Sensitivity Analysis of Multistage Compressor Characteristics Under the Spray Atomization Effect Using a CFD Model

Abstract

:1. Introduction

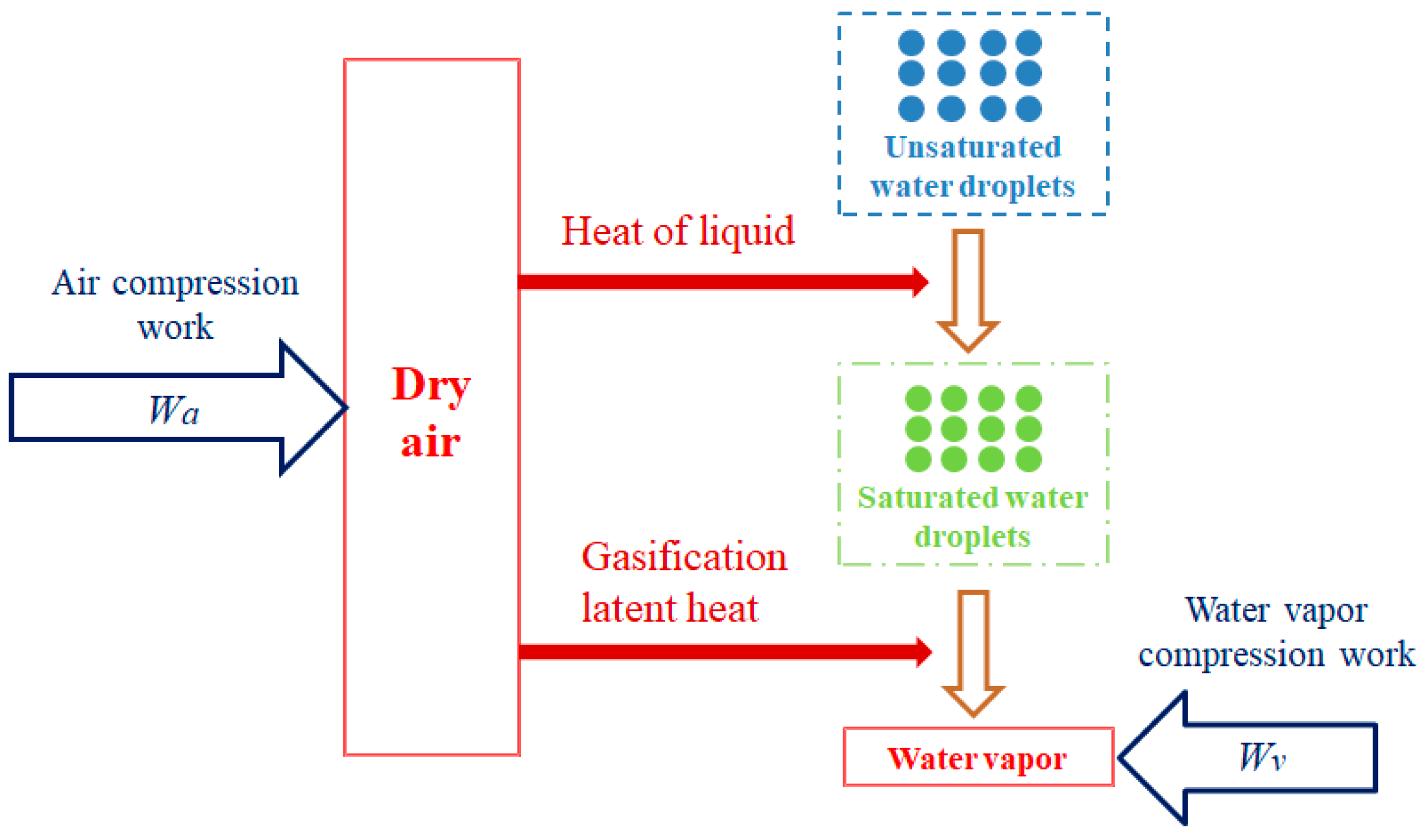

2. Numerical Research Methods

2.1. Numerical Model

2.1.1. Governing Equations of the Continuous Phase

2.1.2. Governing Equations of the Dispersed Phase

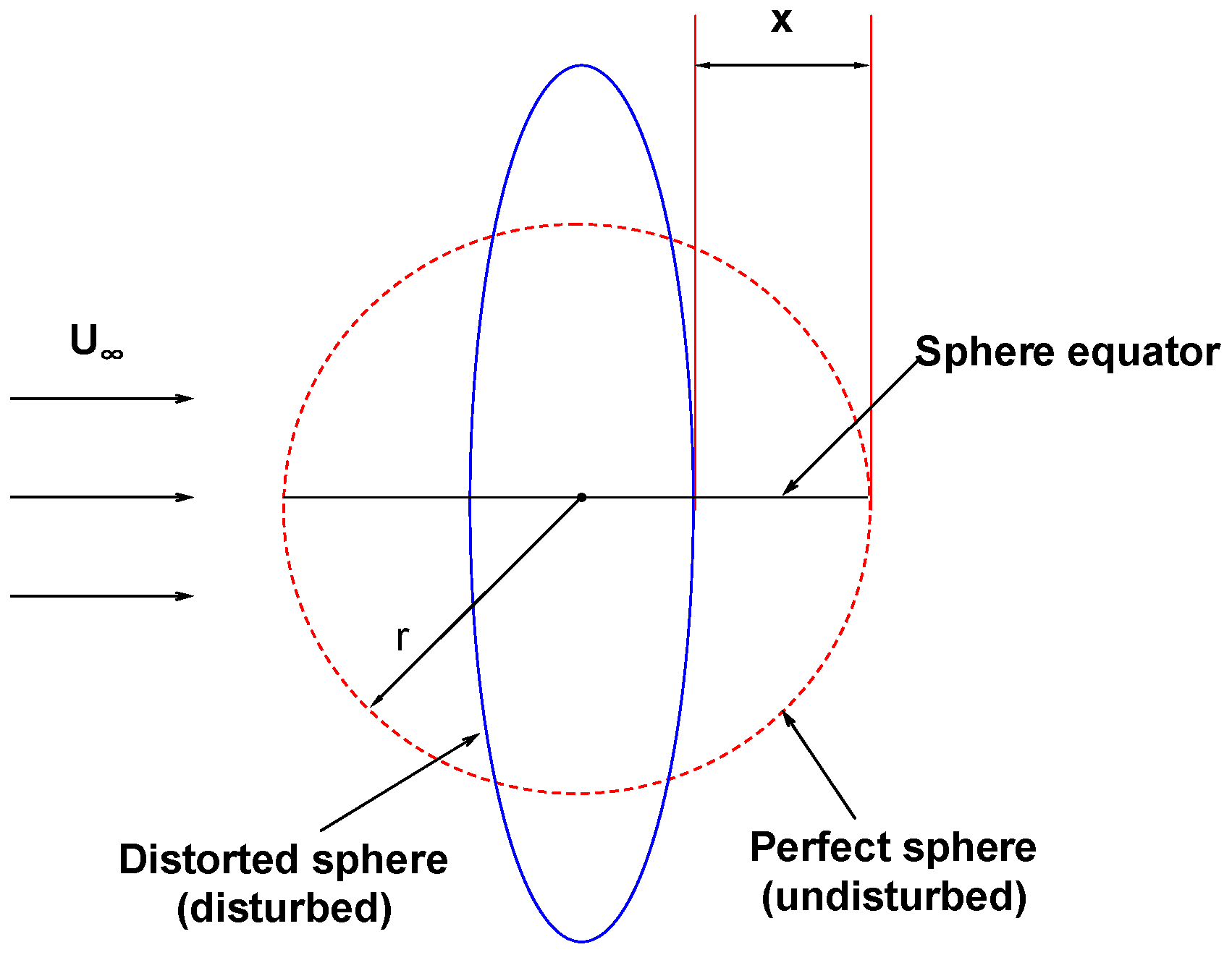

2.2. Secondary Aerodynamic Breakup Model of Water Droplet

2.3. Droplets Breakup Model When Impacting on the Blade Surface

- (1)

- Adhesion: water droplets adhere to the wall in a nearly spherical form.

- (2)

- Rebounding: water droplets bounce off the wall after hitting against it.

- (3)

- Spread: water droplets spread out on the wall to form a fluid film.

- (4)

- Splashing: several smaller droplets are formed when the water droplets collide with the wall and some remain on the wall.

