Evaluation of Alternatives for Improving the Thermal Resistance of Window Glazing Edges

Abstract

1. Introduction

2. Previous Studies and Setup of Alternatives

3. Alternative Configurations and Temperature Difference Ratio and U-factor Evaluation Methods

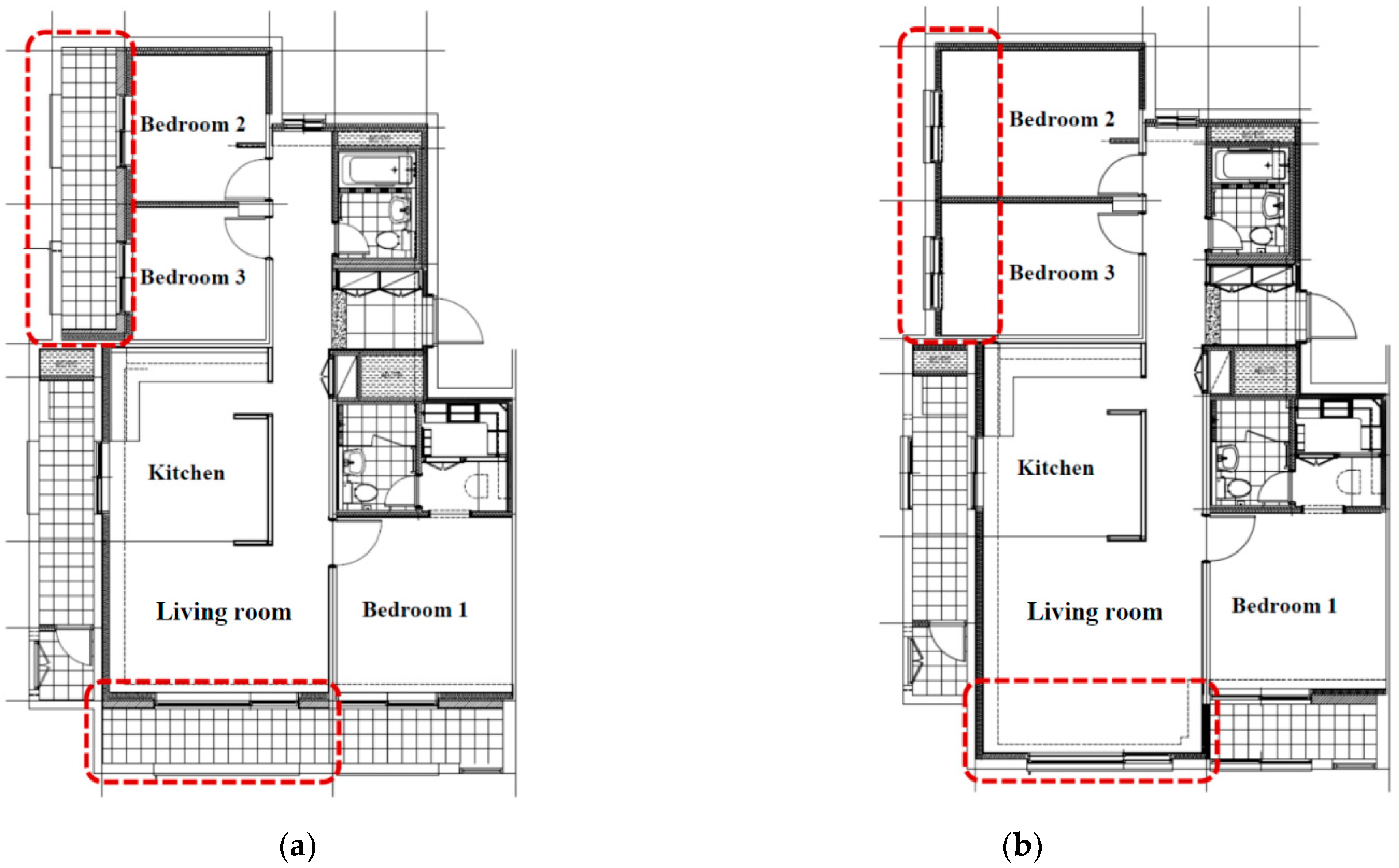

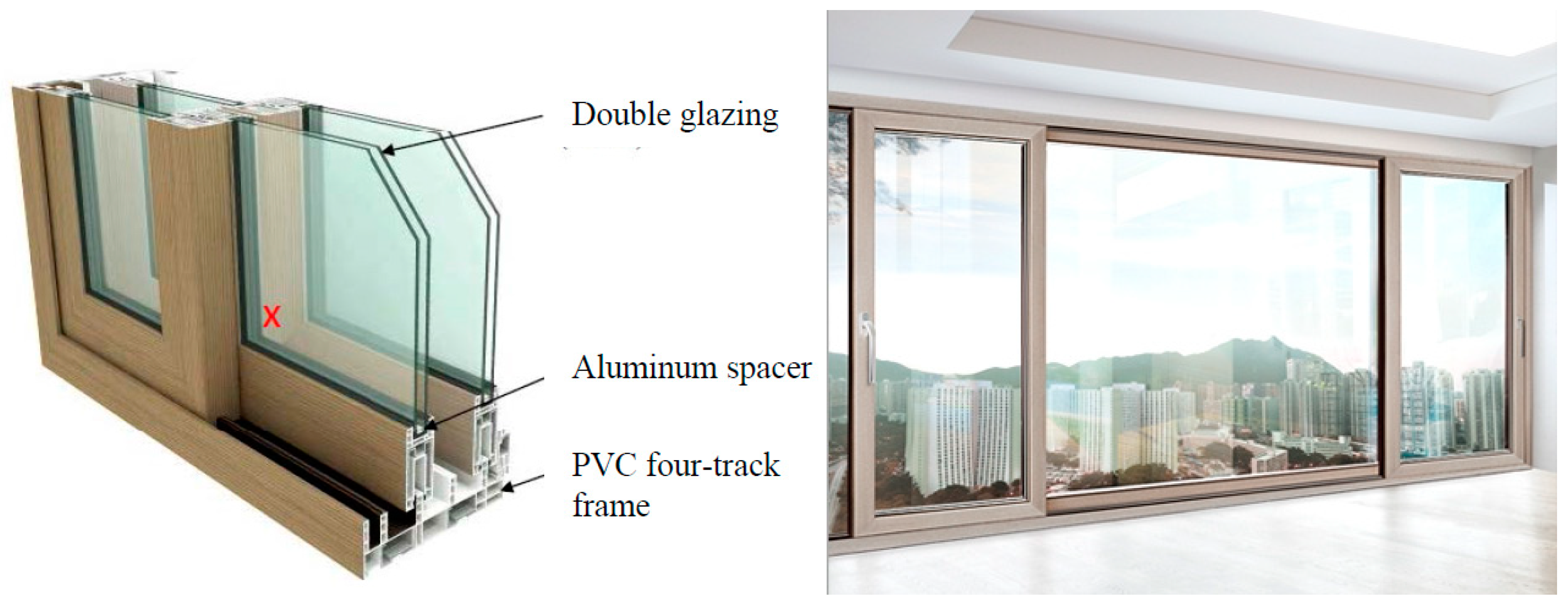

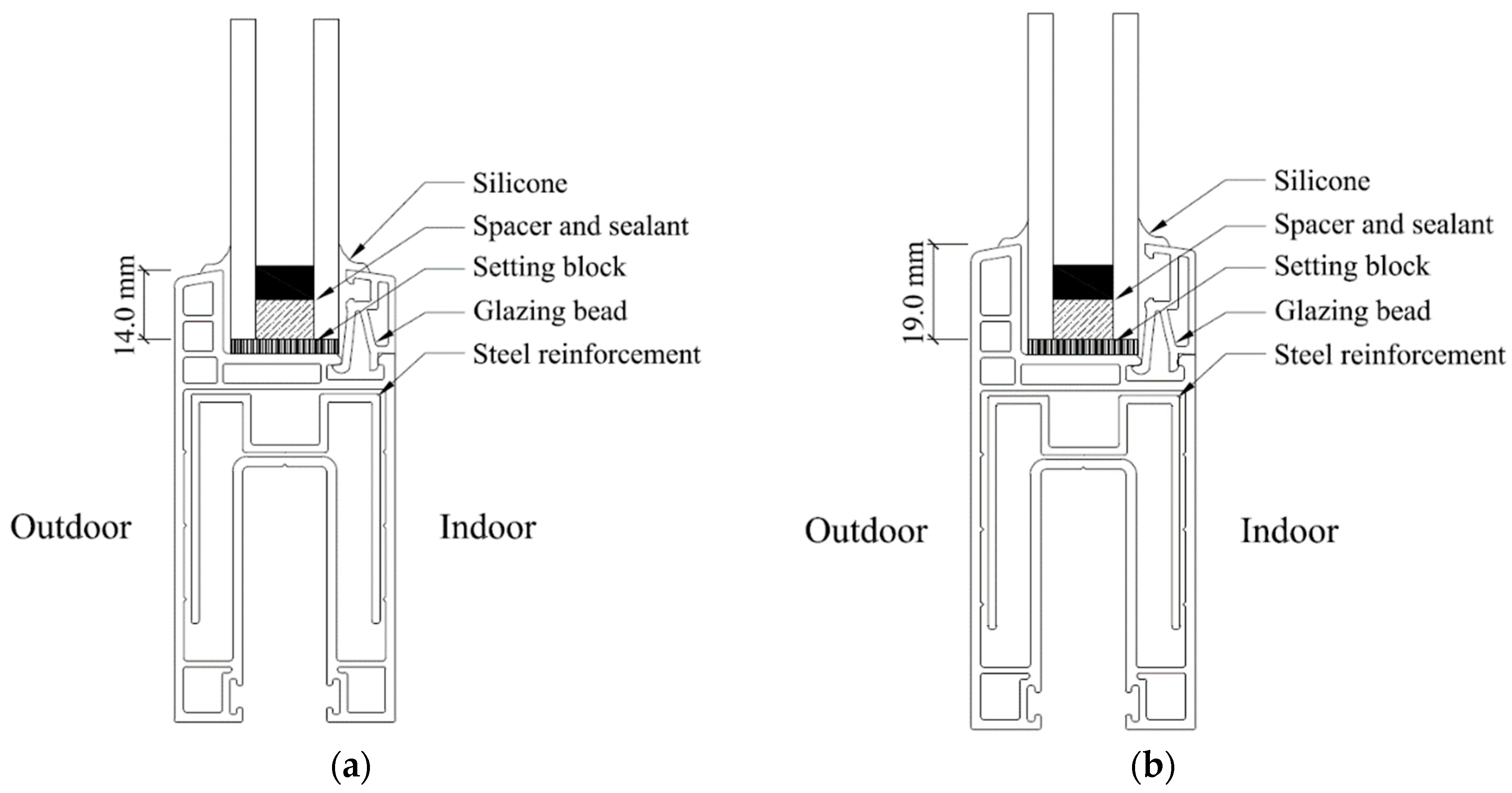

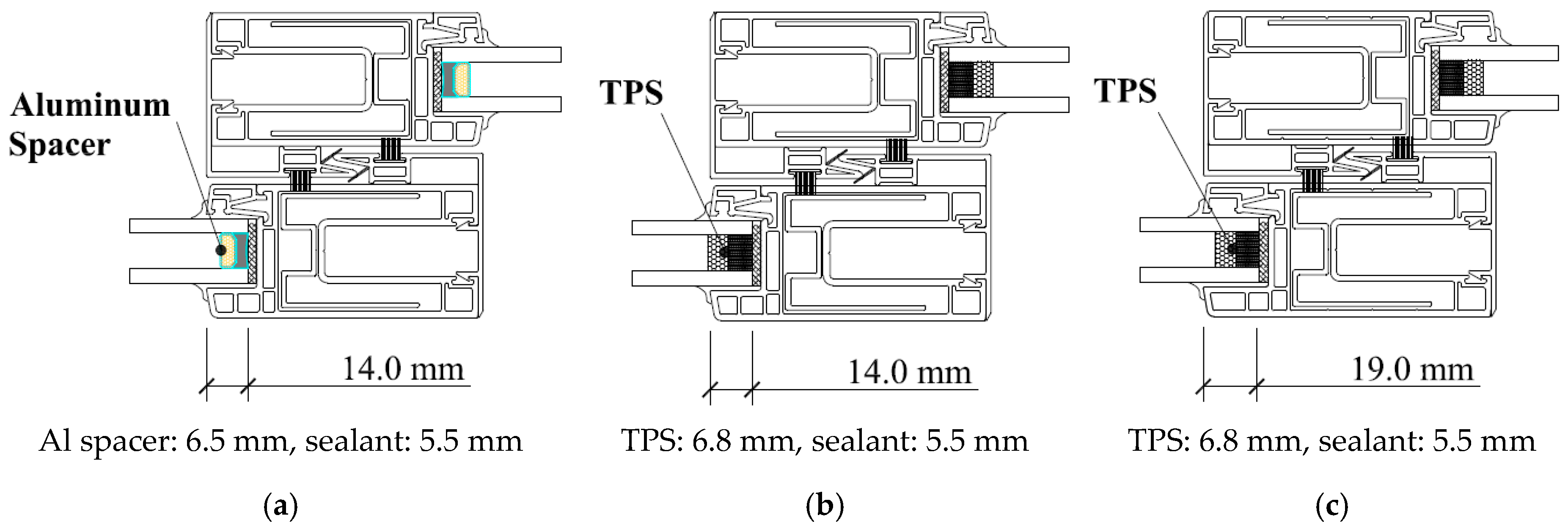

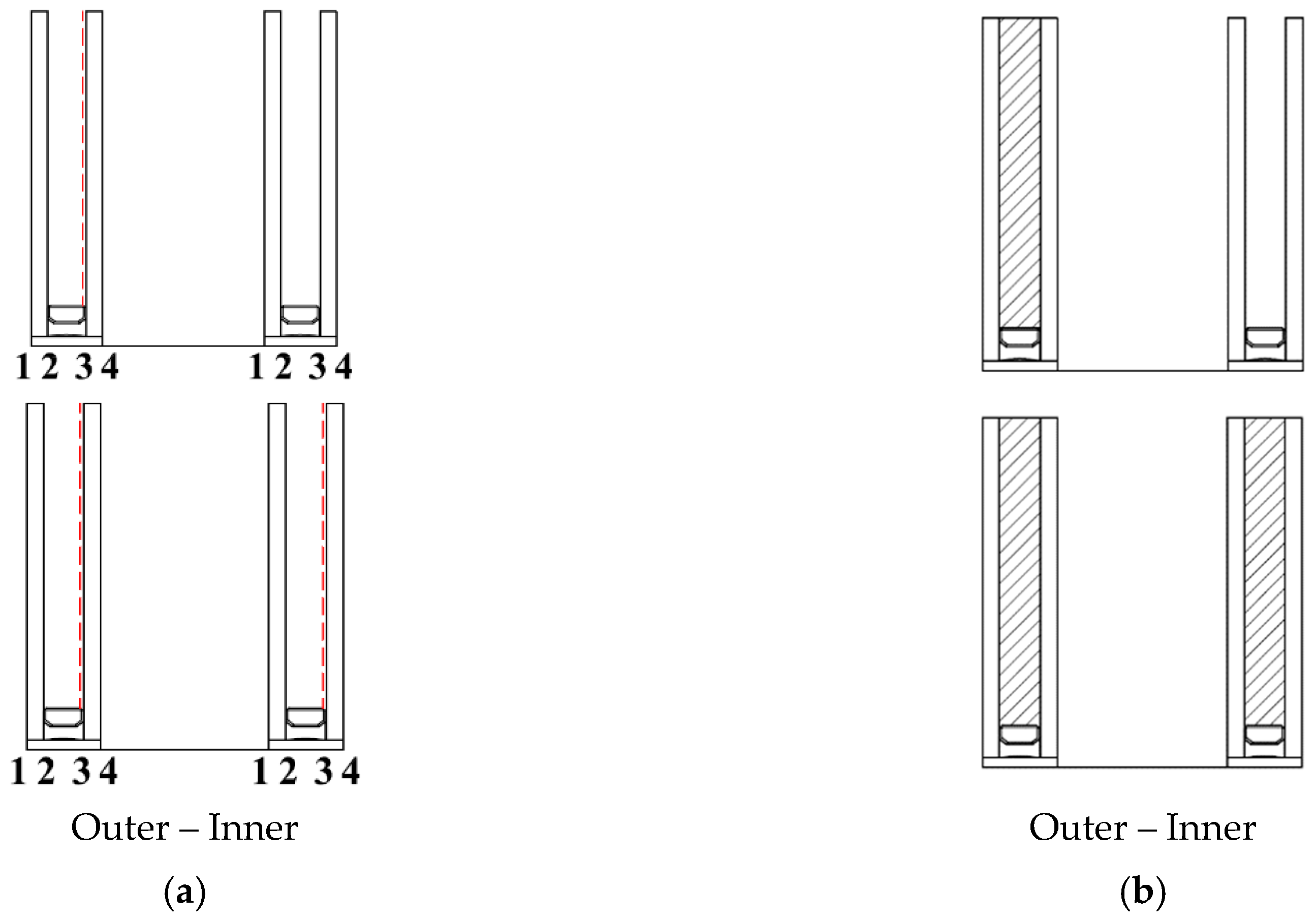

3.1. Alternative Configurations

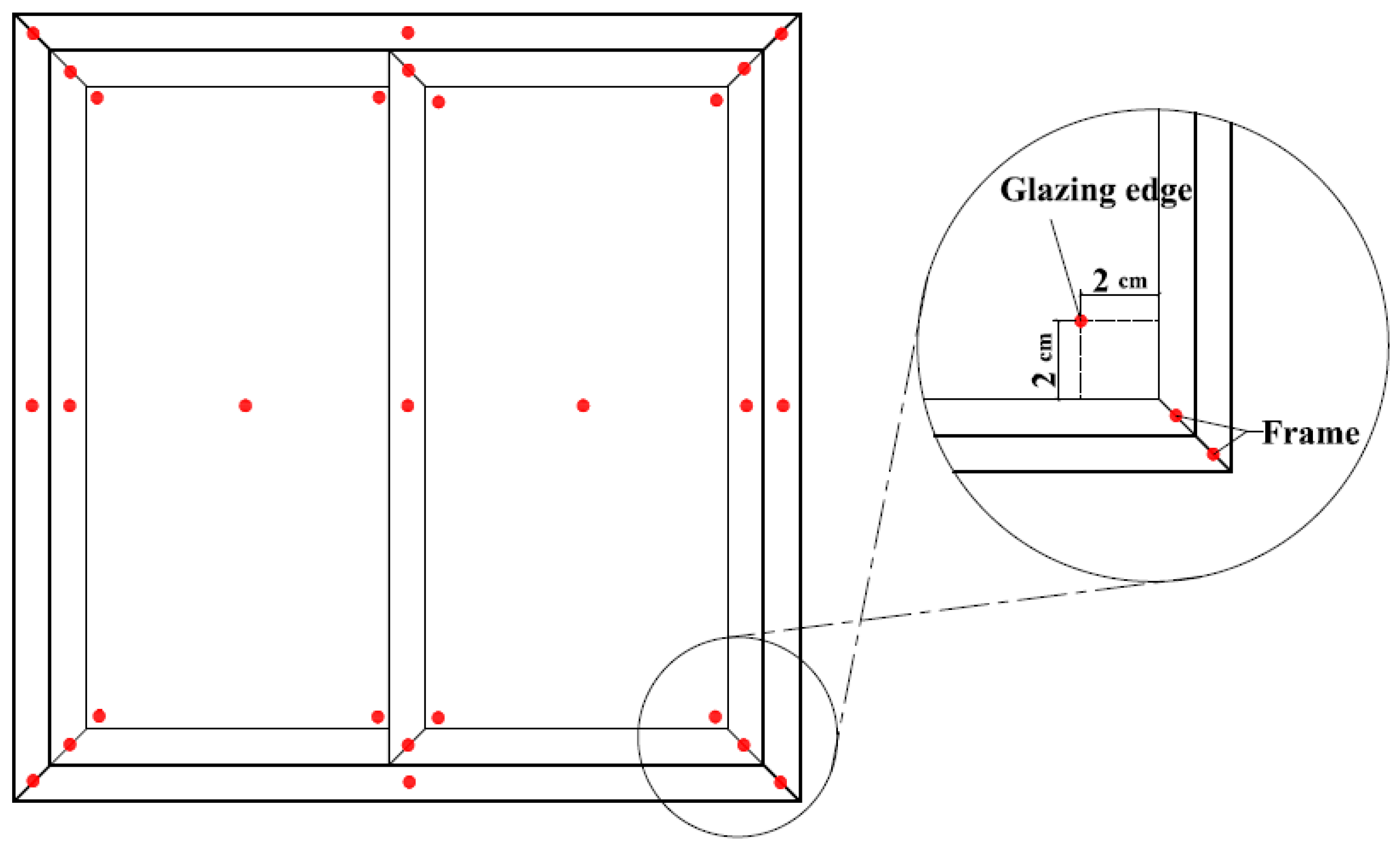

3.2. TDR Evaluation Method

3.2.1. Evaluation Overview

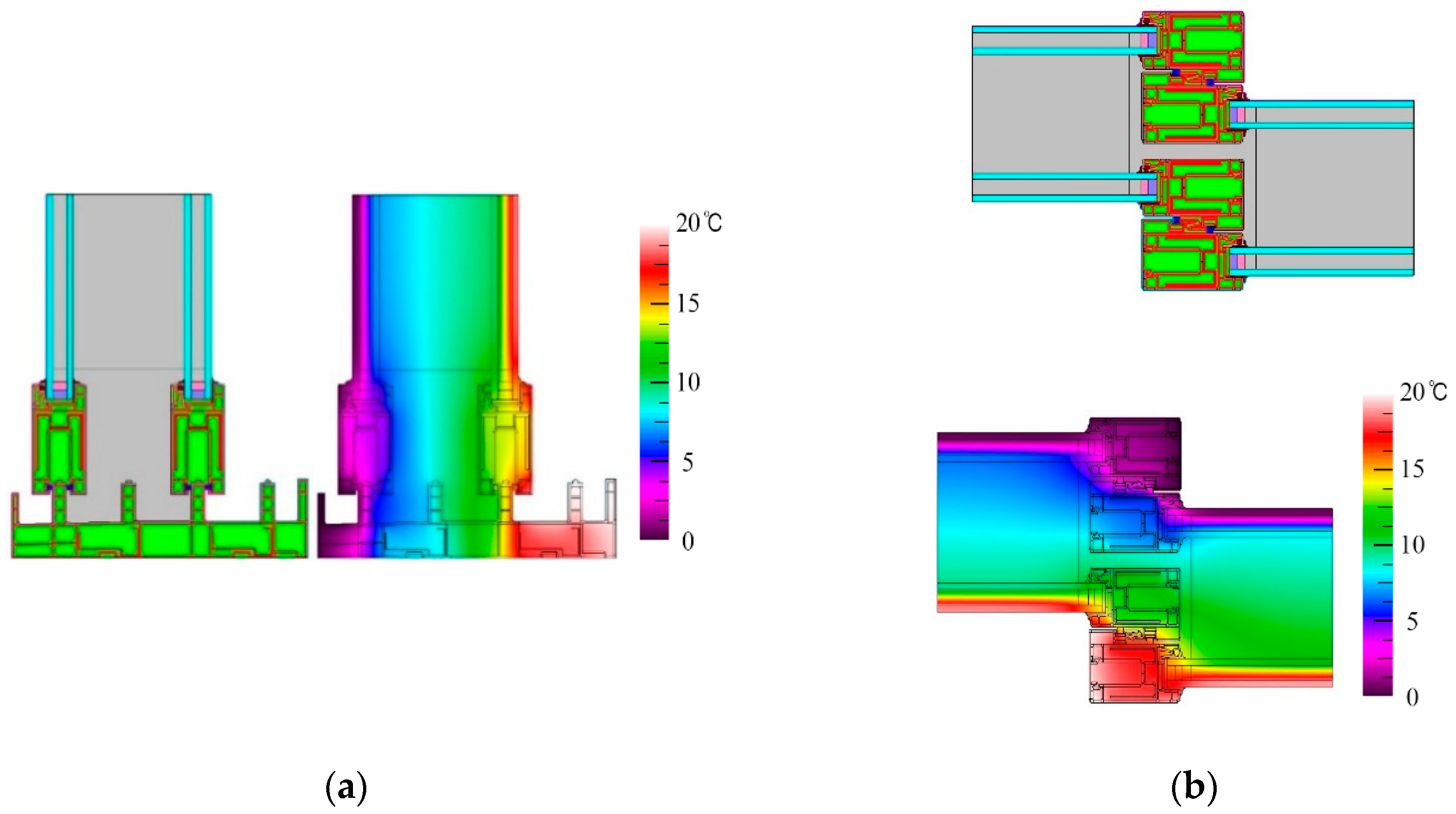

3.2.2. Simulation Method

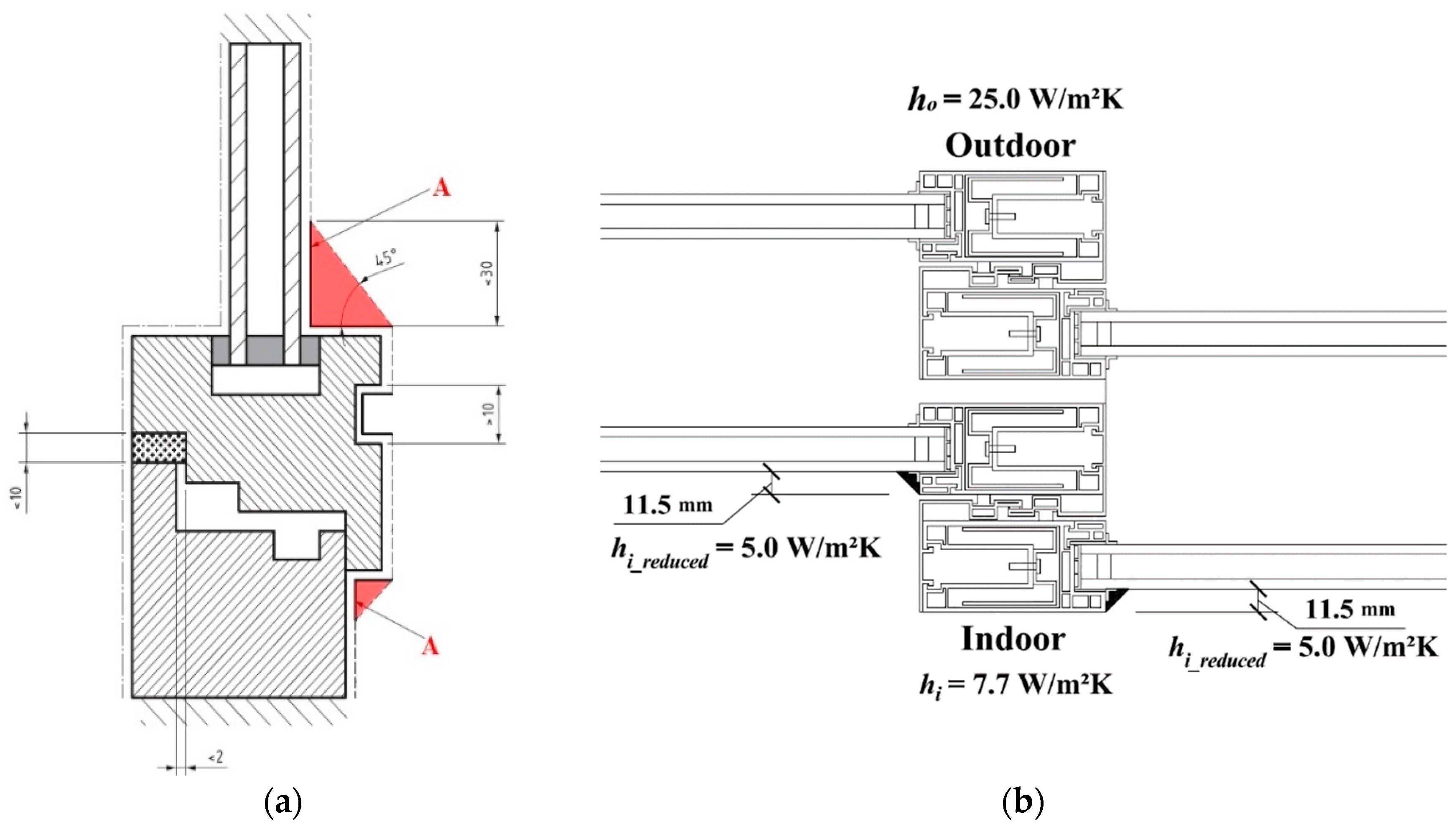

3.3. U-Factor Evaluation Method

3.3.1. Evaluation Overview

3.3.2. Simulation Method

4. TDR and U-Factor Evaluation Results

4.1. TDR Evaluation Results

4.2. U-Factor Evaluation Results

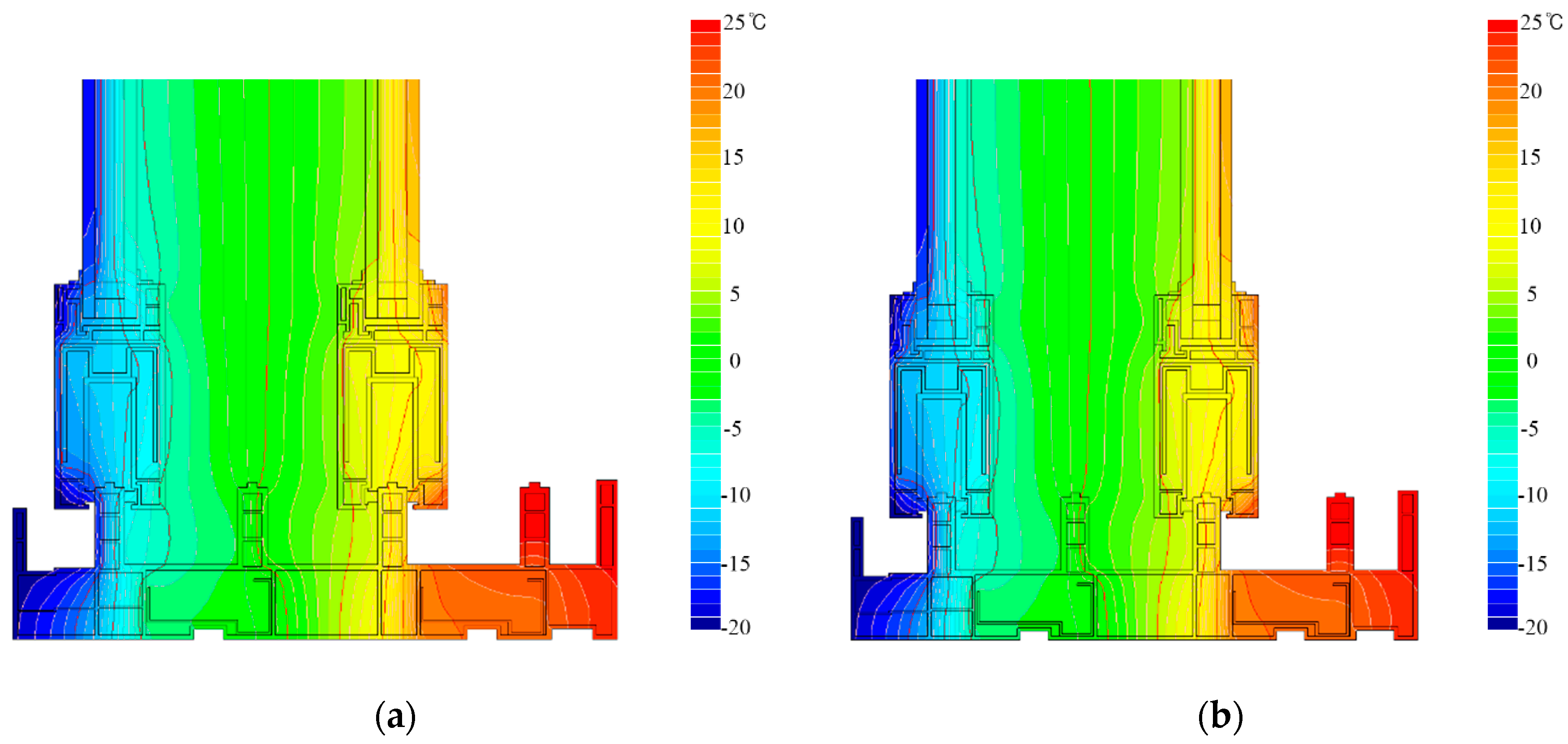

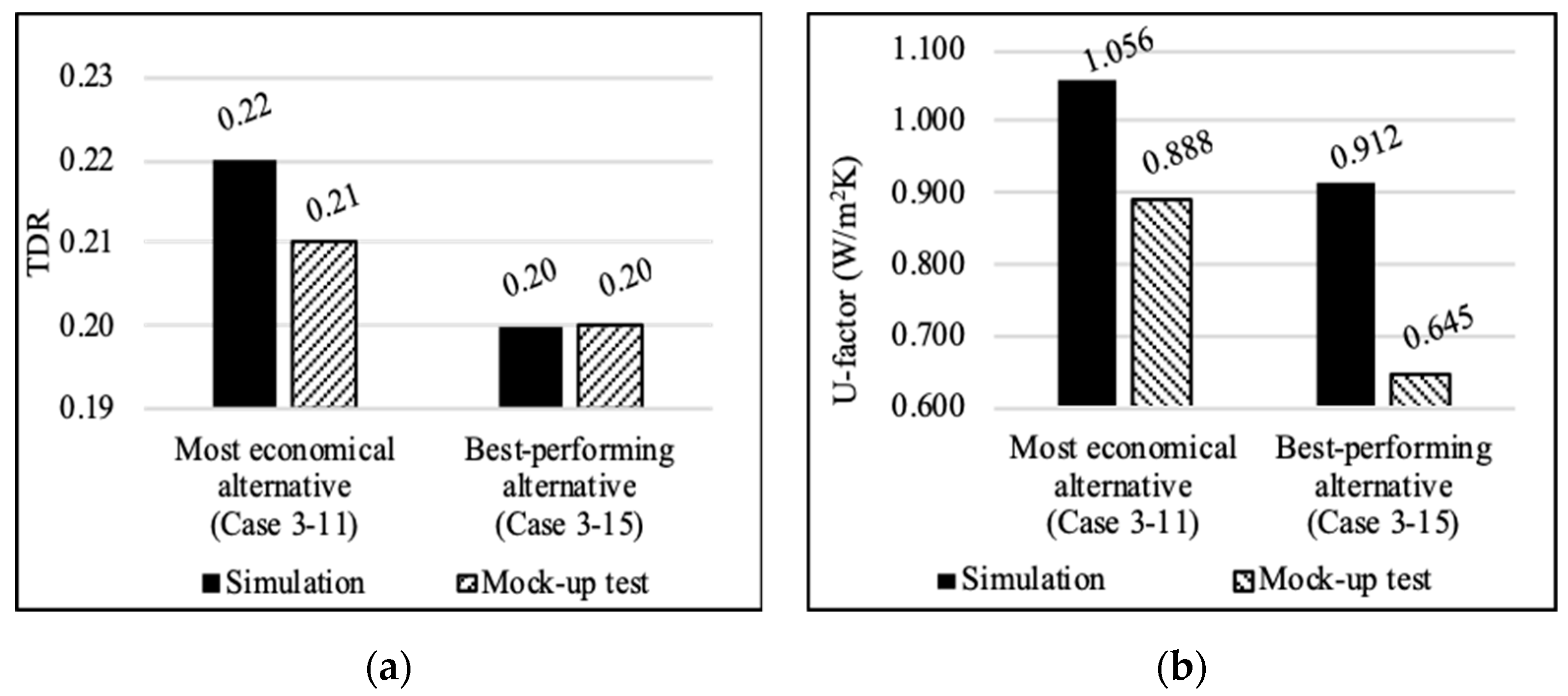

5. Performance Verification through Mock-up Tests

5.1. Mock-up Test Methods

