Three-Dimensional Inverse Design Method for Hydraulic Machinery

Abstract

1. Introduction

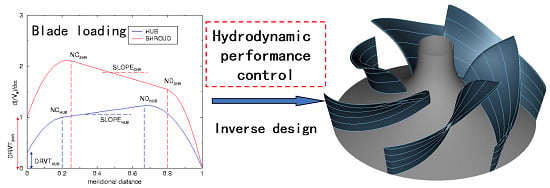

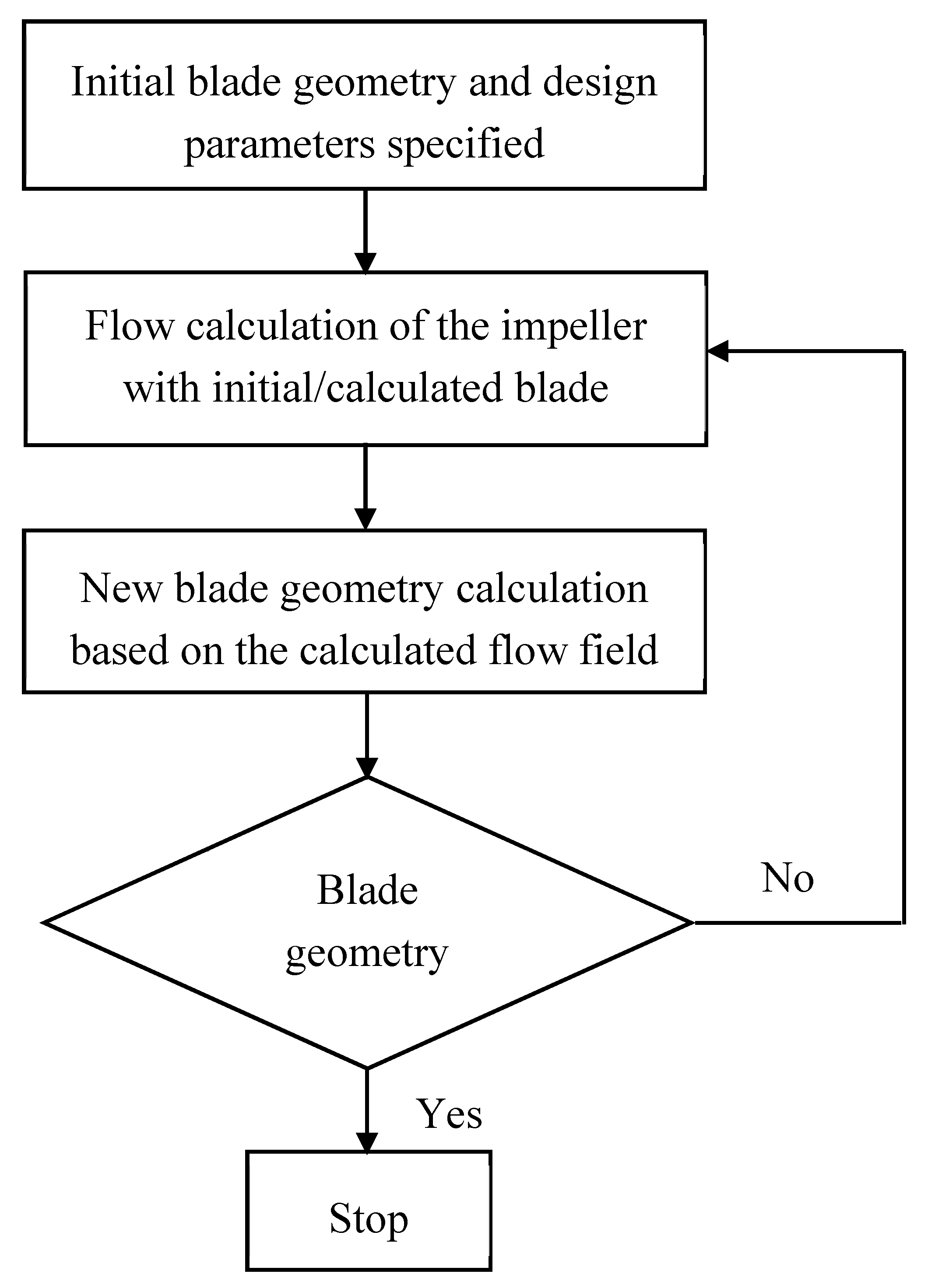

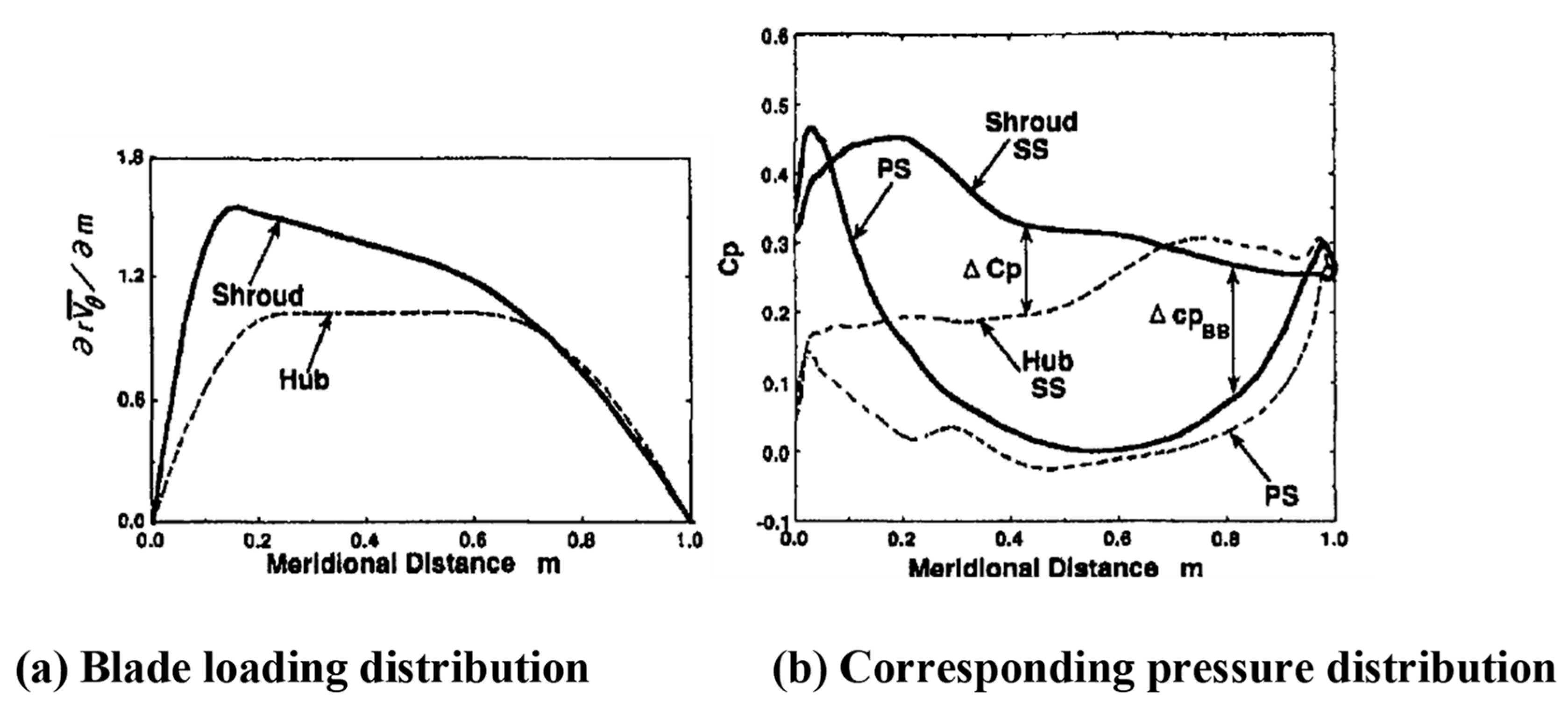

2. Description of the Inverse Design Method

2.1. Basic Idea

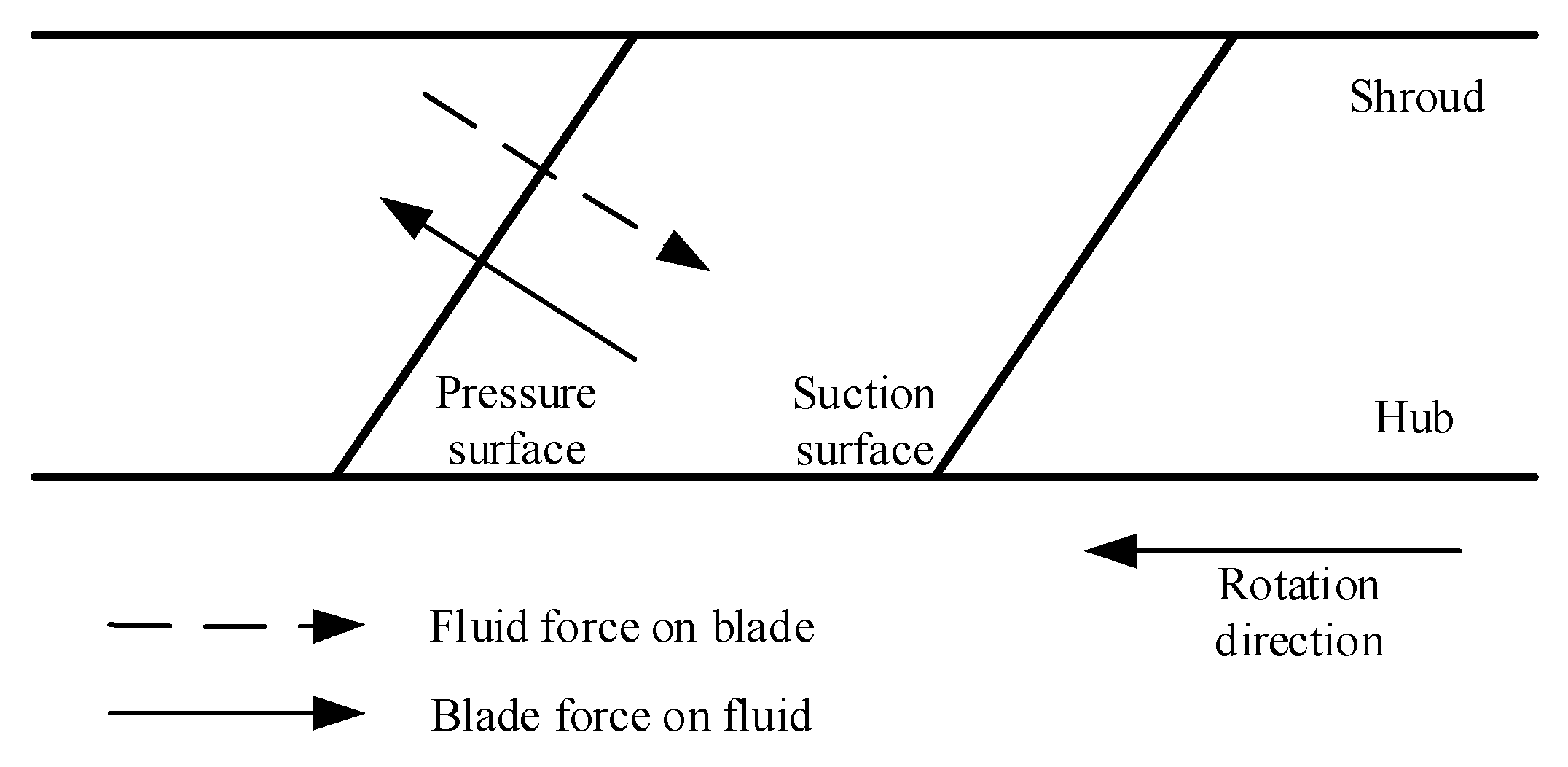

2.2. Flow Calculation Based on Potential Theory

2.2.1. Calculation of Circumferentially-Averaged Velocity

2.2.2. Calculation of Periodic Velocity

2.3. Blade Geometry Calculation Based on Flow Tangential Condition

2.4. Convergency of the Inverse Design Method

2.5. Main Input Design Parameters