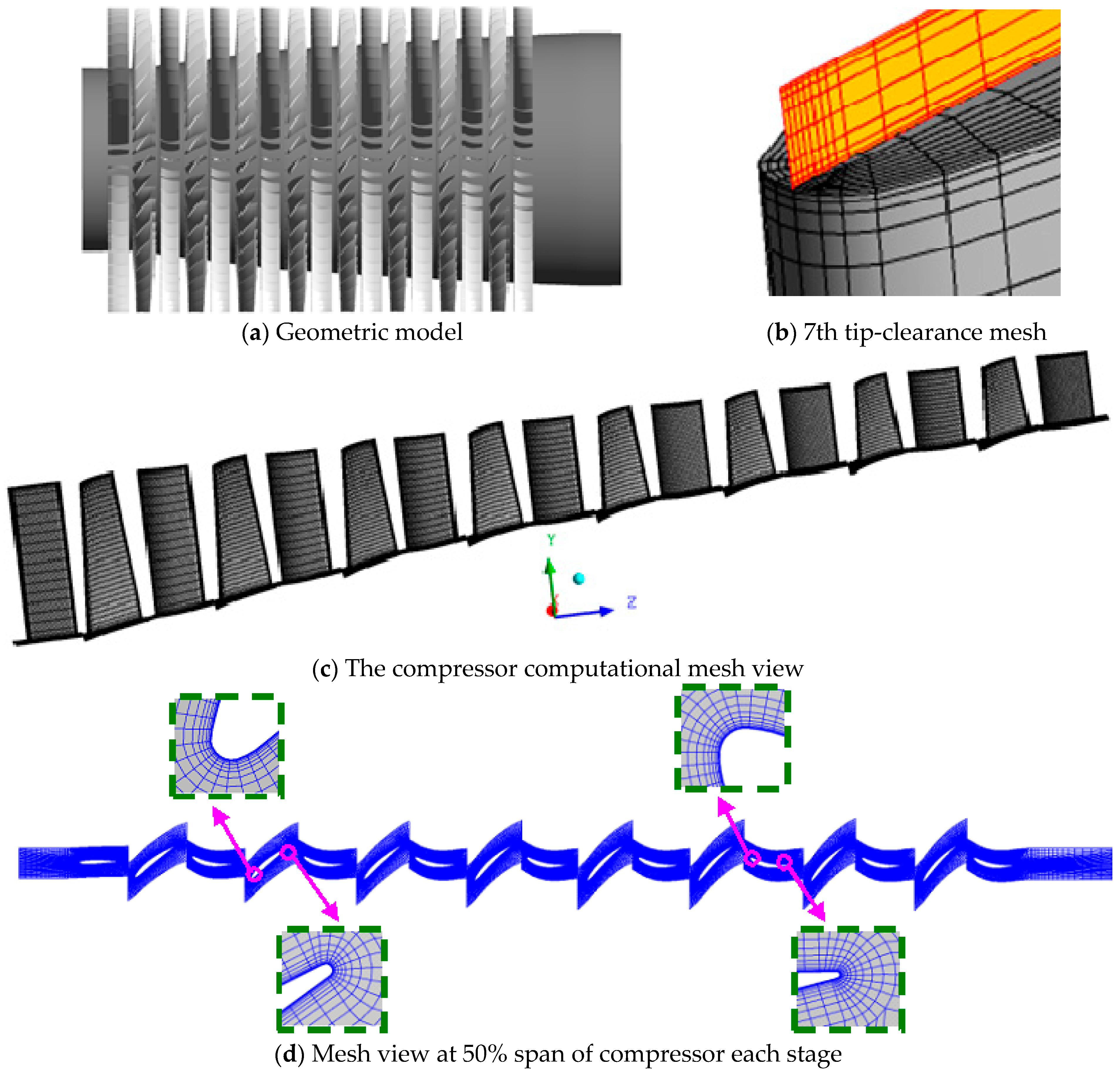

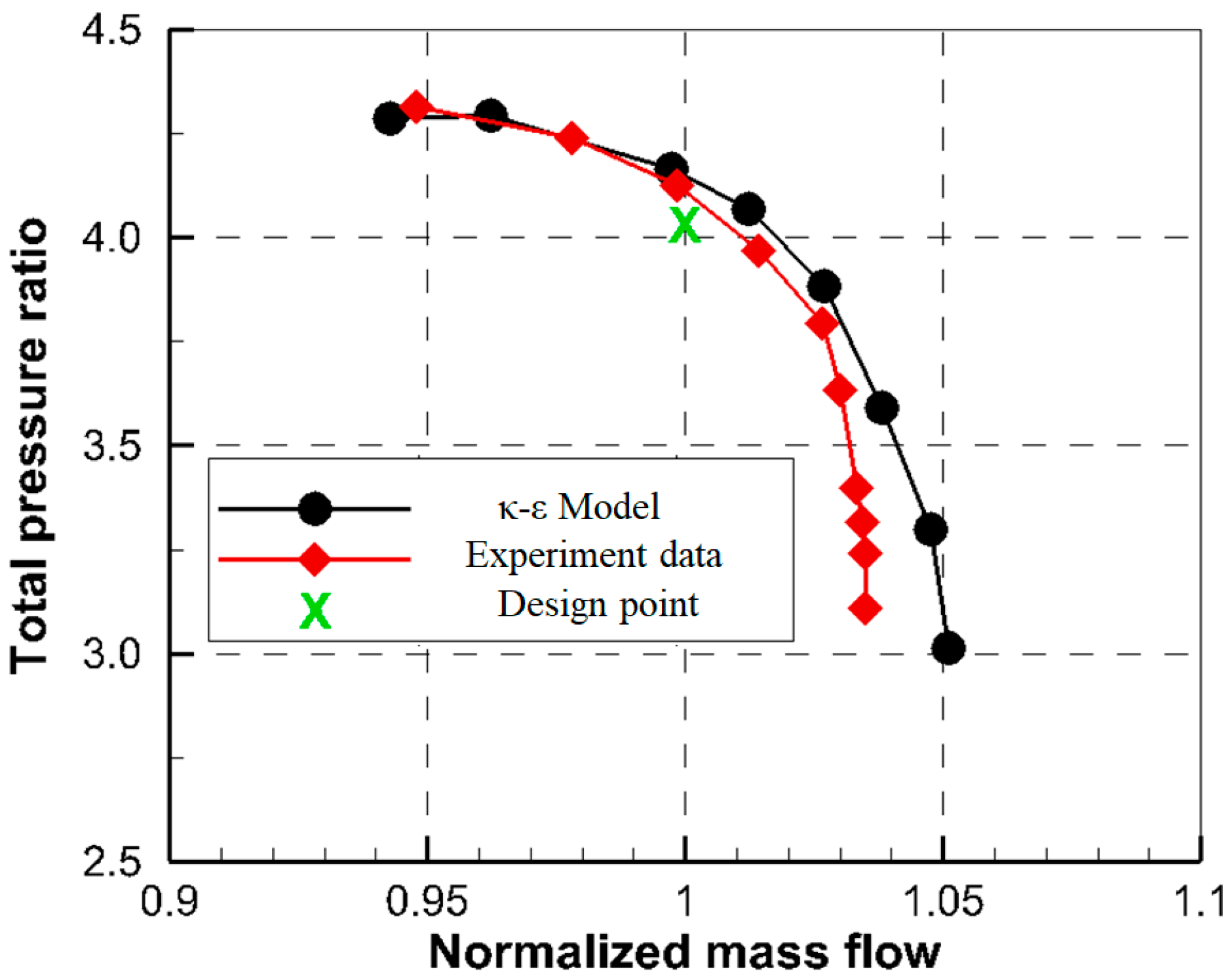

2.4. Calculation Model

2.4.1. Configuration of the Compressor

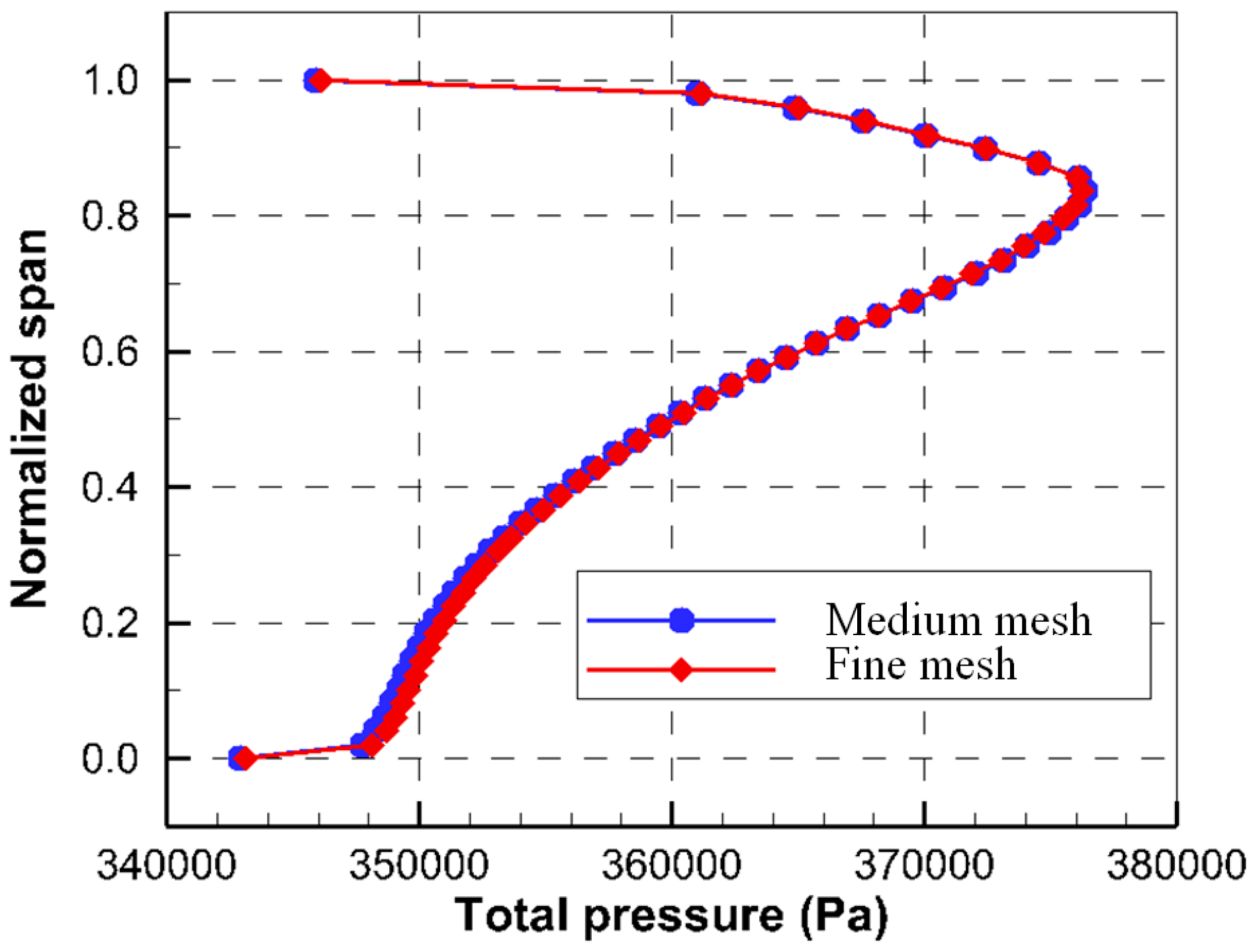

2.4.2. Turbulence Model and Boundary Conditions

3. Results and Discussions

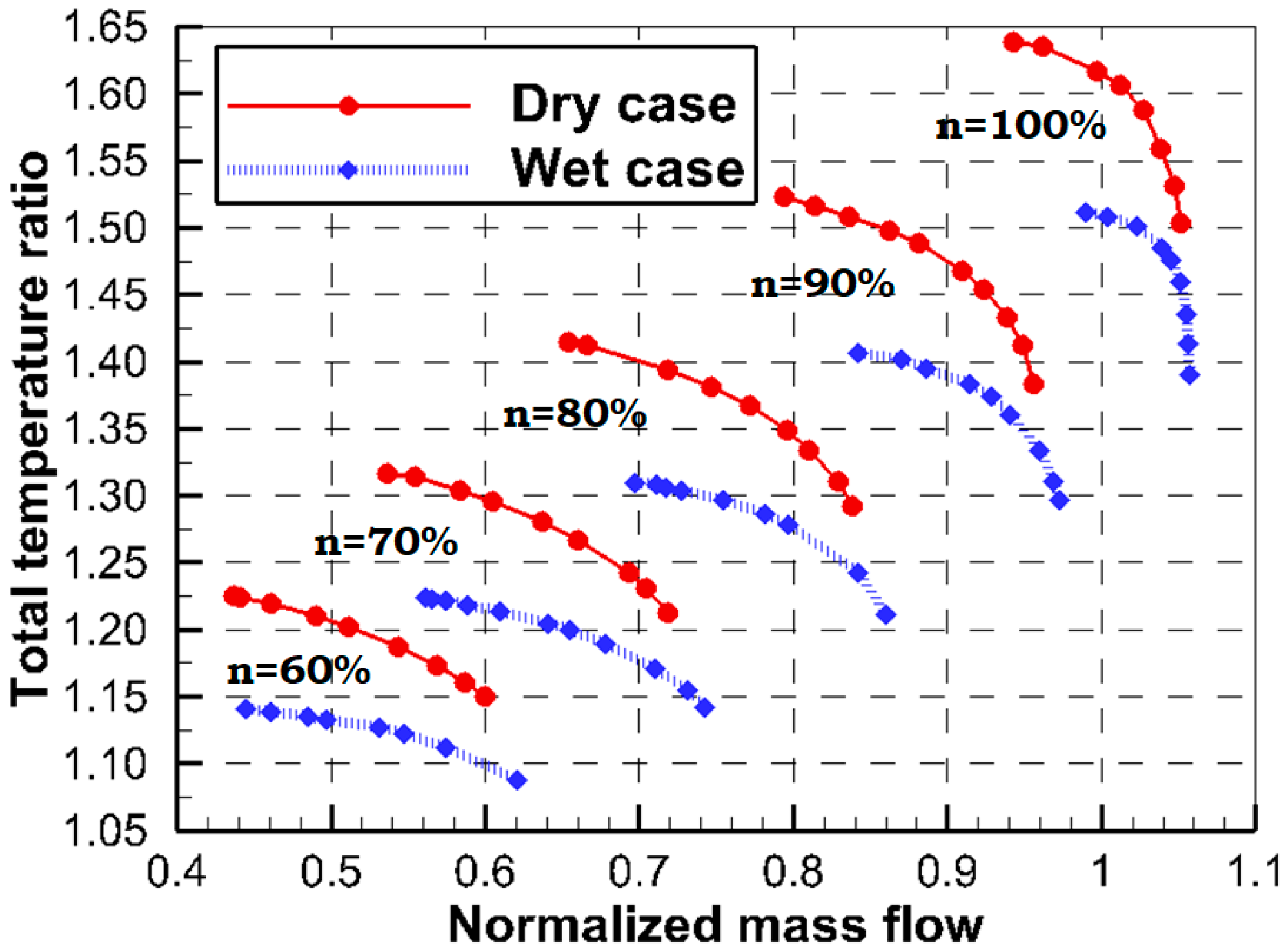

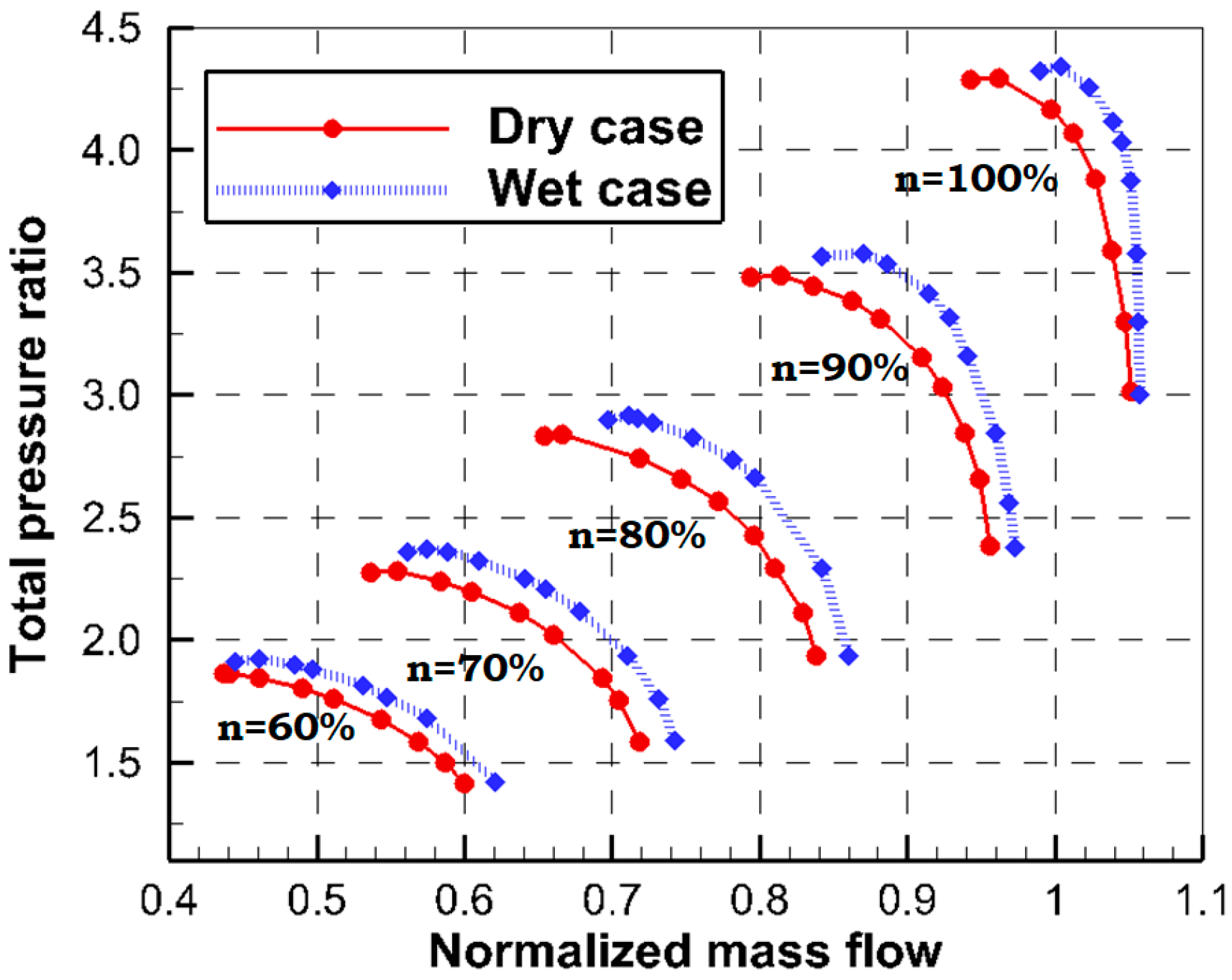

