Designing Policies and Programmes for Improved Energy Efficiency in Industrial SMEs

Abstract

1. Introduction

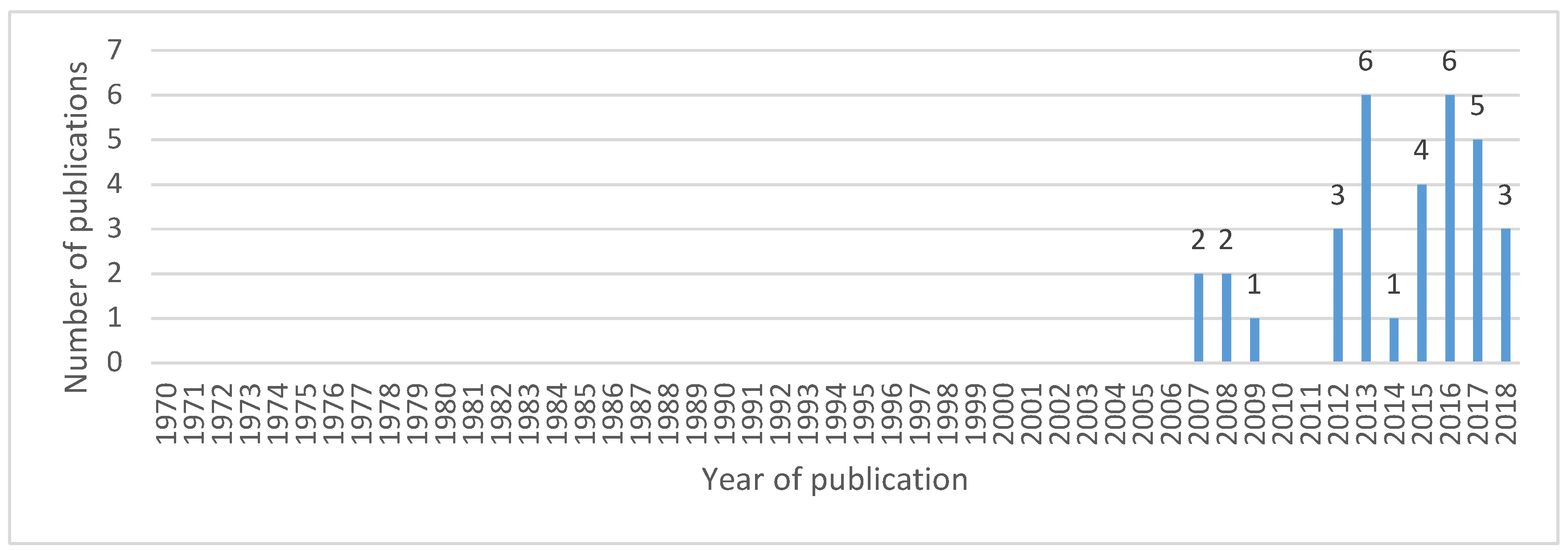

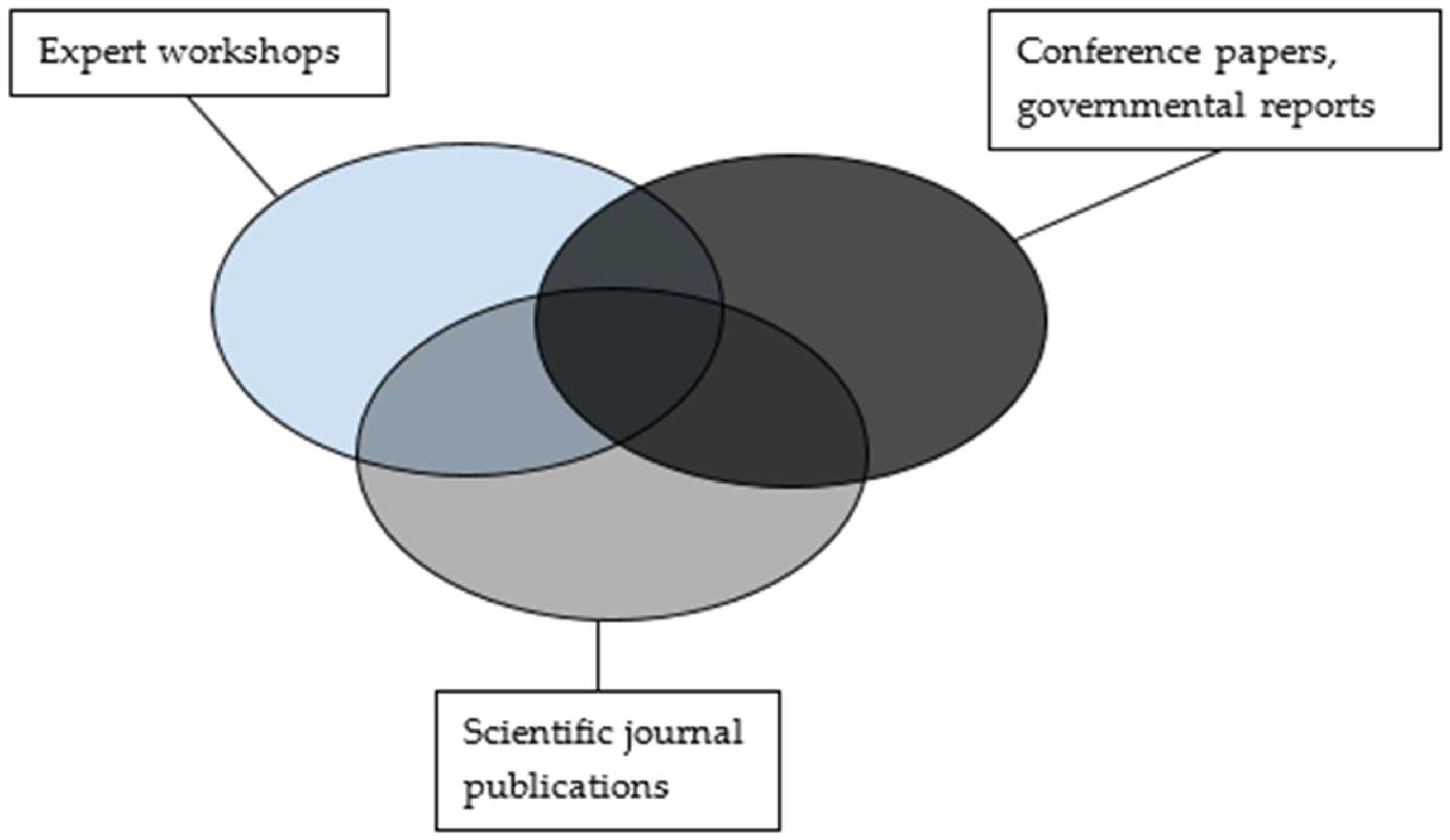

2. Method and Delimitations

3. Results

3.1. Barriers and Drivers

3.2. Energy Programme

3.3. General Category

4. Analysis

5. Concluding Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Geographical Focus | Industrial Sector | Study Method | Study Focus | Ref. | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Country | Single Sector | Multiple Sectors | Literature Review | Conceptual | Quantitative | Qualitative | Barriers | Drivers | Energy Program | Other | |

