Abstract

A novel heating technology is presented to analyze the influence of inlet air heating on gas turbine efficiency under partial load. This technology uses the waste heat of a low-temperature heat sources, which includes but is not limited to the exhaust gas of a combined-cycle heat-recovery steam generator or a single-cycle gas turbine. A calculation model of the equilibrium running point is used for the given load and the characteristic curves of the compressor and the turbine to study the mechanism of the inlet air heating technology. Then, the equilibrium running line is calculated and drawn in the characteristic curves of the compressor and the turbine. The factors for gas turbine efficiency are discussed through the calculated equilibrium running line. The results show that an increase in inlet air temperature has considerable potential for improving gas turbine efficiency due to the increase in compressor and turbine efficiency. This finding is different from traditional viewpoints. Meanwhile, each partial load has an optimum heating temperature which becomes higher when the load is lower.

1. Introduction

Heavy-duty gas turbines and their combined cycles have the advantages of high thermal efficiency, clean emission, and good flexibility. In the context of energy security, high efficiency, and low carbon development, the function of such turbines is being increasingly pursued [1]. A remarkable feature of gas turbine performance is its sensitivity to atmospheric conditions, and any change in ambient temperature evidently influences the power and efficiency of such gas turbines. Especially in the summer, gas turbine output and efficiency both considerably decrease due to the increase in ambient temperature [2]. Air cooling technologies for gas turbine inlets are often used to improve gas turbine efficiency in gas turbine power plants, such as those in Saudi Arabia [3], Iran [4], India [5], and other countries in West Asia. At present, research on inlet air cooling technology is rich and its application is relatively mature. Many researchers have conducted relevant studies on the analysis and adoption of various inlet air cooling methods to improve the maximum load and efficiency of gas turbines. Kakaras [6] proposed an innovative integrated simulation of the absorption capabilities of refrigerating machine technology to reduce inlet air temperature in gas turbine power plants. De [7] found that imported evaporative cooling technologies are economical and simple to use but are suitable only for dry and hot climates. These imported technologies can effectively improve gas turbine efficiency, output power, and combined cycle efficiency by 3.2%, 110%, and 16%, respectively. Daryl [8] and Sanjeev [9] found that the total output gain of a combined-cycle power station is much higher than that of a gas turbine in single-cycle operation mode due to inlet air cooling. Furthermore, inlet air cooling technology is suitable for gas generator sets that undertake basic load, increasing the load during high-temperature periods.

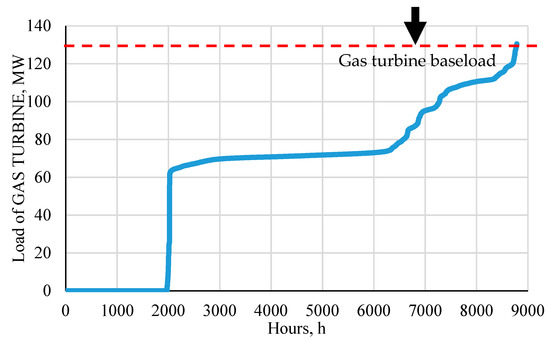

However, many gas turbine plants often work off design, especially in China. For example, Figure 1 shows the actual operating hours of a GE9171E gas turbine in a gas turbine power plant in Tianjin, China. The gas turbine baseload is 128.9 MW on the ISO standard condition, and the actual operating hours are approximately 6760 h in a year. According to Figure 1, the operating hours of the gas turbine are 6289 h under 50–90% load, which is the ratio between the operating power quantity and the rated power capacity. In particular, the operating hours are approximately 50% of a year for around 50% load. That is, the unit basically operates under partial load; thus, inlet air cooling technology is inappropriate.

Figure 1.

Actual operating hours of GE9171E gas turbine in Tianjin, China.

