An Enhanced Method to Assess MPC Performance Based on Multi-Step Slow Feature Analysis

Abstract

1. Introduction

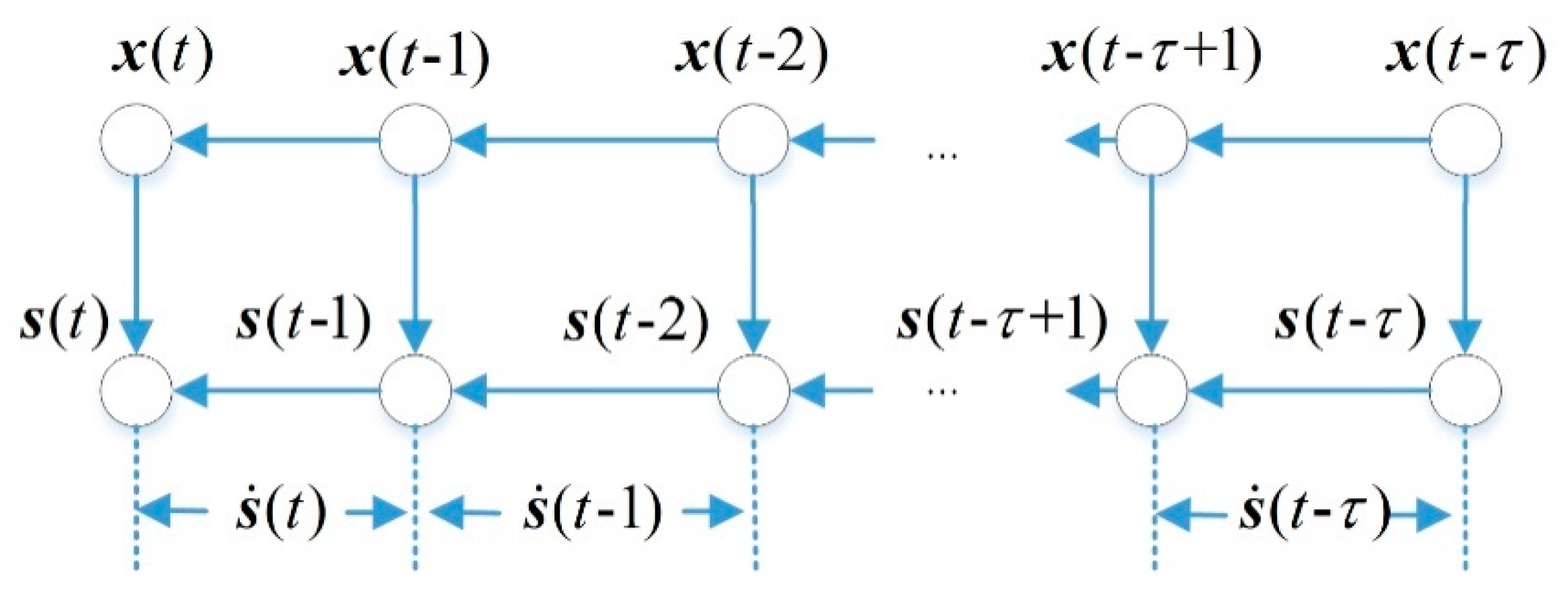

2. Traditional SFA-Based Predictable Index for MPC Performance Assessment

2.1. The Basic Principle of Traditional SFA

2.2. Predictable Index Based on Traditional SFA

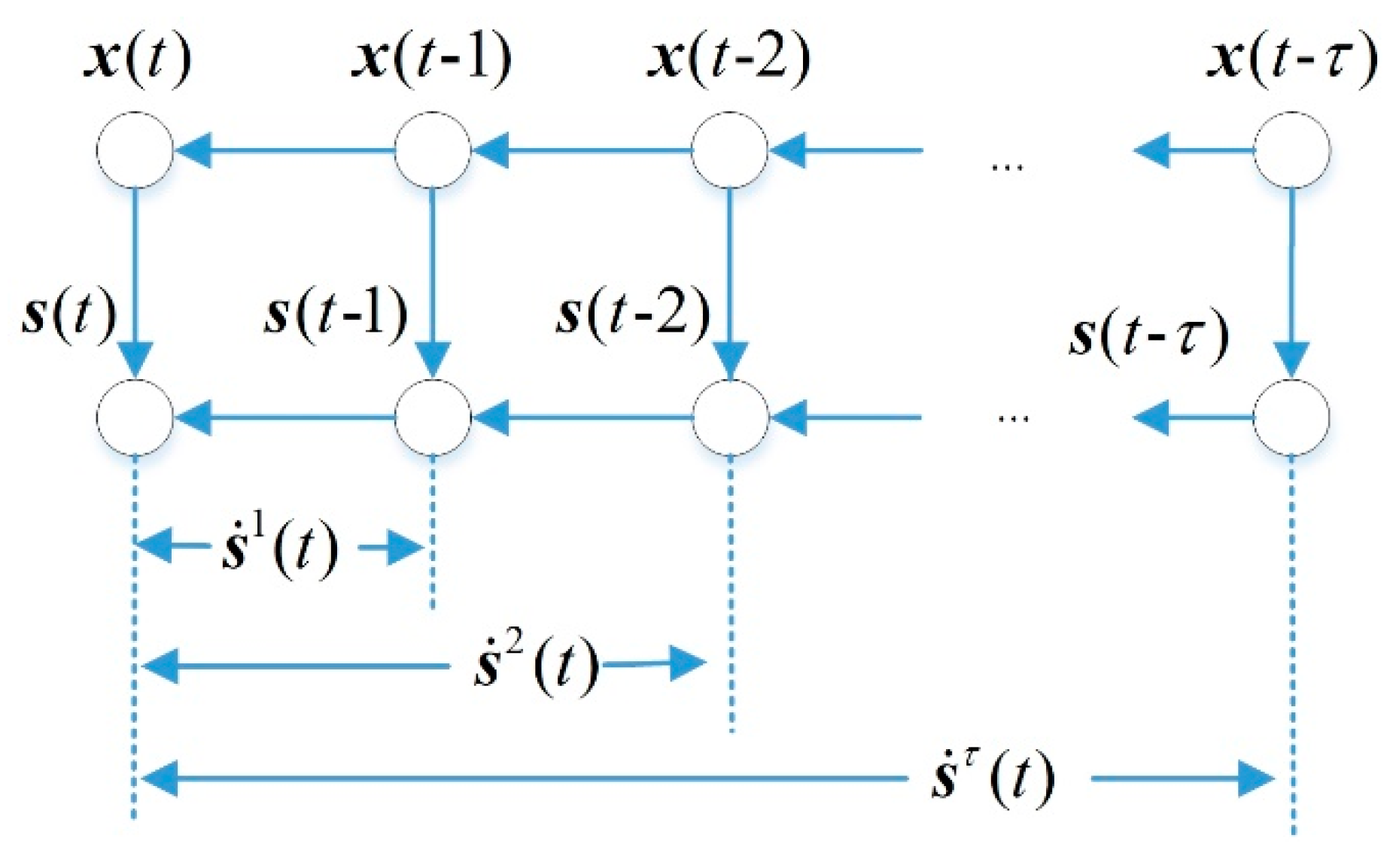

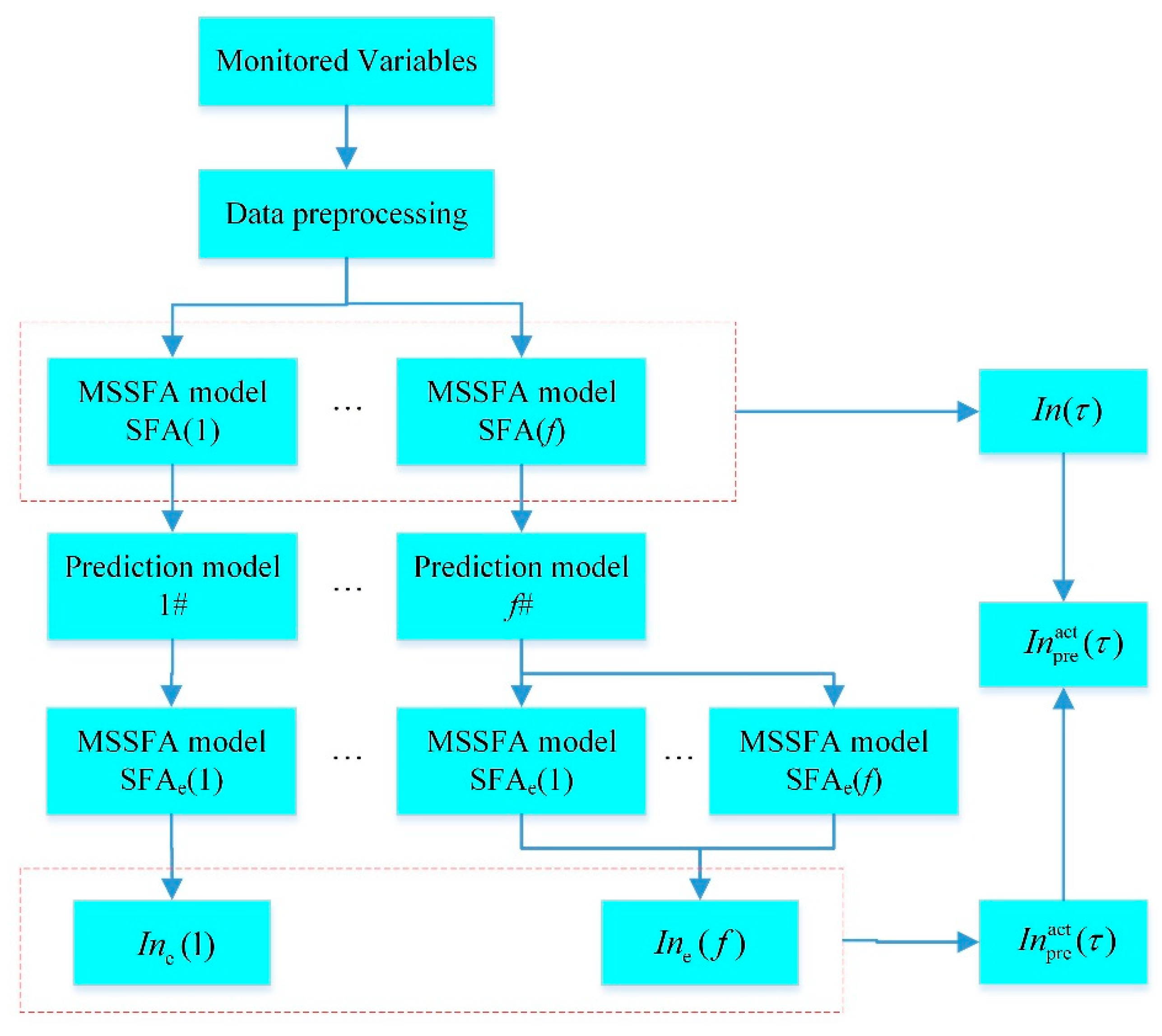