| Italy | x | x | x | [6] | |||||||

| Italy | x | x | x | x | x | [7] | |||||

| Italy | x | x | x | x | x | [8] | |||||

| Germany | x | x | x | x | [25] | ||||||

| Sweden | x | x | x | x | x | [27] | |||||

| Europe | x | x | x | [36] | |||||||

| United Kingdom | x | x | x | x | x | [37] | |||||

| The Netherlands | x | x | x | x | [38] | ||||||

| Italy | x | x | x | [39] | |||||||

| Italy | x | x | x | x | [40] | ||||||

| China | x | x | x | x | [41] | ||||||

| Italy | x | x | x | [42] | |||||||

| Sweden | x | x | x | x | [43] | ||||||

| Portugal | x | x | x | x | [44] | ||||||

| Slovenia | x | x | x | x | [45] | ||||||

| Zimbabwe | x | x | x | [46] | |||||||

| China | x | x | x | [47] | |||||||

| Ireland | x | x | x | x | x | [48] | |||||

| China | x | x | x | x | [51] | ||||||

| Republic of Korea | x | x | x | x | [52] | ||||||

| Italy | x | x | x | x | [54] | ||||||

| Sweden | x | x | x | x | [55] | ||||||

| Australia, Germany, Sweden, USA | x | x | x | x | [56] | ||||||

| China | x | x | x | [58] | |||||||

| China | x | x | x | x | x | [59] | |||||

| Sweden | x | x | x | x | x | x | [60] | ||||

| Turkey | x | x | x | x | [61] | ||||||

| Sweden | x | x | x | x | [57] | ||||||

| China | x | x | x | x | x | [49] | |||||

| Belgium, Japan, Italy, Sweden | x | x | x | [62] | |||||||

| Sri Lanka | x | x | x | x | x | [63] | |||||

| Austria, Czech Republic, Hungary, Italy, Slovenia | x | x | x | x | [50] | ||||||

| Sweden | x | x | x | x | [64] | ||||||

References

- International Energy Agency (IEA). Accelerating Energy Efficiency in Small and Medium-sized Enterprises; OECD/IEA: Paris, France, 2015. [Google Scholar]

- Jaffe, A.B.; Stavins, R.N. The energy-efficiency gap What does it mean? Energy Policy 1994, 22, 804–810. [Google Scholar] [CrossRef]

- Sorrell, S.; Schleich, J.; Scott, S.; Eoin, O.; Fergal, T.; Ulla, B.; Katrin, O.; Peter, R. Reducing barriers to energy efficiency in public and private organisations. Mech. Eng. 2000, 232. [Google Scholar]

- Brunke, J.C.; Johansson, M.; Thollander, P. Empirical investigation of barriers and drivers to the adoption of energy conservation measures, energy management practices and energy services in the Swedish iron and steel industry. J. Clean. Prod. 2014, 84, 509–525. [Google Scholar] [CrossRef]

- Cagno, E.; Worrell, E.; Trianni, A.; Pugliese, G. A novel approach for barriers to industrial energy efficiency. Renew. Sustain. Energy Rev. 2013, 19, 290–308. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A. Exploring drivers for energy efficiency within small- and medium-sized enterprises: First evidences from Italian manufacturing enterprises. Appl. Energy 2013, 104, 276–285. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A.; Spallina, G.; Marchesani, F. Drivers for energy efficiency and their effect on barriers: Empirical evidence from Italian manufacturing enterprises. Energy Effic. 2017, 10, 855–869. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Farné, S. Barriers, drivers and decision-making process for industrial energy efficiency: A broad study among manufacturing small and medium-sized enterprises. Appl. Energy 2016, 162, 1537–1551. [Google Scholar] [CrossRef]

- Rohdin, P.; Thollander, P.; Solding, P. Barriers to and drivers for energy efficiency in the Swedish foundry industry. Energy Policy 2007, 35, 672–677. [Google Scholar] [CrossRef]

- Thollander, P.; Ottosson, M. An energy efficient Swedish pulp and paper industry—Exploring barriers to and driving forces for cost-effective energy efficiency investments. Energy Effic. 2008, 1, 21–34. [Google Scholar] [CrossRef]

- Cooremans, C. Investment in energy efficiency: Do the characteristics of investments matter? Energy Effic. 2012, 5, 497–518. [Google Scholar] [CrossRef]

- Tanaka, K. Review of policies and measures for energy efficiency in industry sector. Energy Policy 2011, 39, 6532–6550. [Google Scholar] [CrossRef]