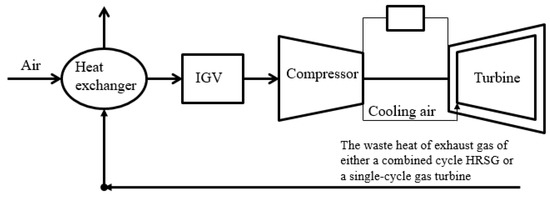

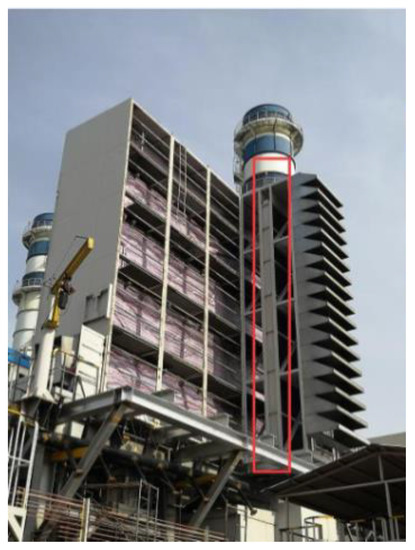

Inlet air heating has been recently found to improve combined-cycle electric efficiency [10]. An inlet air heating system that uses the waste heat of low-temperature heat source Figure 2 was built in the gas turbine power plant in Tianjin Figure 3. The low-temperature heat source includes, but is not limited to, the exhaust gas of a combined- or single-cycle gas turbine.

Figure 2.

Diagram of an inlet air heating system of a gas turbine.

Figure 3.

Inlet air heating system applied in the gas turbine power plant in Tianjin, China.

However, awareness of the benefit of inlet air heating for gas turbine efficiency is low. Increasing the inlet air temperature is traditionally believed to cause reduced gas turbine efficiency due to the resulting increase in the compressor power consumption. This study adopts a calculation model of the equilibrium running point through a single-shaft heavy-duty gas turbine. Results show that a higher inlet air temperature than that of ISO standard conditions has considerable potential for improving gas turbine efficiency under partial load.

2. Equilibrium Running Line and Performance Analysis

2.1. Model and Calculation Method

The research object of this study is a heavy-duty gas turbine with a single-shaft structure. The gas turbine comprises a compressor with IGV, a combustion chamber, and a turbine. Modeling and simulation are generally used to analyze gas turbine performance. Flack [11] calculated the performance of a single-shaft power generation gas turbine using the parameter cycle method based on gas turbine characteristic curves and component-matching conditions. Wang [12,13] developed a thermodynamic cycle calculation method of a three-shaft gas turbine with a hybrid cooling model to investigate the characteristics of gas turbines on a wide load range when the power turbine operates at a fixed physical speed. The cycle calculation model, as the basic work of the research, was initially used for the selected gas turbine, and its compressor, combustion chamber, and turbine modules were all considered. Then, the cooling model was invoked through the turbine module, and the mixing of cool air and gas was assumed to affect temperature and pressure in the turbine inlet. The compressible gas hybrid model of Hartsel [14] is adopted in calculating hybrid pressure loss to compute the time-delay pressure variation of the cooling air and mainstream gas mixture. Horlock [15] and Jonsson [16] simplified the model and directly connected pressure loss to relative cooling air mass flow.

Many researchers have also adopted the equilibrium running line in gas turbine research. Qusai [17] used a single-shaft gas turbine as the research object, established thermodynamic and aerodynamic calculation models for each of its main components, and developed a calculation method for steady-state performance to analyze the distance between the equilibrium running line of the gas generator. Pontus [18,19] discussed the influence of fuel composition on gas turbine performance by analyzing changes in equilibrium running lines of gas generators. In the paper, the classical cycle calculation model with the equilibrium running line and a gas hybrid model [14] are used under specific load conditions to analyze the relational variations in gas turbine efficiency and inlet air temperature.

2.2. Analysis of Compressor Equilibrium Running Line

Inlet temperatures from −15 °C to 62 °C under constant load conditions are selected in this study to analyze the effect of compressor inlet temperature on gas turbine performance comprehensively. The corrected speed and compressor efficiency lines of each inlet temperature are obtained on the basis of the compressor characteristic curve. Seven inlet lines corresponding to varying air temperature conditions are then obtained for simulation.

