Cooling Performance Enhancement of Air-Cooled Condensers by Guiding Air Flow

Abstract

:1. Introduction

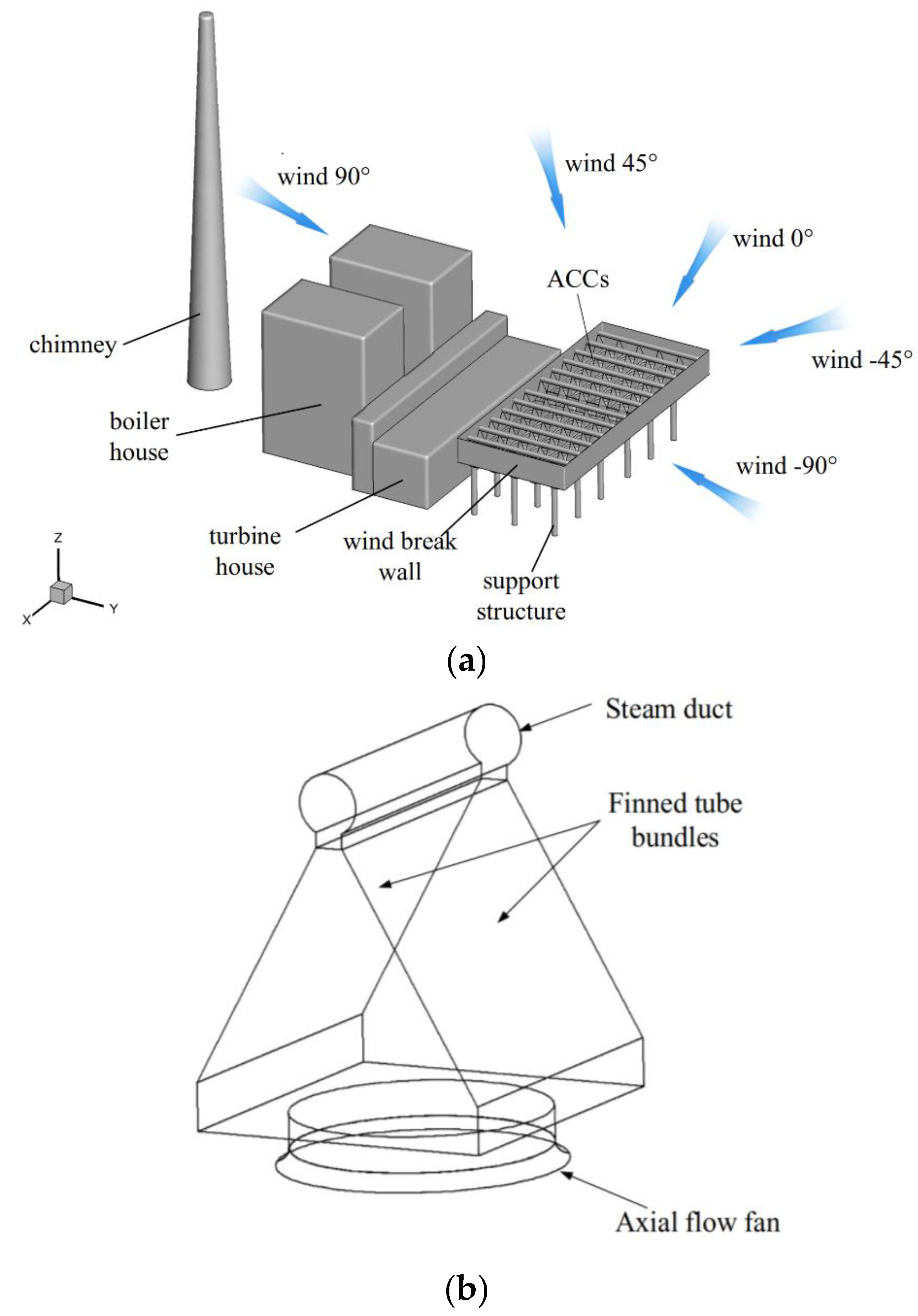

2. Numerical Modeling

2.1. Physical Model

2.2. Mathematical Model

