2.1. Simulation Model Summary

In our simulation model, each customer is given an equal heat demand situation, and so from this situation; the activity in the substations, together with the chosen supply temperature at the connection point, is assessed. Through an iterative function, the return temperatures from both space heating and domestic hot water heat exchangers are obtained, as well as the mass flow rates of each substation. A minimum mass flow rate is determined on the basis of the temperature drop which is considered acceptable from the service pipe (i.e., the pipe between the substation and distribution pipe). If the mass flow rate of the substation activity is greater than the minimum required, then there is no recirculation flow. However, if the current mass flow rate is less than the minimum, the corresponding difference is separated into the third pipe for recirculation to maintain comfort requirements without temperature contamination. The network is separated into sections to determine the mass flow rate propagation: The distribution in supply pipes, and accumulation in return pipes. To obtain an annual assessment, 20 cases were defined, composed of 10 different time intervals according to the outdoor temperature distribution, including diurnal and nocturnal cycles. The aim of the initial analysis was to establish the novel heat distribution technology concept, and to assess the temperature situation. Regarding heat loss, a simplified method for an analysis of the third pipe was applied, and consisted of a separate pipe in the ground, with equal size.

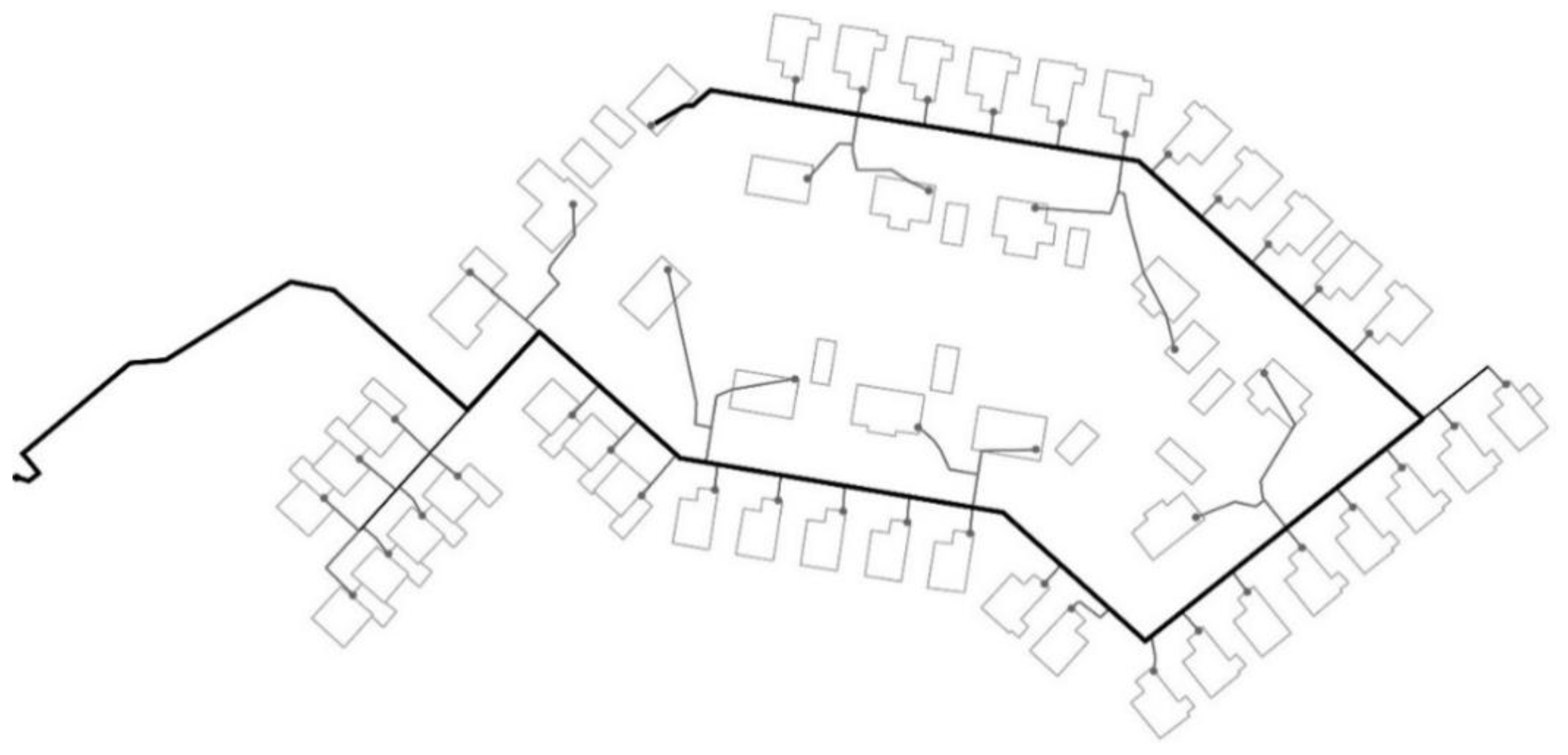

The analysed case area is a low linear heat density single-family housing area, according to

Figure 1. Consisting of 49 single-family houses located in Linköping, each residence is modelled with a floor area of 140 m

2 (i.e., 140 square metres), totalling 6860 m

2. The total length of the network is 1090 m, while the longest route between the connection point and the last customer is 526 m. The chosen case area constitutes one of the more challenging situations regarding pressure drop in the third pipe for recirculation, since an area with a high heat density and a low proportion of heat loss is expected to generate less need for recirculation flow. The case area is branched, whereas looped systems may alleviate system operation. However, to analyse pressure drop in the third pipe in the most challenging conditions, a branched system with low heat density was chosen.

The dimensions of the pipes in the analysed network are designed for domestic hot water capacities and not space heating capacities. In a small distribution network like the one observed, the heat load diversity for domestic hot water is low. Hence, the designed domestic hot water capacities will determine the minimum dimensions of the pipes.