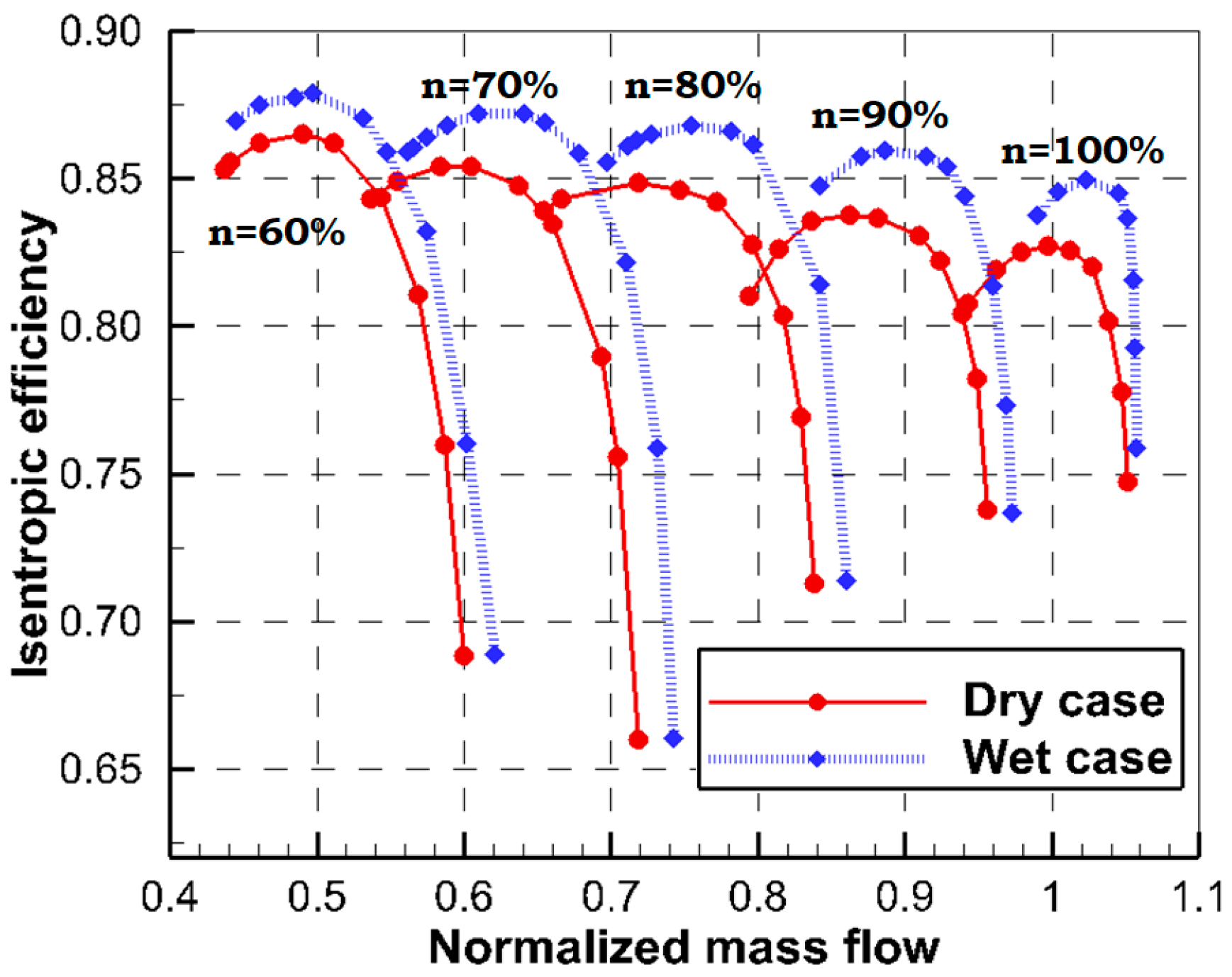

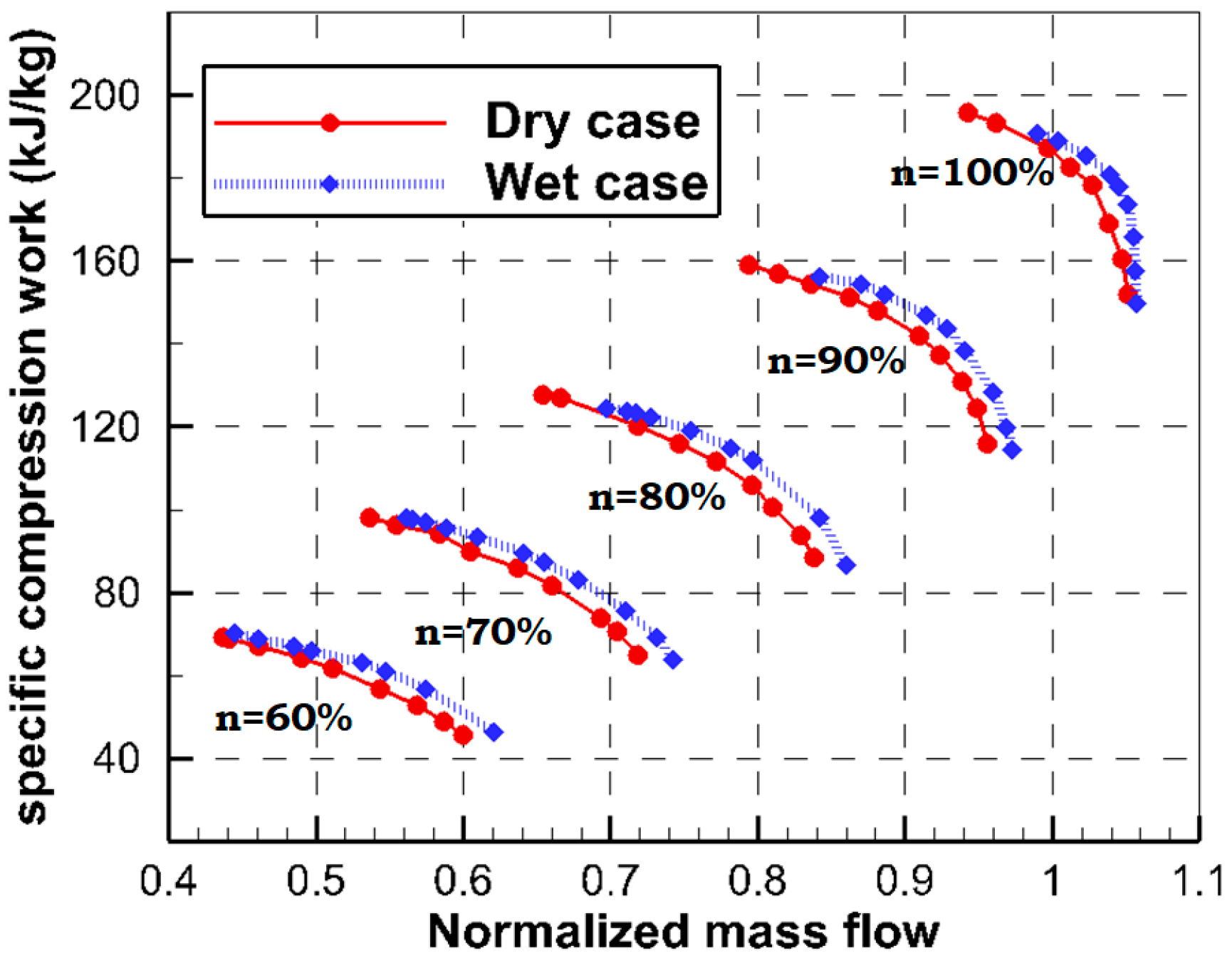

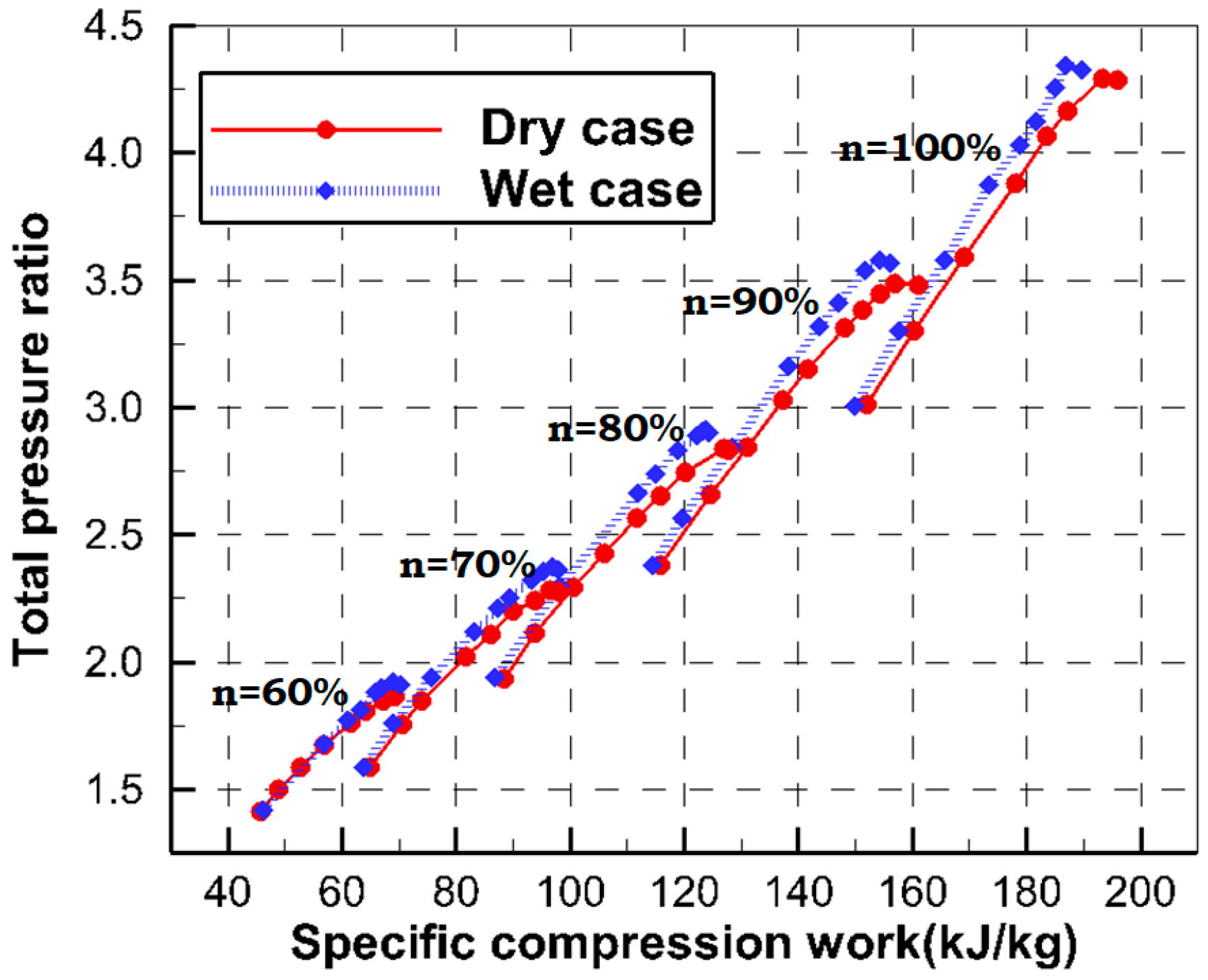

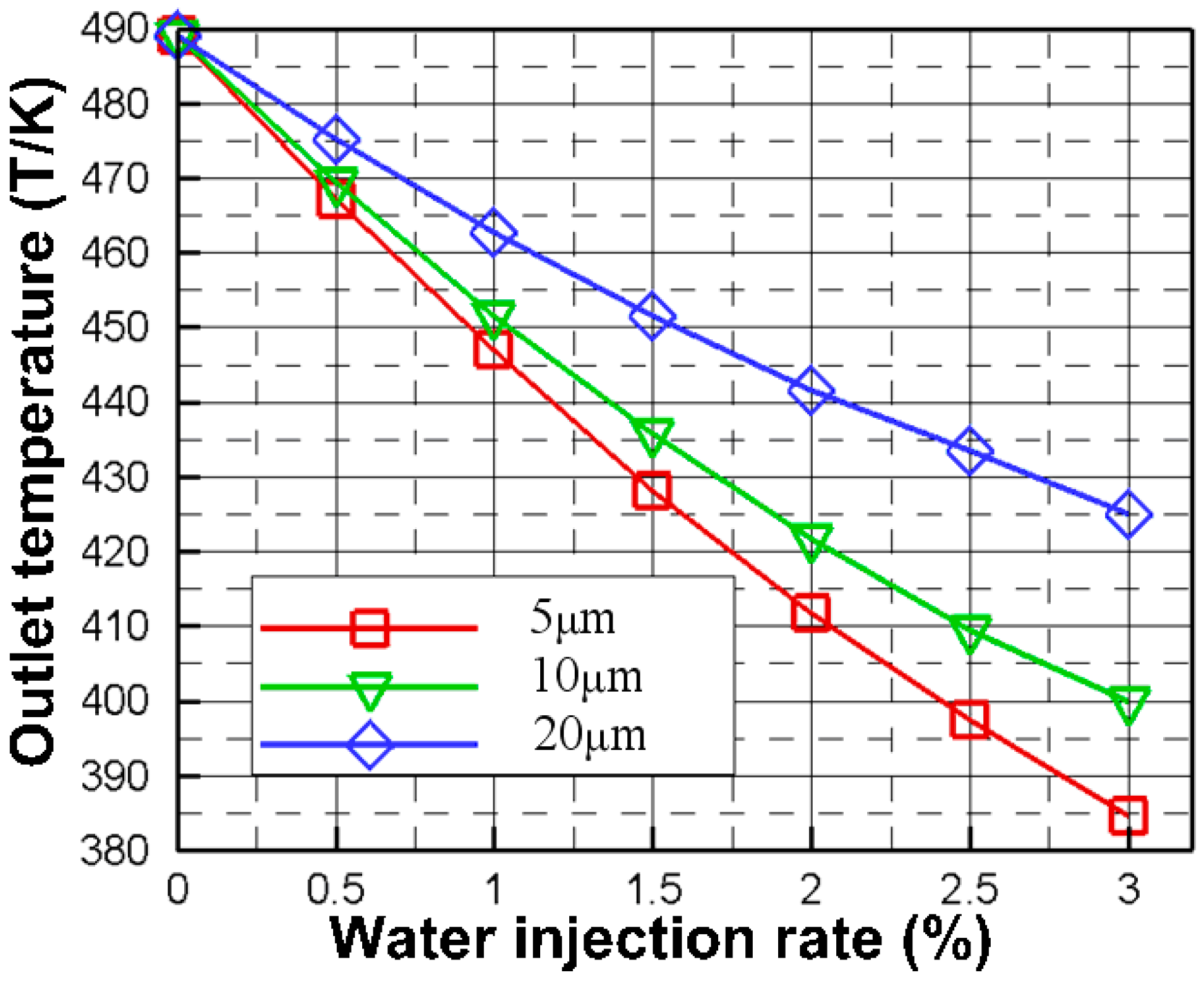

3.1. The Influence of Wet Compression Under the Different Working Condition

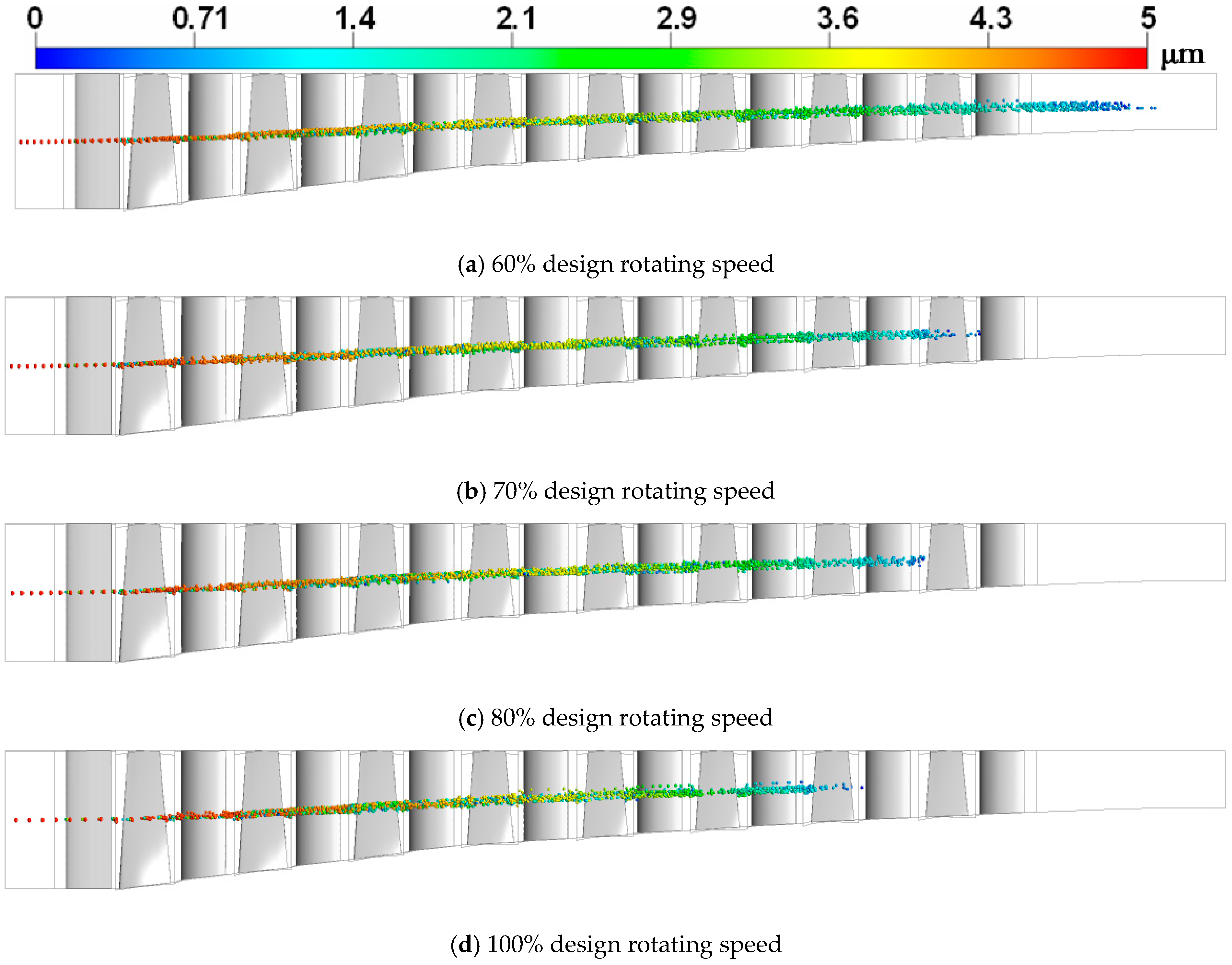

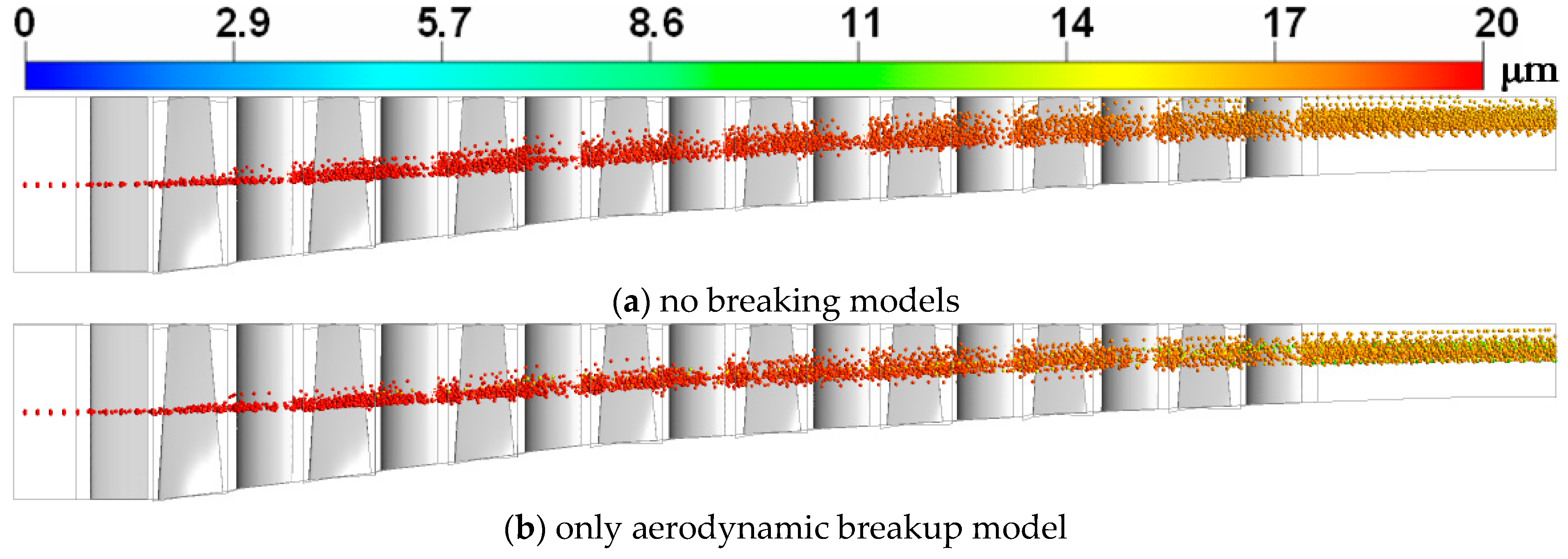

