Environmental Decision Support System for Biogas Upgrading to Feasible Fuel

Abstract

:- -

- BiogasApp_EDSS is a tool considering a wide spectrum of parameters simultaneously

- -

- The EDSS is structured hierarchically to simplify the flow and interactions of data and knowledge

- -

- The EDSS has been validated with a real case-study

- -

- The sensitivity analysis allowed identifying key criteria

- -

- Biotechnologies were competitive alternatives when economic criteria were concerned

1. Introduction

2. Methodology

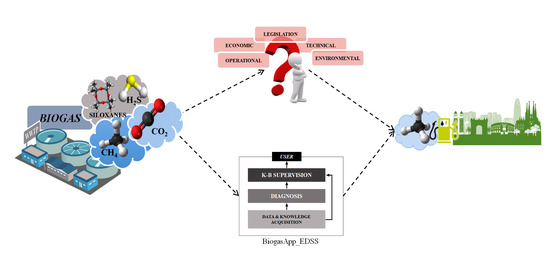

2.1. EDSS Operation

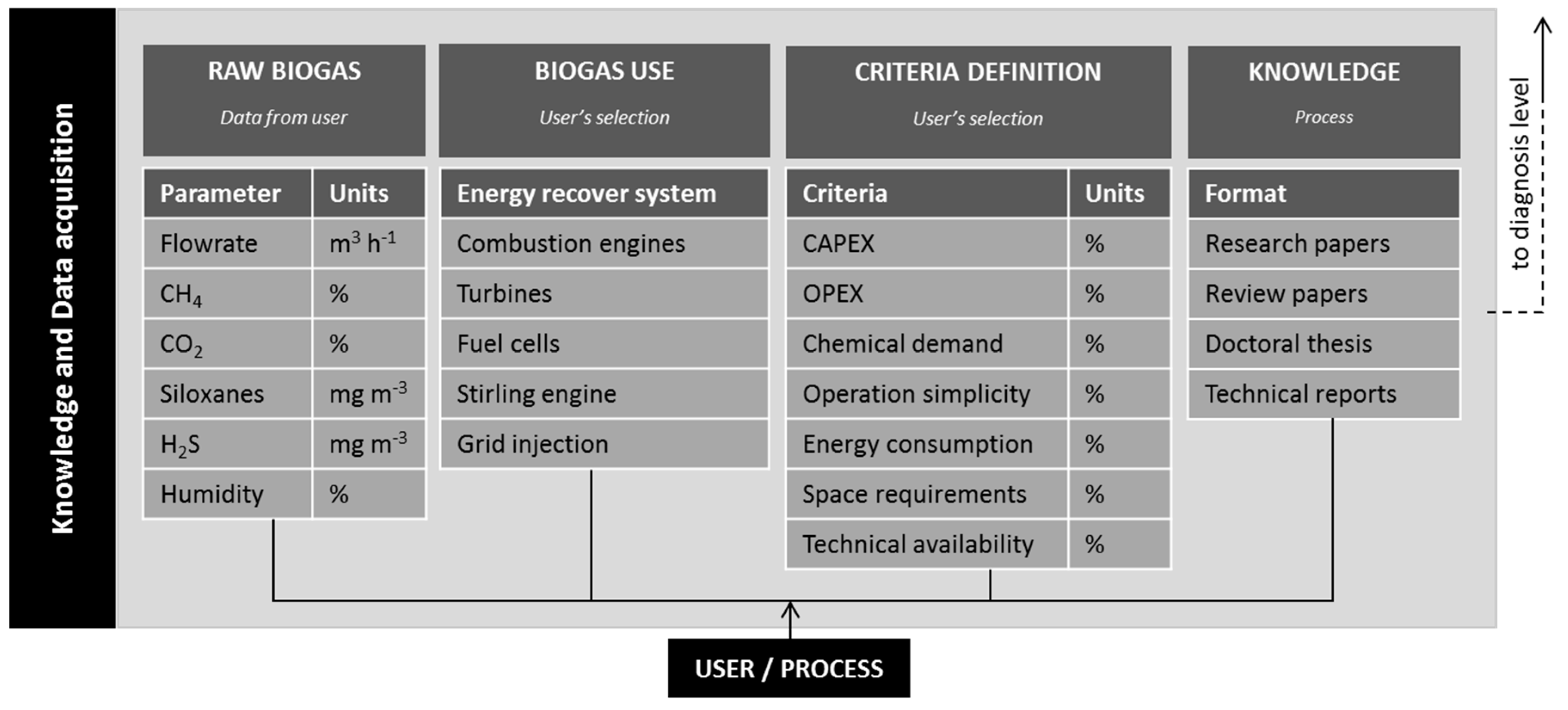

2.1.1. Knowledge and Data Acquisition Level

