Abstract

For new submarine hot oil pipelines, accurate simulation of preheating is difficult owing to complex transient flow and coupled heat transfer happening. Using quasi-steady equations to simulate preheating is inadequate as the hydraulic transient phenomenon is neglected. Considering this fact, this paper constructs an unsteady flow and heat transfer coupled mathematical model for the preheating process. By combining the double method of characteristics (DMOC) and finite element method (FEM), a numerical methodology is proposed, namely, DMOC-FEM. Its accuracy is validated by field data collected from the Bohai sea, China, showing the mean absolute percentage error (MAPE) of 4.27%. Simulation results demonstrate that the preheating medium mainly warms submarine pipe walls rather than the surrounding subsea mud. Furthermore, during the preheating process, the equivalent overall heat transfer coefficients deduced performs more applicably than the inverse-calculation method in presenting the unsteady propagation of fluid temperature with time and distance. Finally, according to the comparison results of 11 preheating plans, subject to a rated heat power and maximum flow, the preheating parameter at a lower fluid temperature combined with a higher flow rate will produce a better preheating effect.

1. Introduction

Driven by the progressive exploration of offshore oil fields, the construction speed and total mileage of submarine crude oil pipelines have been dramatically accelerated per year [1,2]. For new submarine hot oil pipelines that transport waxy and heavy crude oil, pipeline preheating is needed at the initial stage of transportation [3,4,5]. By transmitting a heated preheating medium before crude oil, submarine pipelines and subsea mud are preheated to a predesigned temperature. It avoids the heated crude oil contacting with cold submarine pipes directly after oil injection, which prevents a dramatic temperature drop and viscosity rise of crude oil [6]. Because of high capacity, low viscosity, and easy accessibility, water can be selected as a preheating medium [7].

The preheating process is a three-dimensional unsteady flow and heat transfer coupled process in which the pipeline and the surrounding soil continuously absorb heat from the preheating medium [8]. Before being preheated, fluid in pipelines remains stagnant, while the temperature of the fluid and pipe walls is consistent with the cold subsea environment. Once the hot preheating medium is injected, the internal fluid starts to change continuously in both hydraulic and thermal aspects, until a new steady status forms. Inadequate preheating duration and temperature may weaken the required preheating effect, causing an unexpected increase of viscosity and pressure drop after hot oil transmission. Hence, for a new submarine hot oil pipeline, preheating is indeed a key procedure to decide whether it can be put into production safely and smoothly [6].

Experimental [9,10] and modeling investigations [11,12] have been carried out on the thermal change of submarine hot oil pipelines. Based on the similarity theory, Qi [13] built experimental equipment of submarine oil pipelines to investigate the effect of crude oil temperature, seawater temperature, seawater flow rate, and water content on temperature drop after a pipeline shutdown. Thusyanthan [14] presented a novel laboratory setup using the thermal imaging technique to simulate the heat loss of offshore pipelines and determine the thermal conductivity of offshore clay. Oh [15] created a laboratory-scale experimental apparatus to imitate a submarine pipeline partially or fully buried into the seabed. By analyzing the temperature of a pipe’s external surface, the effect of buried depth on the steady-state heat transfer coefficient was investigated. Through a series of research, Chakraborty [9,10,16,17] illustrated the mechanism of heat loss from offshore buried pipelines by experimental modeling.

Compared with experimental investigations, modeling is more convenient. For solving thermal change during the preheating process, earlier studies have deduced the analytical solution in the theory of linear heat resources or equivalent cylinders [18,19,20]. In recent years, with the development of computing technology [21,22], numerical simulation has become the dominating method for studying the unsteady process of buried oil pipelines [23,24,25]. Based on the adopted numerical heat transfer theories, the algorithms commonly used can be divided into the finite difference method (FDM) [26], the finite element method (FEM) [27] and the finite volume method (FVM) [7,28,29]. The most serious defect of FDM lies in its poor adaptability to complex regions, and that the conservation of discretization equations is difficult to be guaranteed [30]. In comparison, benefiting from unstructured meshing technology, FEM and FVM are more adaptable to handle the irregular computational regions of heat transfer problems, which are applied to buried oil pipelines widely [31,32]. By combining mesh generation and the numerical discretization scheme, numerical simulation is helpful to rapidly predict the parameter changes under unsteady process. In this way, researchers have modeled the preheating of hot oil pipelines to investigate potential tendencies. The most common issues studied include the change of fluid temperature, the soil temperature field, and heat storage as well as oil injection time [12,27]. For example, Wheeler [33] researched the rule of thermal transmission and dissipation of buried oil pipelines with FEM and FDM. Patience [20] studied the starting of a compressible Newtonian fluid in small-distance pipes. In the hypothesis of constant physical properties, Vedeneev [26] presented a thermal analysis of long-distance pipe start-ups with FDM from the aspects of momentum and energy. Xu [34] treated the soil as a porous medium and built a heat-moisture model for waxy crude oil pipelines. The model was verified by experimental data and used to evaluate the operation safety of another pipeline. Lu [35] investigated the influence of ambient temperature and preheating water temperature on the soil temperature field of buried oil pipelines via FVM. With the employment of annular thermal influence regions, Xing [7] established a coupled heat transfer model for crude oil pipeline commissioning and proposed an FDM and FVM combined methodology to solve the temperature of fluid, pipe walls, and soil. An optimization for preheating the Niger crude oil pipeline was performed, too. To accelerate the computational efficiency, Li [28] adopted the parallel computing and matrix method. In addition, Yu [36] established a POD–Galerkin reduced-order model based on FVM for the thermal process of buried oil pipelines, including batching transportation and commissioning.

The studies mentioned are all about onshore pipelines. There is relatively less corresponding research on preheating submarine hot oil pipelines. For submarine pipelines, Barletta [37] transformed the unsteady two-dimensional heat conduction equations into a steady dimensionless form. Solving by FEM software numerically, the rule of heat loss under periodic thermal boundary conditions was performed. Furthermore, he investigated two different start-up cases: The step-rising case and the smooth-rising case [11]. Different preheating effects and transient operation rules were discussed consequently. By studying the effect of the velocity of bottom seawater on the preheating effect in the Bohai sea, Qi [38] demonstrated that the upper boundary of the computational region for subsea mud could be simplified to the Dirichlet boundary at the temperature of seawater. Bai [39] performed a parametric study to evaluate the effects of the thermal power loss, burial depth, pipe diameter, and soil thermal conductivity on the thermal field in the near field of a subsea buried pipeline.

By combining the fluid temperature model with differential equations of unsteady heat conduction, the studies mentioned have established the basic resolving thoughts for preheating submarine hot oil pipelines. It can be concluded that the methods adopted are basically the same as those used to model other unsteady heat transfer problems of buried pipelines, which go through the development procedure from analytical to numerical solution. However, in current simulation research for pipeline preheating processes, one of the biggest problems is the neglect of transient hydraulics due to the main focus on temperature change during preheating. Without the coupled solution of hydrodynamic equations and change in the physical property of the preheating medium [26], most research are regarding preheating as a quasi-steady state process—only presenting the thermal equations of transported fluid [27,38]. In this way, the unsteady hydrodynamics caused by flow and pressure fluctuation cannot be solved simultaneously. The thermal simulation results relevant to hydraulic calculation would also consequently be affected. For example, in reference [11,12], the pressure was absent in the fluid heat dissipation model. In reference [7] and [36], although hydraulics were involved in the fluid model, the hydro–thermal coupling algorithm was not presented. Hence, it is what is very needed to improve the preheating model for submarine hot oil pipelines and to propose corresponding numerical algorithms.

Besides fluid temperature, the overall heat transfer coefficient is another key indicator for hot oil pipelines to reflect its operation status, such as preheating, shutdown, and restarting [40,41]. But it has been not discussed in the above research for preheating operations. Although Zakarian [40], Sund [42], Chakraborty [9] and Magda [43] et al. have studied the overall heat transfer coefficient and shape factor from partially and fully buried submarine pipelines successively, the studies were all in the view of a steady-state model, which cannot be employed for unsteady preheating directly. Given this, it is necessary to establish a computing expression of the overall heat transfer coefficient for submarine hot oil pipelines based on an unsteady-state model. In this way, the operational status of subsea pipelines and transient thermal propagation can be described.