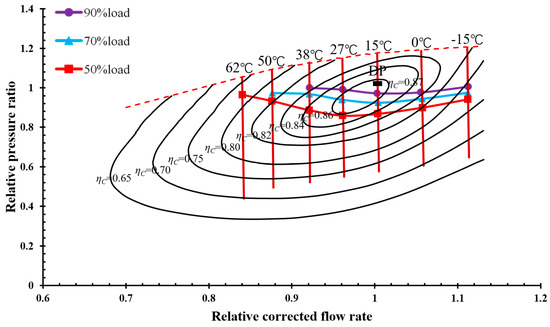

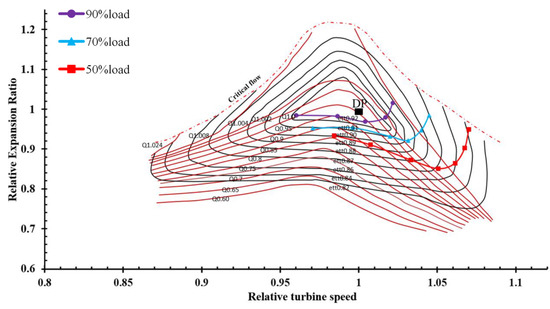

After comparison and analysis of performance changes in certain loads, the multiple equilibrium running lines of these varying loads can be drawn using the calculation method of the equilibrium running line. Thus, the partial loads of 90%, 70%, and 50% are selected for calculation and subsequently for the analysis of changes under partial-load equilibrium running conditions relative to inlet air heating. Then, the calculated equilibrium running points are drawn with the compressor characteristic line under 90%, 70%, and 50% load conditions, as shown in Figure 4. The designed point (DP) is also presented in Figure 5. The relative pressure ratio and corrected mass flow rate are both 1.0, and the compressor and turbine efficiency values are 0.88 and 0.92, respectively.

Figure 4.

Equilibrium running lines on compressor characteristic line.

Figure 5.

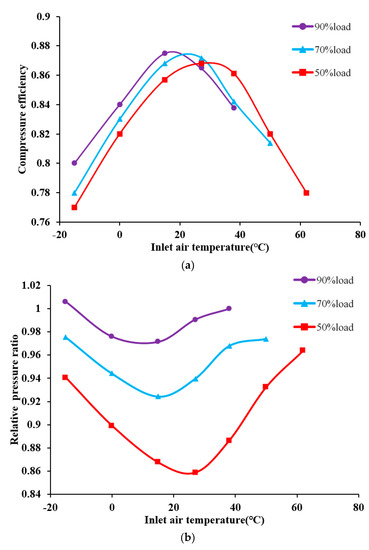

Compressor performance parameters at varying inlet air temperatures. (a) Compressor efficiency; (b) Relative pressure ratio.

As shown in Figure 4, the position of the equilibrium running point gradually moves to the left with the increase in inlet air temperature under constant partial-load conditions, indicating a steady decrease in inlet flow. With the temperature increase from −15 °C to 15 °C, relative pressure ratio tends to gradually decrease, but the change is minimal. Relative pressure ratio tends to demonstrate minimal increase as temperature starts to rise at 15 °C. The changes in compressor inlet air temperature have no notable influence on the relative pressure ratio. However, the change trend of the relative pressure ratio differs between low- and high-temperature air conditions. This difference can be attributed to the varying change trends of compressor efficiency relative to inlet air heating. As depicted by the compressor characteristic curve, compressor efficiency increases from −15 °C to 15 °C, but the trend gradually declines as it reaches 15 °C. A theoretical analysis showed that in maintaining a constant load equilibrium running condition, a certain relative pressure ratio must be increased under a high-temperature air condition to compensate for the noticeable decrease in compressor efficiency. Similarly, a certain relative pressure ratio must be reduced under a low-temperature air condition to offset the marked increase in compressor efficiency. Overall, with an increase in inlet air temperature, the following conditions are observed: the inlet flow considerably decreases, the relative pressure ratio minimally changes, the compressor efficiency markedly varies, and the equilibrium running point approaches the surge line under 90%, 70%, and 50% load conditions.