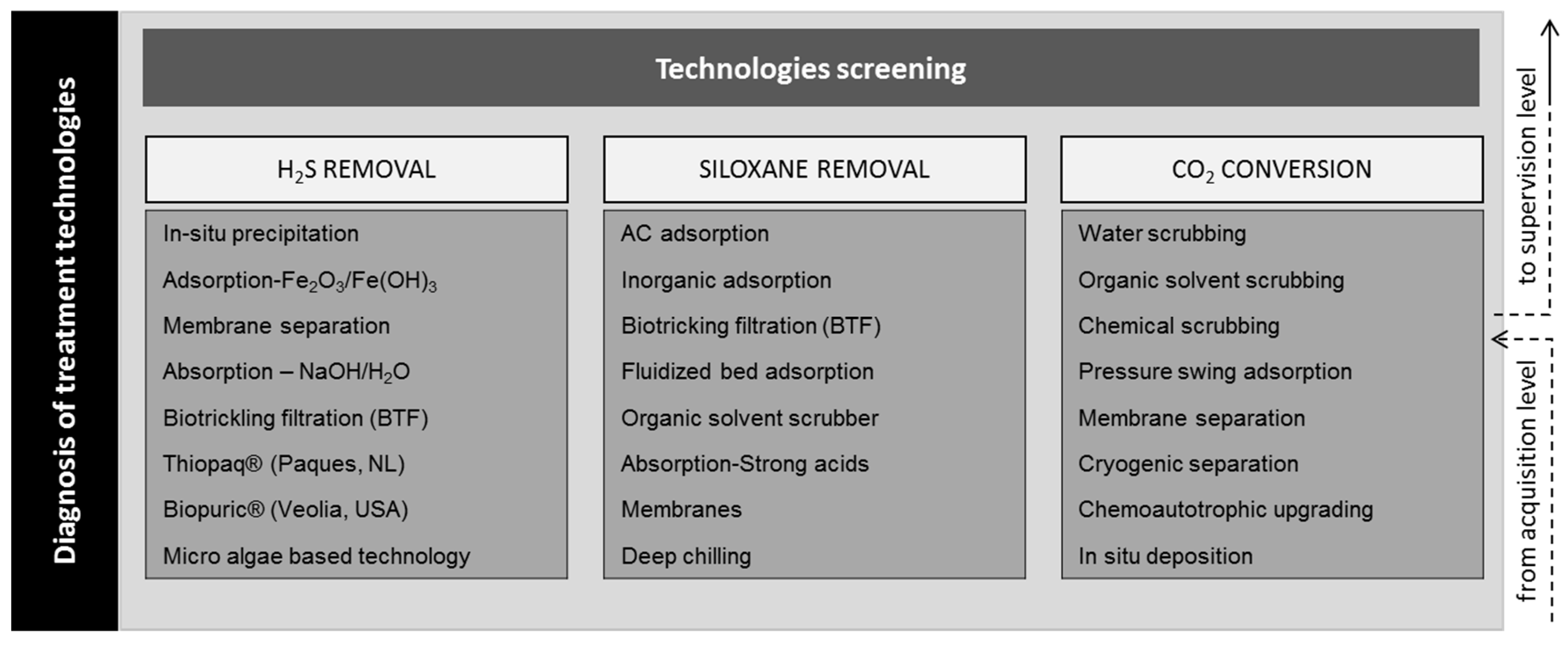

2.1.2. Diagnosis of Treatment Technologies Level

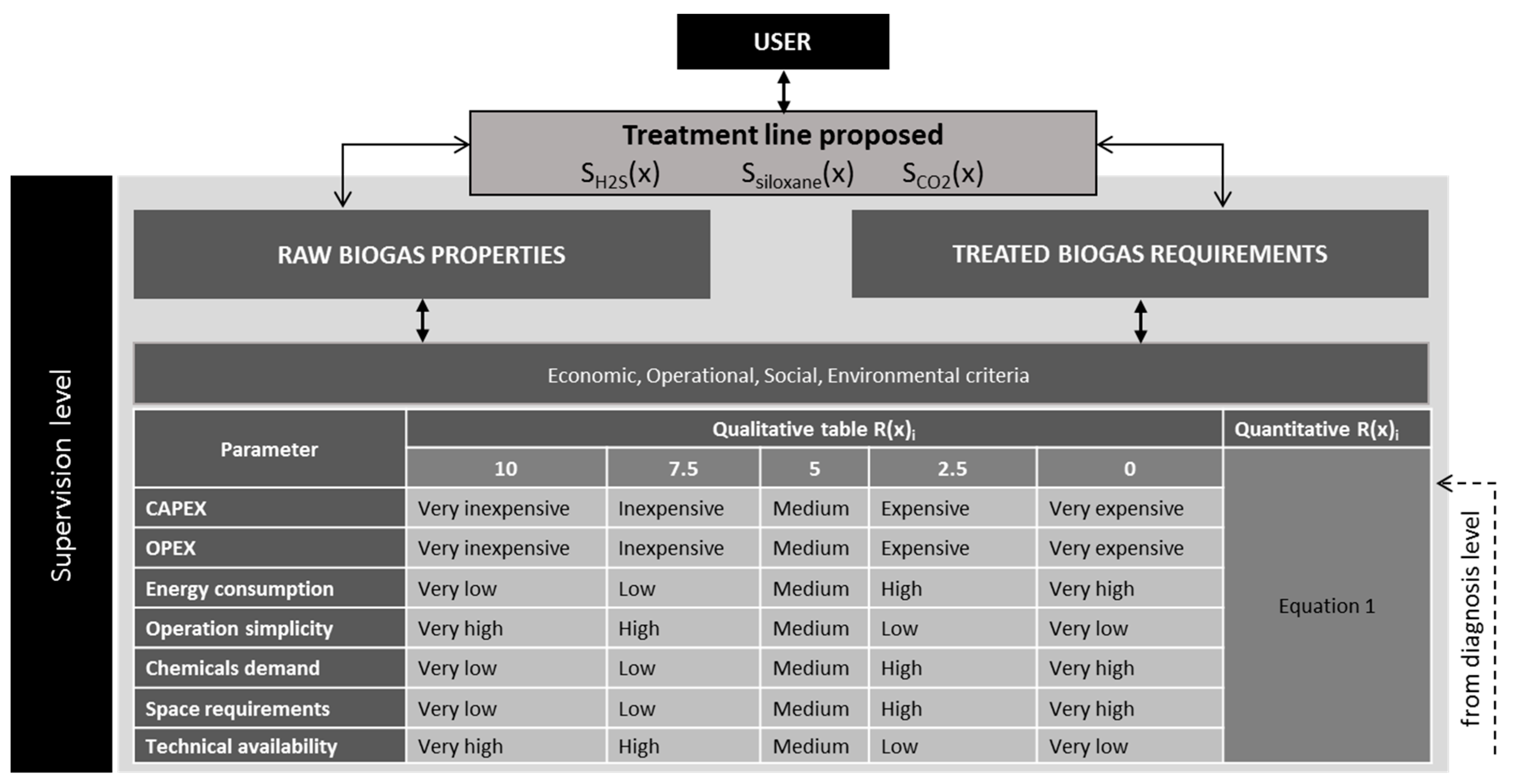

2.1.3. Knowledge-Based Supervision Level

- R(x)i, is the resulting rating for one intermediate technology x regarding criterion I;

- Vit, is the quantitative value for the intermediate technologies;

- Vwt, is the quantitative value for the worst technologies;

- Vbt, is the quantitative value for the best technologies.

- S(X), is the score calculated by BiogasApp_EDSS for a technology X;

- Wi, is the weight given to one criterion (Figure 3);

- R(x)i, is the rating obtained in the criterion;

- n, is the total number of criteria considered.

