Effect of Mixed-Flow Fans with a Newly Shaped Diffuser on Heat Stress of Dairy Cows Based on CFD

Abstract

:1. Introduction

2. Methods

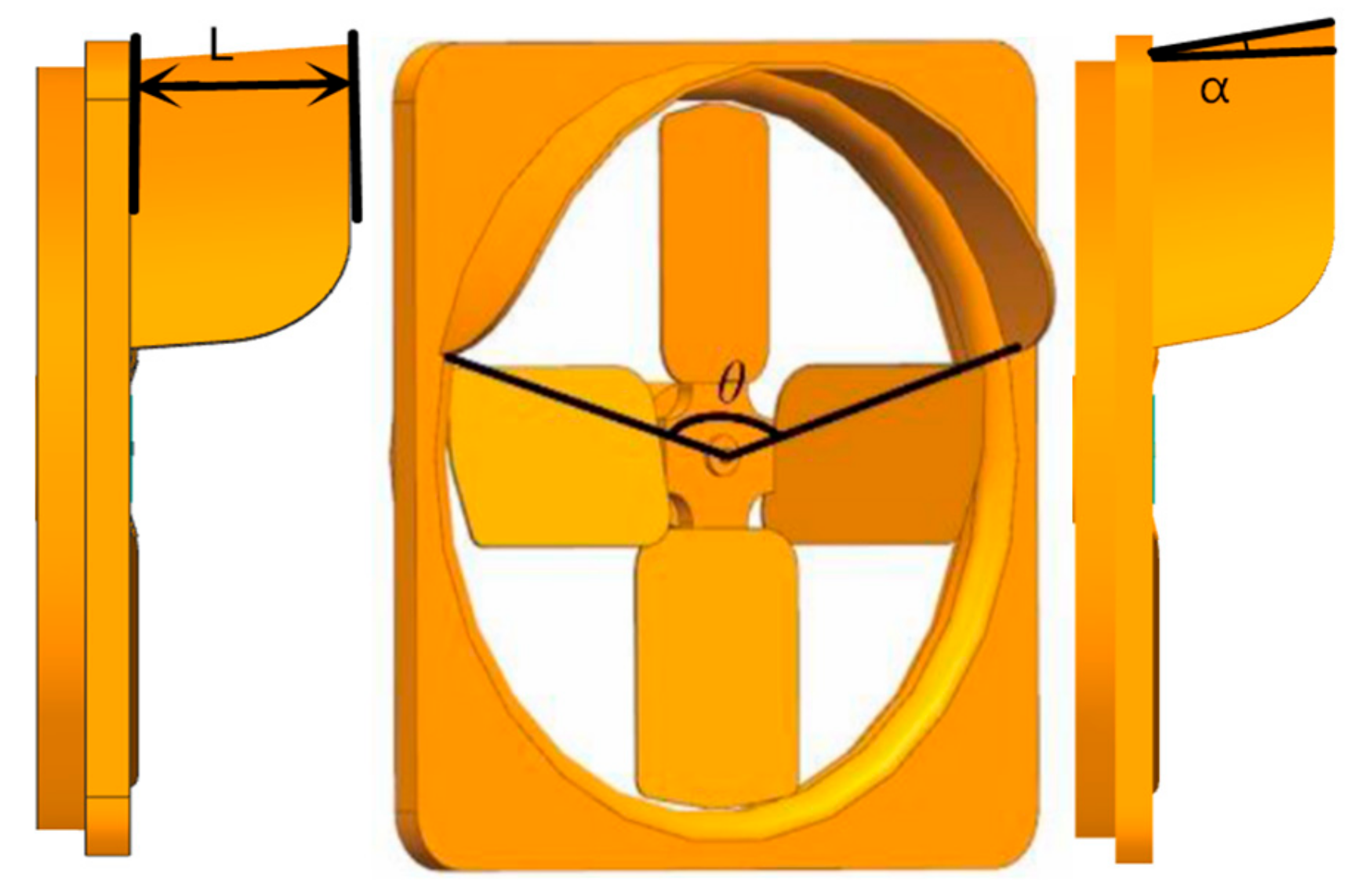

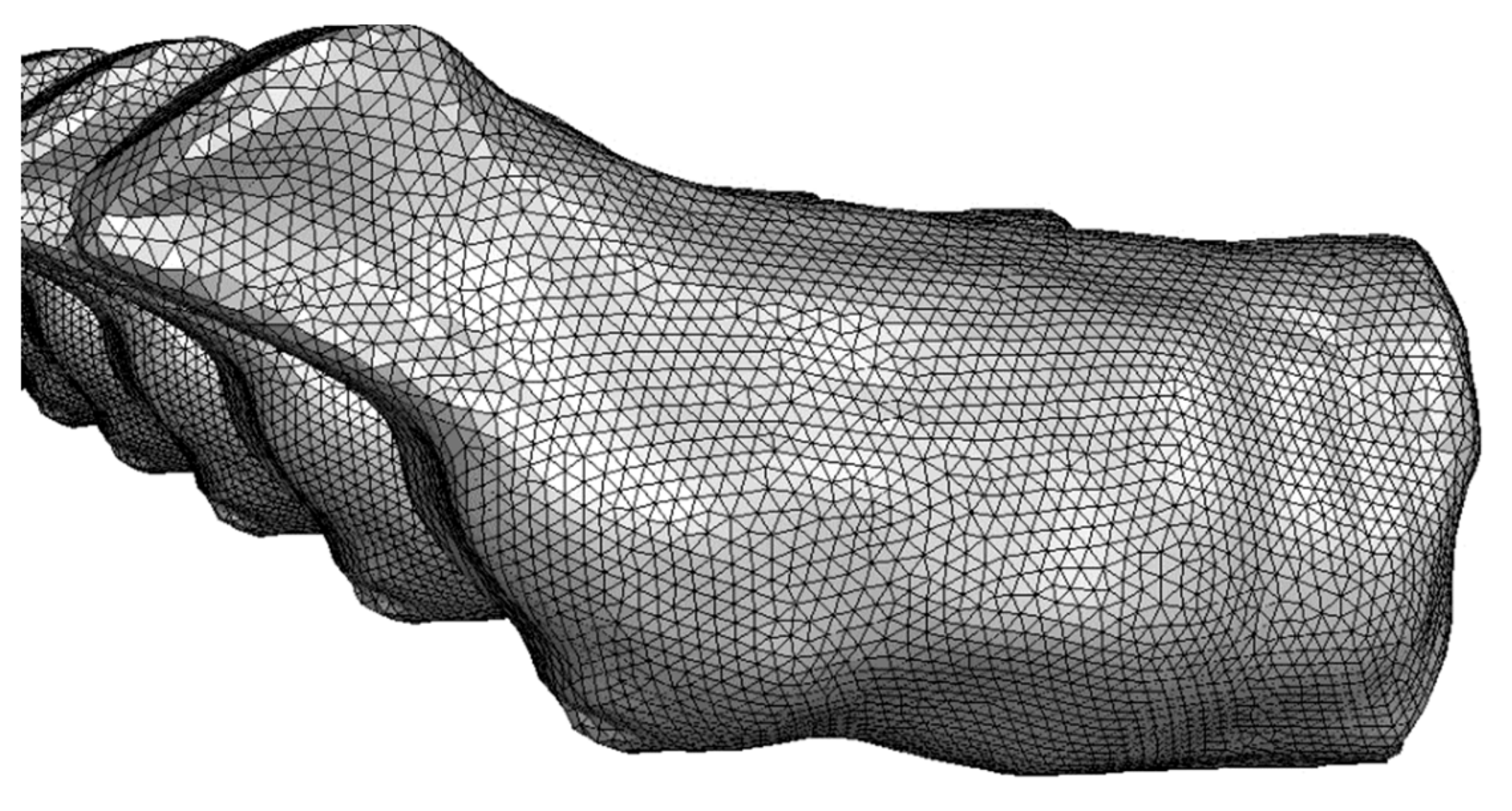