Quantitative analyses are conducted to determine the performance of each equilibrium running point based on Figure 4. Figure 5a,b show the change curves in compressor efficiency and pressure ratio, respectively, relative to inlet air heating. Figure 5a illustrates the compressor efficiencies under 90%, 70%, and 50% load conditions, in which efficiency increases and then decreases with the rise in inlet air temperature. For example, compressor efficiency under 50% load is 77% when inlet air temperature is −15 °C, and the highest compressor efficiency is 86.8% at 27 °C. The relative range of change is remarkable, i.e., 11.3%. In addition, given the same inlet air temperature, a high load in the low-temperature zone corresponds to a high compressor efficiency. By contrast, with the increase in inlet air temperature, a low load corresponds to a high compressor efficiency. The highest compressor efficiencies are 87.5%, 87.2%, and 86.8% under 90%, 70%, and 50% loads, respectively. The relative range of change is approximately 0.7%; thus, a low load indicates a small maximum compressor efficiency value. A decrease in load considerably affects compressor efficiency at constant inlet air temperature. Furthermore, the highest compressor efficiency is realized at a distinct inlet air temperature that is higher as the load diminishes.

As shown in Figure 5b, the relative pressure ratios under 90%, 70%, and 50% load conditions decrease and then increase with the inlet air temperature. For example, the relative pressure ratio under 50% load is 0.94 when inlet air temperature is −15 °C, and the lowest relative pressure ratio is 0.85 at 27 °C. The relative range of change is evident at 9%. Compared with the lowest relative pressure ratio in Figure 5a, that in Figure 5b is apparent near the highest compressor efficiency point. The lowest relative pressure ratios are 0.97, 0.92, and 0.85 under 90%, 70%, and 50% loads, respectively. The change range is noticeable at approximately 12.4%; thus, the lower the load, the smaller the relative pressure ratio. Load change also has an evident influence on relative pressure ratio. In summary, a low load corresponds to a small compressor efficiency and relative pressure ratio at low inlet air temperature, while on a hot day, i.e., 30 °C, a reduced load can increase the compressor efficiency. Load change and inlet air heating have evident effects on compressor efficiency and relative pressure ratio, respectively.

2.3. Analysis of Turbine Equilibrium Running Line

The same equilibrium running line calculation method is also adopted to analyze turbine performance. The same partial loads (i.e., 90%, 70%, and 50%) are selected for calculation. The equilibrium running points of the inlet air temperature, which are drawn from the turbine characteristic curve, are used to obtain the equilibrium running lines under 90%, 70%, and 50% load conditions, as shown in Figure 6.

Figure 6.

Equilibrium running lines on a turbine characteristic line.

In Figure 6, the positions of the equilibrium running points gradually move to the left of the turbine characteristic line with the increase in inlet air temperature under constant load conditions. The corrected speed of the turbine gradually decreases, indicating a steady increase in turbine inlet temperature at a constant load equilibrium running point. The tendency of the relative expansion ratio is identical to that of the relative pressure ratio given the pressure matching relation. However, when inlet air temperature shifts from −15 °C to 15 °C, the changing trend is larger in the relative expansion ratio than in the pressure ratio. The difference can be attributed to the use of the turbine cooling model. When exhaust air cooling is used at relatively low temperatures, exhaust air mass flow is corrected and the hybrid pressure loss increases. These phenomena result in relatively large expansion ratios. The trends are the same under the 90%, 70%, and 50% load conditions. However, with the increase in inlet air temperature, turbine efficiency changes differently for the varying load equilibrium running lines. For example, turbine efficiencies increase gradually with the temperature from −15 °C to 15 °C, but the trends change starting at 15 °C under the 90% and 70% load conditions; in contrast, turbine efficiency increases gradually from 15 °C to 62 °C under a 50% load condition. In summary, with an increase in inlet air temperature, changes in turbine inlet temperature and turbine efficiency become noticeable at a constant load equilibrium running point.