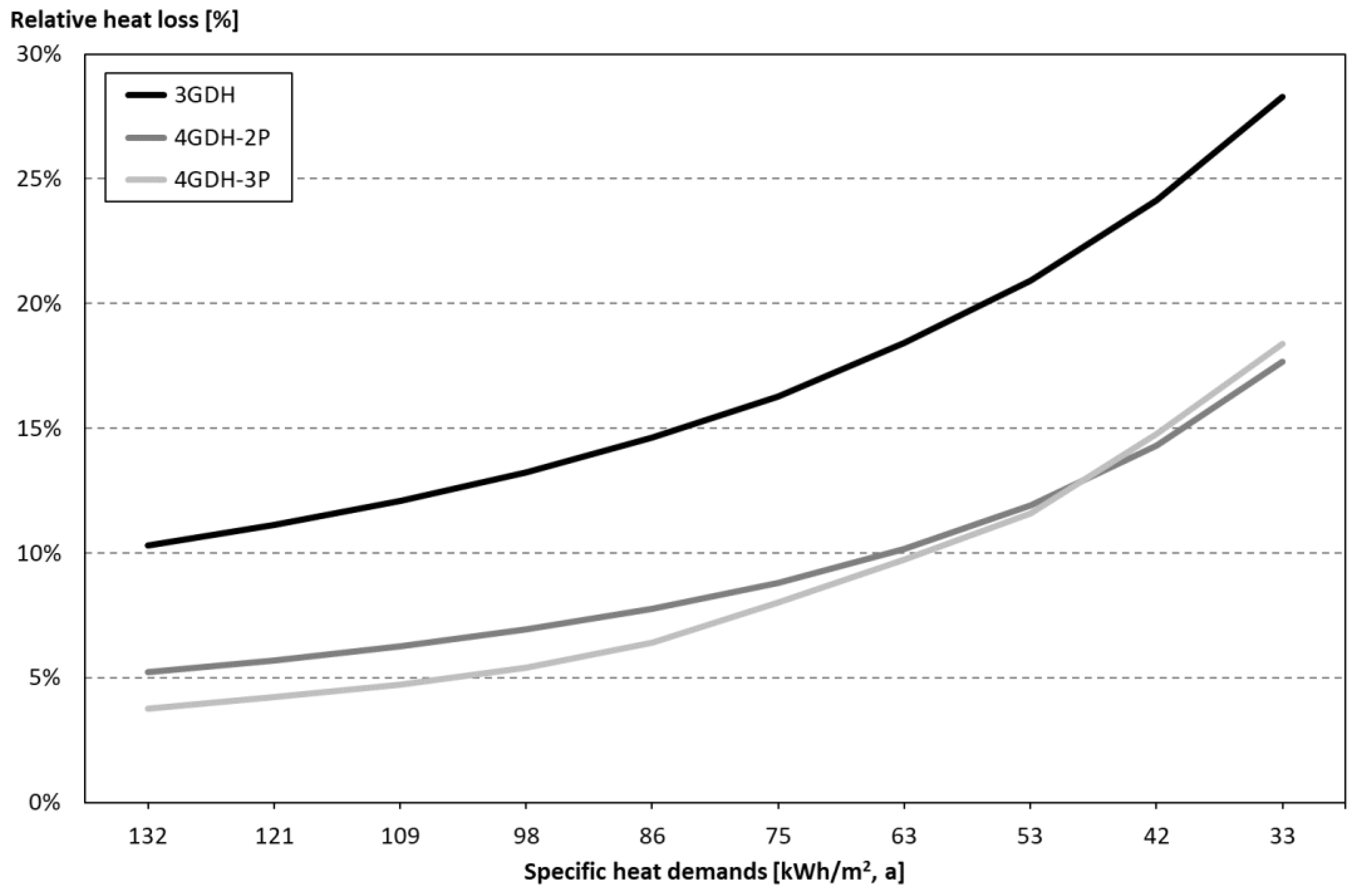

The differentiation between medium and low temperature operation is divided into the third (3GDH) and fourth (4GDH) generations of district heating technology, as defined by [

8]. Implicitly, these terms refer to the distribution technologies without a strategy to avoid temperature contamination between the supply and return during the off-heating season. Specifically, these terms refer to two-pipe systems, and can thus be labelled 3GDH-2P and 4GDH-2P. Hence, by implementing a third pipe in the distribution networks as a strategy to avoid temperature contamination in fourth generation district heating (4GDH), the labelling should read 4GHD-3P, see summary of terminology in

Table 1.

