Optimal Operational Adjustment of a Community-Based Off-Grid Polygeneration Plant using a Fuzzy Mixed Integer Linear Programming Model

Abstract

:1. Introduction

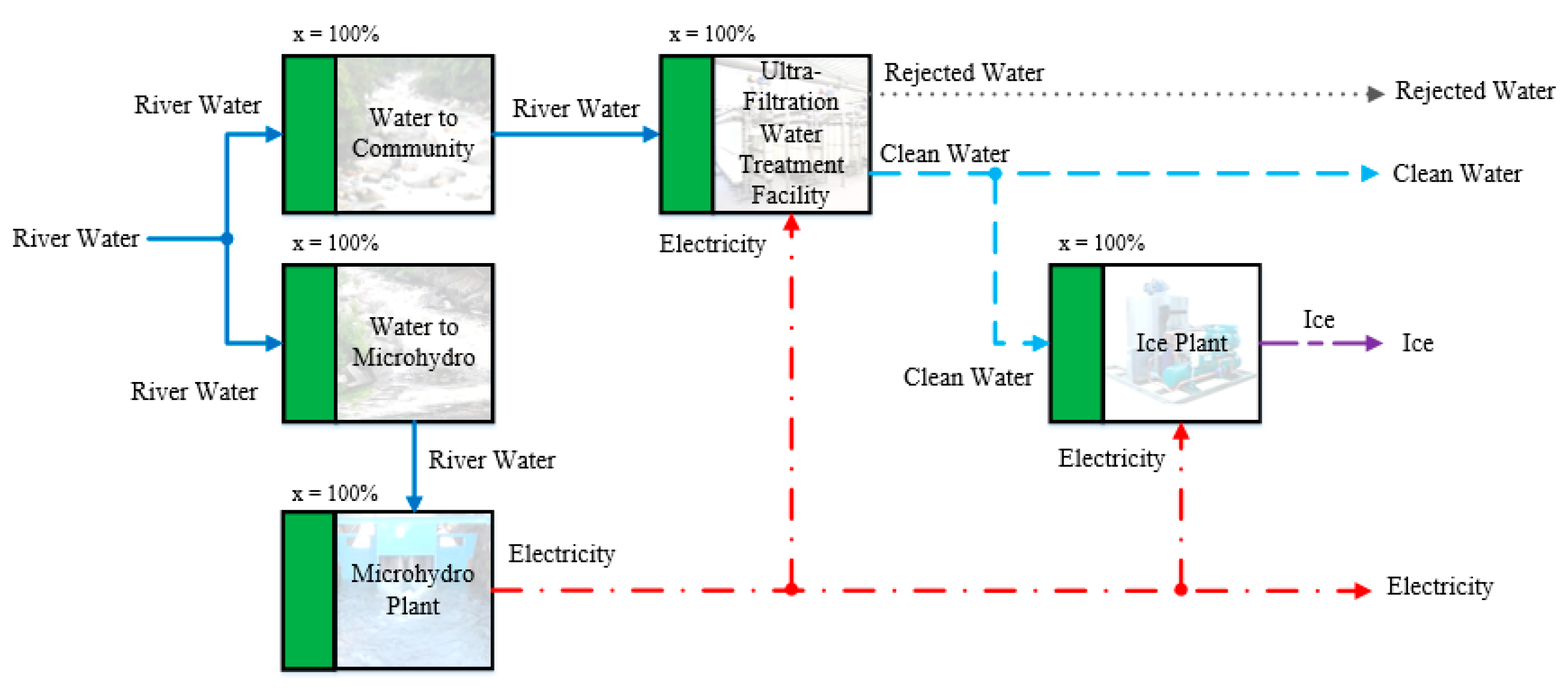

2. Problem Statement

- An off-grid polygeneration system is assumed to have M number of products and N number of installed process units.

- The process units are characterized by fixed input-output stream proportions described by either the yield, efficiency, or the coefficient of performance, depending on the appropriate factor for each unit.

- Each process unit is defined by a minimum part-load operating level below which unstable or uneconomical operation occurs. The input-output ratios of streams for each unit remain fixed for the entire feasible operating range bound by a lower limit (minimum part-load operating level) and an upper limit (the rated capacity with a safety factor). The operational flexibility of the off-grid polygeneration system is defined by this operational range. The off-grid polygeneration system is further assumed to operate at a new steady state mode where the inoperability transpires.

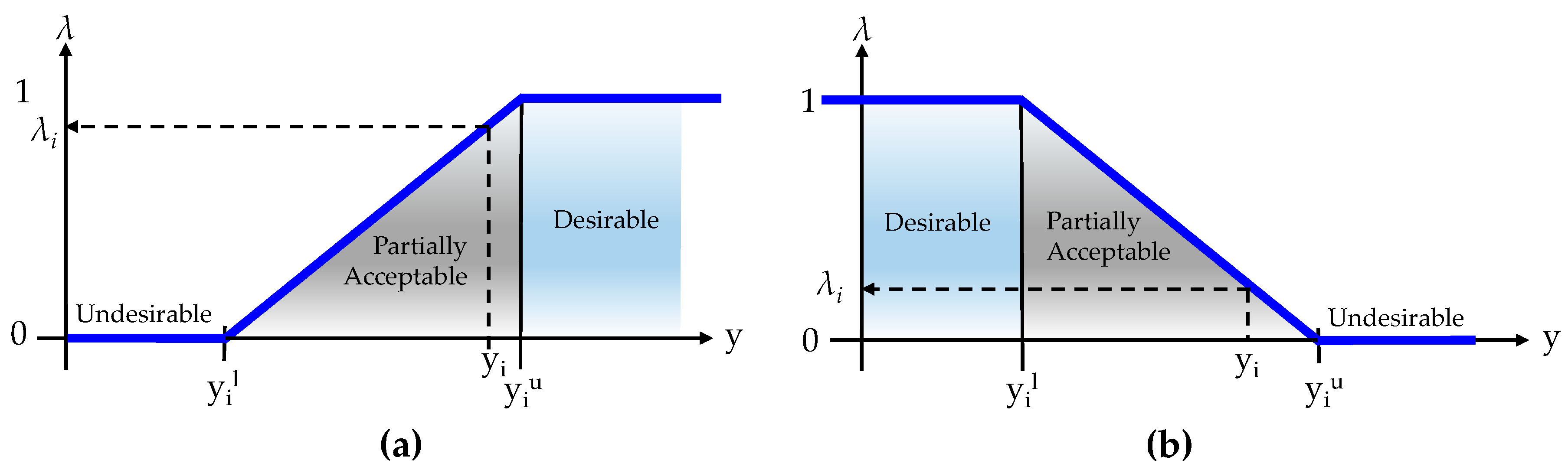

- For each product stream, a fuzzy membership function is defined to describe the limits on net output, as dictated by basic requirements of the community inhabitants and are assumed to be constant. The fuzzy membership functions are assumed to be linear, and can thus be defined by specifying upper and lower limits. The upper limits signify normal requirements, while the lower limits signify the bare minimum requirements.

- The problem is to determine the optimal adjustment of operating capacities and allocation of streams for each process unit given an inoperability on the availability of water (drought scenario).