Considering these facts, this paper establishes a coupled mathematical model for preheating new submarine hot oil pipelines. The numerical algorithm for the coupling resolution of hydrodynamics, thermodynamics, and unsteady heat transfer is provided. Field data was used to verify its accuracy. Furthermore, for analyzing the pipeline operational status during preheating, the temperature, overall heat transfer coefficient, and heat storage are discussed. Based on the designed scenario, an optimization of preheating parameters is performed at the end of this paper.

2. Mathematical Model

The thermal system of submarine pipelines contains the convective heat transfer of fluid in the pipe, the heat conduction of pipe walls and subsea mud. They are affected by a lot of parameters such as temperature and properties of pipe, subsea mud, and seawater. In proposing the mathematical model, the following reasonable assumptions are made in this paper [7,36].

(1) The fluid parameter on a fixed pipeline cross-section is assumed to be uniform. Hence, the pressure, flow rate, and temperature in pipelines only depend on the time and axial location of the pipeline.

(2) By neglecting the axial temperature drop of subsea mud, the heat transfer outside pipelines is assumed to be two dimensional.

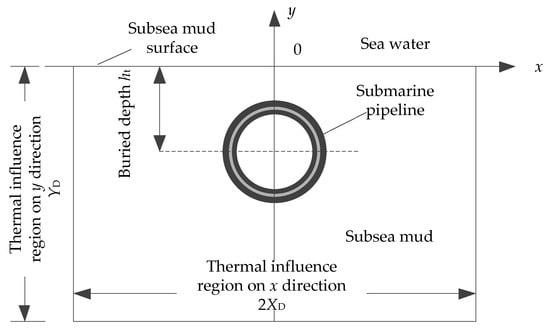

(3) The computational region of heat conduction outside the pipeline is semi-infinite in nature. For solving the problem, a finite thermal influence region is adopted, as shown in Figure 1. According to the published literature, the thermal influence region along buried pipelines can be simplified to 20 × 10 m rectangles [23,44].

Figure 1.

Sketch map of the computational region.

(4) The subsea mud outside the pipeline is modeled as an isotropic medium.

The mathematical model of pipeline preheating consists of hydraulic and thermal coupling, in addition to the thermal coupling of the fluid and the submarine environment. With the simplification mentioned above, the mathematical model is established as follows.

1. Transient flow equation

Equations of continuity, momentum, and energy for liquid are used to model the hydrodynamic and thermodynamic parameters during the preheating operation [44].

where a is the velocity of pressure wave and calculated as Equation (2) [45]

2. Heat transfer equation of submarine pipeline walls.

The submarine pipeline is built in the form of pipe-in-pipe, which is composed of a carrier pipe, insulation, air space, a casing pipe and anticorrosive coating [34,46].

In Equation (3), i = 1, 2, 3, 4, 5 represents the inner steel wall, insulation wall, air space, outer steel wall, and anticorrosive coating, respectively.

3. Heat transfer equation of subsea mud.

The differential equation of unsteady heat conduction is applied to model the thermal diffusion in pipe walls and subsea mud [11].

4. Matching conditions [34,36].

The interface between the fluid and the inner steel wall of submarine pipes:

The interface between the adjacent walls of the submarine pipe:

The interface between the outer wall and the subsea mud:

5. Thermal coupling equation

The heat loss from the fluid to the inner wall for the unit area is selected to couple the preheating medium and the external environment.

6. Boundary conditions

During preheating in this case, the inlet flow rate and temperature of the preheating medium are specified, and the outlet pressure is set to be higher than a fixed value so as to ensure the equipment on the downstream platform operates smoothly, as shown below.

Tin = Tset, Qin = Qset, Hout = Hset

Meanwhile, only the right half of the computational region for subsea mud is taken into consideration because of symmetry. So the boundary conditions of the thermal influence region can be given as follows [7,36]:

T = TD at y = YD

External surfaces of risers in submarine pipelines contact air and seawater directly. Hence, for risers, the Robin condition is employed to model the convective heat transfer between the outer wall and the external environment, as expressed below.

3. Numerical Solution for the Model

The double method of characteristics (DMOC) combined with the finite element method (FEM), namely DMOC-FEM, is established to solve the mathematical model numerically.

3.1. DMOC for Solving the Flow Equations

The partial differential Equation (1) for transient flow can be transformed into hydrodynamic and thermodynamic characteristic equations, as shown below.

Hydrodynamic characteristic equation [45,47]:

Thermodynamic characteristic equation:

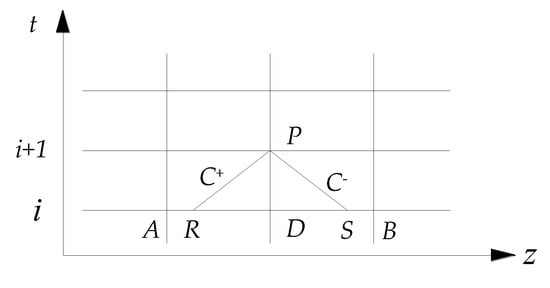

Integrating the first ordinary differential equation in Equation (17) along dz/dt = ±a, the hydrodynamic characteristic equations are discretized into difference schemes, as expressed by Equations (19) and (20).

Hence the unknown fluid pressure and flow rate at point P in Figure 2 can be solved numerically:

where

Figure 2.

Grid for solving Equation (17).

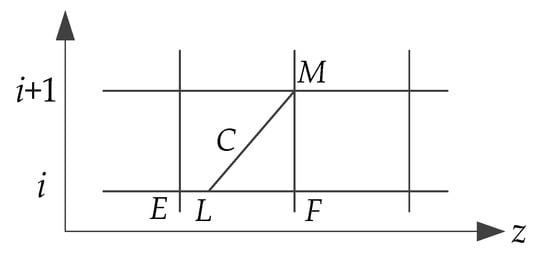

Integrating Equation (18) along dz/dt = V, the unknown fluid temperature at point M in Figure 3 can be solved by Equation (24).

Figure 3.

Grid for solving Equation (18).

For the inlet and outlet of the pipeline, pressure and flow rate can be solved by single characteristic line.

3.2. FEM for Solving the Heat Transfer Equations of Pipe Walls and Subsea Mud

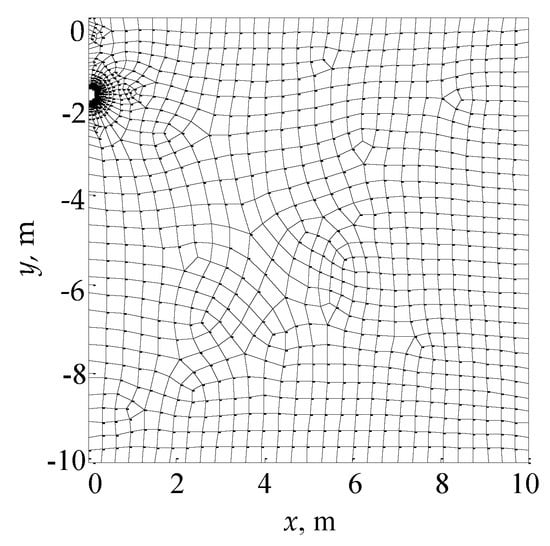

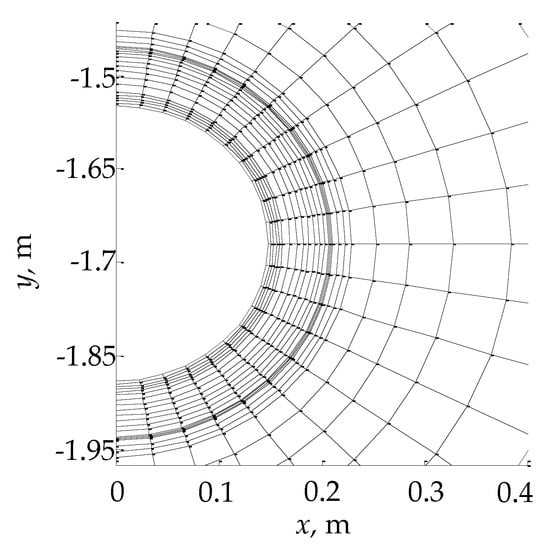

For convenience and higher accuracy, quadrilateral meshes are applied to discretize the pipe walls and subsea mud, as shown in Figure 4. The pipe walls are discretized with structured meshes in polar coordinates, as shown in Figure 5. The subsea mud is discretized with unstructured quadrilateral meshes. The closer to the inner pipe, the greater the temperature gradient would be. Hence denser meshes are generated accordingly. Figure 5 illustrates the enlarged view of meshes around the pipe.