2.2. Specific Heat Loss Assessment

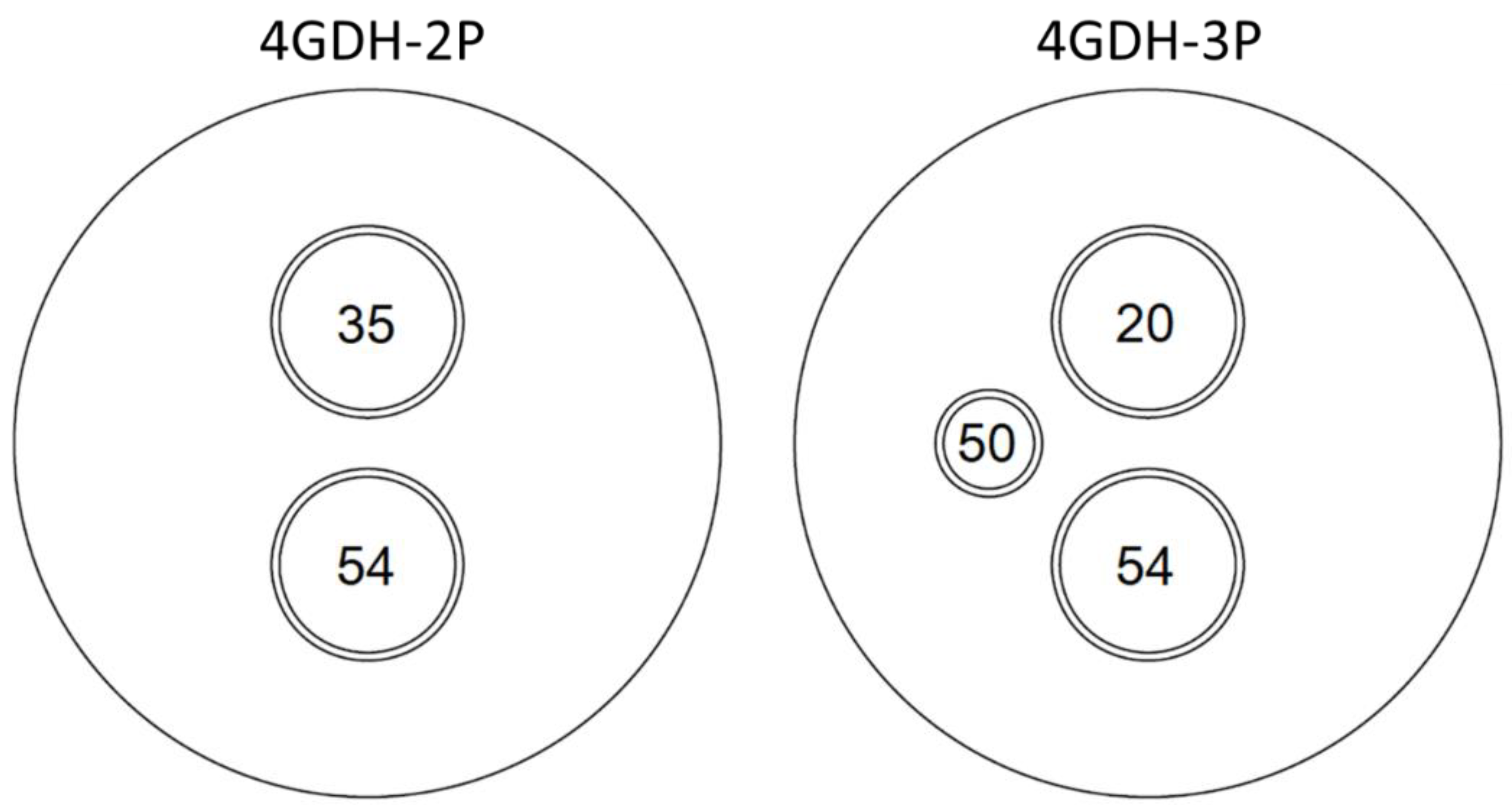

This section refers to the first research question about the assessment of specific heat loss for different pipe configurations. If three-pipe systems were to be applied by utilising a standard twin pipe with a single pipe, the hypothetical results would be increased heat loss, and increased demand during construction (excavation). If, on the other hand, the third pipe is integrated with the current standard twin pipes during manufacturing, as depicted in

Figure 2, then the hypothetical result is that any heat loss from recirculation can be mitigated, while the excavation is kept constant. Other challenges or requirements in manufacturing or construction may arise; however, such issues are not analysed further in this paper.

To establish a framework for the analysis of the overall heat transfer coefficients, K [W/(m

2 K)], a theoretical framework for heat loss is presented in the following paragraphs. Research on steady-state heat loss from insulated pipes by Wallentén (1991) [

11] presented approximate formulas for the heat loss from the pipes, considering (i) heat loss from one or two pipes in the ground, (ii) heat loss from two pipes embedded in circular insulation, and (iii) heat loss from two pipes in the ground, embedded in circular insulation.

The approximate formula for heat loss from two pipes embedded in circular insulation is cited in the European Standard EN 15698-1:2009 [

12] for calculation of the heat loss coefficient (linear thermal transmittance), λ [W/(m K)]. The preferred method by the standard is to refer to the heat loss by the length of pipe instead of the hot surface area, which is the case of the heat transfer coefficient.

The research presented by Wallentén [

11] is derived with the use of the multipole method to compute the conductive heat flows to and between the pipes in a composite cylinder, which was presented by Bennet, Claesson and Hellström in 1987 [

13], where the source code for computation also is published. The multipole method analyses the steady-state heat conduction in a two-dimensional circular region perpendicular to the pipes. The defined region is considered homogeneous. For the defined region, the pipes are located within an inner circular region, which is surrounded by an annulus of different thermal conductivity. The multipole method was developed to assess the heat extraction from boreholes and ground heat storage. The method is featured in more recent research [

14,

15].

The approximate formula presented in [

11] considers two pipes. However, the multipole method can be utilised to determine the steady-state, two-dimensional heat loss from district heating pipes with different pipe configurations. In this paper, the multipole method is utilised to determine the specific heat flow rates [W/m] for different standard two-pipe (twin) configurations, and the proposed three-pipe configurations.

Information related to the determination of pipe geometries is presented in the following paragraphs. Information about steel pipe dimensions (DN15-1200) and casing dimensions are specified in the European Standard EN 253:2009+A2:2015 [

16], while information about twin-pipe market configurations regarding steel pipes (DN15-250), casing dimeters (insulation series 1–3), and the distance between the steel pipes, is specified in [

12]. No specified information regarding the steel pipes in the size range of DN6-10 has been identified. These small pipe sizes will be considered for the recirculation pipe assessment. Hence, the estimated properties for these small pipes have been derived from the European Standard EN 10220:2002 [

17].