3. Fuzzy Mixed Integer Linear Programming Model

4. Case Study

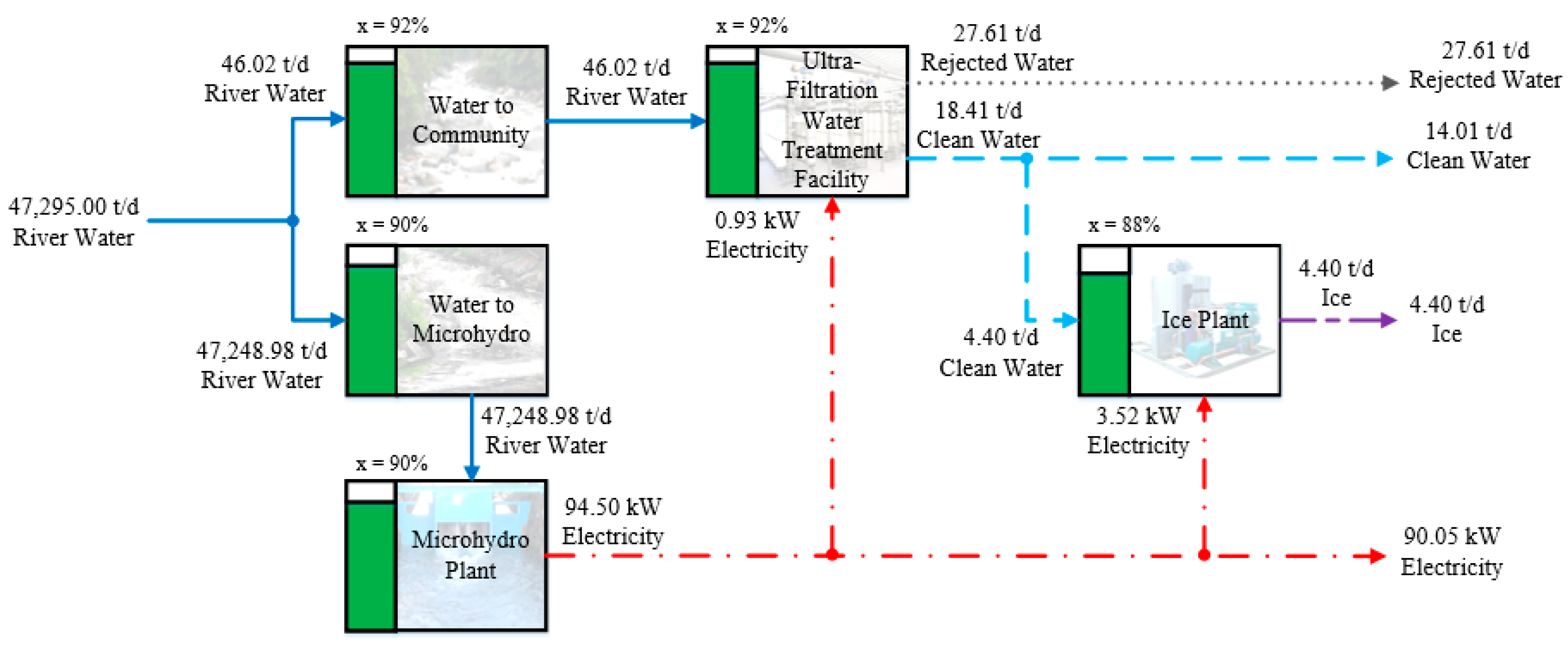

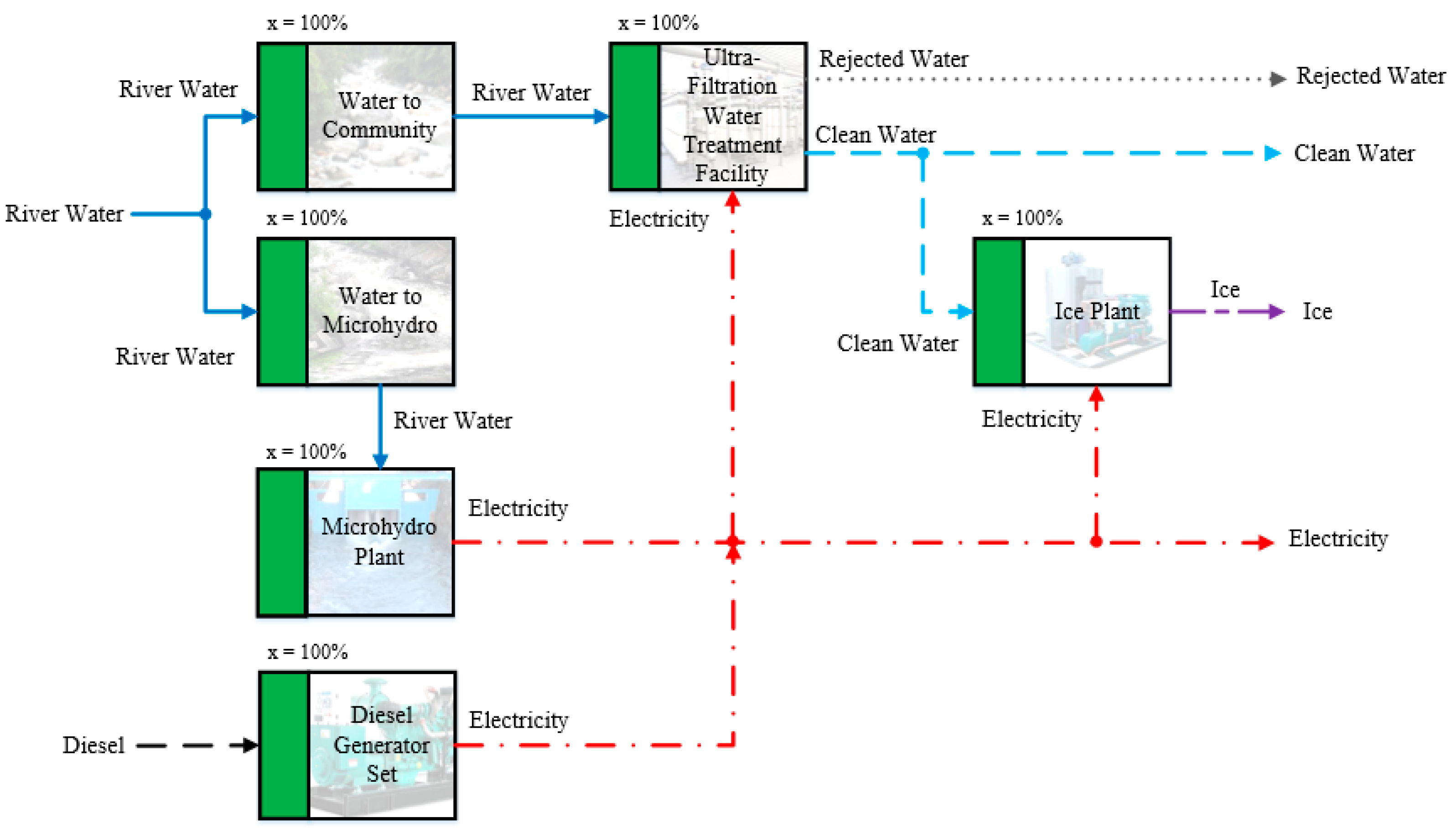

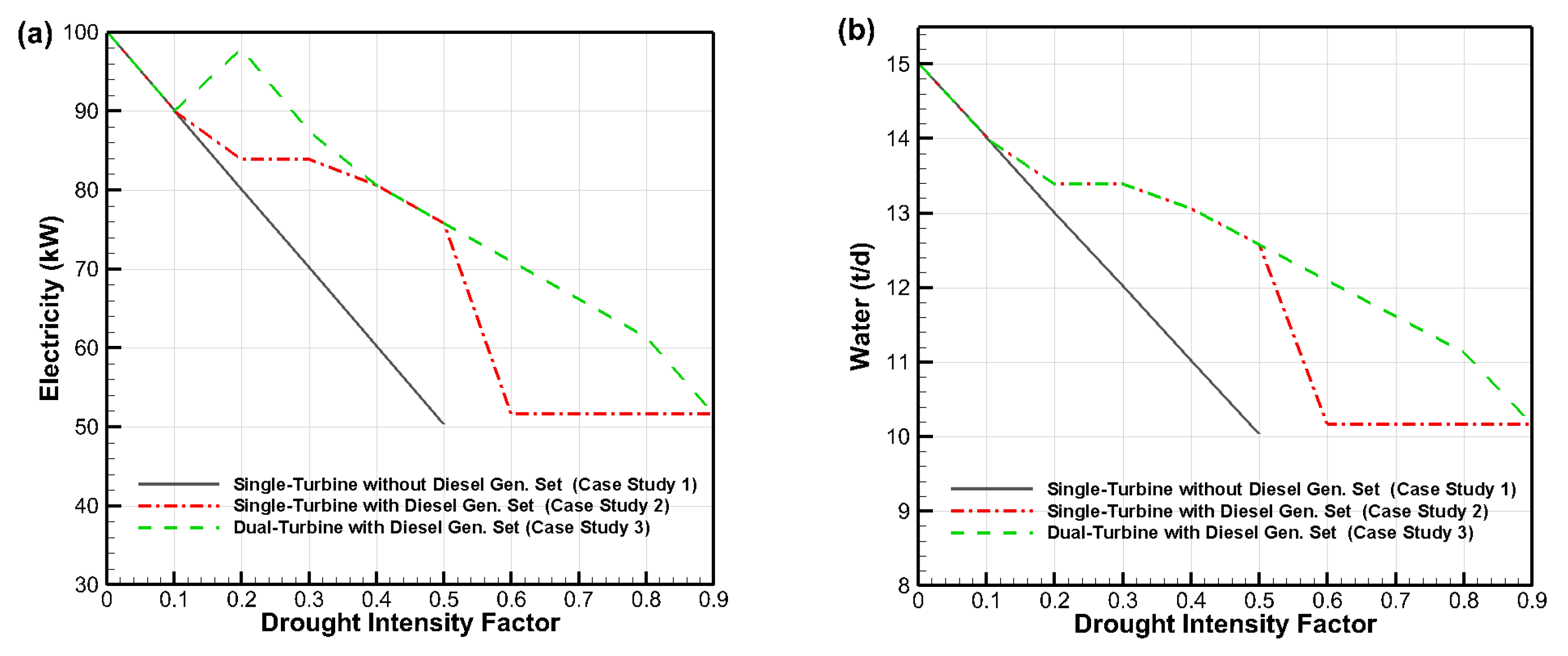

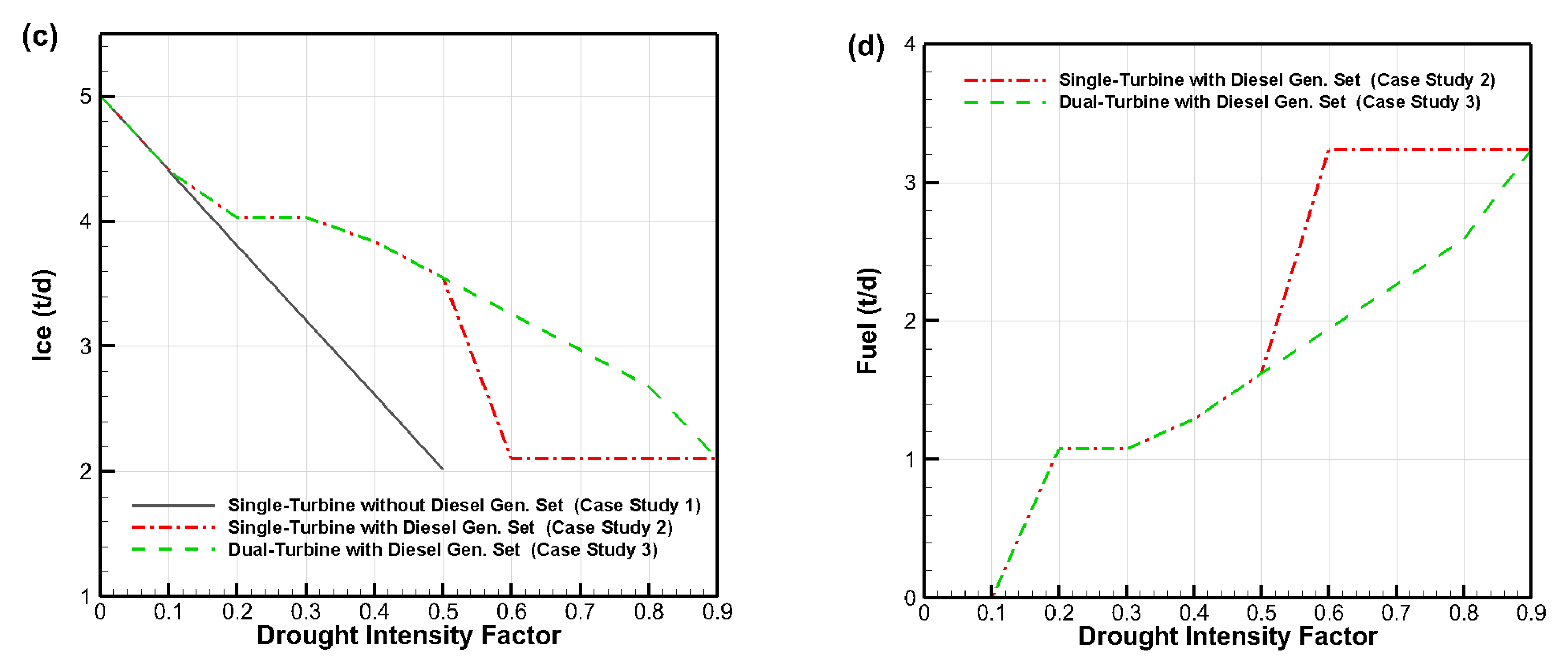

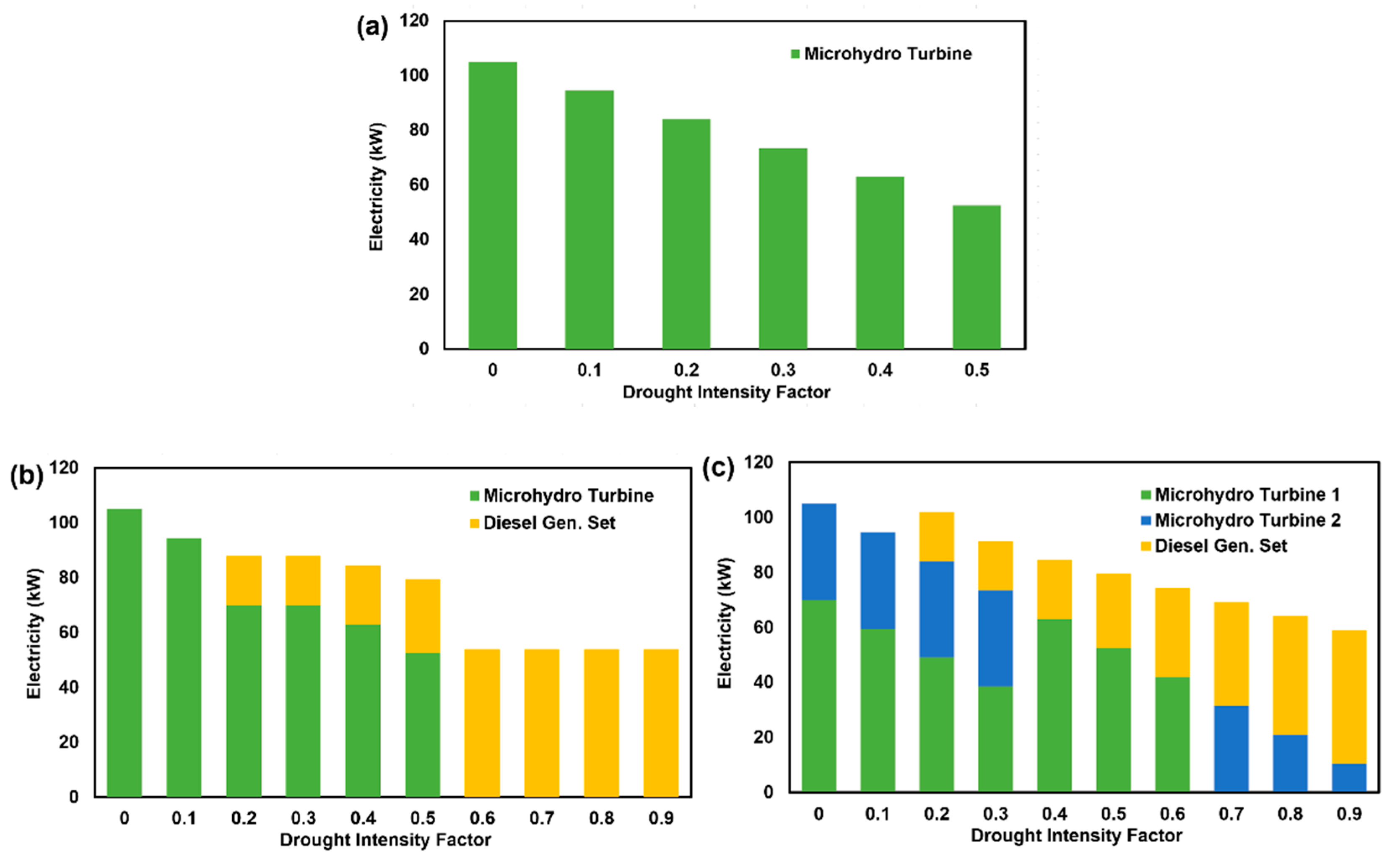

4.1. Case Study 1

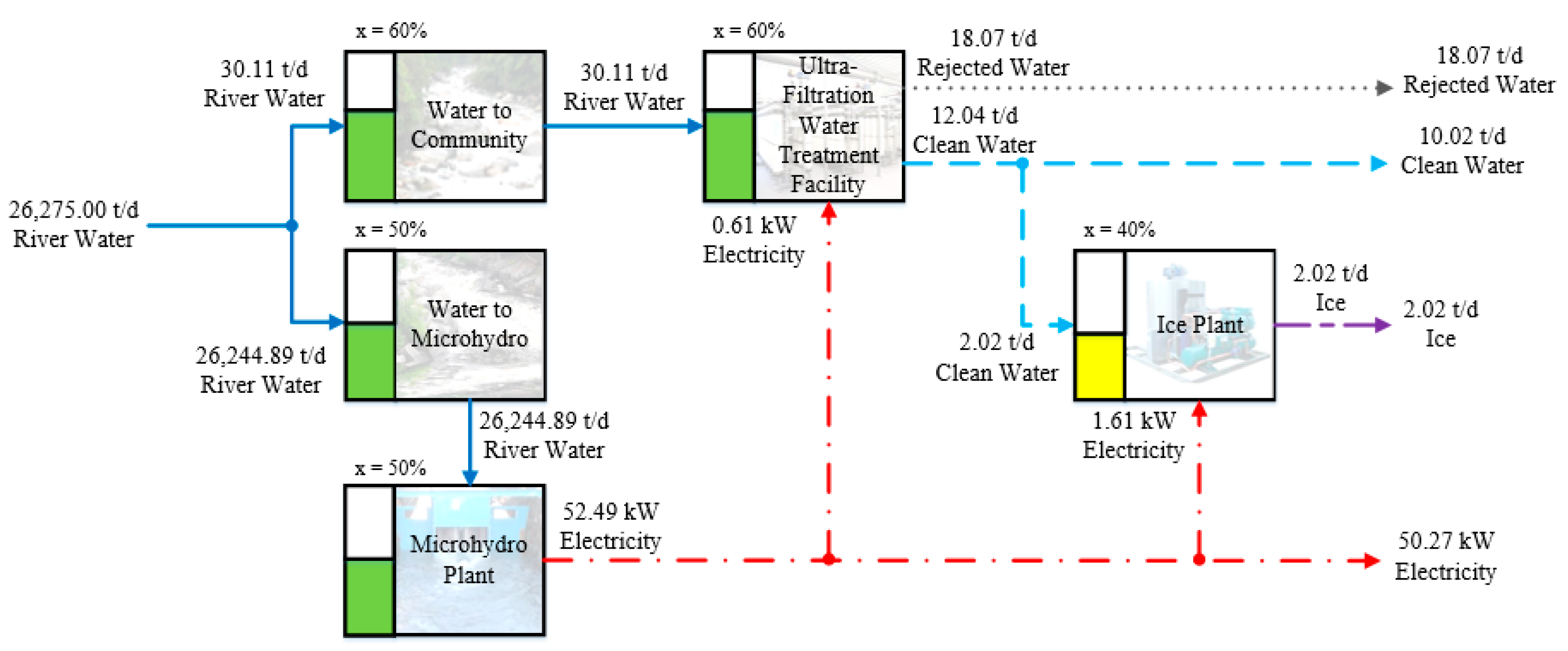

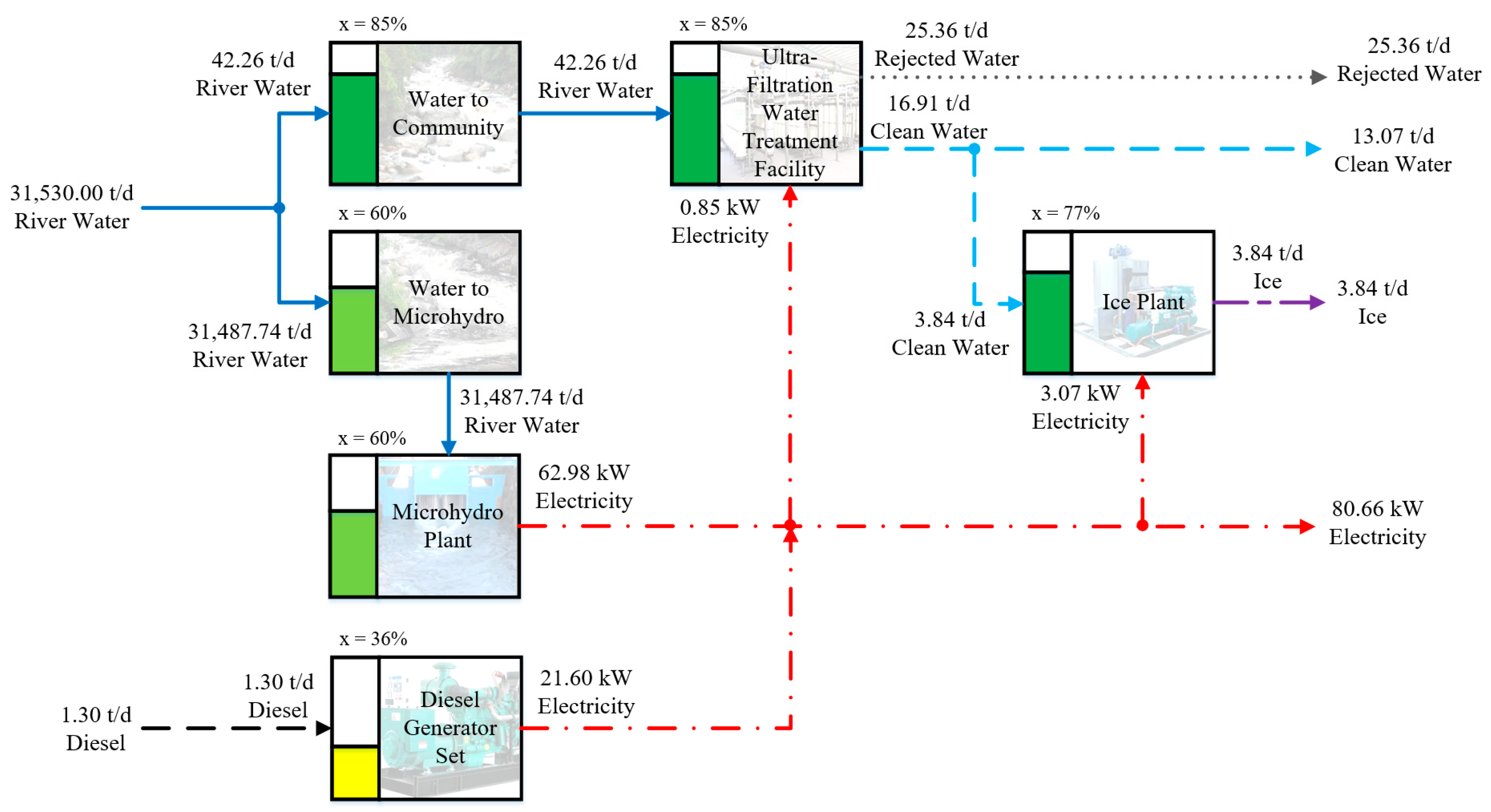

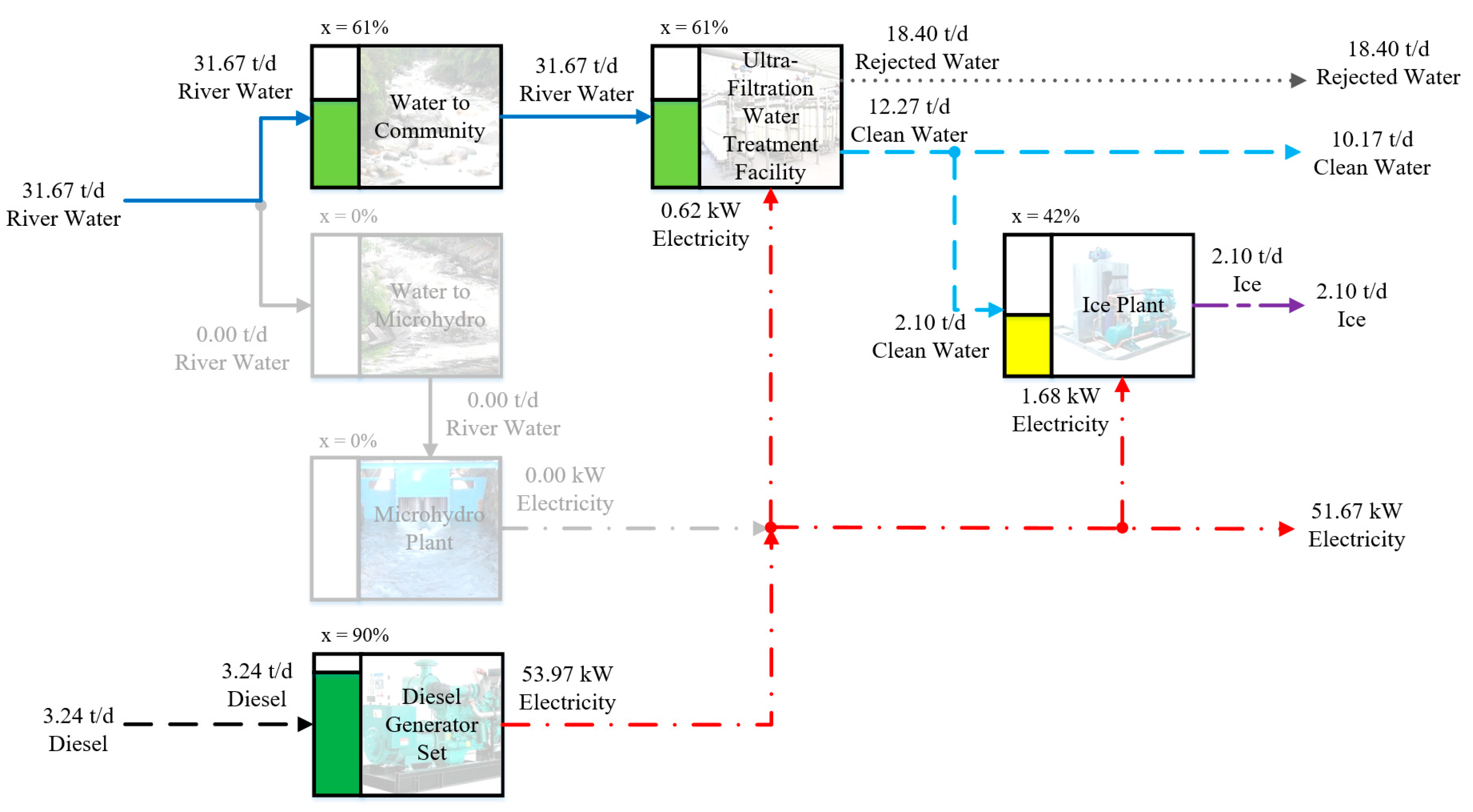

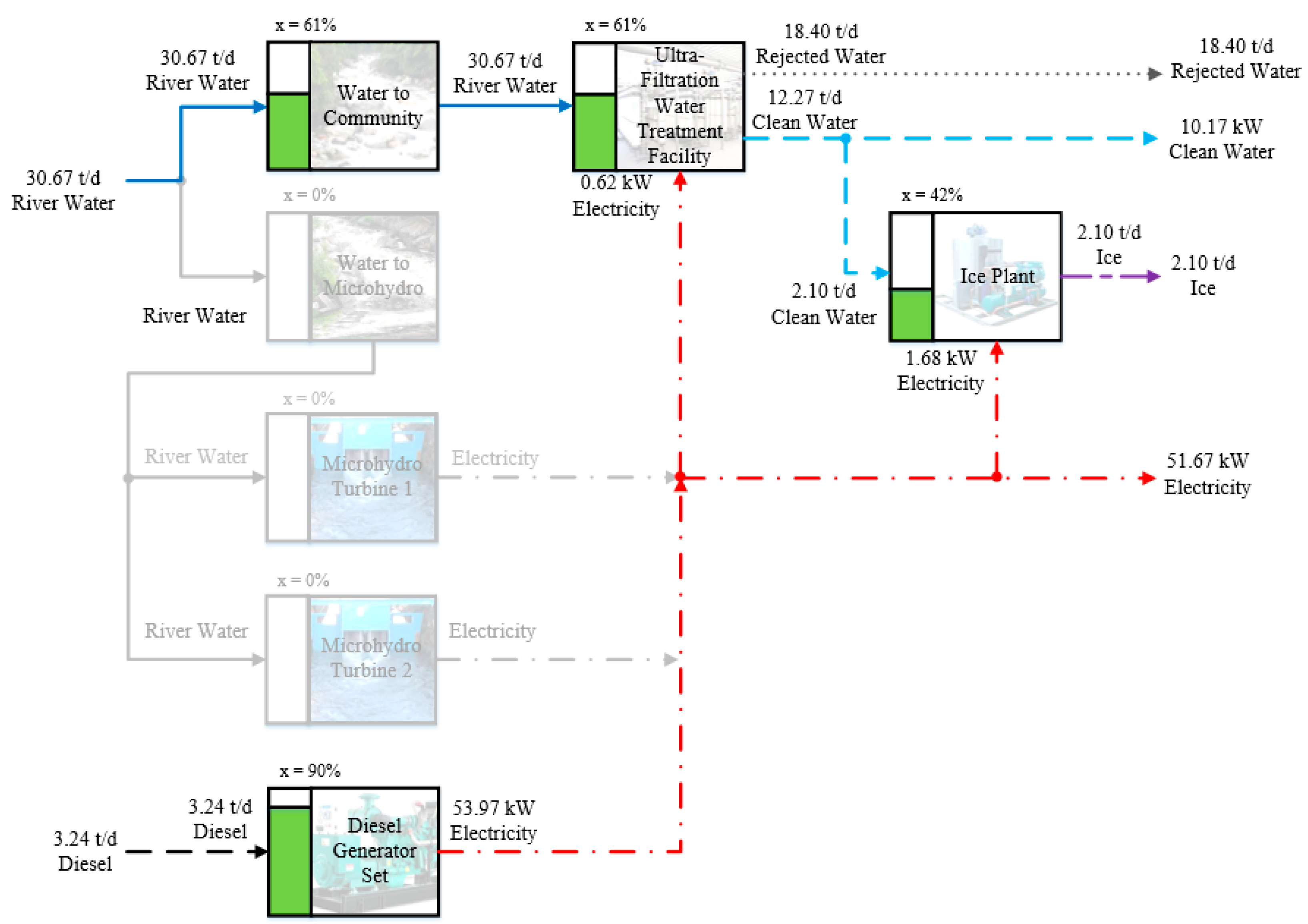

4.2. Case Study 2

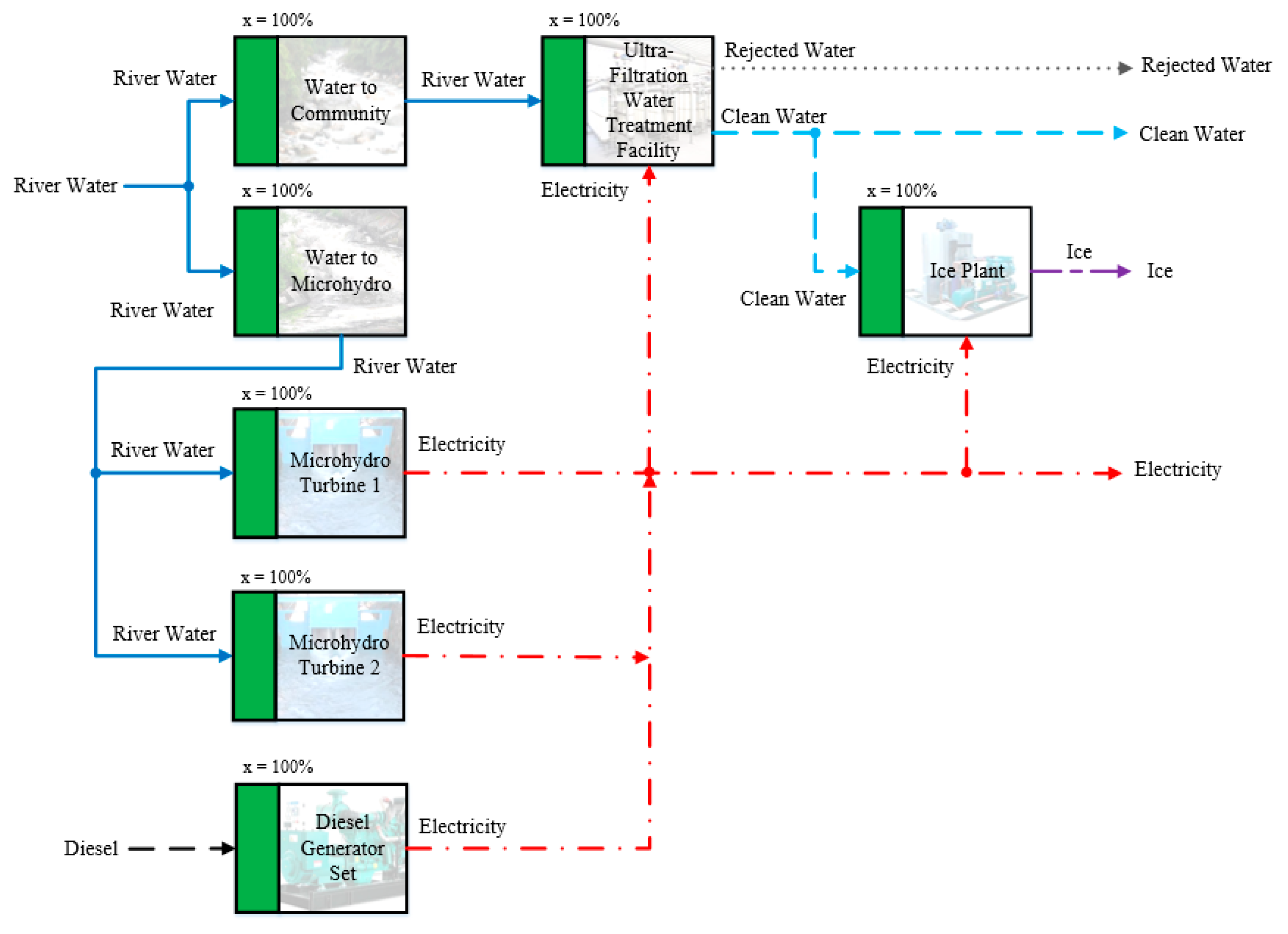

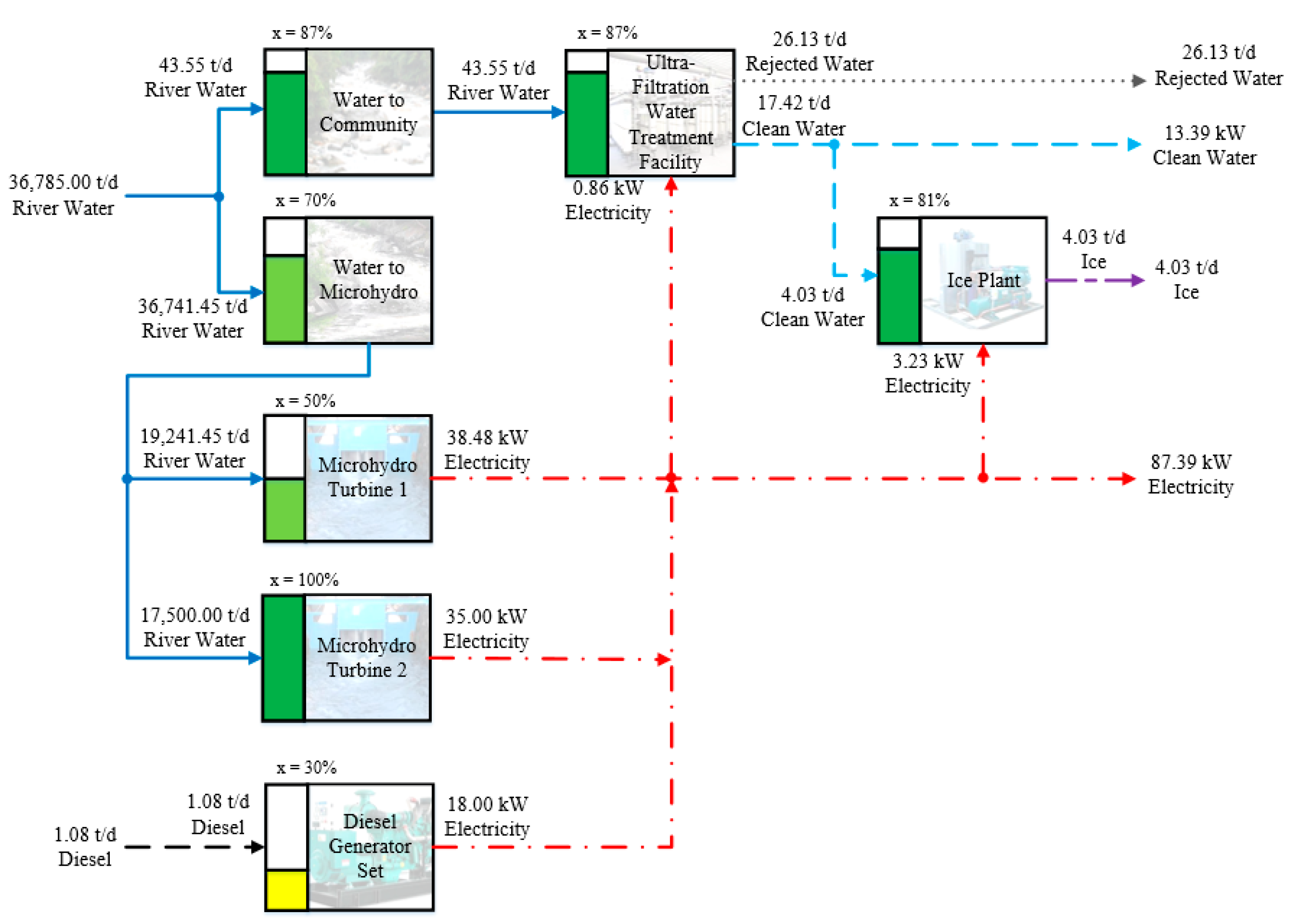

4.3. Case Study 3

