Carbon Emission Evaluation Based on Multi-Objective Balance of Sewing Assembly Line in Apparel Industry

Abstract

:1. Introduction

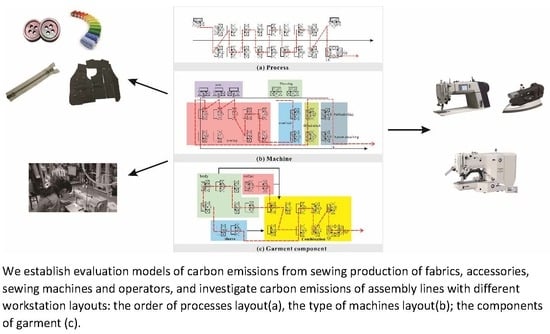

2. Construction of Carbon Emission Evaluation Models

2.1. Carbon Emission of Fabric Consumption

2.2. Carbon Emission of Accessory Consumption

2.3. Energy Consumption of Discontinuous Sewing Machines

2.4. Energy Consumption of Continuous Sewing Machines

2.5. Carbon Emission of Sewing Machines

2.6. Carbon Emission of Operators

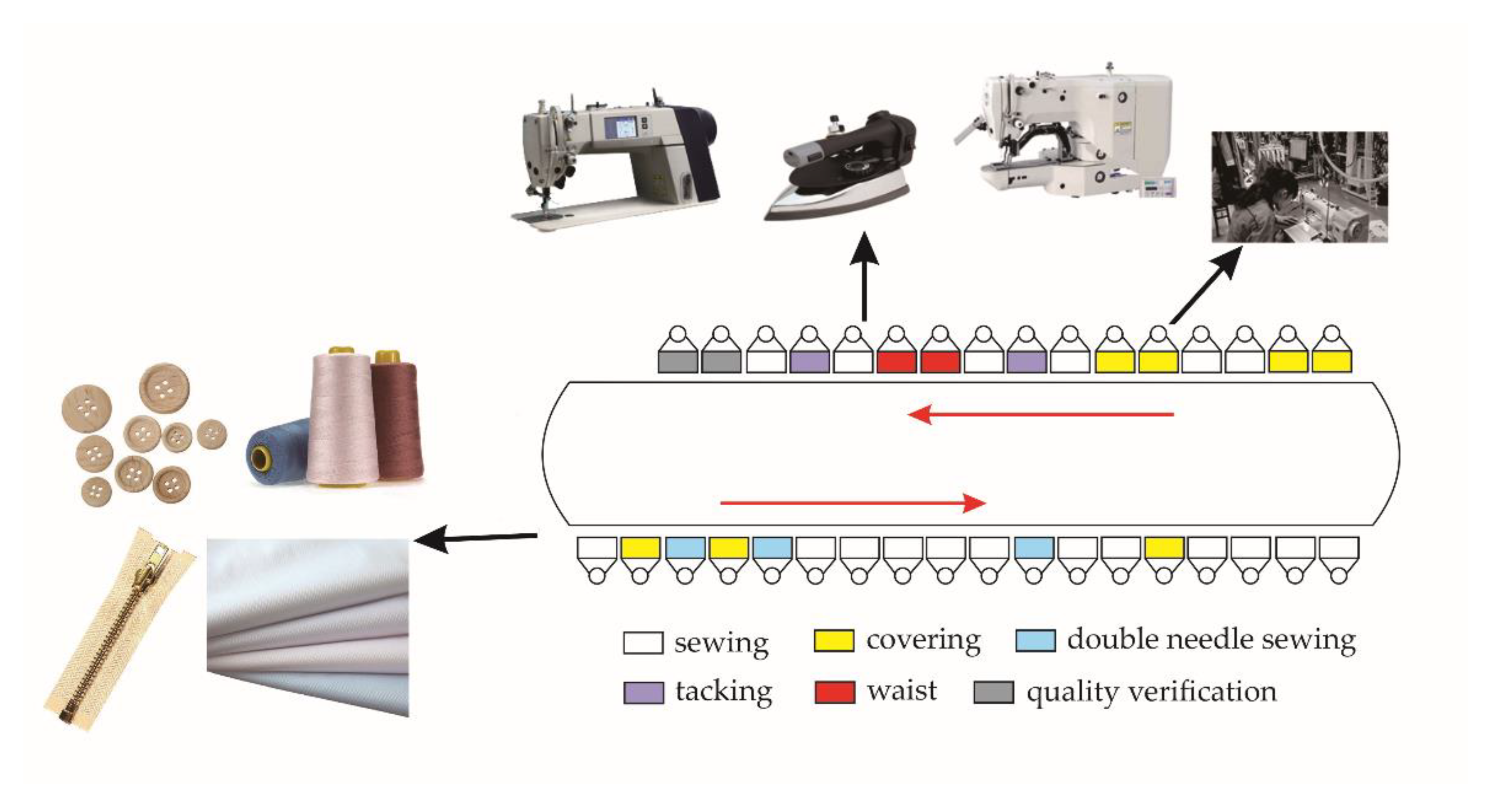

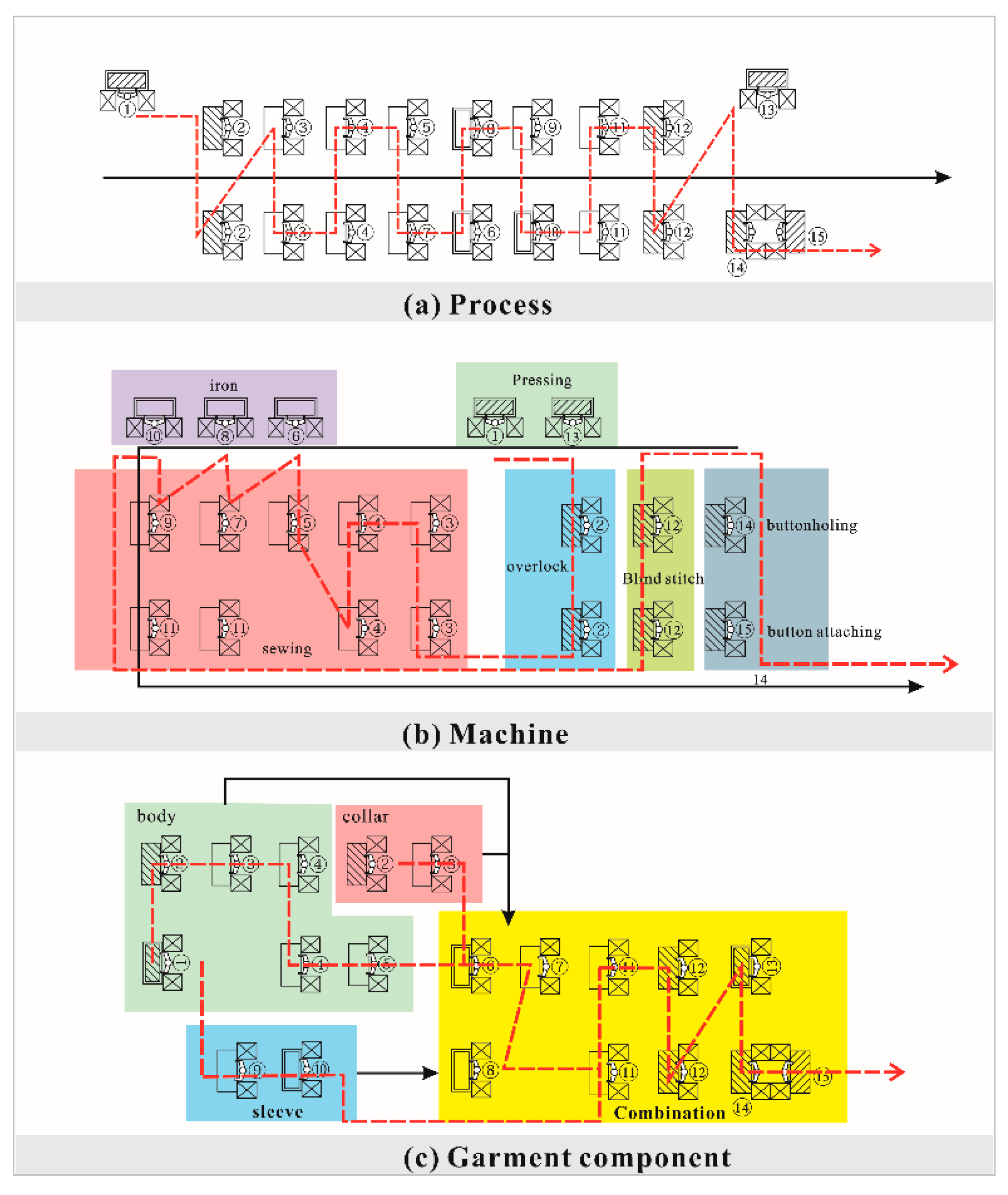

3. Multi-Objective Balance Model of Garment Sewing Assembly Line

3.1. Assumptions

- The total production of garment products, operating time of each process and process order are known.

- The types and quantities of sewing machines used in each process are known.

- Each operator uses only one type of sewing machine.

- Each operator only works on one process at a time.

- Operators have similar operation proficiency in each process.

- Some processes can be operated at different workstations.

3.2. Constraints

3.3. Objective Function