2.2. Case Study Validation

2.3. Case Study Sensitivity Analysis

3. Results and Discussion

3.1. BiogasApp_EDSS Evaluation

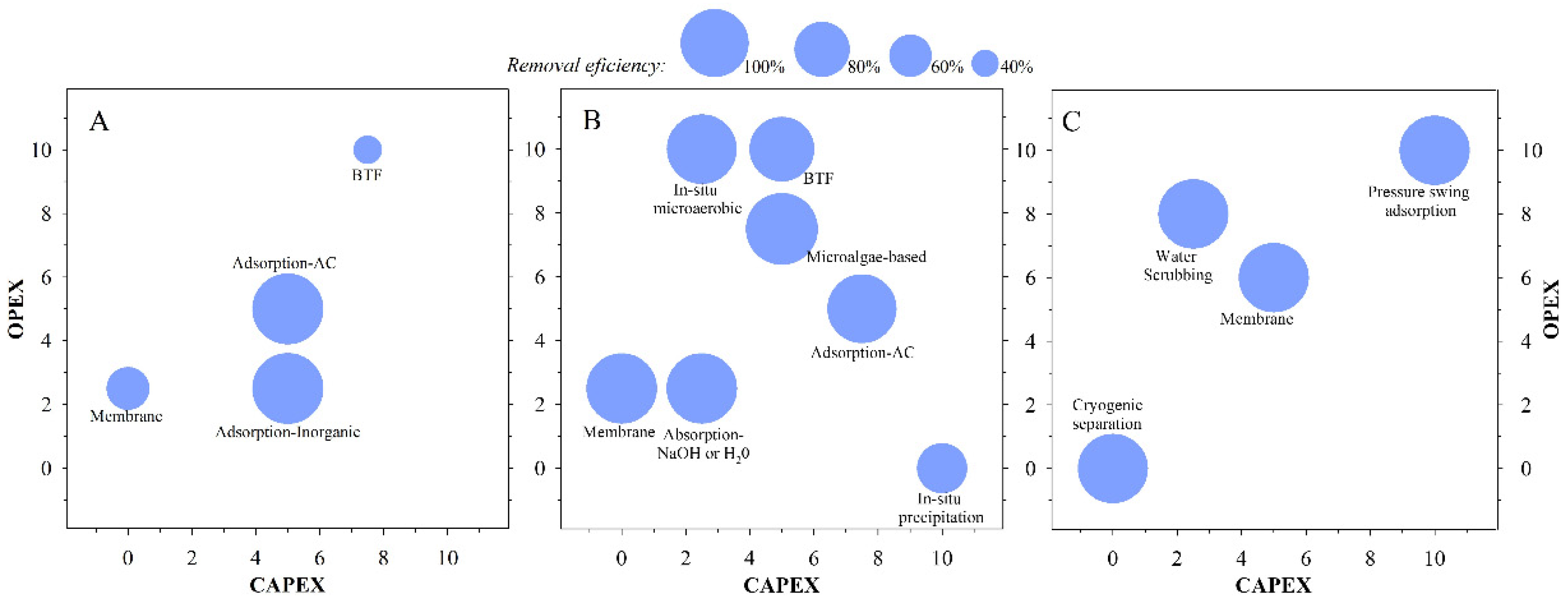

3.2. Case Study Validation

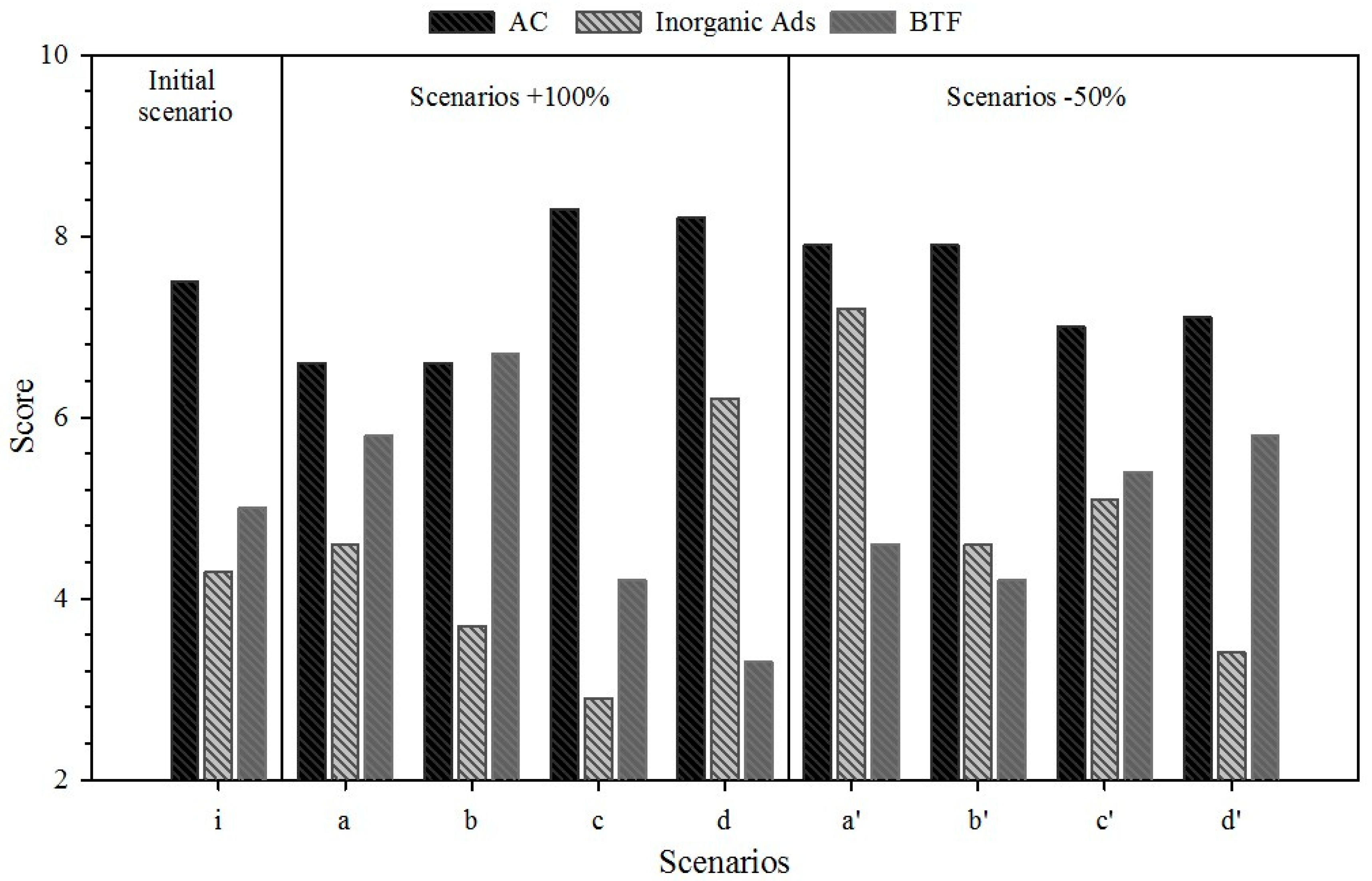

3.3. Case Study Sensitivity Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| EDSS | Environmental decision support system |

| GHG | Greenhouse gas |

| ECS | Energy conversion system |

| WWTP | Wastewater treatment plant |

| AC | Activated carbon |

| BTF | Biotrickling filter |

| ICE | Internal combustion engine |

| PAFC | Phosphoric acid fuel cell |

| SOFC | Solid oxide fuel cell |

| RE | Removal efficiency |

| CAPEX | Capital expenses |

| OPEX | Operating expenses |

References

- Ullah Khan, I.; Hafiz Dzarfan Othman, M.; Hashim, H.; Matsuura, T.; Ismail, A.F.; Rezaei-DashtArzhandi, M.; Wan Azelee, I. Biogas as a renewable energy fuel—A review of biogas upgrading, utilisation and storage. Energy Convers. Manag. 2017, 150, 277–294. [Google Scholar] [CrossRef]

- Baccioli, A.; Ferrari, L.; Guiller, R.; Yousfi, O.; Vizza, F.; Desideri, U. Feasibility Analysis of Bio-Methane Production in a Biogas Plant: A Case Study. Energies 2019, 12, 473. [Google Scholar] [CrossRef]