5.2. Mock-up Test Results Compared with Simulation Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Alawadhi, E.M. Effect of an incompletely closed window shutter on indoor illuminance level and heat gain. Energy Build. 2016, 110, 112–119. [Google Scholar] [CrossRef]

- Bellia, L.; Minichiello, F. A simple evaluator of building envelope moisture condensation according to a European Standard. Build. Environ. 2003, 38, 457–468. [Google Scholar] [CrossRef]

- Gao, T.; Ihara, T.; Grynning, S.; Jelle, B.P.; Lien, A.G. Perspective of aerogel glazings in energy efficient buildings. Build. Environ. 2016, 95, 405–413. [Google Scholar] [CrossRef]

- Gläser, H.J.; Ulrich, S. Condensation on the outdoor surface of window glazing—Calculation methods, key parameters and prevention with low-emissivity coatings. Thin Solid Film. 2013, 532, 127–131. [Google Scholar] [CrossRef]

- Hassouneh, K.; Alshboul, A.; Al-Salaymeh, A. Influence of windows on the energy balance of apartment buildings in Amman. Energy Convers. Manag. 2010, 51, 1583–1591. [Google Scholar] [CrossRef]

- Hong, G.; Kim, D.; Kim, B. Experimental investigation of thermal behaviours in window systems by monitoring of surface condensation using full-scale measurements and simulation tools. Energies 2016, 9, 979. [Google Scholar] [CrossRef]