Figure 4.

Meshes of calculation region.

Figure 5.

Enlarged view of meshes around the pipe center.

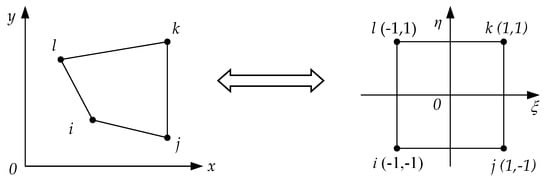

FEM based on 4-node quadrilateral isoparametric elements is adopted to solve the differential heat transfer equations of pipe walls and subsea mud. Figure 6 illustrates the mapping relation for the same element in physical and parametric space, respectively. Combining the weighted residual method (WRM) and the Galerkin method (GM), for every element, the integral residual of node temperature is expressed by Equations (27)–(35).

Figure 6.

Mapping relation between the unstructured quadrangles and isoparametric elements.

In Equations (31) and (32), the Gaussian method is used to solve the surface integral. J is the Jacobian matrix mapping from parametric space (ξ0η) to physical space (x0y). Equations (33) to (35) represents the correction of temperature stiffness matrix and load vector caused by boundary conditions.

It has been proved that the velocity of the bottom seawater has little effect on the heat transfer of submarine pipelines [48,49]. The velocity of bottom water studied in this paper is about 0.5–1 m/s, resulting in the thermal resistance being less than 0.005 m2⋅°C /W [38]. Meanwhile, the mass transfer between the bottom water and seabed surface reduces the thermal resistance further. Hence, for a numerical solution, the upper boundary of the computational region is simplified to the Dirichlet boundary at the temperature of seawater [17,42], which is solved through multiplying with a considerably big number in this paper.

Sum up the whole weighted residuals of every element and make it be zero, as expressed by Equation (36). Thus the differential equations of unsteady heat transfer can be expressed in the matrix form of Equation (37). The backward difference is used to discretize Equation (37) for obtaining the temperature of pipe walls and subsea mud in the next time step. A more detailed derivation process can be found in References [50] and [51].

3.3. Steady-State Parameters for Initial Conditions

Before starting the preheating, the pipeline is filled with cold water for pressure testing. Hence, the temperature of water and pipe walls is equilibrium with the subsea mud.

3.4. Numerical Solution Procedure

It is known from Equations (17) and (18) that, along the pipeline, the destabilization of fluid hydraulic parameters spreads at pressure wave speed (dz/dt = ±a), while that of fluid temperature propagates at flow velocity (dz/dt = V). Hence, two grids along pipeline are constructed, as shown in Figure 2 and Figure 3. The stability condition of grids is given as below.

For solving Equations (19)–(22):

For solving Equation (24):

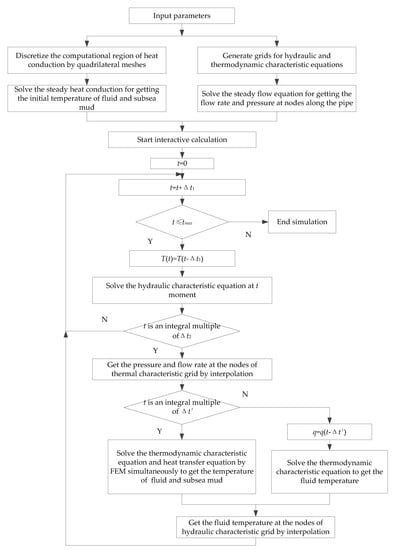

Since the pressure wave is far greater than the velocity of fluid flow, Δt1 is much less than Δt2. For a coupling solution numerically, we set Δt2 as integer multiples of Δt1. That means one thermodynamic calculation is performed after several times of hydrodynamic calculations. Along the pipe distance, the parameter distribution between the two grid systems is obtained by interpolation.

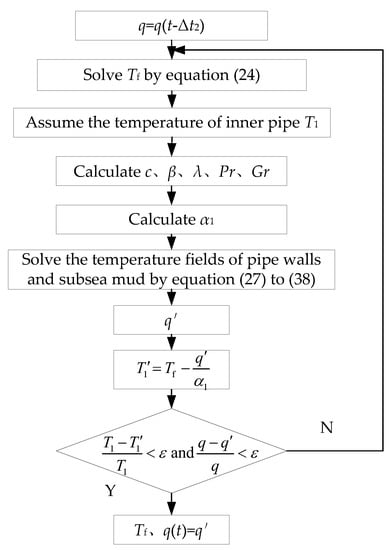

The finite element calculation for the temperature of the pipe walls and subsea mud is performed simultaneously with the solution of thermodynamic characteristic equations. The heat loss flux q from the fluid to the inner wall of the pipelines is selected as the coupling parameter between the fluid and the external environment. In this paper, the heat loss q at a previous time step is used as an initial value to iteratively solve the fluid and subsea mud temperature of the next time step, as shown in Figure 7. The whole numerical calculation procedure is illustrated in Figure 8. To accelerate computation, the time interval for finite element calculation Δt’ is set as integral times of that for solving the thermodynamic characteristic equtations, namely Δt2.

Figure 7.

Resolution procedure of heat loss flux and fluid temperature.

Figure 8.

The coupled calculation process of double method of characteristics (DMOC) combined with the finite element method (FEM).

4. Results and Discussion

4.1. Verifying the Simulation Results

The modeled new submarine hot oil pipeline is buried in the Bohai sea, China. By transporting hot water, the preheating flow rate is 150 m3/h and inlet temperature is 70 °C. A fixed pressure of 700 kPa for pipeline outlet is specified due to downstream operational requirements. The basic pipe parameters are given in Table 1 and more details are given in Appendix A.

Table 1.

Parameters of submarine pipeline.

The proposed mathematical algorithm is programed with Matlab software, the MathWorks company, Natick, Massachusetts, USA. By setting the model conditions as field operational parameters, a numerical simulation for preheating the new submarine hot oil pipeline is performed. Accurate physical properties of the preheating medium are needed during calculation. In our work, they are determined by fitting the data of Chinese standard and published literature [52,53]. The temperature-dependent calculation formulas are expressed by Equations (41) to (47).

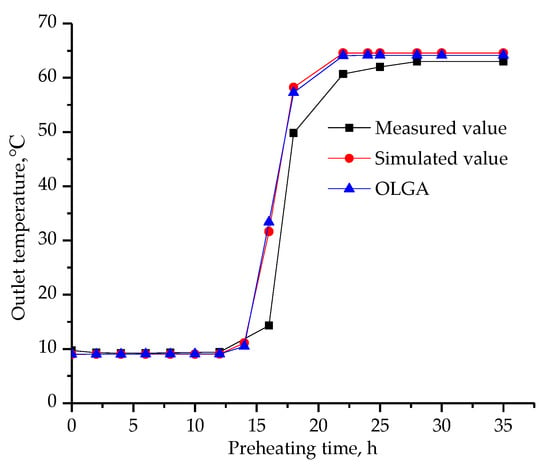

OLGA, Schlumberger company, Huston, Texas, US, is a market-leading computational code for simulating the flow of oil, water, and gas in wells, pipelines, and receiving facilities [54]. Its applications contain flow analysis and assurance [55,56], slug tracking [57], compositional tracking [58], pigging [59], and so on. OLGA has been accepted as an industry-standard tool for dynamic multiphase flow simulation and research [8]. Therefore, for comparison, the preheating process is also simulated with the OLGA simulator (Version 2015). Input parameters for OLGA code, including inlet and outlet conditions, pipeline buried depth, pipeline composition and physical properties, environmental temperature and so on are all the same as those for the approach proposed. The measured and simulated pipe outlet temperature is illustrated in Table 2 and Figure 9.

Table 2.

Comparison of simulated outlet temperature with the field measured value.

Figure 9.