- Patinvoh, R.J.; Osadolor, O.A.; Chandolias, K.; Sárvári Horváth, I.; Taherzadeh, M.J. Innovative pretreatment strategies for biogas production. Bioresour. Technol. 2017, 224, 13–24. [Google Scholar] [CrossRef] [Green Version]

- Pavi, S.; Kramer, L.E.; Gomes, L.P.; Miranda, L.A.S. Biogas production from co-digestion of organic fraction of municipal solid waste and fruit and vegetable waste. Bioresour. Technol. 2017, 228, 362–367. [Google Scholar] [CrossRef]

- Florio, C.; Fiorentino, G.; Corcelli, F.; Ulgiati, S.; Dumontet, S.; Güsewell, J.; Eltrop, L. A Life Cycle Assessment of Biomethane Production from Waste Feedstock Through Different Upgrading Technologies. Energies 2019, 12, 718. [Google Scholar] [CrossRef]

- Papurello, D.; Silvestri, S.; Tomasi, L.; Belcari, I.; Biasioli, F.; Santarelli, M. Biowaste for SOFCs. Energy Procedia 2016, 101, 424–431. [Google Scholar]

- Felca, A.T.A.; Barros, R.M.; Tiago Filho, G.L.; dos Santos, I.F.S.; Ribeiro, E.M. Analysis of biogas produced by the anaerobic digestion of sludge generated at wastewater treatment plants in the South of Minas Gerais, Brazil as a potential energy source. Sustain. Cities Soc. 2018, 41, 139–153. [Google Scholar] [CrossRef]

- Papurello, D.; Tomasi, L.; Silvestri, S.; Belcari, I.; Santarelli, M.; Smeacetto, F.; Biasioli, F. Biogas trace compound removal with ashes using proton transfer reaction time-of-flight mass spectrometry as innovative detection tool. Fuel Process. Technol. 2016, 145, 62–75. [Google Scholar] [CrossRef] [Green Version]

- Arrhenius, K.; Fischer, A.; Büker, O. Methods for Sampling Biogas and Biomethane on Adsorbent Tubes after Collection in Gas Bags. Appl. Sci. 2019, 9, 1171. [Google Scholar] [CrossRef]

- Raheem, A.; Sikarwar, V.S.; He, J.; Dastyar, W.; Dionysiou, D.D.; Wang, W.; Zhao, M. Opportunities and Challenges in Sustainable Treatment and Resource Reuse of Sewage Sludge: A Review. Chem. Eng. J. 2017. [Google Scholar] [CrossRef]

- Papurello, D.; Lanzini, A. SOFC single cells fed by biogas: Experimental tests with trace contaminants. Waste Manag. 2018, 72, 306–312. [Google Scholar] [CrossRef] [PubMed]

- Budzianowski, W.M.; Wylock, C.E.; Marciniak, P.A. Power requirements of biogas upgrading by water scrubbing and biomethane compression: Comparative analysis of various plant configurations. Energy Convers. Manag. 2017, 141, 2–19. [Google Scholar] [CrossRef]

- Baldinelli, A.; Barelli, L.; Bidini, G. Upgrading versus reforming: An energy and exergy analysis of two Solid Oxide Fuel Cell-based systems for a convenient biogas-to-electricity conversion. Energy Convers. Manag. 2017, 138, 360–374. [Google Scholar] [CrossRef]

- Lyng, K.-A.; Brekke, A. Environmental Life Cycle Assessment of Biogas as a Fuel for Transport Compared with Alternative Fuels. Energies 2019, 12, 532. [Google Scholar] [CrossRef]

- Rasi, S.; Läntelä, J.; Rintala, J. Trace compounds affecting biogas energy utilization—A review. Energy Convers. Manag. 2011, 52, 3369–3375. [Google Scholar] [CrossRef]

- Aguilera, P.G.; Gutiérrez Ortiz, F.J. Techno-economic assessment of biogas plant upgrading by adsorption of hydrogen sulfide on treated sewage–sludge. Energy Convers. Manag. 2016, 126, 411–420. [Google Scholar] [CrossRef]

- De Arespacochaga, N.; Valderrama, C.; Mesa, C.; Bouchy, L.; Cortina, J.L. Biogas biological desulphurisation under extremely acidic conditions for energetic valorisation in Solid Oxide Fuel Cells. Chem. Eng. J. 2014, 255, 677–685. [Google Scholar] [CrossRef]

- Fortuny, M.; Baeza, J.A.; Gamisans, X.; Casas, C.; Lafuente, J.; Deshusses, M.A.; Gabriel, D. Biological sweetening of energy gases mimics in biotrickling filters. Chemosphere 2008, 71, 10–17. [Google Scholar] [CrossRef] [PubMed]

- Papurello, D.; Santarelli, M.; Fiorilli, S. Physical activation of waste-derived materials for biogas cleaning. Energies 2018, 11, 2338. [Google Scholar] [CrossRef]

- De Arespacochaga, N.; Valderrama, C.; Raich-Montiu, J.; Crest, M.; Mehta, S.; Cortina, J.L. Understanding the effects of the origin, occurrence, monitoring, control, fate and removal of siloxanes on the energetic valorization of sewage biogas—A review. Renew. Sustain. Energy Rev. 2015, 52, 366–381. [Google Scholar] [CrossRef] [Green Version]