- Moon, H.J.; Ryu, S.H.; Kim, J.T. The effect of moisture transportation on energy efficiency and IAQ in residential buildings. Energy Build. 2014, 75, 439–446. [Google Scholar] [CrossRef]

- Song, S.-Y.; Jo, J.-H.; Yeo, M.-S.; Kim, Y.-D.; Song, K.-D. Evaluation of inside surface condensation in double glazing window system with insulation spacer: A case study of residential complex. Build. Environ. 2007, 42, 940–950. [Google Scholar] [CrossRef]

- Ministry of Land, Infrastructure and Transportation; Korean Design Standard for Preventing Condensation in Apartment Buildings, No. 2016-835; Ministry of Land, Infrastructure and Transportation: Sejong, Korea, 2016. (In Korean)

- Song, S.-Y.; Park, S.; Lee, H.-H.; Oh, H.; Lim, J.-H. Development of Building Technology to Improve the Living Performance Closely Related with Lifestyle to Realize the Housing Welfare; Annual Research Rep. III, Annex 3; Ministry of Land, Infrastructure and Transport: Seoul, Korea, 2016.

- Physibel. TRISCO Manual of Version 12.0w, Maldegem, Belgium, 2010. Available online: http://www.physibel.be (accessed on 25 February 2018).

- Lawrence Berkeley National Laboratory. THERM 7/WINDOW 7 NFRC Simulation Manual. 2017. Available online: https://windows.lbl.gov/sites/default/files/Downloads/NFRCSim7-July2017.pdf (accessed on 25 February 2018).

- Lawrence Berkeley National Laboratory. THERM Material Library, THERM 6.3. 2012. Available online: https://windows.lbl.gov/software/window (accessed on 25 February 2018).

- Baldinelli, G.; Bianchi, F. Windows thermal resistance: Infrared thermography aided comparative analysis among finite volumes simulations and experimental methods. Appl. Energy 2014, 136, 250–258. [Google Scholar] [CrossRef]

- Carlos, J.S. Optimizing the ventilated double window for solar collection. Sol. Energy 2017, 150, 454–462. [Google Scholar] [CrossRef]

- Liu, M.; Wittchen, K.B.; Heiselberg, P.K.; Winther, F.V. Development of a simplified and dynamic method for double glazing façade with night insulation and validated by full-scale façade element. Energy Build. 2013, 58, 163–171. [Google Scholar] [CrossRef]

- Hien, W.N.; Liping, W.; Chandra, A.N.; Pandey, A.R.; Xiaolin, W. Effects of double glazed facade on energy consumption, thermal comfort and condensation for a typical office building in Singapore. Energy Build. 2005, 37, 563–572. [Google Scholar] [CrossRef]