The curve of outlet temperature with time.

To quantify the simulation accuracy, absolute relative error (ARE) and mean absolute percentage error (MAPE) are applied. The expressions are defined as following [60]:

It can be seen from Table 2 and Figure 9 that, at the preheating time of 16 hours, the calculated outlet temperature both by the method established and OLGA code shows the highest ARE. This may be due to the fact that before being preheated, the submarine pipeline is filled with cold water, of which fluid temperature keeps equivalent to surroundings. After being injected, the hot water head will exchange mass and heat with the cold water, thus leading to measured outlet temperature rising later than the simulated value for almost 1 hour. As the preheating time increases, the outlet temperature difference between measured and simulated value decreases gradually. At the preheating time of 35 hours, ARE for the established method and the OLGA simulator drops to 1.92% and 2.51%, respectively.

Except for the singular point mentioned, the remaining simulated results fitted well with field data. MAPE for the established method and the OLGA simulator in Table 2 was 4.27% and 4.84%, respectively. Furthermore, it can be seen that the simulation result from both approaches keeps highly consistent. The biggest and mean percentage deviation between the two numerical methods is 5.54% and 0.95%, respectively. Considering that OLGA is one of the most outstanding transient simulators and has been employed widely, the comparable simulation result indicates that the accuracy of the methodology established in this paper is reliable in terms of preheating. Above all, the accuracy of the mathematical approach proposed is verified.

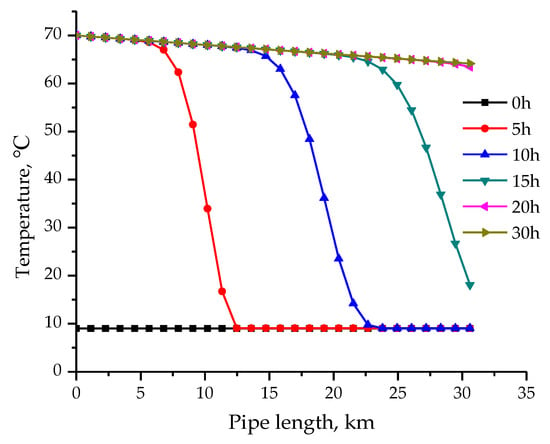

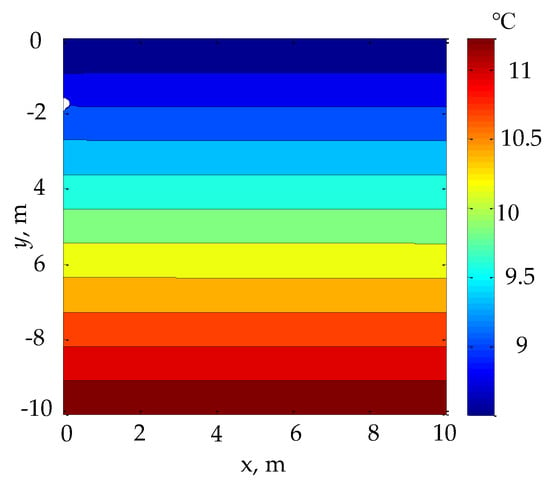

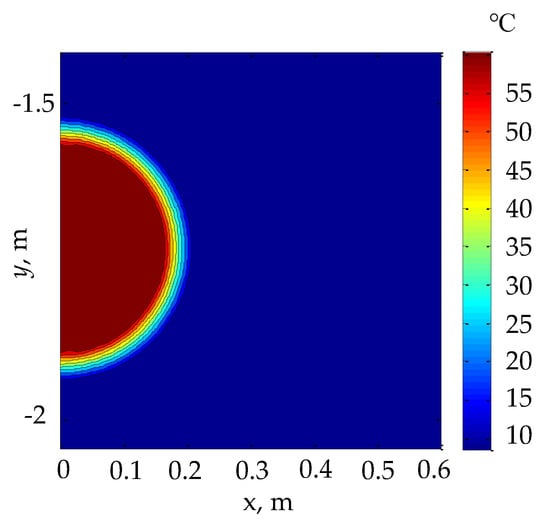

Figure 10 illustrates the temperature change with time along the pipeline, and Figure 11 and Figure 12 show the temperature field around submarine pipes before and after being preheated. Compared with the initial temperature field, thermal change on subsea mud is weak while thermal change on the pipe walls happens to be much greater. In contrast, for onshore pipelines, preheating brings a dramatic temperature increase in both pipe walls and surrounding soil [11,27,36]. It is therefore indicated in Figure 12 that hot water mainly warms every pipe wall rather than subsea mud, which can be concluded as a unique feature for preheating submarine pipelines. After a reasonable analysis, this can be due to the higher specific heat capacity value of subsea mud which is fully saturated by seawater, as well as the handling of the upper boundary of the subsea mud computational region by the Dirichlet boundary.

Figure 10.

Fluid temperature distribution along the pipeline during preheating process.

Figure 11.

Initial temperature field of subsea mud before being preheated.

Figure 12.

Enlarged view of temperature field around the submarine pipe after being preheated.

4.2. Variation of Heat Storage of Subsea Mud during the Preheating Process

The variation of heat storage of subsea mud can also reflect the thermal dissipation from pipe walls to subsea surroundings during preheating process. The formula of heat storage change of subsea mud for unit pipe length in the computational region is given as below:

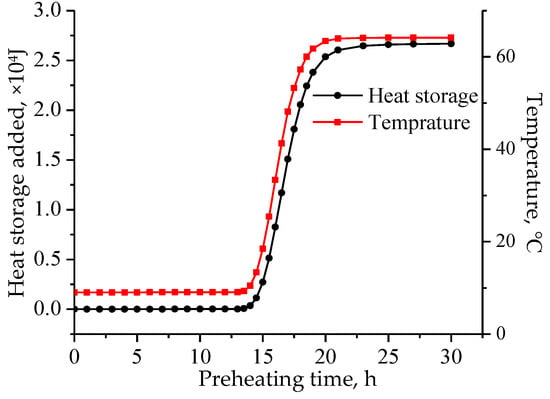

According to Equations (50) and (51), heat storage of subsea mud varies with time and distance during the preheating process. Taking the last computational region of the buried section as an example, the change of heat storage of subsea mud and fluid temperature with time is revealed in Figure 13. It can be seen that heat storage continues to rise during the preheating process. Its tendency keeps in accordance with fluid temperature closely. When the fluid temperature rises, the increment of heat storage becomes larger. Upon the temperature getting stable, the increment tends to be unchanged. The heat storage of subsea mud therefore can be an indicator for presenting the thermal change for the preheating process.

Figure 13.

Variation of heat storage and temperature with time at the last section of buried pipeline during the preheating process.

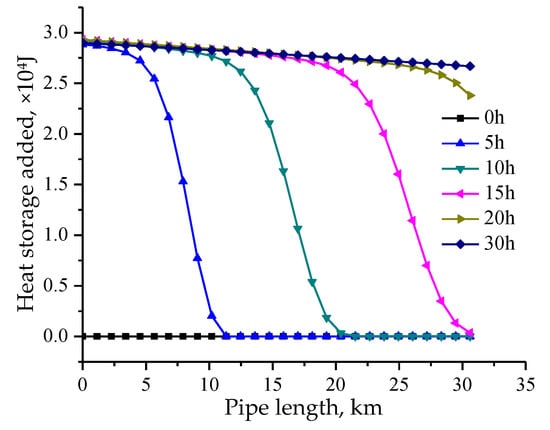

Figure 14 shows an increment of heat storage along the pipeline during the preheating process, which happens to be similar to fluid temperature distribution in tendency, too. By calculation, the total heat storage added in the thermal influence region is about 3.77 × 107 kJ, which amounts to an average temperature increase of subsea mud by just 0.0024 °C. This demonstrates that the warming effect of subsea mud by the preheating medium is weak and explains why only the temperature of pipe walls changes notably in Figure 12. Hence, it can be also inferred that the preheating medium is used to warm the pipe walls rather than subsea mud.

Figure 14.

Increment of heat storage along the pipeline during the preheating process.