2.3. Grid System and Independence Check

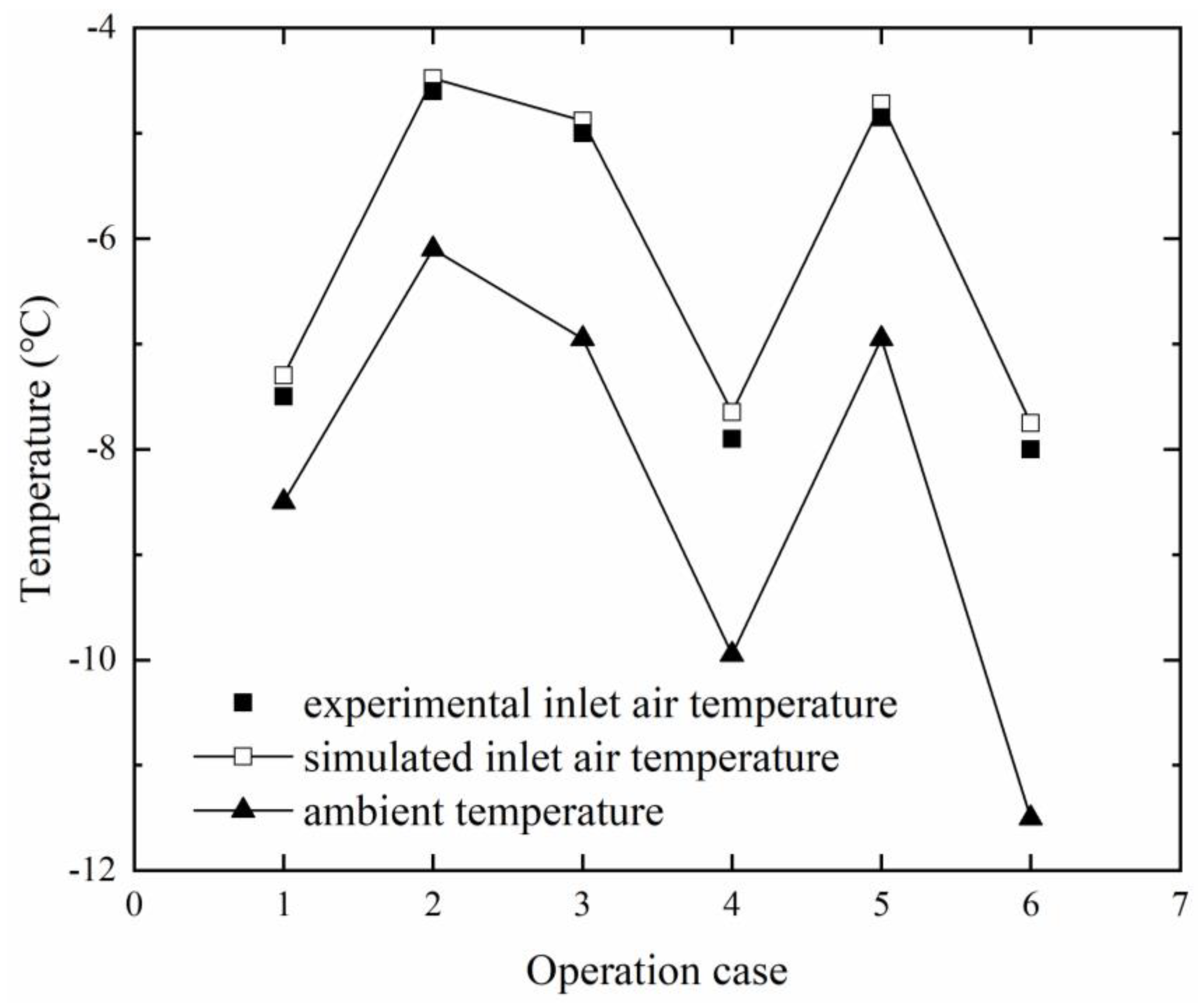

2.4. Experimental Validation

3. Results

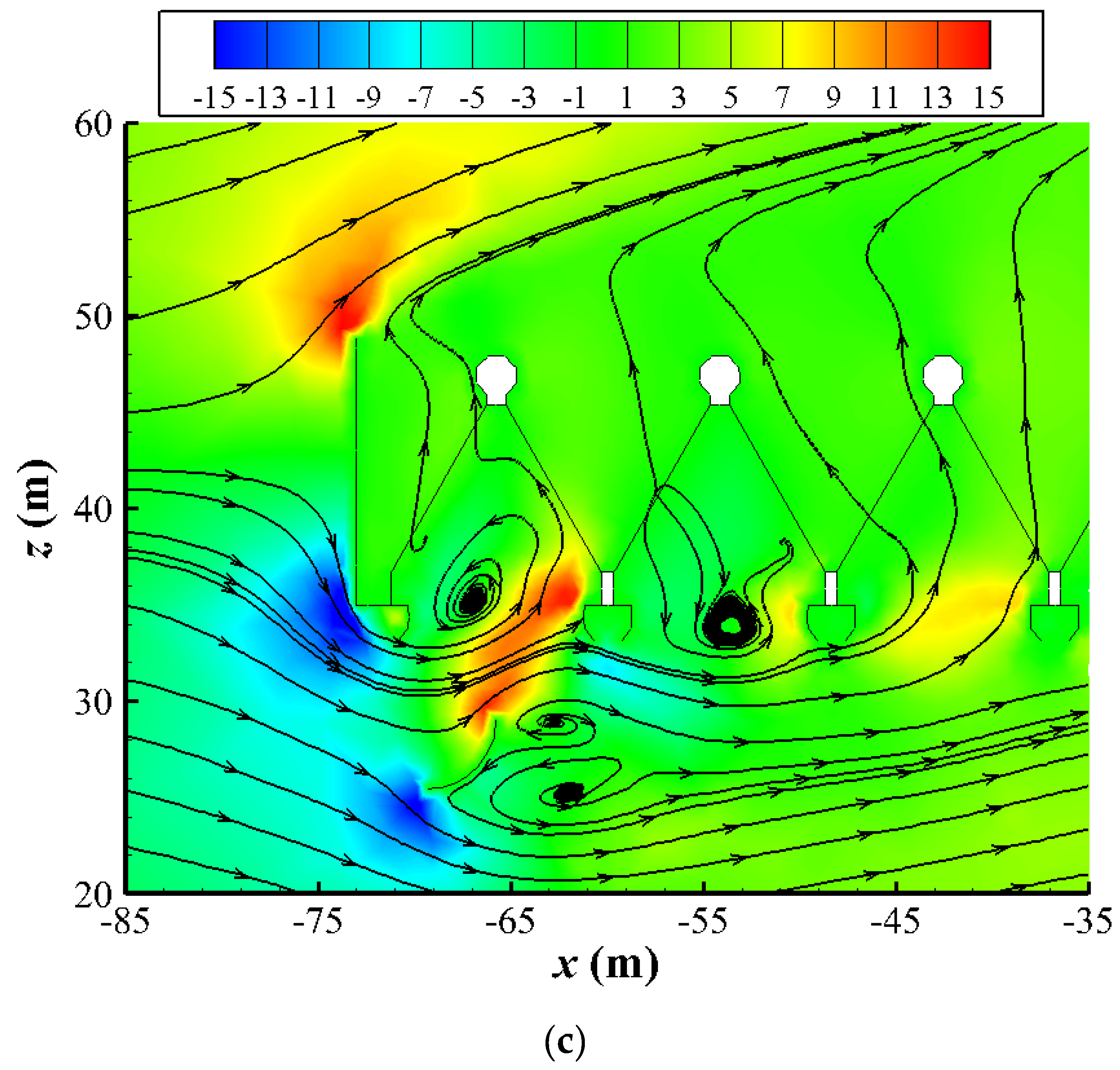

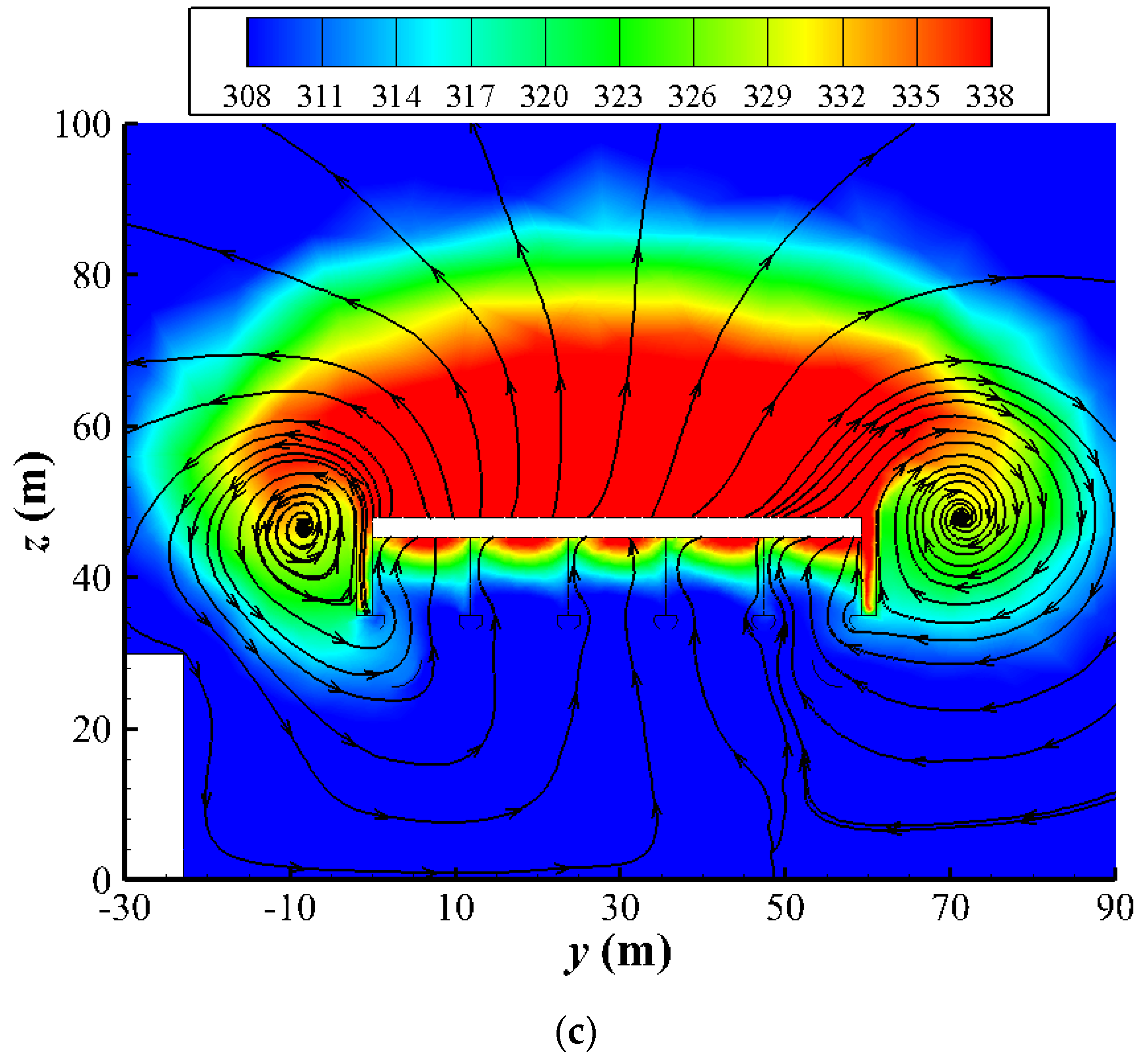

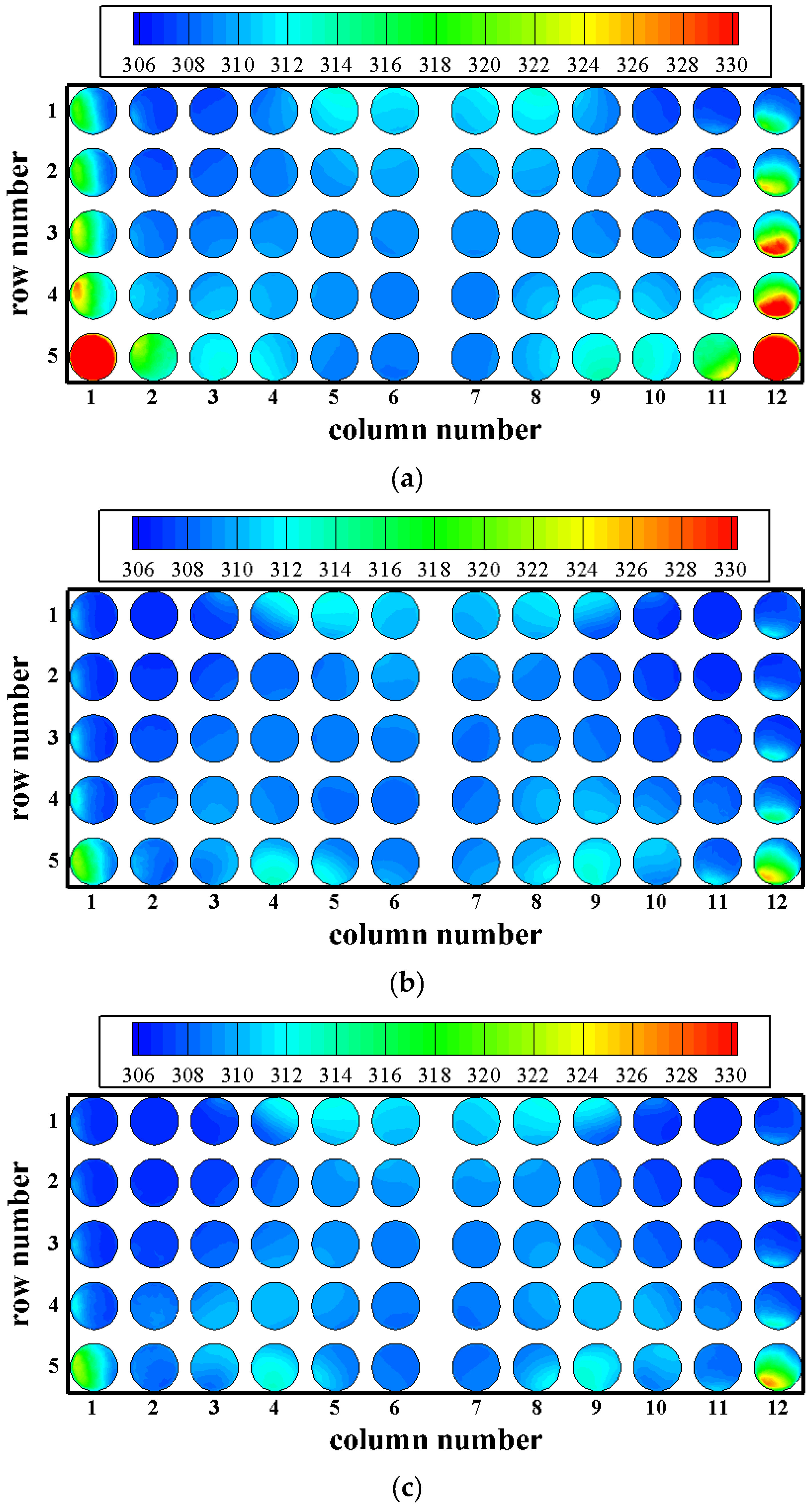

