1. Introduction

With the wide concern on the gradual depletion and pollution emission of fossil fuels, renewable energy such as wind and solar has been significantly developed [

1,

2]. To effectively utilize renewable energy, microgrid (MG) technology has been intensively investigated, since an MG can integrate various distributed generations, energy storage units, load, and control devices together. In addition, the combined heat and power (CHP) system can provide both electricity and heat to users, and it has been widely applied in many MGs due to its high energy efficiency. Such a CHP-based MG system is composed of both electric and thermal energy sources, which is covered by the new concept of energy internet [

3], where the efficient utilization of multiple energy resources is emphasized. Thus, the study of the CHP-based MG systems is significant for practical applications.

There are already a significant amount of studies on the design and operation of the CHP-based MG system. In [

4], a sizing strategy of power sources and energy storage system is proposed for an autonomy MG. A novel methodology is developed to offer a range of MG designs for an isolated community in [

5], where each of them is optimal for a given consumption pattern. Different design options in building services are presented in [

6] by using a fuel cell micro-CHP. In [

7], an MG model is studied for planning the micro-CHP systems in agreement with the Portuguese energy legal framework, and thus it can design, evaluate, and optimize from the techno-economic point of view for any micro-CHP plant. In [

8,

9], the optimal sizing of an energy storage system and CHP units in an MG is obtained by the cost benefit analysis method. In [

10], a promising energy supply chain network is proposed based on residential-scale micro-generation through micro-CHP systems. The interchange of electrical energy can take place among the members of this domestic MG, which is connected to the distribution network for potential power interchange. Considering the trade-off between total annual cost and electrical system unavailability, a mixed-integer linear programming (MILP) approach is proposed for the design of a neighborhood-based energy system [

11]. Moreover, CHP-based MG systems can also include drinkable water and cooling system [

12]. In [

13], different energy storage options are considered in the design and management of a hybrid CHP-based MG system, and then the presented model is optimized by the particle swarm optimization (PSO) method. In [

14], the optimal design and operation strategy of a trigeneration system is presented under both the stand-alone and grid-connected modes.

Extensive work has been done for the optimal operation of the CHP-based MG system. In [

15,

16], the optimal matching between the electric power source and electric load, and also the heat source and heat load, are considered within the CHP-based MG systems. In [

17], an optimal dispatch model of a CHP-based MG system is proposed with heating, cooling, and electricity at the regional level, and a demand response (DR) mechanism is designed accordingly. In [

18,

19], the optimal energy management of different CHP-based MG systems is discussed to promote the energy exchange among buildings by utilizing various renewable energy resources. In [

20], the building thermal inertia is discussed, and a feasible region method is presented for the optimization of a CHP-based MG system. In [

21], a rolling horizon approach is introduced to deal with uncertainties of a CHP-based MG system associated to production and consumption. In [

22], a new techno-economic model is proposed for a CHP-based MG system to investigate the business case under different combinations of services. Considering the coordination of fuel cell and CHP, an optimal economic dispatch model is studied for an industrial CHP-based MG system [

23].

Furthermore, traditional optimization problems of the CHP-based MG system mainly target at the minimization of economic cost, then gradually environmental impact has also been considered along with the economic cost. In [

24], greenhouse gas emission and energy consumption are both considered in the presented model of an industrial CHP-based MG system. Aiming to minimize the operation and emission costs, an optimization procedure is developed in [

25] for the day-ahead scheduling of a CHP-based MG system. A probabilistic multi-objective optimization model of a CHP-based MG system is proposed in [

26] considering operating cost and pollution emissions minimization under uncertain environment. However, most of the above research in [

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26] mainly considers electric power exchange with the distribution network, and thus the economic benefit and flexibility of CHP-based MG systems may be limited.