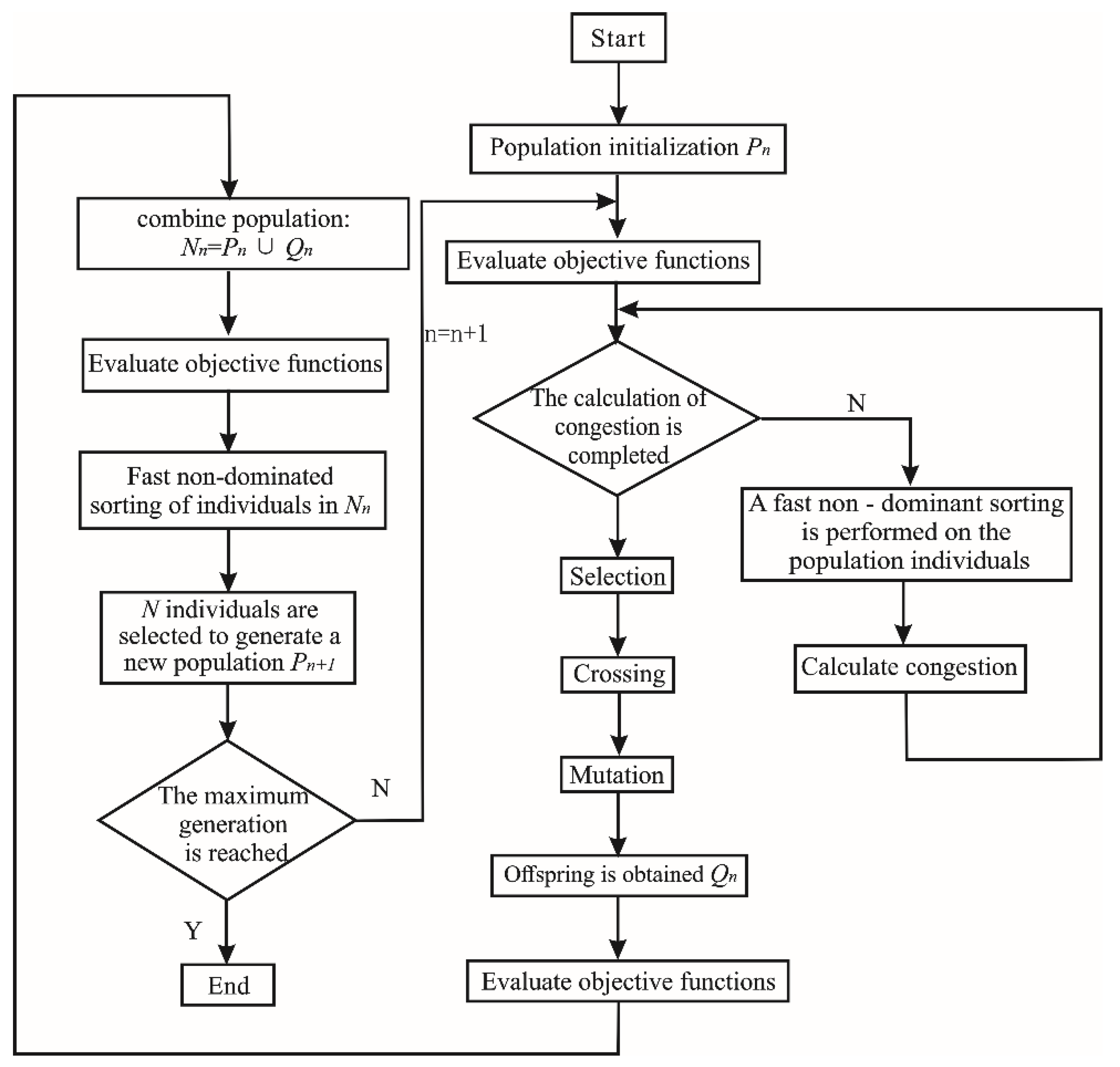

4. Multi-Objective Balance Optimization Method

- Step 1

- Workstations are coded by a real number (Section 4.1).

- Step 2

- The overall size is set, and the initial population is generated based on the constraints (Section 4.2).

- Step 3

- According to the objective function value of each individual, the fast-non-dominant sorting of the contemporary population (Section 4.3) and the congestion distance (Section 4.3) are calculated.

- Step 4

- Based on the results of the ranking and congestion distance calculations, the tournament mechanism is adopted for selection (Section 4.4), then two individuals are randomly selected for crossing (Section 4.5) and mutation (Section 4.6).

- Step 5

- Elite retention strategy is adopted (Section 4.4). The father and the subpopulation are combined. A new generation of populations is generated by combining the populations by rapid non-dominant sequencing and virtual congestion distances.

- Step 6

- The number of iterations is increased by 1, and the operation returns to step 3. This loop will continue until the maximum number of iterations is reached.

