Evaluation of Heat Transfer Performance of a Multi-Disc Sorption Bed Dedicated for Adsorption Cooling Technology

Abstract

1. Adsorption Cooling Technology

1.1. Environmental Demands

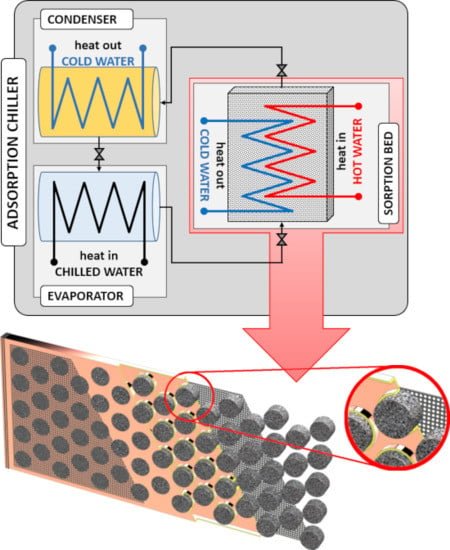

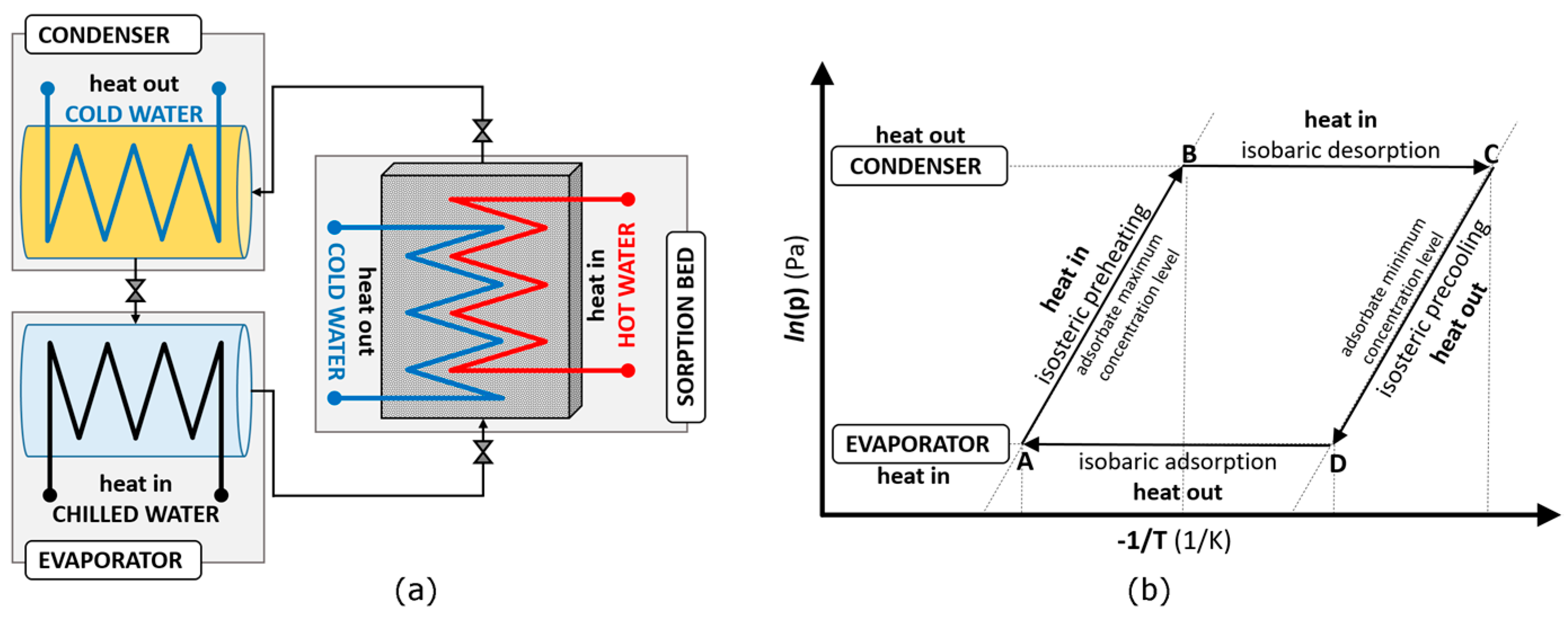

1.2. Adsorption Chillers

1.3. Design and Operation

1.4. Literature Review

1.5. The Main Aim of the Work

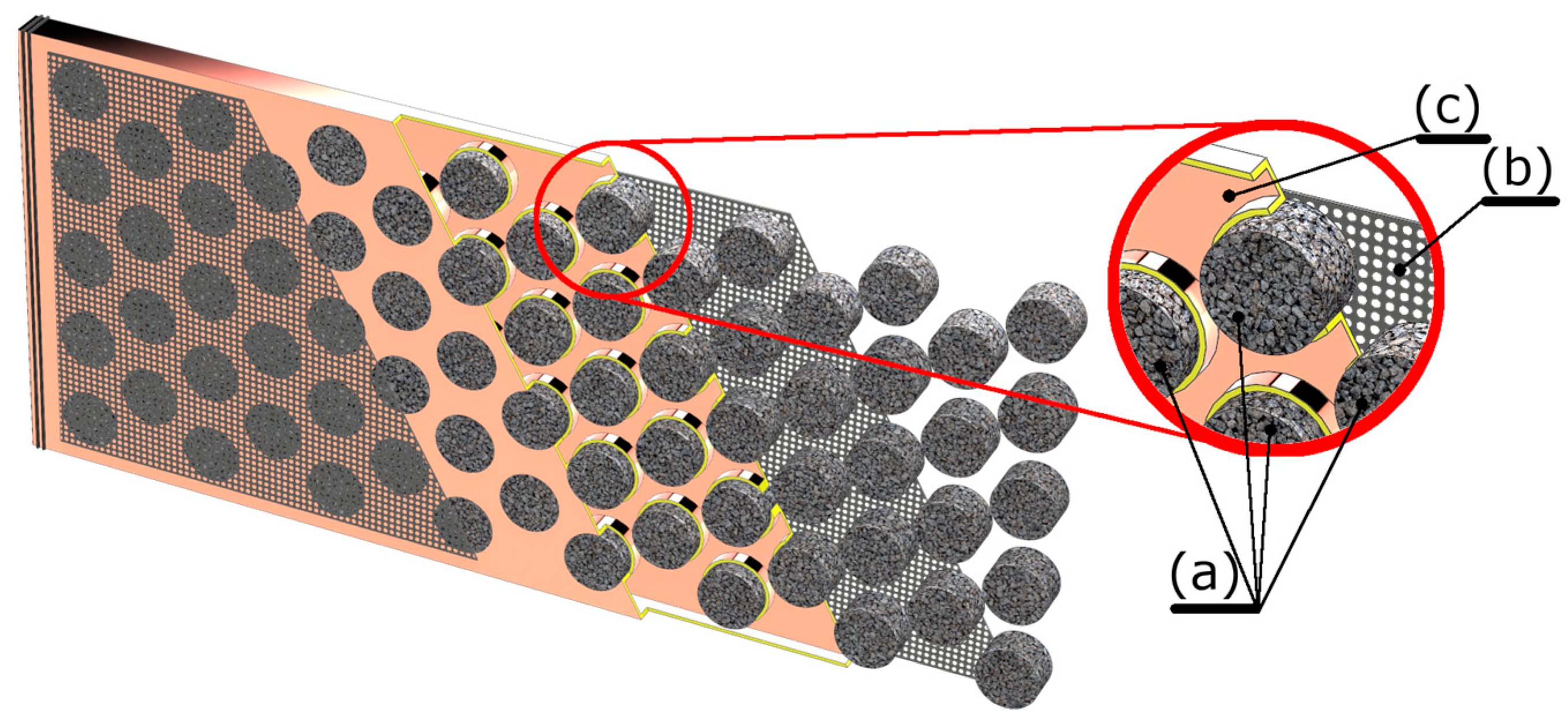