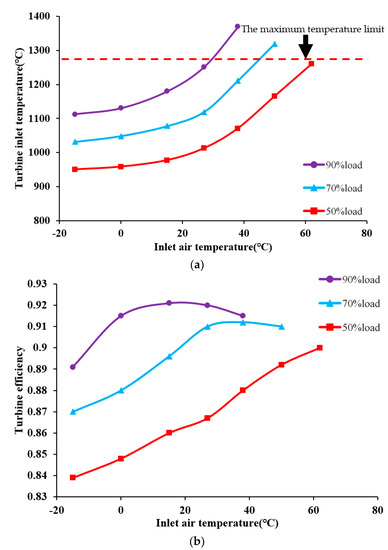

Quantitative analyses are performed on the basis of Figure 6 to determine the performance change in each equilibrium running point, as demonstrated in Figure 7a,b. These figures correspond to the variation curves of turbine efficiency and inlet temperature relative to inlet air heating. Figure 7a illustrates the gradual increase in turbine inlet temperature in which the increasing trend is significant relative to inlet air heating under the 90%, 70%, and 50% load conditions. For example, the turbine inlet temperatures are 950.98 °C at −15 °C and 1260.9 °C at 62 °C under the 50% load condition. An average increase of 5 °C in inlet air temperature requires an increase of 30 °C in the turbine inlet temperature. Turbine inlet temperature reaches the maximum temperature limit under the 90% load when the inlet air temperature is approximately 30 °C. Moreover, the turbine inlet temperature reaches the maximum temperature limit with 70% load when the inlet temperature is approximately 45 °C. In contrast, the maximum temperature limit under the 50% load condition is only realized when the inlet temperature reaches 62 °C. In summary, the turbine inlet temperature will reach its limit when the inlet air temperature rises to a certain temperature. Moreover, the higher the load, the faster the temperature reaches the limit under partial load conditions.

Figure 7.

Turbine performance parameters with varying inlet air temperatures. (a) Turbine inlet temperature; (b) Turbine efficiency

Figure 7b plots the change trends of turbine efficiency relative to inlet air heating under 90%, 70%, and 50% load conditions. Turbine efficiency increases and then declines under the 90% load. When the inlet air temperature is −15 °C, the value is 89.1%. The maximum value is 92.1% at 15 °C with 3% variations. Turbine efficiency also increases and then declines under the 70% load. When the inlet temperature is −15 °C, the value is 87%. The maximum value is 91.2% at 38 °C with 4.2% variations. Moreover, turbine efficiency increases gradually within the calculation range under the 50% load. When the inlet temperature is −15 °C, the value is 83.9%. The maximum value is 90% at 62 °C with 6.1% variations. These findings indicate that the lower the load, the higher the optimal inlet air temperature and the more obvious the influence on turbine efficiency. In addition, within a certain range of inlet air temperature, the turbine efficiency relative to inlet air heating under low-load conditions will exceed that under high-load conditions. In summary, the higher the load, the higher the required turbine inlet temperature and efficiency. However, the turbine inlet temperature will reach the temperature limit rapidly, and the turbine efficiency will decrease after a certain increase given the rise in inlet temperature. Therefore, load change and inlet air heating significantly affect the turbine inlet temperature and efficiency.