- Price, L. Voluntary Agreements for Energy Efficiency or GHG Emissions Reduction in Industry: An Assessment of Programs Around the World. In Proceedings of the ACEEE Summer Study on Energy Efficiency in Industry, West Point, NY, USA, 19–22 June 2005; pp. 114–125. [Google Scholar]

- Price, L.; Lu, H. Industrial energy auditing and assessments: A survey of programs around the world. In Proceedings of the ECEEE 2011 Summer Study, Presqu’île de Giens, France, 6–11 June 2011; pp. 629–640. [Google Scholar]

- Ramírez, C.A.A.; Patel, M.; Blok, K. The non-energy intensive manufacturing sector. An energy analysis relating to the Netherlands. Energy 2005, 30, 749–767. [Google Scholar] [CrossRef]

- Backlund, S.; Broberg, S.; Ottosson, M.; Thollander, P. Energy efficiency potentials and energy management practices in Swedish firms. In Proceedings of the ECEEE 2012 Industry Summer Study, Arnhem, The Netherlands, 11–14 September 2012. [Google Scholar]

- World Trade Organization World Trade Report 2016; WTO: Geneve, Switzerland, 2016.

- European Commission. Commission Recommendation of 6 May 2003 concerning the definition of micro, small and medium-sized enterprises. Off. J. Eur. Union 2003, 2003, 36–41. [Google Scholar]

- Thollander, P.; Zubizarreta, R.; Morales, I.; Kimura, O.; Cornelis, E.; Karlsson, M.; Söderström, M.; Backlund, S. Energy End-Use Policies and Programs towards Industrial SMEs—The Case of Japan, Belgium, Spain and Sweden. 2014. Available online: https://iea-industry.org/app/uploads/annex-xvi-task_1.pdf (accessed on 8 April 2019).

- Shipley, A.M.; Elliott, R.N. Energy Efficiency Programs for Small and Medium Sized Industry. In Proceedings of the ACEEE Summer Study on Energy Efficiency in Industry, Tarrytown, NY, USA, 24–27 July 2001; pp. 183–196. [Google Scholar]

- European Commission. Directive 2006/32/EC of the European Parliament and of the Council of 5 April 2006 on Energy End-use Efficiency and Energy Services and Repealing Council Directive 93/76/EEC. Off. J. Eur. Union 2006, 4. [Google Scholar]

- Thollander, P.; Dotzauer, E. An energy efficiency program for Swedish industrial small- and medium-sized enterprises. J. Clean. Prod. 2010, 18, 1339–1346. [Google Scholar] [CrossRef]

- European Commission. Directive 2012/27/EU of the European Parliament and of the counsil of 25 October 2012 on energy efficiency, amending Directives 2009/125/EC and 2010/30/EU and repealing Directives 2004/8/EC and 2006/32/EC. Off. J. Eur. Union 2012. [Google Scholar]

- Bertoldi, P.; Rezessy, S.; Bürer, M.J. Will emission trading promote end-use energy efficiency and renewable energy projects? In Proceedings of ACEEE Summer Study on Energy Efficiency in Industry. West Point, NY, USA, 19–22 June 2005; pp. 4–12. [Google Scholar]

- Fleiter, T.; Gruber, E.; Eichhammer, W.; Worrell, E. The German energy audit program for firms-a cost-effective way to improve energy efficiency? Energy Effic. 2012, 5, 447–469. [Google Scholar] [CrossRef]

- Anderson, S.T.; Newell, R.G. Information programs for technology adoption: The case of energy-efficiency audits. Resour. Energy Econ. 2004, 26, 27–50. [Google Scholar] [CrossRef]

- Thollander, P.; Danestig, M.; Rohdin, P. Energy policies for increased industrial energy efficiency: Evaluation of a local energy programme for manufacturing SMEs. Energy Policy 2007, 35, 5774–5783. [Google Scholar] [CrossRef]