Data from [

12,

16,

17] are sufficient to establish the geometries to compute heat loss for twin pipes at each respective insulation series. Furthermore, the geometries for a twin-pipe configuration with an additional third recirculation pipe, the three-pipe configuration, can be determined. While varying the coordinates of the third pipes, the supply and return pipes remained fixed in their original position. The centres of the recirculation pipes are fixed in the y-axis of the casing origins and are varied in the x-axis, depending on the number of displacements (see

Figure 2), so that the minimum distance from the supply and return pipes is equal to the minimum distance for that of the supply and return pipes, according to [

12].

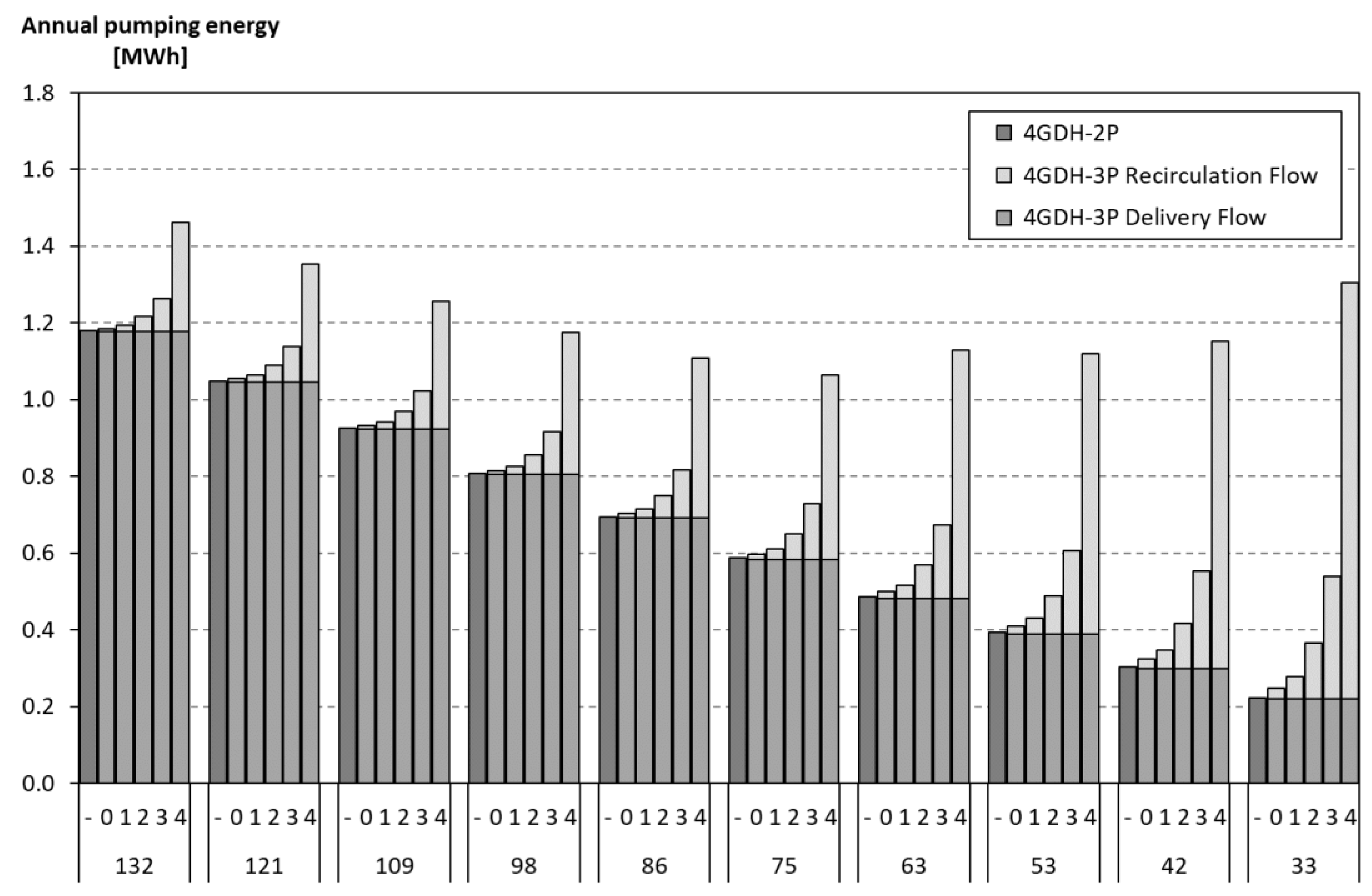

The categorisation for the sizing assessment is arranged according to the ordinary reference twin pipe denoted by a (-), while the recirculation pipe is divided in a number of downward displacements (5) ranging from 0 to 4, where a 0 denotes a recirculation pipe with equal dimensions to the supply and return pipes, a 1 denotes a recirculation pipe with smaller dimensions by one standard size, compared to the supply and return pipes, etc. Thus, as the size of the third pipe decreases, the distance from the supply and return pipes is adjusted to match the standard minimum distance between pipes.

Apart from the coordinates for the pipe geometries, the multipole method requires the numerical values for the radius of the outer circle of analysis and the thermal conductivity for the outer circular region (soil) and the inner circular region (insulation).

According to [

11], the radius of the outer circle can be substituted with twice the depth. It is unclear what the depth norm at construction is. Pipes are not required to be laid at a frost-free depth, which corresponds to approximately below 1 m in southern Scandinavia. However, 1 m is the assumed depth for laying pipe [

2]. Hence, the numerical value for the diameter of the outer circle is chosen to be 2 m.

According to Ref. [

16], thermal conductivity for insulation in unaged conditions should not exceed 0.029 W/(m K). Thermal conductivity increases with temperature. An approximate formula to determine the thermal conductivity of polyurethane foam within a specified temperature interval was presented by Bøhm and Kristjansson in 2005 [

18]. The numerical value of thermal conductivity for the insulation material in this analysis is set to 0.026 W/(m K), which is the same as that used by one of the large pipe manufacturing companies in the product catalogue [

19]. The thermal conductivity of soil is difficult to estimate due to the variation in moisture content, soil composition, and homogeneity. However, a constant of 1.5 W/(m K) is utilised in the present analysis, corresponding to [

18].