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- The World Bank. Designing Sustainable off-Grid Rural Electrification Projects: Principles and Practices; Research Working Papers; The World Bank: Washington, DC, USA, 2008. [Google Scholar]

- Banerjee, S.G.; Bhatia, M.; Portale, E.; Schers, J.; Dorner, D.; Azuela, G.E.; Jaques, I.S.; Ashok, P.E.; Bushueva, I.; Angelou, N.; et al. Global Tracking Framework. Sustain. Energy All World Bank 2013, 3, 289. [Google Scholar]

- United Nations. Affordable and Clean Energy: Energy Efficient; United Nations: New York, NY, USA, 2018. [Google Scholar]

- The World Bank. State of Energy Access Report 2017; The World Bank: Washington, DC, USA, 2017. [Google Scholar]

- IRENA. Off-Grid Renewable Energy Solutions: Global and Regional Status and Trends; IRENA: Abu Dhabi, UAE, 2018; pp. 1–20. [Google Scholar]

- Perry, S.; Klemeš, J.; Bulatov, I. Integrating waste and renewable energy to reduce the carbon footprint of locally integrated energy sectors. Energy 2008, 33, 1489–1497. [Google Scholar] [CrossRef]

- Lee, J.Y.; Aviso, K.B.; Tan, R.R. Optimal Sizing and Design of Hybrid Power Systems. ACS Sustain. Chem. Eng. 2018, 6, 2482–2490. [Google Scholar] [CrossRef]

- Lee, J.Y.; Lu, Y.C.; Aviso, K.B.; Tan, R.R. Mathematical programming for optimal design of hybrid power systems with uncertainties. Chem. Eng. Trans. 2018, 70, 67–72. [Google Scholar]