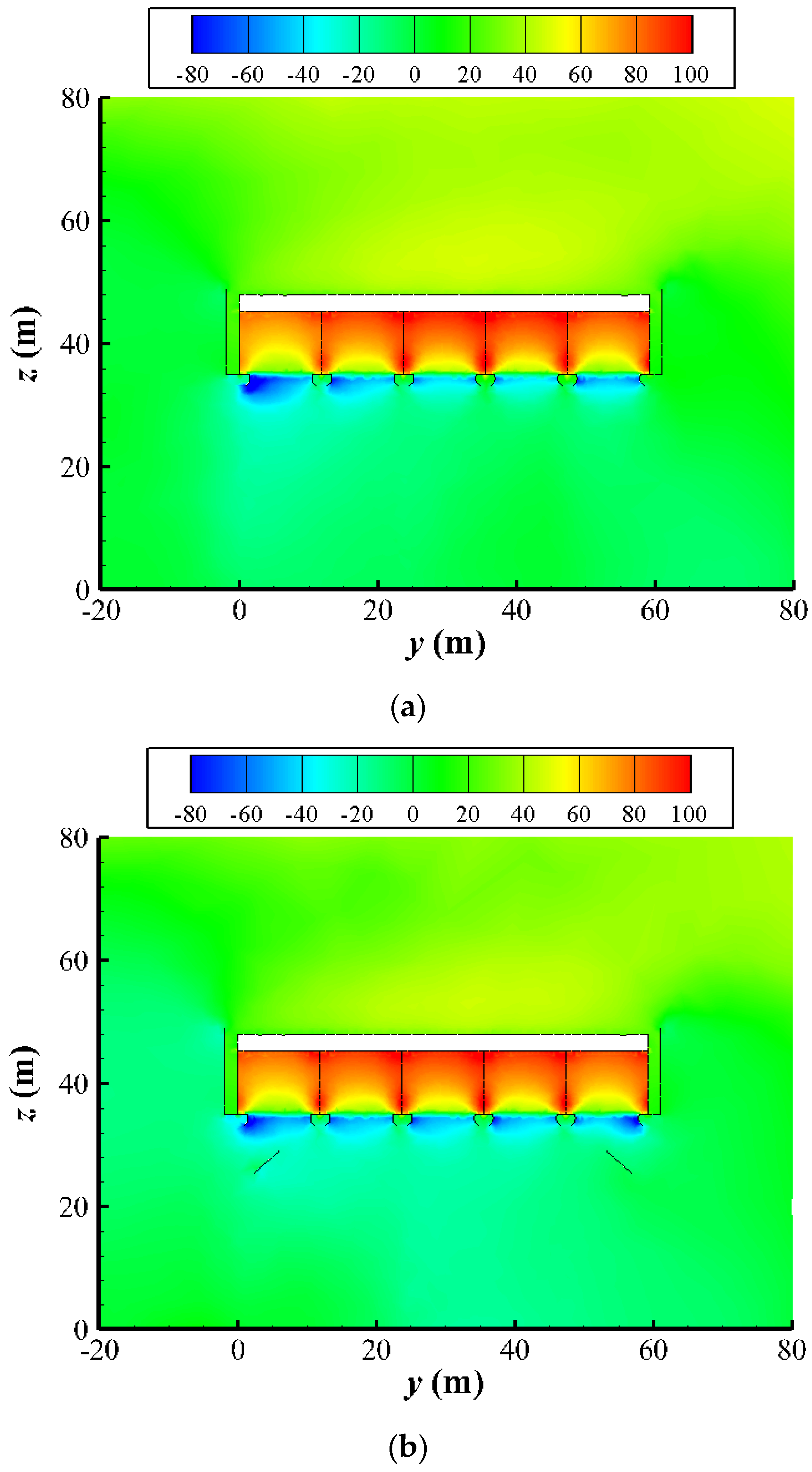

3.1. Variable Fields Analyses

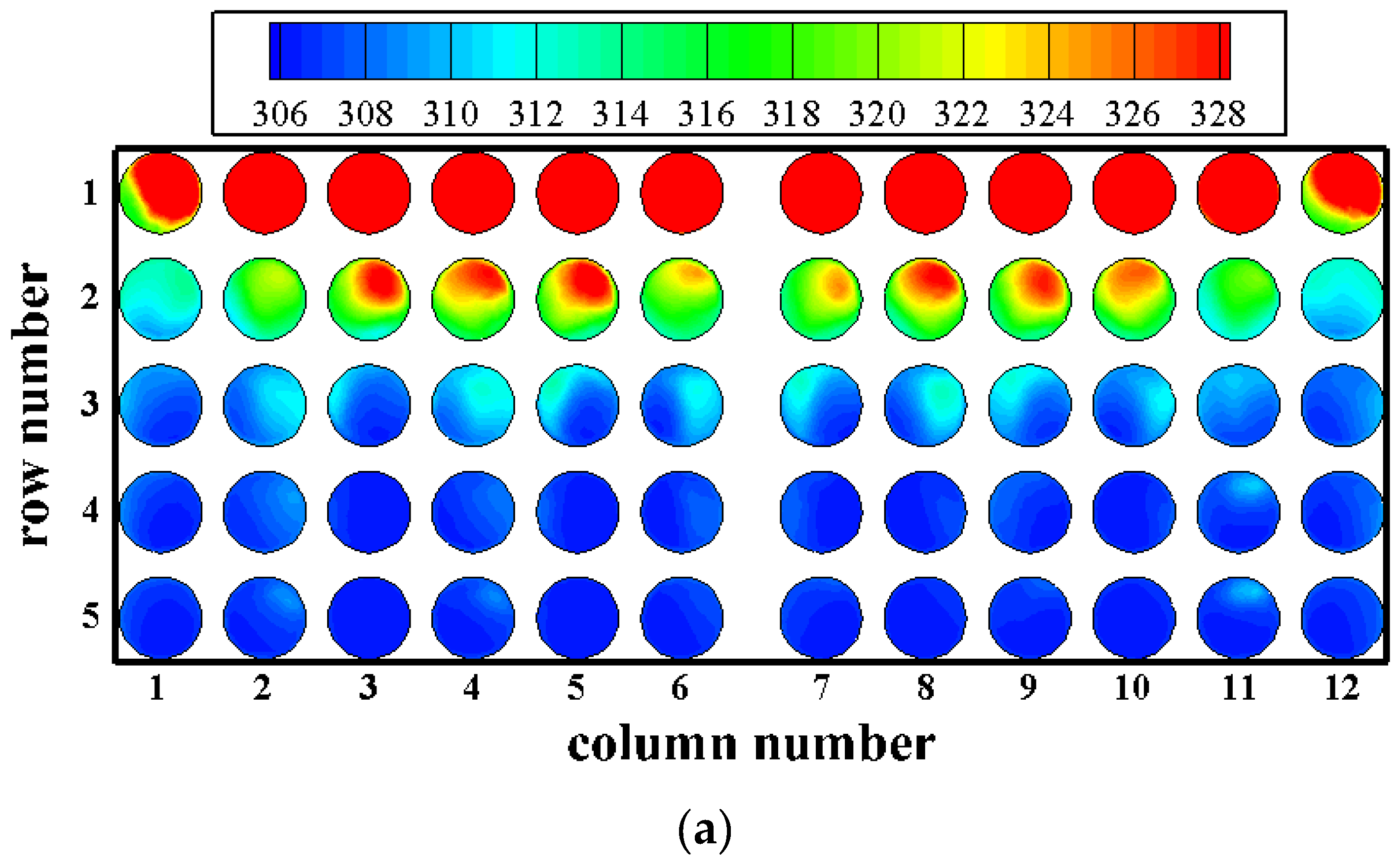

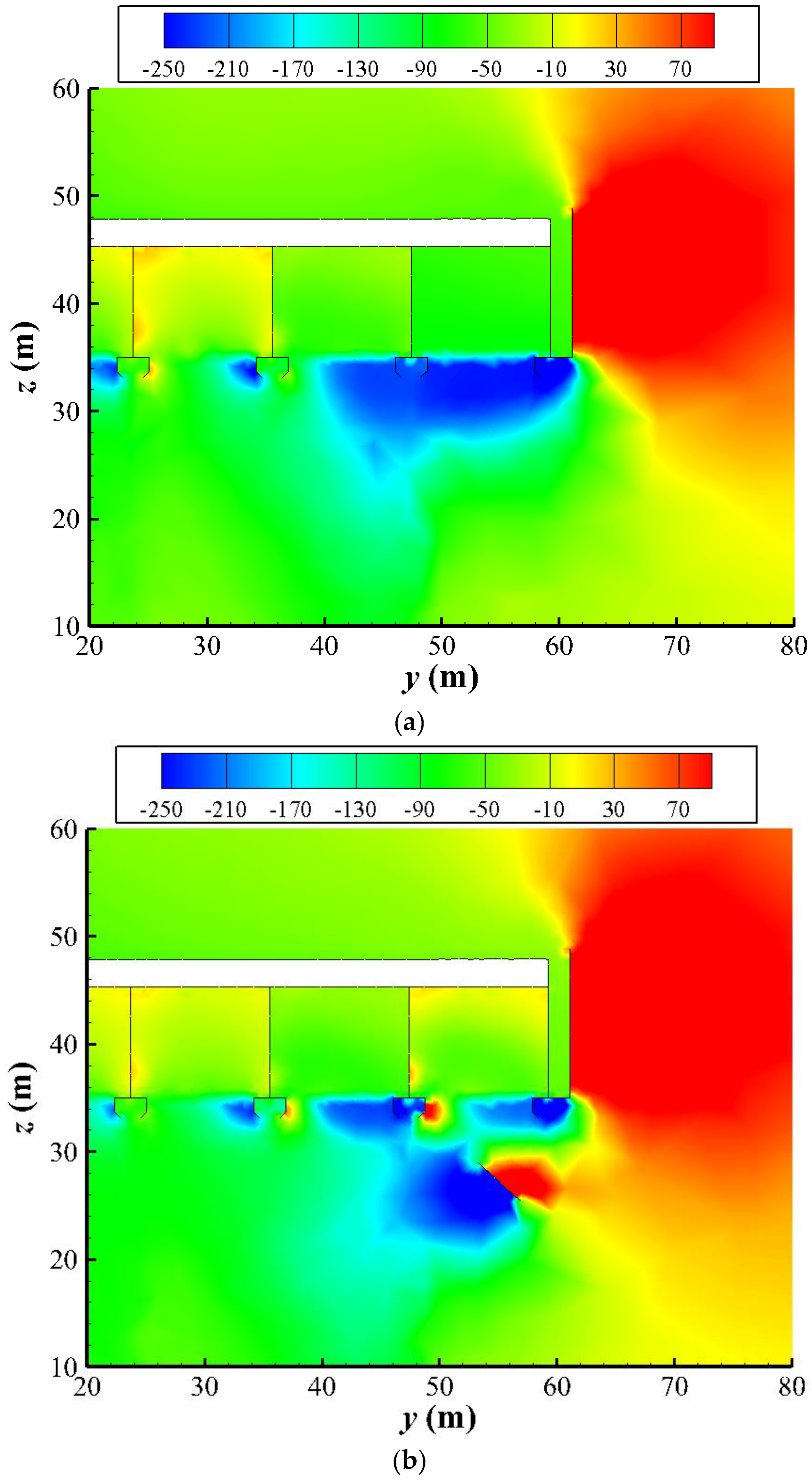

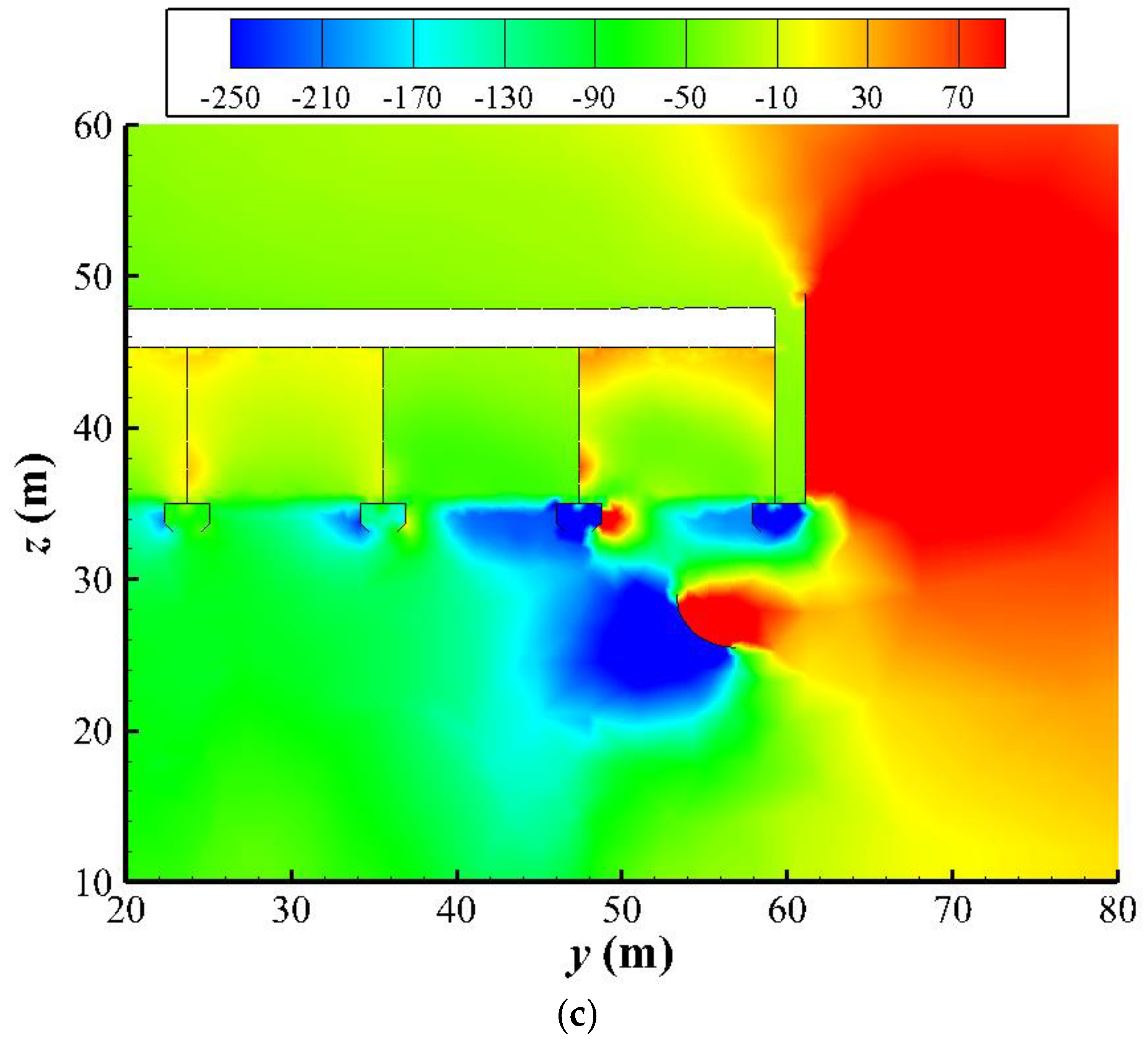

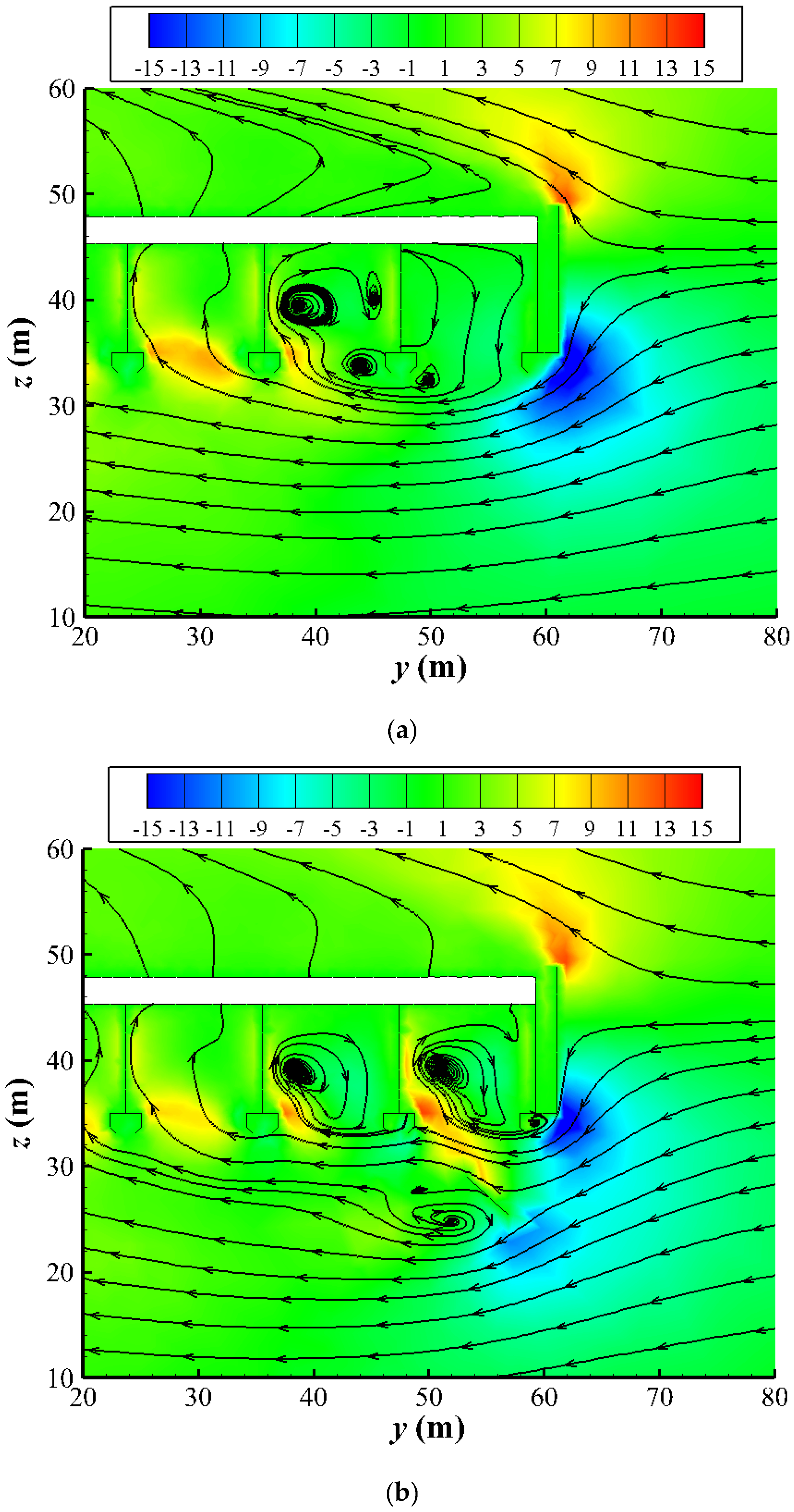