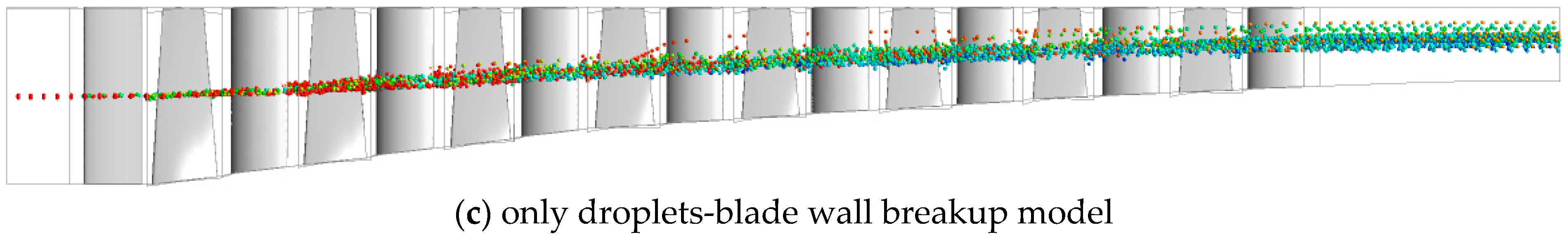

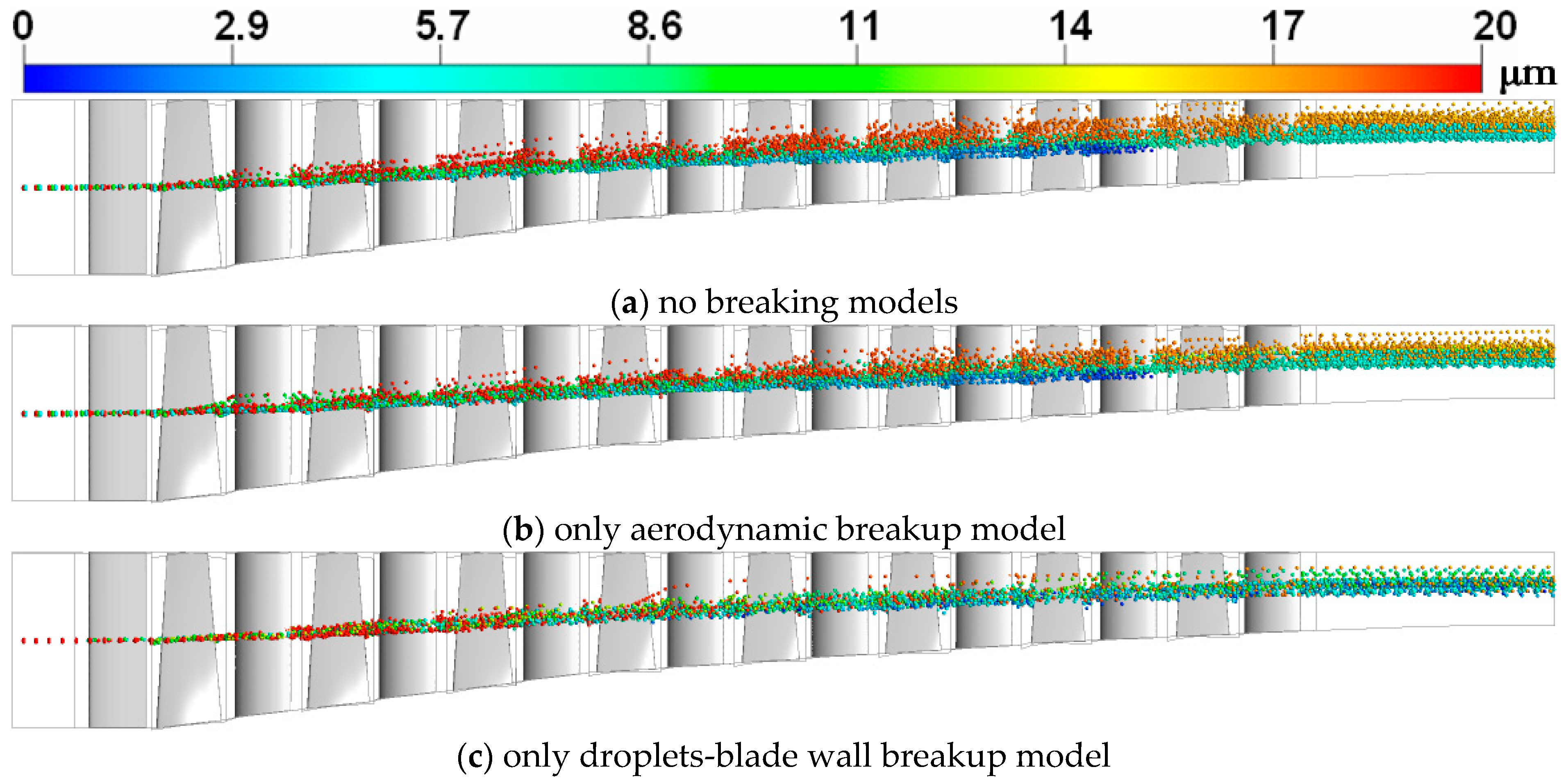

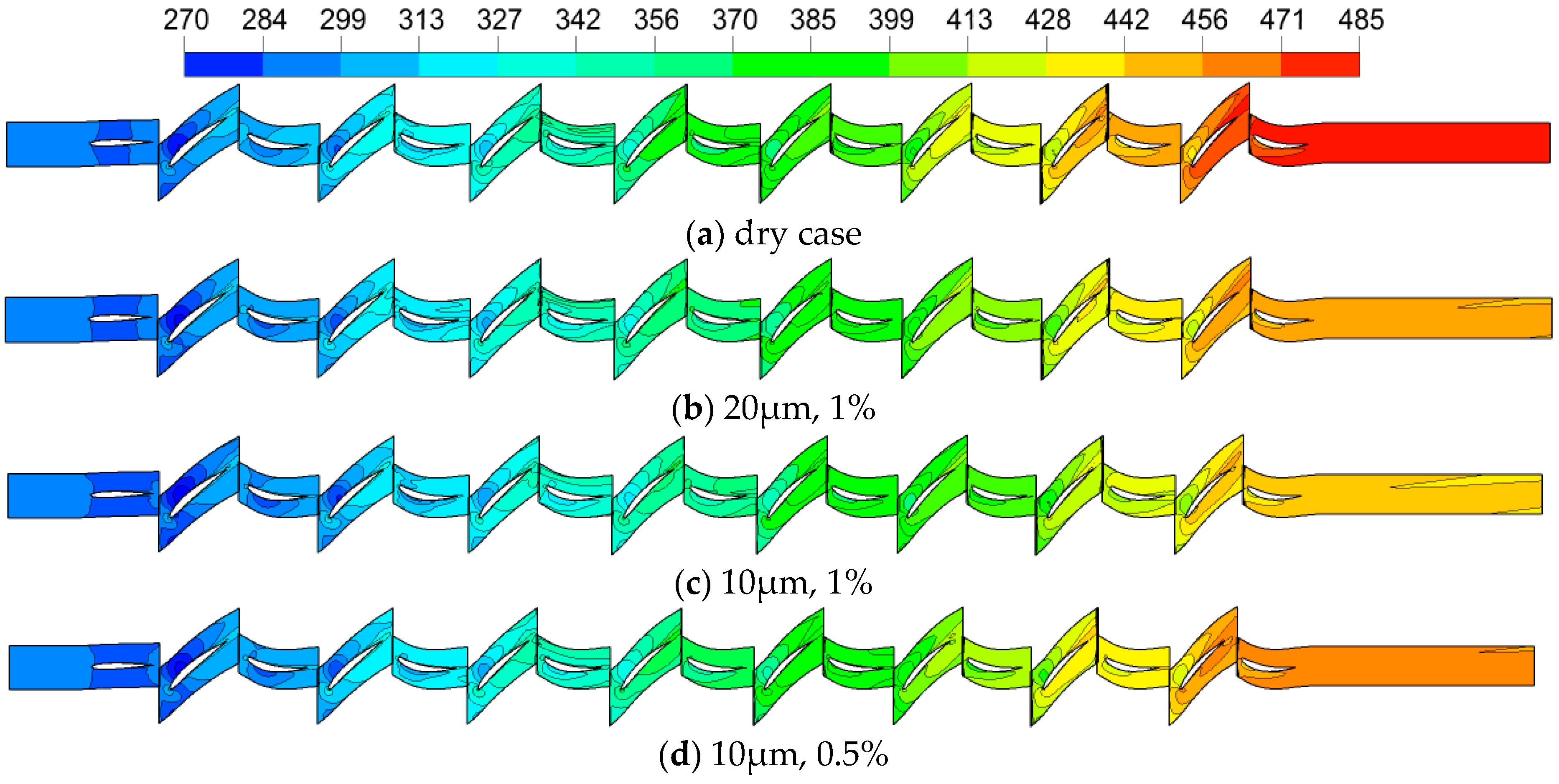

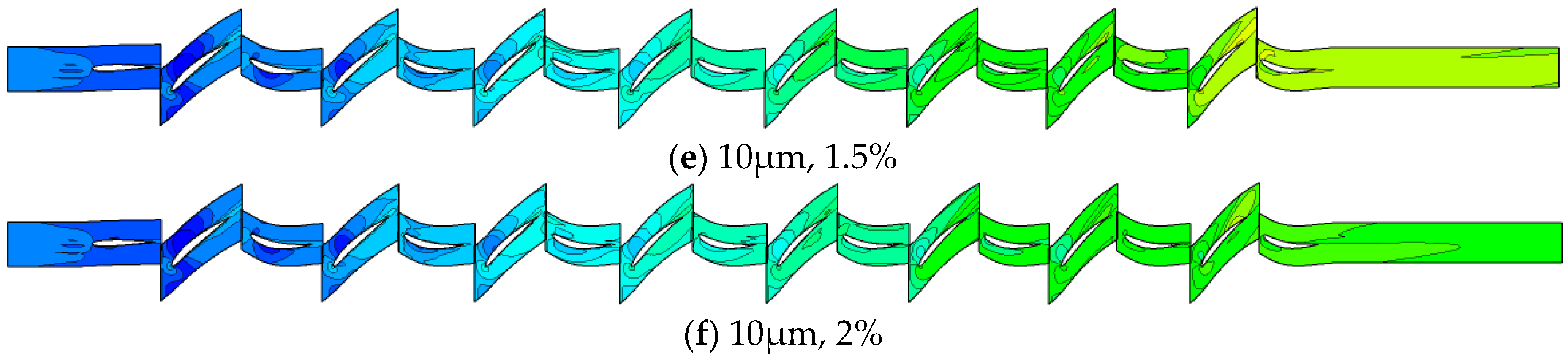

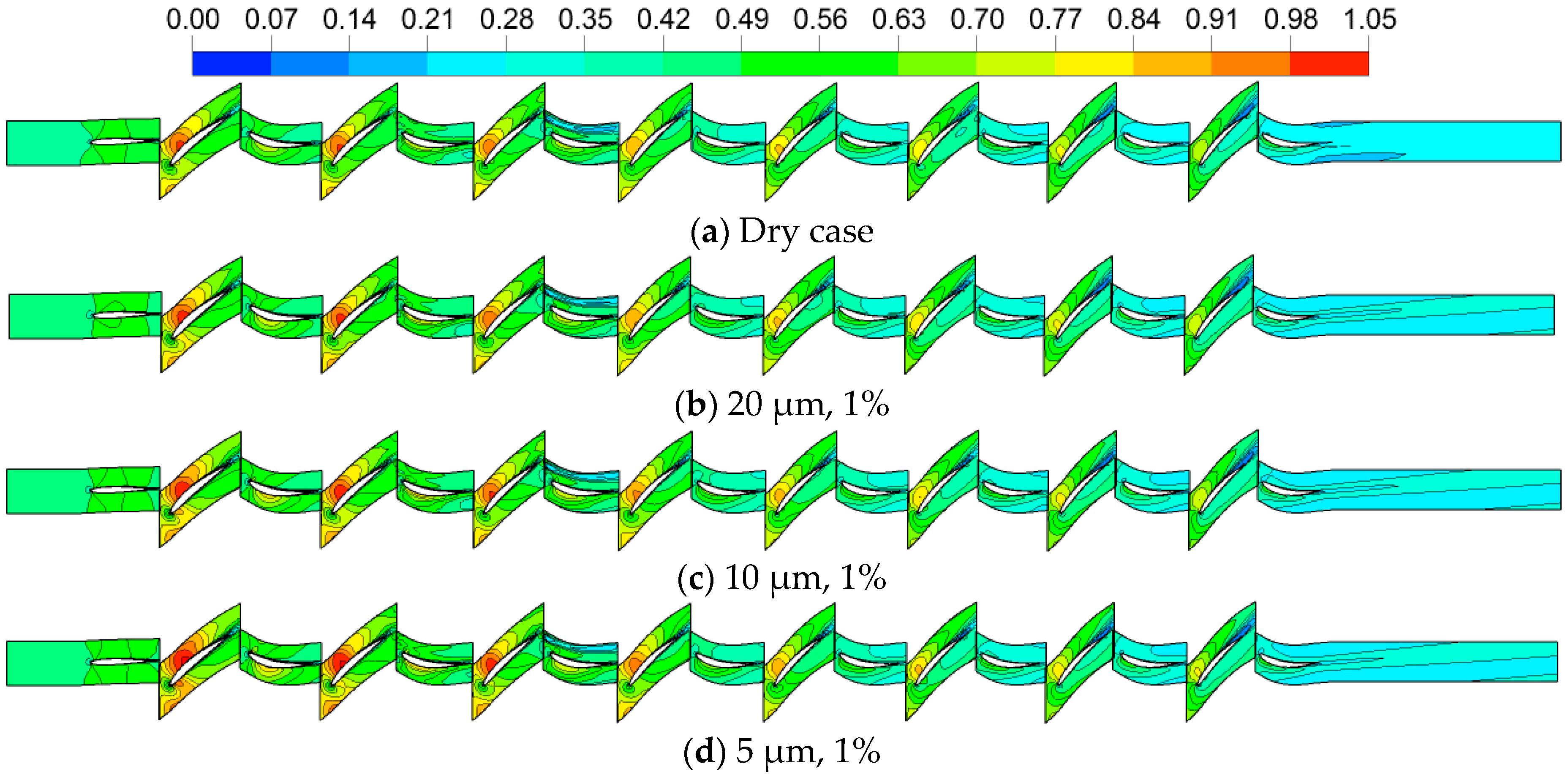

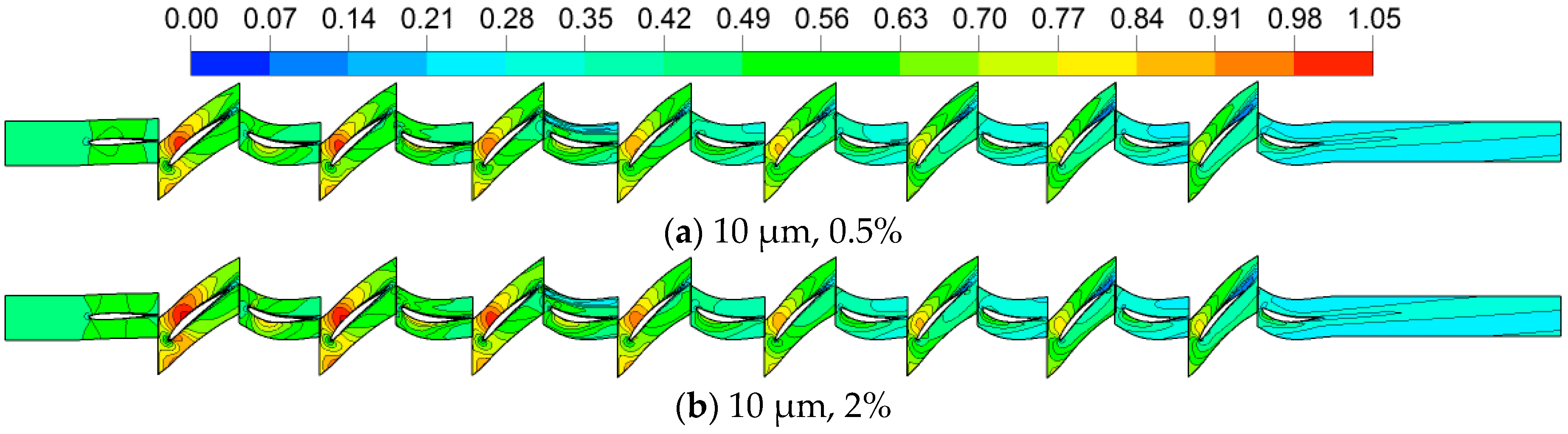

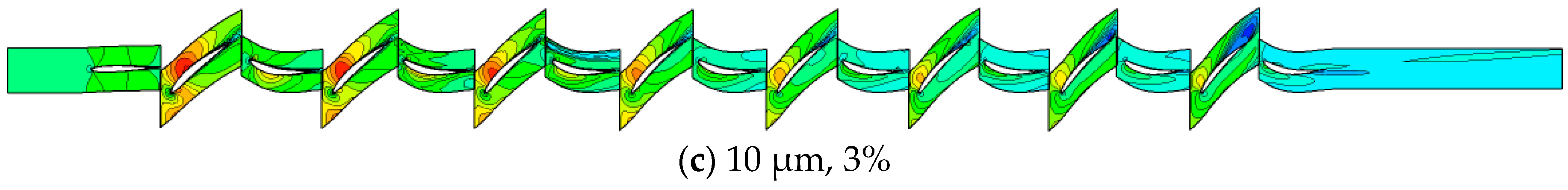

3.2. Movement and Evaporation of Water Droplets in the Multistage Axial Compressor