3. The Proposed Enhanced Multi-Step Predictable Index Based on Multi-Step SFA Method

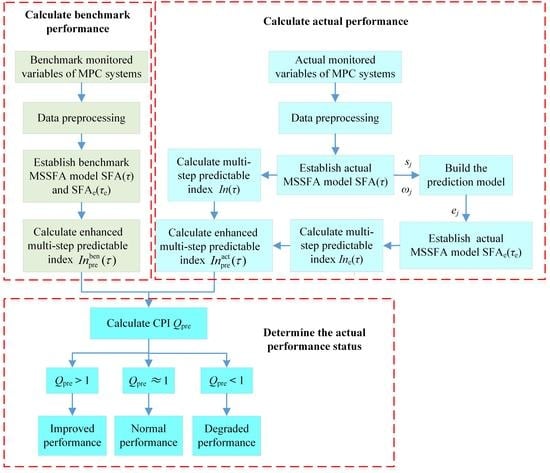

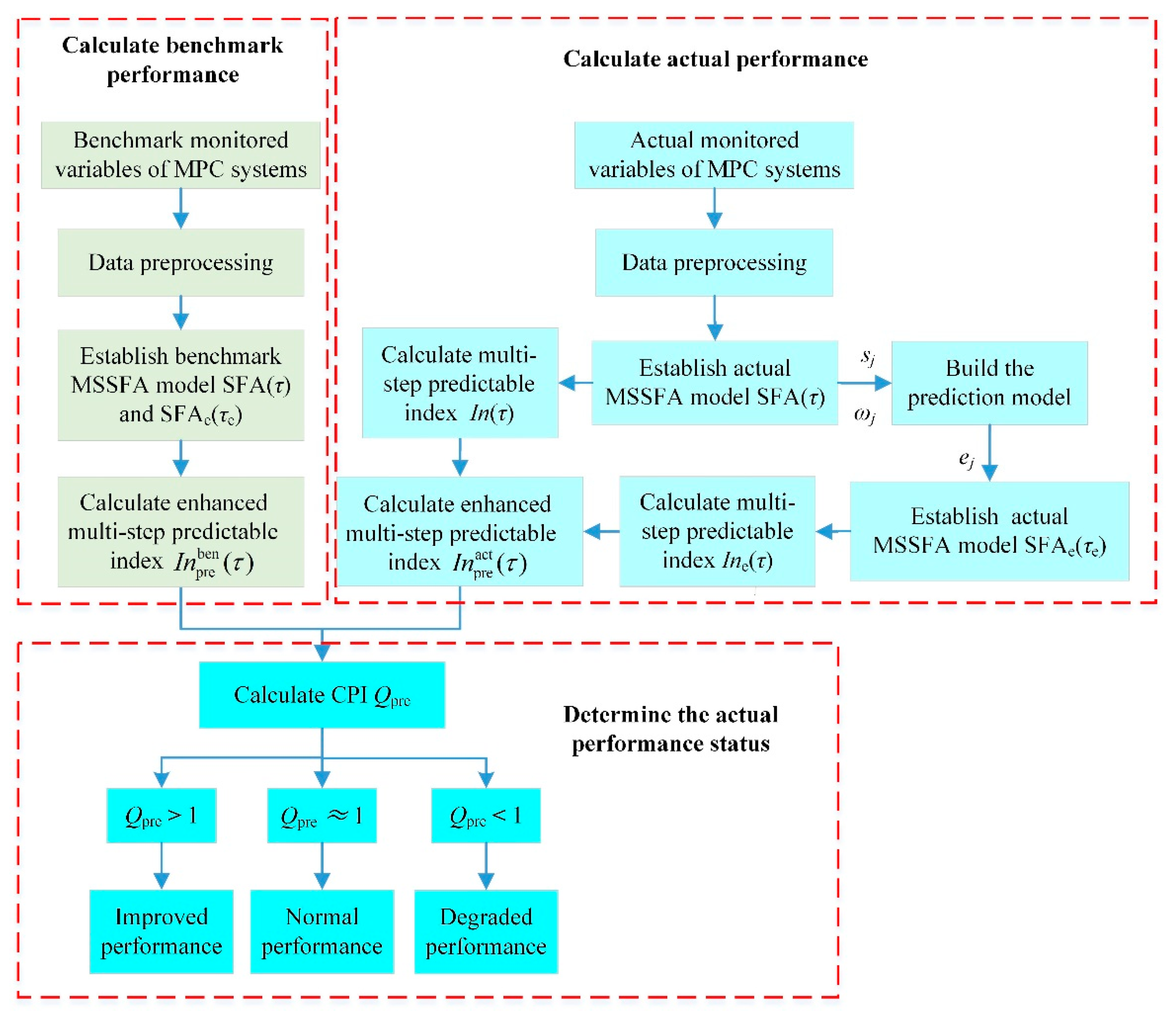

4. Performance Assessment Procedure of Enhanced Multi-Step Predictable Index Based on MSSFA

- (1)

- The monitored variables when the MPC is in a good state are selected from the historical data contained in the DCS database for calculating the benchmark performance of the MPC.