4.3. Overall Heat Transfer Coefficient during the Preheating Process

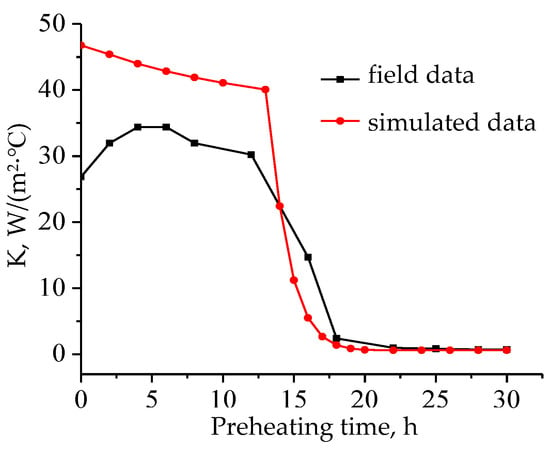

The overall heat transfer coefficient is another key parameter to reflect the operational status of pipelines. Based on the Sukhoff formula for a temperature drop of crude oil pipelines [61], an inverse-calculation method allows the overall heat transfer coefficient to be determined with the inlet and outlet fluid temperature, as expressed by Equation (52).

Field and simulated data in Table 2 is used to reversely calculate the overall heat transfer coefficients during preheating, as shown in Figure 15. It can be seen that, the inverse computation result seriously fluctuates with time. Especially before hot water reaches the pipeline’s outlet, the calculation result stays at a high level due to the huge temperature difference between two ends of the pipe. Only after the arrival of hot water at the pipe outlet can the effective heat transfer coefficients be obtained with inverse-calculation. In other words, the overall heat transfer coefficient defined by Equation (52) can just describe a macro change, not a true reflection of the pipelines’ operational status. It is incompetent in representing the real and detailed unsteady fluid and thermal propagation. Therefore, a new calculation model for overall heat transfer under preheating processes is needed.

Figure 15.

Overall heat transfer coefficient calculated with Equation (52).

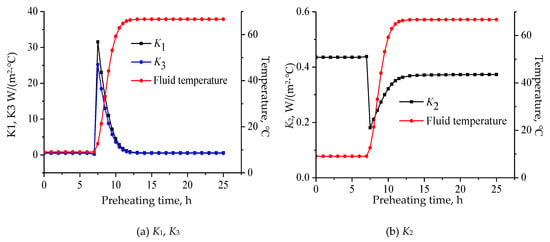

As is known, pipeline overall heat transfer coefficients are defined as heat loss on a pipe surface caused by the unit temperature difference on unit heat transfer area per second [40]. Considering the unsteady heat transfer characteristics of preheating for every pipe cross-section, three equivalent heat transfer coefficients are proposed in the form of Equations (53)–(55).

In the above equations, equivalent overall heat transfer coefficients depend on the temperature of the fluid and the adjacent subsea mud, the pipe diameter, heat loss flux qi, and the location of the calculated pipe section. Referring to relevant literature, the overall heat transfer coefficient of submarine pipelines can be calculated by using different pipe diameters according to different requirements [40]. Hence, three calculated diameters are adopted in the proposed formula. D0 is the inner diameter of the submarine pipeline, while Dw represents the diameter of the outer wall. Dh is the half of D0 plus Dw. Taking the middle position of the submarine pipeline as an example, the variation of equivalent heat transfer coefficients with time is given in Figure 16.

Figure 16.

Variation of equivalent heat transfer coefficients and fluid temperature with time.

It can be seen that, K1, K2, and K3 all have extreme values during the preheating operation. Owing to different diameters and heat fluxes selected, the values of K1, K2, and K3 for the same section are not identical, but their tendency appears similar. Equivalent overall heat transfer coefficients keep unchanged until the fluid temperature start to rise, which is an indicator of preheating medium arrival. Thus the heat dissipation to the inner wall named q1 begins to increase dramtically at the same time. In contrast, due to the high thermal resistance of pipe insulation, the temperature of subsea mud in contact with the outer pipe and heat loss from the outer wall named q2 rises to a smaller extent. Thus an increasing temperature difference between the fluid and the surrounding mud happens. The growth rate of q1 is much higher than that of temperature difference, while the increase of q2 is relatively lower. Therefore, K1 and K3 increase while K2 decreases apparently at the moment of the temperature elevating. With the thermal system of the fluid, the submarine pipe and the subsea mud turning to steady-state, the equivalent heat transfer coefficients move towards stable values gradually. Above all, the equivalent overall heat transfers deduced make up for the deficiency of the inverse-calculation method, thus it can be an effective indicator in representing the detailed unsteady fluid and thermal propagation during the preheating process.

4.4. Optimization of Preheating Parameters

Water supplied by the upstream platform has the maximum flow rates of 350 m3/h and an average temperature of 55 °C, which will be warmed by heaters with the total power of 2500 kw. Subject to the rated thermal load of the heaters and maximum flow rate, there are multiple operational parameters. Hence, to field operators, it is of significance to answer the question of which operating plan can produce the best preheating effect.

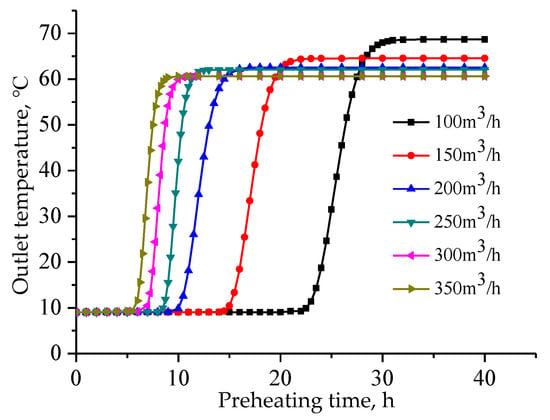

In using the numerical methodology proposed, the preheating effects caused by operational parameters can be evaluated regarding outlet temperature, preheating time consumption and water consumption. Comparing the simulated results allows for the optimization of the preheating plans. Figure 17 illustrates the changes of outlet temperature with time in six preheating plans. More details are listed in Table 3 and Figure 18 and Figure 19.

Figure 17.

Changes of outlet temperature with time in six preheating plans.

Table 3.

Comparison of the preheating effect of preheating plan at the full play of thermal load.

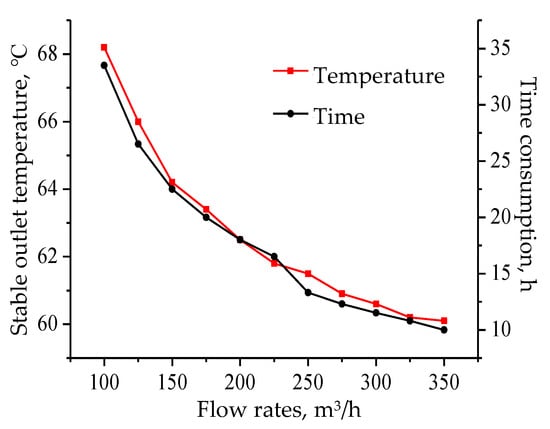

Figure 18.

Stable outlet temperature and time consumption in 11 preheating plans.

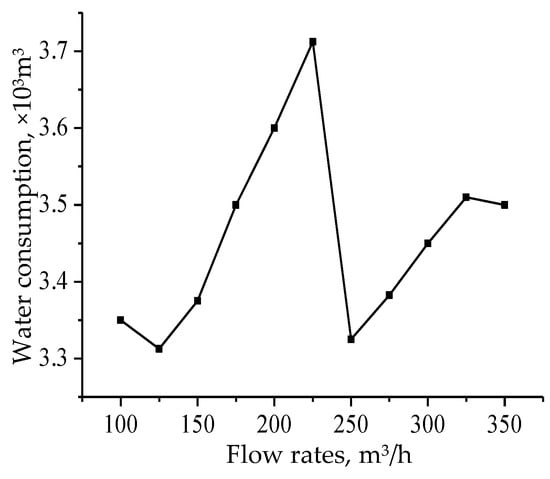

Figure 19.

Water consumption of 11 preheating plans modeled.

Simulation results demonstrate that, limited by a rated heating power, a higher flow rate of preheating medium combined with a relatively lower inlet temperature can produce better preheating effects. The operational parameter of 350 m3/h and 61.8 °C can save as much as 12.5 hours compared to the preheating plan of 150 m3/h, 70.1 °C, in the reduction of just 4.1 °C of stable outlet temperature.