2. Research Object

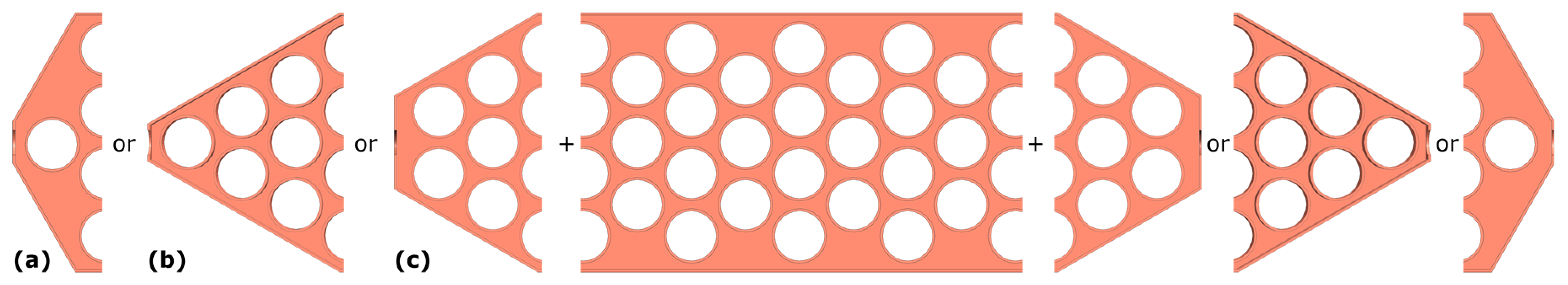

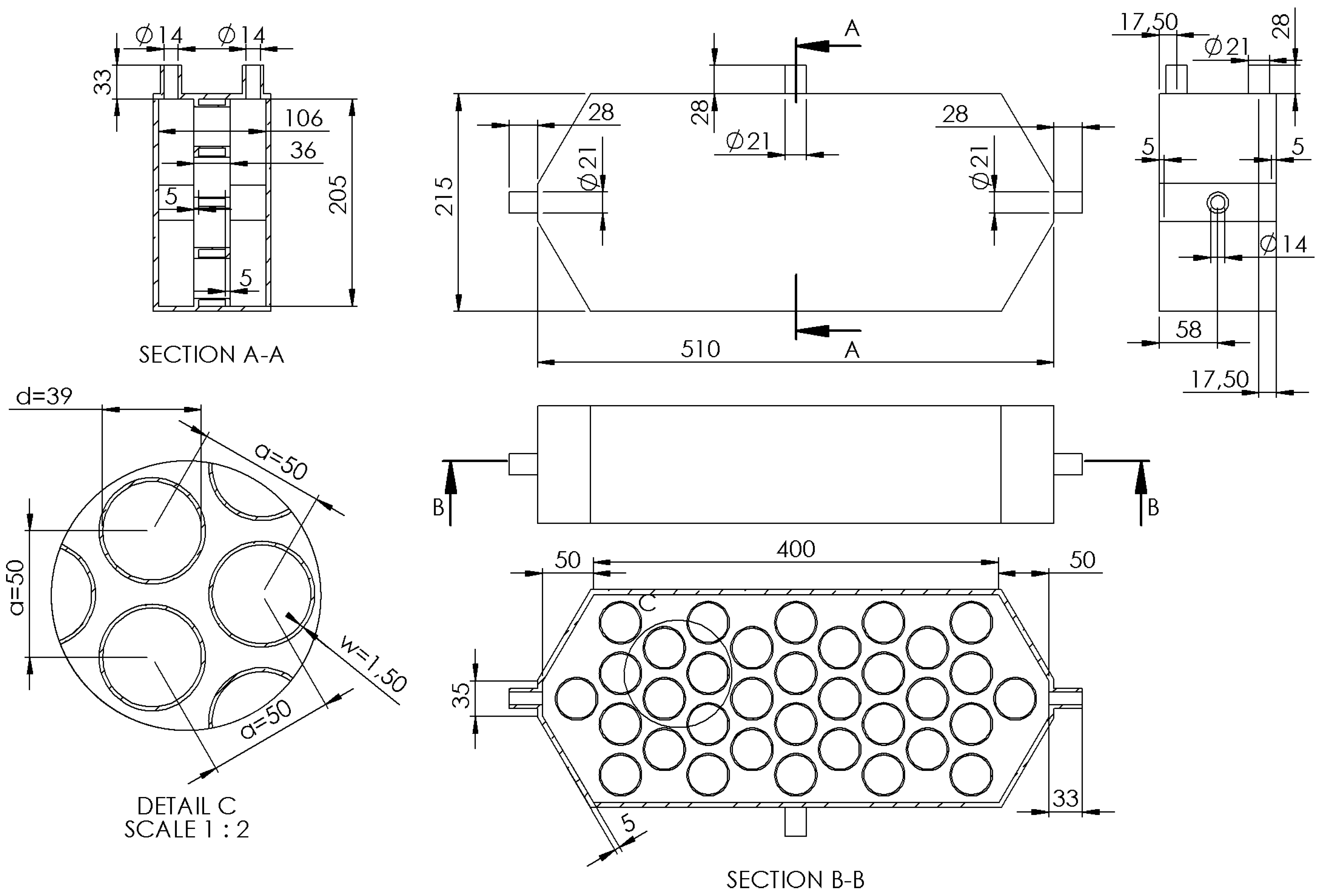

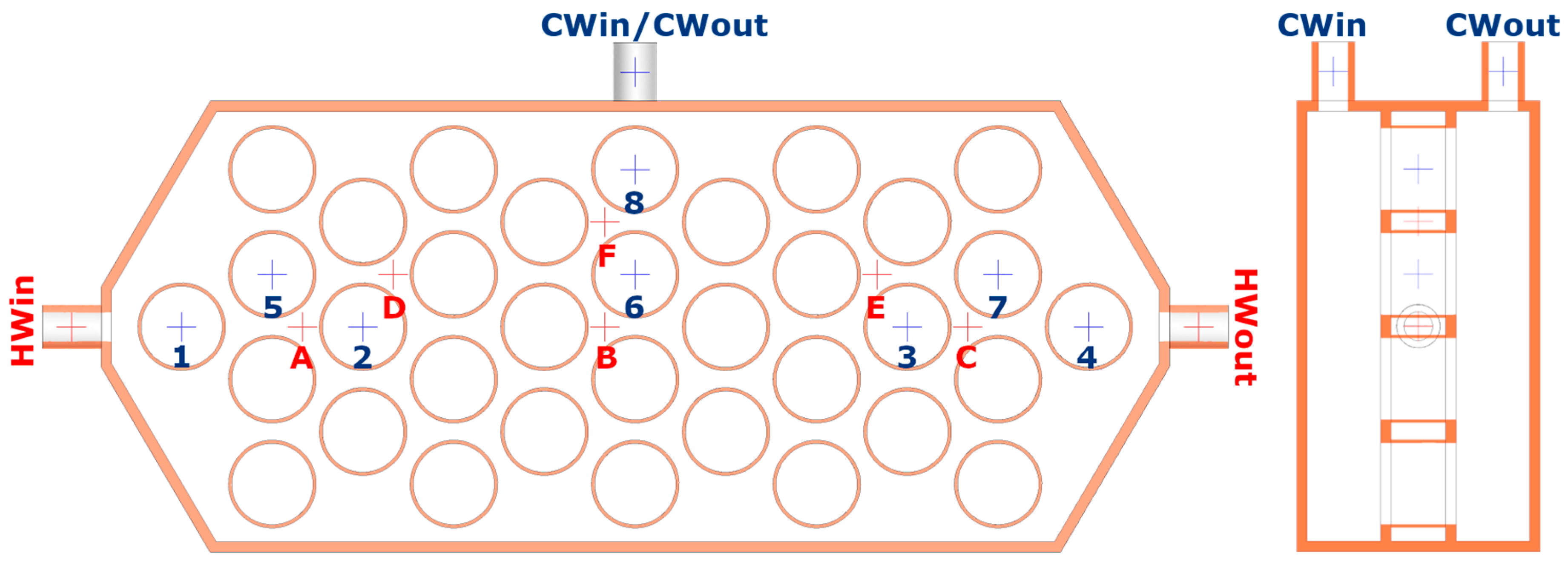

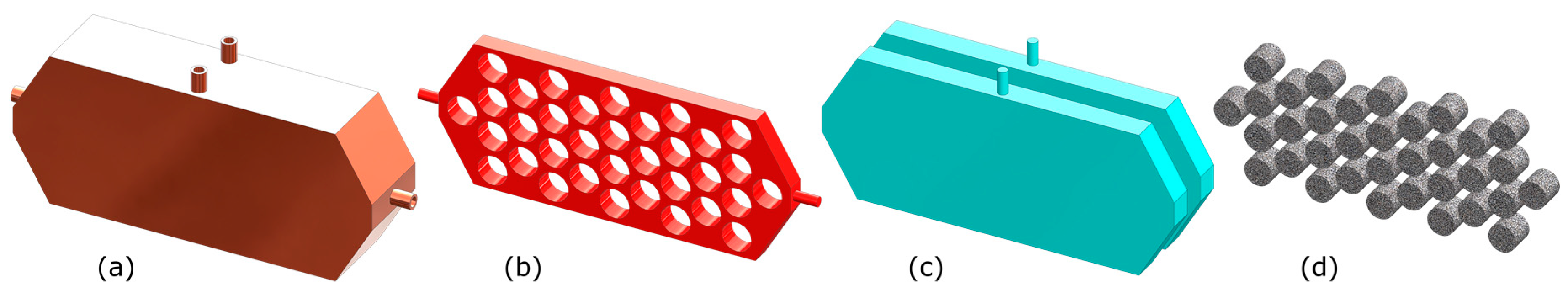

2.1. Multi-Disc Sorption Bed Design

2.2. Inlet/Outlet Manifolds

2.3. Lab-Scale Prototype

3. Research Methods

3.1. Experimental Research

3.2. Numerical Research

3.2.1. CFD Tool

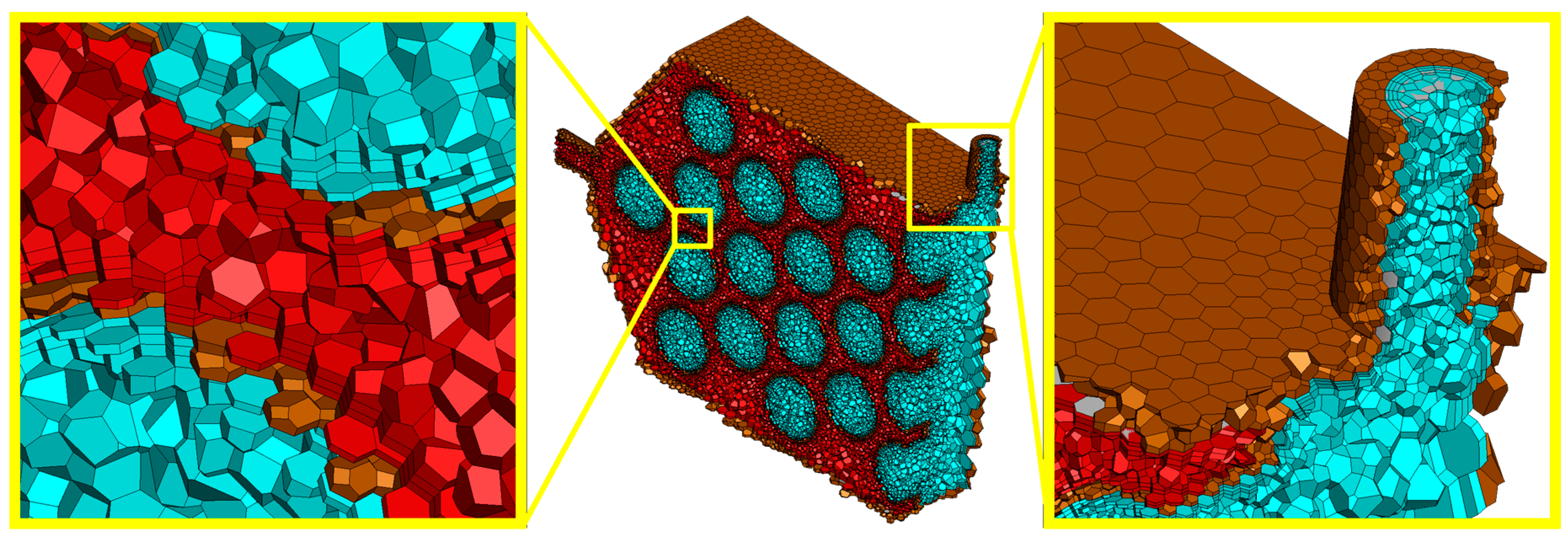