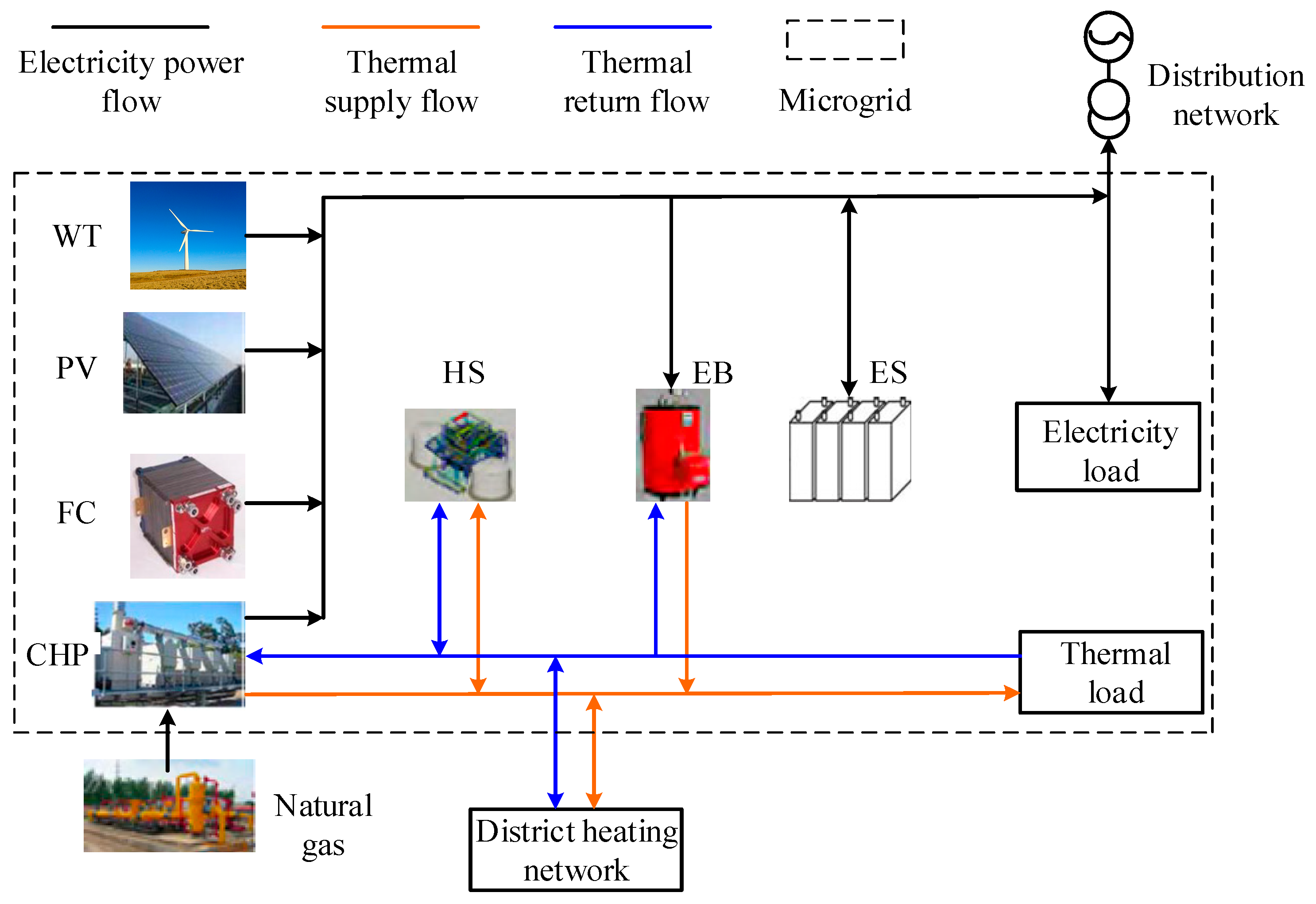

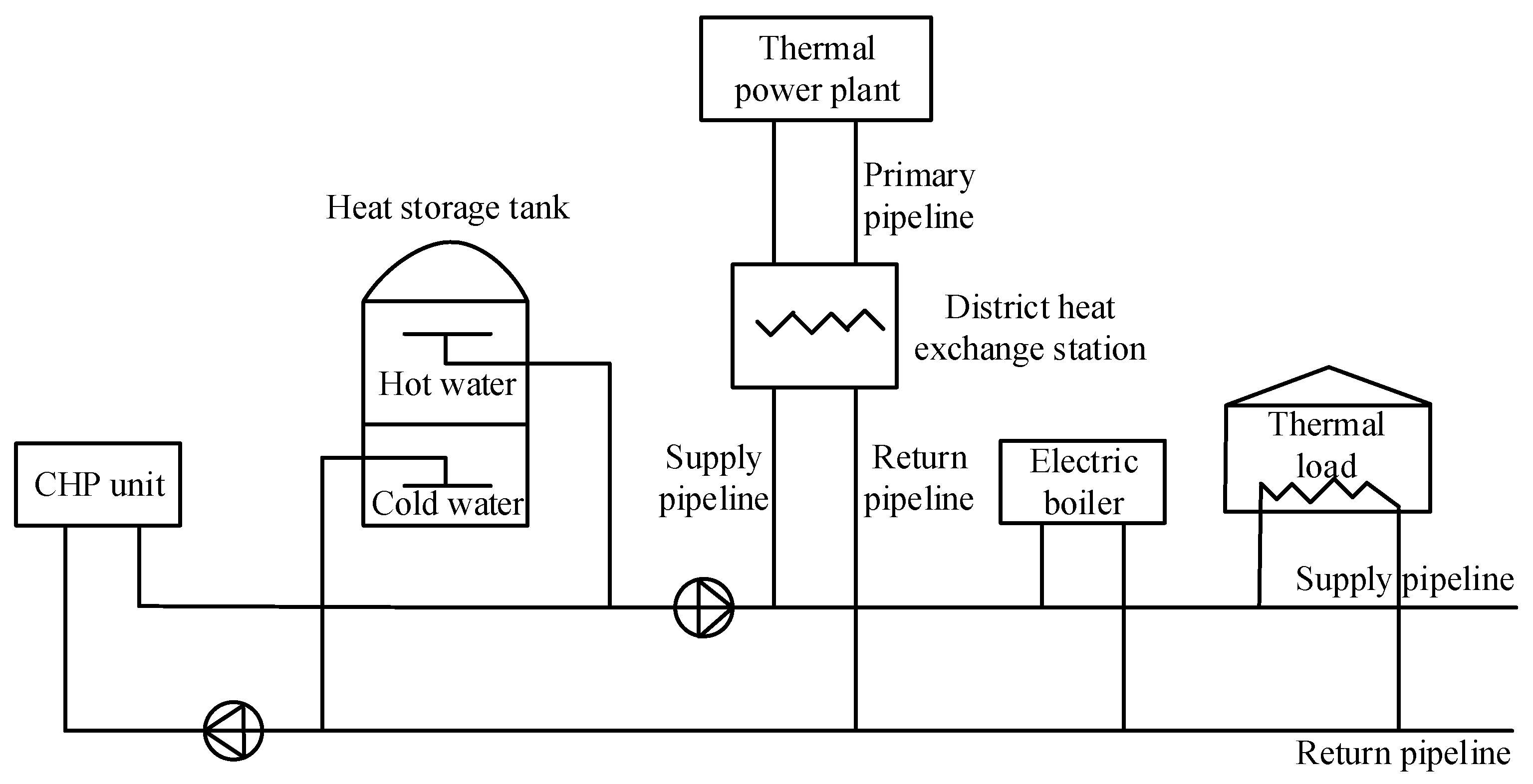

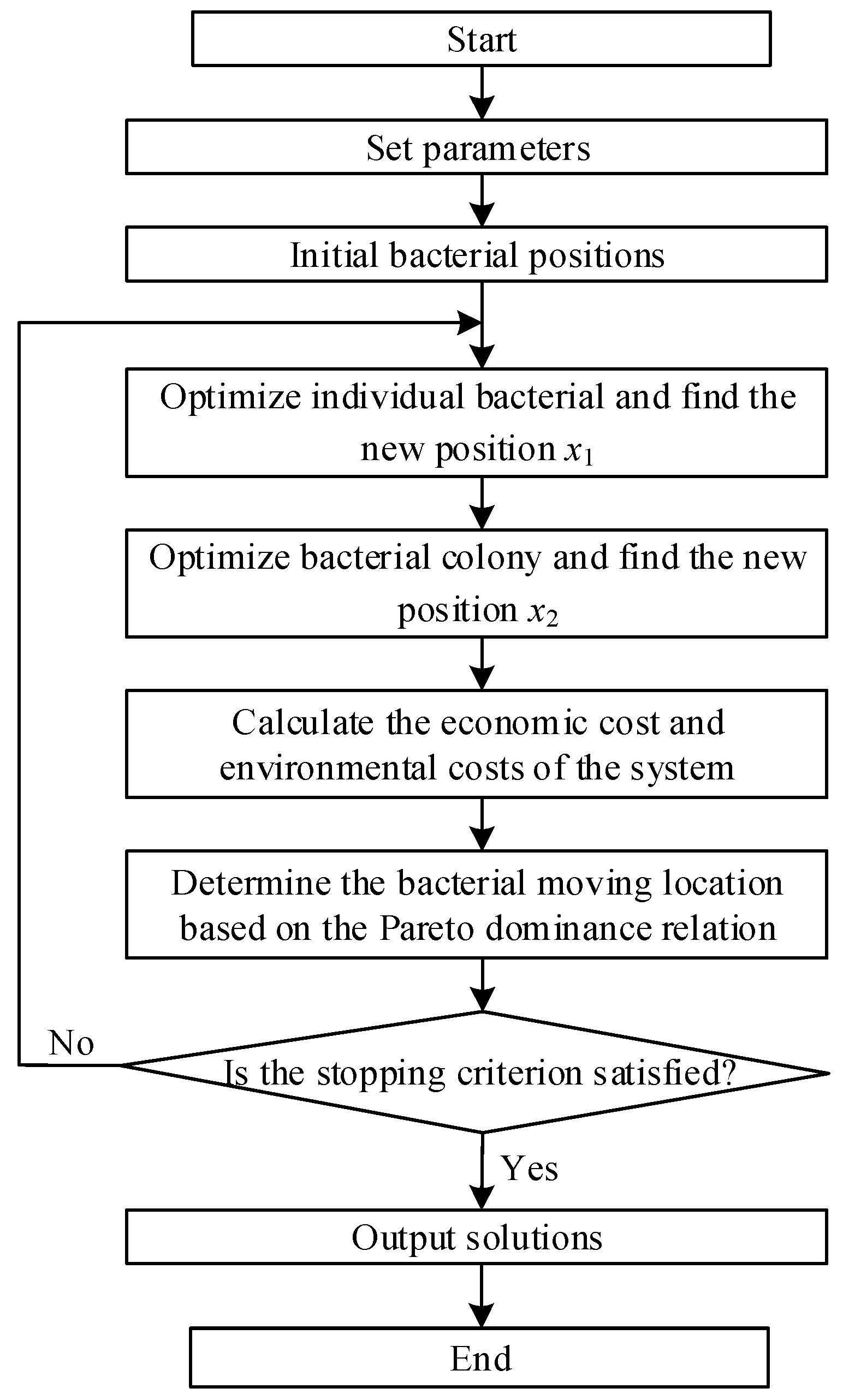

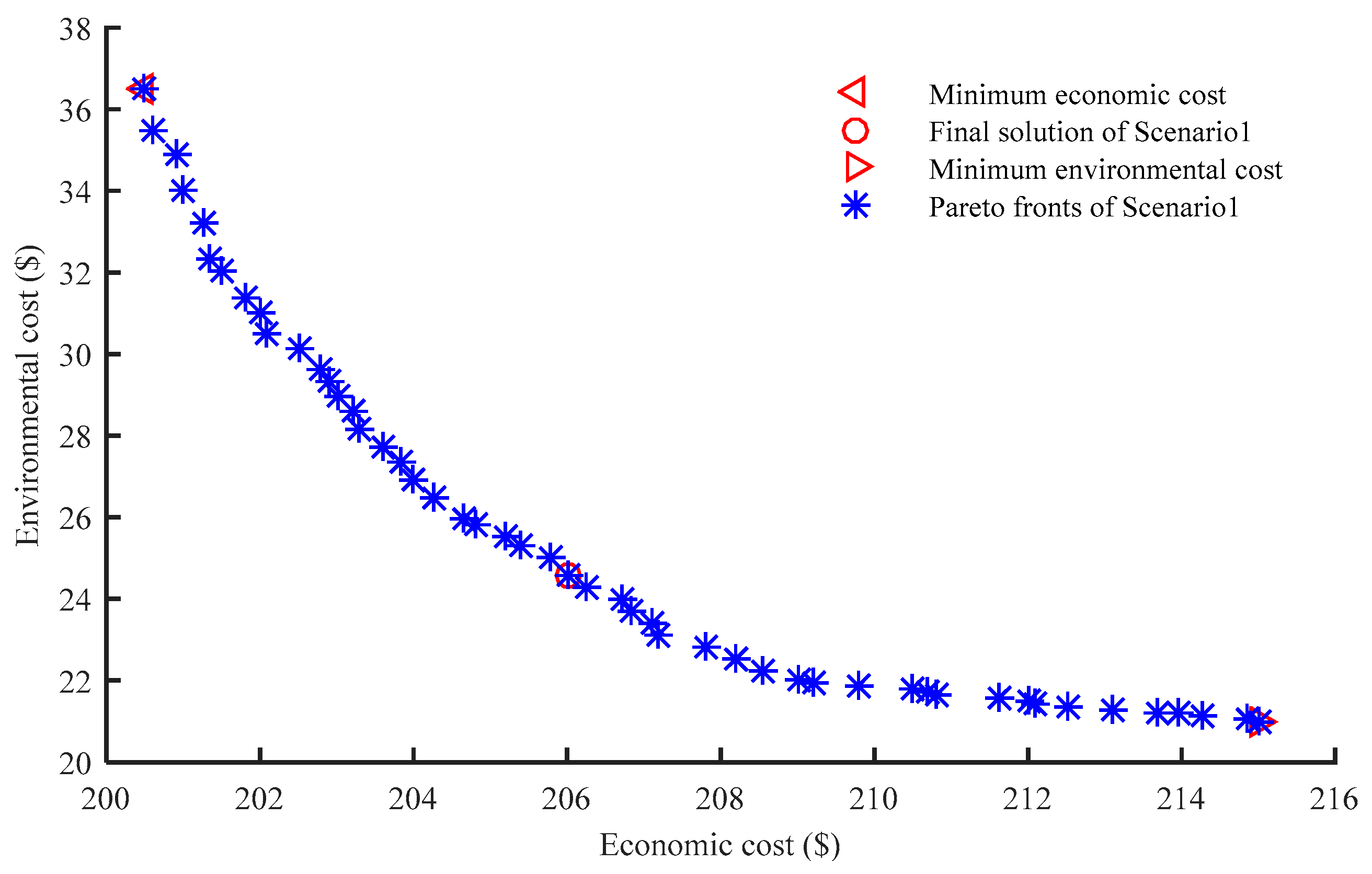

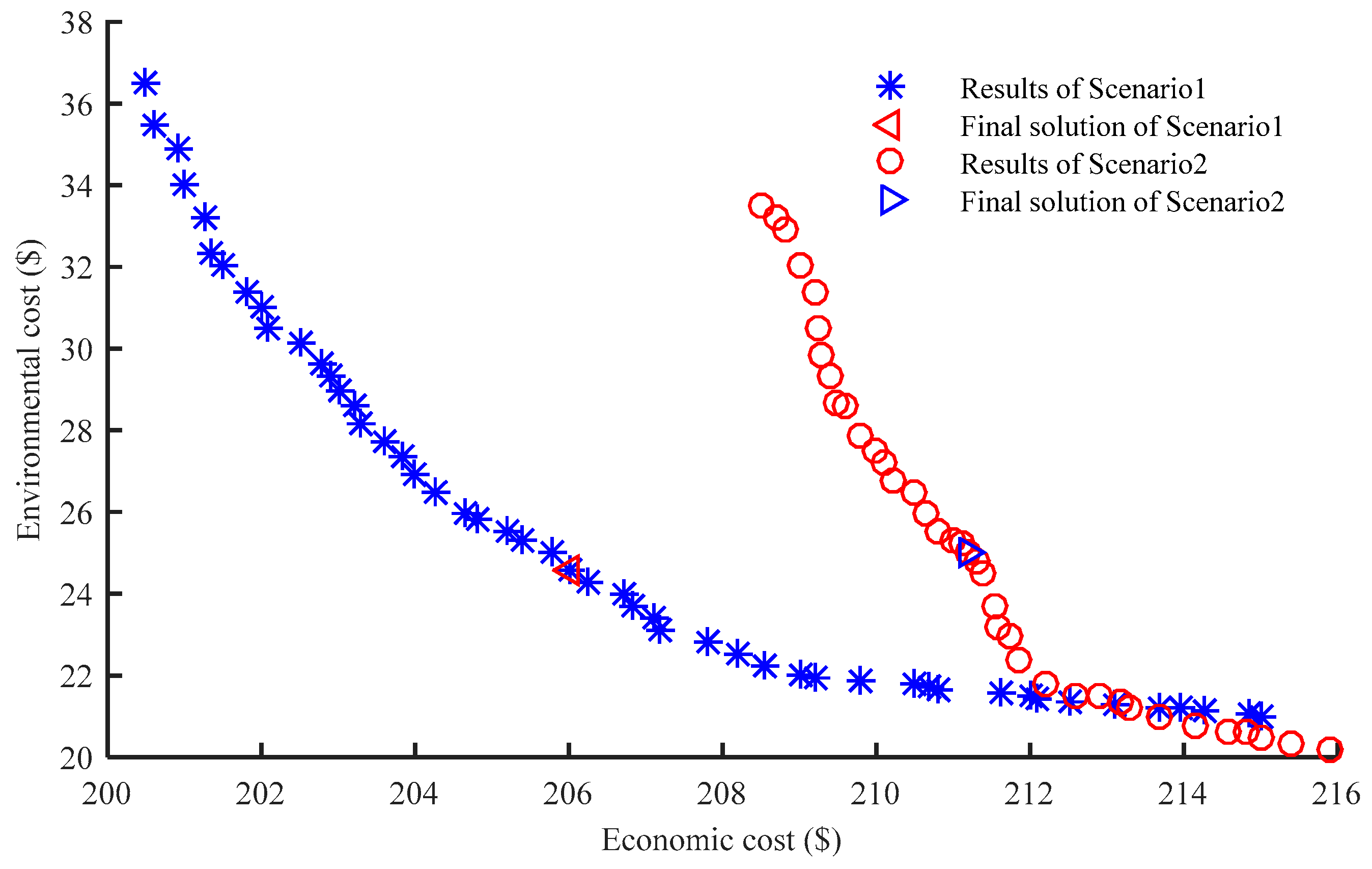

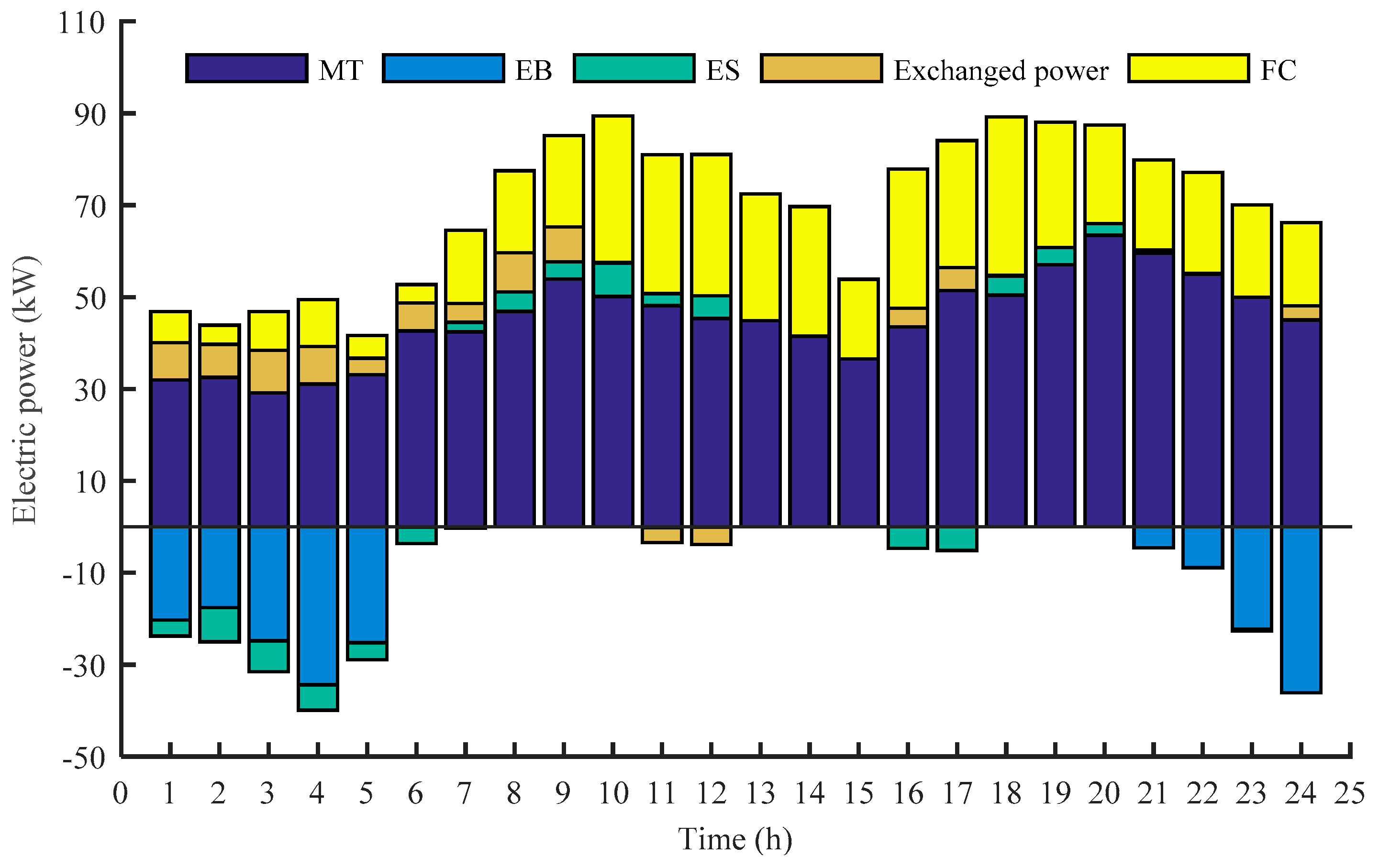

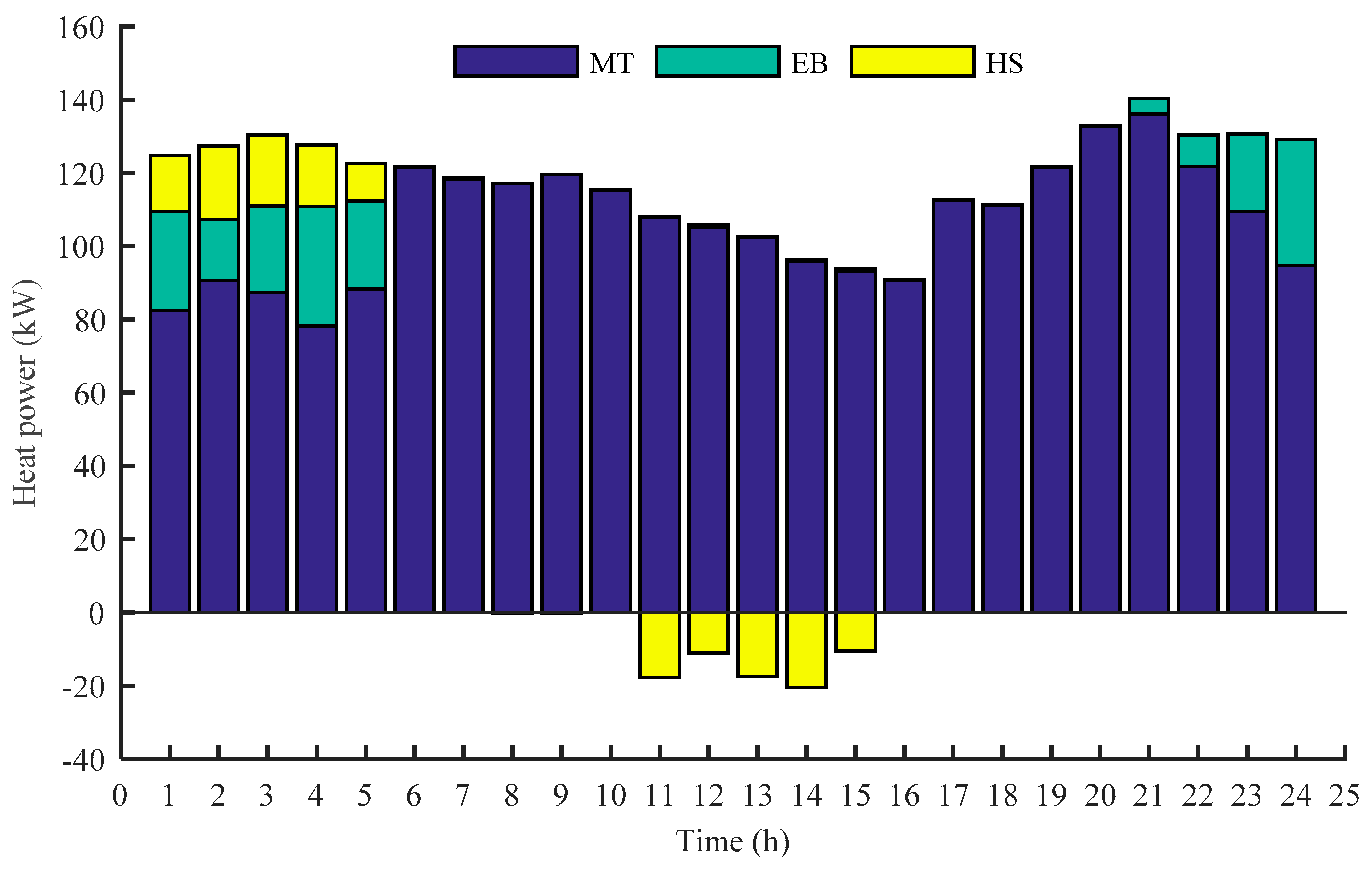

In view of the above problem, this paper establishes mathematical models for a CHP-based MG system including a CHP unit