- Cho, W.; Iwamoto, S.; Kato, S. Condensation risk due to variations in airtightness and thermal insulation of an office building in warm and wet climate. Energies 2016, 9, 875. [Google Scholar] [CrossRef]

- Park, S.; Kim, M.; Lim, J.-H.; Song, S.-Y. Influence of drainage holes on condensation risk and air-tightness of windows an experimental case study of triple glazing PVC windows. J. Asian Archit. Build. Eng. 2017, 16, 83–90. [Google Scholar] [CrossRef]

- Bakonyi, D.; Dobszay, G. Simulation aided optimization of a historic window’s refurbishment. Energy Build. 2016, 126, 51–69. [Google Scholar] [CrossRef]

- Smith, N.; Isaacs, N.; Burgess, J.; Cox-Smith, I. Thermal performance of secondary glazing as a retrofit alternative for single-glazed windows. Energy Build. 2012, 54, 47–51. [Google Scholar] [CrossRef]

- Koo, S.-Y. Comparative analysis of window thermal performance calculation method between window certification systems. J. Archit. Inst. Korea 2015, 31, 119–127. (In Korean) [Google Scholar]

- Park, S.; Koo, S.-Y.; Lim, J.-H.; Seong, Y.-B.; Song, S.-Y. Condensation resistance evaluation of a double-sliding window system for apartment buildings. Procedia Eng. 2016, 146, 60–68. [Google Scholar] [CrossRef]

- Ewha Womans University. The Development of Building Technology to Improve the Living Performance Closely Related with Life Style to Realize the Housing Welfare; Annual R&D Report, Annex 3 Condensation; Environmental-Friendly Architecture Laboratory: Seoul, Korea, 2016. (In Korean) [Google Scholar]

- Korean Standard Association. KS F 2295 Test Method of Dew Condensation for Windows and Doors; Korean Standard Association: Chungcheongbuk-do, Korea, 2014. (In Korean) [Google Scholar]

- ISO 10211:2017. Thermal Bridges in Building Construction—Heat Flows and Surface Temperatures—Detailed Calculations; International Standard Organization: Geneva, Switzerland, 2017. [Google Scholar]

- Park, S.; Song, S.-Y. Case study on the inspection and repair of window condensation problems in a new apartment complex. J. Perform. Constr. Facil. 2018, 32, 04018071. [Google Scholar] [CrossRef]

- Accreditation Secretariat for Window-Set Simulation. The Assessments. Available online: https://window-sim.or.kr:6001/contents/contents.php (accessed on 10 November 2018). (In Korean).