3. Flow Control Based on Inverse Design Method

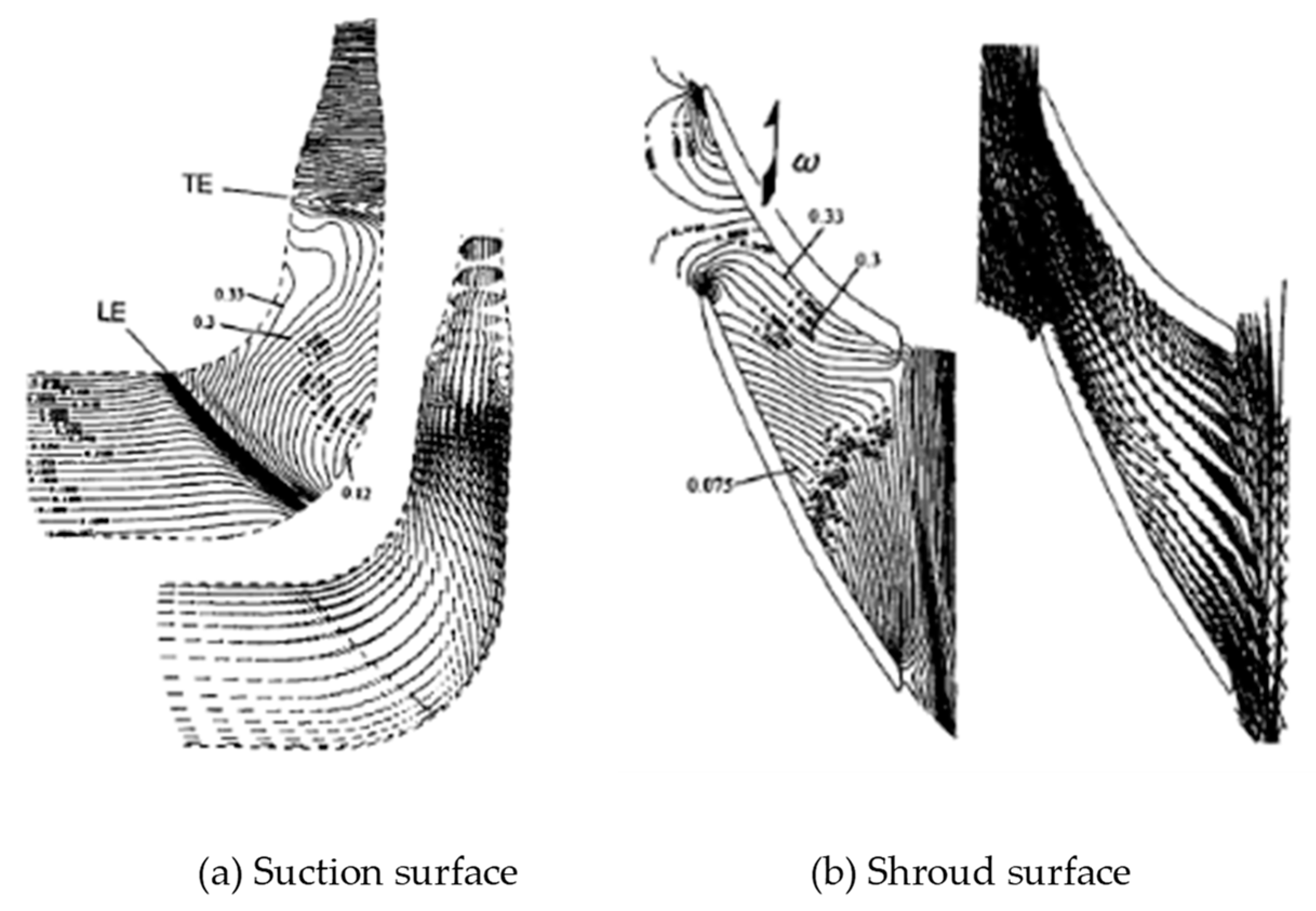

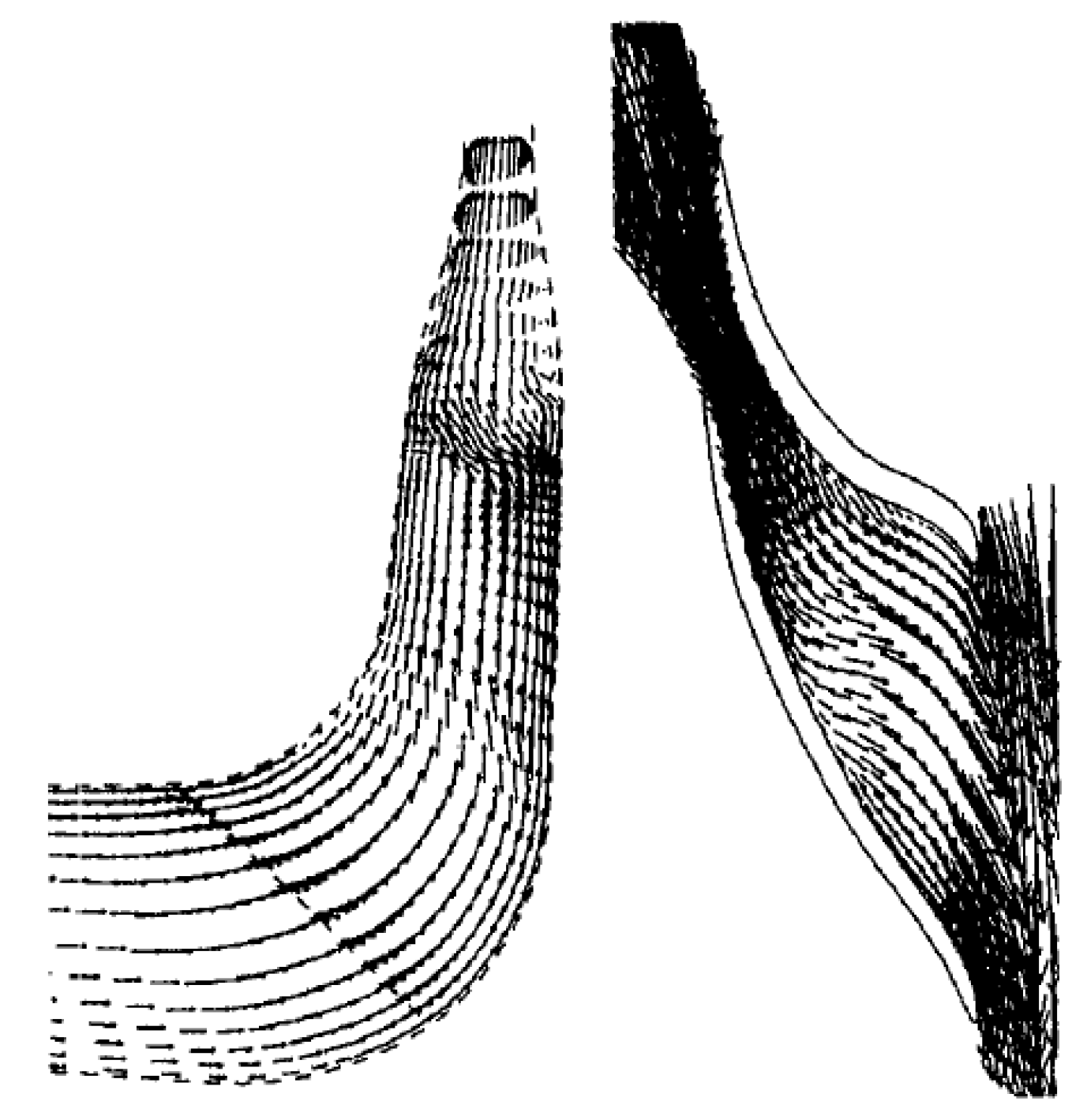

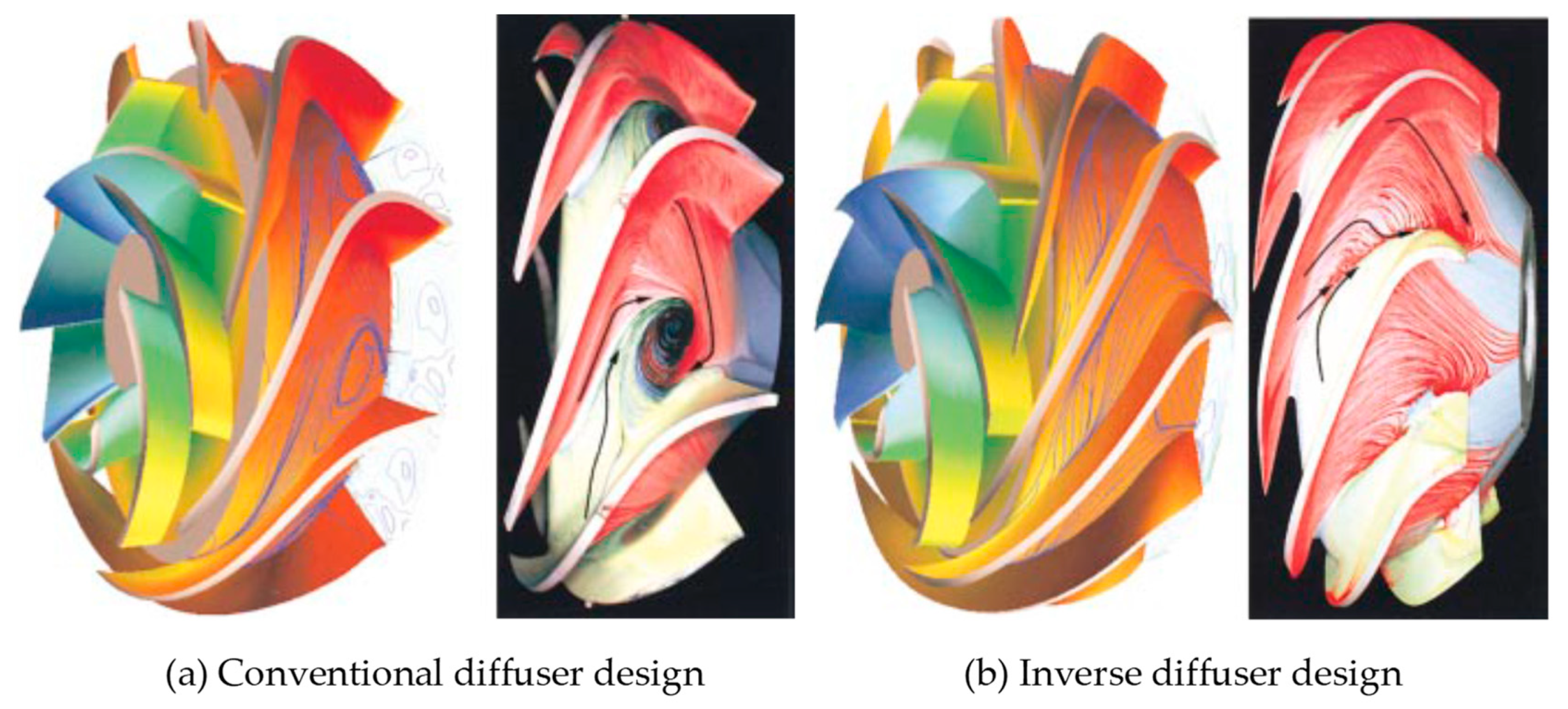

3.1. Suppression of Secondary Flow

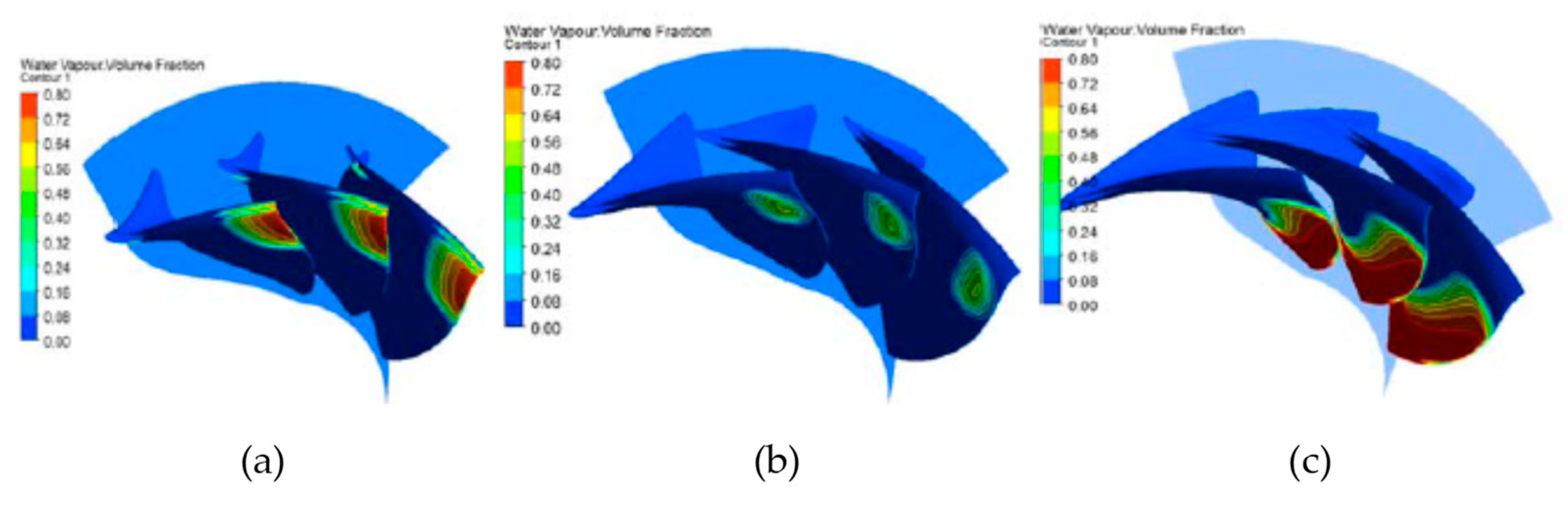

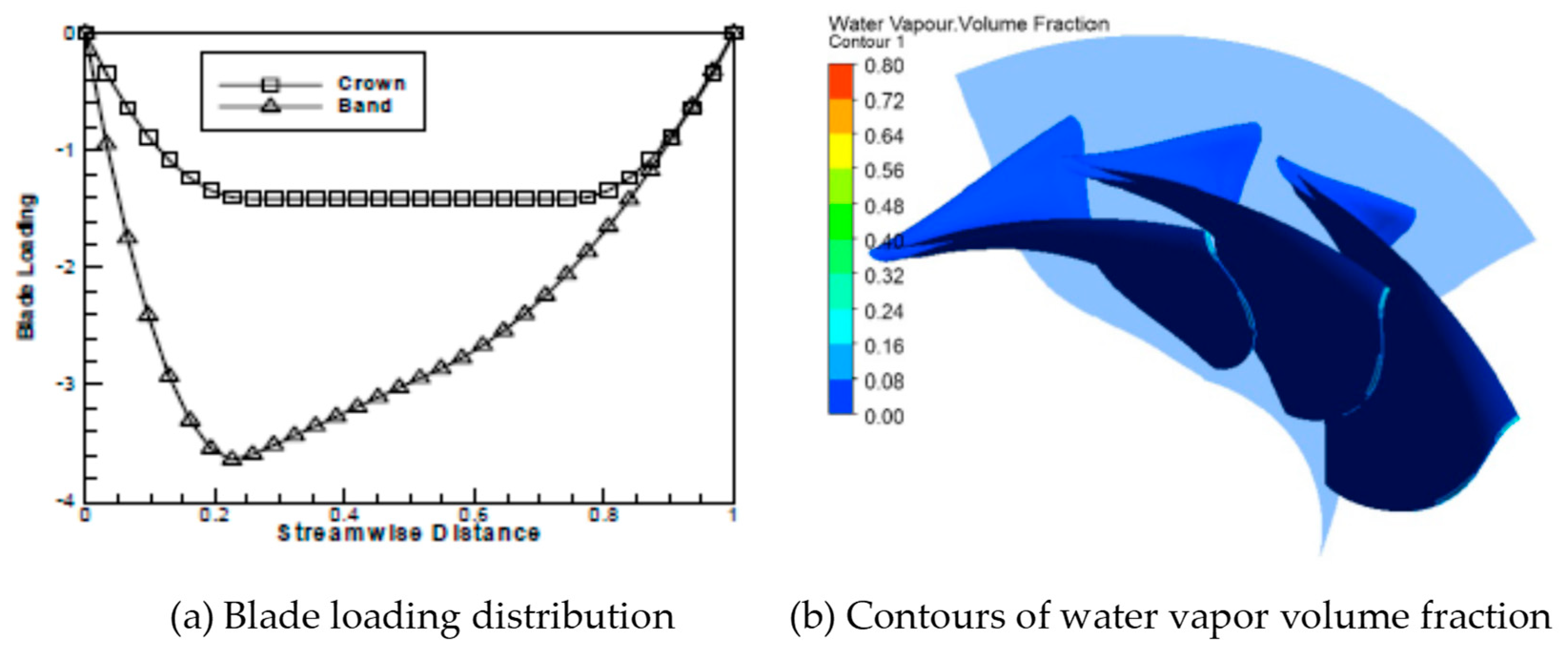

3.2. Suppression of Cavitation

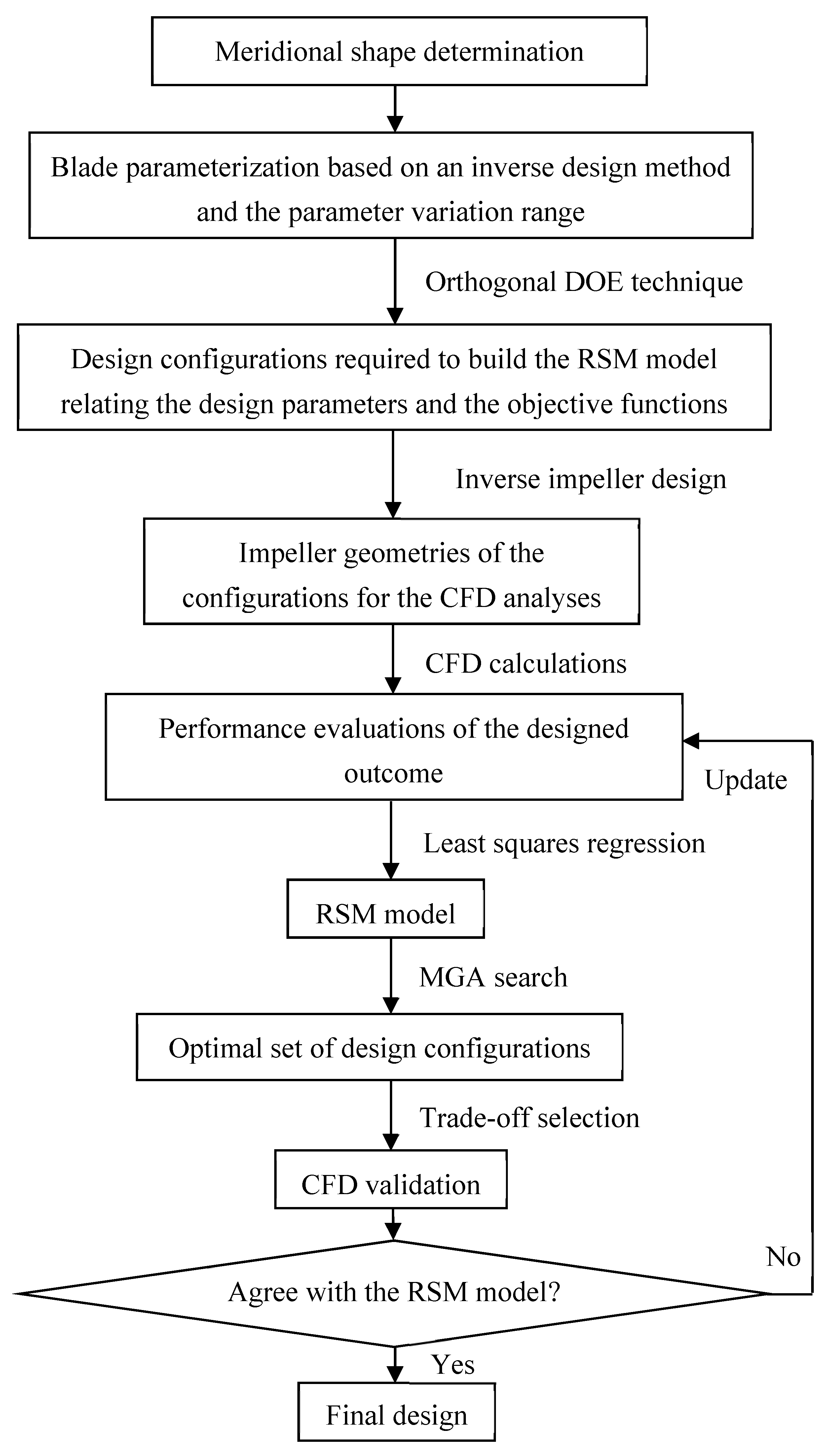

4. Application of the Inverse Design Method to Optimization

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hawthorne, W.R.; Wang, C.; McCune, J.E.; Tan, C.S. Theory of Blade Design for Large Deflections: Part I—Two-Dimensional Cascade. J. Eng. Gas Turbines Power 1984, 106, 346–353. [Google Scholar] [CrossRef]