- Geem, Z.W. Optimal Scheduling of Multiple Dam System Using Harmony Search Algorithm. In Computational and Ambient Intelligence; IWANN 2007. Lecture Notes in Computer Science; Sandoval, F., Prieto, A., Cabestany, J., Graña, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; Volume 4507, pp. 316–323. [Google Scholar]

- Agarkar, B.D.; Barve, S.B. A Review on Hybrid solar/wind/hydro power generation system. Int. J. Curr. Eng. Technol. 2011, 4, 188–191. [Google Scholar]

- Walmsley, T.G.; Walmsley, M.R.W.; Varbanov, P.S.; Klemeš, J.J. Energy Ratio analysis and accounting for renewable and non-renewable electricity generation: A review. Renew. Sustain. Energy Rev. 2018, 98, 328–345. [Google Scholar] [CrossRef]

- Ubando, A.T.; Marfori, I.A.V.; Aviso, K.B.; Tan, R.R. Optimal synthesis of a community-based off-grid polygeneration plant using fuzzy mixed integer linear programming model. Chem. Eng. Trans. 2018, 70, 955–960. [Google Scholar]

- Serra, L.M.; Lozano, M.-A.; Ramos, J.; Ensinas, A.V.; Nebra, S.A. Polygeneration and efficient use of natural resources. Energy 2009, 34, 575–586. [Google Scholar] [CrossRef]

- Adams, T.A.; Ghouse, J.H. Polygeneration of fuels and chemicals. Curr. Opin. Chem. Eng. 2015, 10, 87–93. [Google Scholar] [CrossRef]