3.2.2. Computational Domain and Discretization

- ΔVi—volume of the ith cell;

- N—total number of cells in the computational domain;

3.2.3. Boundary Conditions and Model Settings

- —hot water mass flow rate (kg/s);

- —cold water mass flow rate (kg/s);

3.2.4. Sorption Modeling

4. Results and Discussion

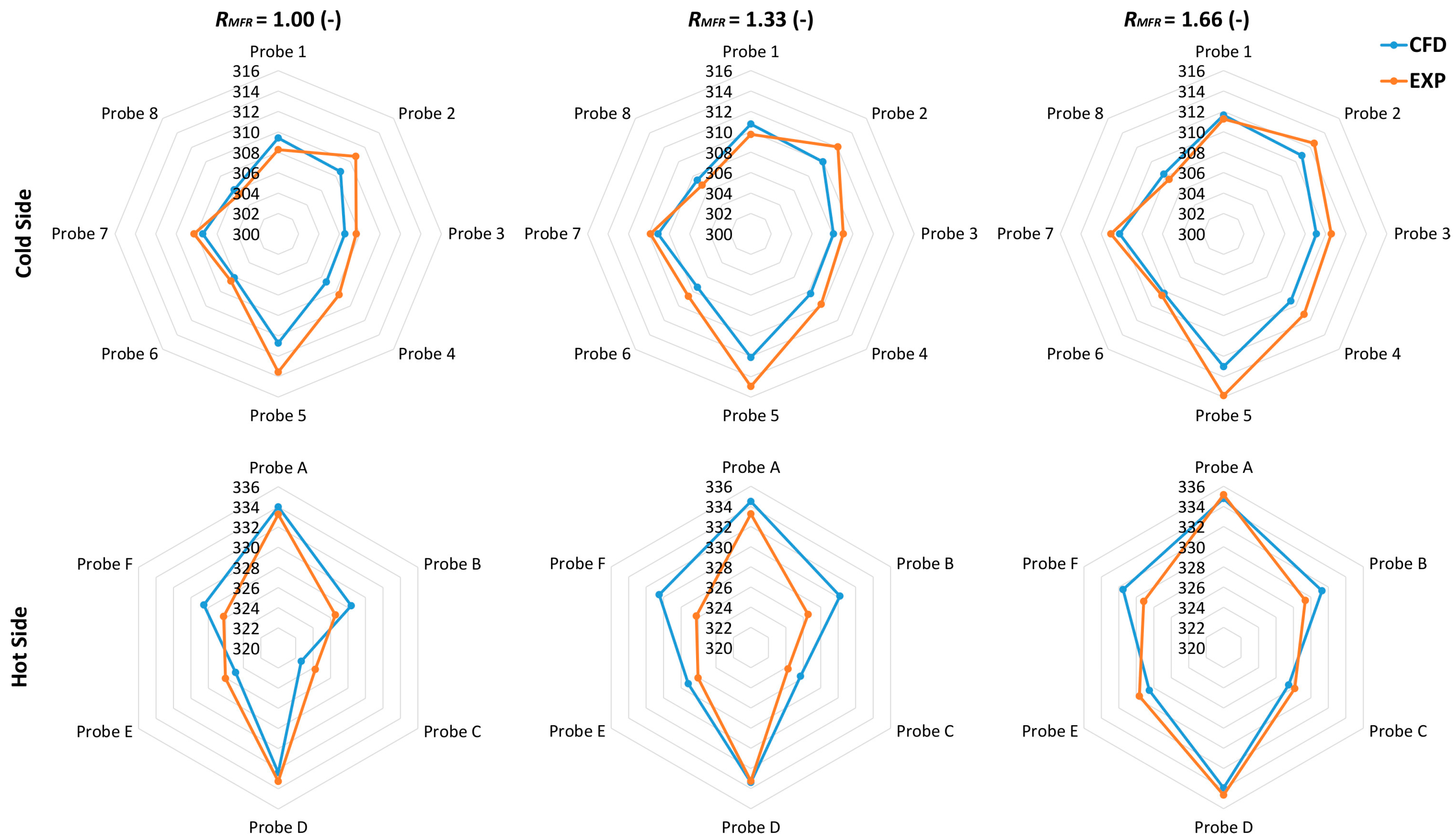

4.1. Heat Transfer Efficiency

- HWin—hot water inlet temperature (K);