2.1. Optimization of the Geometric Parameters of the Diffuser

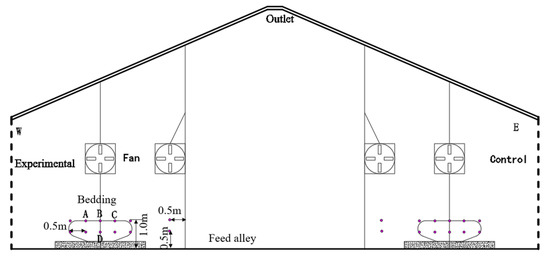

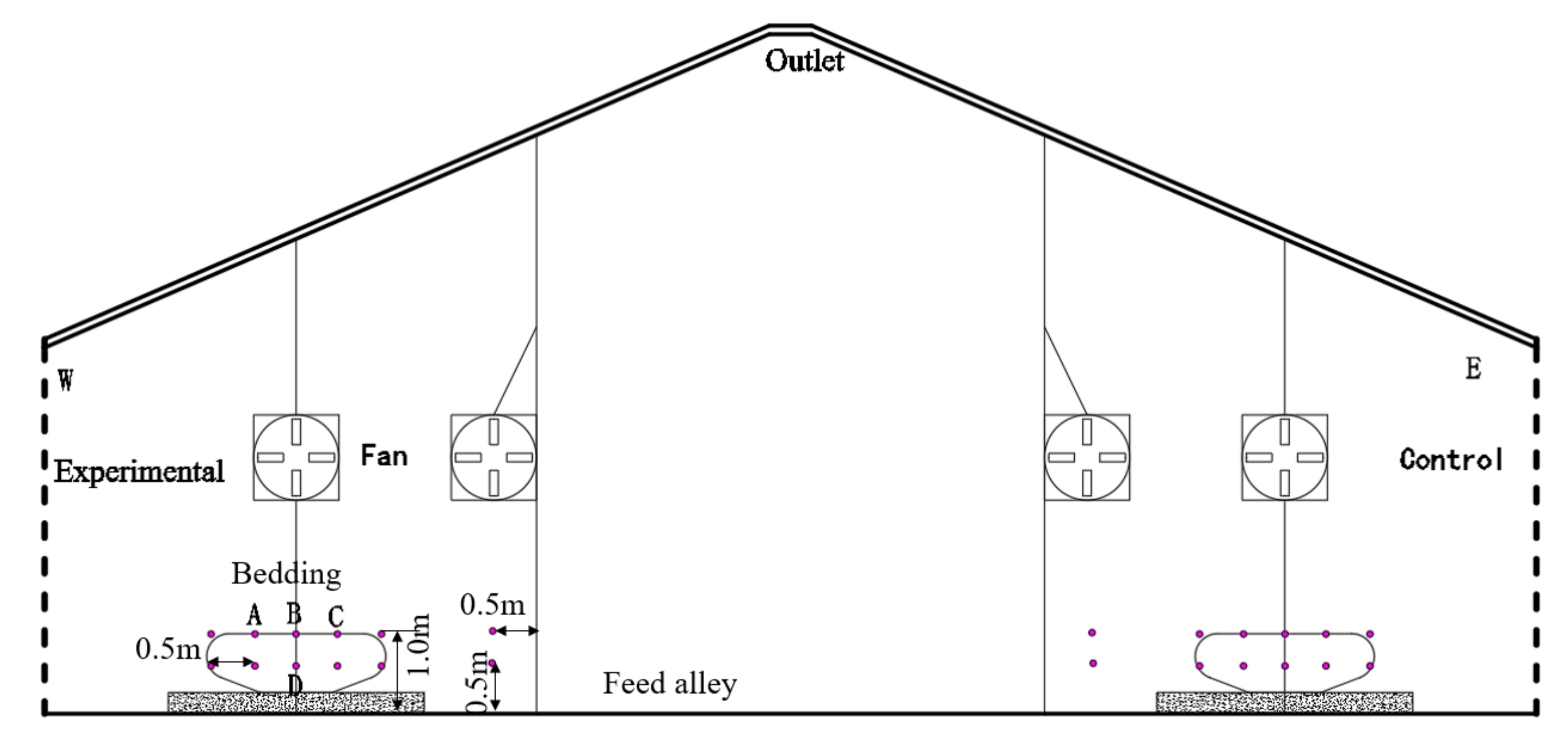

2.2. Field Test

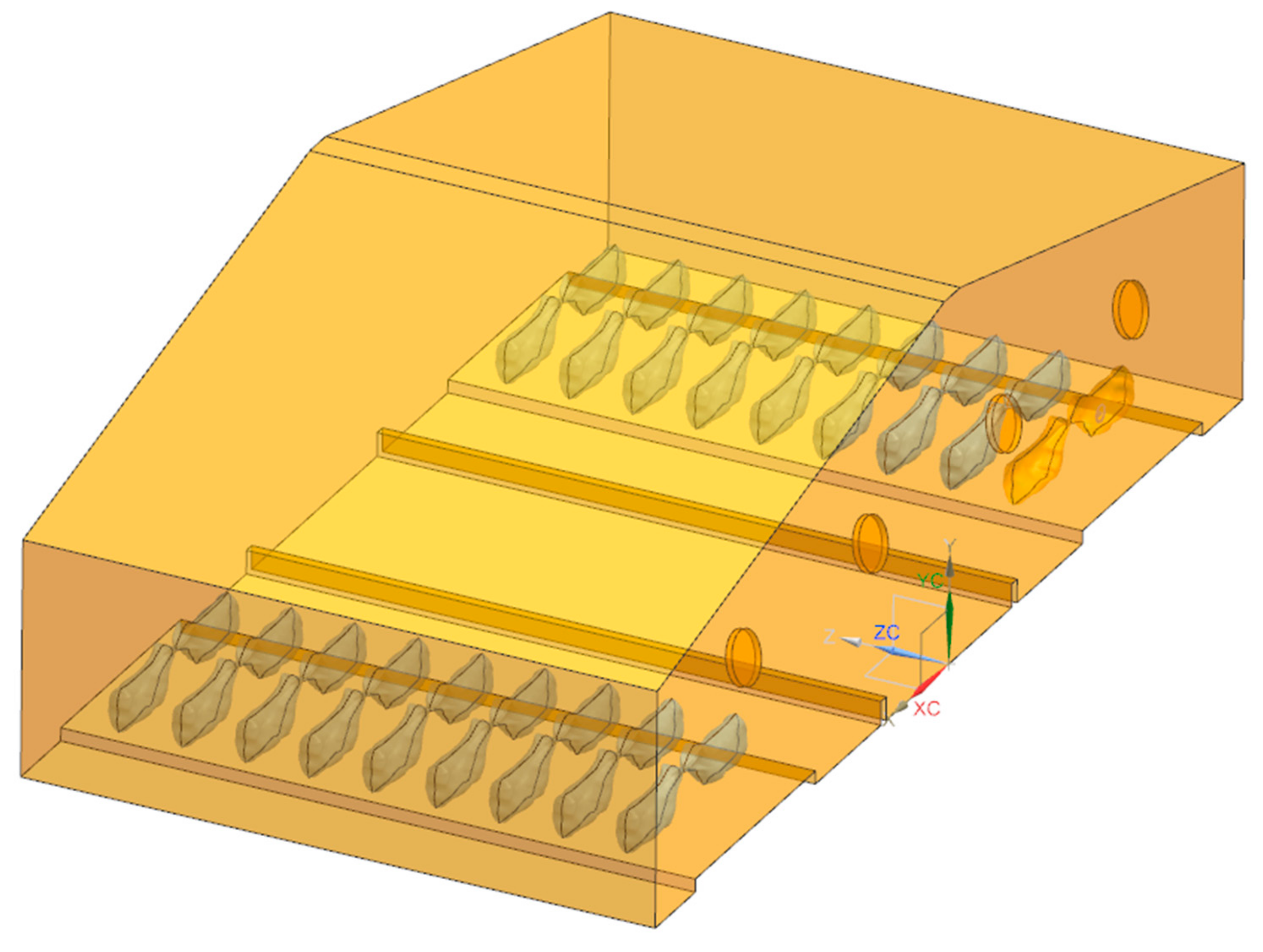