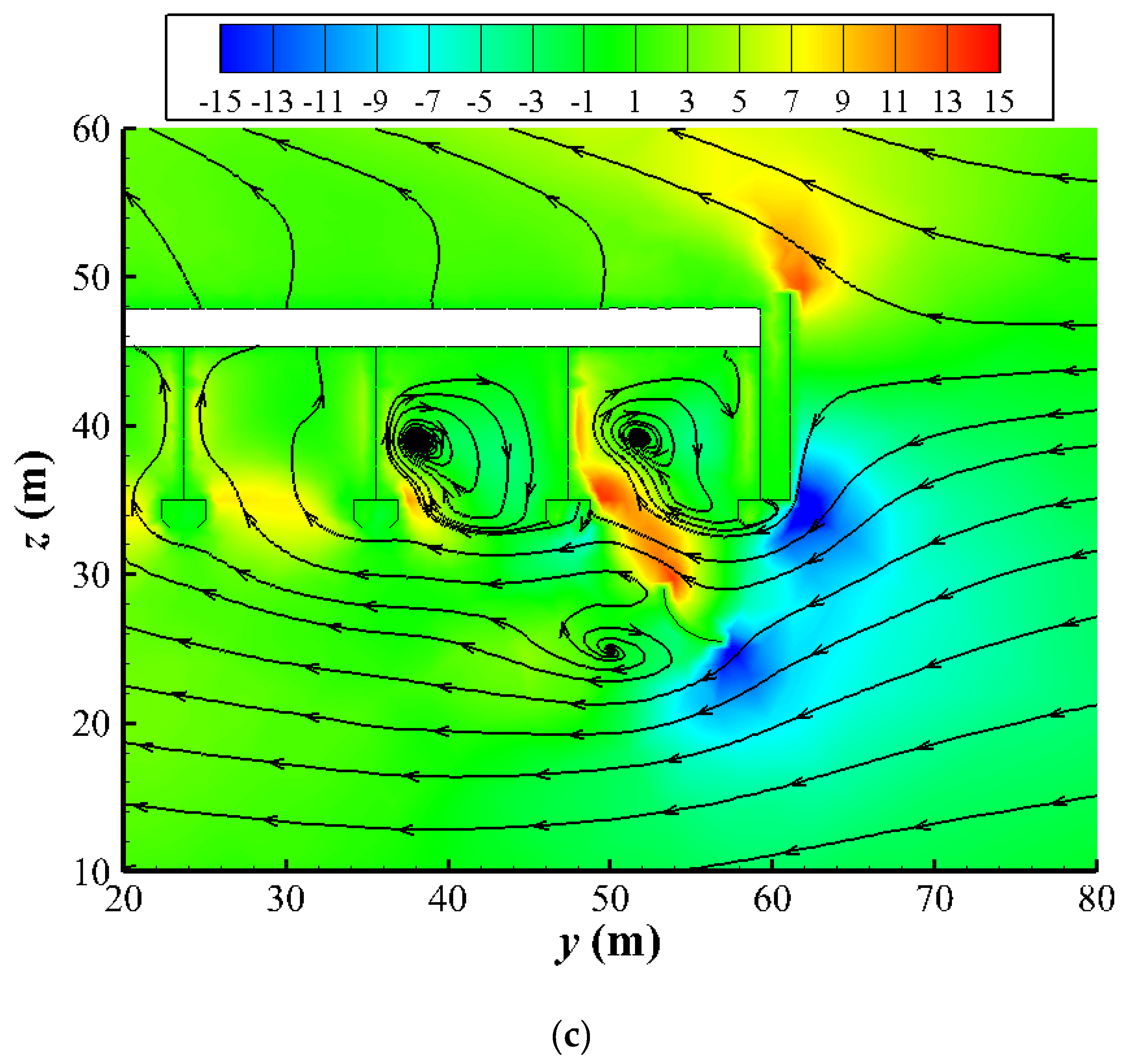

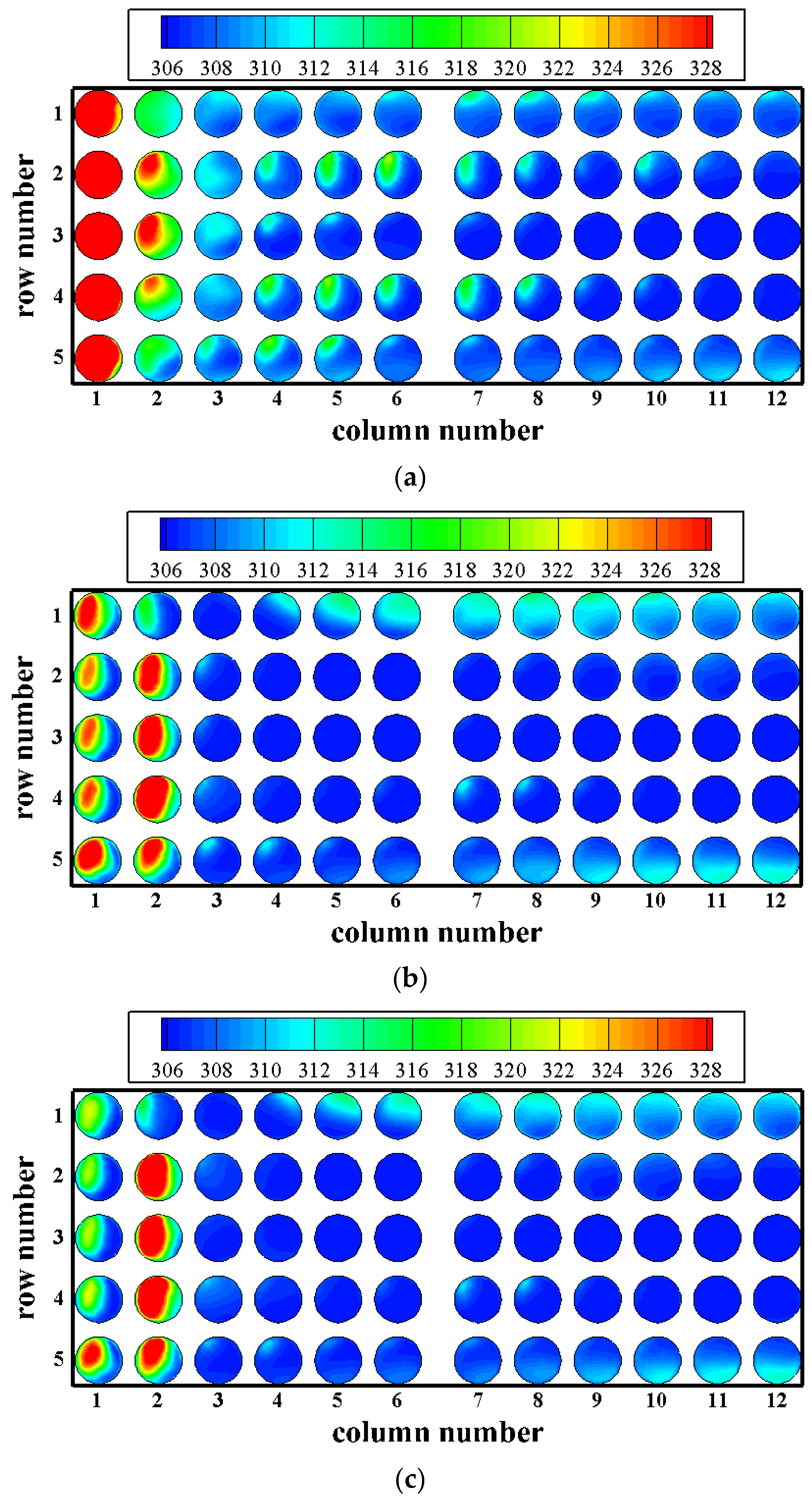

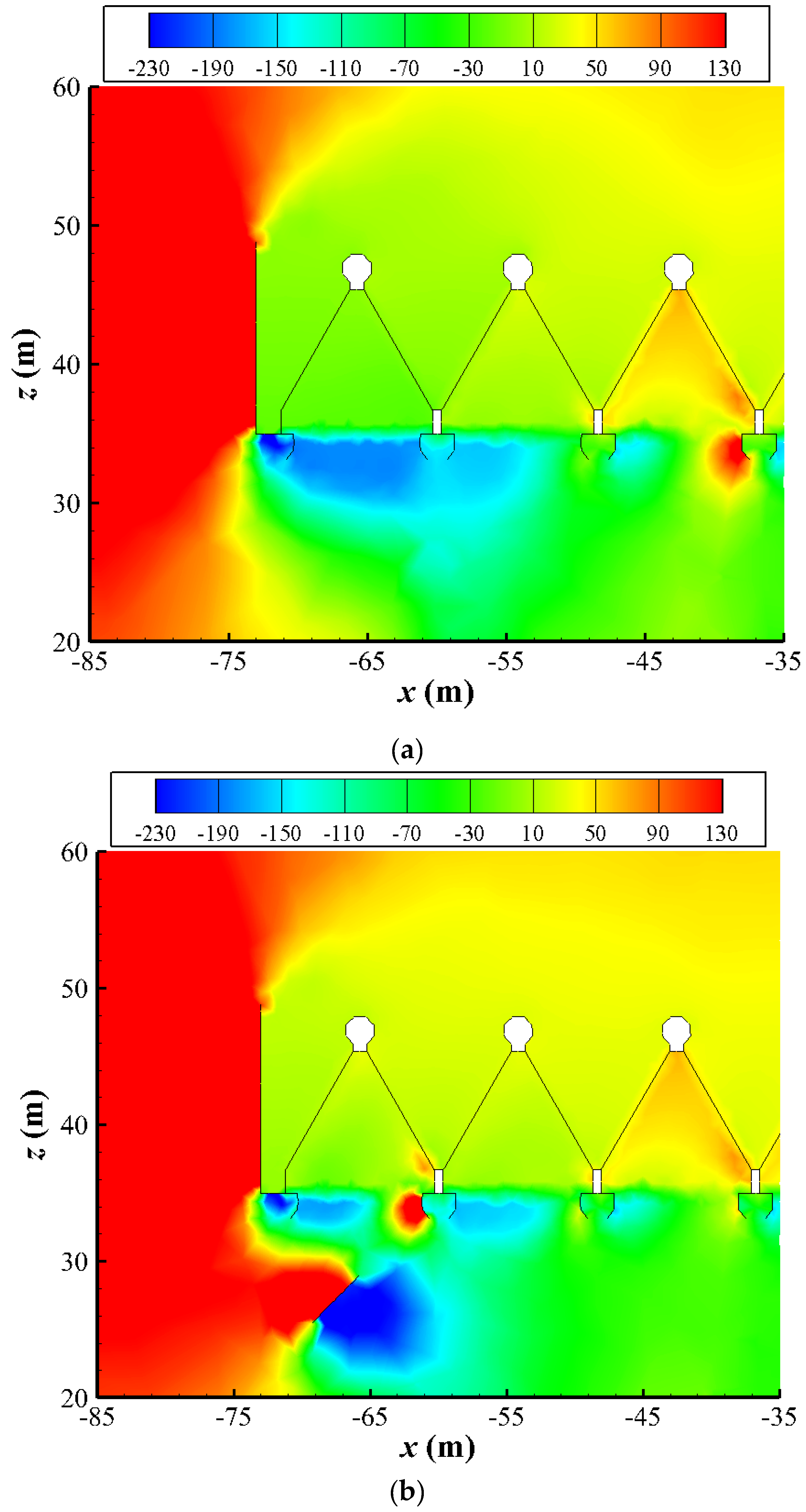

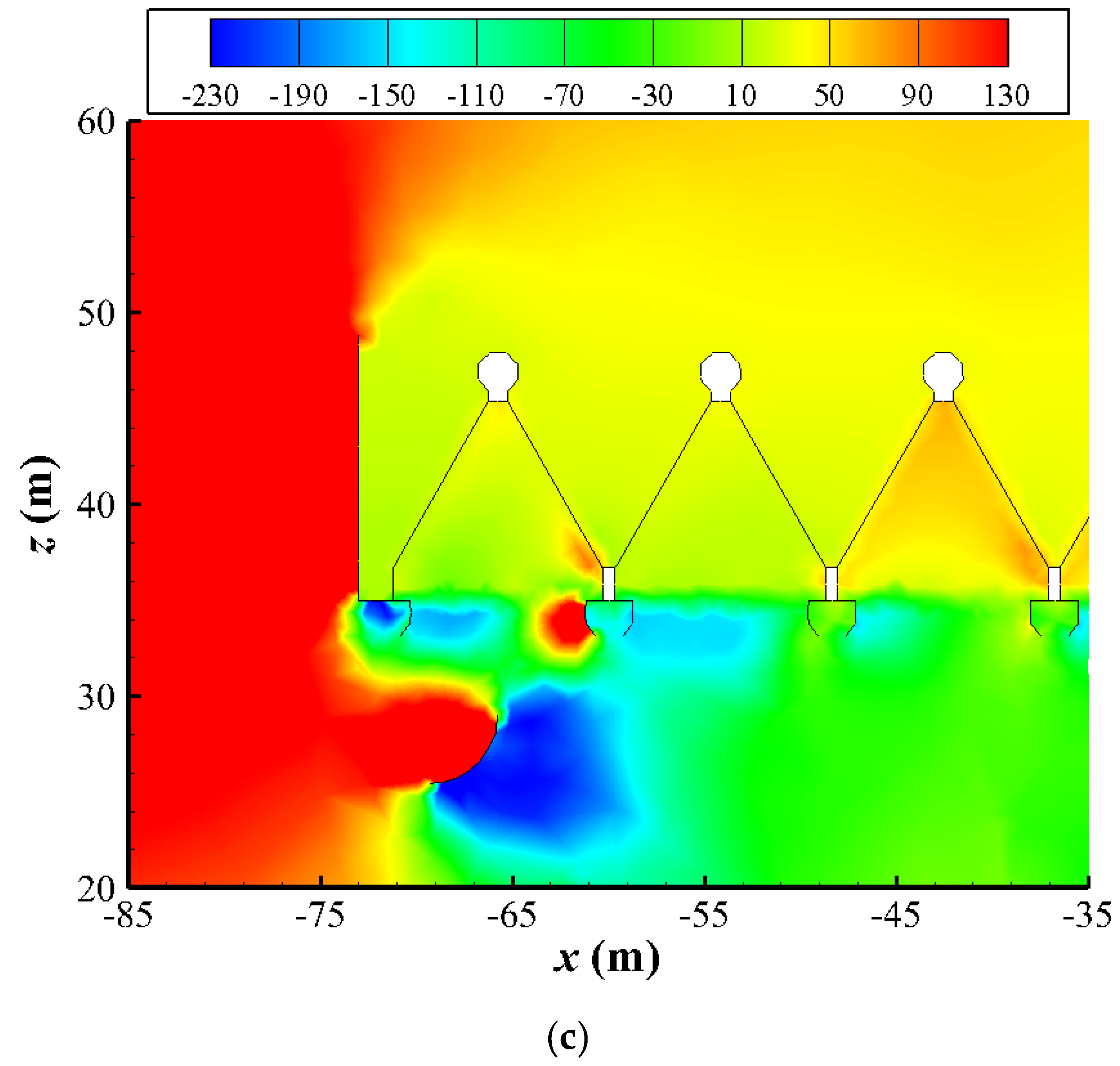

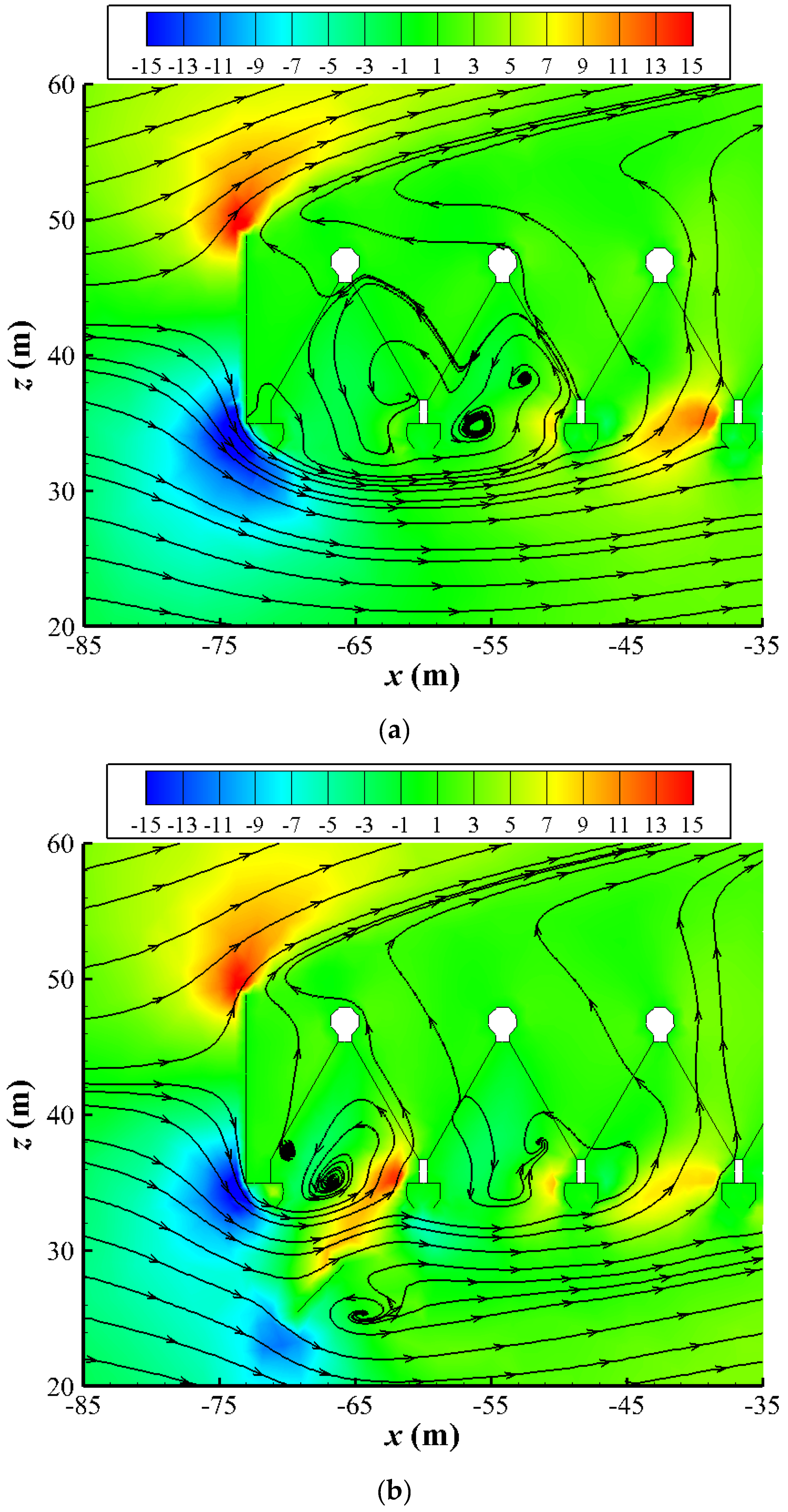