- HWout—hot water outlet temperature (K);

- CWin—cold water inlet temperature (K);

- CWout—cold water outlet temperature (K);

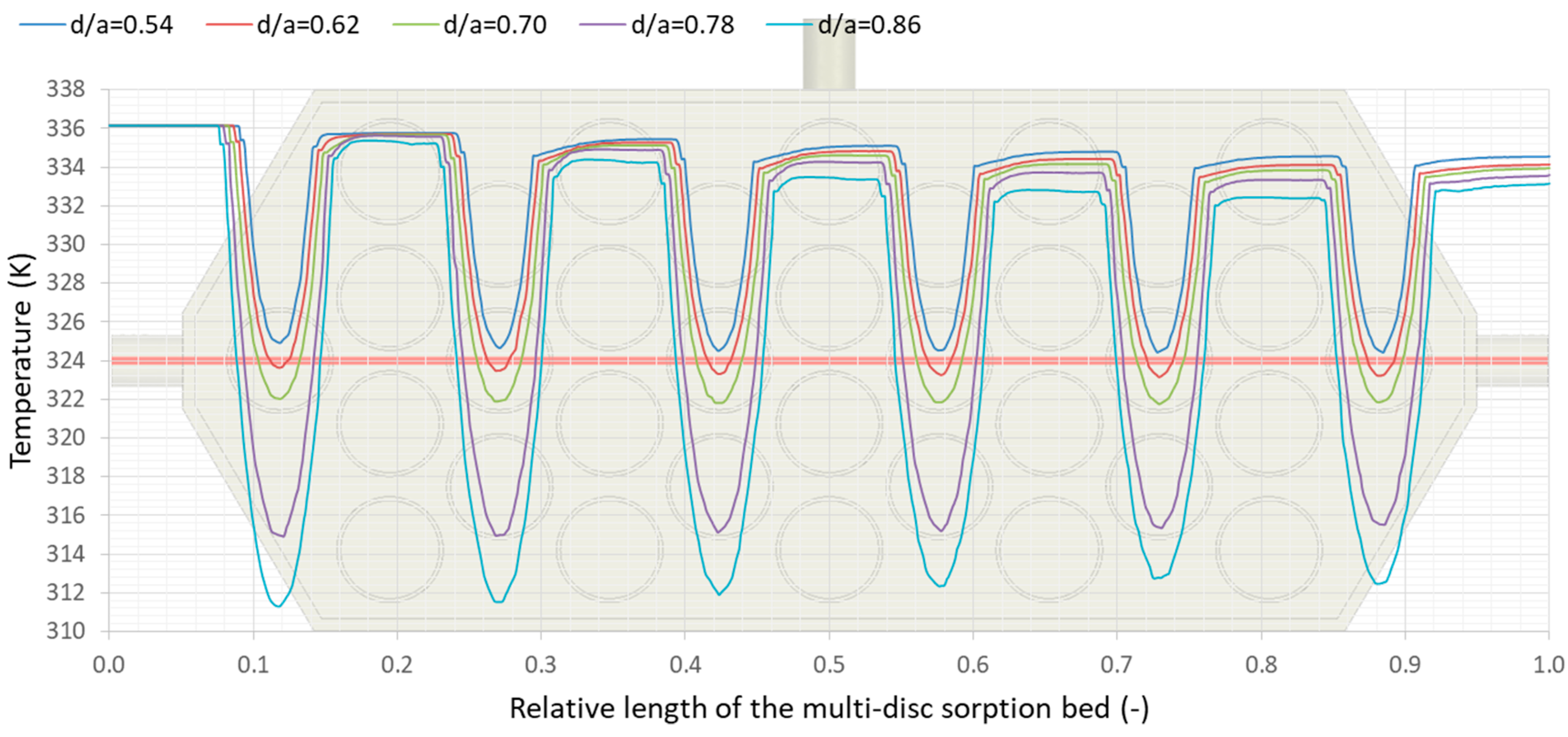

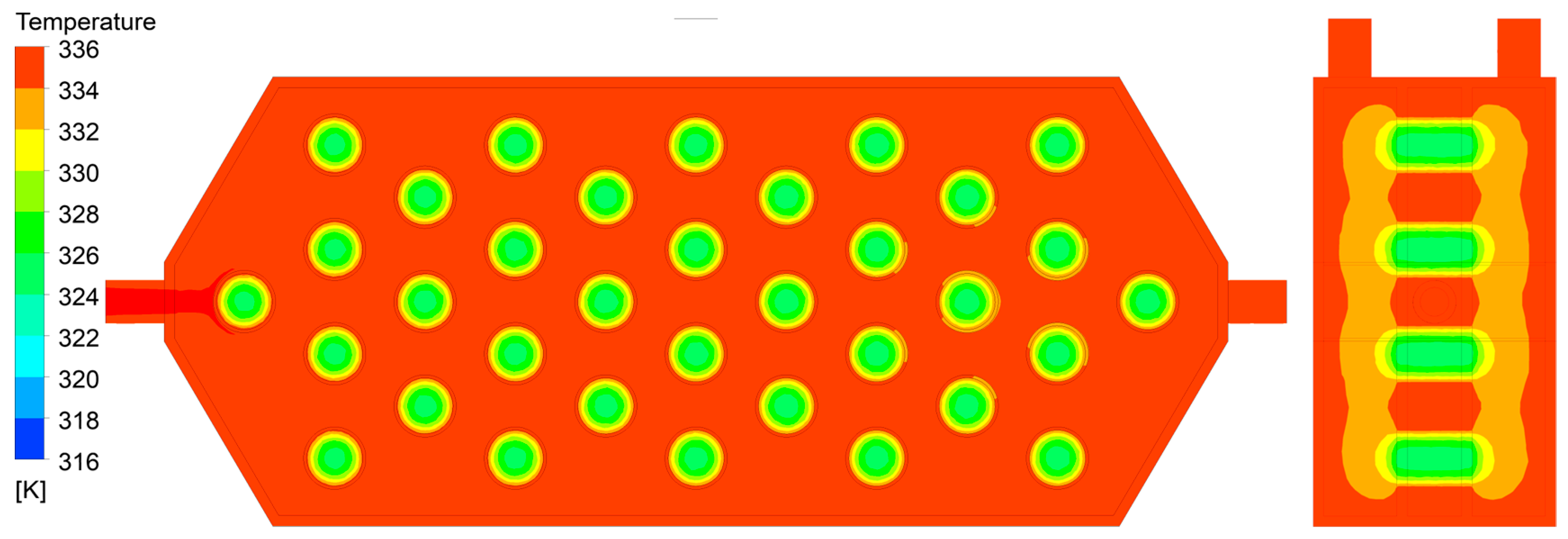

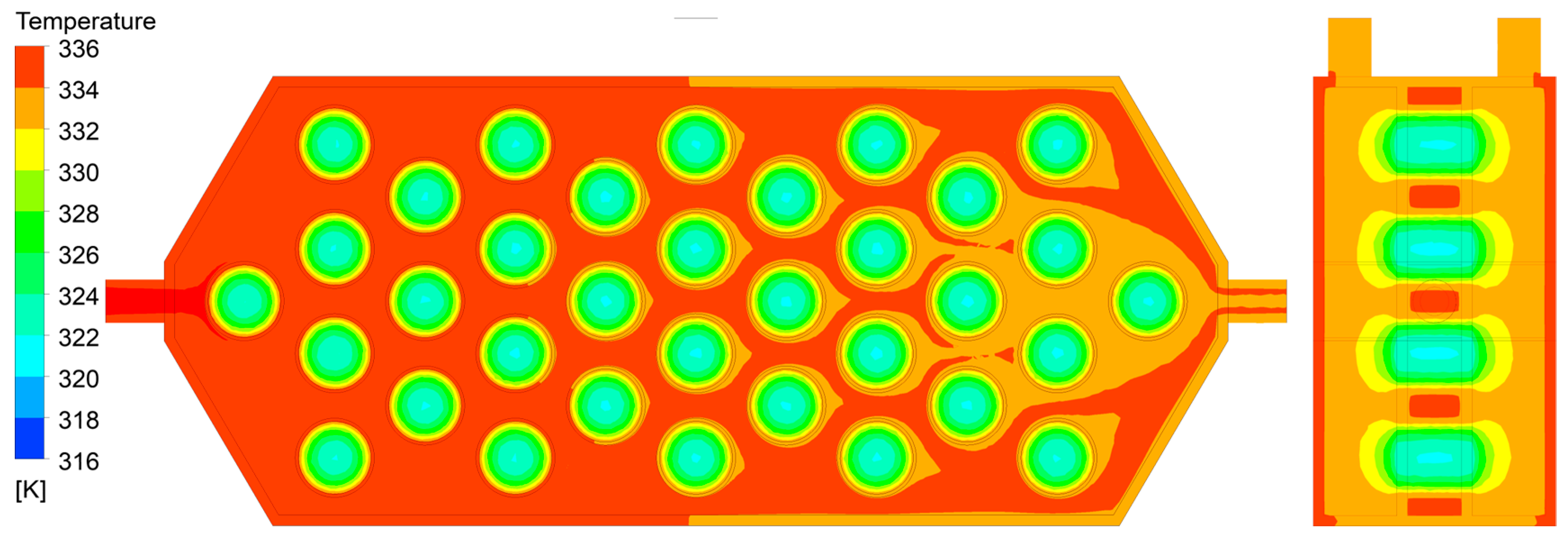

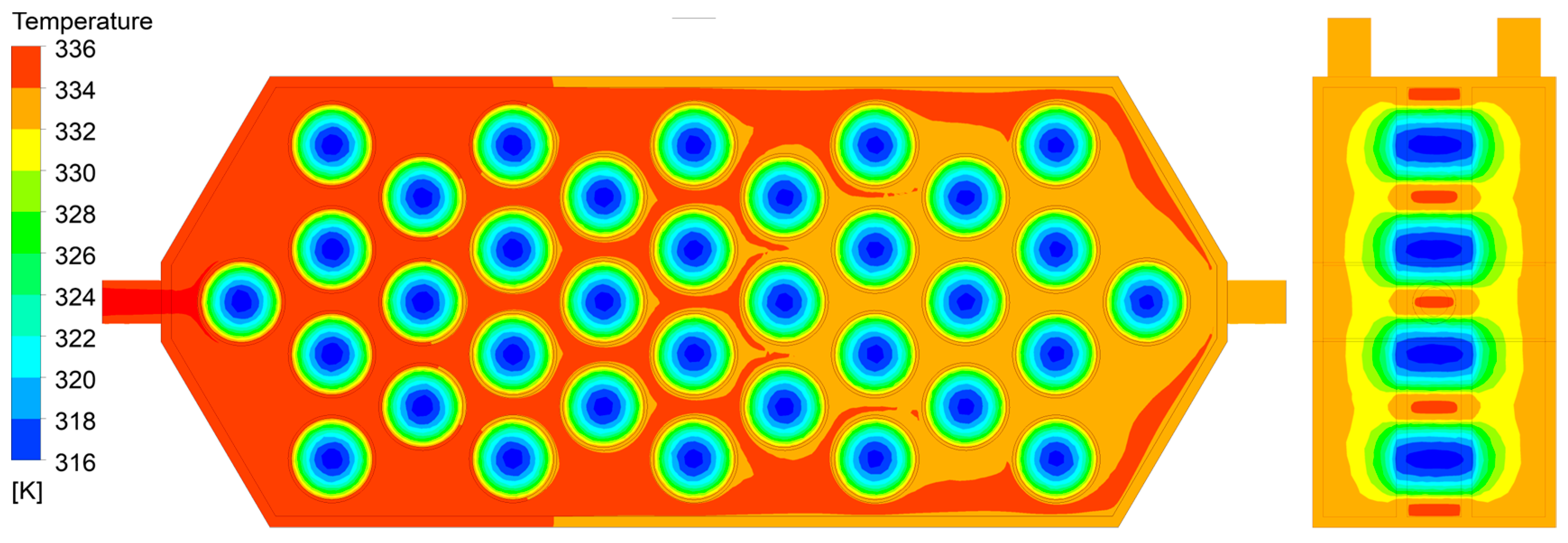

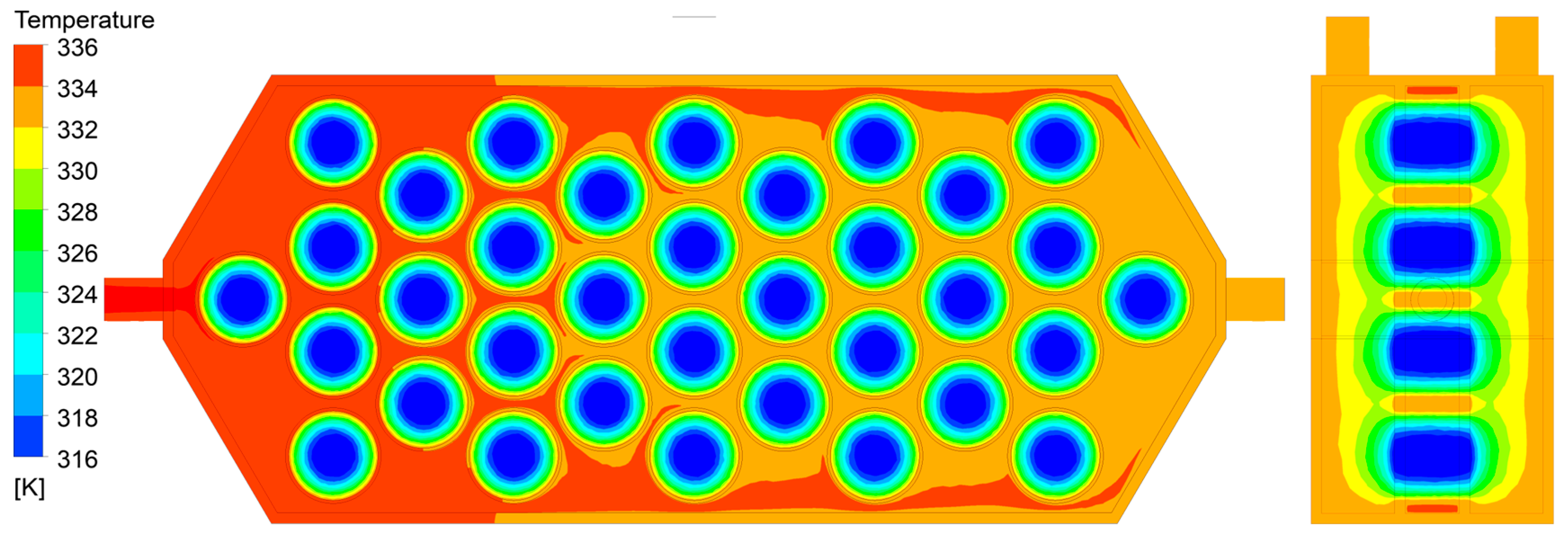

4.2. Temperature Field in the Sorption Bed

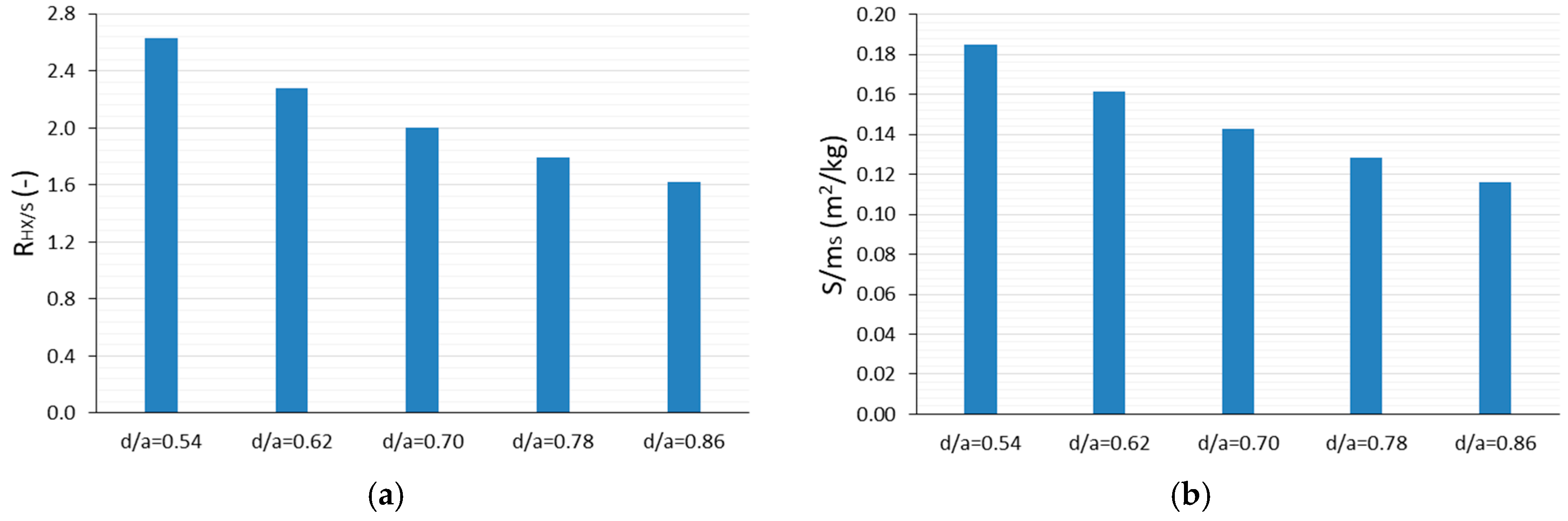

4.3. Weight and Dimension Factors

5. Conclusions

Funding

Conflicts of Interest

References

- Alsaman, A.; Askalany, A.; Ahmed, M.; Ali, E.; Harby, K.; Diab, M. Simulation model for silica gel-water adsorption cooling system powered by renewable energy. In Proceedings of the 3rd International Conference on Energy Engineering Faculty, of Energy Engineering, Aswan University, Aswan, Egypt, 28–30 December 2015. [Google Scholar]

- Elsheniti, M.B.; Hassab, M.A.; Attia, A.-E. Examination of effects of operating and geometric parameters on the performance of a two-bed adsorption chiller. Appl. Therm. Eng. 2018, 146, 674–687. [Google Scholar] [CrossRef]

- Sultana, T. Effect of overall thermal conductance with different mass allocation on a two stage adsorption chiller employing re-heat scheme. Master’s Thesis, Bangladesh University of Engineering and Technology, Dhaka, Bangladesh, 2008. [Google Scholar]