2.4. Analysis of Gas Turbine Efficiency

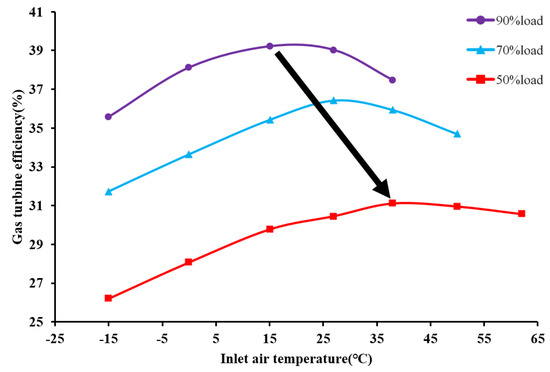

On the basis of the calculation of gas turbine efficiency (the ratio between the output power W and the fuel calorific value) at each equilibrium running point, the gas turbine efficiency on the equilibrium running lines relative to inlet air temperature is comprehensively analyzed under partial-load conditions (i.e., 90%, 70%, and 50%), as exhibited in Figure 8. Gas turbine efficiency increases and then decreases with inlet air heating under the three partial loads. This finding indicates that inlet air heating within a certain range benefits gas turbine efficiency, and the optimal inlet air temperature can be realized. In accordance with the comparative results, the maximum values of gas turbine efficiency are reached at 15 °C under the 90% load, 27 °C under the 70% load, and 38 °C under the 50% load. These values of maximum gas turbine efficiency for the different partial loads relative to varying inlet air temperatures represent a straight line. The lower the load, the higher the inlet air temperature. Consequently, the highest gas turbine efficiency is achieved and enhanced. Meanwhile, given the same load conditions, the lower the inlet temperature, the lower the gas turbine efficiency if the inlet air temperature is lower than the optimum value (15 °C at 90% load, 27 °C at 70% load, and 38 °C at 50% load). For example, under a 90% load condition, the gas turbine efficiency is 35.57% when the inlet temperature is −15 °C, and the maximum value is 39.21% at 15 °C, thereby indicating an efficiency improvement of 3.64%. Under a 70% load condition, the efficiency is 31.72% when the inlet temperature is −15 °C, and the maximum value is 36.43% at 27 °C, thus implying an efficiency improvement of 4.71%. Under a 50% load condition, the efficiency is 26.2% when inlet temperature is −15 °C, and the maximum value is 31.1% at 38 °C, thereby suggesting an efficiency improvement of nearly 5%. These findings indicate that the lower the inlet air temperature, the lower the gas turbine efficiency. In cases where inlet air heating technologies are used, the higher the inlet air temperature, the more evident the gas turbine efficiency improvement at lower loads.

Figure 8.

Gas turbine efficiency with varying inlet air temperatures.

The influence of inlet air heating on gas turbine efficiency is analyzed on the basis of the combined interpretations of Figure 5 and Figure 7. The improvement of gas turbine efficiency at low temperatures from −15 °C to 15 °C can be explained by the increased values of compressor and turbine efficiencies relative to turbine inlet temperature even when the rise in inlet temperature results in the increase in compressor power consumption and decrease in compression ratio under the 90%, 70%, and 50% load conditions.

Under a 70% load condition, gas turbine efficiency is promoted from 15 °C to 27 °C. This observation corresponds to the gradual rise in compressor efficiency. The pressure ratio increases simultaneously, and turbine inlet temperature and efficiency also increase. The decline beyond 27 °C can be attributed to the declining trend of compressor and turbine efficiencies, and the increasing trend of the pressure ratio ultimately flattens.

Under a 50% load condition, the decline in gas turbine efficiency can be attributed to the rise in inlet air temperature to 38 °C. Although the pressure ratio, turbine inlet temperature, and turbine efficiency have increasing trends, they cannot compensate for the negative impact caused by the apparent decrease in compressor efficiency.

In summary, the analysis of the different constant partial-load conditions implies that inlet air heating significantly affects compressor efficiency, pressure ratio, turbine inlet temperature, and turbine efficiency. Given the increase in inlet air temperature, the trends of pressure ratio and gas turbine efficiency differ, but the trends of compressor and turbine efficiencies are consistent with that of gas turbine efficiency. Inlet air temperature rises relative to the maximum efficiency when the load decreases. The trend of turbine efficiency is nearly similar to that of gas turbine efficiency. In addition, the turbine inlet temperature increases gradually. The findings can be explained by the improvements in turbine and compressor efficiencies, the increase in turbine inlet temperature, and most especially by the increase in compressor and turbine efficiencies, which were found to be crucial in this study.

3. Operating Data from a Gas Turbine Power Plant

Some operating data are presented in Table 1. The data in this table are obtained from the gas turbine power plant in Tianjin. These data support the research result. In Table 1, an increase in inlet air temperature can improve gas turbine efficiency when the load rate (the operating power quantity divided by the baseload) is constant.

Table 1.

Operating data from the gas turbine power plant in Tianjin.

Given that the compressor and turbine characteristic curves, which cannot be provided by the power plant, are different from those in Section 2, the operating data in Table 1 demonstrate some differences from the calculated data (Figure 8) in the quantification. However, these operating data also support the finding that a high inlet air temperature has considerable potential for improving gas turbine efficiency. These data can also be explained through the analysis in Section 2. A gas turbine that operates in partial load indicates that the running point is under an off-design condition. Furthermore, the running point tends to the design condition when the air temperature tends to the optimal temperature, thereby increasing the compressor and turbine efficiencies and improving the gas turbine efficiency. Therefore, the findings presented in Section 2 can be applied to other engines and have extensive applicability.