- (2)

- Normalize the selected monitored variables so that the variable data is zero mean and unit variance.

- (3)

- Based on the benchmark monitored variables, build the MSSFA model SFA(τ) and SFAe(τe) under benchmark performance using Equation (20).

- (4)

- Based on the MSSFA model, calculate the enhanced multi-step predictable index as the benchmark performance.

- (1)

- Collect actual monitored variables from the MPC system and built MSSFA model SFA(τ) under actual performance.

- (2)

- Calculate the multi-step predictable index using Equation (22) and build the prediction model using Equation (23) to predict the SFs of SFA(τ).

- (3)

- According to the prediction error of the SFs, build MSSFA model SFAe(τe) and calculate the corresponding multi-step predictable index using Equation (25).

- (4)

- Calculate the enhanced multi-step predictable index using Equation (26) as the actual performance.

- (1)

- Calculate the CPI using Equation (27).

- (2)

- Determine the actual performance: if , the actual performance is improved relative to the selected benchmark performance; if , the actual performance is equivalent to the selected benchmark performance; if , the actual performance is degraded relative to the selected benchmark performance.

5. Case Study

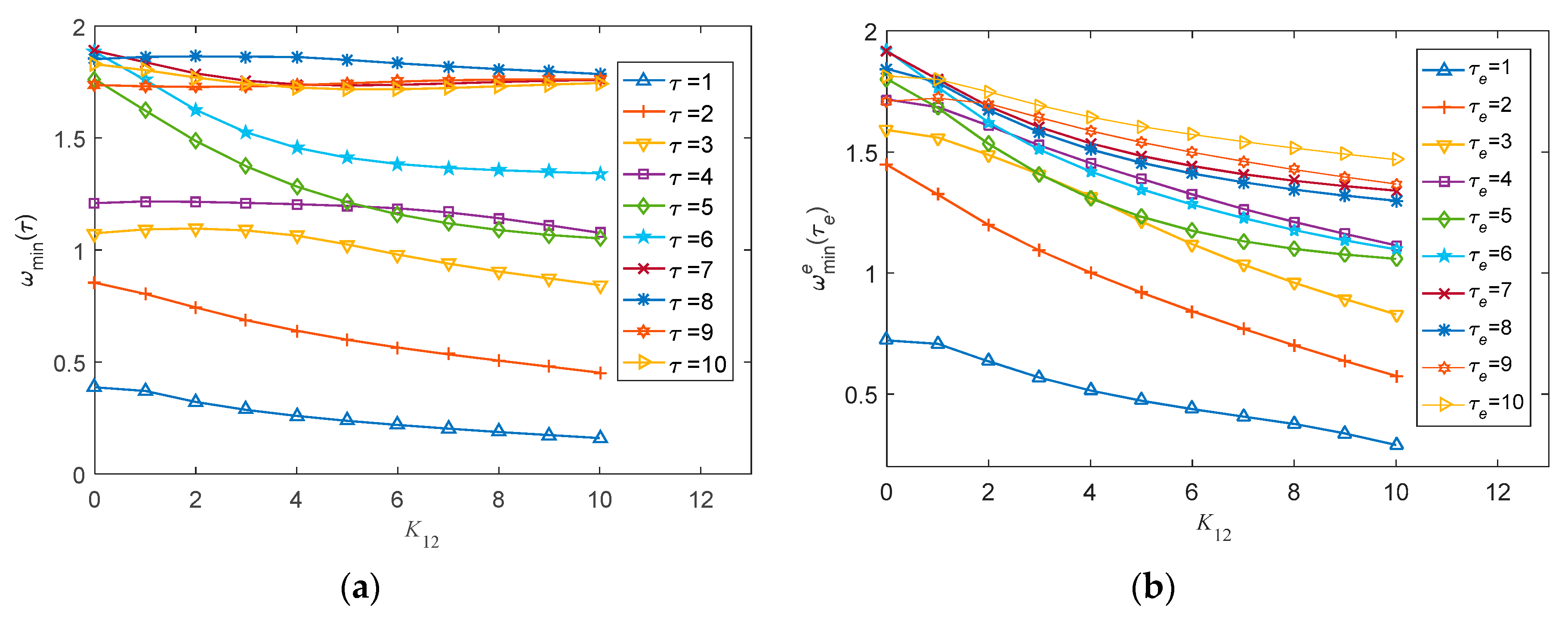

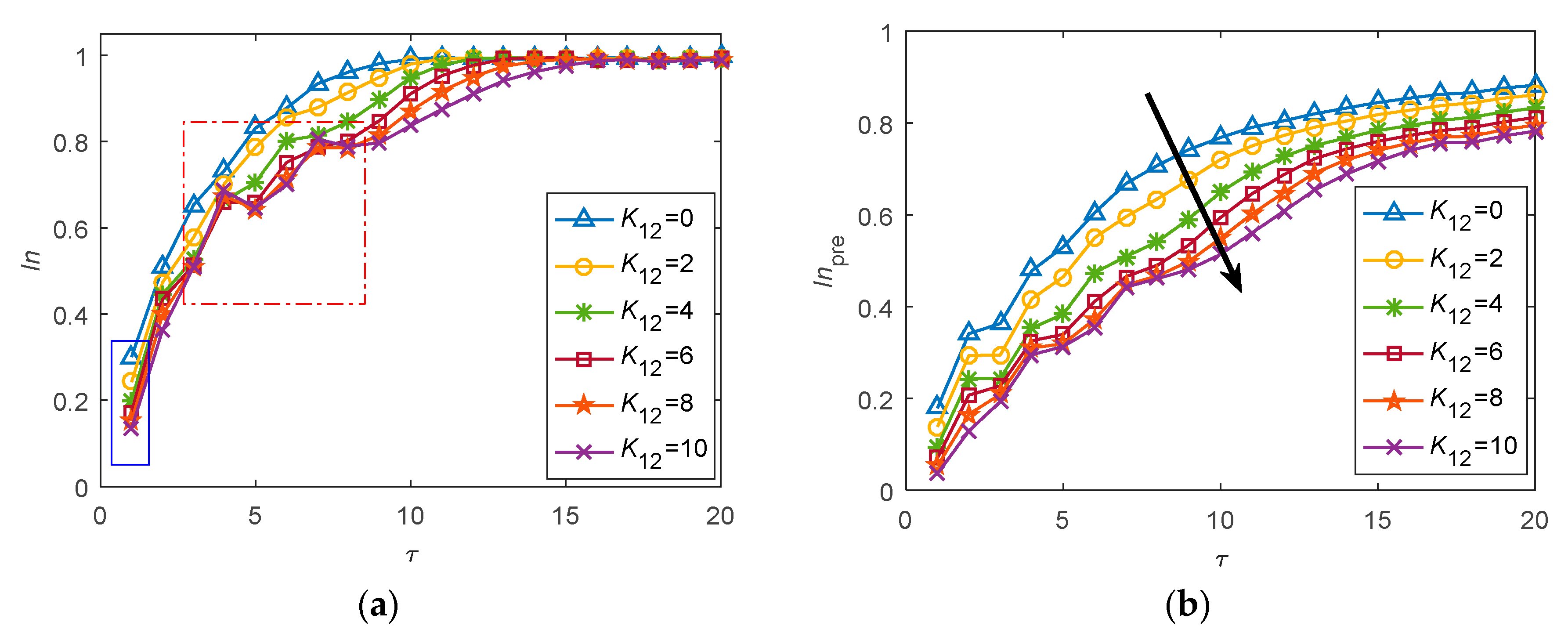