Figure 18 and Figure 19 clarify the variation of stable outlet temperatures, time consumption and water consumption with flow rates. It can be seen that, the stable outlet temperature and preheating time consumption decreases when the preheating flow rate increases, while the water consumption fluctuates in a certain range. Compared with the simulation result in Section 4.1, preheating with the flow rate of 250 m3/h will lead to the inlet and stable outlet temperature decreasing by 5.8 °C and 2.7 °C, respectively. But the preheating time and water consumption can save as much as 9.2 hours and 50 m3. In the case of a preheating flow of 350 m3/h, although the preheating time is further reduced, the total water consumption increases. Meanwhile the required inlet pressure will dramatically rises up to 2.9 times. Considering the above aspects, for this submarine pipeline, the operational parameter of 250 m3/h and 65 °C is the optimal preheating plan among the modeled scenarios.

5. Conclusions

For better numerical simulation of the preheating of submarine pipelines, a mathematical model including equations of continuity, momentum, energy and unsteady heat transfer for submarine pipeline preheating was established. Then, a novel model that combined double MOC and FEM, namely DMOC-FEM, was proposed to solve the model numerically. Its accuracy is verified by comparing simulated values with field data and the OLGA simulator. By discussing the temperature, heat storage of subsea mud, heat transfer coefficient and preheating plans, the main conclusions can be summarized as follows:

(1) Compared with the initial status, the temperature of pipe walls after being preheated obviously increases while that of the surrounding subsea mud rises weakly. Meanwhile, the change of heat storage of subsea mud keeps in accordance with fluid temperature during the preheating process. Combining the temperature and heat storage calculation results, it can be concluded that a hot preheating medium mainly warms every pipe wall rather than subsea mud.

(2) It is pointed out in this work that the inverse-calculation method is not suitable for determining the overall heat transfer coefficient during the preheating process. Hence, considering the computational section, temperature of the fluid, pipe walls and subsea mud as well as the heat loss flux, three equivalent overall heat transfer coefficients named K1, K2, and K3 are proposed. Being closely related to the fluid temperature, the equivalent values deduced make up for the deficiency of the inverse-calculation method, and can be an indicator in representing the detailed unsteady fluid and thermal propagation during the preheating process.

(3) Subject to a rated heating power and an extreme preheating flow rate, the preheating parameter at a lower fluid temperature combined with a higher flow rate can produce better preheating effects. Considering the outlet temperature, preheating time and water consumption, the operational parameter of 250 m3/h and 65 °C is the optimal preheating plan among the modeled 11 preheating plans. In comparison with the preheating parameter of 150 m3/h and 70 °C which is adopted in practice, the optimal plan will save the preheating time of 9.2 hours and water consumption of 50 m3

The proposed mathematical model has been proven to be able to provide an accurate simulation for preheating submarine hot oil pipelines. With reasonable boundary conditions, the model is applicable for onshore crude oil pipelines, too. However, preheating is just the first step in pipeline commissioning which is followed by oil transportation. Due to the difference in temperature, the flow rate and physical properties between crude oil and the preheating medium, after oil injection, the parameters along pipelines will be redistributed. The transient process after oil injection can be further studied based on the proposed methodology in this work.

Author Contributions

Conceptualization, Z.Y.; methodology, Y.W. and S.W.; validation, D.W., and Y.W.; writing—original draft preparation, Y.W.; writing—review and editing, N.W. and Y.W.

Funding

This work was funded by the Scientific Research Program Funded by Shaanxi Provincial Education Department (Program No.18JK0629 and 16JK1608) and the National Natural Science Foundation of China (Program No.41502311 and 51704236).

Conflicts of Interest

The authors declare no conflict of interest.

Acronyms

| MOC | method of characteristics |

| DMOC | double method of characteristics |

| FDM | finite difference method |

| FEM | finite element method |

| FVM | finite volume method |

| WRM | weighted residual method |

| GM | Galerkin method |

| ARE | absolute relative error |

| MAPE | mean absolute percentage error |

Abbreviations

| A | cross-section area of submarine pipeline (m2) |

| Ai | area of element i (m2) |

| C | heat capacity matrix |

| D0 | inner diameter of submarine pipeline (m) |

| Dh | average value of inner and outer diameter of insulation (m) |

| Dw | outer diameter of pipe (m) |

| E | Young’s modulus of elasticity (Pa) |

| F | fluid compressibility factor (Pa-1) |

| G | mass flow (kg/s) |

| Gr | Grashof number |

| H | pressure head (m) |

| L | pipe length (m) |

| J | Jacobian matrix |

| K | temperature stiffness matrix |

| K | overall heat transfer coefficient, (W/(m2·°C)) |

| K1, K2, K3 | Equivalent heat transfer coefficients (W/(m2·°C)) |

| Nm, Nn | interpolation function |

| P(t) | temperature load vector at t moment |

| Pr | Prandtl number |

| Q | flow rate (m3/s) |

| R | matrix of integral residual |

| R | radius (m) |

| R0 | inner diameter of inner steel wall (m) |

| R5 | outer diameter of pipe walls (m) |

| S | elevation (m) |

| T | temperature matrix to be solved |

| T | temperature (°C) |

| T0 | temperature at buried depth (°C) |

| TD | temperature at thermostatic layer of subsea mud (°C) |

| temperature of node j in element i at t moment (°C) | |

| V | flow velocity (m/s) |

| XD | half of thermal influence region on x direction (m) |

| YD | thermal influence region on y direction (m) |

| Z | total number of elements |

| a | pressure wave velocity (m/s) |

| c | heat capacity, (J/(kg⋅°C)) |

| cmn | element of heat capacity matrix |

| f | hydraulic friction coefficient |

| g | gravitational acceleration (m/s2) |

| h | specific enthalpy of fluid (J/kg) |

| ht | buried depth of pipeline (m) |

| k | fluid elastic coefficient (Pa) |

| kmn | element of temperature stiffness matrix |

| p | pressure (Pa) |

| q | heat loss from fluid to inner wall per unit area and time (W/m2) |

| q1 | heat flux from transported fluid to inner pipe wall per unit length (W/m) |

| q2 | heat flux from outer wall of pipe per unit length to subsea mud (W/m) |

| r | radius (m) |

| s | length of element boundary (m) |

| t | time (s) |

| u | specific internal energy of fluid (J/kg) |

| z | axial direction of the submarine pipeline (m) |

Greeks

| α | convective heat transfer coefficient (W/(m2·°C)) |

| α1 | convective heat transfer coefficient between fluid and inner pipe wall (W/(m2·°C)) |

| β | expansion coefficient (1/°C) |

| ρ | density (kg/m3) |

| ρ0 | standard density, (kg/m3) |

| θ | dip angle of submarine pipeline (rad) |

| λ | thermal conductivity, (W/(m·°C)) |

| μ | dynamic viscosity (Pa⋅s) |

| ψ | pipe correction factor |

| δ | wall thickness (m) |

| temperature change of element i from initial temperature, (°C) | |

| ΔH(t) | variation of heat storage in the thermal influence zone at t moment (J) |

| Δkmn | correction of elemental temperature stiffness matrix caused by third boundary condition |

| Δpm | correction of elemental heat capacity matrix caused by third boundary condition |

| Δt | time interval in the numerical calculation (s) |

| Δz | space interval in the numerical calculation (m) |

Subscript

| s | subsea mud |

| a | air |

| sea | sea |

| in | inlet |

| out | outlet |

| set | set |

| f | fluid |

Superscript

| e | elemet |

Appendix A

Table A1.

Detailed parameter of the submarine pipeline.

Table A1.

Detailed parameter of the submarine pipeline.

| Content | Value |

|---|---|

| Carrier pipe | Φ 324 × 14.3 |

| Casing pipe | Φ 457 × 17.5 |

| Length | 30 km |

| Roughness | 0.04572 mm |

| Insulation material | Polyurethane foam |

| Buried depth | 1.5 m from seabed to top of external pipe |

| Single riser length (in sea) | 18 m |

| Single riser length (in air) | 10 m |

Table A2.

Physical property of subsea mud.

Table A2.