2.3. CFD Simulation of a Barn

3. Results and Discussion

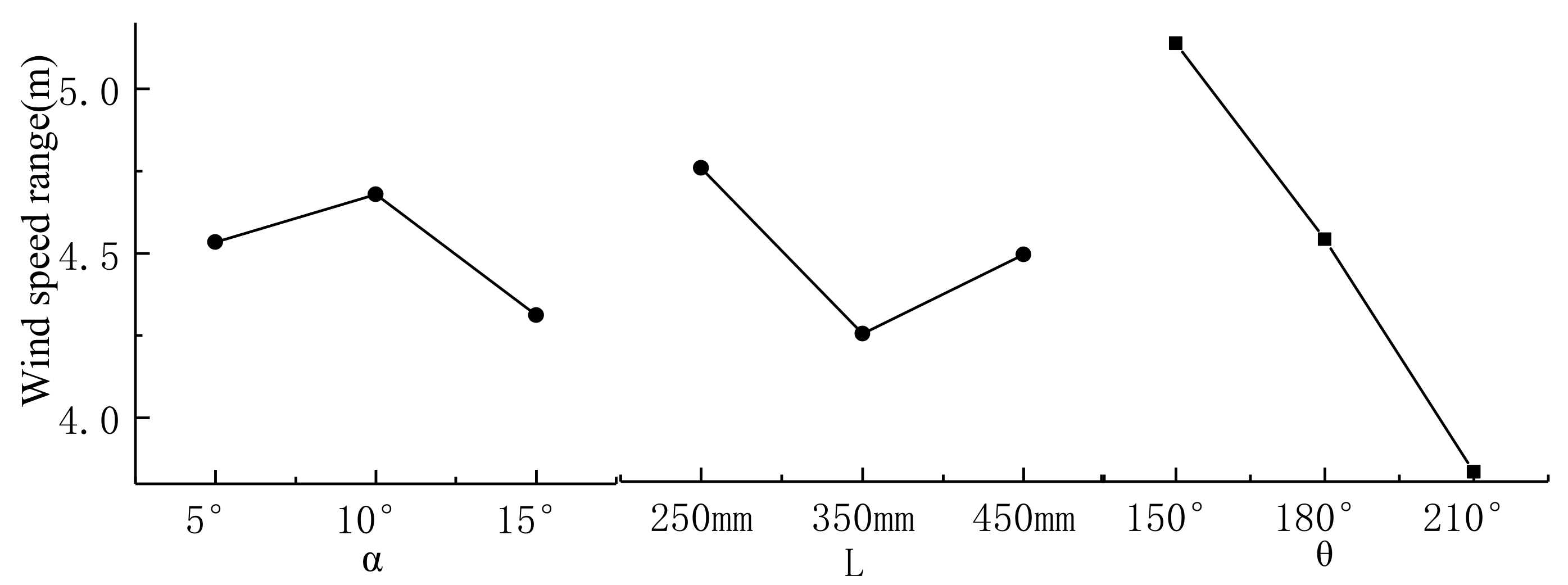

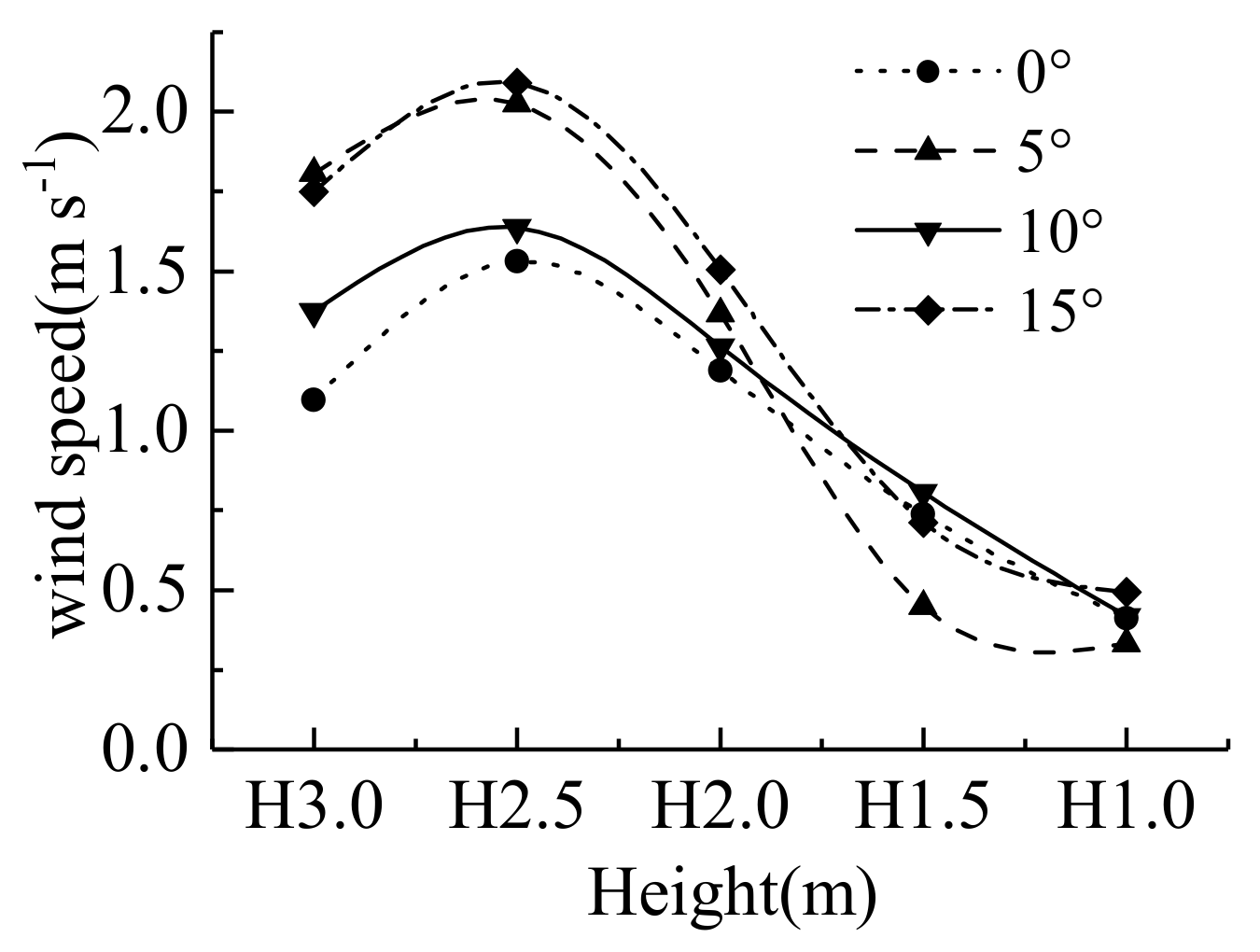

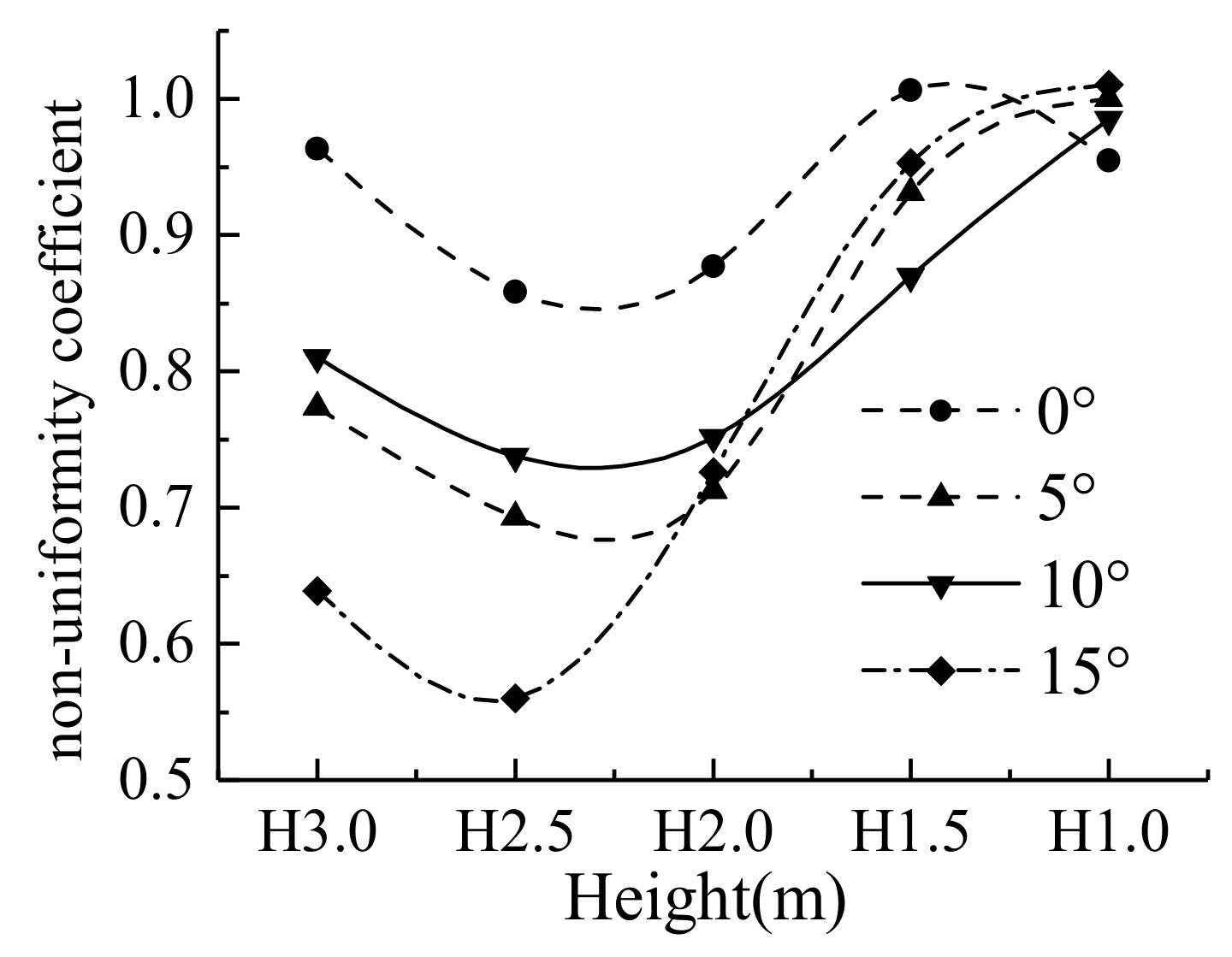

3.1. Optimization of the Elevation Angle