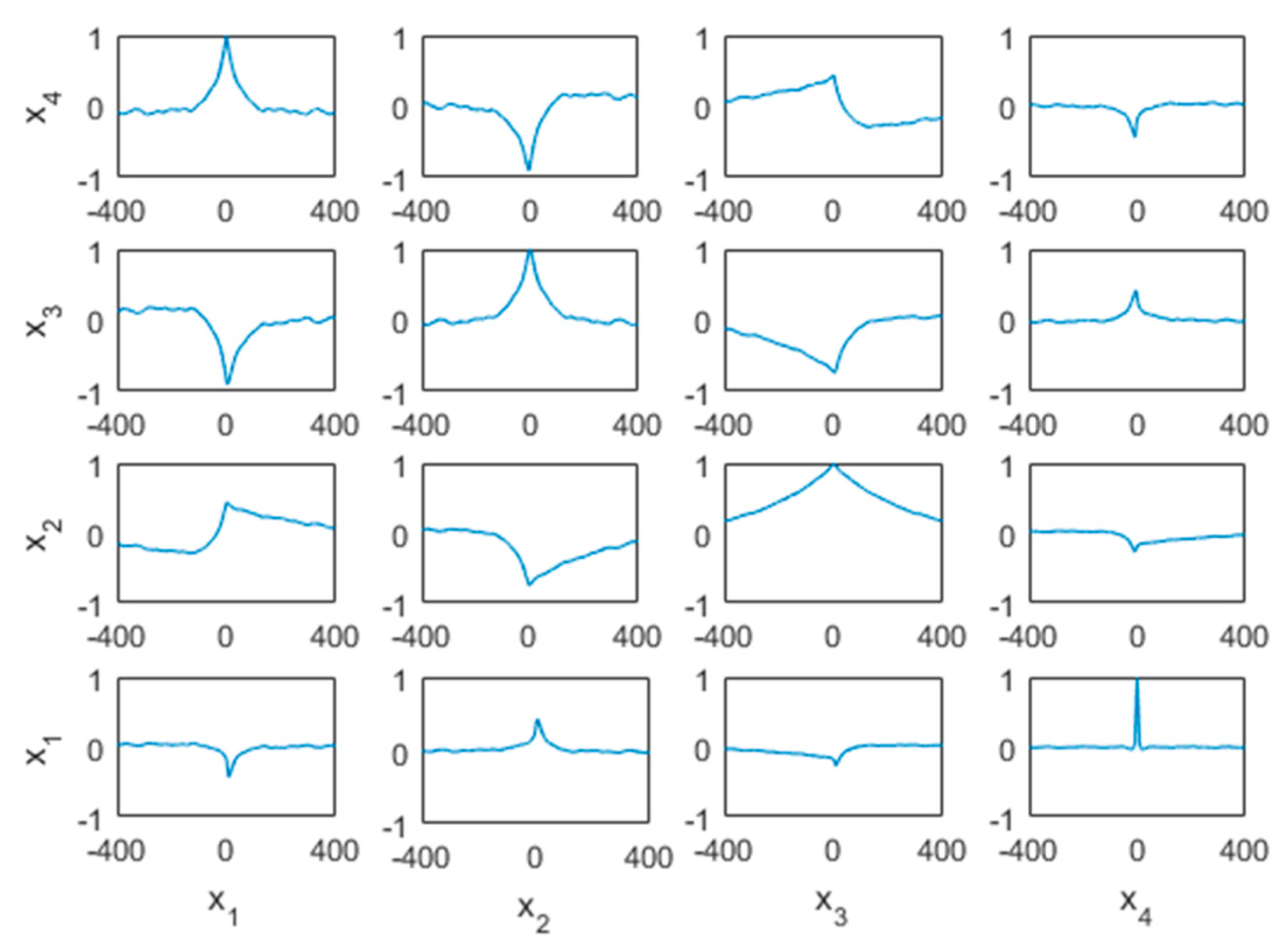

5.1. Numerical Example

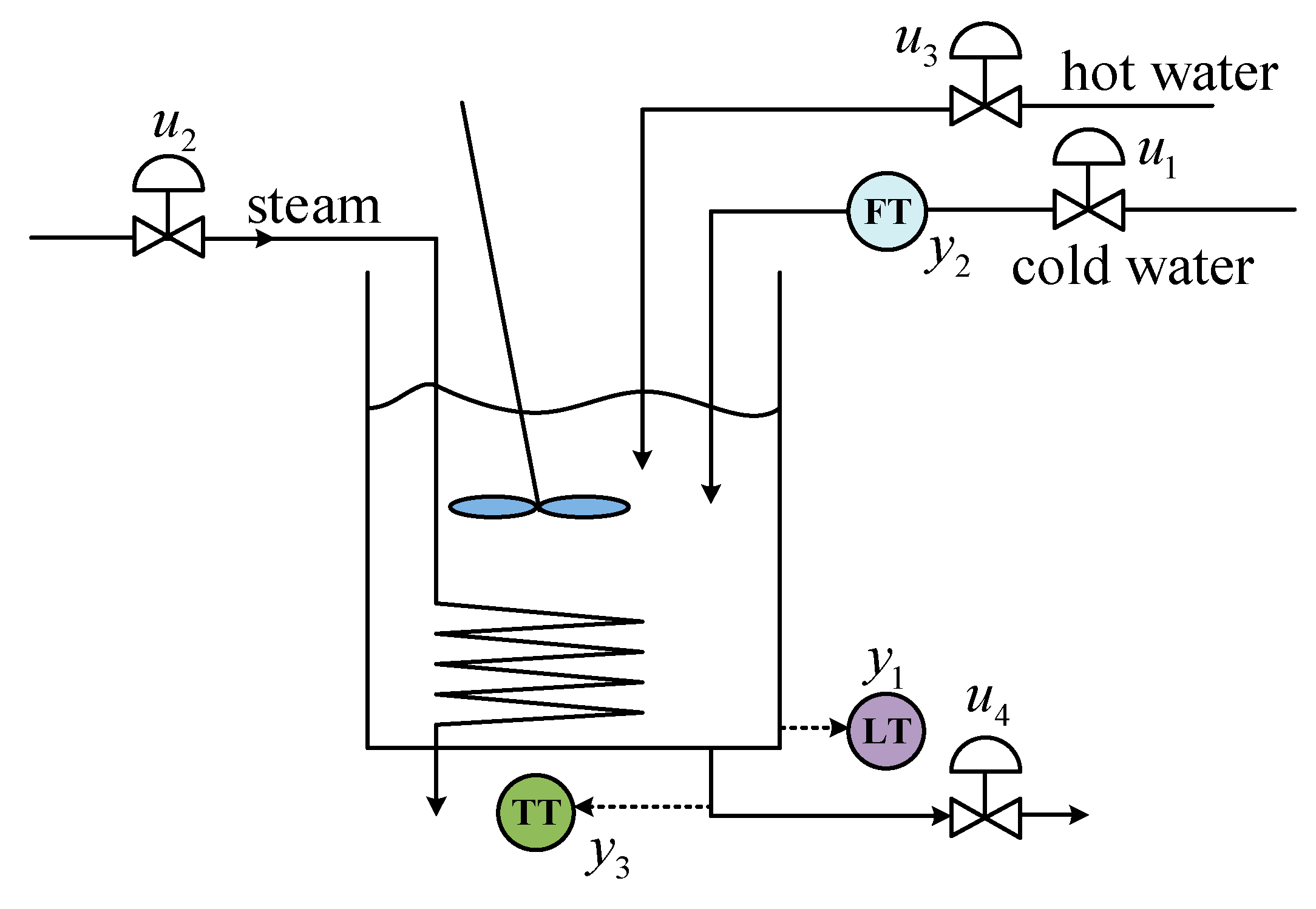

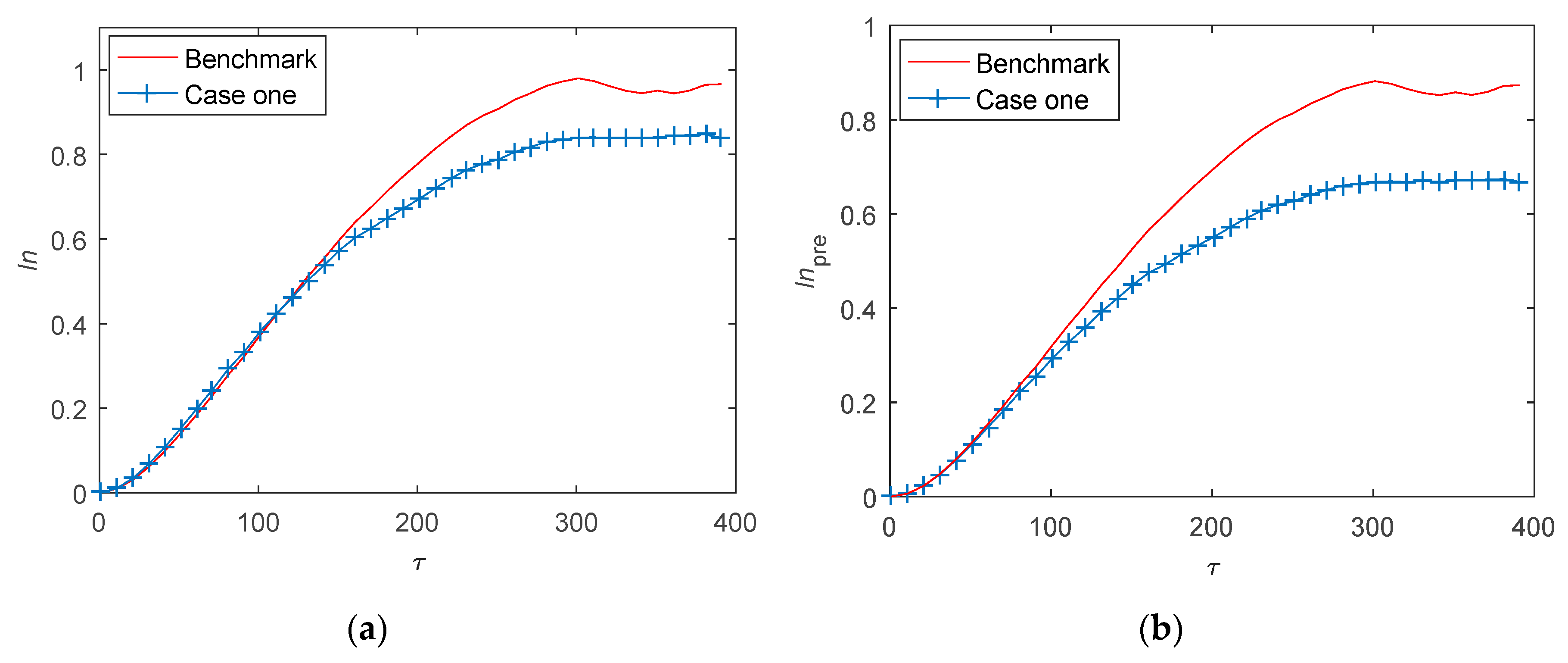

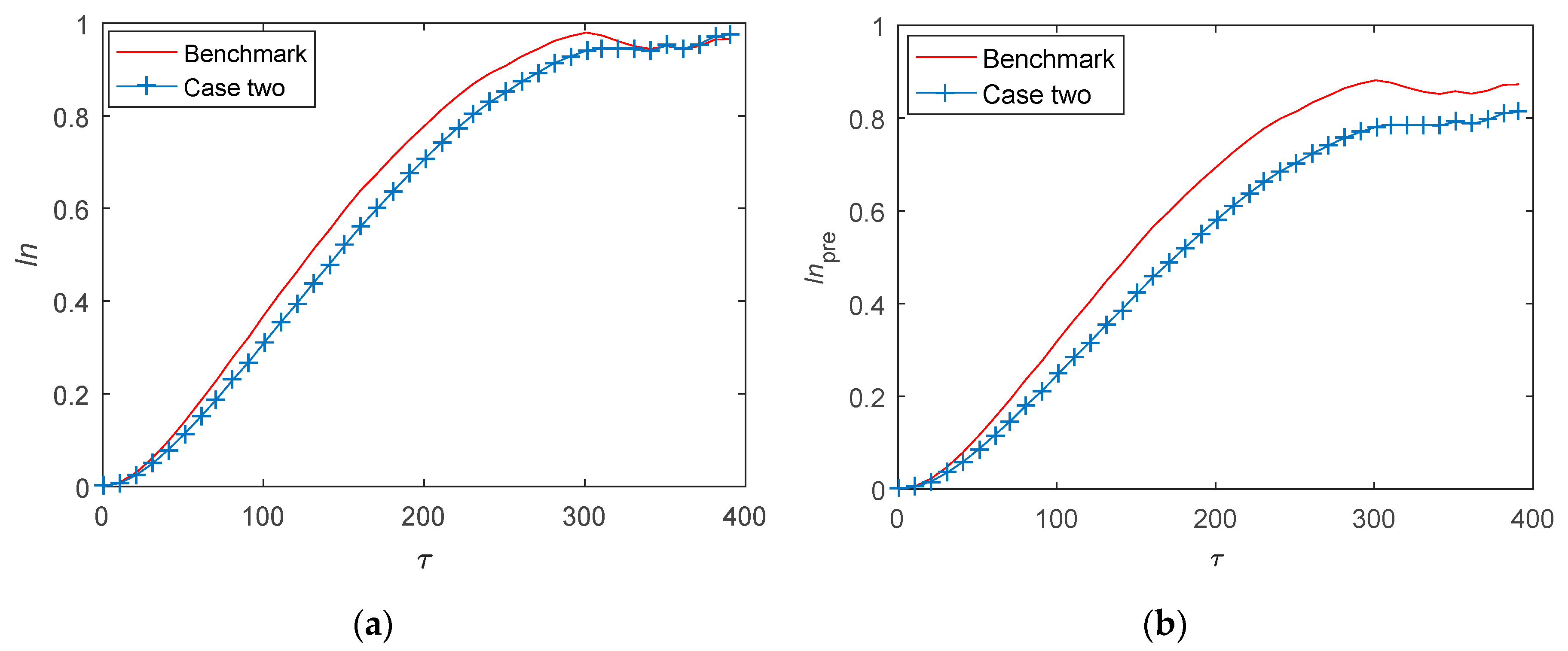

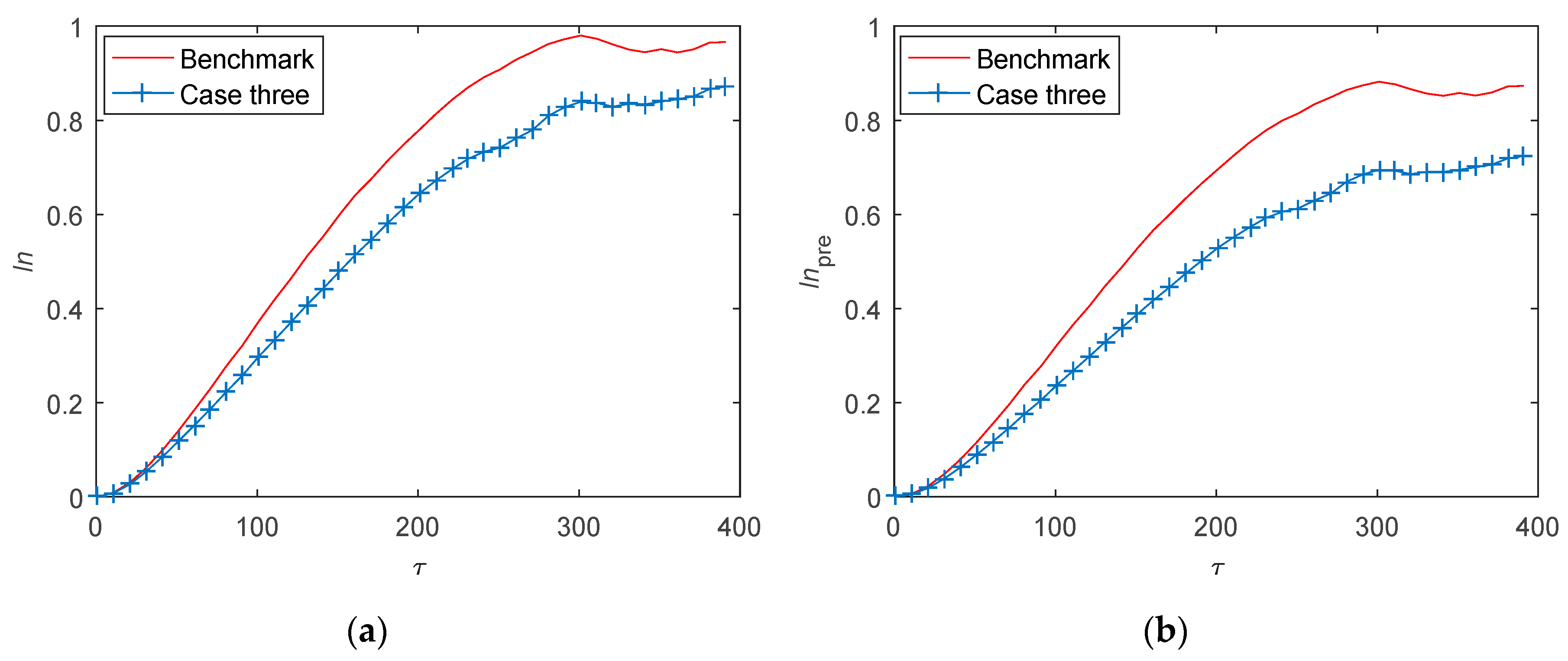

5.2. Continuous Stirred Tank Heater

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| SFA | slow feature analysis |

| MSSFA | multi-step SFA |

| SF | slow feature |

| MPC | model predictive controller |

| PCA | principle component analysis |

| CPA | control performance assessment |

| CSTH | continuous stirred tank heater |

| CPI | control performance index |

| AR | autoregressive |

| PLS | partial least squares |

References

- Xi, G.; Li, D.; Lin, S. Model predictive control—Status and challenges. Acta Autom. Sin. 2013, 39, 222–236. [Google Scholar] [CrossRef]

- Qin, S.J.; Badgwell, T.A. A survey of industrial model predictive control technology. Control Eng. Pract. 2003, 11, 733–764. [Google Scholar] [CrossRef]

- Tian, X.; Chen, G.; Chen, S. A data-based approach for multivariate model predictive control performance monitoring. Neurocomputing 2011, 74, 588–597. [Google Scholar] [CrossRef]

- Zheng, Y.; Wei, Y.; Li, S. Coupling degree clustering-based distributed model predictive control network design. IEEE Trans. Autom. Sci. Eng. 2018, 15, 1749–1758. [Google Scholar] [CrossRef]