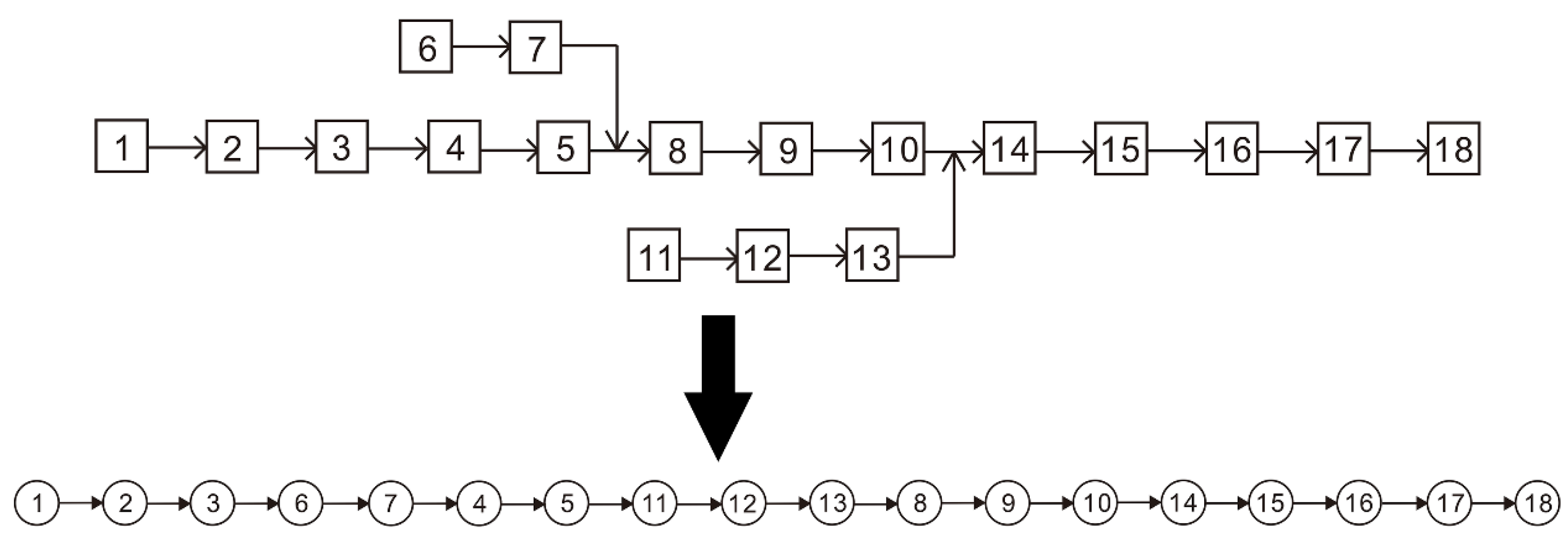

4.1. Coding

4.2. Population Initialization and Decoding

- Step 1

- The minimum theoretical production pitch time, the value range of the pitch time, and the minimum number of workstations are calculated.

- Step 2

- The processes are assigned to the workstations according to the sequence of processes in the chromosome. If the operating time of each workstation is less than the theoretical pitch time, the pitch time is the smallest in the chromosome arrangement, the iteration is stopped. Otherwise, the next step is taken.

- Step 3

- when the ith process is assigned to the jth workstation, the operating time is less than the minimum pitch time, the (i+1)th process is added to the jth workstation. Then it is judged whether operation time of the jth workstation meets the pitch time limit after the (i+1)th process is added.

- Step 4

- If the operating time of the jth workstation is greater than the maximum pitch time, the ith process is assigned into the (j+1)th workstation.

- Step 5

- The above allocation processes are repeated until all the processes in the chromosome have been assigned.

4.3. Fast Non-Dominated Sorting and Calculating Congestion

4.4. Operation Selection

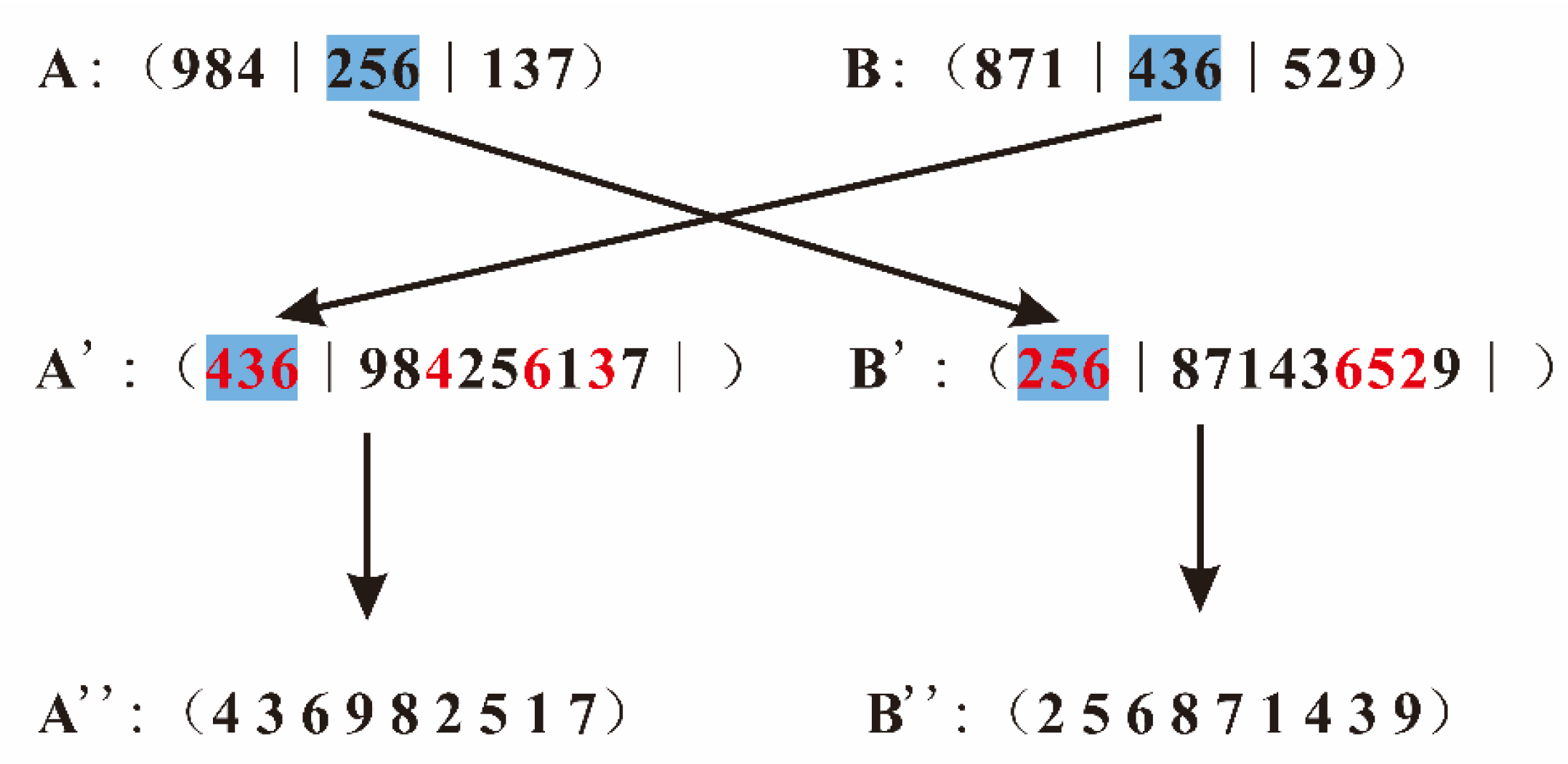

4.5. Crossing Operation

- Step 1

- A crossover region is randomly selected in the parent chromosome. It is assumed that the intersection of two parental chromosomes is: A = 984 ∣ 256 ∣ 137; B = 871 ∣ 436 ∣ 529, where “|” represents the intersection area.

- Step 2

- The intersection region of the A chromosome is inserted in front of the B chromosome. The intersection region of the B chromosome is inserted in front of the A chromosome. Two intermediate individuals A’ and B’ are obtained.

- Step 3

- The same genes in A’ and B’ are deleted, and the two new chromosomes A’’ and B’’ are obtained. Figure 5 shows the crossing operation.