However, the test data summarized in Table 1 show a difference in gas turbine efficiency, which is approximately 50% of the predictions depicted in Figure 8 (test data nearly 1%, predictions approximately 2%). Therefore, the effect of inlet air heating on gas turbine efficiency under partial load may differ for various gas turbines. Section 2.4 explains one unfavorable and three favorable factors for gas turbine efficiency when using inlet air heating technology. The unfavorable factor refers to the increase in compressor power consumption, and the three favorable factors denote the increase in compressor efficiency, turbine efficiency, and turbine inlet temperature. The turbine inlet temperature increases with increasing of the inlet air temperature, as illustrated in Figure 7a. However, as shown in Figure 5a and Figure 7b, compressor and turbine efficiencies display peaks, which correspond to different inlet air temperatures. Simultaneously, change amplitudes of the three factors maybe different for different gas turbine. Thus, a matching relationship occurs between compressor efficiency, turbine efficiency, and turbine inlet temperature at different inlet air temperatures. If the three factors do not match well, then the gas turbine efficiency will be directly affected or even reduced if the unfavorable factor cannot be overcome by the three favorable factors.

Therefore, inlet air heating demonstrates the considerable potential for improving gas turbine efficiency under partial load. However, whether the inlet air heating is acceptable must be analyzed in accordance with the characteristics of different gas turbine units.

4. Conclusions

A novel inlet air heating technology for gas turbines under partial-load conditions is proposed. This technology uses waste heat of a low-temperature heat source to increase the compressor inlet air temperature. A calculation method is used for the compressor and turbine equilibrium running lines to study the mechanism of the heating technology. The equilibrium running lines obtained through the method involve three conditions, namely, 90%, 70%, and 50% partial loads. On the basis of the combined results of compressor efficiency, relative pressure ratio, turbine inlet temperature, and turbine efficiency, the effectual mechanisms of different inlet temperatures on gas turbine efficiency are comprehensively analyzed. The conclusions drawn from the analyses are presented as follows:

- (1).

- The inlet air heating technology has considerable potential for improving gas turbine efficiency, which is different from the traditional viewpoint.

- (2).

- An optimal inlet temperature exists for a certain load. Therefore, heating technology is appropriate when the ambient temperature is lower than the optimal inlet temperature; otherwise, cooling technology is appropriate.

- (3).

- A low load indicates a high optimal inlet temperature and a noticeable gas turbine efficiency improvement. Thus, heating technology, rather than cooling technology, under partial-load conditions is required.

- (4).

- The gas turbine efficiency improvement caused by inlet air heating under partial-load conditions can be explained. That is, inlet air temperature tends to the optimal temperature to make the running point tend to the design condition. Thus, turbine inlet temperature is known to rise, and compressor and turbine efficiencies increase as discovered in this study.

Author Contributions

Conceptualization, Z.L., X.R. and X.L.; Data curation, Z.T., Z.Y. and W.Z.; Investigation, X.R., Z.Y., H.Z., T.Z., W.Z. and X.L.; Methodology, X.R., X.L.; Supervision, X.L.; Validation, Z.L., W.Z. and X.L.; Writing—Original draft, W.Z.

Funding

This work is supported by Project 2017-II-0007-0021 of the National Science and Technology Major Project of China.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Acronyms | |

| HRSG | heat recovery steam generator |

| IGV | inlet guide vane |

| 0D | 0 dimension |

| DP | designed point |

| ISO | Temperature-15 (°C), Relative Humidity-60%, Ambient Pressure at Sea Level |

References

- Liu, Z.; Wang, W. Current status and development trend of gas power generation in China. Int. Pet. Econ. 2018, 26, 43–50. [Google Scholar]

- De Sa, A.; Al Zubaidy, S. Gas turbine performance at varying ambient temperature. Appl. Therm. Eng. 2011, 31, 2735–2739. [Google Scholar] [CrossRef]