- Jelali, M. Control Performance Management in Industrial Automation; Springer: London, UK, 2013. [Google Scholar]

- Desborough, L. Increasing customer value of industrial control performance monitoring-Honeywell’s experience. In Proceedings of the Sixth International Conference on Chemical Process Control, Tucson, AZ, USA, 7–12 January 2001; p. 6. [Google Scholar]

- Starr, K.D.; Petersen, H.; Bauer, M. Control loop performance monitoring—ABB’s experience over two decades. IFAC-PapersOnLine 2016, 49, 526–532. [Google Scholar] [CrossRef]

- Schäfer, J.; Cinar, A. Multivariable MPC system performance assessment, monitoring, and diagnosis. J. Process Control 2004, 14, 113–129. [Google Scholar] [CrossRef]

- Gao, X.; Yang, F.; Shang, C.; Huang, D. A review of control loop monitoring and diagnosis: Prospects of controller maintenance in big data era. Chin. J. Chem. Eng. 2016, 24, 952–962. [Google Scholar] [CrossRef]

- Albarbar, A.; Arar, A. Performance Assessment and Improvement of Central Receivers Used for Solar Thermal Plants. Energies 2019, 12, 3079. [Google Scholar] [CrossRef]

- Zhao, H.; Guo, S.; Zhao, H. Comprehensive performance assessment on various battery energy storage systems. Energies 2018, 11, 2841. [Google Scholar] [CrossRef]

- Bauer, M.; Horch, A.; Xie, L.; Jelali, M.; Thornhill, N. The current state of control loop performance monitoring—A survey of application in industry. J. Process Control 2016, 38, 1–10. [Google Scholar] [CrossRef]

