisation of a network of logistics service providers. Int. J. Phys. Distrib. Logist. Manag. 2003, 33, 209–228. [Google Scholar] [CrossRef]

- Grant, D.B.; Lambert, D.M.; Stock, J.R.; Ellram, L.M. Fundamentals of Logistics Management; McGraw-Hill Higher Education: New York, NY, USA, 2006. [Google Scholar]

- Mentzer, J.T.; DeWitt, W.; Keebler, J.S.; Soonhoong, M.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining supply chain management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Hassini, E.; Surti, C.; Searcy, C. A literature review and a case study of sustainable supply chains with a focus on metrics. Int. J. Prod. Econ. 2012, 140, 69–82. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Reefke, H.; Sundaram, D. Key themes and research opportunities in sustainable supply chain management—Identification and evaluation. Omega 2017, 66, 195–211. [Google Scholar] [CrossRef]

- Kirchoff, J.F.; Tate, W.L.; Mollenkopf, D.A. The impact of strategic organizational orientations on green supply chain management and firm performance. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 269–292. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, X.; Tang, O.; Price, L.; Zhang, S.; Zhu, W. Supply chain collaboration for sustainability: A literature review and future research agenda. Int. J. Prod. Econ. 2017, 194, 73–87. [Google Scholar] [CrossRef]

- Green, K.W.; Toms, L.C.; Clark, J. Impact of market orientation on environmental sustainability strategy. Manag. Res. Rev. 2015, 38, 217–238. [Google Scholar] [CrossRef]

- Gold, S.; Seuring, S.; Beske, P. Sustainable supply chain management and inter-organizational resources: A literature review. Corp. Soc. Responsib. Environ. Manag. 2010, 17, 230–245. [Google Scholar] [CrossRef]

- Bowen, F.E.; Cousins, P.D.; Lamming, R.C.; Farnk, A.C. The role of supply management capabilities in green supply. Prod. Oper. Manag. 2001, 10, 174–189. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Sarkis, J.; Wang, X. Assessing green supply chain practices in the Ghanaian mining industry: A framework and evaluation. Int. J. Prod. Econ. 2016, 181, 325–341. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Environmental management and manufacturing performance: The role of collaboration in the supply chain. Int. J. Prod. Econ. 2008, 111, 299–315. [Google Scholar] [CrossRef]

- Rivera-Camino, J. Re-evaluating green marketing strategy: A stakeholder perspective. Eur. J. Mark. 2007, 41, 1328–1358. [Google Scholar] [CrossRef]

- Harms, D. Environmental sustainability and supply chain management—A framework of cross-functional integration and knowledge transfer. J. Environ. Sustain. 2011, 1, 1–23. [Google Scholar] [CrossRef]

- Moses, A.; Åhlström, P. Problems in cross-functional sourcing decision processes. J. Purch. Supply Manag. 2008, 14, 87–99. [Google Scholar] [CrossRef]

- Lorenzoni, G.; Lipparini, A. The leveraging of inter-firm relationships as a distinctive organizational capability: A longitudinal study. Strateg. Manag. J. 1999, 20, 317–338. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K.-H. Invited Contribution: An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Carter, C.R.; Jennings, M.M. The role of purchasing in corporate social responsibility: A structural equation analysis. J. Bus. Logist. 2004, 25, 145–186. [Google Scholar] [CrossRef]

- Mamic, I. Managing Global Supply Chain: The Sports Footwear, Apparel and Retail Sectors. J. Bus. Ethics 2005, 59, 81–100. [Google Scholar] [CrossRef]

- Spence, L.; Bourlakis, M. The evolution from corporate social responsibility to supply chain responsibility: The case of Waitrose. Supply Chain Manag. 2009, 14, 291–302. [Google Scholar] [CrossRef]

- Cooper, M.C.; Ellram, L.M.; Gardner, J.T.; Hanks, A.M. Meshing multiple alliances. J. Bus. Logist. 1997, 18, 67–90. [Google Scholar]