- Khan, M.Z.I.; Alam, K.; Saha, B.B.; Hamamoto, Y.; Akisawa, A.; Kashiwagi, T. Parametric study of a two-stage adsorption chiller using re-heat—The effect of overall thermal conductance and adsorbent mass on system performance. Int. J. Therm. Sci. 2006, 45, 511–519. [Google Scholar] [CrossRef]

- Saha, B.B.; Koyama, S.; Kashiwagi, T.; Akisawa, A.; Ng, K.C.; Chua, H.T. Waste heat driven dual-mode, multi-stage, multi-bed regenerative adsorption system. Int. J. Refrig. 2003, 26, 749–757. [Google Scholar] [CrossRef]

- Sur, A.; Das, R.K. Review of technology used to improve heat and mass transfer characteristics of adsorption refrigeration system. Int. J. Air Cond. Refrig. 2016, 24, 1630003. [Google Scholar] [CrossRef]

- Hassan, H.; Mohamad, A.; Alyousef, Y.; Al-Ansary, H. A review on the equations of state for the working pairs used in adsorption cooling systems. Renew. Sustain. Energy Rev. 2015, 45, 600–609. [Google Scholar] [CrossRef]

- Voyiatzis, E.; Stefanakis, N.; Palyvos, J.; Papadopoulos, A. Computational study of a novel continuous solar adsorption chiller: Performance prediction and adsorbent selection. Int. J. Energy Res. 2007, 31, 931–946. [Google Scholar] [CrossRef]

- Sztekler, K.; Kalawa, W.; Stefanski, S.; Krzywanski, J.; Grabowska, K.; Sosnowski, M.; Nowak, W. The influence of adsorption chillers on CHP power plants. MATEC Web Conf. 2018, 240, 05033. [Google Scholar] [CrossRef]