The specific heat flow output rate is given as Φ/L [W/m] for each involved pipe. For modelling purposes, the individual values of these pipes are recalculated as heat transfer coefficients, K [W/(m

2, K)], which refer to the surface area of the media pipes, rather than the length of pipes. The reason is that the use of heat transfer coefficients is a common practice in fundamental heat transfer theory. Hence, heat transfer coefficients for supply, return and recirculation pipes are determined according to Equation (1):

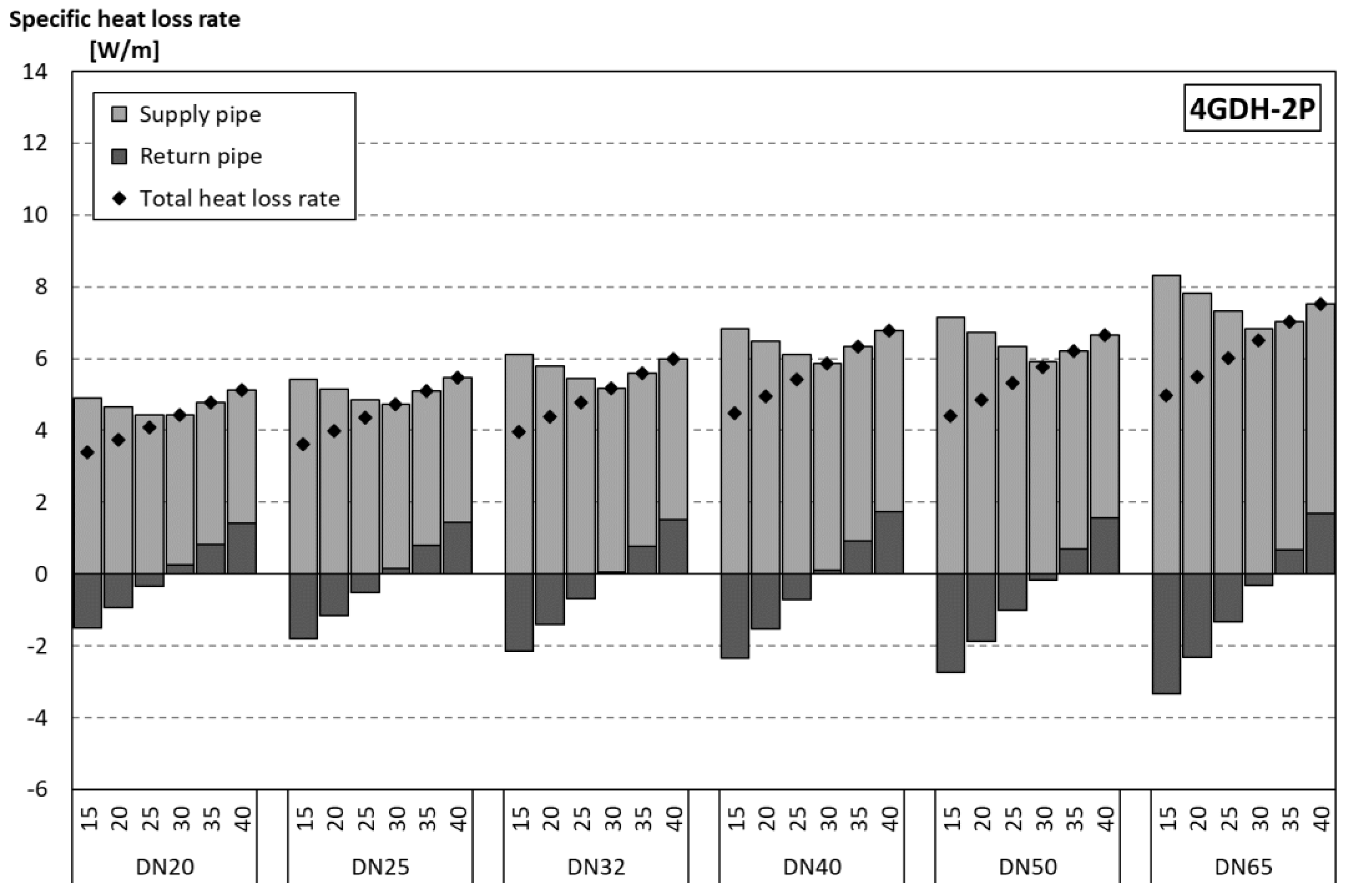

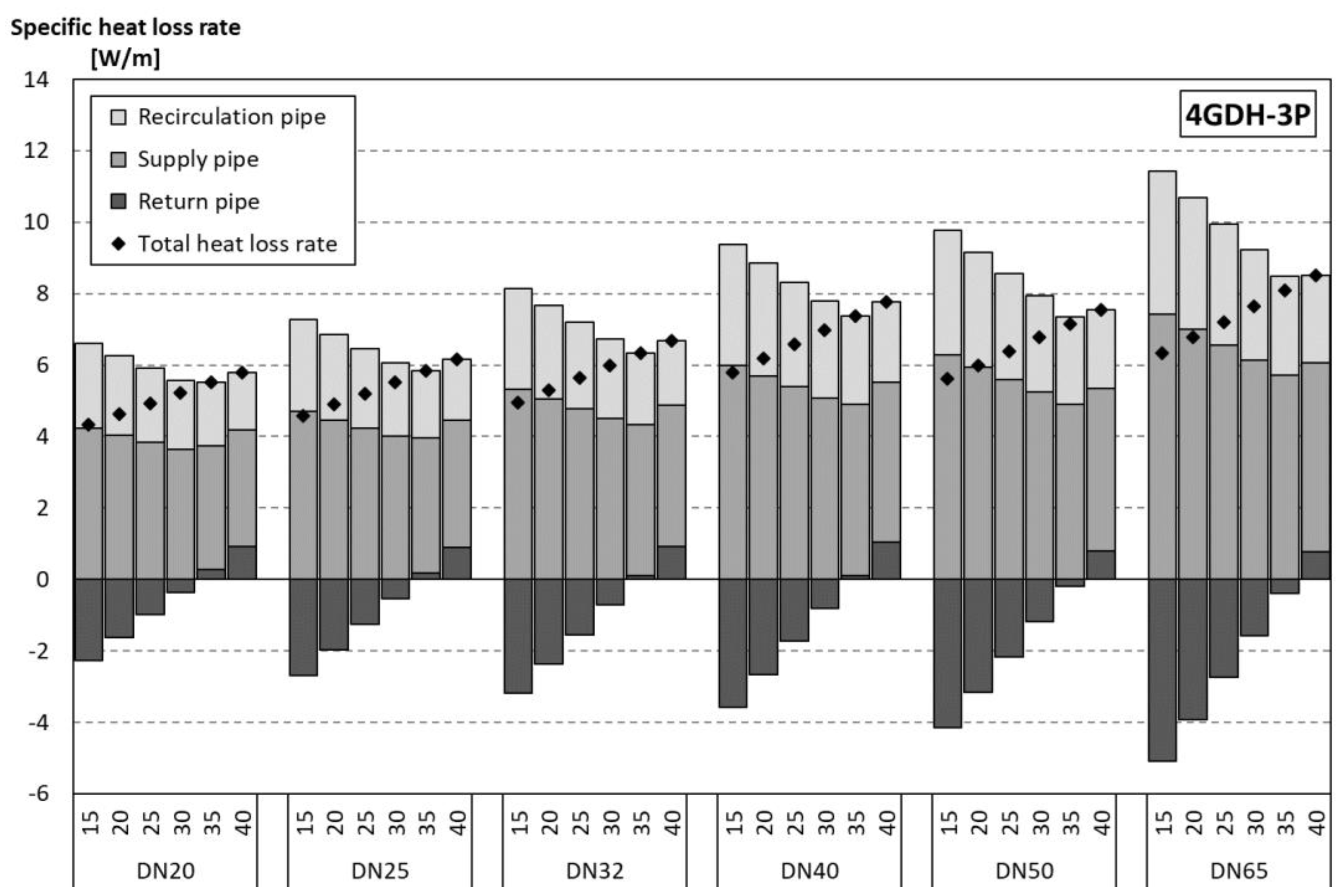

The parametric outcome is determined with the variation of pipe size (DN20-DN250), insulation level (1–3), number of displacements (0–4), and return temperatures (15–40 °C). The other parameters, the supply temperature and recirculation temperature, remain constant at annual average temperatures, which is 54 °C for the supply pipe, and 50 °C for the recirculation pipe, while the annual average ambient temperature is set to 10 °C. The variation of the return temperature is set to steps of Δt equal to 5 °C, and the integer values in between are generated through interpolation.