- Grimble, M.J. Controller performance benchmarking and tuning using generalised minimum variance control. Automatica 2002, 38, 2111–2119. [Google Scholar] [CrossRef]

- Huang, B. Multivariate Statistical Methods for Control Loop Performance Assessment. Ph.D. Thesis, University of Alberta, Edmonton, AB, Canada, 1998. [Google Scholar]

- Julien, R.H.; Foley, M.W.; Cluett, W.R. Performance assessment using a model predictive control benchmark. J. Process Control 2004, 14, 441–456. [Google Scholar] [CrossRef]

- Morari, M.; Lee, J.H. Model predictive control: Past, present and future. Comput. Chem. Eng. 1999, 23, 667–682. [Google Scholar] [CrossRef]

- Zhang, Y.; Henson, M.A. A performance measure for constrained model predictive controllers. In Proceedings of the 1999 European Control Conference (ECC), Naples, Italy, 25–28 June 2019; pp. 918–923. [Google Scholar]

- Patwardhan, R.S.; Shah, S.L.; Qi, K.Z. Assessing the performance of model predictive controllers. Can. J. Chem. Eng. 2002, 80, 954–966. [Google Scholar] [CrossRef]

- Cai, L.; Thornhill, N.F.; Kuenzel, S.; Pal, B.C. Wide-area monitoring of power systems using principal component analysis and k-nearest neighbor analysis. IEEE Trans. Power Syst. 2018, 33, 4913–4923. [Google Scholar] [CrossRef]