- Sztekler, K.; Kalawa, W.; Nowak, W.; Stefanski, S.; Krzywanski, J.; Grabowska, K. Using the adsorption chillers for waste heat utilisation from the CCS installation. EPJ Web Conf. 2018, 180, 02106. [Google Scholar] [CrossRef]

- Sztekler, K.; Kalawa, W.; Nowak, W.; Stefanski, S.; Krzywanski, J.; Grabowska, K. Using the adsorption chillers for utilisation of waste heat from rotary kilns. EPJ Web Conf. 2018, 180, 02105. [Google Scholar] [CrossRef]

- Rezk, A.; Al-Dadah, R.; Mahmoud, S.; Elsayed, A. Effects of contact resistance and metal additives in finned-tube adsorbent beds on the performance of silica gel/water adsorption chiller. Appl. Therm. Eng. 2013, 53, 278–284. [Google Scholar] [CrossRef]

- Saravanan, R.; Maiya, M.P. Thermodynamic comparison of water-based working fluid combinations for a vapour absorption refrigeration system. Appl. Therm. Eng. 1998, 18, 553–568. [Google Scholar] [CrossRef]

- Kurniawan, A.; Rachmat, A. Others CFD Simulation of Silica Gel as an Adsorbent on Finned Tube Adsorbent Bed. E3S Web Conf. 2018, 67, 01014. [Google Scholar] [CrossRef]

- Pyrka, P. Modelowanie trójzłożowej chłodziarki adsorpcyjnej. Zesz. Energetyczne 2014, 1, 205–216. [Google Scholar]

- White, J. Literature review on adsorption cooling systems. Lat. Am. Caribb. J. Eng. Educ. 2013. Available online: https://www.researchgate.net/publication/289127089_LITERATURE_REVIEW_ON_ADSORPTION_COOLING_SYSTEMS (accessed on 8 December 2019).