- Thollander, P.; Cornelis, E.; Kimura, O.; Morales, I.; Zubizarreta Jiménez, R.; Backlund, S.; Karlsson, M.; Söderström, M. The design and structure of effective energy end-use policies and programs towards industrial SMEs. In Proceedings of the ECEEE 2014 Industrial Summer Study—Retool for a Competitive and Sustainable Indutry, Arnhem, The Netherlands, 2–5 June 2014; pp. 75–81. [Google Scholar]

- Trianni, A.; Cagno, E. Dealing with barriers to energy efficiency and SMEs: Some empirical evidences. Energy 2012, 37, 494–504. [Google Scholar] [CrossRef]

- Sorrell, S.; Mallett, A.; Nye, S. Barriers to Industrial Energy Efficiency: A Literature Review; working paper 10; United Nations Industrial Development Organization: Vienna, Austria, 2011. [Google Scholar]

- Schulze, M.; Nehler, H.; Ottosson, M.; Thollander, P. Energy management in industry—A systematic review of previous findings and an integrative conceptual framework. J. Clean. Prod. 2015, 112, 3692–3708. [Google Scholar] [CrossRef]

- D’Agostino, A.L.; Sovacool, B.K.; Trott, K.; Ramos, C.R.; Saleem, S.; Ong, Y. What’s the state of energy studies research?: A content analysis of three leading journals from 1999 to 2008. Energy 2011, 36. [Google Scholar] [CrossRef]

- Lindén, A.L.; Carlsson-Kanyama, A. Voluntary agreements—A measure for energy-efficiency in industry? Lessons from a Swedish programme. Energy Policy 2002, 30, 897–905. [Google Scholar] [CrossRef]

- Sorrell, S.; Schleich, J.; O’malley, E.; Scott, S. The Economics of Energy Efficiency: Barriers to Profitable Investments; Edward Elgar Publishing: Cheltenham, UK, 2004. [Google Scholar]

- Reddy, B.S. Barriers and drivers to energy efficiency—A new taxonomical approach. Energy Convers. Manag. 2013, 74, 403–416. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Thollander, P.; Backlund, S. Barriers to industrial energy efficiency in foundries: A European comparison. J. Clean. Prod. 2013, 40, 161–176. [Google Scholar] [CrossRef]

- Bradford, J.; Fraser, E.D.G. Local authorities, climate change and small and medium enterprises: Identifying effective policy instruments to reduce energy use and carbon emissions. Corp. Soc. Responsib. Environ. Manag. 2008, 15, 156–172. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A.; Abeelen, C.; Worrell, E.; Miggiano, F. Barriers and drivers for energy efficiency: Different perspectives from an exploratory study in the Netherlands. Energy Convers. Manag. 2015, 102, 26–38. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Worrell, E.; Pugliese, G. Empirical investigation of energy efficiency barriers in Italian manufacturing SMEs. Energy 2013, 49, 444–458. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A. Evaluating the barriers to specific industrial energy efficiency measures: An exploratory study in small and medium-sized enterprises. J. Clean. Prod. 2014, 82, 70–83. [Google Scholar] [CrossRef]

- Kostka, G.; Moslener, U.; Andreas, J. Barriers to increasing energy efficiency: Evidence from small-and medium-sized enterprises in China. J. Clean. Prod. 2013, 57, 59–68. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Worrell, E. Innovation and adoption of energy efficient technologies: An exploratory analysis of Italian primary metal manufacturing SMEs. Energy Policy 2013, 61, 430–440. [Google Scholar] [CrossRef]

- Backman, F. Barriers to Energy Efficiency in Swedish Non-Energy-Intensive Micro- and Small-Sized Enterprises—A Case Study of a Local Energy Program. Energies 2017, 10, 100. [Google Scholar] [CrossRef]

- Henriques, J.; Catarino, J. Motivating towards energy efficiency in small and medium enterprises. J. Clean. Prod. 2016, 139, 42–50. [Google Scholar] [CrossRef]