- Hawthorne, W.R.; McCune, J.E.; Wang, C.; Tan, C.S. Theory of Blade Design for Large Deflections: Part II—Annular Cascades. J. Eng. Gas Turbines Power 1984, 106, 354–365. [Google Scholar] [CrossRef]

- Peng, G.; Cao, S.; Ishizuka, M.; Hayama, S. Design optimization of axial flow hydraulic turbine runner: Part I—An improved Q3D inverse method. Int. J. Numer. Methods Fluids 2002, 39, 517–531. [Google Scholar] [CrossRef]

- Cao, S.L.; Peng, G.; Yu, Z. Hydrodynamic Design of Rotodynamic Pump Impeller for Multiphase Pumping by Combined Approach of Inverse Design and CFD Analysis. J. Fluids Eng. 2005, 127, 330–338. [Google Scholar] [CrossRef]

- Wu, C.H. A General Theory of Three-Dimensional Flow in Subsonic and Supersonic Turbomachines of Axial-, Radial-, and Mixed-Flow Types; NASA Technical Reports Server NACA-TN-2604; Lewis Flight Propulsion Laboratory: Cleveland, OH, USA, 1952. [Google Scholar]

- Zangeneh, M. A compressible three-dimensional design method for radial and mixed flow turbomachinery blades. Int. J. Numer. Methods Fluids 1991, 13, 599–624. [Google Scholar] [CrossRef]

- Zangeneh, M. Development of a 3D Inverse Design Code for Application to Different Turbo and Hydraulic Machinery Components. In Proceedings of the JSME Centennial Grand Congress, Tokyo, Japan, 13–16 July 1997; Volume I, pp. 195–200. [Google Scholar]

- Borges, J.E. A Three-Dimensional Inverse Method for Turbomachinery: Part I—Theory. J. Turbomach. 1990, 112, 346–354. [Google Scholar] [CrossRef]

- Yin, J.; Wang, D. Review on applications of 3D inverse design method for pump. Chin. J. Mech. Eng. 2014, 27, 520–527. [Google Scholar] [CrossRef]

- Sogawa, Y.; Nohmi, M.; Sakurai, T.; Goto, A. Hydrodynamic Design System for Pumps Based on 3-D CAD, CFD, and Inverse Design Method. J. Fluids Eng. 2002, 124, 329–335. [Google Scholar]