- Shahzad, M.W.; Ybyraiymkul, D.; Burhan, M.; Oh, S.J.; Ng, K.C. An innovative pressure swing adsorption cycle. AIP Conf. Proc. 2019, 2062, 020057. [Google Scholar]

- Grabowska, K.; Sosnowski, M.; Krzywanski, J.; Sztekler, K.; Kalawa, W.; Zylka, A.; Nowak, W. The Numerical Comparison of Heat Transfer in a Coated and Fixed Bed of an Adsorption Chiller. J. Therm. Sci. 2018, 27, 421–426. [Google Scholar] [CrossRef]

- Xu, S.Z.; Wang, L.W.; Wang, R.Z. Thermodynamic analysis of single-stage and multi-stage adsorption refrigeration cycles with activated carbon–ammonia working pair. Energy Convers. Manag. 2016, 117, 31–42. [Google Scholar] [CrossRef]

- Starace, G.; Fiorentino, M.; Meleleo, B.; Risolo, C. The hybrid method applied to the plate-finned tube evaporator geometry. Int. J. Refrig. 2018, 88, 67–77. [Google Scholar] [CrossRef]

- Fiorentino, M.; Starace, G. The design of countercurrent evaporative condensers with the hybrid method. Appl. Therm. Eng. 2018, 130, 889–898. [Google Scholar] [CrossRef]

- Elsheniti, M.B.; Elsamni, O.A.; Al-dadah Raya, K.; Mahmoud, S.; Elsayed, E.; Saleh, K. Adsorption refrigeration technologies. In Sustainable Air Conditioning Systems; BoD—Books on Demand: Norderstedt, Germany, 2018. [Google Scholar]

- Wu, W.-D.; Zhang, H.; Men, C. Performance of a modified zeolite 13X-water adsorptive cooling module powered by exhaust waste heat. Int. J. Therm. Sci. 2011, 50, 2042–2049. [Google Scholar] [CrossRef]

- Sakoda, A.; Suzuki, M. Fundamental study on solar powered adsorption cooling system. J. Chem. Eng. Jpn. 1984, 17, 52–57. [Google Scholar] [CrossRef]

- Sakoda, A.; Suzuki, M. Simultaneous Transport of Heat and Adsorbate in Closed Type Adsorption Cooling System Utilizing Solar Heat. J. Sol. Energy Eng. Trans. Asme. J. Sol. Energy Eng. 1986, 108, 239–245. [Google Scholar] [CrossRef]

- Bahrehmand, H.; Khajehpour, M.; Bahrami, M. Finding optimal conductive additive content to enhance the performance of coated sorption beds: An experimental study. Appl. Therm. Eng. 2018, 143, 308–315. [Google Scholar] [CrossRef]

- Kim, D.-S.; Chang, Y.-S.; Lee, D.-Y. Modelling of an adsorption chiller with adsorbent-coated heat exchangers: Feasibility of a polymer-water adsorption chiller. Energy 2018, 164, 1044–1061. [Google Scholar] [CrossRef]

- Li, A.; Thu, K.; Ismail, A.B.; Shahzad, M.W.; Ng, K.C. Performance of adsorbent-embedded heat exchangers using binder-coating method. Int. J. Heat Mass Transf. 2016, 92, 149–157. [Google Scholar] [CrossRef]

- Grabowska, K.; Krzywanski, J.; Nowak, W.; Wesolowska, M. Construction of an innovative adsorbent bed configuration in the adsorption chiller-Selection criteria for effective sorbent-glue pair. Energy 2018, 151, 317–323. [Google Scholar] [CrossRef]

- Chang, K.-S.; Chen, M.-T.; Chung, T.-W. Effects of the thickness and particle size of silica gel on the heat and mass transfer performance of a silica gel-coated bed for air-conditioning adsorption systems. Appl. Therm. Eng. 2005, 25, 2330–2340. [Google Scholar] [CrossRef]

- Grabowska, K.; Sosnowski, M.; Krzywanski, J.; Sztekler, K.; Kalawa, W.; Zylka, A.; Nowak, W. Analysis of heat transfer in a coated bed of an adsorption chiller. MATEC Web Conf. 2018, 240, 01010. [Google Scholar] [CrossRef]

- Aristov, Y.I.; Glaznev, I.S.; Girnik, I.S. Optimization of adsorption dynamics in adsorptive chillers: Loose grains configuration. Energy 2012, 46, 484–492. [Google Scholar] [CrossRef]

- Askalany, A.A.; Henninger, S.K.; Ghazy, M.; Saha, B.B. Effect of improving thermal conductivity of the adsorbent on performance of adsorption cooling system. Appl. Therm. Eng. 2017, 110, 695–702. [Google Scholar] [CrossRef]

- Girnik, I.S.; Aristov, Y.I. Making adsorptive chillers more fast and efficient: The effect of bi-dispersed adsorbent bed. Appl. Therm. Eng. 2016, 106, 254–256. [Google Scholar] [CrossRef]

- Demir, H.; Mobedi, M.; Ülkü, S. Effects of porosity on heat and mass transfer in a granular adsorbent bed. Int. Commun. Heat Mass Transf. 2009, 36, 372–377. [Google Scholar] [CrossRef]

- Alam, K.C.A.; Saha, B.B.; Kang, Y.T.; Akisawa, A.; Kashiwagi, T. Heat exchanger design effect on the system performance of silica gel adsorption refrigeration systems. Int. J. Heat Mass Transf. 2000, 43, 4419–4431. [Google Scholar] [CrossRef]

- Sosnowski, M.; Grabowska, K.; Krzywanski, J.; Nowak, W.; Sztekler, K.; Kalawa, W. The effect of heat exchanger geometry on adsorption chiller performance. J. Phys. Conf. Ser. 2018, 1101, 012037. [Google Scholar] [CrossRef]

- Hong, S.; Ahn, S.; Kwon, O.; Chung, J. Optimization of a fin-tube type adsorption chiller by design of experiment. Int. J. Refrig. 2015, 49, 49–56. [Google Scholar] [CrossRef]

- Ilis, G.G.; Demir, H.; Mobedi, M.; Saha, B.B. A new adsorbent bed design: Optimization of geometric parameters and metal additive for the performance improvement. Appl. Therm. Eng. 2019, 162, 114270. [Google Scholar] [CrossRef]

- Gong, L.; Wang, R.; Xia, Z.; Chen, C. Design and performance prediction of a new generation adsorption chiller using composite adsorbent. Energy Convers. Manag. 2011, 52, 2345–2350. [Google Scholar] [CrossRef]

- Rogala, Z. Adsorption chiller using flat-tube adsorbers—Performance assessment and optimization. Appl. Therm. Eng. 2017, 121, 431–442. [Google Scholar] [CrossRef]

- Çağlar, A. The effect of fin design parameters on the heat transfer enhancement in the adsorbent bed of a thermal wave cycle. Appl. Therm. Eng. 2016, 104, 386–393. [Google Scholar] [CrossRef]

- Pajdak, A.; Kudasik, M.; Skoczylas, N.; Wierzbicki, M.; Braga, L.T.P. Studies on the competitive sorption of CO2 and CH4 on hard coal. Int. J. Greenh. Gas Control 2019, 90, 102789. [Google Scholar] [CrossRef]

- Pajdak, A.; Skoczylas, N.; Dębski, A.; Grzegorek, J.; Maziarz, W.; Kudasik, M. CO2 and CH4 sorption on carbon nanomaterials and coals—Comparative characteristics. J. Nat. Gas Sci. Eng. 2019, 72, 103003. [Google Scholar] [CrossRef]

- Intini, M.; Goldsworthy, M.; White, S.; Joppolo, C.M. Experimental analysis and numerical modelling of an AQSOA zeolite desiccant wheel. Appl. Therm. Eng. 2015, 80, 20–30. [Google Scholar] [CrossRef]

- Gurgel, J.; Andrade Filho, L.; Grenier, P.; Meunier, F. Thermal diffusivity and adsorption kinetics of silica-gel/water. Adsorption 2001, 7, 211–219. [Google Scholar] [CrossRef]

- Demir, H.; Mobedi, M.; Ülkü, S. A review on adsorption heat pump: Problems and solutions. Renew. Sustain. Energy Rev. 2008, 12, 2381–2403. [Google Scholar] [CrossRef]

- Krzywanski, J.; Grabowska, K.; Sosnowski, M.; Zylka, A.; Sztekler, K.; Kalawa, W.; Wójcik, T.; Nowak, W. Modeling of a re-heat two-stage adsorption chiller by AI approach. MATEC Web Conf. 2018, 240, 05014. [Google Scholar] [CrossRef]