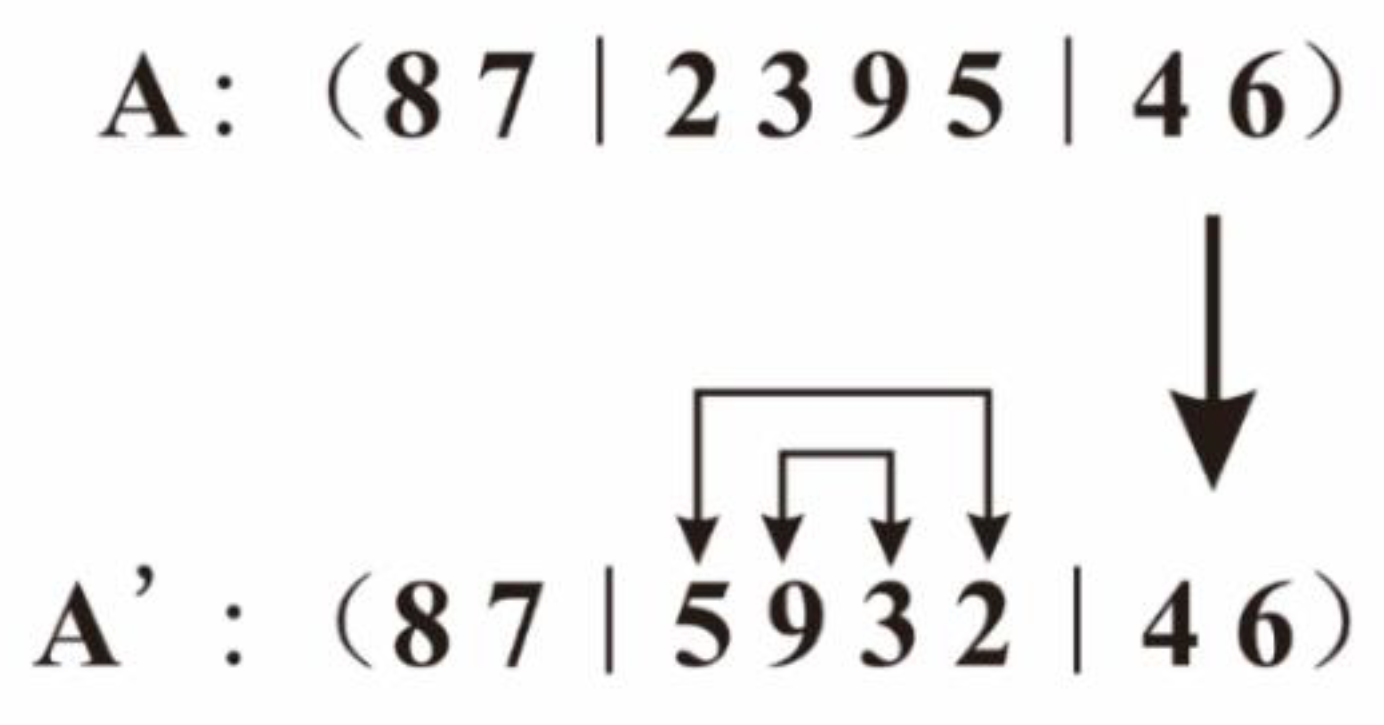

4.6. Mutation Operation.

- Step 1

- Two mutation points are randomly selected on the chromosome. It is assumed that chromosome A = 87239546, and 2 and 5 are selected as mutation points, namely: A = 87 ∣ 2359 ∣ 46, where “|” represents the intersection area.

- Step 2

- The gene of the variant region is inserted into the original gene position in reverse order to obtain a new chromosome A’. The mutation operation is shown in Figure 6.