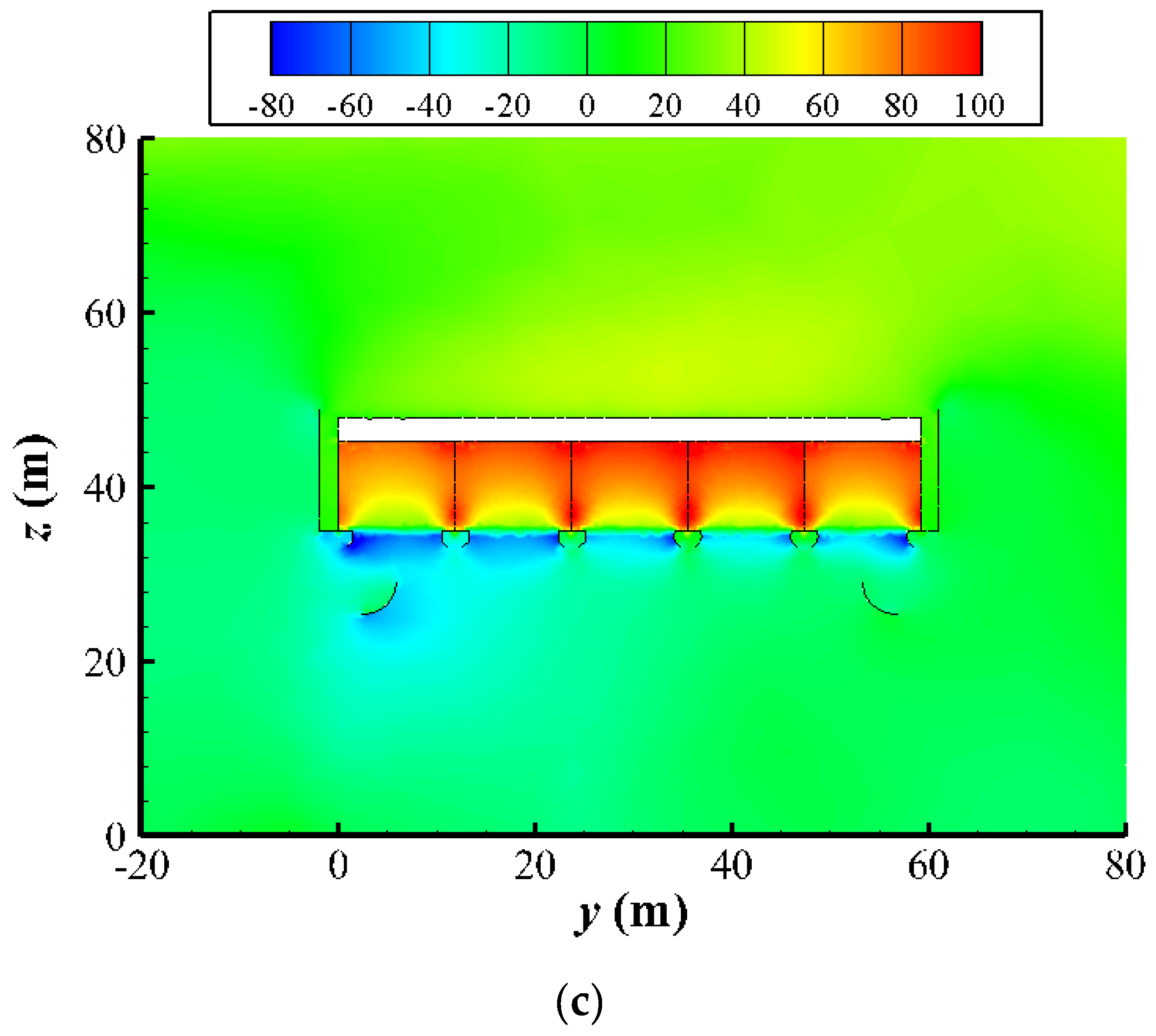

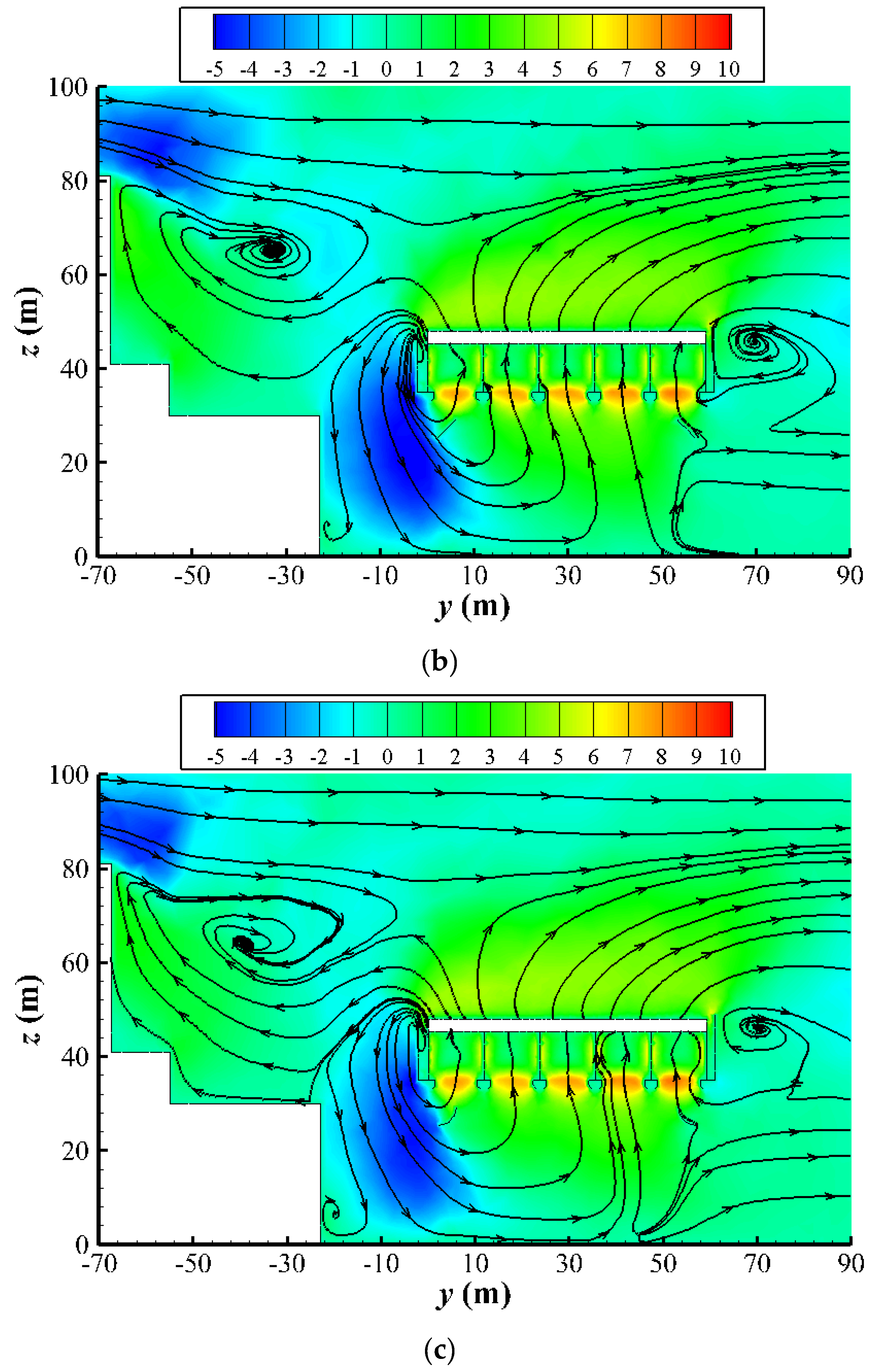

3.1.1. Wind Direction of −90°

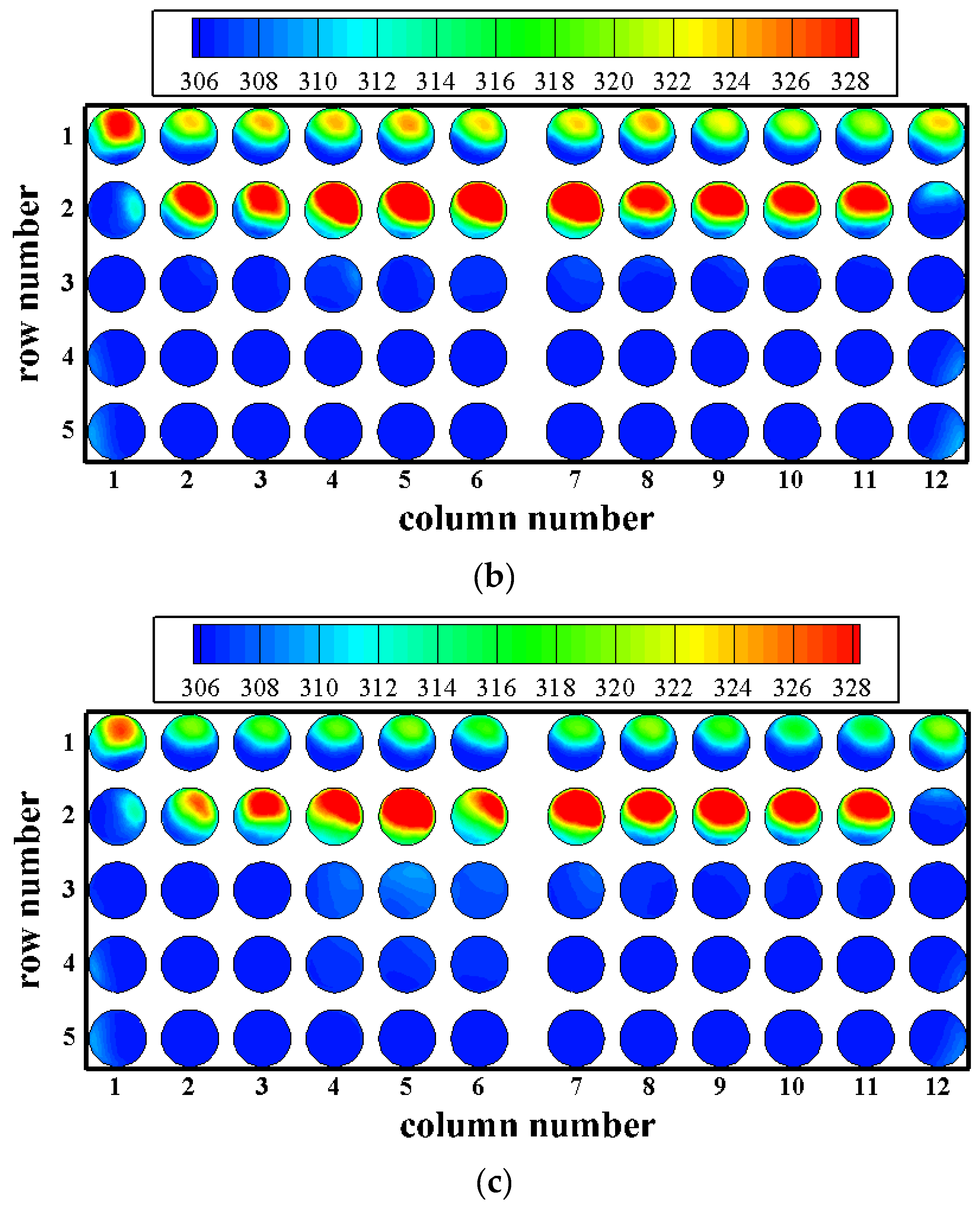

3.1.2. Wind Direction of 0°

3.1.3. Wind Direction of 90°

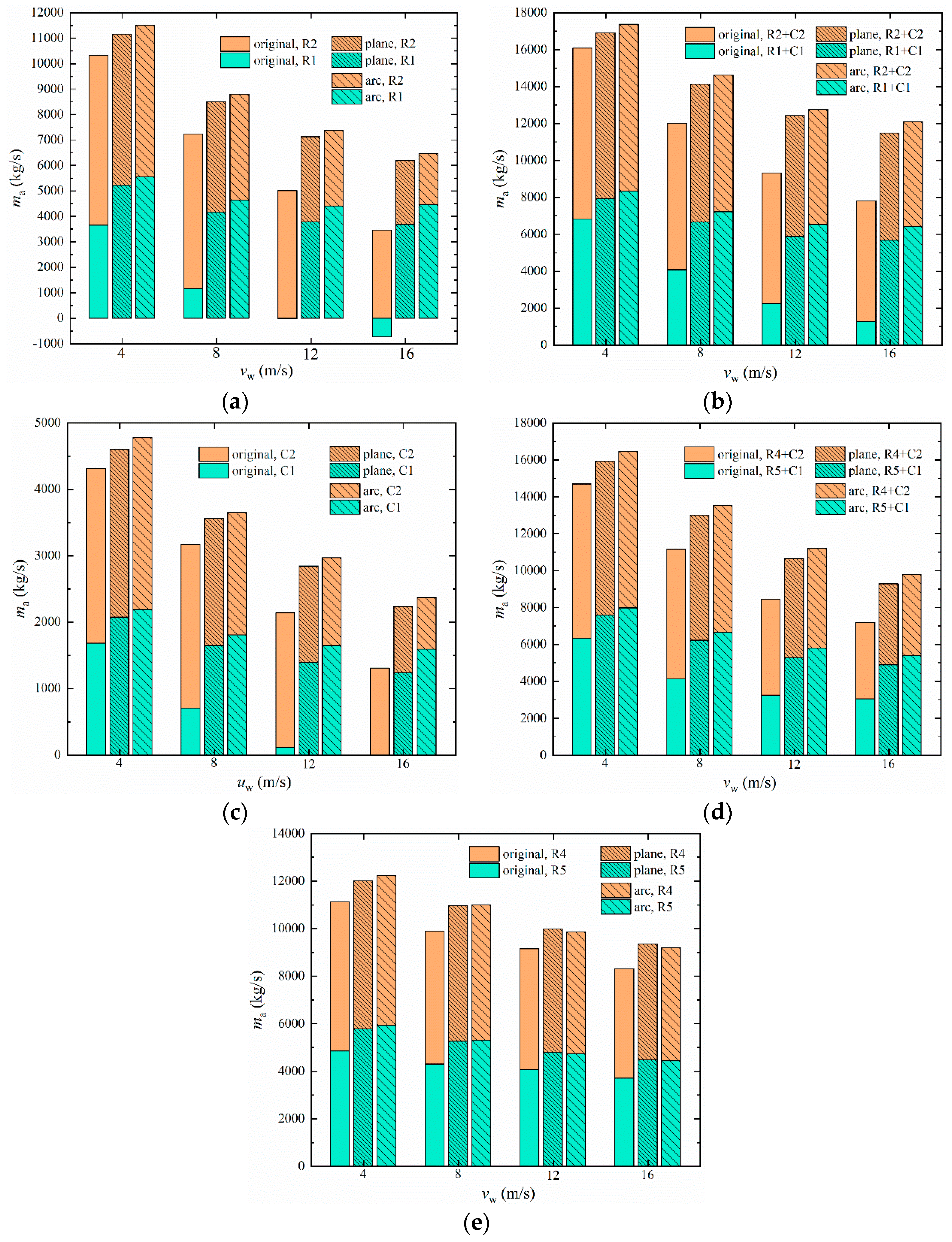