- Krzywanski, J.; Grabowska, K.; Herman, F.; Pyrka, P.; Sosnowski, M.; Prauzner, T.; Nowak, W. Optimization of a three-bed adsorption chiller by genetic algorithms and neural networks. Energy Convers. Manag. 2017, 153, 313–322. [Google Scholar] [CrossRef]

- Krzywanski, J.; Grabowska, K.; Sosnowski, M.; Zylka, A.; Sztekler, K.; Kalawa, W.; Wojcik, T.; Nowak, W. An adaptive neuro-fuzzy model of a re-heat two-stage adsorption chiller. Therm. Sci. 2019, 23, 1053–1063. [Google Scholar] [CrossRef]

- Papakokkinos, G.; Castro, J.; López, J.; Oliva, A. A generalized computational model for the simulation of adsorption packed bed reactors—Parametric study of five reactor geometries for cooling applications. Appl. Energy 2019, 235, 409–427. [Google Scholar] [CrossRef]

- Sosnowski, M. Computational domain discretization in numerical analysis of forced convective heat transfer within packed beds of granular materials. Eng. Mech. 2018, 2018, 801–804. [Google Scholar]

- Sosnowski, M.; Krzywanski, J.; Grabowska, K.; Gnatowska, R. Polyhedral meshing in numerical analysis of conjugate heat transfer. EPJ Web Conf. 2018, 180, 02096. [Google Scholar] [CrossRef]

- Sosnowski, M. Computational domain discretization in numerical analysis of flow within granular materials. EPJ Web Conf. 2018, 180, 02095. [Google Scholar] [CrossRef][Green Version]

- Sosnowski, M.; Gnatowska, R.; Sobczyk, J.; Wodziak, W. Numerical modelling of flow field within a packed bed of granular material. J. Phys. Conf. Ser. 2018, 1101, 012036. [Google Scholar] [CrossRef]

- Mitra, S.; Oh, S.T.; Saha, B.B.; Dutta, P.; Srinivasan, K. Simulation study of the adsorption dynamics of cylindrical silica gel particles. Heat Transf. Res. 2015, 46, 123–140. [Google Scholar] [CrossRef]

- Khan, M.Z.I.; Alam, K.C.A.; Saha, B.B.; Akisawa, A.; Kashiwagi, T. Study on a re-heat two-stage adsorption chiller—The influence of thermal capacitance ratio, overall thermal conductance ratio and adsorbent mass on system performance. Appl. Therm. Eng. 2007, 27, 1677–1685. [Google Scholar] [CrossRef]

- Wang, R.Z.; Xia, Z.Z.; Wang, L.W.; Lu, Z.S.; Li, S.L.; Li, T.X.; Wu, J.Y.; He, S. Heat transfer design in adsorption refrigeration systems for efficient use of low-grade thermal energy. Energy 2011, 36, 5425–5439. [Google Scholar] [CrossRef]

- Antonellis, S.D.; Joppolo, C.M.; Molinaroli, L.; Pasini, A. Simulation and energy efficiency analysis of desiccant wheel systems for drying processes. Energy 2012, 37, 336–345. [Google Scholar] [CrossRef]

- ANSYS. Fluent Mosaic Technology Automatically Combines Disparate Meshes with Polyhedral Elements for Fast, Accurate Flow Resolution; ANSYS: Canonsburg, PA, USA, 2018. [Google Scholar]

- Sosnowski, M.; Gnatowska, R.; Sobczyk, J.; Wodziak, W. Computational domain discretization for CFD analysis of flow in a granular packed bed. J. Theor. Appl. Mech. 2019, 57, 833–842. [Google Scholar] [CrossRef]

- Sosnowski, M.; Gnatowska, R.; Grabowska, K.; Krzywański, J.; Jamrozik, A. Numerical Analysis of Flow in Building Arrangement: Computational Domain Discretization. Appl. Sci. 2019, 9, 941. [Google Scholar] [CrossRef]

- Eça, L.; Hoekstra, M. A procedure for the estimation of the numerical uncertainty of CFD calculations based on grid refinement studies. J. Comput. Phys. 2014, 262, 104–130. [Google Scholar] [CrossRef]

- Sosnowski, M.; Krzywanski, J.; Scurek, R. A Fuzzy Logic Approach for the Reduction of Mesh-Induced Error in CFD Analysis: A Case Study of an Impinging Jet. Entropy 2019, 21, 1047. [Google Scholar] [CrossRef]

- Celik, I.B.; Ghia, U.; Roache, P.J. Others Procedure for estimation and reporting of uncertainty due to discretization in CFD applications. J. Fluids Eng. Trans. ASME 2008, 130, 078001. [Google Scholar]

- Kakac, S.; Liu, H.; Pramuanjaroenkij, A. Heat Exchangers: Selection, Rating, and Thermal Design; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

| h/a (-) | N (-) | LMTD (K) | H (-) | R (-) | ε (-) | εi+1/εI (-) | P (-) | ea (%) | GCI (%) |

|---|---|---|---|---|---|---|---|---|---|

| 4.7·10−2 | 888 694 | 25.84 | 2.3603 | 1.3680 | −0.31 | converged | 2.867 | 1.20% | 1.03% |

| 6.5·10−2 | 347 133 | 25.53 | 3.2289 | 1.3067 | −0.10 | ||||

| 8.4·10−2 | 155 590 | 25.43 | 4.2192 | - | - |

| Material | Density (kg·m−3) | Specific Heat (J·kg−1·K−1) | Thermal Cond. (W·m−1·K−1) | Viscosity (kg·m−1·s−1) |

|---|---|---|---|---|

| water (liquid) | 998.2 | 4182 | 0.6 | 1.003·10−3 |

| water (vapor) | 0.5542 | f(T) | 0.0261 | 1.34·10−5 |

| silica gel | 800 | 924 | 0.18 | - |

| copper | 8978 | 381 | 387.6 | - |

| Analyzed Case | LMTD (K) | P (-) | R (-) | F (-) | F×LMTD (K) |

|---|---|---|---|---|---|

| RMFR = 1.00; EXP | 27.19 | 0.306 | 1.000 | 0.975 | 26.51 |

| RMFR = 1.00; CFD | 25.84 | 0.326 | 1.017 | 0.970 | 25.07 |

| RMFR = 1.33; EXP | 27.47 | 0.340 | 0.776 | 0.985 | 27.06 |

| RMFR = 1.33; CFD | 26.70 | 0.361 | 0.742 | 0.985 | 26.30 |

| RMFR = 1.66; EXP | 28.23 | 0.363 | 0.588 | 0.985 | 27.80 |

| RMFR = 1.66; CFD | 27.16 | 0.384 | 0.598 | 0.980 | 26.62 |

| d/a (-) | 0.54 | 0.62 | 0.70 | 0.78 | 0.86 |

|---|---|---|---|---|---|

| ΔTHW (K) | 1.71 | 2.10 | 2.24 | 2.52 | 2.89 |

| HP% (%) | 0 | 23 | 31 | 47 | 69 |

| ΔpHW% (%) | 0 | 2 | 5 | 12 | 43 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sosnowski, M. Evaluation of Heat Transfer Performance of a Multi-Disc Sorption Bed Dedicated for Adsorption Cooling Technology. Energies 2019, 12, 4660. https://doi.org/10.3390/en12244660

Sosnowski M. Evaluation of Heat Transfer Performance of a Multi-Disc Sorption Bed Dedicated for Adsorption Cooling Technology. Energies. 2019; 12(24):4660. https://doi.org/10.3390/en12244660

Chicago/Turabian StyleSosnowski, Marcin. 2019. "Evaluation of Heat Transfer Performance of a Multi-Disc Sorption Bed Dedicated for Adsorption Cooling Technology" Energies 12, no. 24: 4660. https://doi.org/10.3390/en12244660

APA StyleSosnowski, M. (2019). Evaluation of Heat Transfer Performance of a Multi-Disc Sorption Bed Dedicated for Adsorption Cooling Technology. Energies, 12(24), 4660. https://doi.org/10.3390/en12244660