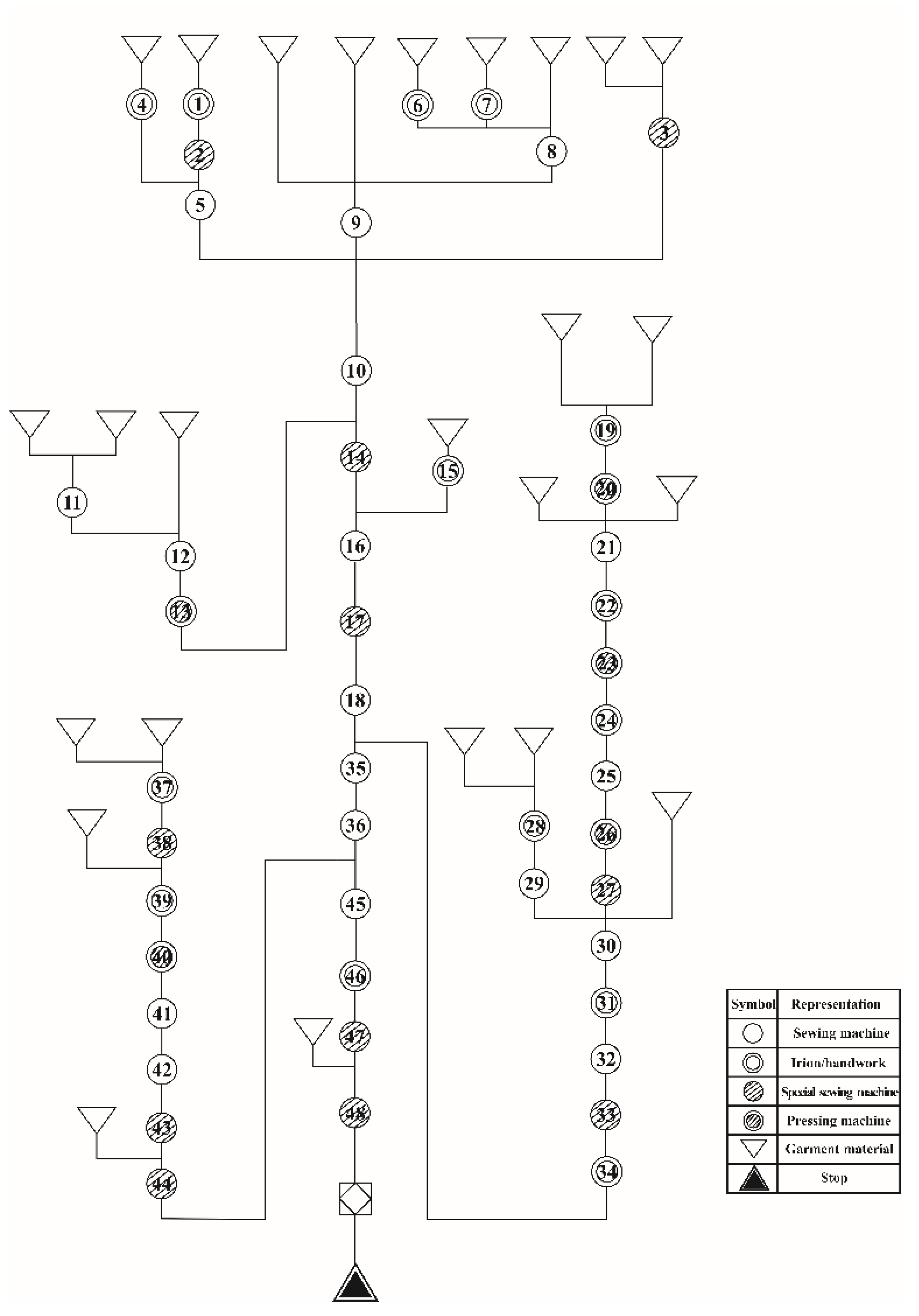

5. Case Study

5.1. Experimental Data and Parameter Setting

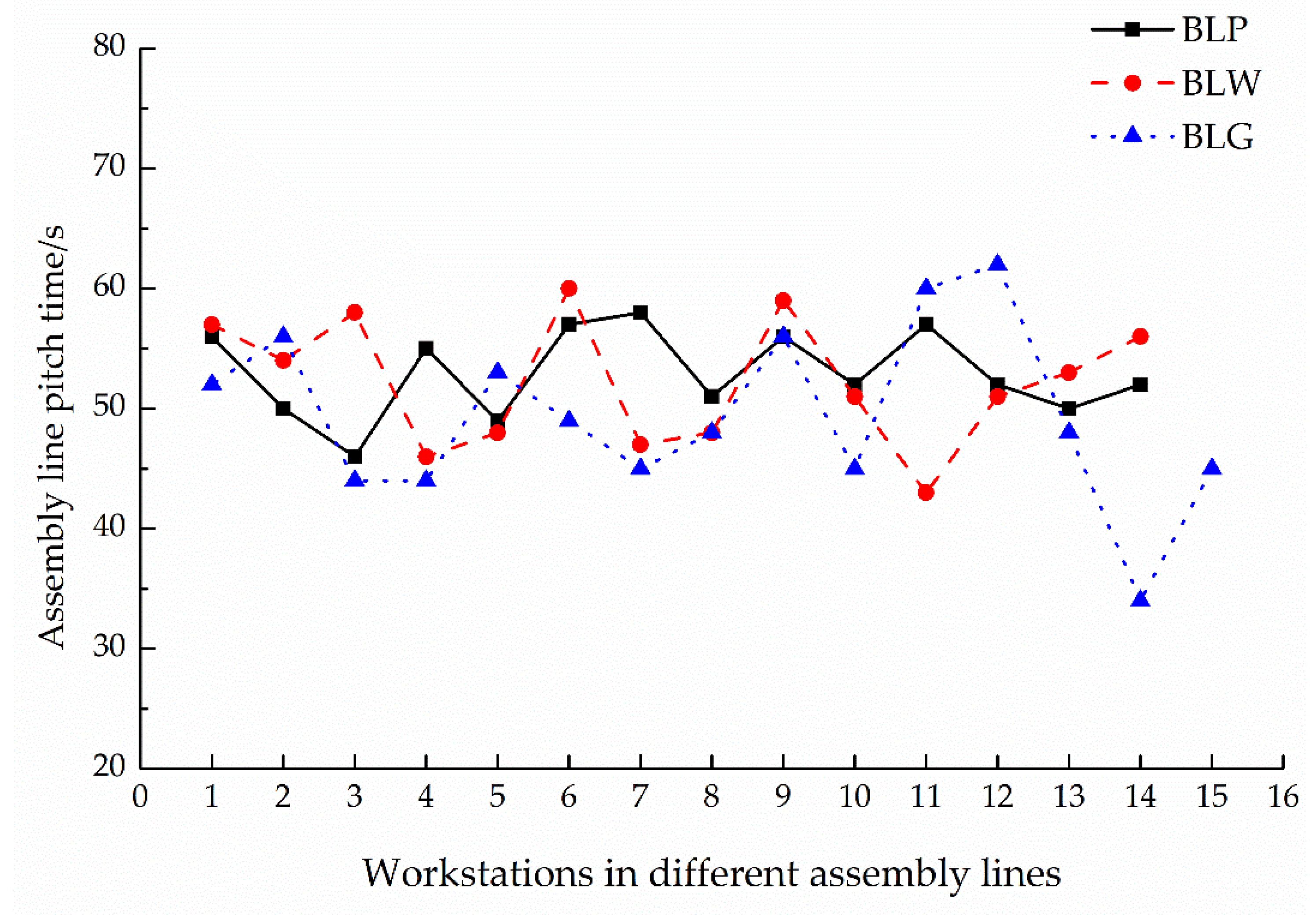

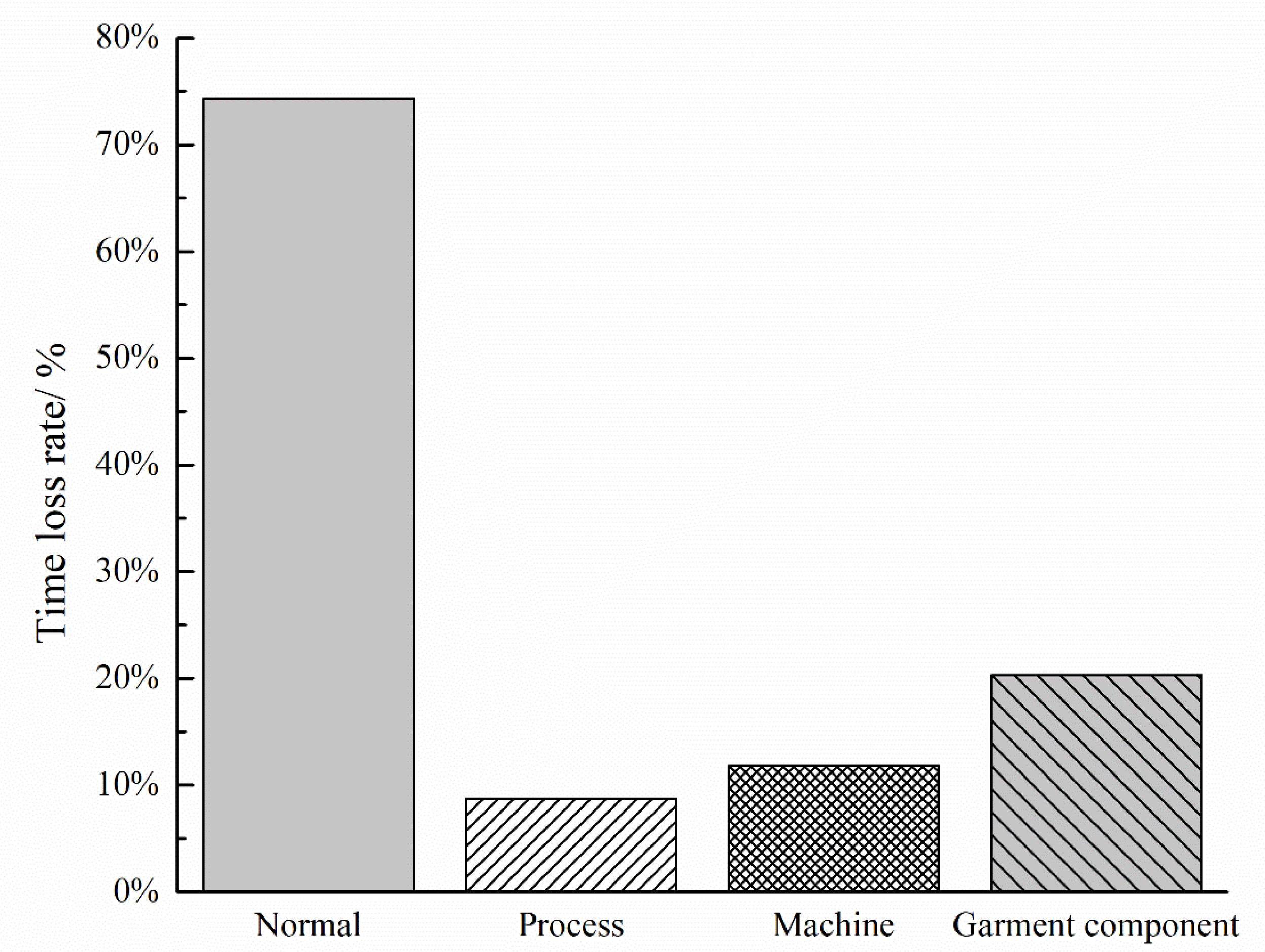

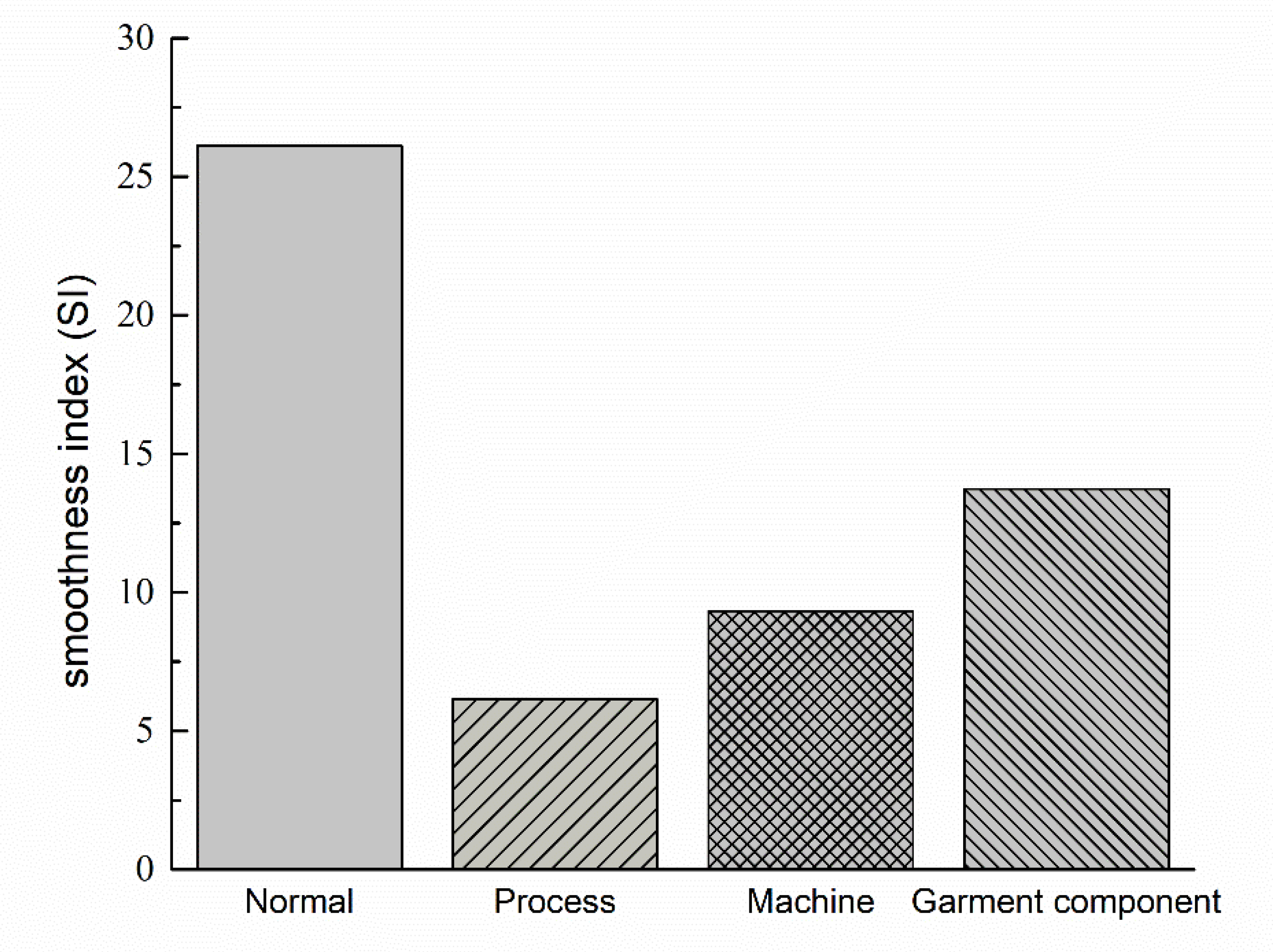

5.2. Analysis of Balancing the Assembly Line of the Men’s Shirt

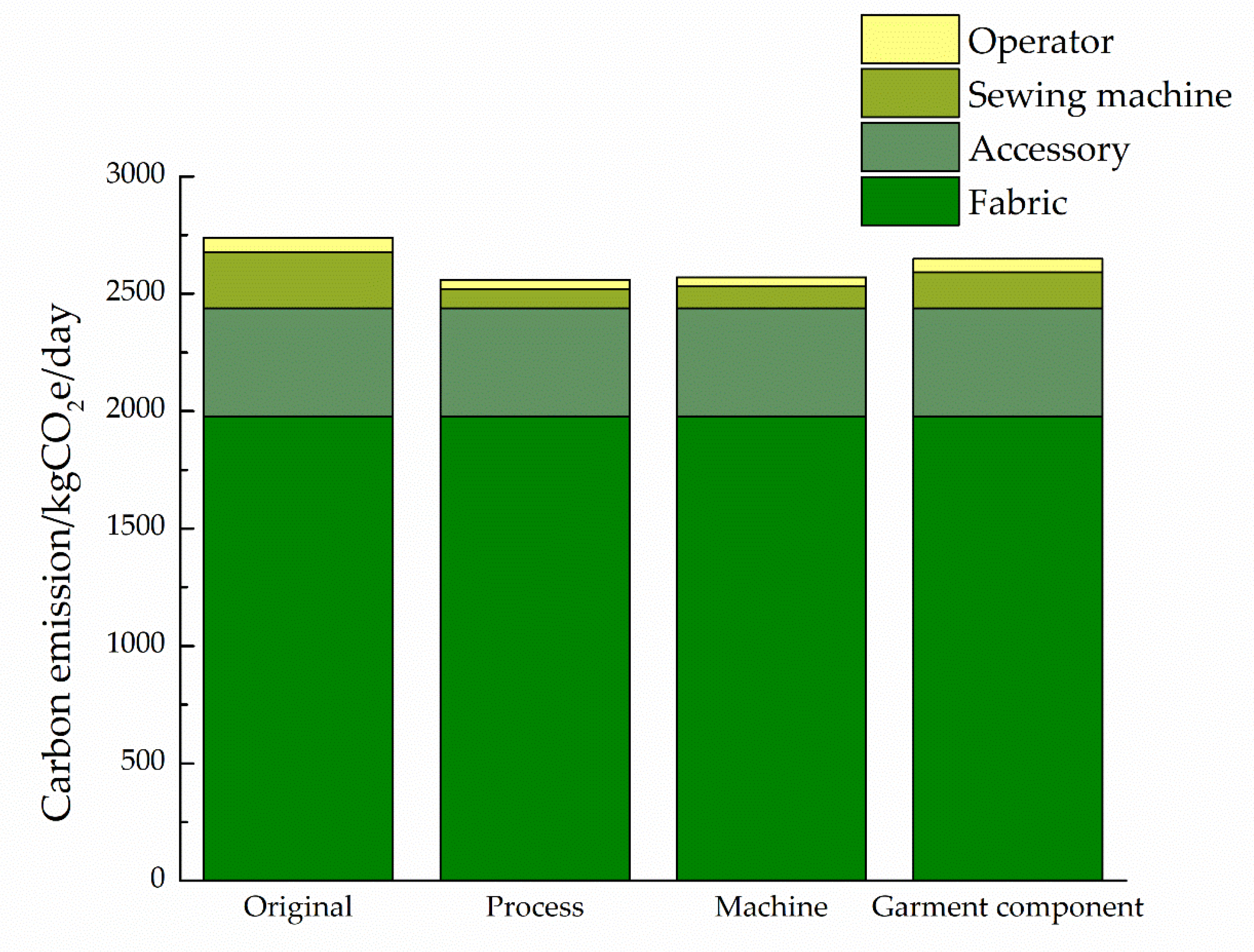

5.3. Analysis of Carbon Emissions in the Men’s Shirt Sewing Process

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, N.; Chang, D.; Shi, X.; Yuan, J.; Gao, Y. Analysis and Design of Typical Automated Container Terminals Layout Considering Carbon Emissions. Sustainability 2019, 10, 2957. [Google Scholar] [CrossRef]

- Chau, C.K.; Leung, T.M.; Ng, W.Y. A review on life cycle evaluation, life cycle energy evaluation and life cycle carbon emissions evaluation on buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Liu, L.; Chen, C.; Zhao, Y.; Zhao, E. China’s carbon-emissions trading: Overview, challenges and future. Renew. Sustain. Energy Rev. 2015, 49, 254–266. [Google Scholar] [CrossRef]

- Narayan, P.K.; Saboori, B.; Soleymani, A. Economic growth and carbon emissions. Econ. Modell. 2015, 53, 388–397. [Google Scholar] [CrossRef]

- He, P.; Zhang, W.; Xu, X.; Bian, Y. Production lot-sizing and carbon emissions under cap-and-trade and carbon tax regulations. J. Clean. Prod. 2015, 103, 241–248. [Google Scholar] [CrossRef]

- Claudio, L. Waste couture: Environmental impact of the clothing industry. Environ. Health Perspect. 2007, 9, 449–454. [Google Scholar] [CrossRef]

- Islam, M.M.; Khan, A.M.; Khan, M.M.R. Minimization of reworks in quality and productivity improvement in the apparel industry. Int. J. Eng. 2013, 4, 2305–8269. [Google Scholar]

- Thompson, E.R. Clustering of foreign direct investment and enhanced technology transfer: Evidence from Hong Kong garment firms in China. World Dev. 2002, 5, 873–889. [Google Scholar] [CrossRef]

- Banister, J. Manufacturing earnings and compensation in China. Mon. Lab. Rev. 2015, 128, 22. [Google Scholar]