- Dewil, R.; Appels, L.; Baeyens, J. Energy use of biogas hampered by the presence of siloxanes. Energy Convers. Manag. 2006, 47, 1711–1722. [Google Scholar] [CrossRef] [Green Version]

- De Arespacochaga, N.; Valderrama, C.; Mesa, C.; Bouchy, L.; Cortina, J.L. Biogas deep clean-up based on adsorption technologies for Solid Oxide Fuel Cell applications. Chem. Eng. J. 2014, 255, 593–603. [Google Scholar] [CrossRef]

- Cabrera-Codony, A.; Gonzalez-Olmos, R.; Martín, M.J.J. Regeneration of siloxane-exhausted activated carbon by advanced oxidation processes. J. Hazard. Mater. 2015, 285, 501–508. [Google Scholar] [CrossRef] [PubMed]

- Santos-Clotas, E.; Cabrera-Codony, A.; Ruiz, B.; Fuente, E.; Martín, M.J. Sewage biogas efficient purification by means of lignocellulosic waste-based activated carbons. Bioresour. Technol. 2019, 275, 207–215. [Google Scholar] [CrossRef] [PubMed]

- Soreanu, G. Insights into siloxane removal from biogas in biotrickling filters via process mapping-based analysis. Chemosphere 2016, 146, 539–546. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, J.; Li, H.; Chekani, S.; Liu, L. Investigation of thermal integration between biogas production and upgrading. Energy Convers. Manag. 2015, 102, 131–139. [Google Scholar] [CrossRef]

- Scholz, M.; Melin, T.; Wessling, M. Transforming biogas into biomethane using membrane technology. Renew. Sustain. Energy Rev. 2013, 17, 199–212. [Google Scholar] [CrossRef]

- Andriani, D.; Wresta, A.; Atmaja, T.D.; Saepudin, A. A Review on Optimization Production and Upgrading Biogas Through CO2 Removal Using Various Techniques. Appl. Biochem. Biotechnol. 2014, 172, 1909–1928. [Google Scholar] [CrossRef]

- Muñoz, R.; Meier, L.; Diaz, I.; Jeison, D. A review on the state-of-the-art of physical/chemical and biological technologies for biogas upgrading. Rev. Environ. Sci. Biotechnol. 2015, 14, 727–759. [Google Scholar] [CrossRef] [Green Version]

- Kumar, M.; Sundaram, S.; Gnansounou, E.; Larroche, C.; Thakur, I.S. Carbon dioxide capture, storage and production of biofuel and biomaterials by bacteria: A review. Bioresour. Technol. 2018, 247, 1059–1068. [Google Scholar] [CrossRef]

- Collet, P.; Flottes, E.; Favre, A.; Raynal, L.; Pierre, H.; Capela, S.; Peregrina, C. Techno-economic and Life Cycle Assessment of methane production via biogas upgrading and power to gas technology. Appl. Energy 2017, 192, 282–295. [Google Scholar] [CrossRef]

- Awe, O.W.; Zhao, Y.; Nzihou, A.; Minh, D.P.; Lyczko, N. A Review of Biogas Utilisation, Purification and Upgrading Technologies. Waste Biomass Valoriz. 2017, 8, 267–283. [Google Scholar] [CrossRef]

- Bauer, F.; Hulteberg, C.; Persson, T.; Tamm, D. Biogas upgrading—Review of commercial technologies. Swedish Gas Technol. Centre SGC Raport, 2013. Available online: http://www.sgc.se/ckfinder/userfiles/files/SGC270.pdf (accessed on 1 March 2018).

- Poch, M.; Comas, J.; Rodríguez-Roda, I.; Sànchez-Marrè, M.; Cortés, U. Designing and building real environmental decision support systems. Environ. Model. Softw. 2004, 19, 857–873. [Google Scholar] [CrossRef]

- Hamouda, M.A.; Anderson, W.B.; Huck, P.M. Decision support systems in water and wastewater treatment process selection and design: A review. Water Sci. Technol. 2009, 60, 1767–1770. [Google Scholar] [CrossRef]

- Garrido-Baserba, M.; Molinos-Senante, M.; Abelleira-Pereira, J.M.; Fdez-Güelfo, L.A.; Poch, M.; Hernández-Sancho, F. Selecting sewage sludge treatment alternatives in modern wastewater treatment plants using environmental decision support systems. J. Clean. Prod. 2015, 107, 410–419. [Google Scholar] [CrossRef]

- Garrido-Baserba, M.; Reif, R.; Hernández, F.; Poch, M. Implementation of a knowledge-based methodology in a decision support system for the design of suitable wastewater treatment process flow diagrams. J. Environ. Manag. 2012, 112, 384–391. [Google Scholar] [CrossRef]

- Castillo, A.; Porro, J.; Garrido-Baserba, M.; Rosso, D.; Renzi, D.; Fatone, F.; Gómez, V.; Comas, J.; Poch, M. Validation of a decision support tool for wastewater treatment selection. J. Environ. Manag. 2016, 184, 409–418. [Google Scholar] [CrossRef]