3.2. Field Test Results

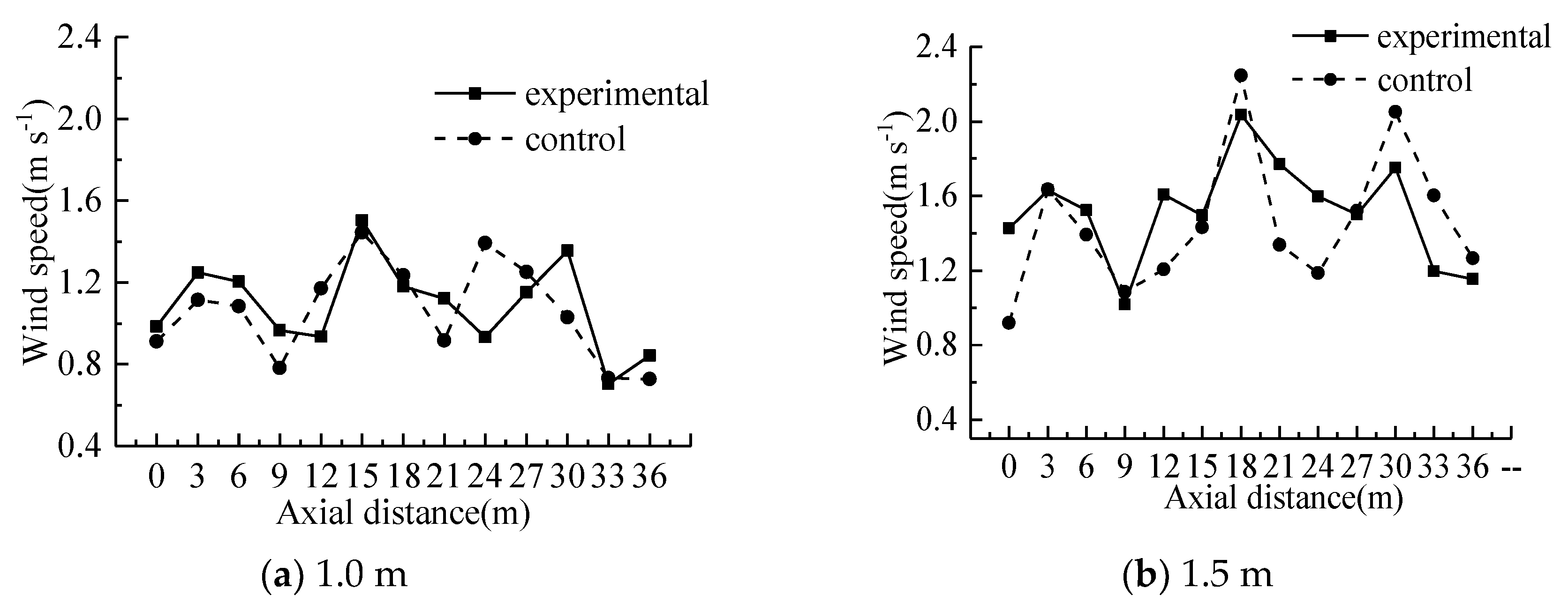

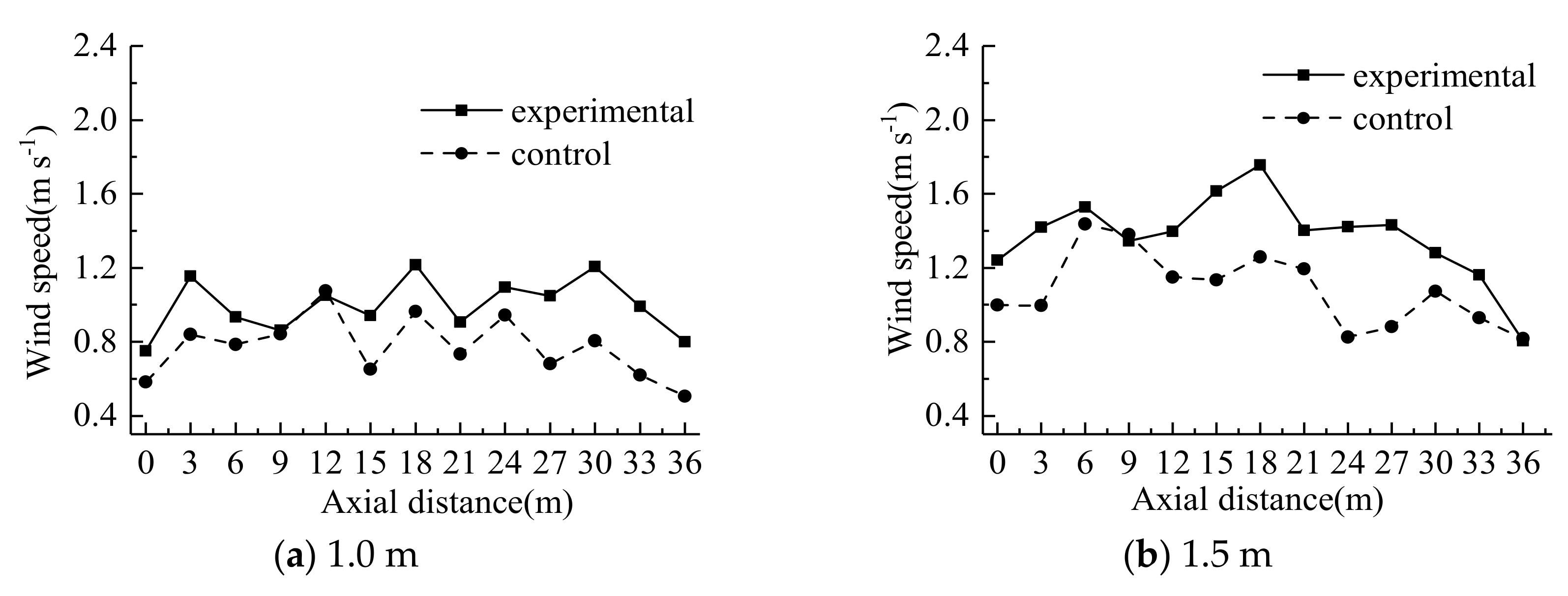

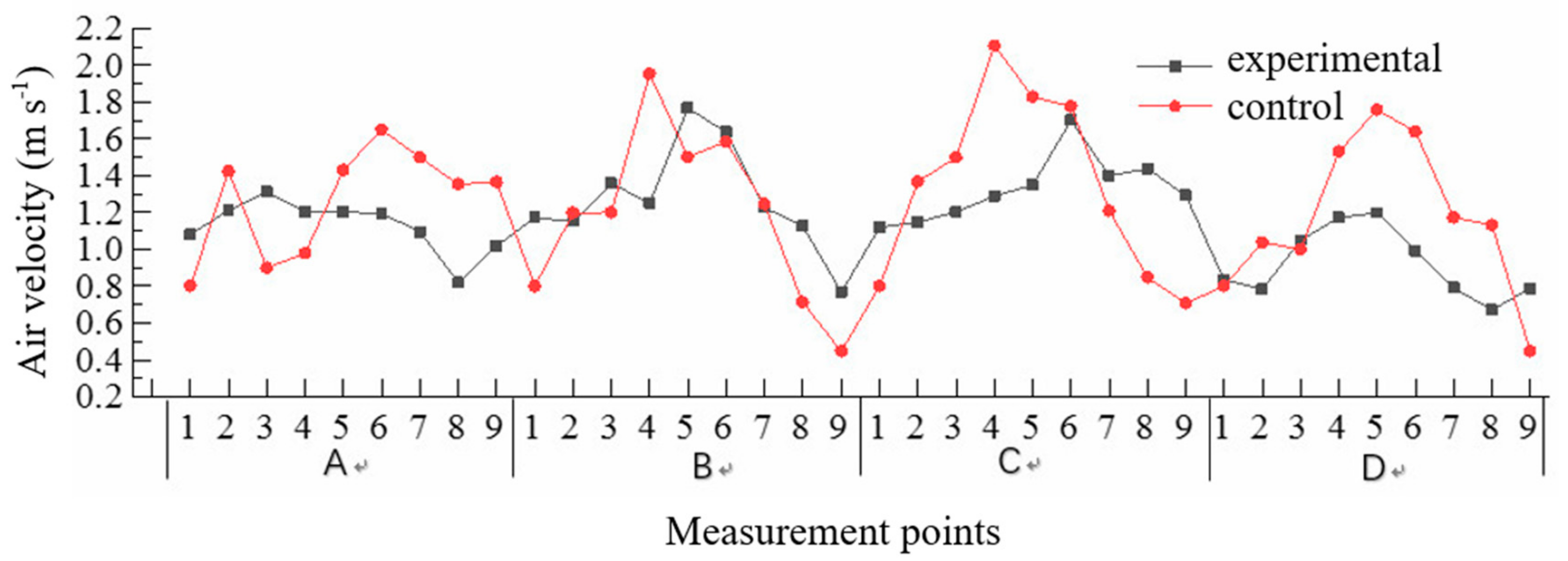

3.2.1. Wind Speed

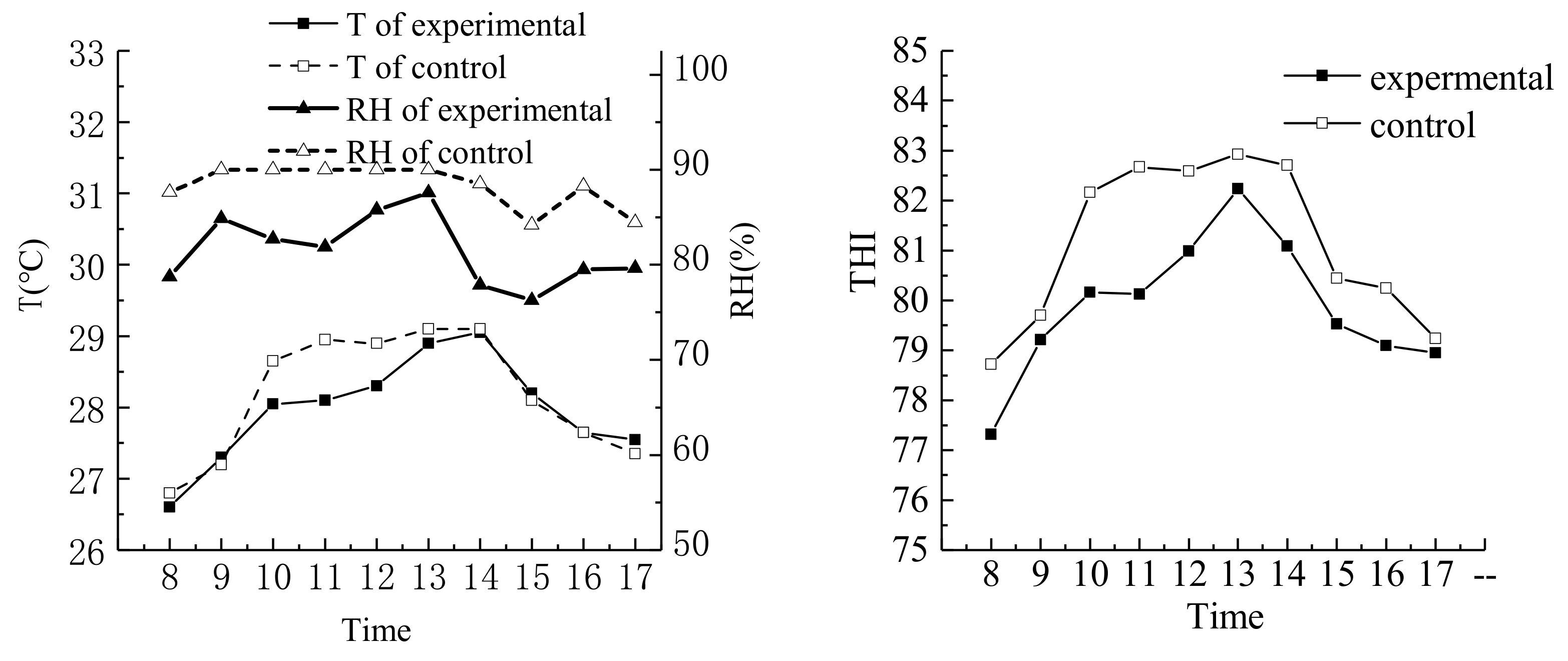