- Ashihara, K.; Goto, A. Study on Pump Impeller with Splitter Blades Designed by 3-D Inverse Design Method. In Proceedings of the ASME Fluids Engineering Division Summer Meeting, Boston, MA, USA, 11–15 June 2000. [Google Scholar]

- Sakurai, T.; Saito, S.; Goto, A.; Ashihara, K. Pump Design System Based on Inverse Design Method and Its Application to Development of Diffuser Pump Series. In Proceedings of the 3rd ASME/JSME Joint Fluid Engineering Conference, San Francisco, CA, USA, 18–23 July 1999. [Google Scholar]

- Daneshkah, K.; Zangeneh, M. Parametric design of a Francis turbine runner by means of a three-dimensional inverse design method. IOP Conf. Ser. Earth Environ. Sci. 2010, 12, 12058. [Google Scholar] [CrossRef]

- Okamoto, H.; Goto, A. Suppression of Cavitation in a Francis Turbine Runner by Application of 3D Inverse Design Method. In Proceedings of the ASME Joint U.S.-European Fluids Engineering Division Conference, Montreal, QC, Canada, 14–18 July 2002. [Google Scholar]

- Zangeneh, M. Inverse Design of Centrifugal Compressor Vaned Diffusers in Inlet Shear Flows. J. Turbomach. 1996, 118, 385–393. [Google Scholar] [CrossRef]

- Zangeneh, M.; Schleer, M.; Pløger, F.; Roduner, C.; Ribi, B.; Abhari, R.S.; Hong, S.S. Investigation of an Inversely Designed Centrifugal Compressor Stage—Part I: Design and Numerical Verification. J. Turbomach. 2004, 126, 73–81. [Google Scholar] [CrossRef]

- Schleer, M.; Zangeneh, M.; Roduner, C.; Ribi, B.; Pløger, F.; Abhari, R.S.; Hong, S.S. Investigation of an Inversely Designed Centrifugal Compressor Stage—Part II: Experimental Investigations. J. Turbomach. 2004, 126, 82–90. [Google Scholar] [CrossRef]

- Goto, A.; Zangeneh, M. Compact Design of Diffuser Pumps Using Three-Dimensional Inverse Design Method. In Proceedings of the 3rd ASME/JSME Joint Fluids Engineering Conference, San Francisco, CA, USA, 18–23 July 1999. [Google Scholar]

- Goto, A.; Zangeneh, M. Hydrodynamic Design of Pump Diffuser Using Inverse Design Method and CFD, ASME. J. Fluids Eng. 2002, 124, 319–328. [Google Scholar] [CrossRef]

- Vogt, D.; Roduner, C.; Zangeneh, M. Improving a Vaned Diffuser for a Given Centrifugal Impeller by 3D Inverse Design. In Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, The Netherlands, 3–6 June 2002. [Google Scholar]

- Ashihara, K.; Goto, A.; Kamijo, K.; Yamada, H. Improvements of Inducer Inlet Backflow Characteristics Using 3-D Inverse Design Method. In Proceedings of the 38th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Indianapolis, IN, USA, 7–10 July 2002. [Google Scholar] [CrossRef]

- Ashihara, K.; Goto, A. Effects of Blade Loading on Pump Inducer Performance and Flow Fields. In Proceedings of the ASME 2002 Joint U.S.-European Fluids Engineering Division Conference, Montreal, QC, Canada, 14–18 July 2002. [Google Scholar] [CrossRef]

- Zangeneh, M. Inviscid-Viscous Interaction Method for Three-Dimensional Inverse Design of Centrifugal Impellers. J. Turbomach. 1994, 116, 280–290. [Google Scholar] [CrossRef]

- Molinari, M.; Dawes, W.N. Review of evolution of compressor design process and future perspectives. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2006, 220, 761–771. [Google Scholar] [CrossRef]

- Page, J.H.; Watson, R.; Ali, Z.; Hield, P.; Tucker, P.G. Advances of Turbomachinery Design Optimization. In Proceedings of the 53rd AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 5–9 January 2015. [Google Scholar]

- Páscoa, J.; Mendes, A.; Gato, L.; Páscoa, J. A fast iterative inverse method for turbomachinery blade design. Mech. Res. Commun. 2009, 36, 630–637. [Google Scholar] [CrossRef]

- Choo, B.M.F.; Zangeneh, M. Development of an (Adaptive) Unstructured 2-D Inverse Design Method for Turbomachinery Blades. In Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, The Netherlands, 3–6 June 2002. [Google Scholar]

- Roidl, B.; Ghaly, W. Dual Point Redesign of Axial Turbines Using a Viscous Inverse Design Method. In Proceedings of the ASME Turbo Expo: Power for Land, Sea, and Air, Orlando, FL, USA, 8–12 June 2009. [Google Scholar]

- Mohammad, T.R. A Viscous Inverse Design Method for Internal and External Flow over Airfoils Using CFD Techniques. In Proceedings of the V European Conference on Computational Fluid Dynamics, Lisbon, Portugal, 14–17 June 2010. [Google Scholar]

- Daneshkhah, K.; Ghaly, W. Aerodynamic Inverse Design for Viscous Flow in Turbomachinery Blading. J. Propuls. Power 2007, 23, 814–820. [Google Scholar] [CrossRef]

- Daneshkhah, K.; Ghaly, W. An Inverse Blade Design Method for Subsonic and Transonic Viscous Flow in Compressors and Turbines. Inverse Probl. Sci. Eng. 2006, 14, 211–231. [Google Scholar] [CrossRef]

- Daneshkhah, K.; Ghaly, W. An inverse design method for viscous flow in turbomachinery blading using a wall virtual movement. Inverse Probl. Sci. Eng. 2009, 17, 381–397. [Google Scholar] [CrossRef]

- Roidl, B.; Ghaly, W. Redesign of a Low Speed Turbine Stage Using a New Viscous Inverse Design Method. J. Turbomach. 2010, 133, 011009. [Google Scholar] [CrossRef]

- Thompkins, W.T.; Tong, S.S. Inverse or Design Calculations for Nonpotential Flow in Turbomachinery Blade Passages. J. Eng. Power 1982, 104, 281–285. [Google Scholar] [CrossRef]

- Tong, S.S.; Thompkins, W.T. A Design Calculation Procedure for Shock-Free or Strong Passage Shock Turbomachinery Cascades. J. Eng. Power 1983, 105, 369–376. [Google Scholar] [CrossRef]

- Ferlauto, M.; Marsilio, R. A viscous inverse method for aerodynamic design. Comput. Fluids 2006, 35, 304–325. [Google Scholar] [CrossRef]

- Mohammad, T.R. Inverse Approach to Turbomachinery Blade Design. AIAA J. 2009, 47, 703–709. [Google Scholar] [CrossRef]

- Yang, J.G.; Liu, Y.; Wang, X.F. 3D Viscous Inverse Design of Turbomachinery Using One-Equation Turbulence Model. In Proceedings of the ASME Turbo Expo: Turbomachinery Technical Conference & Exposition, Seoul, Korea, 13–17 June 2016. [Google Scholar]

- Yang, J.; Liu, Y.; Wang, X.; Wu, H. An Improved Steady Inverse Method for Turbomachinery Aerodynamic Design. Inverse Probl. Eng. 2017, 25, 633–651. [Google Scholar] [CrossRef]