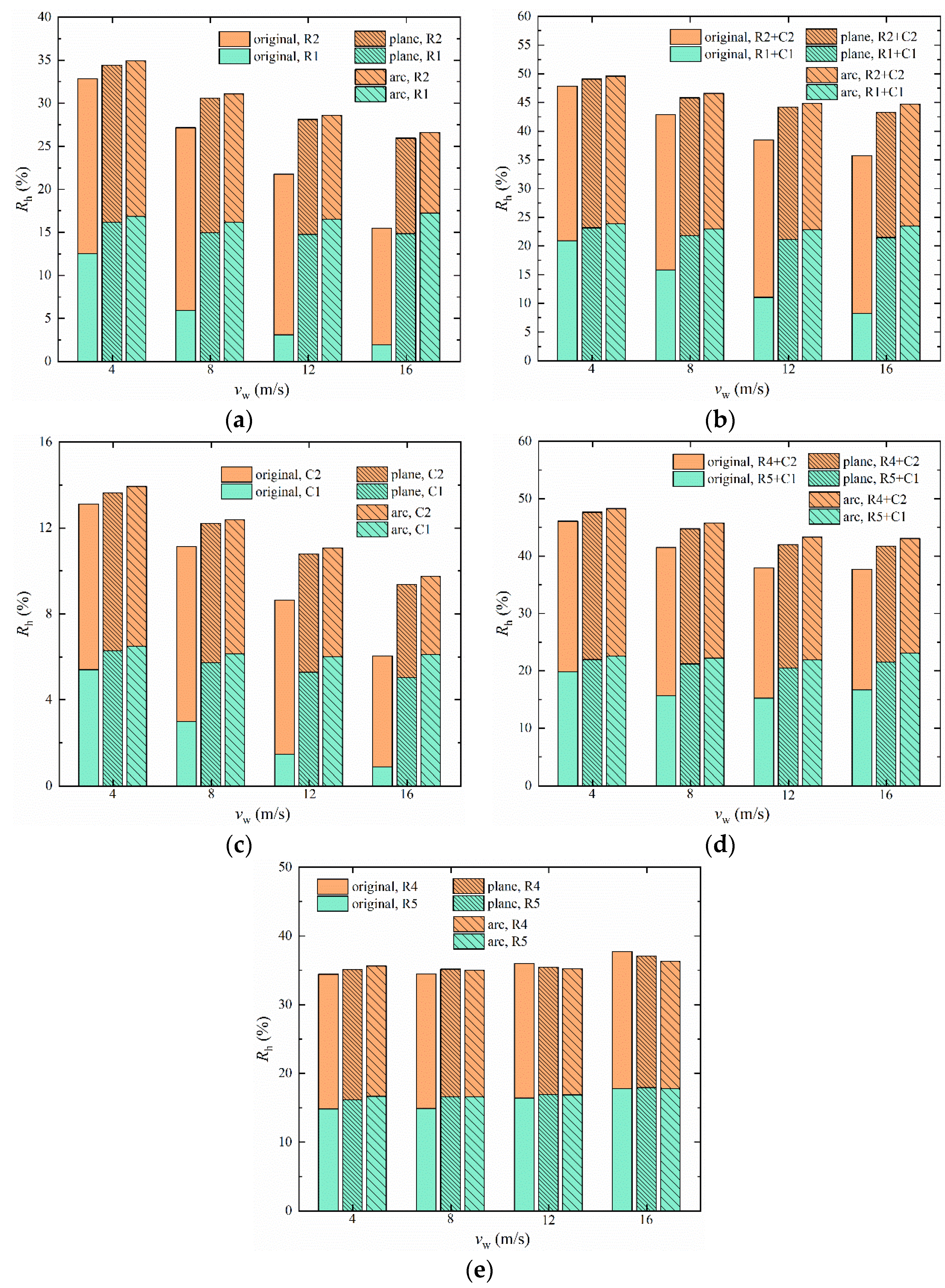

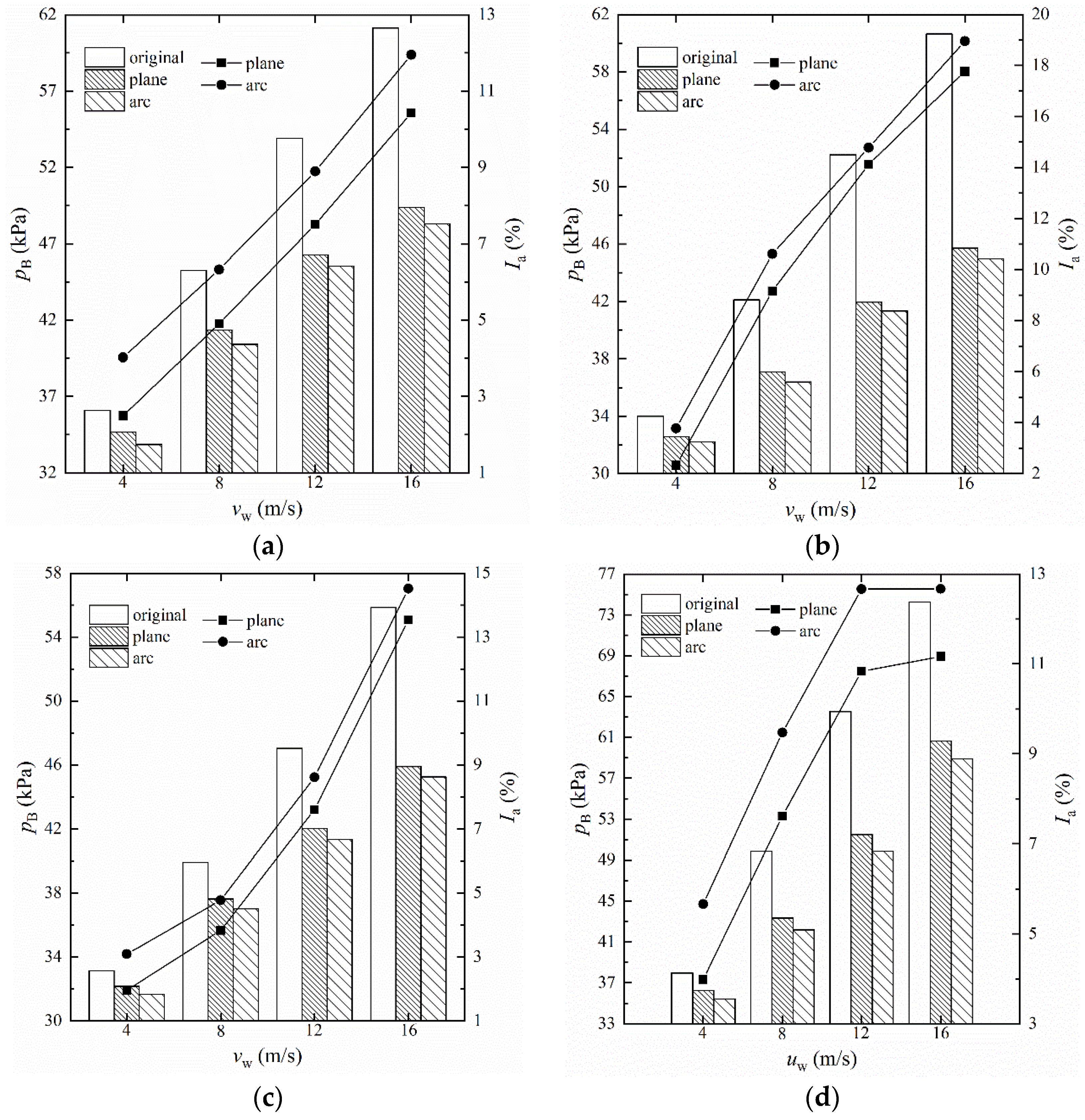

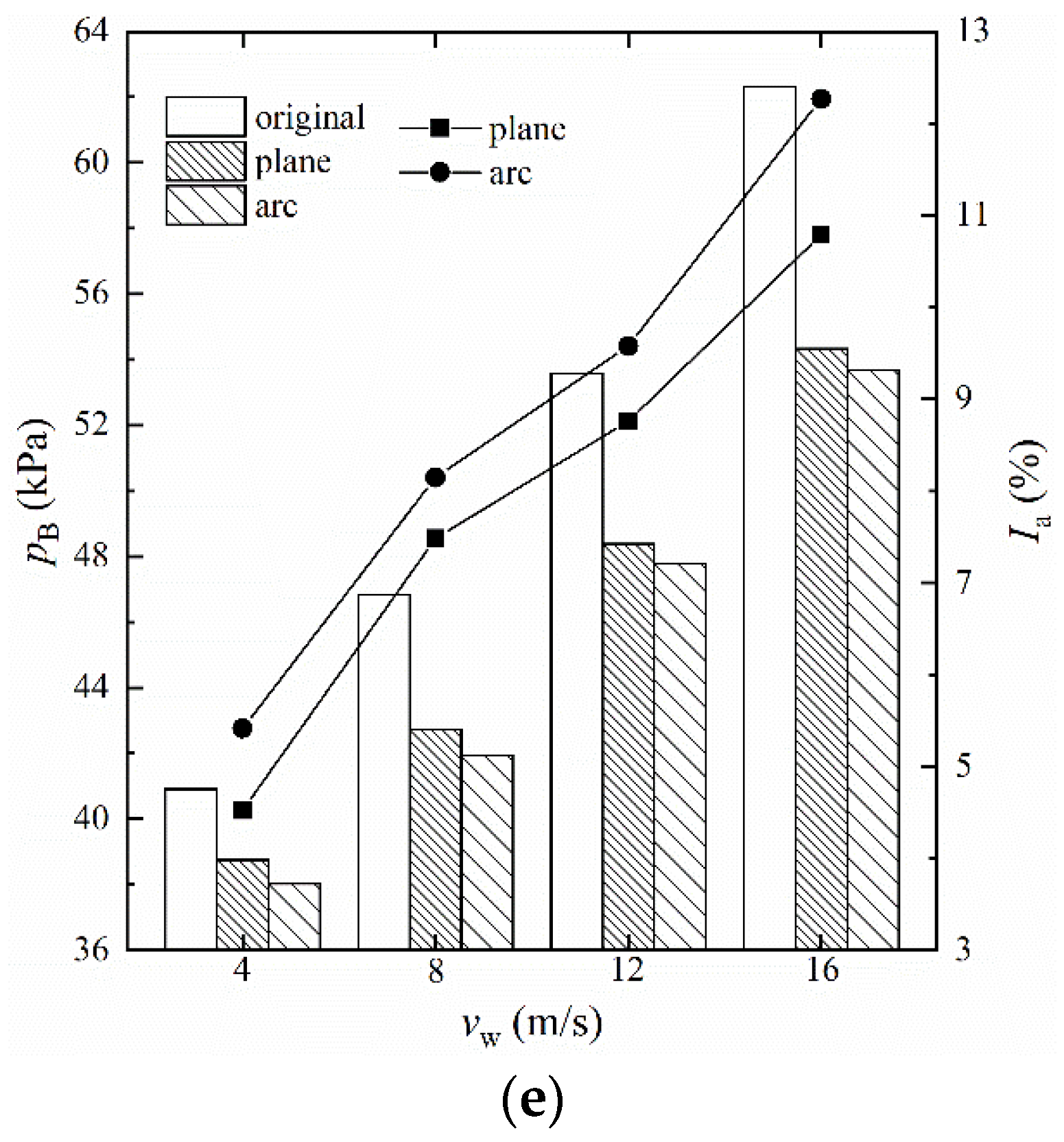

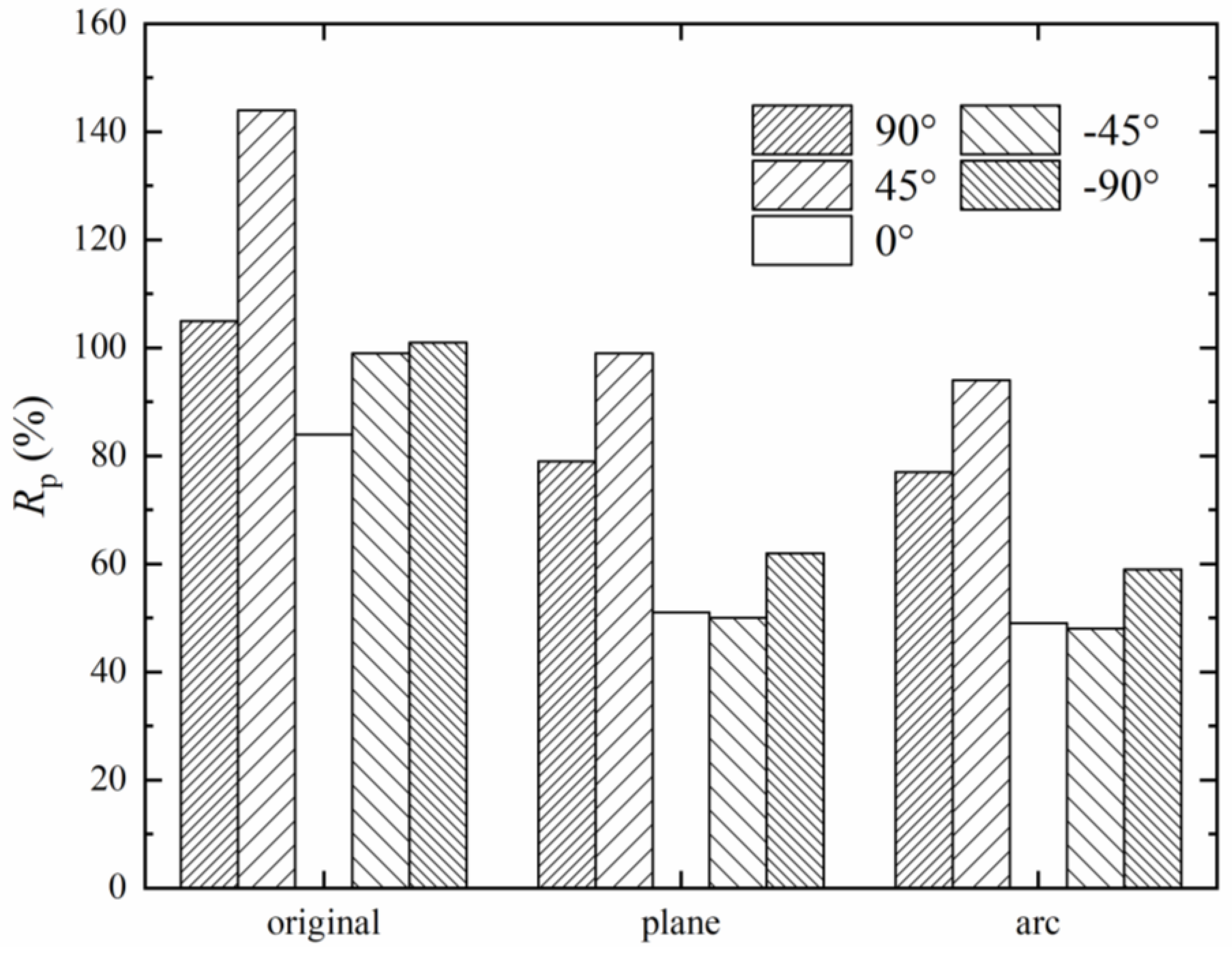

3.2. Thermo-Flow Performance Analyses

3.2.1. Local Flow Rate and Heat Rejection

3.2.2. Total Flow Rate and Back Pressure

3.2.3. Comparison of Different Wind Directions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| C1, C1ε, C2, C3ε | constants in turbulence equations |