- Hrovatin, N.; Dolsak, N.; Zoric, J. Factors impacting investments in energy efficiency and clean technologies: Empirical evidence from Slovenian manufacturing firms. J. Clean. Prod. 2015, 127. [Google Scholar] [CrossRef]

- Muzamwese, T.C. Challenges and opportunities for mainstreaming industrial energy efficiency in small-to-medium-sized industries in Zimbabwe. Wiley Interdiscip. Rev. Energy Environ. 2016, 5, 510–518. [Google Scholar] [CrossRef]

- Dong, J.; Huo, H. Identification of financing barriers to energy efficiency in small and medium-sized enterprises by integrating the fuzzy delphi and fuzzy DEMATEL Approaches. Energies 2017, 10, 1172. [Google Scholar]

- Dixon-O’Mara, C.; Ryan, L. Energy efficiency in the food retail sector: Barriers, drivers and acceptable policies. Energy Effic. 2018, 11, 445–464. [Google Scholar] [CrossRef]

- Kong, D.; Feng, Q.; Zhou, Y.; Xue, L. Local implementation for green-manufacturing technology diffusion policy in China: From the user firms’ perspectives. J. Clean. Prod. 2016, 129, 113–124. [Google Scholar] [CrossRef]

- Viesi, D.; Pozzar, F.; Federici, A.; Crema, L.; Mahbub, M.S. Energy efficiency and sustainability assessment of about 500 small and medium-sized enterprises in Central Europe region. Energy Policy 2017, 105, 363–374. [Google Scholar] [CrossRef]

- Lo, K.; Li, H.; Wang, M. Energy conservation in China’s energy-intensive enterprises: An empirical study of the Ten-Thousand Enterprises Program. Energy Sustain. Dev. 2015, 27, 105–111. [Google Scholar] [CrossRef]

- Suk, S.; Liu, X.; Sudo, K. A survey study of energy saving activities of industrial companies in the Republic of Korea. J. Clean. Prod. 2013, 41, 301–311. [Google Scholar] [CrossRef]

- Backlund, S.; Thollander, P. Impact after three years of the Swedish energy audit program. Energy 2015, 82, 54–60. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A. Analysis of the Most Effective Energy Efficiency Opportunities in Manufacturing Primary Metals, Plastics, and Textiles Small- and Medium-Sized Enterprises. J. Energy Resour. Technol. 2012, 134, 021005. [Google Scholar] [CrossRef]

- Paramonova, S.; Thollander, P. Ex-post impact and process evaluation of the Swedish energy audit policy programme for small and medium-sized enterprises. J. Clean. Prod. 2016, 135, 932–949. [Google Scholar] [CrossRef]

- Andersson, E.; Arfwidsson, O.; Bergstrand, V.; Thollander, P. A study of the comparability of energy audit program evaluations. J. Clean. Prod. 2017, 142, 2133–2139. [Google Scholar] [CrossRef]

- Paramonova, S.; Thollander, P. Energy-efficiency networks for SMEs: Learning from the Swedish experience. Renew. Sustain. Energy Rev. 2016, 65, 295–307. [Google Scholar] [CrossRef]

- Liu, X.; Niu, D.; Bao, C.; Suk, S.; Shishime, T. A survey study of energy saving activities of industrial companies in Taicang, China. J. Clean. Prod. 2012, 26, 79–89. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, G. Energy saving technologies and productive efficiency in the Chinese iron and steel sector. Energy 2008, 33, 525–537. [Google Scholar] [CrossRef]

- Palm, J. Placing barriers to industrial energy efficiency in a social context: A discussion of lifestyle categorisation. Energy Effic. 2009, 2, 263–270. [Google Scholar] [CrossRef]

- Önüt, S.; Soner, S. Analysis of energy use and efficiency in Turkish manufacturing sector SMEs. Energy Convers. Manag. 2007, 48, 384–394. [Google Scholar] [CrossRef]