- Laurenti, R.; Redwood, M.; Puig, R.; Frostell, B. Measuring the environmental footprint of leather Processing technologies. J. Ind. Ecol. 2017, 5, 1180–1187. [Google Scholar] [CrossRef]

- Zaffalon, V. Climate change, carbon mitigation and textiles. Text.World. 2010, 160, 34–35. [Google Scholar]

- Wang, C.; Wang, L.; Liu, X.; Du, C.; Ding, D.; Jia, J.; Yan, Y.; Wu, G. Carbon footprint of textile throughout its life cycle: A case study of Chinese cotton shirts. J. Clean. Prod. 2015, 108, 464–475. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Xiao, R.; Yuan, Z. Life cycle evaluation of cotton T-shirts in China. Int. J. Life Cycle Eval. 2015, 7, 994–1004. [Google Scholar] [CrossRef]

- Yan, Y.; Wang, C.; Ding, D.; Zhang, Y.N.; Wu, G.; Wang, L.H.; Liu, X.L.; Du, C.; Zhang, Y.J.; Zhao, C.L. Industrial carbon footprint of several typical Chinese textile fabrics. Acta Ecol. Sin. 2016, 36, 119–125. [Google Scholar] [CrossRef]

- Çay, A. Energy consumption and energy saving potential in clothing industry. Energy 2018, 159, 74–85. [Google Scholar] [CrossRef]

- Butnariu, A.; Avasilcai, S. Research on the possibility to apply ecological footprint as environmental performance indicator for the textile industry. Procedia Soc. Behav. Sci. 2014, 124, 344–350. [Google Scholar] [CrossRef]

- Herva, M.; Álvarez, A.; Roca, E. Combined application of energy and material flow analysis and ecological footprint for the environmental evaluation of a tailoring factory. J. Hazard Mater. 2012, 237, 231–239. [Google Scholar] [CrossRef]

- Van Der Velden, N.M.; Vogtländer, J.G. Monetisation of external socio-economic costs of industrial production: A social-LCA-based case of clothing production. J. Clean. Prod. 2017, 153, 320–330. [Google Scholar] [CrossRef]

- Wong, W.K.; Leung, S.Y.S.; Au, K.F. Real-time GA-based rescheduling approach for the pre-sewing stage of an apparel manufacturing process. Int. J. Adv. Manuf. Technol. 2005, 25, 180–188. [Google Scholar] [CrossRef]