- Deng, X.; Tian, X.; Chen, S.; Harris, C.J. Nonlinear Process Fault Diagnosis Based on Serial Principal Component Analysis. IEEE Trans. Neural Netw. Learn. Syst. 2018, 29, 560–572. [Google Scholar] [CrossRef]

- AlGhazzawi, A.; Lennox, B. Model predictive control monitoring using multivariate statistics. J. Process Control 2009, 19, 314–327. [Google Scholar] [CrossRef]

- Shang, L.; Tian, X.; Cao, Y.; Cai, L. MPC performance monitoring and diagnosis based on dissimilarity analysis of pls cross-product matrix. Acta Autom. Sin. 2017, 43, 271–279. [Google Scholar]

- Ge, Z. Review on data-driven modeling and monitoring for plant-wide industrial processes. Chemom. Intell. Lab. Syst. 2017, 171, 16–25. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, S. Performance monitoring and diagnosis of multivariable model predictive control using statistical analysis. Chin. J. Chem. Eng. 2006, 14, 207–215. [Google Scholar]

- Zhao, S.J.; Zhang, J.; Xu, Y.M. Performance monitoring of processes with multiple operating modes through multiple PLS models. J. Process Control 2006, 16, 763–772. [Google Scholar] [CrossRef]

- Yu, J.; Qin, S. Statistical MIMO controller performance monitoring. Part I: Datadriven covariance benchmark. J. Process Control 2008, 18, 277–296. [Google Scholar] [CrossRef]

- Yu, J.; Qin, S. Statistical MIMO controller performance monitoring. Part II: Performance diagnosis. J. Process Control 2008, 18, 297–319. [Google Scholar] [CrossRef]

- Li, C.; Huang, B.; Zheng, D.; Qian, F. Multi-input-multi-output (MIMO) control system performance monitoring based on dissimilarity analysis. Ind. Eng. Chem. Res. 2014, 53, 18226–18235. [Google Scholar] [CrossRef]

- Yan, Z.; Chan, C.; Yao, Y. Multivariate control performance assessment and control system monitoring via hypothesis test on output covariance matrices. Ind. Eng. Chem. Res. 2015, 54, 5261–5272. [Google Scholar] [CrossRef]

- Wu, P. Performance monitoring of MIMO control system using Kullback-Leibler divergence. Can. J. Chem. Eng. 2018, 96, 1559–1565. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, G.; Li, N.; Zhang, J.; Li, S.; Wang, L. Data-driven performance monitoring for model predictive control using a mahalanobis distance based overall index. Asian J. Control 2019, 21, 891–907. [Google Scholar] [CrossRef]

- Xu, Y.; Li, N.; Li, S. A Data-driven performance assessment approach for MPC using improved distance similarity factor. In Proceedings of the IEEE 10th Conference on Industrial Electronics and Applications (ICIEA), Auckland, New Zealand, 15–17 June 2015; pp. 1870–1875. [Google Scholar]

- Shang, C.; Yang, F.; Gao, X.; Huang, X.; Johan, A.K.; Huang, D. Concurrent monitoring of operating condition deviations and process dynamics anomalies with slow feature analysis. AIChE J. 2015, 61, 3666–3682. [Google Scholar] [CrossRef]

- Shang, C.; Huang, B.; Yang, F.; Huang, D. Slow feature analysis for monitoring and diagnosis of control performance. J. Process Control 2016, 39, 21–34. [Google Scholar] [CrossRef]

- Zhang, H.; Tian, X.; Deng, X.; Cao, Y. Multiphase batch process with transitions monitoring based on global preserving statistics slow feature analysis. Neurocomputing 2018, 293, 64–86. [Google Scholar] [CrossRef]

- Shang, C.; Huang, B.; Yang, F.; Huang, D. Probabilistic slow feature analysis-based representation learning from massive process data for soft sensor modeling. AIChE J. 2015, 61, 4126–4139. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, C. Fine-scale online assessment of glycemic control performance based on temporal feature analysis. Ind. Eng. Chem. Res. 2019, 58, 4374–4386. [Google Scholar] [CrossRef]

- Qin, Y.; Zhao, C. Comprehensive process decomposition for closed-loop process monitoring with quality-relevant slow feature analysis. J. Process Control 2019, 77, 141–154. [Google Scholar] [CrossRef]

- Shang, L.; Wang, Y.; Deng, X.; Cao, Y.; Wang, P.; Wang, Y. A model predictive control performance monitoring and grading strategy based on improved slow feature analysis. IEEE Access 2019, 7, 50897–50911. [Google Scholar] [CrossRef]

- Huang, B.; Ding, S.; Thornhill, N. Alternative solutions to multivariate control performance assessment problems. J. Process Control 2006, 16, 457–471. [Google Scholar] [CrossRef]

- Thornhill, N.F.; Oettinger, M.; Fedenczuk, P. Refinery-wide control loop performance assessment. J. Process Control 1999, 9, 109–124. [Google Scholar] [CrossRef][Green Version]

- Thornhill, N.F.; Patwardhan, S.C.; Shah, S.L. A continuous stirred tank heater simulation model with applications. J. Process Control 2008, 18, 347–360. [Google Scholar] [CrossRef]

| 0 | 2 | 4 | 6 | 8 | 10 | |

|---|---|---|---|---|---|---|

| 1.0000 | 0.9673 | 0.9307 | 0.9074 | 0.8888 | 0.8729 | |

| 1.0000 | 0.9316 | 0.8488 | 0.7963 | 0.7575 | 0.7268 |

| Parameter | Description | Parameter | Description |

|---|---|---|---|

| the level of water | the volume of water | ||

| the cold water flow into the tank | the hot water flow into the tank | ||

| the outflow from the tank | the total enthalpy in the tank | ||

| the specific enthalpy of hot water feed | the specific enthalpy of cold water feed | ||