- Thollander, P.; Paramonova, S.; Cornelis, E.; Kimura, O.; Trianni, A.; Karlsson, M.; Cagno, E.; Morales, I.; Jiménez Navarro, J.P. International study on energy end-use data among industrial SMEs (small and medium-sized enterprises) and energy end-use efficiency improvement opportunities. J. Clean. Prod. 2015, 104, 282–296. [Google Scholar] [CrossRef]

- Pathirana, S.; Yarime, M. Introducing energy efficient technologies in small- and medium-sized enterprises in the apparel industry: A case study of Sri Lanka. J. Clean. Prod. 2018, 178, 247–257. [Google Scholar] [CrossRef]

- Andersson, E.; Arfwidsson, O.; Thollander, P. Benchmarking energy performance of industrial small and medium-sized enterprises using an energy efficiency index: Results based on an energy audit policy program. J. Clean. Prod. 2018, 182, 883–895. [Google Scholar] [CrossRef]

- European Commission. A Study on Energy Efficiency in Enterprises: Energy Audits and Energy Management Systems. European Commission: Brussels, Belgium, 2016. [Google Scholar]

- Finman, H.; Laitner, J. Industry, energy efficiency and productivity improvements. In Proceedings of the ACEEE Summer Study on Energy Efficiency in Industry, Tarrytown, NY, USA, 24–27 July 2001; pp. 561–570. [Google Scholar]

| Design Step | Comment |

|---|---|

| Decide primary target sector group | Primary target sector group should be set and, preferably, should be as homogenous as possible, both in terms of sector(s) and company size. |

| Map the annual energy | The annual energy demand and end-use is important and mapping the energy use and major technologies and processes are key steps. The share of energy use in support and production processes varies between sectors. |

| Review the current energy policies | For the major energy end-using technologies and processes in the former step, it is important to assess which existing public policy programs are in place and thus already provide support for deployment. |

| Make an energy efficiency potential estimation | Using available policy documents and scientific papers, an estimation should be made of the energy efficiency potential for the policy program. If no documents and studies are available, one can undertake a pilot ex-ante study where companies are asked about this. |

| Review the barriers and drivers for energy efficiency | Review the scientific publications regarding barriers and drivers for the specific sector group targeted. If the information regarding barriers and/or drivers for the targeted sector group is scarce, this could be supplemented with interviews or questionnaires in a pre-phase study. |

| Suggest appropriate policy | Consider the most appropriate policy or policy mix in relation to the findings in the previous steps. |

| Evaluate the impact of the policy programme | Make an evaluation of the policy programme to evaluate the achieved energy efficiency and cost-effectiveness of the programme. Include the expected implementation rate in the potential estimation. Anderson and Newell [26] found that approximately half of the energy efficiency measures in the American IAC were implemented and evaluation of the Swedish Project Highland showed an implementation rate of above 40% [27]. A common estimation of the implementation rate can be 50%. Further, aim to include quantified non-energy-benefits (NEBs) in the assessment of energy efficiency measures which could cut the payback time of measures [66]. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Johansson, I.; Mardan, N.; Cornelis, E.; Kimura, O.; Thollander, P. Designing Policies and Programmes for Improved Energy Efficiency in Industrial SMEs. Energies 2019, 12, 1338. https://doi.org/10.3390/en12071338

Johansson I, Mardan N, Cornelis E, Kimura O, Thollander P. Designing Policies and Programmes for Improved Energy Efficiency in Industrial SMEs. Energies. 2019; 12(7):1338. https://doi.org/10.3390/en12071338

Chicago/Turabian StyleJohansson, Ida, Nawzad Mardan, Erwin Cornelis, Osamu Kimura, and Patrik Thollander. 2019. "Designing Policies and Programmes for Improved Energy Efficiency in Industrial SMEs" Energies 12, no. 7: 1338. https://doi.org/10.3390/en12071338

APA StyleJohansson, I., Mardan, N., Cornelis, E., Kimura, O., & Thollander, P. (2019). Designing Policies and Programmes for Improved Energy Efficiency in Industrial SMEs. Energies, 12(7), 1338. https://doi.org/10.3390/en12071338