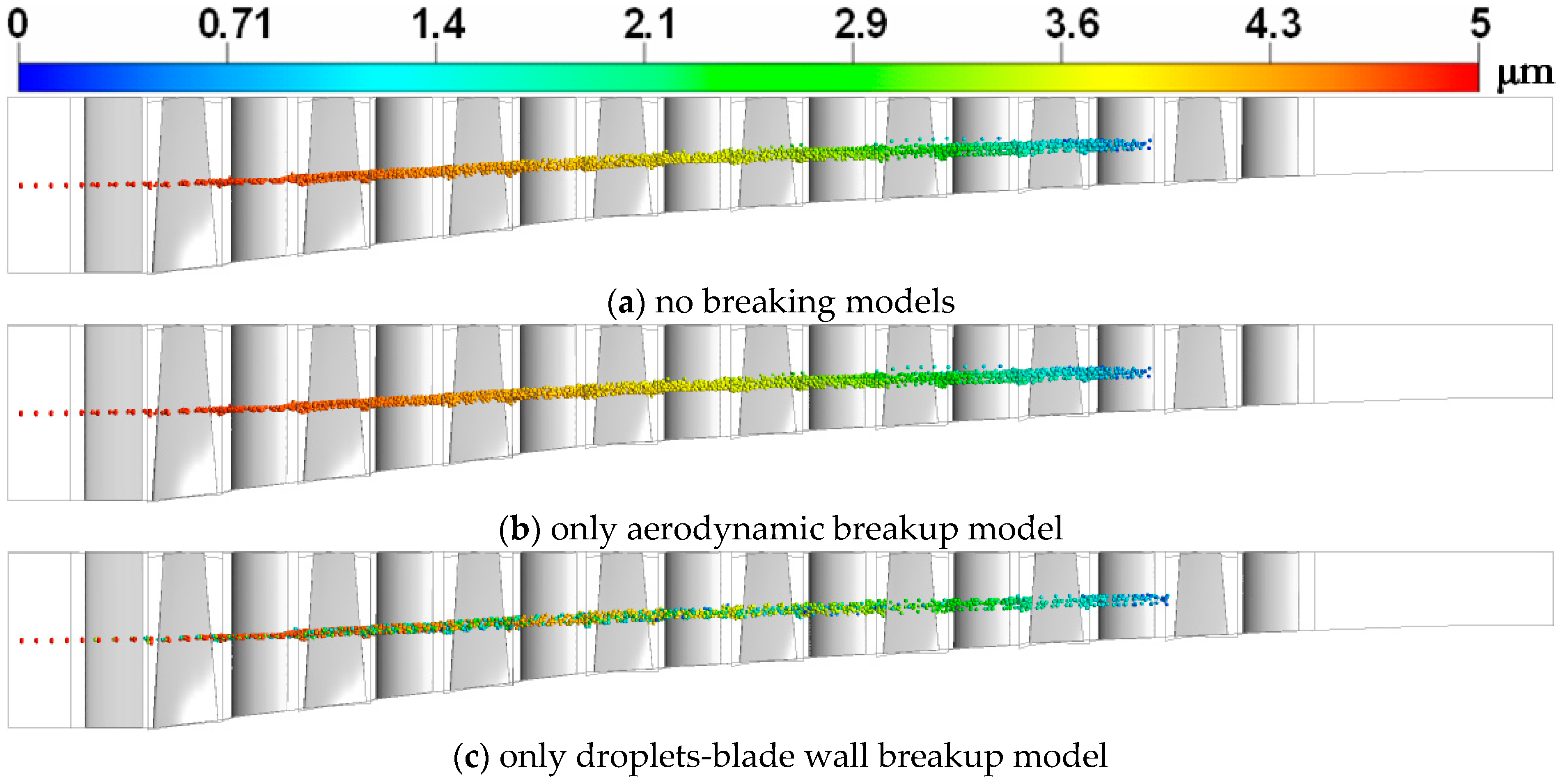

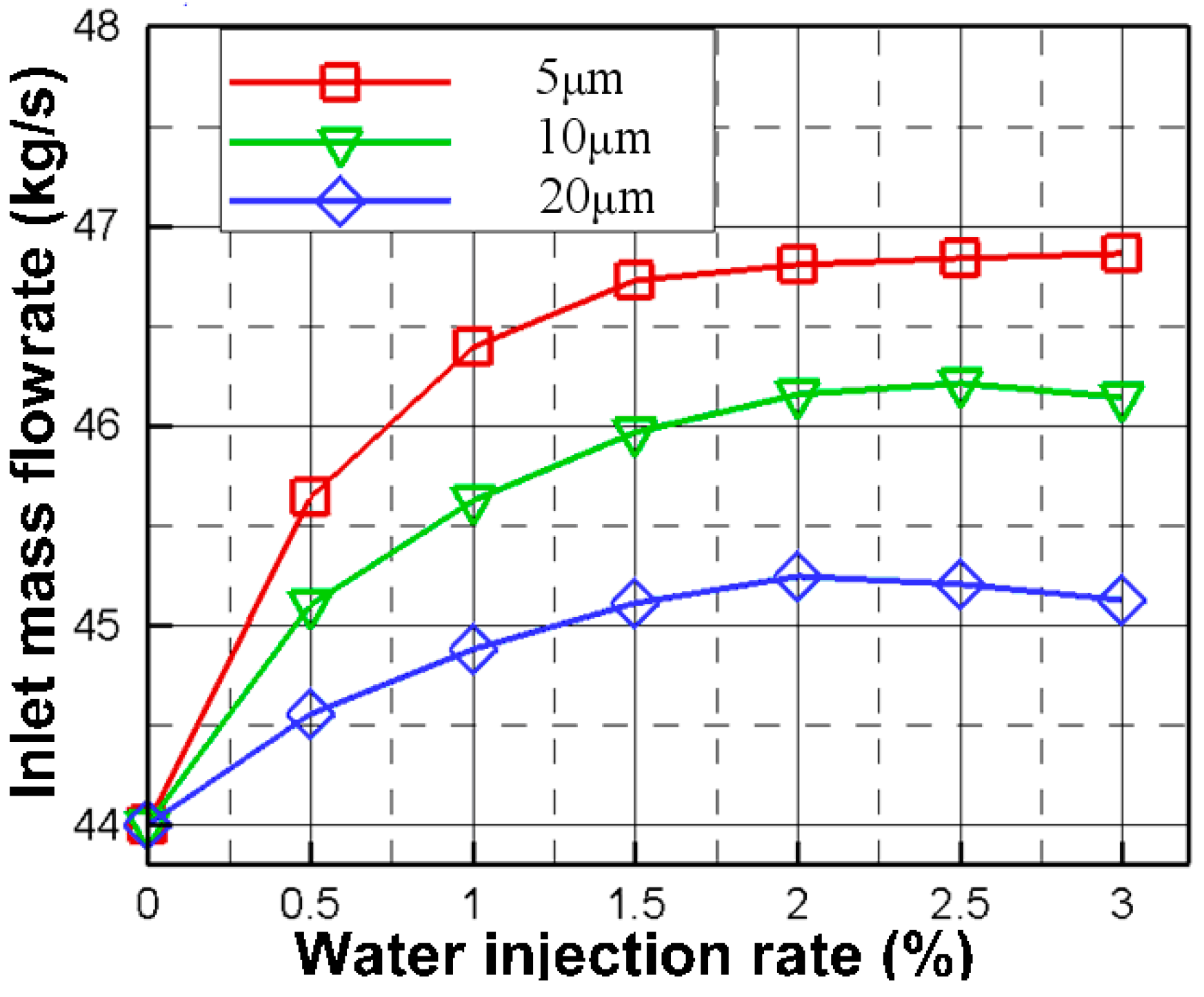

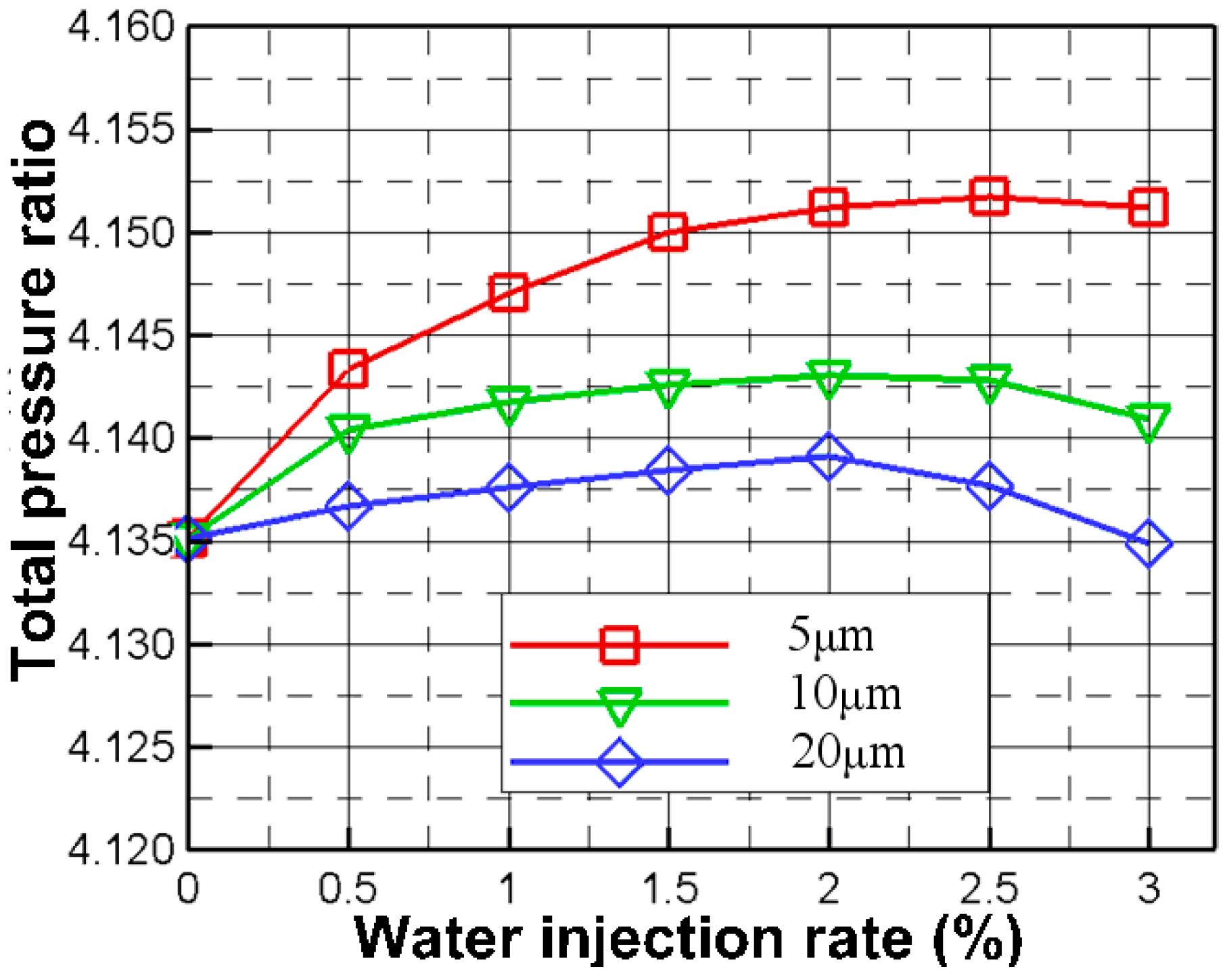

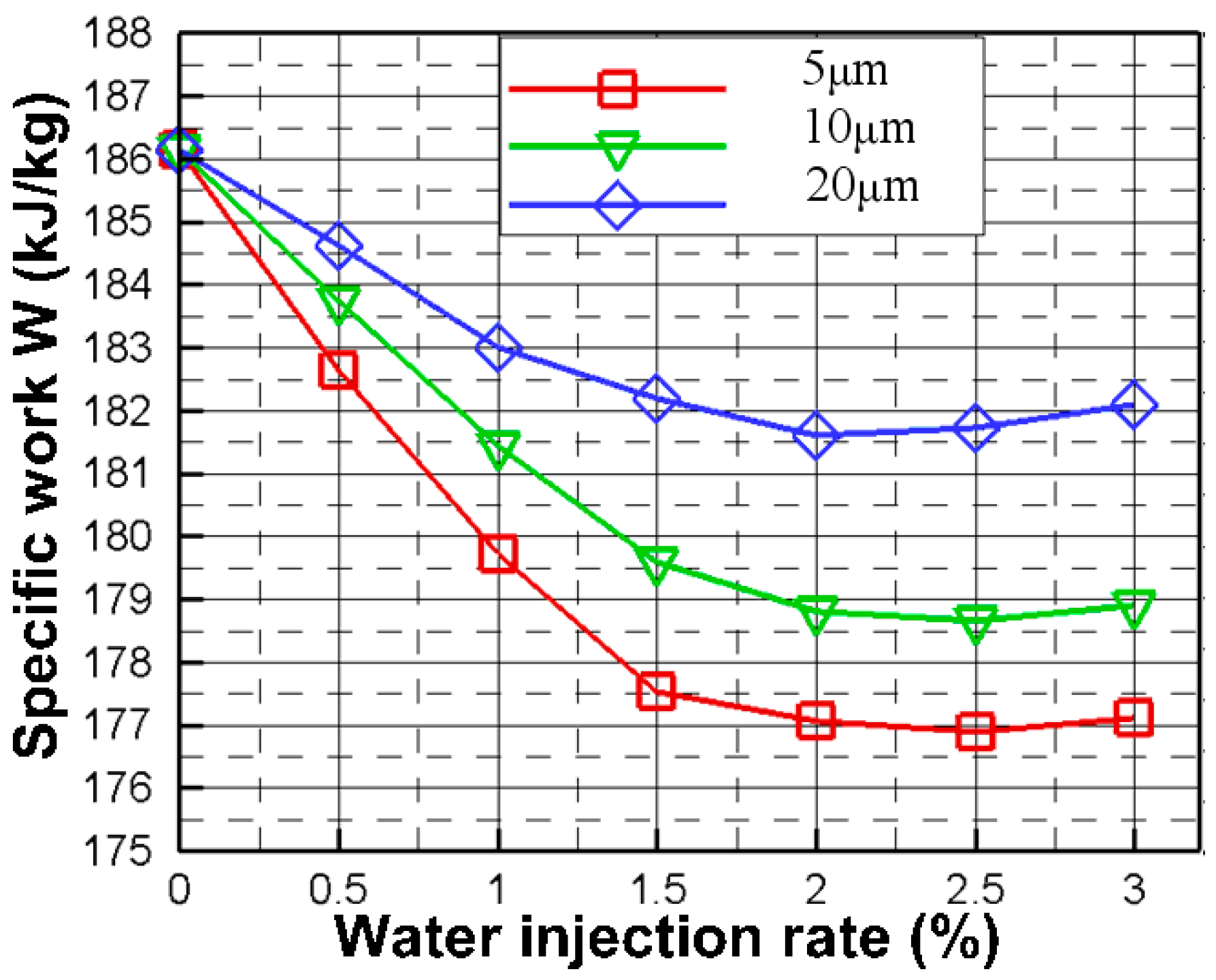

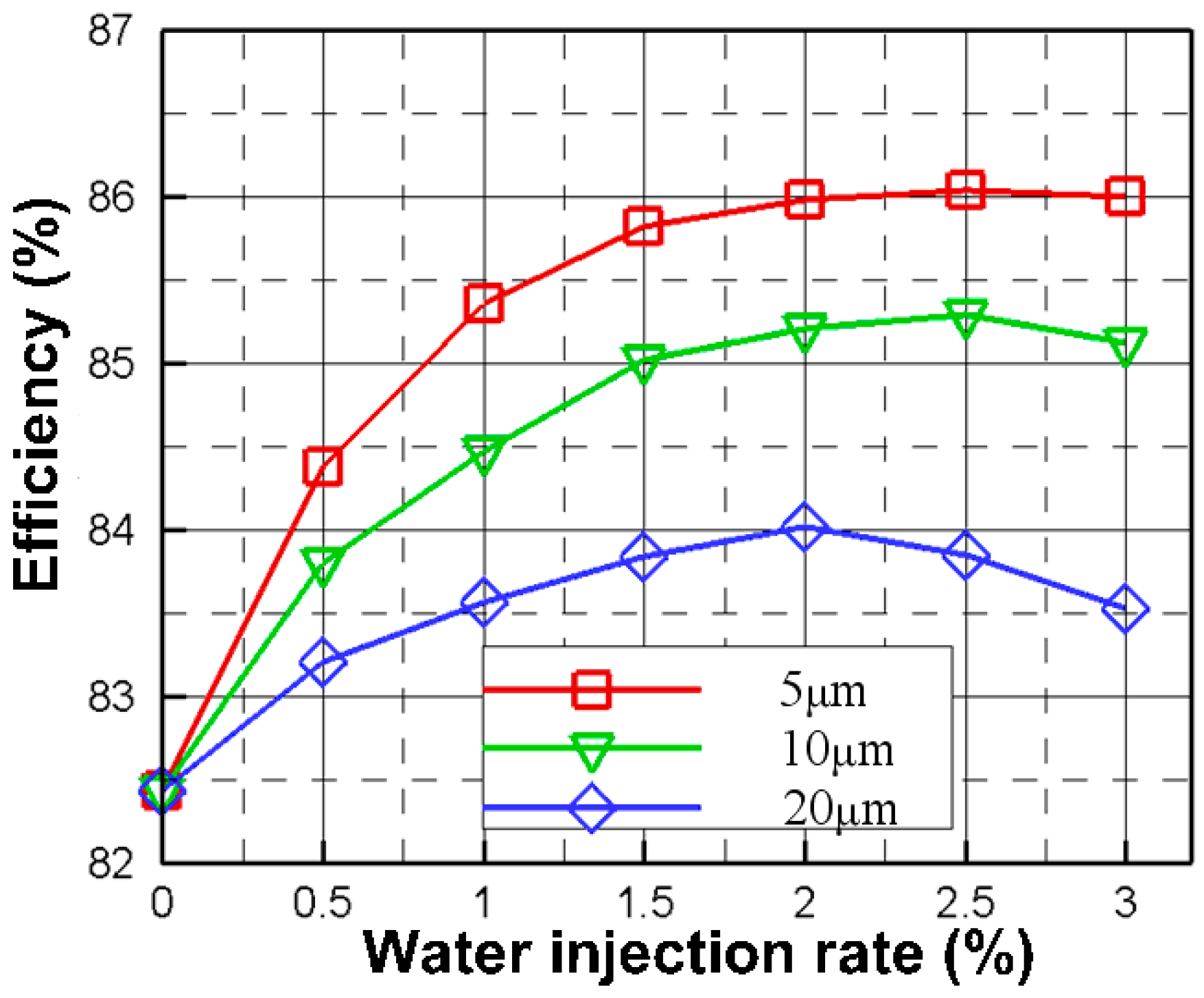

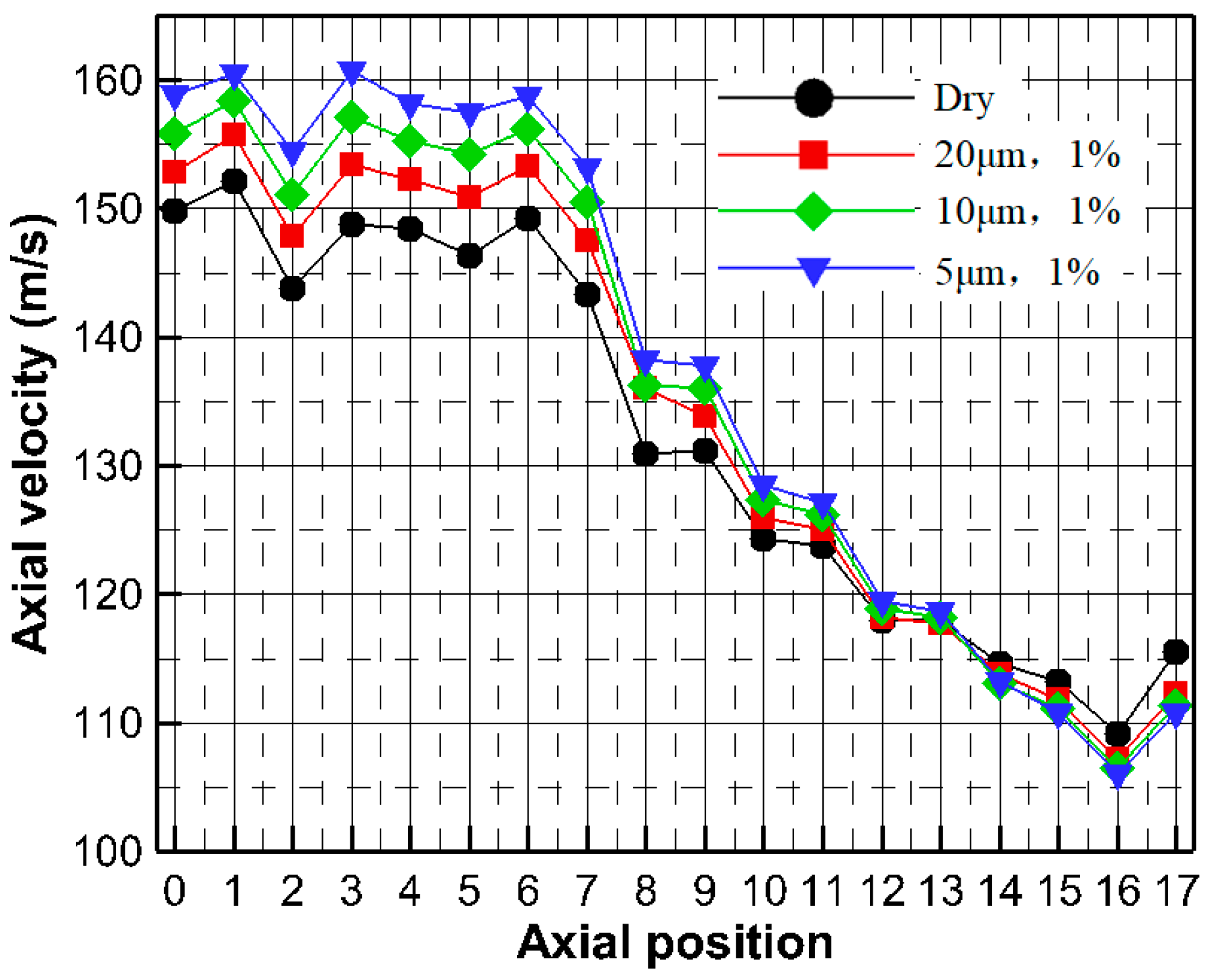

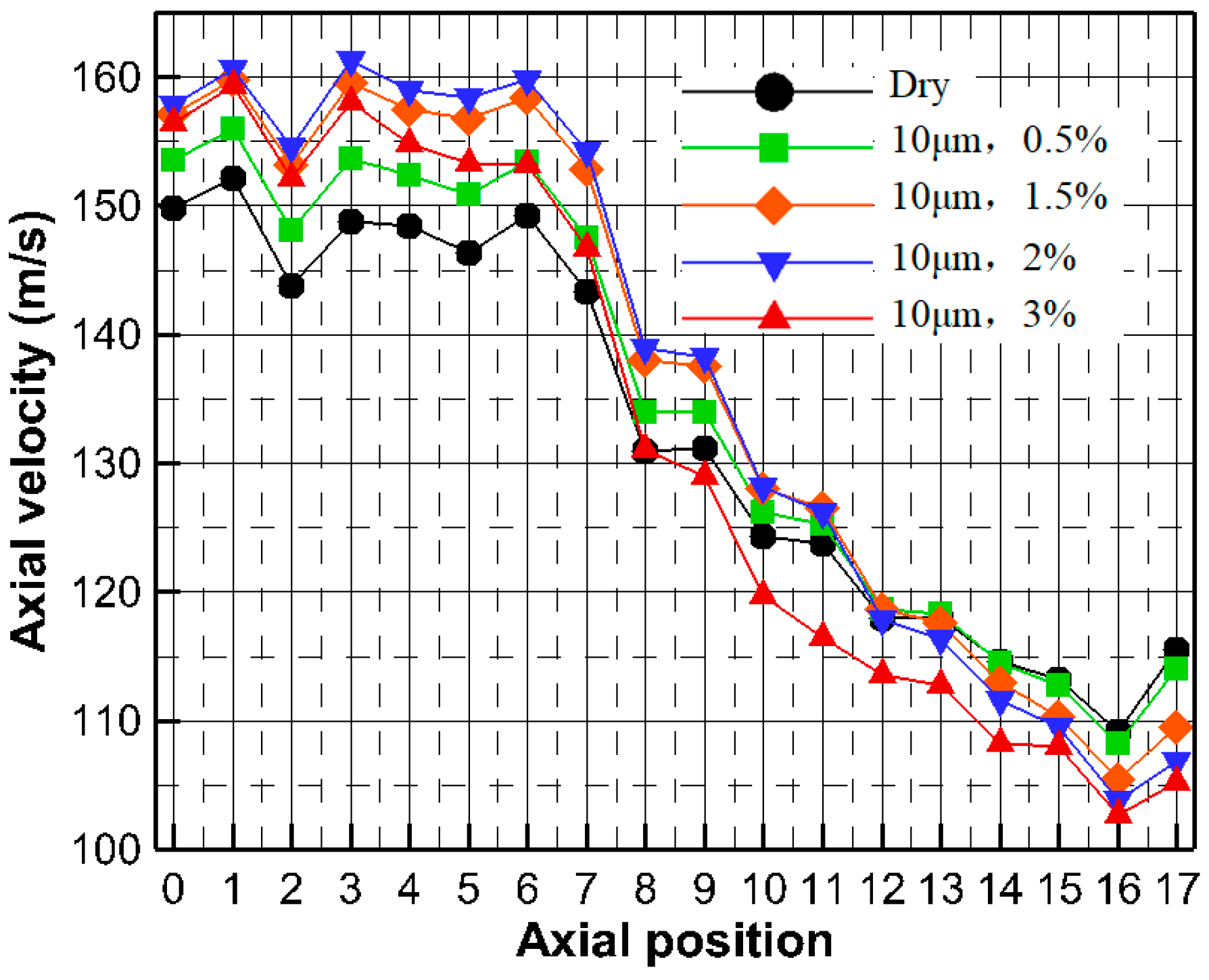