2.3. Pressure Loss Assessment

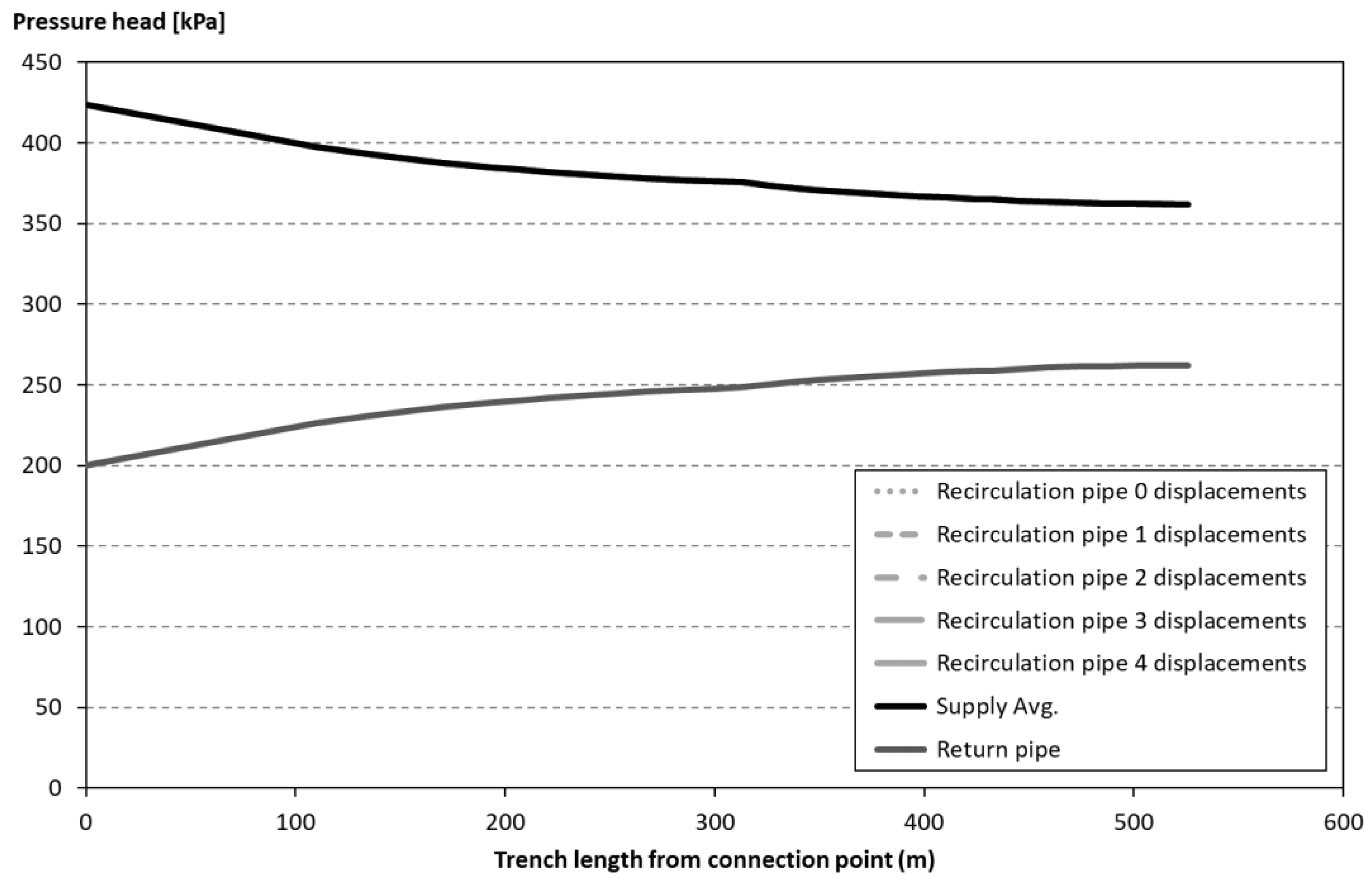

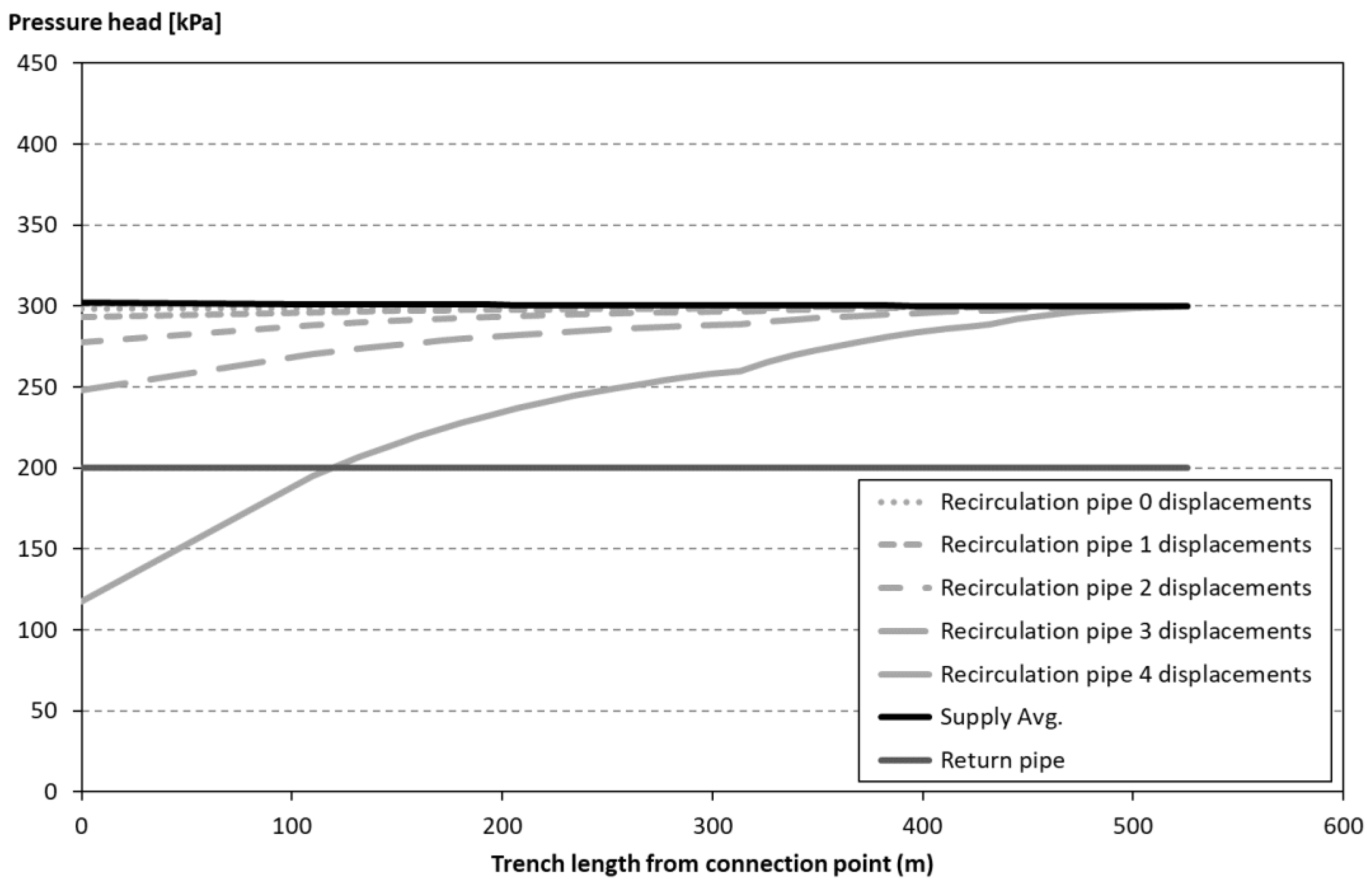

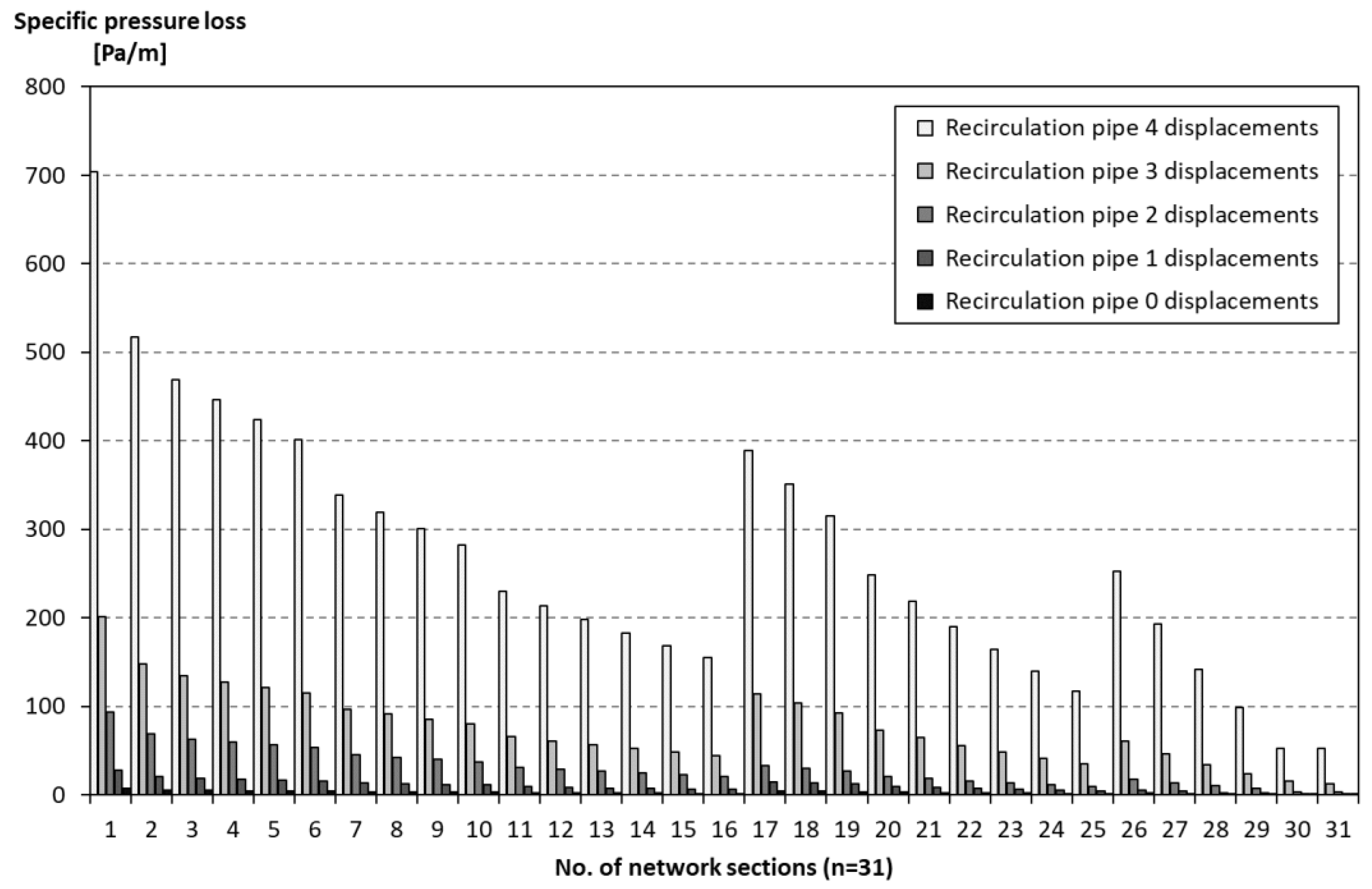

This section refers to the second research question about differential pressure assessment. The design condition for the third pipe occurs at no load situations. In the analysis, this situation is substituted with the case of the highest outdoor temperatures at night time, when no space heating demand nor domestic hot water demand occurs among customers. The design conditions are associated with low flow rates; thus, small pressure head loss is anticipated.

The longest route along the network is also the critical route, constituting the highest pressure head loss, since all other shorter possible routes of the observed case area network should exhibit less total pressure head loss. Thus, the longest route is utilised to display the pressure situation.

The pressure drop Δp [Pa] is determined and summed for each section length of pipe L [m] for the longest route in the case area network (see

Figure 1, according to Equation (2) found in [

2]). The minimum recirculation flow rate

[kg/s] is defined in [

10]. In the equation, the friction factor λ = 0.025 [-] and the density ρ = 1000 [kg/m

3] are all treated as constants, while the inner pipe diameter d

i [m] is changed accordingly, depending on pipe configuration. The pressure drop depends on the inner pipe diameter raised to the power of five. Hence, the changes of inner pipe diameter have a major influence on the pressure drop outcome:

A commonly used criterion is that the pressure gradients in the supply flow direction should be consistent with the values of the specific pressure drop that ranges between 50 and 200 Pa/m [