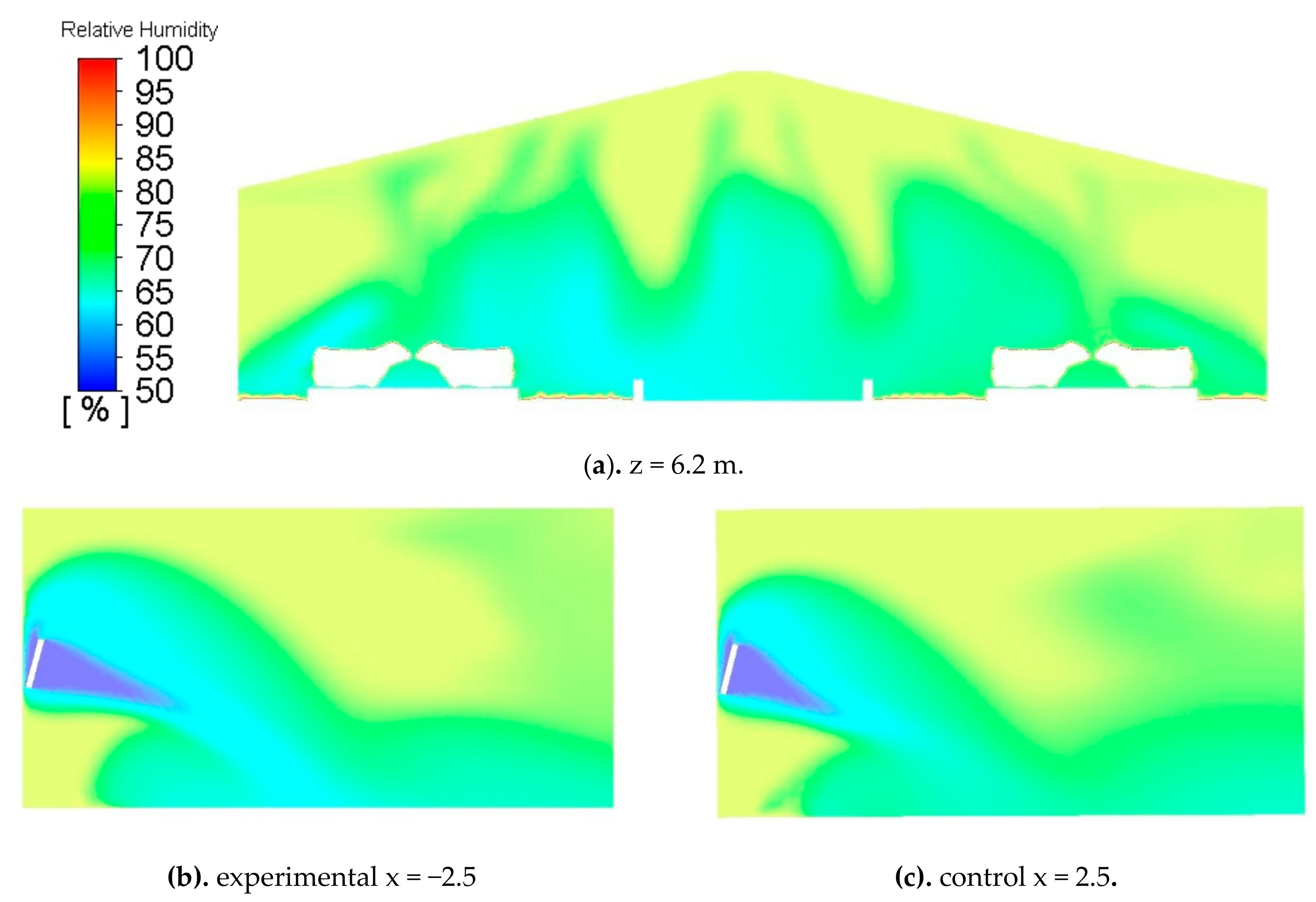

3.2.2. Temperature and Relative Humidity

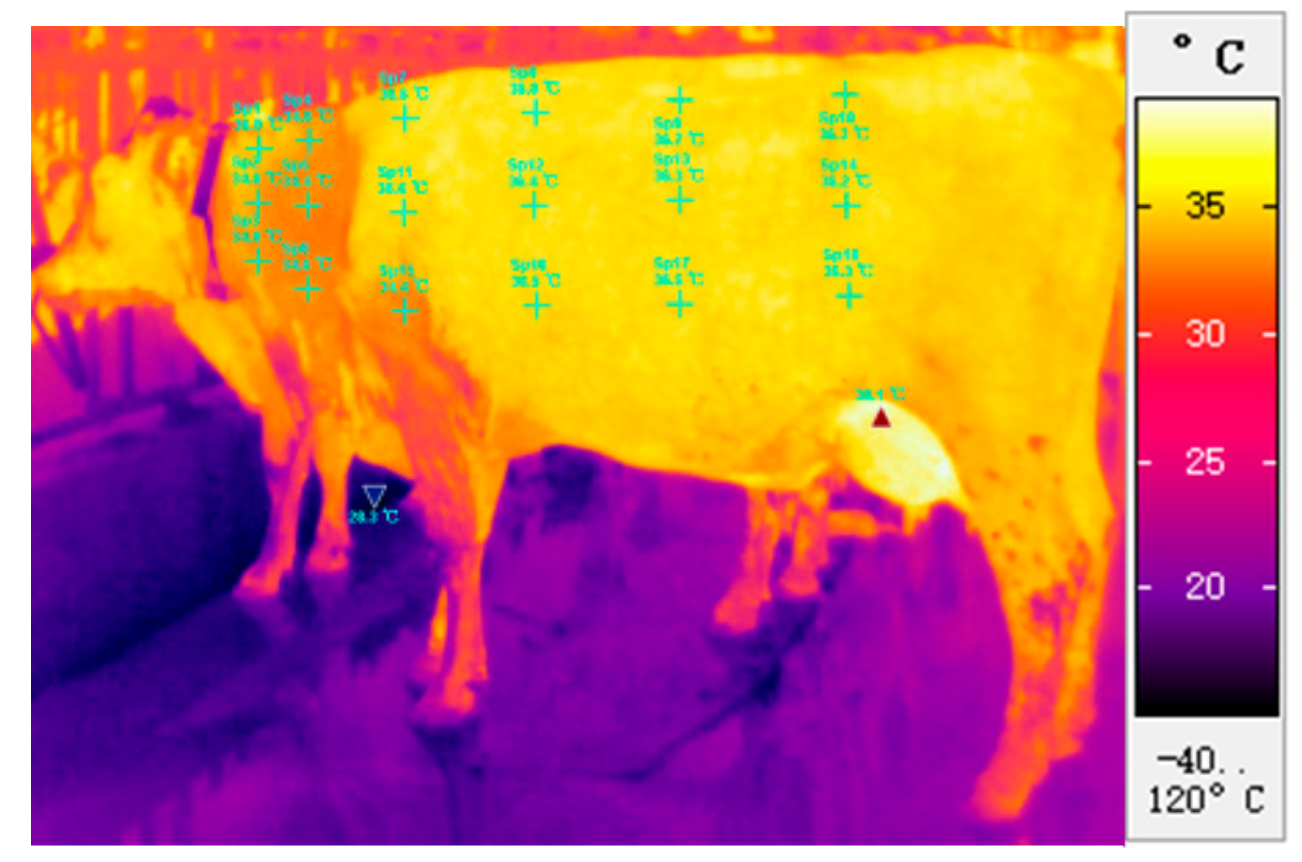

3.2.3. Average Body Temperature

3.2.4. Respiratory Rate of the Cows