3.3. Compressor Performance Analysis at the Design Operating Condition with Different Wet Compression Cases

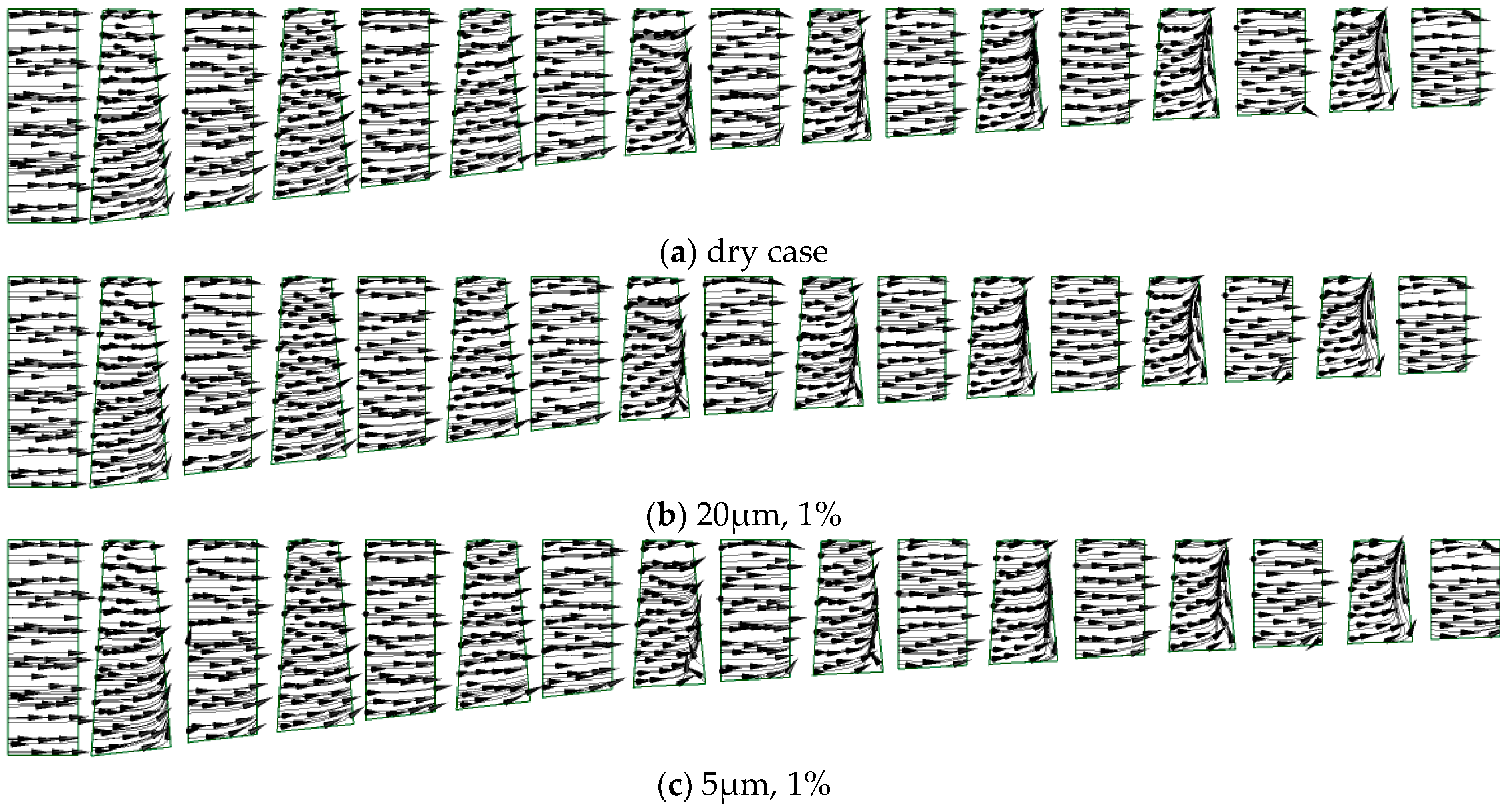

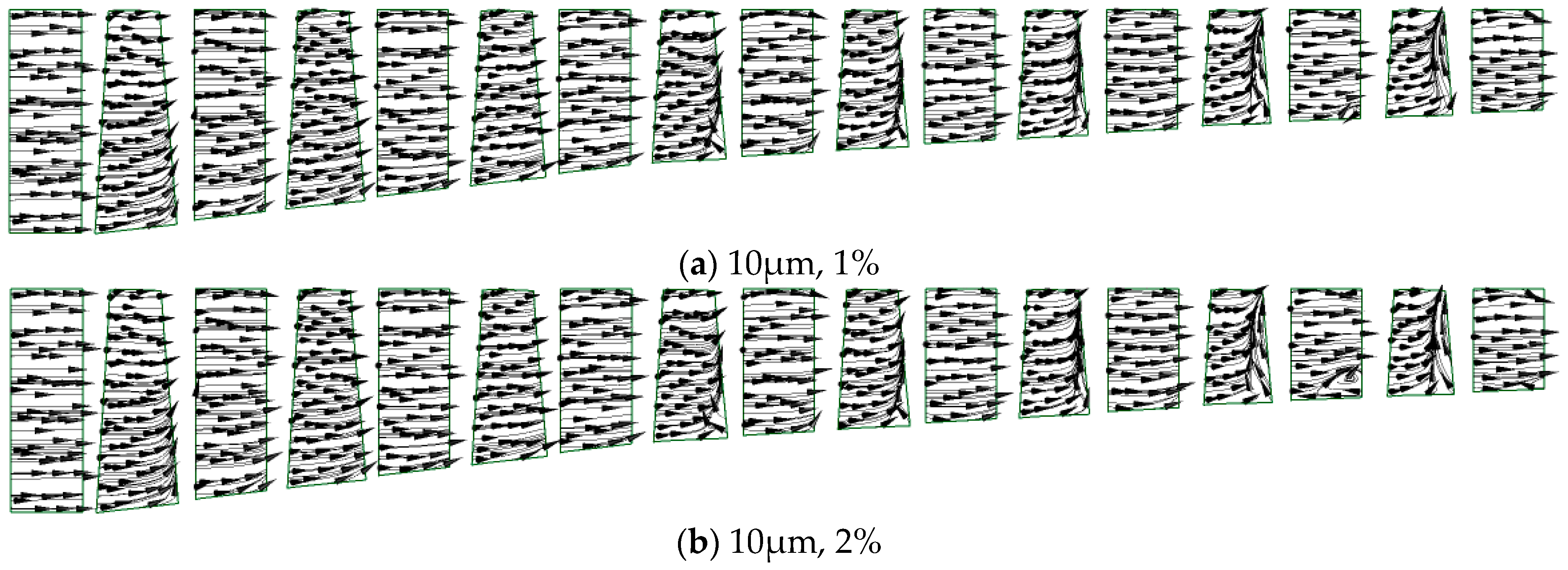

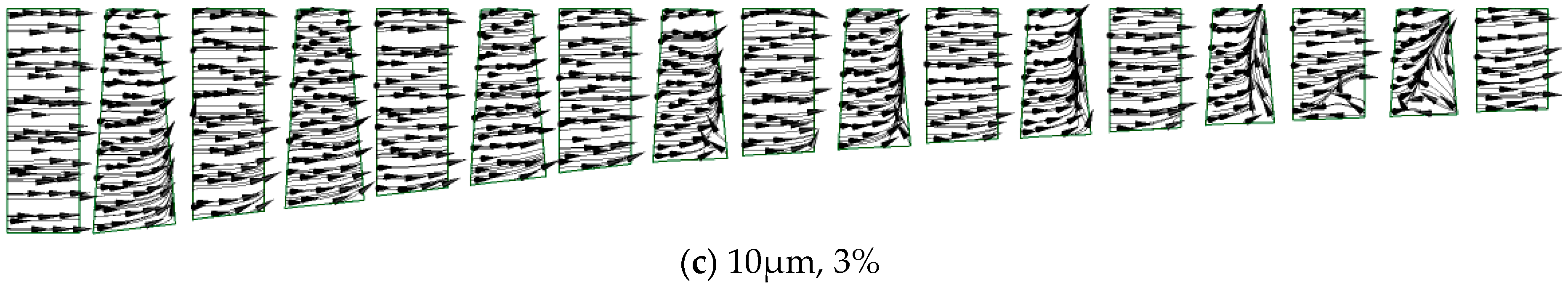

3.4. Analysis of Compressor Flow Distribution and Streamline at the Design Operating Condition with Different Wet Compression Cases