- Agpak, K.; Gökçen, H. Assembly line balancing: Two resource constrained cases. Int. J. Prod. Econ. 2005, 96, 129–140. [Google Scholar] [CrossRef]

- Pearce, B.W.; Antani, K.; Mears, L.; Funk, K.; Mayorga, M.E.; Kurz, M.E. An effective integer program for a general assembly line balancing problem with parallel workers and additional assignment restrictions. J. Manuf. Syst. 2019, 50, 180–192. [Google Scholar] [CrossRef]

- Akyol, S.D.; Baykasoğlu, A.; Ergo, A.L. WABP: A multiple rule based constructive randomized search algorithm for solving assembly line worker assignment and balancing problem under ergonomic risk factors. J. Intell. Manuf. 2019, 1, 291–302. [Google Scholar] [CrossRef]

- Song, B.L.; Wong, W.K.; Fan, J.T.; Chan, S.F. A recursive operator allocation approach for assembly line-balancing optimization problem with the consideration of operator efficiency. Comput. Ind. Eng. 2006, 51, 585–608. [Google Scholar] [CrossRef]

- Wong, W.K.; Mok, P.Y.; Leung, S.Y.S. Developing a genetic optimization approach to balance an apparel assembly line. Int. J. Adv. Manuf. Technol. 2006, 28, 387–394. [Google Scholar] [CrossRef]

- Guo, Z.X.; Wong, W.K.; Leung, S.Y.S.; Fan, J.T.; Chan, S.F. Mathematical model and genetic optimization for the job shop scheduling problem in a mixed-and multi-product assembly environment: A case study based on the apparel industry. Comput. Ind. Eng. 2006, 3, 202–219. [Google Scholar] [CrossRef]

- Zaman, T.; Paul, S.K.; Azeem, A. Sustainable operator assignment in an assembly line using genetic algorithm. Int. J. Prod. Res. 2012, 18, 5077–5084. [Google Scholar] [CrossRef]

- Chen, J.C.; Chen, C.C.; Lin, Y.J.; Lin, C.J.; Chen, T.Y. Assembly line balancing problem of sewing lines in garment industry. In Proceedings of the 2014 International Conference on Industrial Engineering and Operations Management, Bali, Indonesia, 7–9 January 2014. [Google Scholar]