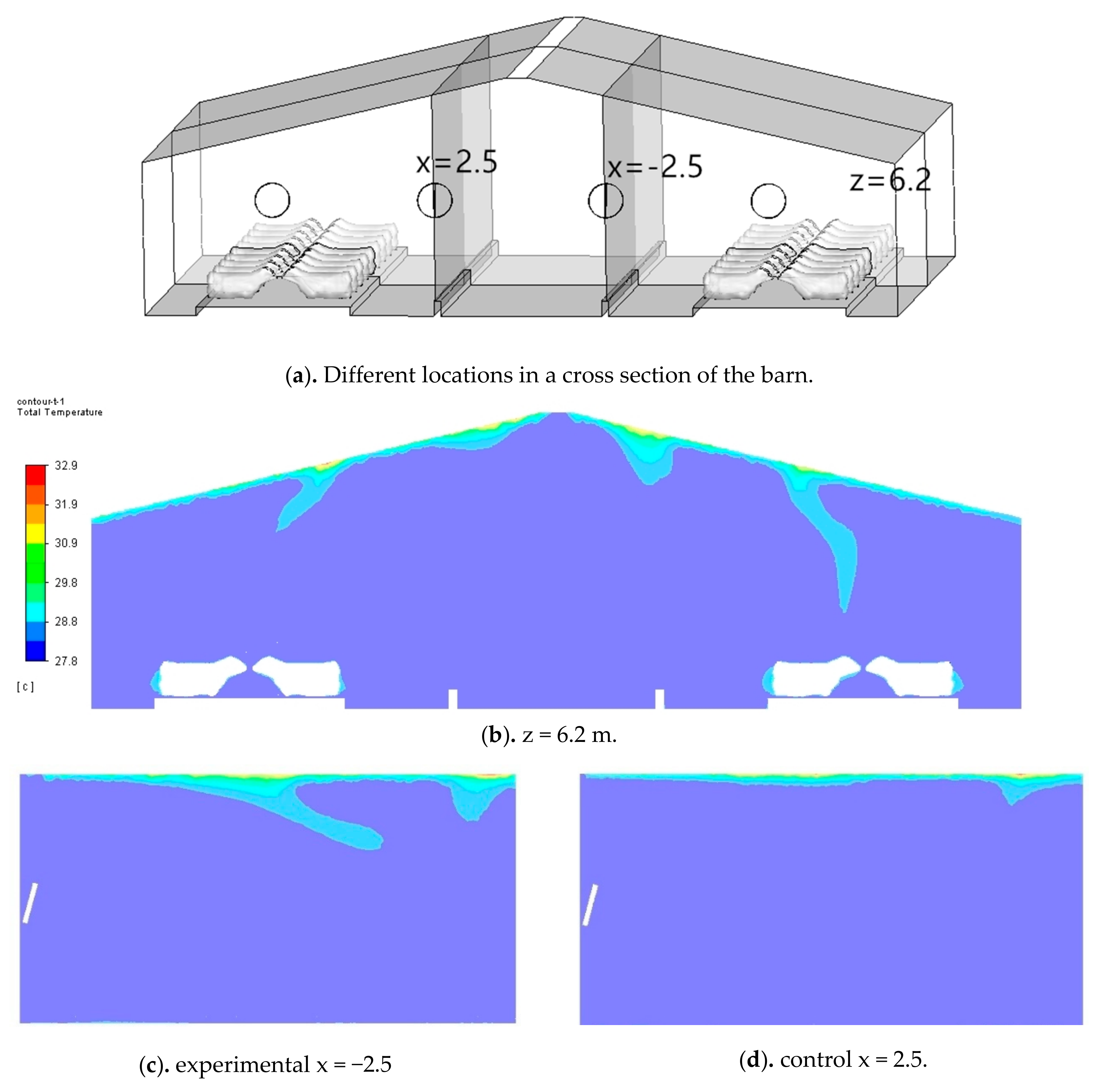

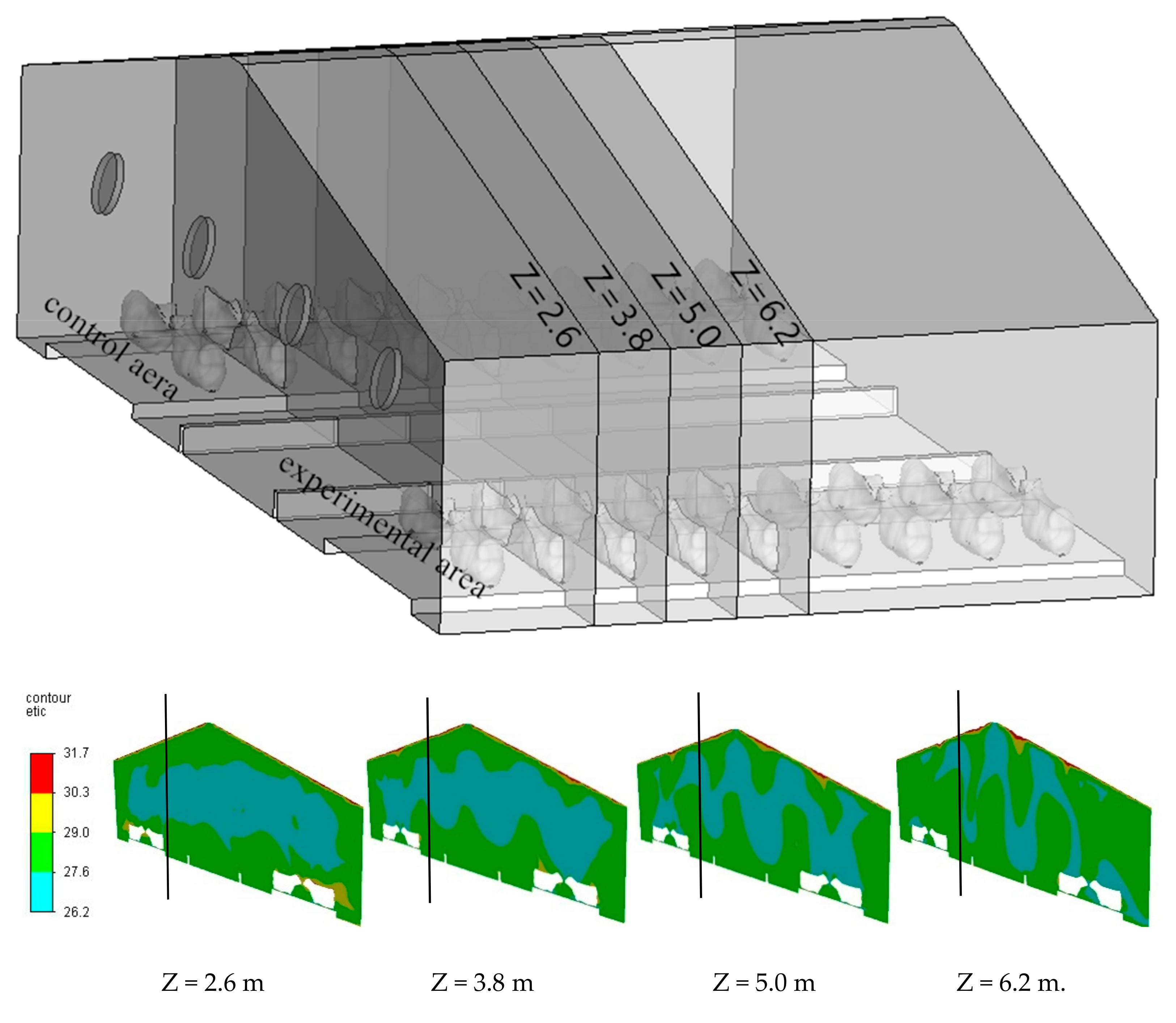

3.3. CFD Simulation Results of Cowshed

3.3.1. Model Validation

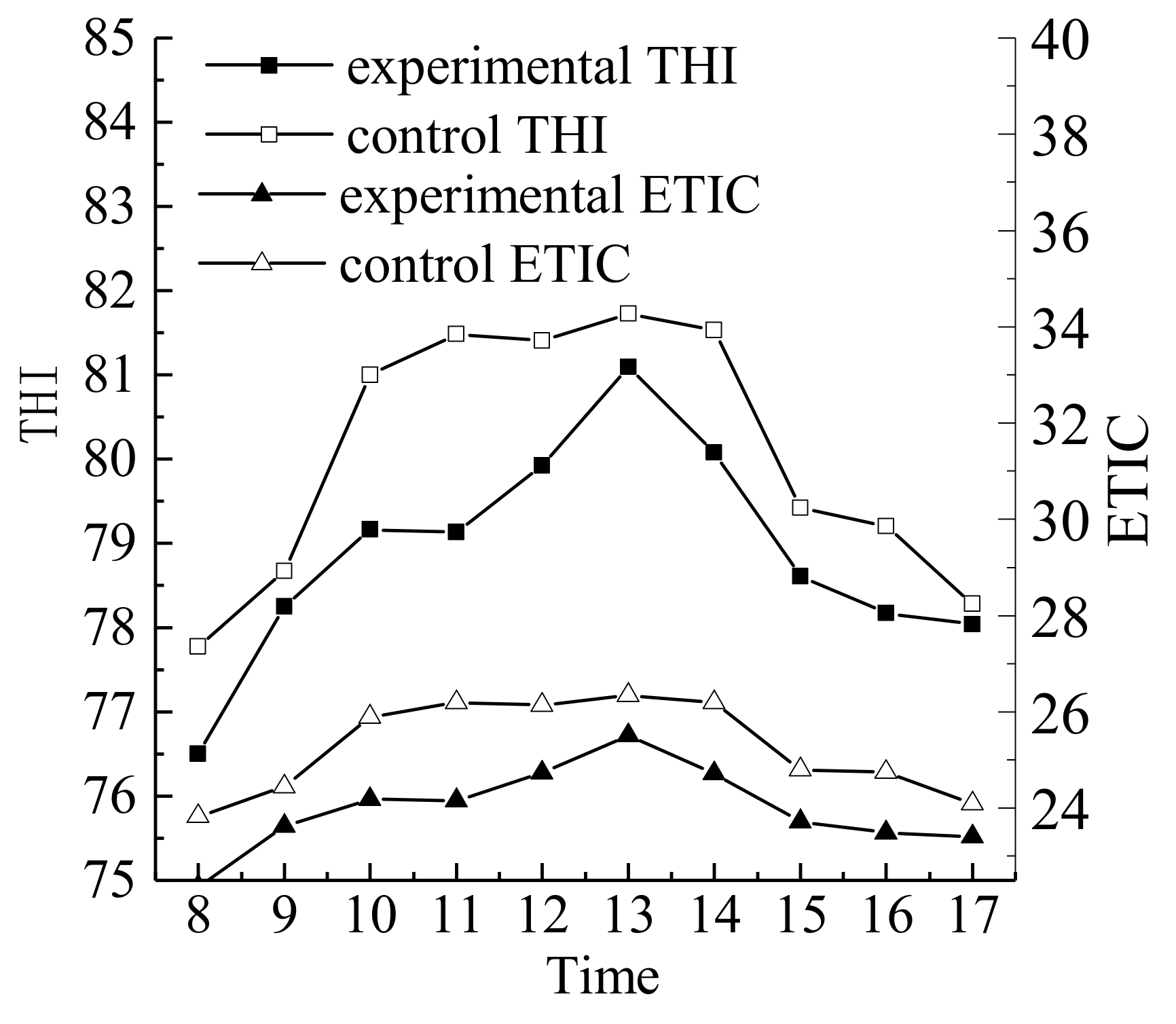

3.3.2. ETIC

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Das, R.; Sailo, L.; Verma, N.; Bharti, P.; Saikia, J. Impact of heat stress on health and performance of dairy animals: A review. Vet. World 2016, 9, 260. [Google Scholar] [CrossRef] [PubMed]