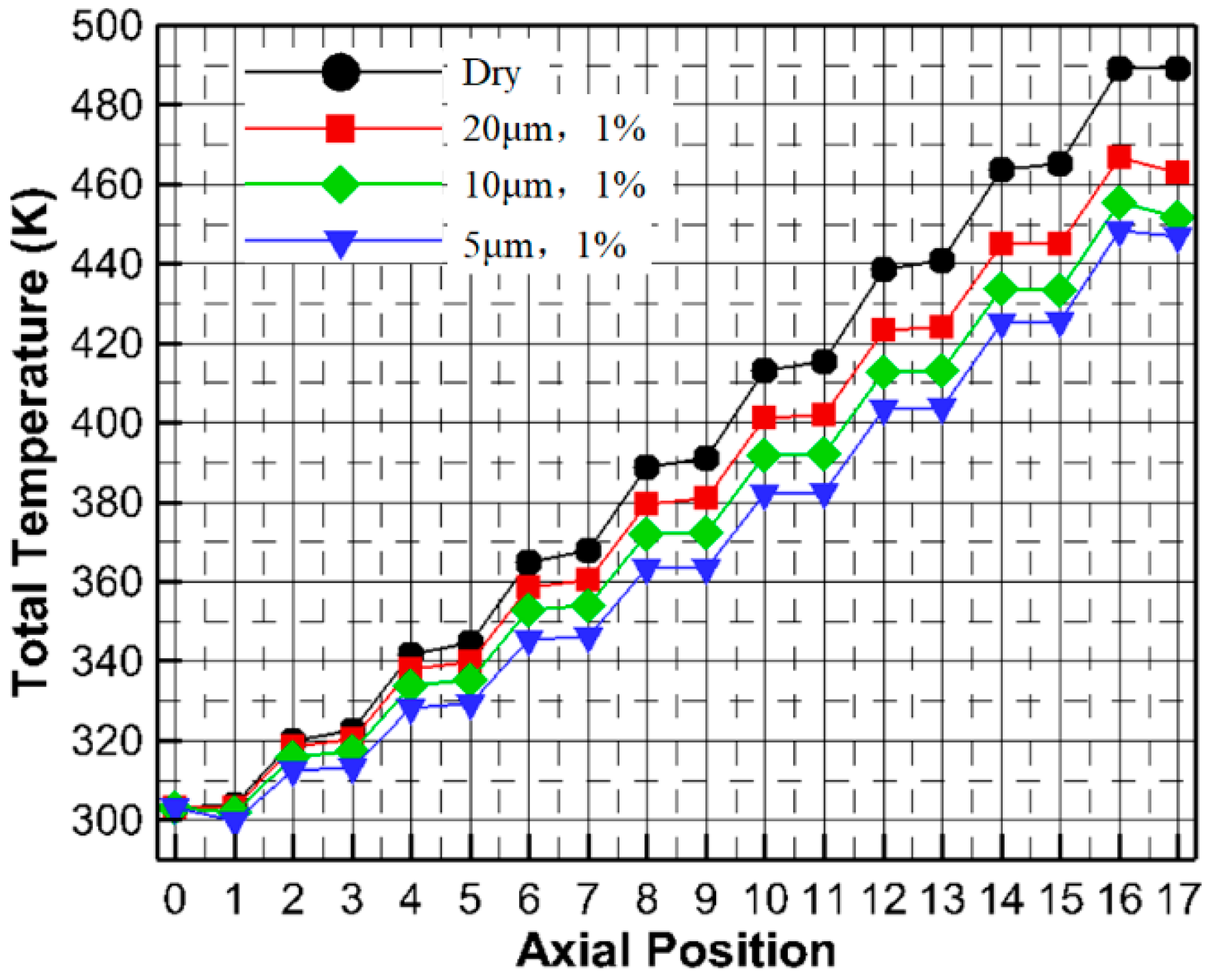

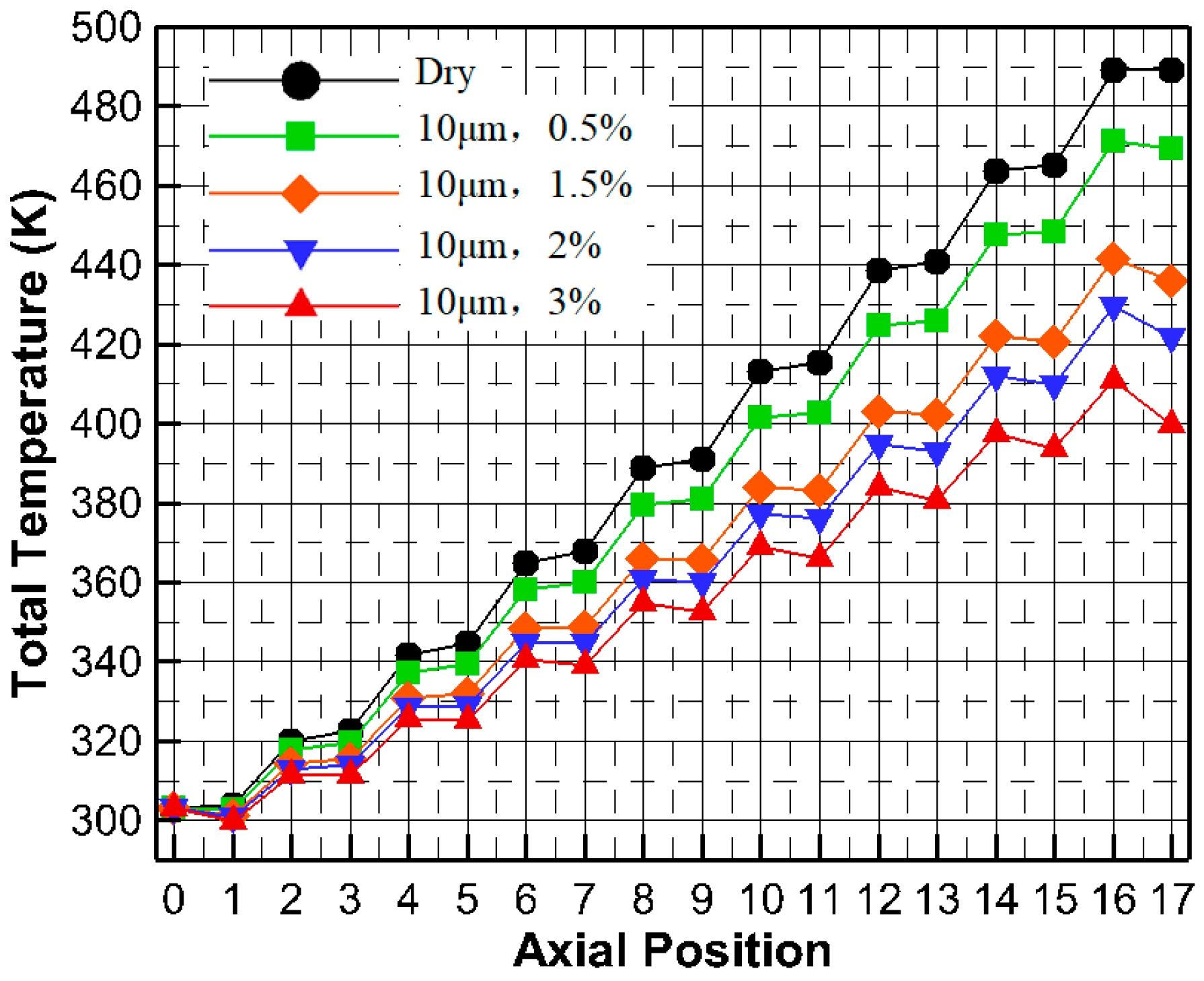

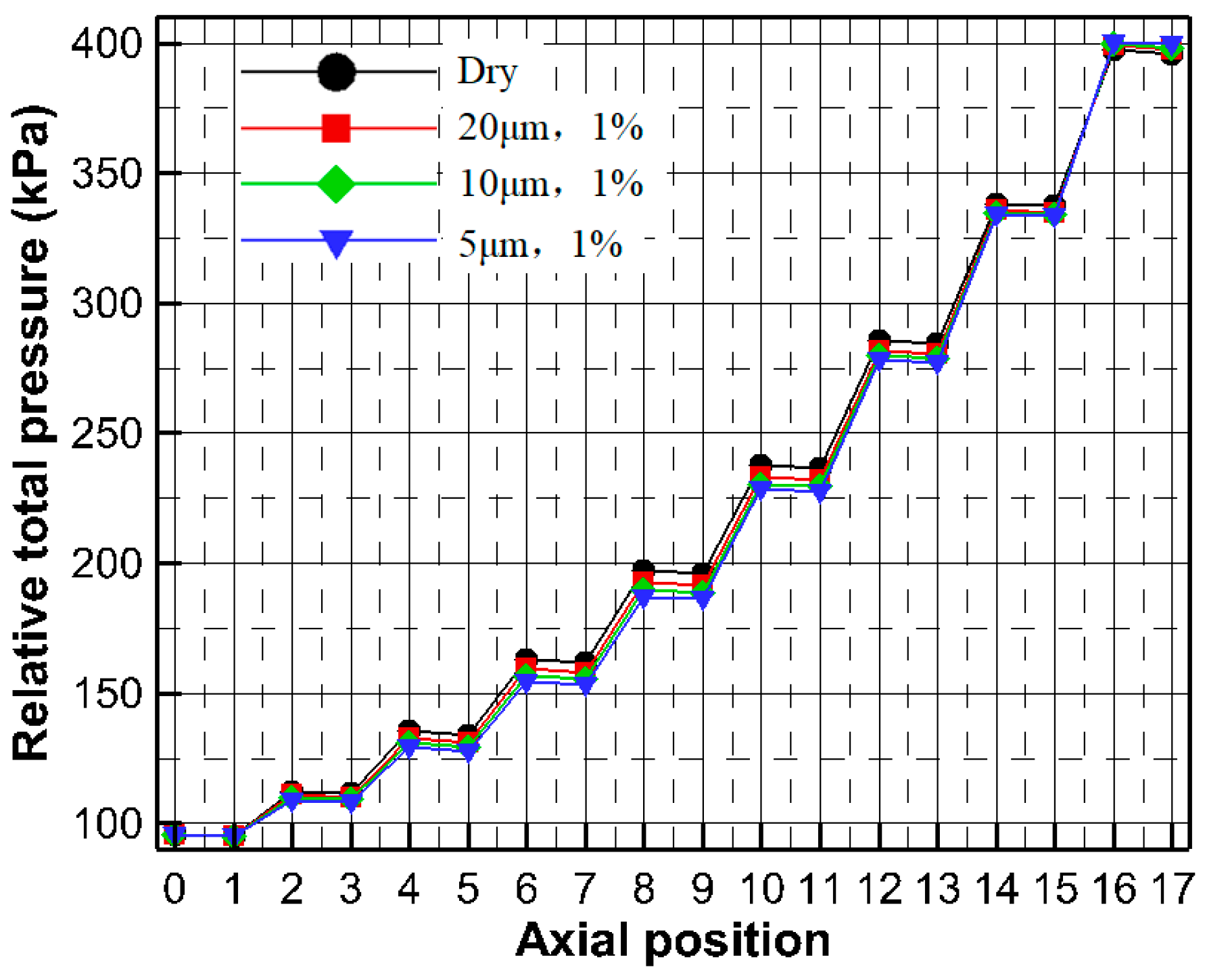

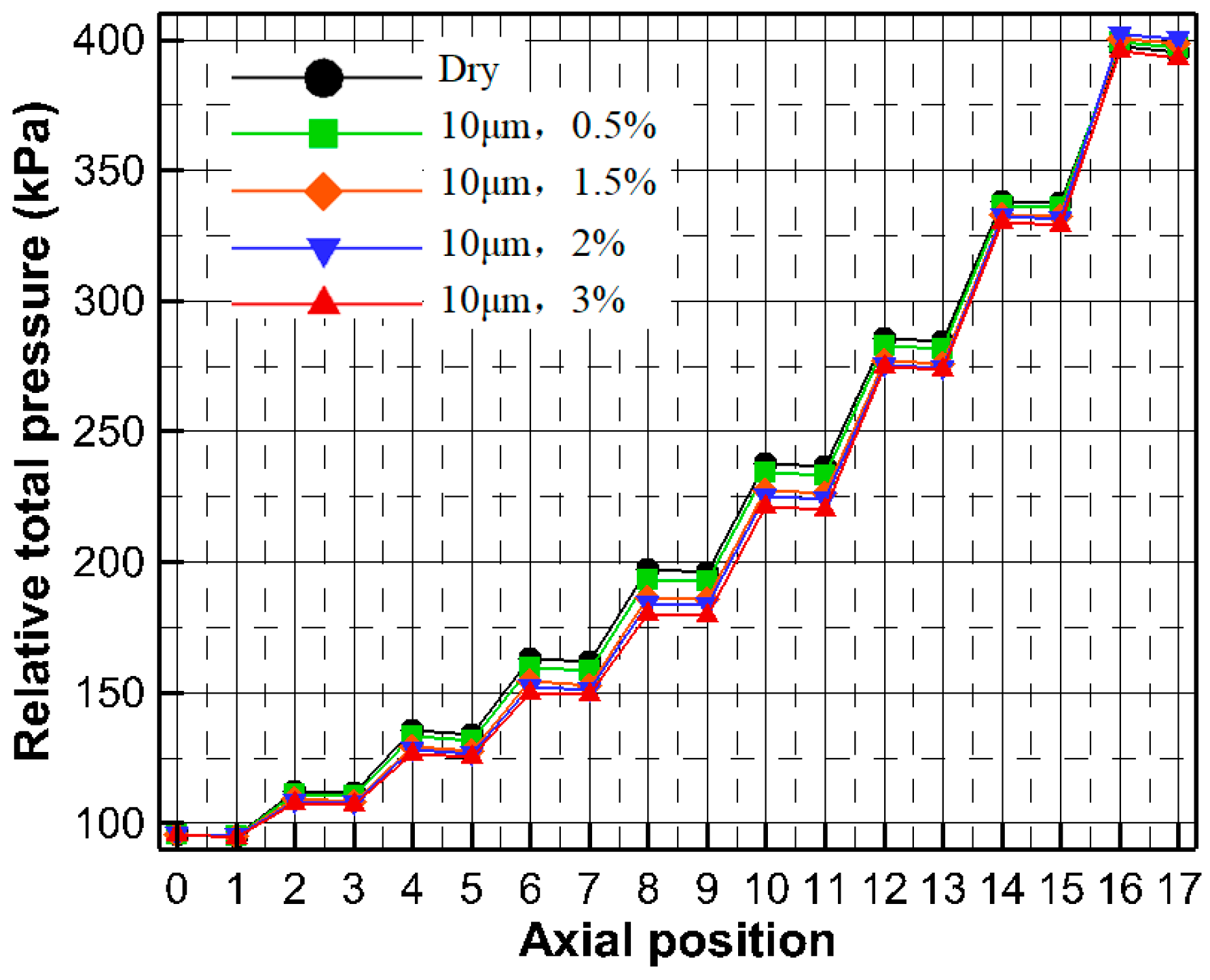

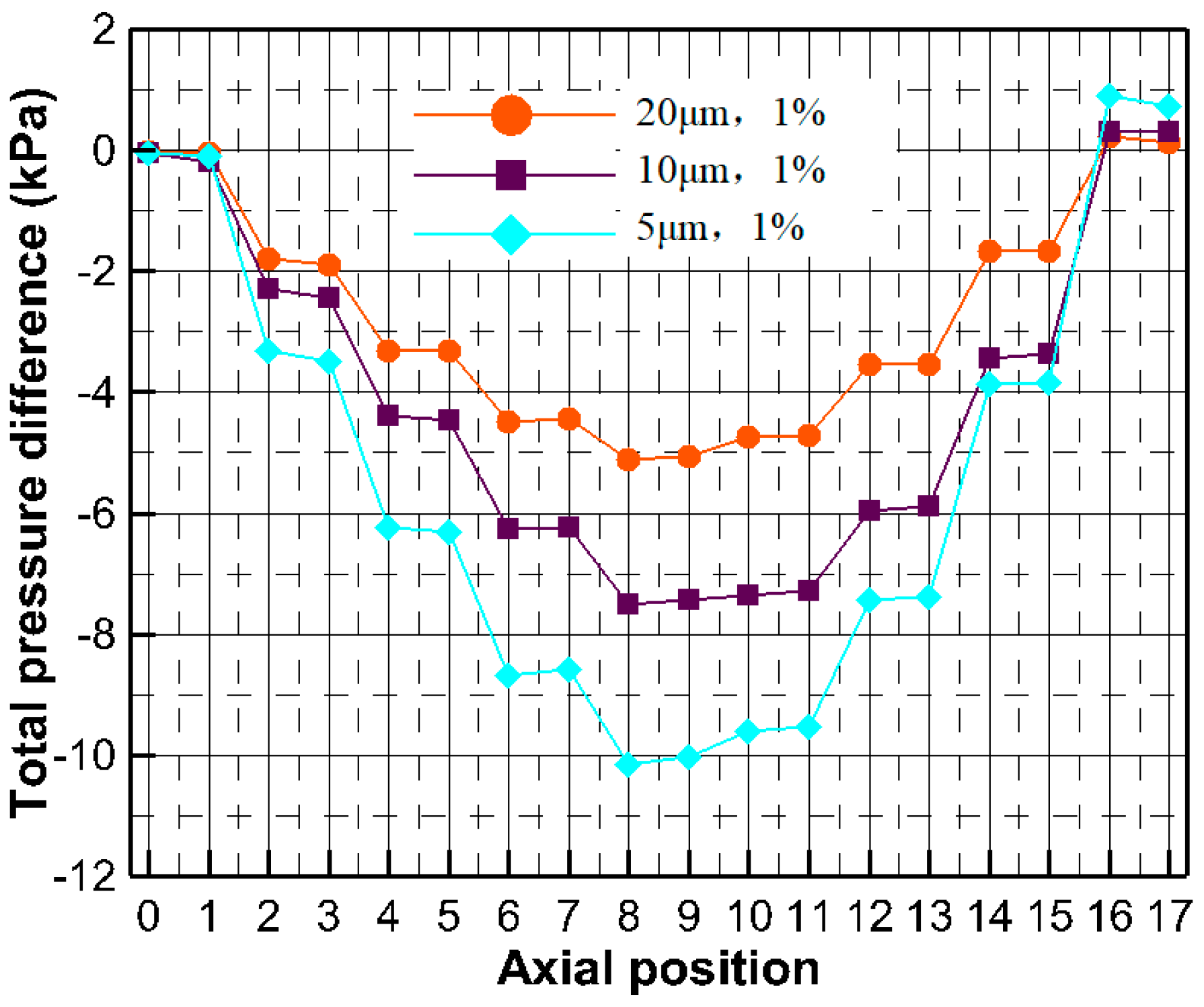

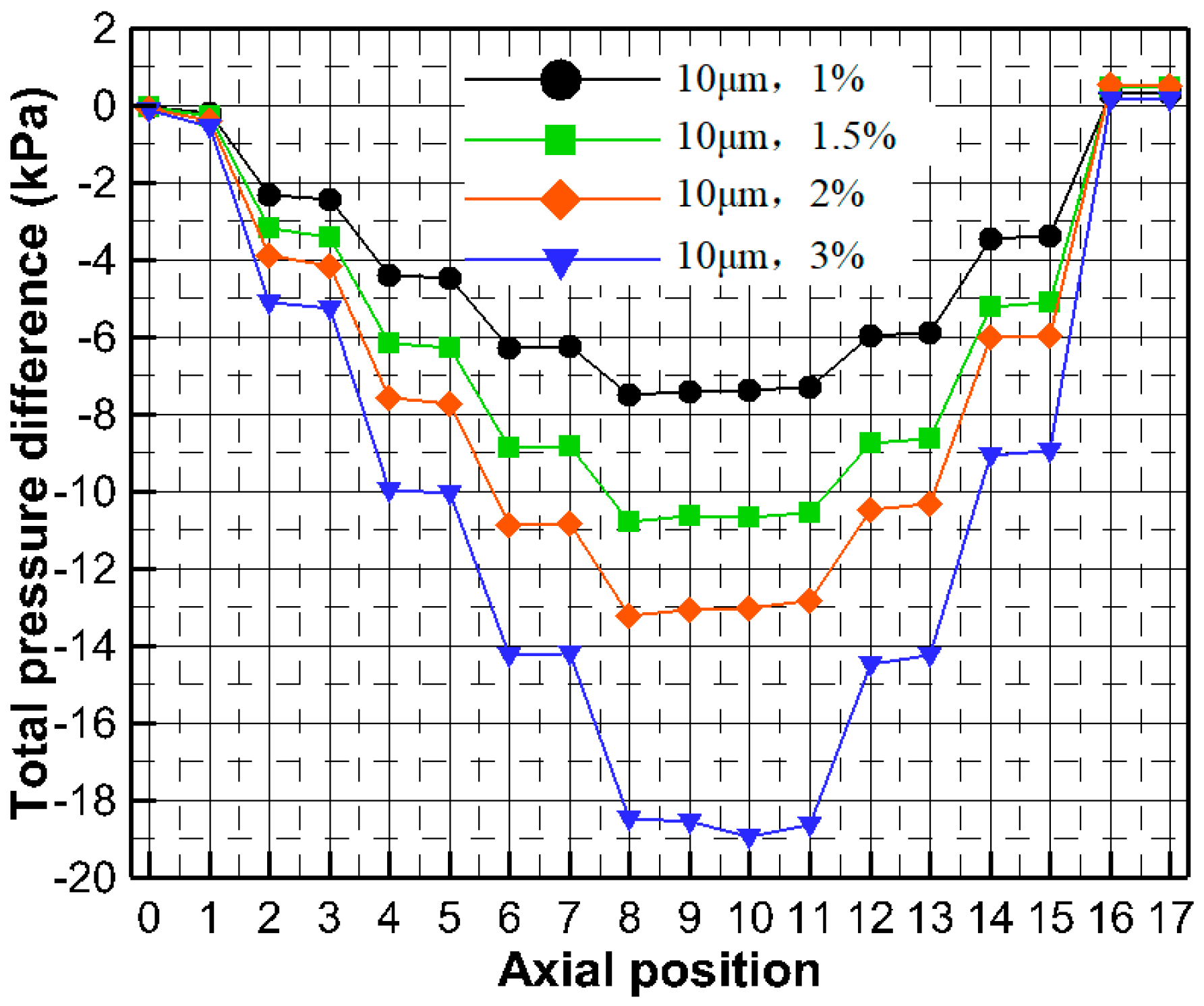

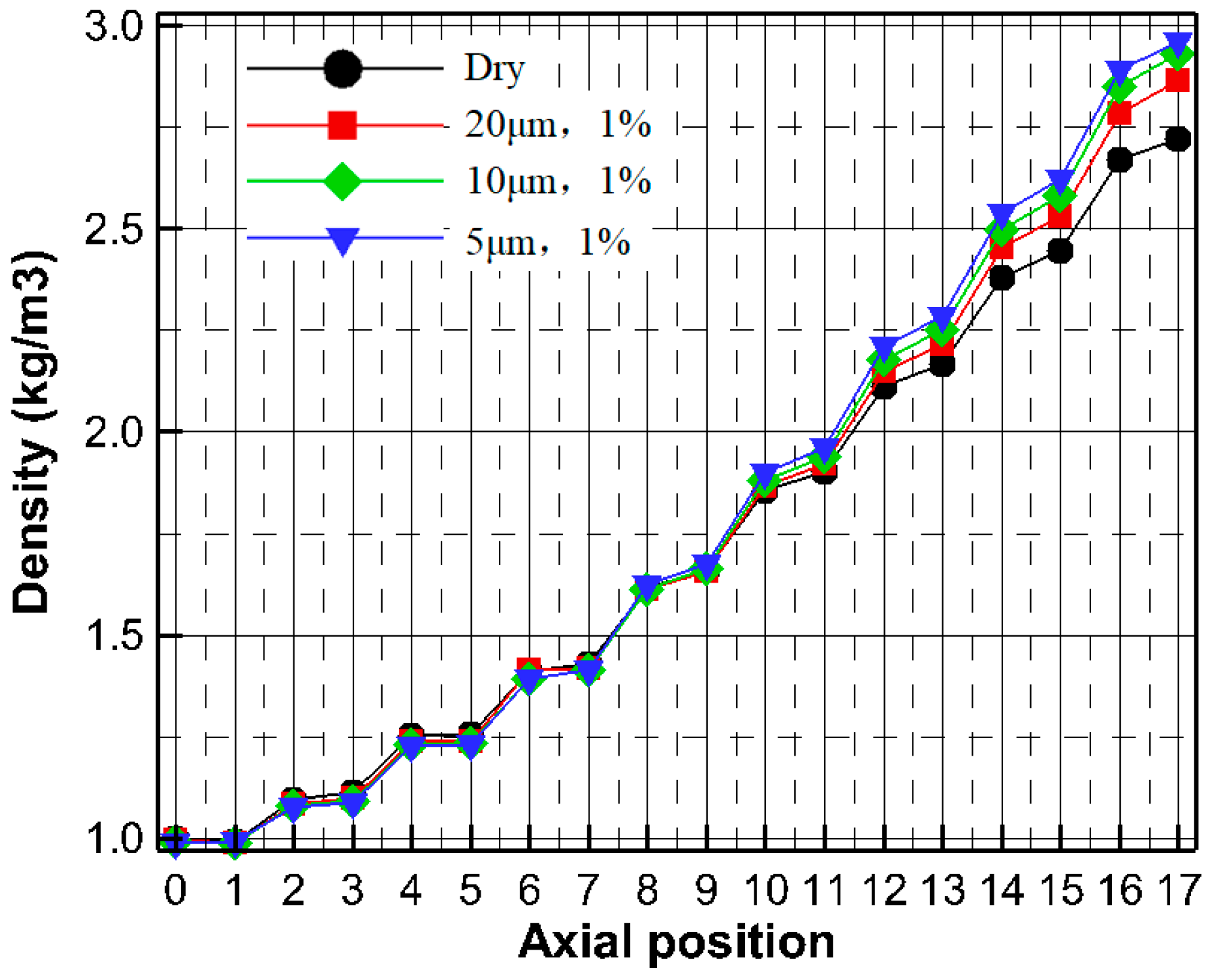

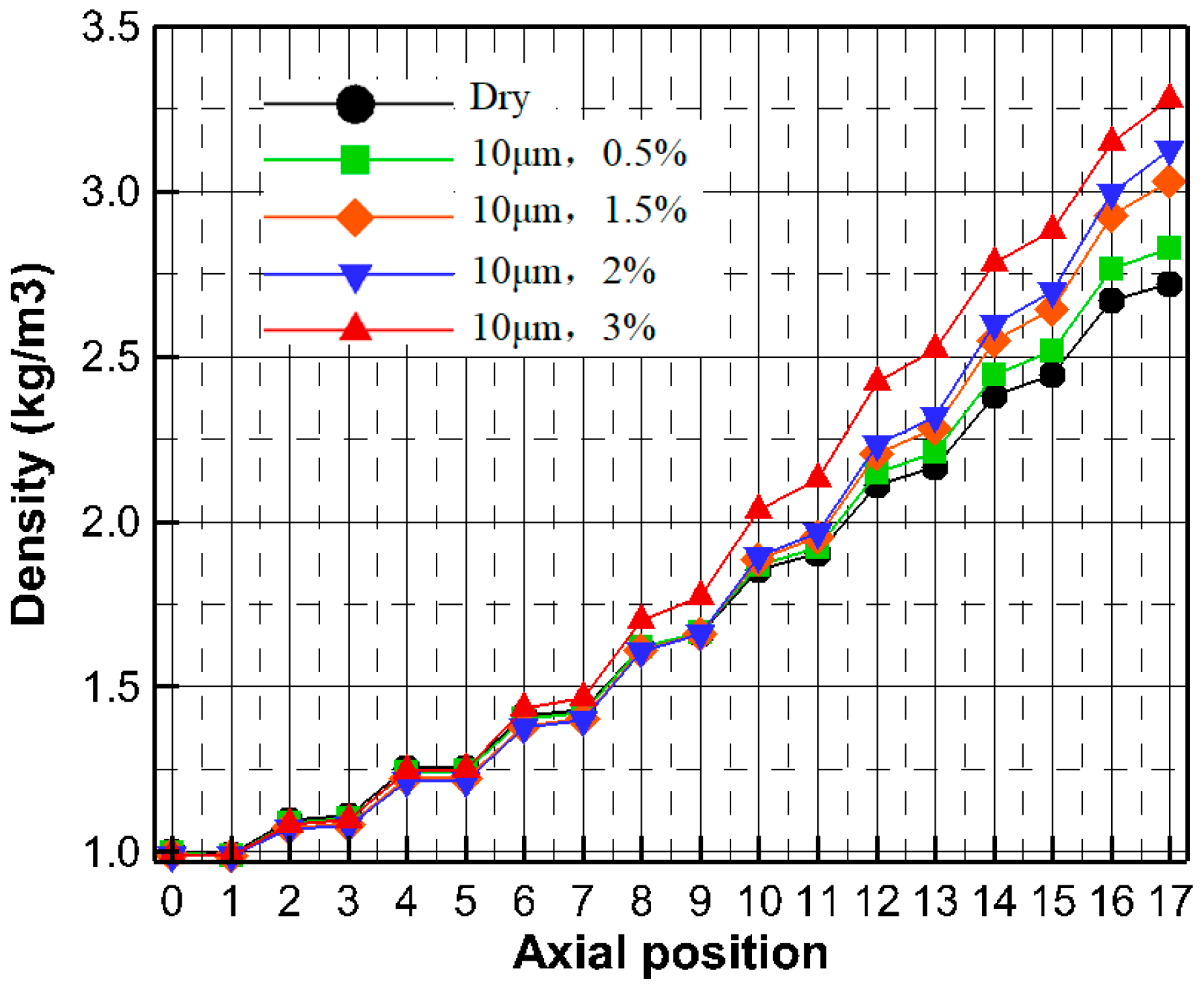

3.5. Compressor Stage-by-Stage Performance at the Design Operating Condition with Different Wet Compression Cases

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Zheng, Q.; Sun, Y.; Li, S.; Wang, Y. Thermodynamic analyses on wet compression process in the compressor of gas turbine. In Proceedings of the ASME Turbo Expo 2002, Amsterdam, The Netherlands, 3–6 June 2002. ASME Paper No: GT2002-30590. [Google Scholar]

- Meher-Homji, C.B.; Chaker, M. Parametric analysis of combined cycles equipped with inlet fogging. In Proceedings of the ASME Turbo Expo 2013, San Antonio, TX, USA, 3–7 June 2013. ASME Paper No: GT2013-94526. [Google Scholar]

- Chiang, H.W.D.; Wang, P.Y. Gas turbine power augmentation by inlet fogging. Int. J. Turbo Jet-Eng. 2006, 23, 259–276. [Google Scholar] [CrossRef]

- Bhargava, R.; Meher-Homji, C.B. Parametric analysis of existing gas turbines with inlet evaporative and overspray fogging. In Proceedings of the ASME Turbo Expo 2002, Amsterdam, The Netherlands, 3–6 June 2002. ASME Paper No: GT2002-30560. [Google Scholar]

- De Lucia, M.; Lanfranchi, C.; Boggio, V. Benefits of compressor inlet air cooling for gas turbine cogeneration plants. J. Eng. Gas Turbines Power 1996, 118, 598–603. [Google Scholar] [CrossRef]

- Sexton, W.R.; Sexton, M.R. The effects of wet compression on gas turbine engine operating performance. In Proceedings of the ASME Turbo Expo 2003, Atlanta, GA, USA, 16–19 June 2003. ASME Paper No: GT2003-38045. [Google Scholar]

- Najjar, Y.S.H. Enhancement of performance of gas turbine engines by inlet air cooling and cogeneration system. Appl. Therm. Eng. 1996, 16, 163–173. [Google Scholar] [CrossRef]

- Sun, L.; Zheng, Q.; Luo, M.; Li, Y.; Bhargava, R.K. Understanding behavior of water droplet in a transonic compressor rotor with wet compression. In Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air, Glasgow, UK, 14–18 June 2010. ASME Paper No. GT2010-23141. [Google Scholar]

- Bhargava, R.K.; Meher-Homji, C.B.; Chaker, M.A.; Peretto, A.; Bianchi, M.; Melino, F.; Ingistov, S. Gas turbine fogging technology—A state-of-the-art review, part I: Inlet evaporative fogging—Analytical and experimental aspects. J. Eng. Gas Turbines Power 2007, 129, 71–82. [Google Scholar] [CrossRef]

- Cao, L.; Lin, A.; Li, Y.; Xiao, B. Optimum tilt angle of flow guide in steam turbine exhaust hood considering the effect of last stage flow field. Chin. J. Mech. Eng. 2017, 30, 866–875. [Google Scholar] [CrossRef]

- Bianchi, M.; Melino, F.; Peretto, A.; Spina, P.R.; Bhargava, R.; Ingistov, S. A parametric study of interstage injection on GE frame 7 EA gas turbine. In Proceedings of the ASME Turbo Expo 2004: Power for Land, Sea, and Air, Vienna, Austria, 14–17 June 2004. ASME Paper No. GT2004-53042.. [Google Scholar]

- Lin, A.; Zheng, Q.; Yang, L.; Zhang, H. Effect of inlet air pre-cooling of water injection on compressor performance at high flight Mach. J. Appl. Fluid. Mech. 2019, 12, 421–431. [Google Scholar]

- Kleinschmidt, R.V. Value of wet compression in gas-turbine cycles. Mech. Eng. 1947, 69, 115–116. [Google Scholar]

- Roumeliotis, I.; Mathioudakis, K. Evaluation of water injection effect on compressor and engine performance and operability. Appl. Energy 2010, 87, 1207–1216. [Google Scholar] [CrossRef]

- Horlock, J.H. Compressor performance with water injection. In Proceedings of the ASME Turbo Expo 2001, New Orleans, LA, USA, 4–7 June 2001. ASME Paper No: 2001-GT0343. [Google Scholar]

- Moon, S.; Li, T.; Sato, K.; Yokohata, H. Governing parameters and dynamics of turbulent spray atomization from modern GDI injectors. Energy 2017, 127, 89–100. [Google Scholar] [CrossRef]

- Agarwal, A.; Trujillo, M.F. A closer look at linear stability theory in modeling spray atomization. Int. J. Multiph. Flow 2018, 109, 1–13. [Google Scholar] [CrossRef]

- Anez, J.; Ahmed, A.; Hecht, N.; Duret, B.; Reveillon, J.; Demoulin, F.X. Eulerian–Lagrangian spray atomization model coupled with interface capturing method for diesel injectors. Int. J. Multiph. Flow 2018. [Google Scholar] [CrossRef]

- Bhargava, R.; Meher-Homji, C.B. Parametric analysis of existing gas turbines with inlet evaporative and overspray fogging. J. Eng. Gas Turbines Power 2005, 127, 145–158. [Google Scholar] [CrossRef]

- Lin, A.; Sun, Y.; Zhang, H.; Lin, X.; Yang, L.; Zheng, Q. Fluctuating characteristics of air-mist mixture flow with conjugate wall-film motion in a compressor of gas turbine. Appl. Therm. Eng. 2018, 142, 779–792. [Google Scholar] [CrossRef]

- Bhargava, R.; Meher-Homji, C.B.; Chaker, M.A.; Bianchi, M.; Melino, F.; Peretto, A.; Ingistov, S. Gas turbine fogging technology: A state-of-the-art review—Part II Overspray fogging-Analytical and experimental aspects. J. Eng. Gas Turbines Power 2007, 129, 454–460. [Google Scholar] [CrossRef]