| e | exponent in the wind speed equation |

| fn | polynomial coefficient for fan pressure rise |

| Gb | turbulent kinetic energy source term due to buoyancy |

| Gk | turbulent kinetic energy source term due to mean velocity gradients |

| gn | polynomial coefficient for fan tangential velocity |

| h | coefficient of convection heat transfer (W/m2/K) |

| h’ | empirical coefficient of convection heat transfer (W/m2/K) |

| hn | polynomial coefficient for convection heat transfer coefficient |

| hs | exhaust steam enthalpy (J/kg) |

| hwa | condensate water enthalpy (J/kg) |

| I | dimensionless improvement (%) |

| k | turbulent kinetic energy (m2/s2) |

| kL | flow loss coefficient |

| N | number |

| L | length of finned tube bundles |

| m | mass flow rate (kg/s) |

| p | pressure (Pa) |

| Prt | turbulent Prandtl number for energy |

| q | heat flux (W/m) |

| Rh | heat rejection share of upwind cells on ACCs |

| r | radial distance from fan center (m) |

| rn | polynomial coefficient for loss coefficient |

| S | modulus of the mean rate-of-strain tensor |

| Sφ | inherent source term in the conservation equation for scalar φ |

| Sφ’ | additional source term in the conservation equation for scalar φ |

| t | temperature (°C) |

| v | velocity (m/s) |

| z | height above the ground (m) |

| Greek symbols | |

| Γ | diffusion coefficient (m2/s) |

| ε | turbulent kinetic energy dissipation (m2/s3) |

| μ, μt, μe | dynamic, turbulent and effective viscosity, respectively (kg/m/s) |

| σk, σε, σt | turbulent Prandtl number for k, ε and t, respectively |

| Φ | heat rejection (W) |

| density (kg/m3) | |

| scalar variable | |

| Subscripts | |

| 1 | inlet |

| 2 | outlet |

| a | air |

| ad | air deflector |

| f | face |

| i, j, k | component in x, y, and z direction, respectively |

| pa | parallel to the gravitational vector |

| pe | perpendicular to the gravitational vector |

| o | original |

| up | upwind |

| s | steam |

| wa | water |

| w | wind |

| θ | tangential |

References

- Engelbrecht, R.; Meyer, C.J.; van der Spuy, S.J. Modelling Strategy for the Analysis of Forced Draft Air-Cooled Condensers using Rotational Fan Models. J. Therm. Sci. Eng. Appl. 2019, 11, 51011. [Google Scholar] [CrossRef]

- Butler, C.; Grimes, R. The effect of wind on the optimal design and performance of a modular air-cooled condenser for a concentrated solar power plant. Energy 2014, 68, 886–895. [Google Scholar] [CrossRef]

- Hotchkiss, P.J.; Meyer, C.J.; Von Backström, T.W. Numerical investigation into the effect of cross-flow on the performance of axial flow fans in forced draught air-cooled heat exchangers. Appl. Therm. Eng. 2006, 26, 200–208. [Google Scholar] [CrossRef]

- Yang, L.J.; Du, X.Z.; Yang, Y.P. Wind effect on the thermo-flow performances and its decay characteristics for air-cooled condensers in a power plant. Int. J. Therm. Sci. 2012, 53, 175–187. [Google Scholar] [CrossRef]

- Liu, P.; Duan, H.; Zhao, W. Numerical investigation of hot air recirculation of air-cooled condensers at a large power plant. Appl. Therm. Eng. 2009, 29, 1927–1934. [Google Scholar] [CrossRef]

- Chen, L.; Yang, L.; Du, X.; Yang, Y. Novel air-cooled condenser with V-frame cells and induced axial flow fans. Int. J. Heat Mass Transf. 2018, 117, 167–182. [Google Scholar] [CrossRef]

- Li, J.; Bai, Y.; Li, B. Operation of air cooled condensers for optimized back pressure at ambient wind. Appl. Therm. Eng. 2018, 128, 1340–1350. [Google Scholar] [CrossRef]

- Jin, R.; Yang, X.; Yang, L.; Du, X.; Yang, Y. Square array of air-cooled condensers to improve thermo-flow performances under windy conditions. Int. J. Heat Mass Transf. 2018, 127, 717–729. [Google Scholar] [CrossRef]

- Chen, L.; Yang, L.; Du, X.; Yang, Y. A novel layout of air-cooled condensers to improve thermo-flow performances. Appl. Energy 2016, 165, 244–259. [Google Scholar] [CrossRef]

- Zhou, Y.; Cheng, Y.; Zhang, N.; Shi, H. Numerical simulation study of novel air-cooled condenser with lateral air supply. Case Stud. Therm. Eng. 2019, 13, 100354. [Google Scholar] [CrossRef]

- Darbandi, M.; Behzadi, H.R.K.; Farhangmehr, V.; Schneider, G.E. Using CFD Simulations to Improve the Air-Cooled Steam Condenser Performance in Severe Windy Conditions via Proper Tuning of Blades Pitch Angles. In Proceedings of the ASME 2018 5th Joint US-European Fluids Engineering Division Summer Meeting, Montreal, QC, Canada, 15–19 July 2018; pp. V2T–V11T. [Google Scholar]

- Zhang, X.; Wu, T. Effects of diffuser orifice plate on the performance of air-cooled steam condenser. Appl. Therm. Eng. 2016, 98, 179–188. [Google Scholar] [CrossRef]

- Gu, H.; Zhe, Z.; Wang, H.; Qi, C. A numerical study on the effect of roof windbreak structures in an air-cooled system. Appl. Therm. Eng. 2015, 90, 684–693. [Google Scholar] [CrossRef]

- Gao, X.F.; Zhang, C.W.; Wei, J.J.; Yu, B. Performance prediction of an improved air-cooled steam condenser with deflector under strong wind. Appl. Therm. Eng. 2010, 30, 2663–2669. [Google Scholar] [CrossRef]

- Yang, L.; Du, X.; Yang, Y. Measures against the adverse impact of natural wind on air-cooled condensers in power plant. Sci. China Technol. Sci. 2010, 53, 1320–1327. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, H. Effects of windbreak mesh on thermo-flow characteristics of air-cooled steam condenser under windy conditions. Appl. Therm. Eng. 2015, 85, 21–32. [Google Scholar] [CrossRef]

- Xu, B.; Bhagwat, S.; Xu, H.; Rokoni, A.; McCarthy, M.; Sun, Y. System-level analysis of a novel air-cooled condenser using spray freezing of phase change materials. Appl. Therm. Eng. 2018, 131, 102–114. [Google Scholar] [CrossRef]

- Huang, X.; Chen, L.; Kong, Y.; Yang, L.; Du, X. Effects of geometric structures of air deflectors on thermo-flow performances of air-cooled condenser. Int. J. Heat Mass Transf. 2018, 118, 1022–1039. [Google Scholar] [CrossRef]

- Tao, W.Q. Numerical Heat Transfer; Xi’an Jiaotong University Press: Xi’an, China, 2002. [Google Scholar]

- Fluent, A. ANSYS Fluent Theory Guide (Release 14.0); ANSYS Inc.: Canonsburg, PA, USA, 2011. [Google Scholar]

- Duvenhage, K.; Kroger, D.G. The influence of wind on the performance of forced draught air-cooled heat exchangers. J. Wind Eng. Ind. Aerodyn. 1996, 62, 259–277. [Google Scholar] [CrossRef]

- Yang, L.J.; Du, X.Z.; Yang, Y.P. Influences of wind-break wall configurations upon flow and heat transfer characteristics of air-cooled condensers in a power plant. Int. J. Therm. Sci. 2011, 50, 2050–2061. [Google Scholar] [CrossRef]

- Kong, Y.; Wang, W.; Huang, X.; Yang, L.; Du, X.; Yang, Y. Circularly arranged air-cooled condensers to restrain adverse wind effects. Appl. Therm. Eng. 2017, 124, 202–223. [Google Scholar] [CrossRef]

| Equations | |||

|---|---|---|---|

| Continuity | 1 | 0 | 0 |

| x-Momentum | vi | ||

| y-Momentum | vj | ||

| z-Momentum | vk | ||

| Energy | t | 0 | |

| Turbulence kinetic energy | k | ||

| Turbulence dissipation rate |

| Item | Mesh 1 and Mesh 2 | Mesh 2 and Mesh 3 |

|---|---|---|

| The error of the total mass flow rate | 1.28% | 0.21% |

| Maximum error of individual fan mass flow rate | 2.34% | 0.32% |

| Case | Experiment | Simulation | ||||||

|---|---|---|---|---|---|---|---|---|

| ma (kg/s) | ta1 (°C) | ta2 (°C) | Φ (kW) | ma (kg/s) | ta1 (°C) | ta2 (°C) | Φ (kW) | |

| 1 | 8.19 | 7.81 | 85.8 | 641.93 | 8.22 | 7.81 | 92.81 | 702.2 |

| 2 | 9.7 | 7.82 | 83.4 | 736.79 | 9.54 | 7.82 | 90.43 | 792.08 |

| 3 | 11.21 | 7.31 | 77 | 785.13 | 11.08 | 7.31 | 84.22 | 856.53 |

| 4 | 12.73 | 7.07 | 72.1 | 831.97 | 12.95 | 7.07 | 77.75 | 919.96 |

| 5 | 14.62 | 6.96 | 67.5 | 889.52 | 14.96 | 6.96 | 72.12 | 979.71 |

| 6 | 17.39 | 7.91 | 62.7 | 957.56 | 17.98 | 7.91 | 65.85 | 1047.05 |

| 7 | 19.9 | 6.96 | 57.1 | 1002.77 | 21.5 | 6.96 | 57.83 | 1099.35 |

| 8 | 22.05 | 6.2 | 55.9 | 1101.36 | 22.09 | 6.2 | 58.13 | 1152.91 |

| 9 | 24.82 | 6.3 | 53.9 | 1187.33 | 23.58 | 6.3 | 57.5 | 1213.39 |

| 10 | 27.72 | 5.74 | 51.5 | 1274.81 | 27.77 | 5.74 | 51.14 | 1267.19 |

| Case | pB (kPa) | Ia (%) |

|---|---|---|

| without air deflectors | 30.4 | – |

| with plane deflectors | 30.3 | 0.33 |

| with arc deflectors | 30.2 | 0.97 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, X.; Chen, L.; Yang, L.; Du, X.; Yang, Y. Cooling Performance Enhancement of Air-Cooled Condensers by Guiding Air Flow. Energies 2019, 12, 3503. https://doi.org/10.3390/en12183503

Huang X, Chen L, Yang L, Du X, Yang Y. Cooling Performance Enhancement of Air-Cooled Condensers by Guiding Air Flow. Energies. 2019; 12(18):3503. https://doi.org/10.3390/en12183503

Chicago/Turabian StyleHuang, Xianwei, Lin Chen, Lijun Yang, Xiaoze Du, and Yongping Yang. 2019. "Cooling Performance Enhancement of Air-Cooled Condensers by Guiding Air Flow" Energies 12, no. 18: 3503. https://doi.org/10.3390/en12183503

APA StyleHuang, X., Chen, L., Yang, L., Du, X., & Yang, Y. (2019). Cooling Performance Enhancement of Air-Cooled Condensers by Guiding Air Flow. Energies, 12(18), 3503. https://doi.org/10.3390/en12183503