- Qiu, X.; Ji, M.; Dang, T. Three-Dimensional Viscous Inverse Method for Axial Blade Design. Inverse Probl. Eng. 2009, 17, 1019–1036. [Google Scholar] [CrossRef]

- Demeulenaere, A.; Léonard, O.; Van den Braembussche, R. A two-dimensional Navier—Stokes inverse solver for compressor and turbine blade design. Proc. Inst. Mech. Eng. Part A J. Power Energy 1997, 211, 299–307. [Google Scholar] [CrossRef]

- De Vito, L.L.; Van den Braembussche, R.A.; Deconinck, H. A Novel Two-Dimensional Viscous Inverse Design Method for Turbomachinery Blading. J. Turbomach. 2003, 125, 310–316. [Google Scholar] [CrossRef]

- Zangeneh, M.; Goto, A.; Harada, H. On the Design Criteria for Suppression of Secondary Flows in Centrifugal and Mixed Flow Impellers. J. Turbomach. 1998, 120, 723–735. [Google Scholar] [CrossRef]

- Zangeneh, M.; Goto, A.; Takemura, T. Suppression of Secondary Flows in a Mixed-Flow Pump Impeller by Application of 3D Inverse Design Method: Part 1—Design and Numerical Validation. In Proceedings of the ASME 1994 International Gas Turbine and Aeroengine Congress and Exposition, The Hague, The Netherlands, 13–16 June 1994. [Google Scholar]

- Goto, A.; Takemura, T.; Zangeneh, M. Suppression of Secondary Flows in a Mixed-Flow Pump Impeller by Application of 3D Inverse Design Method: Part 2—Experimental Validation. In Proceedings of the ASME. Turbo Expo: Power for Land, Sea, and Air, The Hague, The Netherlands, 13–16 June 1994; Volume 1. [Google Scholar] [CrossRef]

- Ashihara, K.; Goto, A. Improvements of pump suction performance using 3D inverse design method. In Proceedings of the 3rd ASME/JSME Joint Fluid Engineering Conference, San Francisco, CA, USA, 18–23 July 1999. [Google Scholar]

- Watanabe, H.; Harada, H. Suppression of Secondary Flows in a Turbine Nozzle with Controlled Stacking Shape and Exit Circulation by 3D Inverse Design Method. In Proceedings of the ASME. Turbo Expo: Power for Land, Sea, and Air, Indianapolis, IN, USA, 7–10 June 1999; Volume 1. [Google Scholar] [CrossRef]

- Bonaiuti, D.; Zangeneh, M.; Aartojarvi, R.; Eriksson, J. Parametric Design of a Waterjet Pump by Means of Inverse Design, CFD Calculations and Experimental Analyses. J. Fluids Eng. 2010, 132, 031104. [Google Scholar] [CrossRef]

- Zangeneh, M.; Goto, A.; Harada, H. On the Role of Three-Dimensional Inverse Design Methods in Turbomachinery Shape Optimization. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1999, 213, 27–42. [Google Scholar] [CrossRef]

- Taddei, S.R.; Larocca, F. Euler-based Throughflow Method for Inverse Design and Optimization of Turbomachinery Blades. Prog. Comput. Fluid Dyn. 2014, 14. [Google Scholar] [CrossRef]

- Maillard, M.; Zangeneh, M. Application of 3D Inverse Design Based Multi-Objective Optimization of Axial Cooling Fan with Large Tip Gab; SAE Technical Paper; SAE International: Detroit, MI, USA, 2014. [Google Scholar] [CrossRef]

- Watanabe, H.; Tsukamoto, H. Design Optimization of Cryogenic Pump Inducer Considering Suction Performance and Cavitation Instability. In Proceedings of the ASME-JSME-KSME Joint Fluids Engineering Conference, Hamamatsu, Japan, 24–29 July 2011. [Google Scholar]

- Kerschberger, P.; Gehrer, A. Hydraulic Development of High Specific-speed Pump-turbines by Means of an Inverse Design Method, Numerical Flow Simulation (CFD) and Model Testing. In Proceedings of the 25th IAHR Symposium on Hydraulic Machinery and Systems, Timisoara, Romania, 20–24 September 2010. [Google Scholar] [CrossRef]

- Ashihara, K.; Guo, S.J.; Goto, A.; Okamoto, H. Optimization of Microturbine Aerodynamics Using CFD, Inverse Design and FEM Structural Analysis: 1st Report: Compressor Design. In Proceedings of the ASME Turbo Expo 2004: Power for Land, Sea, and Air, Vienna, Austria, 14–17 June 2004. [Google Scholar] [CrossRef]

- Ashihara, K.; Guo, S.J.; Goto, A.; Okamoto, H. Optimization of Microturbine Aerodynamics Using CFD, Inverse Design and FEM Structural Analysis: 2nd Report: Turbine Design. In Proceedings of the ASME Turbo Expo 2004: Power for Land, Sea, and Air, Vienna, Austria, 14–17 June 2004. [Google Scholar] [CrossRef]

- Zangeneh, M.; Daneshkhah, K. A Fast 3D Inverse Design Based Multi-Objective Optimization Strategy for Design of Pumps. In Proceedings of the ASME 2009 Fluids Engineering Division Summer Meeting, Vail, CO, USA, 2–6 August 2009. [Google Scholar]

- Yang, W.; Xiao, R. Multiobjective Optimization Design of a Pump–Turbine Impeller Based on an Inverse Design Using a Combination Optimization Strategy. J. Fluids Eng. 2013, 136, 014501. [Google Scholar] [CrossRef]

- Bonaiuti, D.; Zangeneh, M. On the Coupling of Inverse Design and Optimization Techniques for Turbomachinery Blade Design. In Proceedings of the ASME. Turbo Expo: Power for Land, Sea, and Air, Barcelona, Spain, 8–11 May 2006; Volume 6. [Google Scholar]

- Zhu, B.; Wang, X.; Tan, L.; Zhou, D.; Zhao, Y.; Cao, S. Optimization design of a reversible pump–turbine runner with high efficiency and stability. Renew. Energy 2015, 81, 366–376. [Google Scholar] [CrossRef]

- Zangeneh, M.; Mendonça, F.; Hahn, Y.; Cofer, J. 3D Multi-Disciplinary Inverse Design Based Optimization of a Centrifugal Compressor Impeller. In Proceedings of the ASME. Turbo Expo: Power for Land, Sea, and Air, Düsseldorf, Germany, 16–20 June 2014; Volume 2B. [Google Scholar] [CrossRef]

- Bonaiuti, D.; Zangeneh, M. On the Coupling of Inverse Design and Optimization Techniques for the Multiobjective, Multipoint Design of Turbomachinery Blades. J. Turbomach. 2009, 131, 021014. [Google Scholar] [CrossRef]

- Lu, Y.M.; Wang, X.F.; Wang, W.; Zhou, F.M. Application of the Modified Inverse Design Method in the Optimization of the Runner Blade of a Mixed-Flow Pump. Chin. J. Mech. Eng. 2018, 131. [Google Scholar] [CrossRef]

- Ma, Z.; Zhu, B.S.; Rao, C.; Shangguan, Y.H. Comprehensive Hydraulic Improvement and Parametric Analysis of a Francis Turbine Runner. Energies 2019, 12, 307. [Google Scholar] [CrossRef]