- Härtel, C.; Pfeiffer, P. Model analysis of high-fogging effects on the work of compression. In Proceedings of the ASME Turbo Expo 2003, Atlanta, GA, USA, 16–19 June 2003. ASME Paper No: GT2003-38117. [Google Scholar]

- Bardon, M.F. Modified Brayton cycles utilizing alcohol fuels. J. Eng. Power 1982, 104, 341–348. [Google Scholar] [CrossRef]

- Bardon, M.F.; Fortin, C. Methanol dissociative intercooling in gas turbines. In Proceedings of the ASME 1982 International Gas Turbine Conference and Exhibit, London, UK, 18–22 April 1982. Paper No. 82-GT-176. [Google Scholar]

- Hill, P.G. Aerodynamic and thermodynamic effects of coolant injection on axial compressors. Aeronaut. Q. 1963, 14, 331–348. [Google Scholar] [CrossRef]

- Wang, T.; Khan, J.R. Overspray and interstage fog cooling in compressor using stage stacking scheme—Part I: Development of theory and algorithm. In Proceedings of the ASME Turbo Expo 2008: Power for Land, Sea, and Air, Berlin, Germany, 9–13 June 2008. ASME Paper No. GT2008-50322. [Google Scholar]

- Wang, T.; Khan, J.R. Overspray and interstage fog cooling in compressor using stage stacking scheme—Part II: A case study. In Proceedings of the ASME Turbo Expo 2008: Power for Land, Sea, and Air, Berlin, Germany, 9–13 June 2008. ASME Paper No. GT2008-50323. [Google Scholar]

- Abdelwahab, A. An investigation of the use of wet compression in industrial centrifugal compressors. In Proceedings of the ASME Turbo Expo 2006, Barcelona, Spain, 8–11 May 2006. ASME Paper No: GT2006-90695. [Google Scholar]

- Kim, K.H.; Perez-Blanco, H. An assessment of high-fogging potential for enhanced compressor performance. In Proceedings of the ASME Turbo Expo 2006, Barcelona, Spain, 8–11 May 2006. ASME Paper No: GT2006-90482. [Google Scholar]

- Sun, L.; Li, Y.; Zheng, Q.; Bhargava, R. Understanding effects of wet compression on separated flow behavior in an axial compressor stage using CFD analysis. J. Turbomach. 2011, 133, 031026. [Google Scholar] [CrossRef]

- Luo, M.; Zheng, Q.; Sun, L.; Deng, Q.; Chen, J.; Wang, J.; Bhargava, R. The effects of wet compression and blade tip water injection on the stability of a transonic compressor Rotor. ASME J. Eng. Gas Turbines Power 2012, 134, 092001. [Google Scholar] [CrossRef]

- Luo, M.; Zheng, Q.; Sun, L.; Deng, Q.; Li, S.; Liu, C.; Bhargava, R. The numerical simulation of inlet fogging effects on the stable range of a transonic compressor stage. In Proceedings of the ASME Turbo Expo 2011, Vancouver, BC, Canada, 6–10 June 2011. ASME Paper No: GT2011-46124. [Google Scholar]

- Schmehl, R.; Rosskamp, H.; Willmann, M.; Wittig, S. CFD analysis of spray propagation and evaporation including wall film formation and spray/film interactions. Int. J. Heat Fluid Flow 1999, 20, 520–529. [Google Scholar] [CrossRef]

- Bai, C.; Gossman, A.D. Development of Methodology for Spray Impingement Simulation; SAE Technical Paper: New York, NY, USA, 1995. [Google Scholar]

- Launder, B.E.; Spalding, D.B. Splashing Mathematical Models of Turbulence; Academic Press: Cambridge, MA, USA, 1972. [Google Scholar]

- Besharat, M.; Tarinejad, R.; Aalami, M.T.; Ramos, H.M. Study of a compressed air vessel for controlling the pressure surge in water networks: CFD and experimental analysis. Water Resour. Manag. 2016, 30, 2687–2702. [Google Scholar] [CrossRef]

- Chedevergne, F. Analytical wall function including roughness corrections. Int. J. Heat Fluid Flow 2018, 73, 258–269. [Google Scholar] [CrossRef]

| IGV | Stage NO.1 | Stage NO.2 | Stage NO.3 | Stage NO.4 | Stage NO.5 | Stage NO.6 | Stage NO.7 | Stage NO.8 | Total Number |

|---|---|---|---|---|---|---|---|---|---|

| 198,064 | 483,932 | 472,072 | 488,088 | 491,524 | 486,700 | 476,848 | 486,124 | 531,080 | 4,114,432 |

| Boundary Conditions | Shaft Speed (rpm) | 6180, 5562, 4944, 4326, 3708 |

|---|---|---|

| Compressor inlet | Total pressure (Pa) | 95708 |

| Total temperature (K) | 303.15 | |

| Flow direction | axial | |

| Compressor exit | Average static pressure (Pa) | - |

| Water injection at compressor inlet | Injecting rate | 0.5%, 1%, 1.5%, 2%, 2.5%, 3% |

| RR mean diameter (μm) | 5, 10, 20 | |

| Velocity (m/s) | 50 | |

| Temperature (K) | 298.15 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Zheng, Q.; Wang, Q.; Lin, A.; Jiang, Y.; Luo, M. Sensitivity Analysis of Multistage Compressor Characteristics Under the Spray Atomization Effect Using a CFD Model. Energies 2019, 12, 301. https://doi.org/10.3390/en12020301

Liu C, Zheng Q, Wang Q, Lin A, Jiang Y, Luo M. Sensitivity Analysis of Multistage Compressor Characteristics Under the Spray Atomization Effect Using a CFD Model. Energies. 2019; 12(2):301. https://doi.org/10.3390/en12020301

Chicago/Turabian StyleLiu, Chunlei, Qun Zheng, Qi Wang, Aqiang Lin, Yuting Jiang, and Mingcong Luo. 2019. "Sensitivity Analysis of Multistage Compressor Characteristics Under the Spray Atomization Effect Using a CFD Model" Energies 12, no. 2: 301. https://doi.org/10.3390/en12020301

APA StyleLiu, C., Zheng, Q., Wang, Q., Lin, A., Jiang, Y., & Luo, M. (2019). Sensitivity Analysis of Multistage Compressor Characteristics Under the Spray Atomization Effect Using a CFD Model. Energies, 12(2), 301. https://doi.org/10.3390/en12020301