- Kasivisvanathan, H.; Barilea, I.D.U.; Ng, D.K.S.; Tan, R.R. Optimal operational adjustment in multi-functional energy systems in response to process inoperability. Appl. Energy 2013, 102, 492–500. [Google Scholar] [CrossRef]

- Haimes, Y.Y.; Jiang, P. Leontief-based model of risk in complex interconnected infrastructures. J. Infrastruct. Syst. 2001, 7, 1–12. [Google Scholar] [CrossRef]

- Leontief, W. The Structure of American Economy, 1919–1929: An Empirical Application of Equilibrium Analysis; Harvard University Press: Cambridge, MA, USA, 1941; p. 181. [Google Scholar]

- Jiang, P.; Haimes, Y.Y. Risk management for Leontief-based interdependent systems. Risk Anal. 2004, 24, 1215–1229. [Google Scholar] [CrossRef] [PubMed]

- Haimes, Y.Y.; Horowitz, B.M.; Lambert, J.H.; Santos, J.R.; Crowther, K.; Lian, C. Inoperability input-output model for interdependent infrastructure sectors. I: Theory and methodology. J. Infrastruct. Syst. 2005, 11, 80–92. [Google Scholar] [CrossRef]

- Santos, J.R.; Barker, K.; Zelinke, P.J. Sequential decision-making in interdependent sectors with multiobjective inoperability decision trees: Application to biofuel subsidy analysis. Econ. Syst. Res. 2008, 20, 29–56. [Google Scholar] [CrossRef]

- Tan, R.R. A general source-sink model with inoperability constraints for robust energy sector planning. Appl. Energy 2011, 88, 3759–3764. [Google Scholar] [CrossRef]

- Tan, R.R.; Lam, H.L.; Kasivisvanathan, H.; Ng, D.K.S.; Foo, D.C.Y.; Kamal, M.; Hallaler, N.; Klemeš, J.J. An algebraic approach to identifying bottlenecks in linear process models of multifunctional energy systems. Theoret. Found. Chem. Eng. 2012, 46, 642–650. [Google Scholar] [CrossRef]

- Hoq, T.; Nawshad, U.A.; Islam, N.; Syfullah, K.; Rahman, R. Micro Hydro Power: Promising Solution for Off-grid Renewable Energy Source. Int. J. Sci. Eng. Res. 2011, 2, 2–6. [Google Scholar]

- Pasalli, Y.R.; Rehiara, A.B. Design Planning of Micro-hydro Power Plant in Hink River. Procedia Environ. Sci. 2014, 20, 55–63. [Google Scholar] [CrossRef]

- Hongpeechar, B.; Krueasuk, W.; Poungching-Ngam, A.; Bhasaputra, P.; Pattaraprakorn, W. Feasibility study of micro hydro power plant for rural electrification in Thailand by using axial flux permanent magnet. In Proceedings of the 2011 International Conference and Utility Exhibition on Power and Energy Systems: Issues and Prospects for Asia, Pattaya City, Thailand, 28–30 September 2011; pp. 3–6. [Google Scholar]

- Voll, P.; Jennings, M.; Hennen, M.; Shah, N.; Bardow, A. The optimum is not enough: A near-optimal solution paradigm for energy systems synthesis. Energy 2015, 82, 446–456. [Google Scholar] [CrossRef]

- Ray, A.; Jana, K.; De, S. Polygeneration for an off-grid Indian village: Optimization by economic and reliability analysis. Appl. Therm. Eng. 2017, 116, 182–196. [Google Scholar] [CrossRef]

- Khalilpour, K.R.; Vassallo, A. A generic framework for distributed multi-generation and multi-storage energy systems. Energy 2016, 114, 798–813. [Google Scholar] [CrossRef]

- Zimmermann, H.J. Fuzzy programming and linear programming with several objective functions. Fuzzy Sets Syst. 1978, 1, 45–55. [Google Scholar] [CrossRef]

- Ubando, A.T.; Marfori, I.A.; Culaba, A.B.; Dungca, J.R.; Promentilla, M.A.B.; Aviso, K.B.; Tan, R.R. A Systematic Approach for the Optimal Design of an Off-Grid Polygeneration System using Fuzzy Linear Programming Model. In Computer Aided Chemical Engineering; Espuña, A., Graells, M., Puigjaner, L., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; Volume 40, pp. 2191–2196. [Google Scholar]

- Tan, R.R.; Cayamanda, C.D.; Aviso, K.B. P-graph approach to optimal operational adjustment in polygeneration plants under conditions of process inoperability. Appl. Energy 2014, 135, 402–406. [Google Scholar] [CrossRef]

- Chiu, G.M.K.; Aviso, K.B.; Ubando, A.T.; Tan, R.R. Fuzzy linear programming model for the optimal design of a combined cooling, heating, and power plant. In Proceedings of the 2017 IEEE 9th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment and Management (HNICEM), Manila, Philippines, 1–3 December 2017; pp. 1–6. [Google Scholar]

- Mayol, A.P.; Culaba, A.B.; Aviso, K.B.; Ng, D.K.S.; Tan, R.R.; Ubando, A.T. Fuzzy linear programming model for the optimal design of a trigeneration plant with product price variability. In Proceedings of the IEEE Region 10 Annual International Conference, Proceedings/TENCON, Singapore, 22–25 November 2017; pp. 3200–3205. [Google Scholar]

- Ubando, A.T.; Culaba, A.B.; Tan, R.R.; Ng, D.K.S. A Systematic Approach for Optimization of an Algal Biorefinery Using Fuzzy Linear Programming. In Computer Aided Chemical Engineering; Karimi, I.A., Srinivasan, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2012; Volume 31, pp. 805–809. [Google Scholar]

- Ubando, A.T.; Culaba, A.B.; Aviso, K.B.; Tan, R.R.; Cuello, J.L.; Ng, D.K.S.; El-Halwagi, M.M. Fuzzy mixed integer non-linear programming model for the design of an algae-based eco-industrial park with prospective selection of support tenants under product price variability. J. Clean. Prod. 2016, 136, 183–196. [Google Scholar] [CrossRef]

- Ubando, A.T.; Culaba, A.B.; Aviso, K.B.; Ng, D.K.S.; Tan, R.R. Fuzzy mixed-integer linear programming model for optimizing a multi-functional bioenergy system with biochar production for negative carbon emissions. Clean Technol. Environ. Policy 2014, 16, 1537–1549. [Google Scholar] [CrossRef]

- Bairamzadeh, S.; Saidi-Mehrabad, M.; Pishvaee, M.S. Modelling different types of uncertainty in biofuel supply network design and planning: A robust optimization approach. Renew. Energy 2018, 116, 500–517. [Google Scholar] [CrossRef]

- Tan, R.R.; Aviso, K.B.; Cayamanda, C.D.; Chiu, A.S.F.; Promentilla, M.A.B.; Ubando, A.T.; Yu, K.D.S. A fuzzy linear programming enterprise input–output model for optimal crisis operations in industrial complexes. Int. J. Prod. Econ. 2016, 181, 410–418. [Google Scholar] [CrossRef]

- Zimmermann, H.-J. Fuzzy Set Theory- and Its Applications; Springer Seience+Business Media: New York, NY, USA, 1992. [Google Scholar]

- Elbatran, A.H.; Yaakob, O.B.; Ahmed, Y.M.; Shabara, H.M. Operation, performance and economic analysis of low head micro-hydropower turbines for rural and remote areas: A review. Renew. Sustain. Energy Rev. 2015, 43, 40–50. [Google Scholar] [CrossRef]