- Kakaras, E.; Doukelis, A.; Prelipceanu, A.; Karellas, S. Inlet air cooling methods for gas turbine based power plants. Eng. Gas Turbines Power Trans. ASME 2006, 128, 312–317. [Google Scholar] [CrossRef]

- Farzaneh-gord, M.; Deymi-dashtebayaz, M. Effect of various inlet air cooling methods on gas turbine performance. Energy 2011, 36, 1196–1205. [Google Scholar] [CrossRef]

- Mohapatra, A.K. Thermodynamic assessment of impactof inlet air cooling techniques on gas turbine and combined cycle performance. Energy 2014, 68, 191–203. [Google Scholar] [CrossRef]

- Kakaras, E.; Doukelis, S.; Karellas, S. Compressor intake-air cooling in gas turbine plants. Energy 2004, 29, 2347–2358. [Google Scholar] [CrossRef]

- De Lucia, M.; Lanfranchi, C.; Boggio, V. Benefits of compressor inlet air cooling for gas-turbine cogeneration plants. In Proceedings of the International Gas Turbine and Aero-engine Congress and Exposition, Houston TX, USA, 5–8 June 1995. [Google Scholar]

- Brown, D.R. Combustion turbine inlet air cooling economics. Power Technol. Int. 1998, 42, 41–44. [Google Scholar]

- Jolly, S.; Nitzken, J. Evaluation of combustion turbines inlet air cooling system. In Gen Asia. Presented of the Power; New Dehil Press: New Dehil, India, 1998. [Google Scholar]

- Variny, M.; Mierka, O. Improvement of part load efficiency of a combined cycle power plant provisioning ancillary services. Appl. Energy 2009, 86, 88–894. [Google Scholar] [CrossRef]

- Flack, R. Component Matching Analysis for a Power Generation Gas Turbine: Classroom Application. In Proceedings of the ASME Turbo Expo 2002: GT-2002-30155, Amsterdam, The Netherlands, 3–6 June 2002. [Google Scholar]

- Wang, H.; Li, Xu.; Ren, X.; Gu, C.; Ji, Xi. Athermodynamic-cycle performance analysis method and application on a three-shaft gas turbine. Appl. Therm. Eng. 2017, 37, 465–472. [Google Scholar] [CrossRef]

- Gu, C.; Wang, H.; Ji, Xi.; Li, Xu. Development and application of a thermodynamic-cycle performance analysis method of a three-shaft gas turbine. Energy 2016, 112, 307–321. [Google Scholar] [CrossRef]

- Hartsel, J.E. Prediction of Effects of Mass-Transfer Cooling on the Blade-Row Efficiency of Turbine Airfoils. In Proceedings of the 10th Aerospace Sciences Meeting, San Diego, CA, USA, 17–19 January 1972. AIAA Paper. [Google Scholar] [CrossRef]

- Horlock, J.H.; Watson, D.T.; Jones, T.V. Limitations on Gas Turbine Performance Imposed by Large Turbine Cooling Flows. J. Eng. Gas Turbines Power 2001, 123, 487–494. [Google Scholar] [CrossRef]

- Jonsson, M.; Bolland, O.; Bucker, D. Gas turbine cooling model for evaluation of novel cycles. In Proceedings of the ECOS 2005, Trondheim, Norway, 20–22 June 2005. [Google Scholar]

- Al-Hamdan, Q.Z.; Ebaid, M.S. Modeling and Simulation of a Gas Tubrine Engine for Power Generation. J. Eng. Gas Turbines Power 2006, 128, 302–311. [Google Scholar] [CrossRef]

- Eriksson, P.; Genrup, M.; Jonshagen, K. Off-Design Performance Investigation of a Low Calorific Gas Fired Two-Shaft Gas Turbine. In Proceedings of the ASME Turbo Expo 2009: GT2009-59067, Orlando, FL, USA, 8–12 June 2009. [Google Scholar]

- PEriksson, o.; Jonshagen, K.; Klingmann, J. Re-Sizing of a Natural Gas Fired Two-Shaft Gas Turbine for Low Calorific Gas Operation. In Proceedings of the ASME Turbo Expo 2009: GT2009-60386, Orlando, FL, USA, 8–12 June 2009. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).