- Raseman, W.J.; Kasprzyk, J.R.; Rosario-Ortiz, F.L.; Stewart, J.R.; Livneh, B. Emerging investigators series: A critical review of decision support systems for water treatment: Making the case for incorporating climate change and climate extremes. Environ. Sci. Water Res. Technol. 2017, 3, 18–36. [Google Scholar] [CrossRef]

- Billig, E.; Thrän, D. Evaluation of biomethane technologies in Europe—Technical concepts under the scope of a Delphi-Survey embedded in a multi-criteria analysis. Energy 2016, 114, 1176–1186. [Google Scholar] [CrossRef]

- Estrada, J.M.; Kraakman, N.J.R.; Lebrero, R.; Muñoz, R. A sensitivity analysis of process design parameters, commodity prices and robustness on the economics of odour abatement technologies. Biotechnol. Adv. 2012, 30, 1354–1363. [Google Scholar] [CrossRef]

- BOE-A-2013-185 Resolución de 21 de Diciembre de 2012, de la Dirección General de Política Energética y Minas, por la que se Modifica el Protocolo de Detalle PD-01; Agencia Estatal Boletin Oficial Del Estado: Madrid, Spain, 2013; pp. 889–892.

- Ajhar, M.; Travesset, M.; Yüce, S.; Melin, T. Siloxane removal from landfill and digester gas—A technology overview. Bioresour. Technol. 2010, 101, 2913–2923. [Google Scholar] [CrossRef] [PubMed]

- Cabrera-Codony, A.; Montes-Morán, M.A.; Sánchez-Polo, M.; Martín, M.J.; Gonzalez-Olmos, R. Biogas upgrading: Optimal activated carbon properties for siloxane removal. Environ. Sci. Technol. 2014, 48, 7187–7195. [Google Scholar] [CrossRef]

- Cabrera-Codony, A.; Georgi, A.; Gonzalez-Olmos, R.; Valdés, H.; Martín, M.J. Zeolites as recyclable adsorbents/catalysts for biogas upgrading: Removal of octamethylcyclotetrasiloxane. Chem. Eng. J. 2017, 307. [Google Scholar] [CrossRef]

- Popat, S.C.; Deshusses, M.A. Biological removal of siloxanes from landfill and digester gases: Opportunities and challenges. Environ. Sci. Technol. 2008, 42, 8510–8515. [Google Scholar] [CrossRef]

- Ajhar, M.; Bannwarth, S.; Stollenwerk, K.H.; Spalding, G.; Yüce, S.; Wessling, M.; Melin, T. Siloxane removal using silicone-rubber membranes. Sep. Purif. Technol. 2012, 89, 234–244. [Google Scholar] [CrossRef]

- Peredo-Mancilla, D.; Ghouma, I.; Hort, C.; Ghimbeu, C.M.; Jeguirim, M.; Bessieres, D. CO2 and CH2 adsorption behavior of biomass-based activated carbons. Energies 2018, 11, 3136. [Google Scholar] [CrossRef]

- Cabrera-Codony, A.; Santos-Clotas, E.; Ania, C.O.; Martín, M.J. Competitive siloxane adsorption in multicomponent gas streams for biogas upgrading. Chem. Eng. J. 2018, 344, 565–573. [Google Scholar] [CrossRef]

- Jiang, T.; Zhong, W.; Jafari, T.; Du, S.; He, J.; Fu, Y.J.; Singh, P.; Suib, S.L. Siloxane D4 adsorption by mesoporous aluminosilicates. Chem. Eng. J. 2016, 289, 356–364. [Google Scholar] [CrossRef]

- Sigot, L.; Ducom, G.; Benadda, B.; Labouré, C. Adsorption of octamethylcyclotetrasiloxane on silica gel for biogas purification. Fuel 2014, 135, 205–209. [Google Scholar] [CrossRef]

| ECS | Type | Total Siloxane Limit (mg m−3) | H2S Tolerance (mg m−3) | Need to Convert CO2 to CH4 |

|---|---|---|---|---|

| Internal combustion engine | Permissive ICE | 30 | 695 | No |

| Restrictive ICE | 12 | 70 | No | |

| Micro-turbine | Capstone | 0.03 | 6900 | No |

| Fuel cells | PAFC | 0.1 | 28 | No |

| SOFC | 0.01 | 1.4 | No | |

| Stirling engine | Standard | No limit | 1390 | No |

| Grid injection | Spanish legislation | 10 | 10 | Yes (97% CH4) |

| Technology | Brief Description |

|---|---|

| H2S removal | |

| In-situ precipitation | FeS formation by addition of Fe2+/Fe3+ |

| Adsorption-Fe2O3/Fe(OH)3 | Chemical adsorption based in regenerable Fe2O3, Fe(OH)3 or ZnO. |

| Membrane separation | Selective permeation of H2S through membrane and retention of CH4 |

| Absorption- NaOH/H2O | Conversion to elemental sulfur/metal sulfides by basic or water scrubbing |

| Biotrickling filter (BTF) | Biological removal through bacteria in packed bed column after gas-liquid mass transfer |

| In-situ microaerobic | Sulphide oxidizing bacteria grown over the wall and ceiling |

| Thiopaq® (Paques, NL) | Absorption in a caustic solution, followed by oxidation to S by autotrophic bacteria, which is later separated as a byproduct. |