- Aviso, K.B.; Tan, R.R. Fuzzy P-graph for optimal synthesis of cogeneration and trigeneration systems. Energy 2018, 154, 258–268. [Google Scholar] [CrossRef]

| Product Stream | Units | WTC 1 | WTM 2 | UFWT 3 | Ice Plant | MHP 4 | Product/Raw Materials |

|---|---|---|---|---|---|---|---|

| Clean Water | t/day | 0 | 0 | 20 | −5 | 0 | 15 |

| Ice | t/day | 0 | 0 | 0 | 5 | 0 | 5 |

| Electricity | kW | 0 | 0 | −1 | −4 | 105 | 100 |

| Water to community supply | t/day | 50 | 0 | −50 | 0 | 0 | 0 |

| Water to microhydro plant | t/day | 0 | 52,500 | 0 | 0 | −52,500 | 0 |

| Rejected Water | t/day | 0 | 0 | 30 | 0 | 0 | 30 |

| River Water | t/day | −50 | −52,500 | 0 | 0 | 0 | −52,550 |

| Diesel | t/day | 0 | 0 | 0 | 0 | 0 | 0 |

| Drought Level, D | λ | Optimal Process Scaling Vector, x | Optimal Production Level, y | ||||||

|---|---|---|---|---|---|---|---|---|---|

| WTC 1 | WTM 2 | UFWT 3 | Ice Plant | MHP 4 | Electricity (kW) | Clean Water (t/day) | Ice (t/day) | ||

| 0% | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 100.00 | 15.00 | 5.00 |

| 10% | 0.80 | 0.92 | 0.90 | 0.92 | 0.88 | 0.90 | 90.05 | 14.01 | 4.40 |

| 20% | 0.60 | 0.84 | 0.80 | 0.84 | 0.76 | 0.80 | 80.11 | 13.01 | 3.81 |

| 30% | 0.40 | 0.76 | 0.70 | 0.76 | 0.64 | 0.70 | 70.16 | 12.02 | 3.21 |

| 40% | 0.20 | 0.68 | 0.60 | 0.68 | 0.52 | 0.60 | 60.22 | 11.02 | 2.61 |

| 50% | 0.01 | 0.60 | 0.50 | 0.60 | 0.40 | 0.50 | 50.27 | 10.03 | 2.02 |

| Product Stream | Units | WTC 1 | WTM 2 | UFWT 3 | Ice Plant | MHP 4 | DGS 5 | Product/Raw Materials |

|---|---|---|---|---|---|---|---|---|

| Clean Water | t/day | 0 | 0 | 20 | −5 | 0 | 0 | 15 |

| Ice | t/day | 0 | 0 | 0 | 5 | 0 | 0 | 5 |

| Electricity | kW | 0 | 0 | −1 | −4 | 105 | 60 | 160 |

| Water to community supply | t/day | 50 | 0 | −50 | 0 | 0 | 0 | 0 |

| Water to microhydro plant | t/day | 0 | 52,500 | 0 | 0 | −52,500 | 0 | 0 |

| Rejected Water | t/day | 0 | 0 | 30 | 0 | 0 | 0 | 30 |

| River Water | t/day | −50 | −52,500 | 0 | 0 | 0 | 0 | −52,550 |

| Diesel | t/day | 0 | 0 | 0 | 0 | 0 | −3.6 | −3.6 |

| Drought Level, D | λ | Optimal Process Scaling Vector, x | Optimal Production Level, y | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| WTC 1 | WTM 2 | UFWT 3 | Ice Plant | MHP 4 | DGS 5 | Electricity (kW) | Clean Water (t/day) | Ice (t/day) | ||

| 0% | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 0.00 | 100.00 | 15.00 | 5.00 |

| 10% | 0.80 | 0.92 | 0.90 | 0.92 | 0.88 | 0.90 | 0.00 | 90.05 | 14.01 | 4.40 |

| 20% | 0.68 | 0.87 | 0.67 | 0.87 | 0.81 | 0.67 | 0.30 | 83.88 | 13.39 | 4.03 |

| 30% | 0.68 | 0.87 | 0.67 | 0.87 | 0.81 | 0.67 | 0.30 | 83.88 | 13.39 | 4.03 |

| 40% | 0.61 | 0.85 | 0.60 | 0.85 | 0.77 | 0.60 | 0.36 | 80.66 | 13.07 | 3.84 |

| 50% | 0.52 | 0.81 | 0.50 | 0.81 | 0.71 | 0.50 | 0.45 | 75.82 | 12.58 | 3.55 |

| 60% | 0.03 | 0.61 | 0.00 | 0.61 | 0.42 | 0.00 | 0.90 | 51.67 | 10.17 | 2.10 |

| 70% | 0.03 | 0.61 | 0.00 | 0.61 | 0.42 | 0.00 | 0.90 | 51.67 | 10.17 | 2.10 |

| 80% | 0.03 | 0.61 | 0.00 | 0.61 | 0.42 | 0.00 | 0.90 | 51.67 | 10.17 | 2.10 |

| 90% | 0.03 | 0.61 | 0.00 | 0.61 | 0.42 | 0.00 | 0.90 | 51.67 | 10.17 | 2.10 |

| Product Stream | Units | WTC 1 | WTM 2 | UFWT 3 | Ice Plant | MHT1 4 | MHT2 5 | DGS 6 | Product/Raw Materials |

|---|---|---|---|---|---|---|---|---|---|

| Clean Water | t/day | 0 | 0 | 20 | −5 | 0 | 0 | 0 | 15 |

| Ice | t/day | 0 | 0 | 0 | 5 | 0 | 0 | 0 | 5 |

| Electricity | kW | 0 | 0 | −1 | −4 | 70 | 35 | 60 | 160 |

| Water to community supply | t/day | 50 | 0 | −50 | 0 | 0 | 0 | 0 | 0 |

| Water to microhydro plant | t/day | 0 | 52,500 | 0 | 0 | −35,000 | −17,500 | 0 | 0 |

| Rejected Water | t/day | 0 | 0 | 30 | 0 | 0 | 0 | 0 | 30 |

| River Water | t/day | −50 | −52,500 | 0 | 0 | 0 | 0 | 0 | −52,550 |

| Diesel | t/day | 0 | 0 | 0 | 0 | 0 | 0 | −3.6 | −3.6 |

| Drought Level, D | λ | Optimal Process Scaling Vector, x | Optimal Production Level, y | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| WTC 1 | WTM 2 | UFWT 3 | Ice Plant | MHT1 4 | MHT2 5 | DGS 6 | Electricity (kW) | Clean Water (t/day) | Ice (t/day) | ||

| 0% | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 0.00 | 100.00 | 15.00 | 5.00 |

| 10% | 0.80 | 0.92 | 0.90 | 0.92 | 0.88 | 1.00 | 0.70 | 0.00 | 90.05 | 14.01 | 4.40 |

| 20% | 0.68 | 0.87 | 0.80 | 0.87 | 0.81 | 0.70 | 1.00 | 0.30 | 97.90 | 13.39 | 4.03 |

| 30% | 0.68 | 0.87 | 0.70 | 0.87 | 0.81 | 0.55 | 1.00 | 0.30 | 87.39 | 13.39 | 4.03 |

| 40% | 0.61 | 0.85 | 0.60 | 0.85 | 0.77 | 0.90 | 0.00 | 0.36 | 80.66 | 13.07 | 3.84 |

| 50% | 0.52 | 0.81 | 0.50 | 0.81 | 0.71 | 0.75 | 0.00 | 0.45 | 75.82 | 12.58 | 3.55 |

| 60% | 0.36 | 0.77 | 0.40 | 0.77 | 0.65 | 0.60 | 0.00 | 0.54 | 70.99 | 12.10 | 3.26 |

| 70% | 0.32 | 0.73 | 0.30 | 0.73 | 0.59 | 0.00 | 0.90 | 0.63 | 66.15 | 11.62 | 2.97 |

| 80% | 0.23 | 0.69 | 0.20 | 0.69 | 0.54 | 0.00 | 0.60 | 0.72 | 61.32 | 11.13 | 2.68 |

| 90% | 0.13 | 0.61 | 0.00 | 0.61 | 0.42 | 0.00 | 0.00 | 0.90 | 51.67 | 10.17 | 2.10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ubando, A.T.; Marfori, I.A.V., III; Aviso, K.B.; Tan, R.R. Optimal Operational Adjustment of a Community-Based Off-Grid Polygeneration Plant using a Fuzzy Mixed Integer Linear Programming Model. Energies 2019, 12, 636. https://doi.org/10.3390/en12040636

Ubando AT, Marfori IAV III, Aviso KB, Tan RR. Optimal Operational Adjustment of a Community-Based Off-Grid Polygeneration Plant using a Fuzzy Mixed Integer Linear Programming Model. Energies. 2019; 12(4):636. https://doi.org/10.3390/en12040636

Chicago/Turabian StyleUbando, Aristotle T., Isidro Antonio V. Marfori, III, Kathleen B. Aviso, and Raymond R. Tan. 2019. "Optimal Operational Adjustment of a Community-Based Off-Grid Polygeneration Plant using a Fuzzy Mixed Integer Linear Programming Model" Energies 12, no. 4: 636. https://doi.org/10.3390/en12040636

APA StyleUbando, A. T., Marfori, I. A. V., III, Aviso, K. B., & Tan, R. R. (2019). Optimal Operational Adjustment of a Community-Based Off-Grid Polygeneration Plant using a Fuzzy Mixed Integer Linear Programming Model. Energies, 12(4), 636. https://doi.org/10.3390/en12040636