with a micro-turbine and a bromine chiller, a wind turbine, a photovoltaic (PV) system, a fuel cell, an electric boiler, an electric storage (ES) and a heat storage (HS). The CHP-based MG system is connected to both the distribution network and the district heating network, which makes the operation of the CHP-based MG system more flexible. To further analyze the presented CHP-based MG system, a multi-objective optimization model is proposed to minimize both the economic cost and environmental cost. Moreover, the multi-objective optimization model is a multidimensional, non-smooth, nonconvex, and nonlinear optimization problem, and thus an effective solution algorithm is needed. Multi-objective bacterial colony chemotaxis (MOBCC) algorithm is a new colony intelligence optimization algorithm [

27]. This algorithm considers not only the chemotactic strategy but also the communication between the colony members. MOBCC algorithm has been used to solve the economic emission dispatch (EED) problem, and the performance has been improved greatly against other algorithms [

28,

29]. It is gaining more attention due to its advantages of fast convergence and high precision for solving complex optimization problems. Hence, this paper uses MOBCC algorithm to solve the proposed multi-objective optimization model of the CHP-based MG system.

The major contributions of this paper are as follows.

- (1)

A flexible CHP-based MG system is presented by considering the energy exchange with both the distribution network and the district heating network.

- (2)

A multi-objective economic and emission dispatch model is proposed to study the flexible CHP-based MG system by considering the economic cost and environmental cost, and then it is solved by the MOBCC algorithm. After that, the Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) method [

30] is adopted to choose the optimal decision solution for decision makers.

The remainder of the paper is organized as follows.

Section 2 provides the description of the CHP-based MG system, and then the detailed mathematical models are presented;

Section 3 proposes the multi-objective economic and emission dispatch model of the CHP-based MG system;

Section 4 adopts the MOBCC algorithm and TOPSIS method to solve the optimization problem and to obtain the optimal decision solution, respectively. Finally, the main simulation results are discussed in

Section 5 and the key conclusions are presented in

Section 6.