- Rhoads, R.P.; Baumgard, L.H.; Suagee, J.K.; Sanders, S.R. Nutritional interventions to alleviate the negative consequences of heat stress. Adv. Nutr. 2013, 4, 267–276. [Google Scholar] [CrossRef] [PubMed]

- Smith, D.L.; Smith, T.; Rude, B.J.; Ward, S.H. Comparison of the effects of heat stress on milk and component yields and somatic cell score in Holstein and Jersey cows. J. Dairy Sci. 2013, 96, 3028–3033. [Google Scholar] [CrossRef] [PubMed]

- St-Pierre, N.R.; Cobanov, B.; Schnitkey, G. Economic Losses from Heat Stress by US Livestock Industries. J. Dairy Sci. 2003, 86, E52–E77. [Google Scholar] [CrossRef]

- Bottcher, R.W.; Magura, J.R.; Young, J.S.; Baughman, G.R. Baughman. Effects of Tilt Angles on Airflow for Poultry House Mixing Fans. Appl. Eng. Agric. 1995, 11, 721–730. [Google Scholar] [CrossRef]

- Calegari, F.; Calamari, L.; Frazzi, E. Cooling systems of the resting area in free stall dairy barn. Int. J. Biometeorol. 2016, 60, 605–614. [Google Scholar] [CrossRef] [PubMed]

- Gebremedhin, K.G.; Wu, B. Simulation of sensible and latent heat losses from wet-skin surface and fur layer. J. Therm. Biol. 1998, 27, 291–297. [Google Scholar] [CrossRef]

- Cory, W.T.W. Fans & Ventilation: A Practical Guide; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Jung, U.-H.; Kim, J.-H.; Kim, J.-H.; Park, C.-H.; Jun, S.-O.; Choi, Y.-S. Optimum design of diffuser in a small high-speed centrifugal fan using CFD & DOE. J. Mech. Sci. Technol. 2016, 30, 1171–1184. [Google Scholar]

- Sasaki, S.; Suzuki, K.; Onomichi, Y.; Hayashi, H. Influence of diffuser on aerodynamic noise of a forward curved fan. J. Therm. Sci. 2013, 22, 433–438. [Google Scholar] [CrossRef]

- Ding, T.; Fang, L.; Ni, J.-Q.; Shi, Z.; Sun, B.; Wang, Z.; Yao, C. Optimization of Diffuser Parameters for Mixing Fans in Agricultural Buildings. Appl. Eng. Agric. 2017, 34, 437–444. [Google Scholar] [CrossRef]

- Wang, X.; Bjerg, B.S.; Choi, C.Y.; Zong, C.; Zhang, G. A review and quantitative assessment of cattle-related thermal indices. J. Therm. Biol. 2018, 77, 24–37. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Gebremedhin, K.G.; Lee, C.N.; Collier, R.J. Evaluation of Thermal Stress Indices for Cattle. In Proceedings of the 2009 ASABE Annual Meeting, Reno, NV, USA, 21–24 June 2009. [Google Scholar]

- Mader, T.L.; Davis, M.S.; Brown-Brandl, T. Environmental factors influencing heat stress in feedlot cattle. J. Anim. Sci. 2006, 84, 712–719. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Gao, H.; Gebremedhin, K.G.; Bjerg, B.S.; Van Os, J.; Tucker, C.B.; Zhang, G. A Predictive Model of Equivalent Temperature Index for Dairy Cattle (ETIC). J. Therm. Biol. 2018, 76, 165–170. [Google Scholar] [CrossRef] [PubMed]

- Bohmanova, J.; Misztal, I.; Cole, J.B. Temperature-Humidity Indices as Indicators of Milk Production Losses due to Heat Stress. J. Dairy Sci. 2007, 90, 1947–1956. [Google Scholar] [CrossRef] [PubMed]

- Hahn, G.L.; Mader, T.L.; Eigenberg, R.A. Perspective on development of thermal indices for animal studies and management. EAAP Tech. Ser. 2003, 7, 31–44. [Google Scholar]

- Deng, S.; Shi, Z.; Fan, L.; Ding, T. Optimization of installation parameters of mixing fans in open dairy cow house based on CFD. Nongye Jixie Xuebao = Trans. Chin. Soc. Agric. Mach. 2013, 44, 269–274. [Google Scholar]

| Parameters | Sum of Square | Degree of Freedom | Mean Square Error | F | Significance |

|---|---|---|---|---|---|

| α | 0.614 | 2 | 0.307 | 2.141 | (*) |

| θ | 7.754 | 2 | 3.877 | 27.032 | (**) |

| L | 1.176 | 2 | 0.588 | 4.101 | (*) |

| aθ | 0.584 | 4 | 0.146 | 1.021 | - |

| a L | 0.275 | 4 | 0.069 | 0.483 | - |

| θL | 0.788 | 4 | 0.197 | 1.378 | - |

| Error | 1.147 | 8 | 0.143 |

| α° | Average Power kW | Flow Flux m3/h | Energy Efficiency (m3/h)/kW | Difference of Flow Flux | Difference of Energy Efficiency |

|---|---|---|---|---|---|

| prototype | 579 | 12,918 | 22.3 | - | - |

| 0 | 578 | 13,273 | 23.0 | - | - |

| 5 | 570 | 13,335 | 23.4 | 0.47% | 1.88% |

| 10 | 574 | 13,364 | 23.3 | 0.69% | 1.39% |

| 15 | 576 | 13,345 | 23.2 | 0.54% | 0.89% |

| Time | Experimental Temperature (°C) | Control temperature (°C) | Difference | ||||

|---|---|---|---|---|---|---|---|

| Body | Rectal | Average | Body | Rectal | Average | °C | |

| 9:00 | 34.0 ± 0.2 a | 38.8 ± 0.2 a | 35.44 | 35. 0 ± 0.3 a | 38.8 ± 0.2 b | 36.14 | −0.7 |

| 12:00 | 34.9 ± 0.8 a | 38.6 ± 0.2 a | 36.01 | 35.8 ± 0.6 a | 38.9 ± 0.3 a | 36.73 | −0.72 |

| 15:00 | 35.0 ± 0.4 a | 38.8 ± 0.1 a | 35.54 | 35.7 ± 0.4 a | 38.8 ± 0.2 a | 36.63 | −1.09 |

| Time | Experimental min−1 | Control min−1 | Difference min−1 |

|---|---|---|---|

| 9:00 | 68.2 ± 1.7 a | 69.2 ± 2.3 a | −1.0 |

| 12:00 | 68.6 ± 1.5 a | 69.3 ± 2.1 a | −0.7 |

| 15:00 | 67.9 ± 0.7 a | 67.6 ± 1.6 a | 0.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, C.; Shi, Z.; Zhao, Y.; Ding, T. Effect of Mixed-Flow Fans with a Newly Shaped Diffuser on Heat Stress of Dairy Cows Based on CFD. Energies 2019, 12, 4315. https://doi.org/10.3390/en12224315

Yao C, Shi Z, Zhao Y, Ding T. Effect of Mixed-Flow Fans with a Newly Shaped Diffuser on Heat Stress of Dairy Cows Based on CFD. Energies. 2019; 12(22):4315. https://doi.org/10.3390/en12224315

Chicago/Turabian StyleYao, Chunxia, Zhengxiang Shi, Yang Zhao, and Tao Ding. 2019. "Effect of Mixed-Flow Fans with a Newly Shaped Diffuser on Heat Stress of Dairy Cows Based on CFD" Energies 12, no. 22: 4315. https://doi.org/10.3390/en12224315

APA StyleYao, C., Shi, Z., Zhao, Y., & Ding, T. (2019). Effect of Mixed-Flow Fans with a Newly Shaped Diffuser on Heat Stress of Dairy Cows Based on CFD. Energies, 12(22), 4315. https://doi.org/10.3390/en12224315