Physical property of subsea mud.

| Thermal Conductivity (W/(m·°C)) | Density (kg/m3) | Heat Capacity (J/(kg·°C)) |

|---|---|---|

| 10 | 2025 | 2500 |

Table A3.

Physical properties of pipe walls.

Table A3.

Physical properties of pipe walls.

| Pipe Wall | Thickness (mm) | Thermal Conductivity (W/(m·°C)) | Density (kg/m3) | Heat Capacity (J/(kg·°C)) |

|---|---|---|---|---|

| Carrier pipe | 14.3 | 50 | 7850 | 483 |

| Insultaion | 45 | 0.0225 | 50 | 1500 |

| Air space | 4 | 0.02326 | 1.225 | 1000 |

| Casing pipe | 17.5 | 50 | 7850 | 483 |

Table A4.

Operational parameter of preheating.

Table A4.

Operational parameter of preheating.

| Content | Value |

|---|---|

| Preheating medium | Water |

| Preheating flow rate | 150 m3/h |

| Preheating temperature | 70 °C |

| Average temperature of seawater | 9 °C |

| Temperature of bottom seawater | 8.5 °C |

| Air temperature | 10 °C |

References

- Ding, L.; Zhang, J.; Lin, A. A Deep-Sea Pipeline Skin Effect Electric Heat Tracing System. Energies 2019, 12, 2466. [Google Scholar] [CrossRef]

- Zhang, H.; Liang, Y.; Ma, J.; Shen, Y.; Yan, X.; Yuan, M. An improved PSO method for optimal design of subsea oil pipelines. Ocean Eng. 2017, 141, 154–163. [Google Scholar] [CrossRef]

- Cheng, Q.; Gan, Y.; Su, W.; Liu, Y.; Sun, W.; Xu, Y. Research on Exergy Flow Composition and Exergy Loss Mechanisms for Waxy Crude Oil Pipeline Transport Processes. Energies 2017, 10, 1–20. [Google Scholar]

- Martinez-Palou, R.; de Lourdes Mosqueira, M.; Zapata-Rendon, B.; Mar-Juarez, E.; Bernal-Huicochea, C.; de la Cruz Clavel-Lopez, J.; Aburto, J. Transportation of heavy and extra-heavy crude oil by pipeline: A review. J. Petrol. Sci. Eng. 2011, 75, 274–282. [Google Scholar] [CrossRef]

- Hart, A. A review of technologies for transporting heavy crude oil and bitumen via pipelines. J. Petrol. Explor. Prod. Technol. 2014, 4, 327–336. [Google Scholar] [CrossRef]

- Bai, Y.; Bai, Q. Subsea Engineering Handbook; Gulf Professional Publishing: Boston, MA, USA, 2010. [Google Scholar]

- Xing, X.; Dou, D.; Li, Y.; Wu, C. Optimizing control parameters for crude pipeline preheating through numerical simulation. Appl. Therm. Eng. 2013, 51, 890–898. [Google Scholar] [CrossRef]

- Yuan, Z.; Wang, Y.; Xie, Y.; Dai, K.; Ming, L. Study improves subsea pipeline preheating. Oil Gas J. 2014, 112, 88–95. [Google Scholar]

- Chakraborty, S.; Talimi, V. Thermal analysis of offshore buried pipelines through expermental investigations and numerical analysis. In Proceedings of the ASME 2016 International Mechanical Engineering Congress and Exposition (IMECE2016), Phoenix, AZ, USA, 11–17 November 2016. [Google Scholar]

- Chakraborty, S.; Talimi, V.; Muzychka, Y.; McAffee, R.; Piercey, G. Design of experimental and validation of model for offshore buried pipeline thermal analysis. In Proceedings of the 2016 11th International Pipeline Conference, Calgary, AB, Canada, 26–30 Sepetember 2016. [Google Scholar]

- Barletta, A.; Lazzari, S.; Zanchini, E.; Terenzi, A. Transient heat transfer from an offshore buried pipeline during start-up working conditions. Heat Transf. Eng. 2008, 29, 942–949. [Google Scholar] [CrossRef]

- Chen, G.Q.; Zhao, M.H.; Xu, B. Thermal characteristics simulation of the commissioning process for new buried heated oil pipelines. Adv. Mater. Res. 2011, 30, 610–616. [Google Scholar] [CrossRef]

- Qi, H.; Wang, Y.; Wu, G.; Li, D. Experimental study on affecting factors of shutdown time of submarine oil pipeline. In Proceedings of the 2010 International Conference on Intelligent System Design and Engineering Application, Changsha, China, 13–14 October 2010. [Google Scholar]

- Thusyanthan, N.I.; Cleverly, W.; Haigh, S.K.; Ratnam, S. Thermal imaging, thermal conductivity of soil and heat loss from buried pipelines. In Proceedings of the Offshore Pipeline Technology Conference, Amsterdam, The Netherlands, 23–24 February 2011. [Google Scholar]

- Oh, D.; Park, J.M.; Lee, K.H.; Zakarian, E.; Lee, J. Effect of buried depth on steady-state heat-transfer characteristics for pipeline-flow assurance. SPE J. 2014, 19, 1162–1167. [Google Scholar] [CrossRef]

- Chakraborty, S. Experimental Investigation and Modeling of Heat Loss Mechanism from Offshore Buried Pipelines. Master’s Thesis, Memorial University of Newfoundland, St John’s, NL, Canada, 2017. [Google Scholar]

- Chakraboty, S.; Talimi, V.; Muzychka, Y.; McAffee, R. Modeling of heat loss from offshore buried pipeline through experimental investigation and numerical analysis. In Proceedings of the Arctic Technology Conference, St. John’s, NL, Canada, 24–26 October 2016. [Google Scholar]

- Thiyagarajan, R.; Yovanovich, M.M. Thermal resistance of a buried cylinder with constant flux boundary condition. J. Heat Transf. 1974, 96, 249–250. [Google Scholar] [CrossRef]

- Bau, H.H.; Sadhai, S.S. Heat losses from a fluid flowing in a buried pipe. Int. J. Heat Mass Transf. 1982, 25, 1621–1629. [Google Scholar] [CrossRef]

- Patience, G.S.; Mehrotra, A.K. Laminar start-up flow in short pipe lengths. Can. J. Chem. Eng. 1989, 67, 883–888. [Google Scholar] [CrossRef]

- Wei, N.; Li, C.; Peng, X.; Li, Y.; Zeng, F. Daily natural gas consumption forecasting via the application of a novel hybrid model. Appl. Energy 2019, 250, 358–368. [Google Scholar] [CrossRef]

- Wei, N.; Li, C.; Peng, X.; Zeng, F.; Lu, X. Conventional models and artificial intelligence-based models for energy consumption forecasting: A review. J. Petrol. Sci. Eng. 2019, 181, 106187. [Google Scholar] [CrossRef]

- Xu, C.; Yu, B.; Zhang, Z.; Zhang, J.; Wei, J.; Sun, S. Numerical simulation of a buried hot crude oil pipeline during shutdown. Petrol. Sci. 2010, 7, 73–82. [Google Scholar] [CrossRef]

- Yu, W.; Liu, W.; Lai, Y.; Che, X. Nonlinear analysis of coupled temprature-seepage problem of warm oil pipe in permafrost regions of Northeast China. Appl. Therm. Eng. 2014, 70, 988–995. [Google Scholar] [CrossRef]

- Lanzafame, R.; Mauro, S.; Messina, M.; Brusca, S. Heat exchange numerical modeling of a submarine pipeline for crude oil transport. Energy Procedia 2017, 126, 18–25. [Google Scholar] [CrossRef]

- Vedeneev, D.E. Combined thermal-momentum start-up in long pipes. Int. J. Heat Mass Transf. 1990, 33, 78–84. [Google Scholar]

- Ma, G.; Gu, F.; Gu, J.; Li, X. Numerical simulation on soil temperature field around underground hot oil pipelines and medium temperature-drop in the process of staring. In Proceedings of the International Conference on Pipelines and Trenchless Technology 2009, Shanghai, China, 18–21 October 2009. [Google Scholar]

- Li, Y.; Wu, C.; Yu, Y. Parallel computing on the preheating and commissioning of hot oil pipelines. In Proceedings of the 2013 International Conference on Advanced Information Engineering and Education Science (ICAIEES 2013), Beijing, China, 19–20 December 2013. [Google Scholar]