- ISO 10077-2:2017. Thermal Performance of Windows, Doors and Shutters—Calculation of Thermal Transmittance—Part 2: Numerical Method for Frames; International Standard Organization: Geneva, Switzerland, 2017. [Google Scholar]

- Kim, M.-H.; Park, S.-H.; Koo, S.-Y.; Lim, J.-H.; Song, S.-Y. Comparison of surface thermal resistance conditions for the condensation resistance assessment of windows using simulation. J. Archit. Inst. Korea 2016, 32, 113–120. (In Korean) [Google Scholar] [CrossRef]

- Koo, S.-Y.; Park, S.; Song, J.-H.; Song, S.-Y. Effect of surface thermal resistance on the simulation accuracy of the condensation risk assessment for a high-performance window. Energies 2018, 11, 382. [Google Scholar] [CrossRef]

- DIN EN 673. Glass in Building—Determination of Thermal Transmittance (U Value)—Calculation Method; German Institute for Standardization: Berlin, Germany, 2011. [Google Scholar]

- Ministry of Land, Infrastructure and Transportation; Korean Construction Standard for Energy-Efficient Sustainable Residential Buildings, Notification No. 2017-442; Korean Ministry of Land, Infrastructure and Transportation: Sejong, Korea, 2017. (In Korean)

- ISO 15099. Thermal Performance of Windows, Doors, and Shading Devices—Detailed Calculations; International Standard Organization: Geneva, Switzerland, 2003. [Google Scholar]

- National Fenestration Rating Council (NFRC). Procedure for Determining Fenestration Product U-Factors; NFRC 100-2017; National Fenestration Rating Council (NFRC): Greenbelt, MD, USA, 2017. [Google Scholar]

- Korean Standard Association. KS F 2278 Standard Test Method for Thermal Resistance for Windows and Doors; Korean Standard Association: Chungcheongbuk-do, Korea, 2017. (In Korean) [Google Scholar]

- Korea Laboratory Accreditation Scheme (KOLAS). 2018. Available online: https://www.kolas.go.kr/ (assessed on 10 November 2018). (In Korean).

| Measures | Expected Effects | |

|---|---|---|

| Glazing | Insulating spacer 1 - Thermoplastic spacer (TPS) - Thick-walled plastic spacer (Swisspacer) - Thermally broken aluminum spacer (Warm light) - Thin-walled stainless steel spacer (TGI) | Increased indoor surface temperature at the glazing edge |

| Spacer size adjustment | ||

| Insulating cap on the glazing end | ||

| Low-e coating 1 | Increased indoor surface temperature for glazing | |

| Argon or krypton gas filling 1 | ||

| Frame | Insulating cover | Increased indoor surface temperature at the glazing edge and frame |

| Frame structure and size adjustment 1 | ||

| Smaller cells within the frame between the reinforcing steel and frame Insulating cap on the frame extrusions | Increased indoor surface temperature of the frame |

| Division | Spacer | Height of Frame Overlapping Glazing (mm) | Alternative Case | Glazing Configuration | ||

|---|---|---|---|---|---|---|

| Outer 1 | Inner 2 | |||||

| Case 1 | Aluminum | 14.0 | Case 1-0 | Base model | 5CL-12Air-5CL | 5CL-12Air-5CL |

| Case 1-1 | Low-e coating (LE) | 5CL-12Air-5CL | 5CL-12Air-5LE | |||

| Case 1-2 | 5CL-12Air-5LE | 5CL-12Air-5CL | ||||

| Case 1-3 | 5CL-12Air-5LE | 5CL-12Air-5LE | ||||

| Case 1-4 | Argon gas filling (Ar) | 5CL-12Air-5CL | 5CL-12Ar-5CL | |||

| Case 1-5 | 5CL-12Ar-5CL | 5CL-12Air-5CL | ||||

| Case 1-6 | 5CL-12Ar-5CL | 5CL-12Ar-5CL | ||||

| Case 1-7 | Low-e coating and argon gas filling | 5CL-12Air-5CL | 5CL-12Ar-5LE | |||

| Case 1-8 | 5CL-12Air-5LE | 5CL-12Ar-5CL | ||||

| Case 1-9 | 5CL-12Air-5LE | 5CL-12Ar-5LE | ||||

| Case 1-10 | 5CL-12Ar-5CL | 5CL-12Air-5LE | ||||

| Case 1-11 | 5CL-12Ar-5LE | 5CL-12Air-5CL | ||||

| Case 1-12 | 5CL-12Ar-5LE | 5CL-12Air-5LE | ||||

| Case 1-13 | 5CL-12Ar-5CL | 5CL-12Ar-5LE | ||||

| Case 1-14 | 5CL-12Ar-5LE | 5CL-12Ar-5CL | ||||

| Case 1-15 | 5CL-12Ar-5LE | 5CL-12Ar-5LE | ||||

| Case 2 | TPS (Thermoplastic) | 14.0 | Cases 2-0 to 2-15 | Same glazing configurations as Cases 1-0 to 1-15 above | ||

| Case 3 | TPS (Thermoplastic) | 19.0 (+5.0) | Cases 3-0 to 3-15 | Same glazing configurations as Cases 1-0 to 1-15 above | ||

| Region I | Region II | Region III | ||

|---|---|---|---|---|

| Window directly facing the outdoors | Glazing center | 0.16 | 0.18 | 0.20 |

| Glazing edge | 0.22 | 0.24 | 0.27 | |

| Frame | 0.25 | 0.28 | 0.32 | |

| Temperature (°C) | Surface Heat Transfer Coefficient (h, W/m2K) | ||

|---|---|---|---|

| Indoor | Plane surface | 25.0 | 7.7 (hi) |

| Edges or junctions between two surfaces | 5.0 (hi_reduced) | ||

| Outdoor | −20.0 | 25.0 (ho) | |

| Parameter | Value |

|---|---|

| Maximum number of iteration cycles | 5 |

| Maximum number of iterations within each iteration cycle | 10,000 |

| Maximum temperature difference within each iteration cycle | 0.0001 °C |

| Maximum temperature difference between iteration cycles | 0.001 °C |

| Maximum heat flow divergence for a total object | 0.001% |

| Maximum heat flow divergence for any node | 1% |

| Material | Thermal Conductivity (W/mK) | Emissivity | |

|---|---|---|---|

| Glazing | Glass | 1.00 | 0.84 |

| Low-e coating | - | 0.04 | |

| Air | 0.025 | - | |

| Argon (10% air and 90% argon) | 0.017 | - | |

| Spacer | Aluminum | 160.0 | 0.1 |

| Sealant | 0.35 | 0.9 | |

| Desiccant | 0.13 | 0.9 | |

| Insulating spacer | Thermoplastic spacer (TPS) | 0.25 1 | 0.9 |

| Frame | Steel | 50.0 | 0.8 |

| Polyvinyl chloride (PVC) | 0.17 | 0.9 | |

| Glazing bead | 0.17 | 0.9 | |

| Silicon | 0.35 | 0.9 | |

| Ethylene propylene diene monomer (EPDM) | 0.25 | 0.9 | |

| Mohair | 0.14 | 0.9 | |

| Setting block | 0.20 | 0.9 |

| Temperature (°C) | Surface Heat Transfer Coefficient (h, W/m2K) | ||

|---|---|---|---|

| Indoor | Plane surface | 20.0 | 7.7 (hi) |

| Edges or junctions between two surfaces | 5.0 (hi_reduced) | ||

| Outdoor | 0.0 | 25.0 (ho) | |

| Base | Low-e Coating | Argon Gas Filling | Low-e Coating and Argon Gas Filling | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | ||