- Liu, L.H.; Zhu, B.S.; Bai, L.; Liu, X.B.; Zhao, Y. Parametric Design of an Ultrahigh-Head Pump-Turbine Runner Based on Multiobjective Optimization. Energies 2017, 10, 1169. [Google Scholar] [CrossRef]

- Takayama, Y.; Watanabe, H. Multi-objective Design Optimization of a Mixed-flow Pump. In Proceedings of the ASME 2009 Fluids Engineering Division Summer Meeting, Vail, CO, USA, 2–6 August 2009. [Google Scholar] [CrossRef]

- Zhang, J.; Zangeneh, M.; Eynon, P. A 3D Inverse Design Based Multidisciplinary Optimization on the Radial and Mixed-inflow Turbines for Turbochargers. In Proceedings of the 11th International Conference on Turbochargers and Turbocharging, London, UK, 13–14 May 2014. [Google Scholar]

- Reis, C.J.B.; Manzanares-Filho, N.; De Lima, A.M.G. Robust Optimization of Turbomachinery Cascades Using Inverse Methods. J. Braz. Soc. Mech. Sci. Eng. 2016, 38, 297–305. [Google Scholar] [CrossRef]

- Yiu, K.F.C.; Zangeneh, M. Three-Dimensional Automatic Optimization Method for Turbomachinery Blade Design. J. Propuls. Power 2000, 16, 1174–1181. [Google Scholar] [CrossRef]

- Huang, R.F.; Luo, X.W.; Ji, B.; Wang, P.; Yu, A.; Zhai, Z.H.; Zhou, J.J. Multi-objective Optimization of a Mixed-Flow Pump Impeller Using Modified NSGA-II Algorithm. Sci. China Technol. Sci. 2015, 58, 2111–2130. [Google Scholar] [CrossRef]

- Wang, P.; Vera-Morales, M.; Vollmer, M.; Zangeneh, M.; Zhu, B.S.; Ma, Z. Optimization of a Pump-as-turbine Runner Using a 3D Inverse Design Methodology. In Proceedings of the 29th IAHR Symposium on Hydraulic Machinery and Systems, Kyoto, Japan, 16–21 September 2018; Volume 240. [Google Scholar]

- Ashihara, K.; Goto, A. Turbomachinery Blade Design Using 3-D Inverse Design Method, CFD and Optimization Algorithm. In Proceedings of the ASME. Turbo Expo: Power for Land, Sea, and Air, New Orleans, LA, USA, 4–7 June 2001; Volume 1. V001T03A053. [Google Scholar] [CrossRef]

- Hu, Z.N.; Zhu, B.S.; Liu, X.B.; Ma, Z.; Xue, C. Multiobjective Optimization Design of Ultrahigh-head Pump Turbine Runners with Splitter Blades. In Proceedings of the 29th IAHR Symposium on Hydraulic Machinery and Systems, Kyoto, Japan, 16–21 September 2018; Volume 240. [Google Scholar] [CrossRef]

- Zhu, Y.J.; Ju, Y.P.; Zhang, C.H. An Experience-independent Inverse Design Optimization Method of Compressor Cascade Airfoil. J. Power Energy 2018, 233. [Google Scholar] [CrossRef]

- Boselli, P.; Zangeneh, M. An Inverse Design Based Methodology for Rapid 3D Multi-objective/multidisciplinary of Axial Turbines. In Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition, Vancouver, BC, Canada, 6–10 June 2011. [Google Scholar] [CrossRef]

| Target | Design Parameters | Optimization Objectives | Optimization Algorithm | Improvement of Performance | References |

|---|---|---|---|---|---|

| Pump inducer | Blade loading at both hub and tip (5 parameters in total) | (1) Inducer head and efficiency (2) Cavity volume (3) Dispersion of cavity length | IDM + DoE + CFD + PSA | Suction performance and cavitation instability improved | [51] |

| Mixed flow pump | Blade loading at hub, midspan and shroud [68]; Blade stacking [55,69] Wrap angles [61] (8 to 13 parameters in total) | (1) NPSHr, Impeller leading edge sweep angle [55] (2) Efficiency, Pump head [61,69] (3) Efficiency, maximum slope in flow-head curve, and shut-off power/head [64] (4) Efficiency, suction specific speed [68] | IDM + CFD + MOGA/NSGA-II [55,61] IDM + DoE + CFD + RSM + MOGA [64] IDM + CFD + SLP/EP/SA/GA [68] IDM + DoE + CFD + RBNN + NSGA-II [69] | Cavitation performance improved and leading edge sweep reduced [55] Performances at both design and off-design point improved [61,69] Efficiency and suction performance improved [68] | [55,61,64,68,69] |

| Pump-turbine/Pump as turbine | Blade loading at both hub and shroud; Blade stacking; Meridional channel geometry [58] (6 to 9 parameters in total) | (1) Pump mode efficiency/profile loss (2) Turbine mode efficiency/profile loss (3) Minimum pressure at the blade surface [58,63] (4) Secondary loss factor [70] | IDM + DoE + CFD + RSM/RBF + MOGA | Both energy and stability performance in both pump and turbine mode improved | [56,58,63,70,71] |

| Turbine | Blade loading at both hub and shroud; Blade stacking; Meridional channel geometry; Thickness [65,72] (11 to 17 parameters in total) | (1) Efficiency (2) Minimum pressure on the blade surfaces (3) Mass flow parameter [65] (4) Blade lean, stress factor [72] | IDM + DoE + CFD + RSM + NSGA-II [61] IDM + DoE + CFD + FEA + RSM + PSA [65] IDM + CFD + FEA + NSGA-II [72] | Efficiency at both design and off-design point improved [62,65] Efficiency and structural performance improved [72] | [62,65,72] |

| Compressor/Fan | Blade loading at both hub and shroud; Blade stacking; Meridional channel geometry; Blade geometry (16 parameters in total) [73] (4 to 12 parameters in total) | (1) Efficiency (2) Choke margin (3) Peak stress [59] (4) Entropy, blockage [67] (5) Leakage loss, profile loss [74] (6) Pressure distribution [73] | IDM + DoE + CFD/FEA ([59]) + RSM + MOGA IDM + CFD + MOGA [74] IDM + CFD + GA + AM [73] | Both design and off-design performance improved; Structural integrity optimized [58] | [57,59,60,67,73,74] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, W.; Liu, B.; Xiao, R. Three-Dimensional Inverse Design Method for Hydraulic Machinery. Energies 2019, 12, 3210. https://doi.org/10.3390/en12173210

Yang W, Liu B, Xiao R. Three-Dimensional Inverse Design Method for Hydraulic Machinery. Energies. 2019; 12(17):3210. https://doi.org/10.3390/en12173210

Chicago/Turabian StyleYang, Wei, Benqing Liu, and Ruofu Xiao. 2019. "Three-Dimensional Inverse Design Method for Hydraulic Machinery" Energies 12, no. 17: 3210. https://doi.org/10.3390/en12173210

APA StyleYang, W., Liu, B., & Xiao, R. (2019). Three-Dimensional Inverse Design Method for Hydraulic Machinery. Energies, 12(17), 3210. https://doi.org/10.3390/en12173210