- Yuan, Q.; Wu, C.; Yu, B.; Han, D.; Zhang, X.; Cai, L.; Sun, D. Study on the thermal characteristics of crude oil batch pipelining with differential outlet temperature and inconstant flow rate. J. Petrol. Sci. Eng. 2018, 160, 519–530. [Google Scholar] [CrossRef]

- Johnson, C. , Numerical Solution of Partial Differential Equations by the Finite Element Method; Courier Dover Publications: New York, NY, USA, 2012. [Google Scholar]

- Chai, J.; Lee, H.; Patankar, S. Finite volume method for radiation heat transfer. J. Thermophys. Heat Transf. 1994, 8, 419–425. [Google Scholar] [CrossRef]

- Melenk, J.; Babuška, I. The partition of unity finite element method: Basic theory and applications. Comput. Methods Appl. Mesh. Eng. 1996, 139, 289–314. [Google Scholar] [CrossRef]

- Wheeler, J. Simulation of Heat Transfer from a Warm Pipeline Buried in Permafrost; American Institute of Chemical Engineers: New York, NY, USA, 1973. [Google Scholar]

- Xu, B.; Xue, X.; Yao, Z.; Wang, L.; Zhu, F.; Huo, L. Numerical simulation of crude pipeline using moisture-heat coupled thermal equation. Adv. Mater. Res. 2011, 268–270, 154–159. [Google Scholar] [CrossRef]

- Tao, L.; Junsheng, S.; Peixue, J. The influence of ambient temperature and preheating water temperature on temperature field of soil during preheating buried hot crude oil pipeline for startup. Acta Energiae Solars Sinica 2006, 27, 1053–1057. [Google Scholar]

- Yu, G.; Yu, B.; Han, D.; Wang, L. Unsteady-state thermal calculation of buried oil pipeline using a proper orthogonal decomposition reduced-order model. Appl. Therm. Eng. 2013, 51, 177–189. [Google Scholar] [CrossRef]

- Barletta, A.; Zanchinia, E.; Lazzaria, S.; Terenzib, A. Numerical study of heat transfer from an offshore buried pipeline under steady–periodic thermal boundary conditions. Appl. Therm. Eng. 2008, 28, 1168–1176. [Google Scholar] [CrossRef]

- Qi, H. Study on Heat Transfer of Shutdown and Start-Up of Submarine oil Pipeline. Ph.D. Thesis, Daqing Petroleum Institute, Daqing, China, 2009. [Google Scholar]

- Bai, Y.; Niedzwecki, J.M.; Sanchez, M. Numerical investigation of thermal fields around subsea buried pipelines. In Proceedings of the ASME 33rd International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014. [Google Scholar]

- Zakarian, E.; Holbeach, J.; Morgan, J. A holistic approach to steady-state heat transfer from partially and fully buried pipelines. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2012. [Google Scholar]

- Ekweribe, C.; Civan, F. Transient wax gel formation model for shut-in subsea pipelines. J. Energy Resour. Technol. 2011, 133, 033001. [Google Scholar] [CrossRef]

- Sund, F.; Oosterkamp, A.; Hope, S.M. Pipeline modeling- impact of ambient temperature and heat transfer model. In Proceedings of the 2015 International Ocean and Polar Engineering Conference, Kona, HI, USA, 21–26 June 2015. [Google Scholar]

- Magda, W. Comparison of soil models in the thermodynamic analysis of a submarine pipeline buried in seabed sediments. Pol. Marit. Res. 2017, 24, 124–130. [Google Scholar] [CrossRef][Green Version]

- Yu, B.; Li, C.; Zhang, Z.; Liu, X.; Zhang, J.; Wei, J.; Sun, S.; Huang, J. Numerical simulation of a buried hot crude oil pipeline under normal operation. Appl. Therm. Eng. 2010, 30, 2670–2679. [Google Scholar] [CrossRef]

- Wan, W.; Zhang, B.; Chen, X.; Lian, J. Water Hammer Control Analysis of an Intelligent Surge Tank with Spring Self-Adaptive Auxiliary Control System. Energies 2019, 12, 2527. [Google Scholar] [CrossRef]

- Eisler, B.; Mckee, M. Analysis and solutions for warm-up of insulated offshore arctic pipelines during winter construction. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 7–9 February 2011. [Google Scholar]

- Wan, W.; Zhang, B.; Chen, X. Investigation on Water Hammer Control of Centrifugal Pumps in Water Supply Pipeline Systems. Energies 2018, 12, 108. [Google Scholar] [CrossRef]

- Bai, Y.; Niedzwecki, J.M. Modeling deepwater seabed steady-state thermal fields around buried pipeline including trenching and backfill effects. Comput. Geotech. 2014, 61, 221–229. [Google Scholar] [CrossRef]

- Yuan, Q.; Yu, B.; Li, J.; Han, D.; Zhang, W. Study on the restart algorithm for a buried hot oil pipeline based on wavelet collocation method. Int. J. Heat Mass Transf. 2018, 125, 891–907. [Google Scholar] [CrossRef]

- Li, Z.; Cui, X.; Cai, Y. Analysis of heat transfer problems using a novel low-order FEM based on gradient weighted operation. Int. J. Therm. Sci. 2018, 132, 52–64. [Google Scholar] [CrossRef]

- Liu, G.; Quek, S. The Finite Element Method, 2nd ed.; Butterworth Heinemann: Oxford, UK, 2014; pp. 347–396. [Google Scholar]

- General Administration of Quality Supervision Inspection and Quarantine of the People’s Republic of China. Verification Regulation of Pipe Prover; JJG 209—2010; General Administration of Quality Supervision Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2010.

- Wang, Y. Research on the Preheating and Commissioning Process of Subsea Hot Oil Pipeline Based on Numerical Simulation Method. Ph.D. Thesis, Southwest Petroleum University, Chengdu, China, 2016. [Google Scholar]

- Seyfaee, A.; Lashkarbolooki, M.; Esmaeilzadeh, F.; Mowla, D. Investigation of the Effect of Insulation on Wax Deposition in an Iranian Crude Oil Pipeline with OLGA Simulator. J. Disper. Sci. Technol. 2012, 33, 1218–1224. [Google Scholar] [CrossRef]

- Omowunmi, S.C.; Abdulssalam, M.; Janssen, R.; Otigbah, P. Methodology For Characterising Slugs and Operational Mitigation Strategy Using Olga Slug Tracking Module-Egina Deepwater Project. In Proceedings of the Offshore Mediterranean Conference and Exhibition, Ravenna, Italy, 20–22 March 2013. [Google Scholar]

- Kinnari, K.; Labes-Carrier, C.; Lunde, K.; Hemmingsen, P.V.; Davies, S.R.; Boxall, J.A.; Koh, C.A.; Sloan, E.D. Hydrate plug formation prediction tool—An Increasing need for flow assurance in the oil industry. In Proceedings of the 6th International Conference on Gas Hydrates (ICGH 2008), Vancouver, BC, Canada, 6–10 July 2008. [Google Scholar]

- Mokhatab, S.; Towler, B.F. Severe slugging in flexible risers: Review of experimental investigations and OLGA predictions. Petrol. Sci. Technol. 2007, 25, 867–880. [Google Scholar] [CrossRef]

- Volk, M. Displacement & Mixing in Subsea Jumpers–Experimental Data & CFD Simulations. Report of Research Patnership to Secure Energy for America. The University of Tulsa, 22 April 2013. [Google Scholar]

- Xu, X.; Gong, J. Pigging simulation for horizontal gas-condensate pipelines with low-liquid loading. J. Petrol. Sci. Eng. 2005, 48, 272–280. [Google Scholar] [CrossRef]

- Wei, N.; Li, C.; Li, C.; Xie, H.; Du, Z.; Zhang, Q.; Zeng, F. Short-term forecasting of natural gas consumption using factor selection algorithm and optimized support vector regression. J. Energy Resour. Technol. 2019, 141, 032701. [Google Scholar] [CrossRef]

- Jiang, H. Design and Management of Crude Oil Pipeline; Oil Industry Press: Beijing, China, 2010; pp. 172–173. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).