| the density of incoming cold water | the density of incoming hot water | ||

| the density of water leaving the tank | the heat inflow from steam |

| Variable | Operating Points |

|---|---|

| Level/cm | 20.48 |

| Cold water flow/cm3/s | 90.38 |

| Cold water valve/mA | 12.96 |

| Temperature/°C | 42.52 |

| Steam valve/mA | 12.57 |

| Hot water valve/mA | 0 |

| Hot water flow/cm3/s | 0 |

| Case | Parameter | Variation Range |

|---|---|---|

| Case one | Outlet flow | +1.4 cm3/s |

| Case two | Hot water flow | +0.3 cm3/s |

| Case three | Sensor bias in tank level | +1cm |

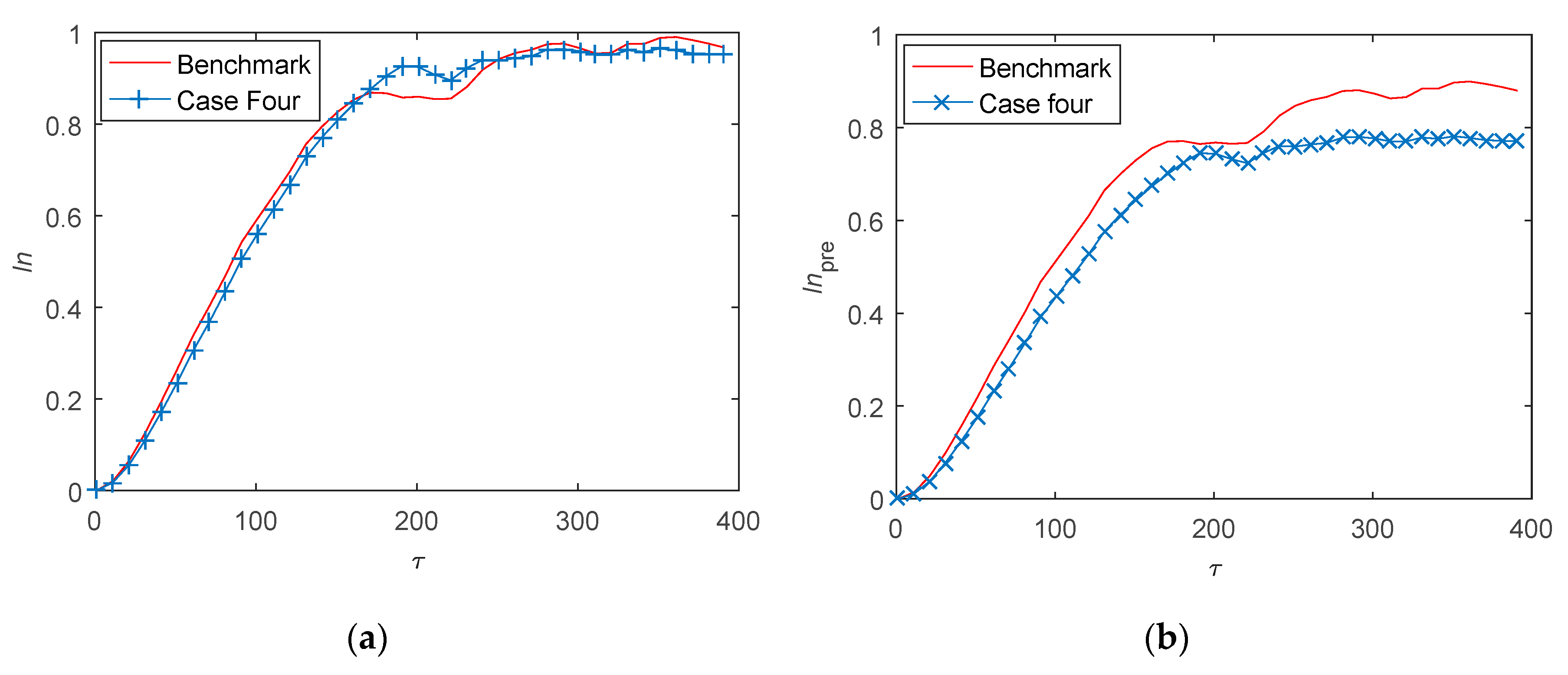

| Case four | Hot water flow | +0.6 cm3/s |

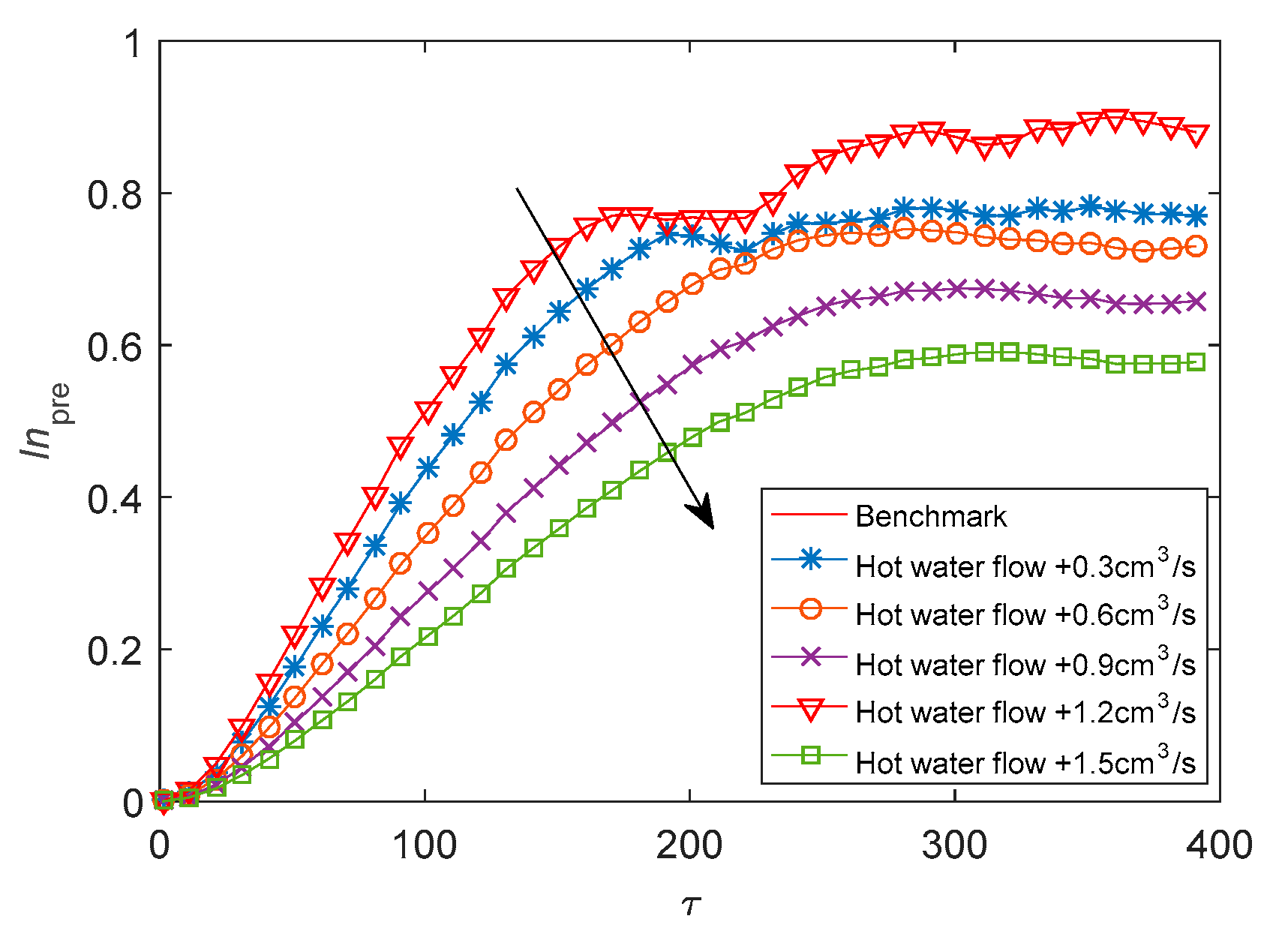

| Case five | Hot water flow | +0.6 cm3/s → +1.5 cm3/s |

| CPIs | Case One | Case Two | Case Three | Case Four |

|---|---|---|---|---|

| 0.9486 | 0.9018 | 0.8404 | 0.9706 | |

| 0.8425 | 0.8310 | 0.7720 | 0.8715 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, L.; Wang, Y.; Deng, X.; Cao, Y.; Wang, P.; Wang, Y. An Enhanced Method to Assess MPC Performance Based on Multi-Step Slow Feature Analysis. Energies 2019, 12, 3799. https://doi.org/10.3390/en12193799

Shang L, Wang Y, Deng X, Cao Y, Wang P, Wang Y. An Enhanced Method to Assess MPC Performance Based on Multi-Step Slow Feature Analysis. Energies. 2019; 12(19):3799. https://doi.org/10.3390/en12193799

Chicago/Turabian StyleShang, Linyuan, Yanjiang Wang, Xiaogang Deng, Yuping Cao, Ping Wang, and Yuhong Wang. 2019. "An Enhanced Method to Assess MPC Performance Based on Multi-Step Slow Feature Analysis" Energies 12, no. 19: 3799. https://doi.org/10.3390/en12193799

APA StyleShang, L., Wang, Y., Deng, X., Cao, Y., Wang, P., & Wang, Y. (2019). An Enhanced Method to Assess MPC Performance Based on Multi-Step Slow Feature Analysis. Energies, 12(19), 3799. https://doi.org/10.3390/en12193799