2], since further increased pump power has a diminishing return on the increased flow velocity. The corresponding pressure conditions should apply to the recirculation flow direction.

The pumping power P

el [W] for the design conditions is calculated according to Equation (3) found in [

2]. In the case of the central control method, the required pressure lift Δp

pump [Pa] for the recirculation pipe corresponds to the largest pressure drop of the case area, according to Equation (2). The pump efficiency η [-] is considered, and in this case, a flat 0.8 is used:

Thus, at the connection point for the case area, the collective sum of the minimum recirculation flow rate is recalculated as the volume flow rate

[m

3/s] according to Equation (4):

Regarding the heat distribution and pressure assessment, a common starting point is to observe the main distribution line, and consider the option in order to avoid oversizing the distribution network sections because of an overestimation of the required domestic hot water capacity, which is common due to the uncertainty in the design, and the lack of measurements [

20]. The attractiveness of smaller pipes lies with less heat loss [

21]. However, in the analysed case area, due to heat loads that are not fully diversified, the piping networks are designed to manage domestic hot water capacity loads. A large proportion of the case area constitutes the service pipe, where the greatest required capacity is determined by domestic hot water preparation, around 35 to 40 kW compared with the design space heating loads at 5 to 10 kW. Hence, pipe dimensions could not be downsized to decrease heat loss, since the area is designed for domestic hot water capacity.