- Stadtler, H. Supply chain management and advanced planning—Basics, overview and challenges. Eur. J. Oper. Res. 2005, 163, 575–588. [Google Scholar] [CrossRef]

- Meyr, H.; Wagner, M.; Rohde, J. Structure of advanced planning systems. In Supply Chain Management and Advanced Planning: Concepts, Models, Software, and Case Studies, 4th ed.; Stadtler, H., Kilger, C., Eds.; Springer: Berlin, Germany, 2008. [Google Scholar]

- Arshinder, K.A.; Deshmukh, S.G. Supply chain coordination: Perspectives, empirical studies and research directions. Int. J. Prod. Econ. 2008, 115, 316–335. [Google Scholar] [CrossRef]

- Sharp, A.; McDermott, P. Workflow Modeling: Tools for Process Improvement and Applications Development, 2nd ed.; Artech House Inc.: Norwood, MA, USA, 2009. [Google Scholar]

- Turner, M.; Houston, P. Going green? Start with sourcing. Supply Chain Manag. Rev. 2009, 13, 14–21. [Google Scholar]

- Signori, P.; Flint, D.J.; Golicic, S. Toward sustainable supply chain orientation (SSCO): Mapping managerial perspectives. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 536–564. [Google Scholar] [CrossRef]

- Jadhav, A.; Orr, S.; Malik, M. The role of supply chain orientation in achieving supply chain sustainability. Int. J. Prod. Econ. 2018. [Google Scholar] [CrossRef]

- Gold, S.; Seuring, S.; Beske, P. The constructs of sustainable supply chain management—A content analysis based on published case studies. Prog. Ind. Ecol. Int. J. 2010, 7, 114–137. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. An inter-sectoral comparison of green supply chain management in China: Drivers and practices. J. Clean. Prod. 2006, 14, 472–486. [Google Scholar] [CrossRef]

- Bansal, P.; McKnight, B. Looking forward, pushing back and peering sideways: Analyzing the sustainability of industrial symbiosis. J. Supply Chain Manag. 2009, 45, 26–37. [Google Scholar] [CrossRef]

- Andersen, S.; Mostue, B.A. Risk analysis and risk management approaches applied to the petroleum industry and their applicability to IO concepts. Saf. Sci. 2012, 50, 2010–2019. [Google Scholar] [CrossRef]

- Yusuf, Y.Y.; Gunasekaran, A.; Musa, A.; El-Berishy, N.M.; Abubakar, T.; Ambursa, H.M. The UK oil and gas supply chains: An empirical analysis of adoption of sustainable measures and performance outcomes. Int. J. Prod. Econ. 2013, 146, 501–514. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B. Multivariate Data Analysis: A Global Perspective; Pearson Education: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Flynn, B.B.; Sakakibara, S.; Schroeder, R.G.; Bates, K.A.; Flynn, E.J. Empirical research methods in operations management. J. Oper. Manag. 1990, 9, 250–284. [Google Scholar] [CrossRef]

- Müller, J.M.; Voigt, K.I. Sustainable industrial value creation in SMEs: A comparison between industry 4.0 and Made in China 2025. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 659–670. [Google Scholar] [CrossRef]

- Beier, G.; Niehoff, S.; Ziems, T.; Xue, B. Sustainability aspects of a digitalized industry–A comparative study from China and Germany. Int. J. Precis. Eng. Manuf. Green Technol. 2017, 4, 227–234. [Google Scholar] [CrossRef]

- Müller, J.M.; Kiel, D.; Voigt, K.I. What drives the implementation of industry 4.0? The role of opportunities and challenges in the context of sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Ceptureanu, E.G.; Ceptureanu, S.I. The impact of adoptive management innovations on medium-sized enterprises from a dynamic capability perspective. Technol. Anal. Strateg. Manag. 2019. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).