| Biopuric® (Veolia, USA) | Sulfur oxidizing microorganisms metabolize H2S into elemental sulfur and sulfuric acid. |

| Microalgae-based | Simultaneous removal of CO2 and H2S by the symbiosis of algae and bacteria in photobioreactors. |

| Siloxanes removal | |

| AC adsorption | Physical adsorption of siloxanes onto activated carbon. |

| Inorganic adsorption | Physical adsorption of siloxanes onto zeolites or silica gel. |

| Biotricking filters | Biological removal through bacteria in packed bed column after gas–liquid mass transfer |

| Fluidized bed adsorption | Siloxane adsorption in a porous material where a part of the bed is continuously regenerated by stripping. |

| Organic solvent scrubber | Siloxanes absorption into organic solvents in spray or packed bed towers. |

| Absorption-strong acids | Reactive absorption using concentrated acid solutions (HNO3 and H2SO4). |

| Membranes | Selective siloxane permeation through diffusion through dense inorganic or polymeric membranes. |

| Deep chilling | Separation by decreasing temperature below ∕25 °C depending on siloxane saturation partial pressure. |

| CO2 Conversion/removal | |

| Water scrubbing | CO2 absorption in water based on its higher aqueous solubility than CH4. |

| Organic solvent scrubbing | Absorption in polyethylene glycol-based high affinity absorbents. |

| Chemical scrubbing | Chemical absorption into alkanol amines/alkali aqueous solutions. |

| Pressure swing adsorption | Selective adsorption of CO2 over CH4 and periodical desorption in different adsorbers for regeneration purposes |

| Membranes | Selective permeation through diffusion through dense inorganic or polymeric membranes. |

| Cryogenic separation | Separation by decreasing temperature below −55 °C to liquefy CO2. |

| Chemoautotrophic upgrading | Bioconversion of CO2 to CH4 by hydrogenotrophic methanogens providing an external H2 injection. |

| Photosynthetic upgrading | Biomass fixation by eukaryotic microalgae and cyanobacteria, helped by the electrons released during water photolysis. |

| In situ desorption | Separation by stripping away the CH4 in a desorption unit taking advantage of the higher solubility of the CO2. |

| Parameter | Value Raw Biogas | Units |

|---|---|---|

| Flowrate | 110 | m3 h−1 |

| CH4 | 65b | % |

| CO2 | 35b | % |

| Siloxanes | 20 | mg m−3 |

| H2S | 500 | mg m−3 |

| Humidity | 97 | % |

| Criteria | Initial Scenario | Scenarios +100% | Scenarios −50% | ||||||

|---|---|---|---|---|---|---|---|---|---|

| i | a | b | c | d | a’ | b’ | c’ | d’ | |

| CAPEX | 25 | 50.0 | 16.7 | 16.7 | 16.7 | 12.5 | 29.2 | 29.2 | 29.2 |

| OPEX | 25 | 16.7 | 50.0 | 16.7 | 16.7 | 29.2 | 12.5 | 29.2 | 29.2 |

| Stage of development | 25 | 16.7 | 16.7 | 50.0 | 16.7 | 29.2 | 29.2 | 12.5 | 29.2 |

| Removal efficiency | 25 | 16.7 | 16.7 | 16.7 | 50.0 | 29.2 | 29.2 | 29.2 | 12.5 |

| Rank nº | Technology | CAPEX | OPEX | Stage of Development | Removal Efficiency * | Total Score | Effluent (mg m−3) |

|---|---|---|---|---|---|---|---|

| 1 | Adsorption—activated carbon (AC) | 5 | 5 | 10 | 9.8 | 7.5 | 0.01 |

| 2 | Adsorption—inorganic | 5 | 2.5 | 0 | 9.8 | 4.3 | 0.01 |

| - | BTF | 7.5 | 10 | 2.5 | 0 | 5.0 | >0.03 |

| - | Membranes | 0 | 2.5 | 2.5 | 3.5 | 2.1 | >0.03 |

| - | Fluid. bed adsorption | 2.5 | 5 | 2.5 | 9,8 | n.f. | - |

| - | Deep chilling | 0 | 0 | 7.5 | 7.5 | n.f. | - |

| - | Absorption—organic | 0 | 0 | 10 | 10 | n.f. | - |

| - | Absorption—acids | 0 | 0 | 0 | 3.5 | n.f. | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos-Clotas, E.; Cabrera-Codony, A.; Castillo, A.; Martín, M.J.; Poch, M.; Monclús, H. Environmental Decision Support System for Biogas Upgrading to Feasible Fuel. Energies 2019, 12, 1546. https://doi.org/10.3390/en12081546

Santos-Clotas E, Cabrera-Codony A, Castillo A, Martín MJ, Poch M, Monclús H. Environmental Decision Support System for Biogas Upgrading to Feasible Fuel. Energies. 2019; 12(8):1546. https://doi.org/10.3390/en12081546

Chicago/Turabian StyleSantos-Clotas, Eric, Alba Cabrera-Codony, Alba Castillo, Maria J. Martín, Manel Poch, and Hèctor Monclús. 2019. "Environmental Decision Support System for Biogas Upgrading to Feasible Fuel" Energies 12, no. 8: 1546. https://doi.org/10.3390/en12081546