| Case 1 | TDR | 0.29 | 0.29 | 0.27 | 0.27 | 0.29 | 0.29 | 0.29 | 0.29 | 0.27 | 0.27 | 0.29 | 0.26 | 0.26 | 0.28 | 0.26 | 0.26 |

| Tsi (°C) | 13.1 | 13.3 | 14.0 | 14.1 | 13.2 | 13.2 | 13.3 | 13.3 | 14.1 | 14.1 | 13.4 | 14.3 | 14.4 | 13.4 | 14.4 | 14.4 | |

| TDR rank | 4 | 4 | 2 | 2 | 4 | 4 | 4 | 4 | 2 | 2 | 4 | 1 | 1 | 3 | 1 | 1 | |

| Case 2 | TDR | 0.26 | 0.26 | 0.24 | 0.23 | 0.26 | 0.26 | 0.25 | 0.24 | 0.24 | 0.22 | 0.24 | 0.23 | 0.22 | 0.24 | 0.23 | 0.22 |

| Tsi (°C) | 14.4 | 14.4 | 15.3 | 15.8 | 14.5 | 14.5 | 14.7 | 15.2 | 15.4 | 15.9 | 15.1 | 15.6 | 16.1 | 15.3 | 15.7 | 16.2 | |

| TDR rank | 5 | 5 | 3 | 2 | 5 | 5 | 4 | 3 | 3 | 1 | 3 | 2 | 1 | 3 | 2 | 1 | |

| Case 3 | TDR | 0.25 | 0.23 | 0.23 | 0.21 | 0.25 | 0.25 | 0.25 | 0.23 | 0.23 | 0.21 | 0.23 | 0.22 | 0.21 | 0.22 | 0.22 | 0.20 |

| Tsi (°C) | 14.7 | 15.5 | 15.6 | 16.3 | 14.8 | 14.8 | 15.0 | 15.8 | 15.8 | 16.5 | 15.6 | 16.0 | 16.6 | 15.9 | 16.1 | 16.8 | |

| TDR rank | 5 | 4 | 4 | 2 | 5 | 5 | 5 | 4 | 4 | 2 | 4 | 3 | 2 | 3 | 3 | 1 | |

: Region I is satisfied (≤0.22);

: Region I is satisfied (≤0.22);  : Region II is satisfied (≤0.24);

: Region II is satisfied (≤0.24);  : Region III is satisfied (≤0.27).

: Region III is satisfied (≤0.27).| Spacer | Height of Frame Overlapping Glazing (mm) | Alternative Case | Glazing Configuration | TDR | Ut (W/m2K) | ||

|---|---|---|---|---|---|---|---|

| Inner | Outer | ||||||

| Case 1 | Aluminum | 14.0 | - | - | - | - | - |

| Case 2 | TPS | 14.0 | Case 2-9 | 5CL-12Ar-5LE | 5CL-12Air-5LE | 0.22 | 0.975 |

| Case 2-12 | 5CL-12Air-5LE | 5CL-12Ar-5LE | 0.22 | 0.962 | |||

| Case 2-15 | 5CL-12Ar-5LE | 5CL-12Ar-5LE | 0.22 | 0.921 | |||

| Case 3 | TPS | 19.0 (+5.0) | Case 3-3 | 5CL-12Air-5LE | 5CL-12Air-5LE | 0.21 | 1.017 |

| Case 3-9 | 5CL-12Ar-5LE | 5CL-12Air-5LE | 0.21 | 0.966 | |||

| Case 3-11 | 5CL-12Air-5CL | 5CL-12Ar-5LE | 0.22 | 1.056 | |||

| Case 3-12 | 5CL-12Air-5LE | 5CL-12Ar-5LE | 0.21 | 0.954 | |||

| Case 3-13 | 5CL-12Ar-5LE | 5CL-12Ar-5CL | 0.22 | 1.081 | |||

| Case 3-14 | 5CL-12Ar-5CL | 5CL-12Ar-5LE | 0.22 | 1.047 | |||

| Case 3-15 | 5CL-12Ar-5LE | 5CL-12Ar-5LE | 0.20 | 0.912 | |||

: Central region is satisfied (≤1.0 W/m2K);

: Central region is satisfied (≤1.0 W/m2K);  : Southern region is satisfied (≤1.2 W/m2K).

: Southern region is satisfied (≤1.2 W/m2K).| Acg (m2) | Aeg (m2) | Afr (m2) | At(m2) | |

| Case 2 | 2.16 | 0.60 | 1.24 | 4.00 |

| Case 3 | 2.11 | 0.60 | 1.29 | 4.00 |

| Ucg (W/m2K) | Ueg (W/m2K) | Ufr (W/m2K) | Ut (W/m2K) | |

| Case 2-9 | 0.680 | 0.907 | 1.489 | 0.975 |

| Case 3-9 | 0.680 | 0.888 | 1.447 | 0.966 |

| Case 2-12 | 0.681 | 0.946 | 1.432 | 0.962 |

| Case 3-12 | 0.681 | 0.922 | 1.391 | 0.954 |

| Case 2-15 | 0.610 | 0.871 | 1.456 | 0.921 |

| Case 3-15 | 0.610 | 0.845 | 1.413 | 0.912 |

| Temperature (°C) | Relative Humidity (%) | Surface Resistance (m2K/W) | |

|---|---|---|---|

| Hot box | 25.0 ± 1.0 | 50.0 ± 1.0 | 0.11 ± 0.02 |

| Cold box | −20.0 ± 1.0 | - | 0.05 ± 0.02 |

| Temperature (°C) | Surface Resistance (m2K/W) | |

|---|---|---|

| Hot box | 20.0 ± 1.0 | 0.12 ± 0.01 |

| Cold box | 0.0 ± 1.0 | 0.05 ± 0.01 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.; Song, S.-Y. Evaluation of Alternatives for Improving the Thermal Resistance of Window Glazing Edges. Energies 2019, 12, 244. https://doi.org/10.3390/en12020244

Park S, Song S-Y. Evaluation of Alternatives for Improving the Thermal Resistance of Window Glazing Edges. Energies. 2019; 12(2):244. https://doi.org/10.3390/en12020244

Chicago/Turabian StylePark, Sihyun, and Seung-Yeong Song. 2019. "Evaluation of Alternatives for Improving the Thermal Resistance of Window Glazing Edges" Energies 12, no. 2: 244. https://doi.org/10.3390/en12020244

APA StylePark, S., & Song, S.-Y. (2019). Evaluation of Alternatives for Improving the Thermal Resistance of Window Glazing Edges. Energies, 12(2), 244. https://doi.org/10.3390/en12020244