- Zhang, W.; Gen, M. An efficient multi-objective genetic algorithm for mixed-model assembly line balancing problem considering demand ratio-based cycle time. J. Intell. Manuf. 2011, 3, 367–378. [Google Scholar] [CrossRef]

- Aydemir-Karadag, A.; Turkbey, O. Multi-objective optimization of stochastic disassembly line balancing with station paralleling. Comput. Ind. Eng. 2013, 3, 413–425. [Google Scholar] [CrossRef]

- Hwang, R.K.; Katayama, H.; Gen, M. U-shaped assembly line balancing problem with genetic algorithm. Int. J. Prod. Res. 2008, 16, 4637–4649. [Google Scholar] [CrossRef]

- Kazemi, S.M.; Ghodsi, R.; Rabbani, M.; Tavakkoli-Moghaddam, R. A novel two-stage genetic algorithm for a mixed-model U-line balancing problem with duplicated tasks. Int. J. Adv. Manuf. Technol. 2011, 55, 1111–1122. [Google Scholar] [CrossRef]

- Akpınar, S.; Bayhan, G.M. A hybrid genetic algorithm for mixed model assembly line balancing problem with parallel workstations and zoning constraints. Eng. Appl. Artif. Intell. 2011, 3, 449–457. [Google Scholar] [CrossRef]

- Bukchin, Y.; Raviv, T. Constraint programming for solving various assembly line balancing problems. Omega 2018, 78, 57–68. [Google Scholar] [CrossRef]

- Polat, O.; Mutlu, Ö.; Özgormus, E. A Mathematical Model for Assembly Line Balancing Problem Type 2 Under Ergonomic Workload Constraint. Ergon. Open J. 2018, 11, 1–10. [Google Scholar] [CrossRef]

- Borba, L.; Ritt, M.; Miralles, C. Exact and heuristic methods for solving the Robotic Assembly Line Balancing Problem. Eur. J. Op. Res. 2018, 1, 146–156. [Google Scholar] [CrossRef]

- Liu, P.; Wang, B.B.; Zhao, X.G.; Duan, X.L.; Huang, N.; Chen, Y.D.; Wang, L.M. Study on Adult Respiratory Rate in China. J. Environ. Health 2014, 31, 953–956. [Google Scholar]

- Radford, E.P., Jr. Ventilation standards for use in artificial respiration. J. Appl. Physiol. 1955, 7, 451–460. [Google Scholar]

- Rahman, M.M.; Nur, F.; Talapatra, S. An Integrated Framework of Applying Line Balancing in Apparel Manufacturing Organization: A Case Study. J. Mech. Eng. 2014, 2, 117–123. [Google Scholar] [CrossRef]

- Eryuruk, S.H.; Kalaoglu, F.; Baskak, M. Assembly line balancing in a clothing company. Fibres Text. East. Eur. 2008, 66, 93–98. [Google Scholar]

- Karabay, G. A Comparative Study on Designing of a Clothing Assembly Line. J. Tekst. Konfeks. 2014, 24, 124–134. [Google Scholar]

- Samouei, P.; Ashayeri, J. Developing optimization and robust models for a mixed-model assembly line balancing problem with semi-automated operations. Appl. Math. Model. 2019, 72, 259–275. [Google Scholar] [CrossRef]

- Baykasoglu, A. Multi-rule multi-objective simulated annealing algorithm for straight and U type assembly line balancing problems. J. Intell. Manuf. 2006, 2, 217–232. [Google Scholar] [CrossRef]

- Baykasoğlu, A.; Dereli, T. Simple and U-type assembly line balancing by using an ant colony based algorithm. Math. Comput. Appl. 2009, 1, 1–12. [Google Scholar] [CrossRef]

| Process Number | Sewing Machines | Operation Time/s | Power/kW |

|---|---|---|---|

| 1 | Electric steam iron | 20 | 1 |

| 2 | Buttonhole stitching | 10 | 0.36 |

| 3 | Button attaching | 14 | 0.25 |

| 4 | Pocket creasing | 30 | 2 |

| 5 | Straight lock stitcher with automatic thread trimmer | 27 | 0.45 |

| 6 | Trademark shearing | 2 | 2 |

| 7 | Trademark shearing | 2 | 2 |

| 8 | Straight lock stitcher with automatic thread trimmer | 25 | 0.45 |

| 9 | Straight lock stitcher with automatic thread trimmer | 22 | 0.45 |

| 10 | Straight lock stitcher with automatic thread trimmer | 20 | 0.45 |

| 11 | Straight lock stitcher with automatic thread trimmer | 10 | 0.45 |

| 12 | Straight lock stitcher with automatic thread trimmer | 18 | 0.45 |

| 13 | Utility press | 10 | 2.2 |

| 14 | Five-thread overlock | 21 | 0.37 |

| 15 | Trademark shearing | 2 | 2 |

| 16 | Straight lock stitcher with automatic thread trimmer | 20 | 0.45 |

| 17 | Five-thread overlock | 30 | 0.37 |

| 18 | Straight lock stitcher with automatic thread trimmer | 22 | 0.37 |

| 19 | Electric steam iron | 18 | 1 |

| 20 | Fusing press machine | 5 | 15 |

| 21 | High-speed straight lock stitcher with automatic thread trimmer | 20 | 0.45 |

| 22 | Collar turning | 10 | 0.3 |

| 23 | Collar former | 20 | 0.5 |

| 24 | Electric steam iron | 12 | 1 |

| 25 | Straight lock stitcher with automatic thread trimmer | 18 | 0.45 |

| 26 | Shirt collar former | 6 | 0.4 |

| 27 | Upper and lower cutting | 10 | 1.3 |

| 28 | Electric steam iron | 7 | 1 |

| 29 | Straight lock stitcher with automatic thread trimmer | 8 | 0.45 |

| 30 | Straight lock stitcher with automatic thread trimmer | 16 | 0.45 |

| 31 | Electric steam iron | 18 | 1 |

| 32 | Straight lock stitcher with automatic thread trimmer | 6 | 0.45 |

| 33 | Shearing collar | 7 | 0.25 |

| 34 | Manual operation | 10 | - |

| 35 | Straight lock stitcher with automatic thread trimmer | 20 | 0.45 |

| 36 | Straight lock stitcher with automatic thread trimmer | 40 | 0.45 |

| 37 | Electric steam iron | 30 | 1 |

| 38 | Straight lock stitcher with automatic thread trimmer | 16 | 0.45 |

| 39 | Electric steam iron | 10 | 1 |

| 40 | Styling press | 15 | 2.3 |

| 41 | Straight lock stitcher with automatic thread trimmer | 10 | 0.45 |

| 42 | Straight lock stitcher with automatic thread trimmer | 12 | 0.45 |

| 43 | Buttonhole stitching | 8 | 0.36 |

| 44 | Button attaching | 10 | 0.25 |

| 45 | Straight lock stitcher with automatic thread trimmer | 40 | 0.45 |

| 46 | Manual operation | 7 | - |

| 47 | Buttonhole stitching | 15 | 0.36 |

| 48 | Button attaching | 12 | 0.25 |

| Workstation Number | BLP | BLM | BLG | |||

|---|---|---|---|---|---|---|

| Process Number | Number of Machines | Process Number | Number of Machines | Process Number | Number of Machines | |

| 1 | 1, 6, 7, 15, 37 | 2 | 5, 41, 21 | 2 | 5, 8 | 1 |

| 2 | 2, 43, 47, 27, 33 | 3 | 18,35, 42 | 1 | 1, 3, 9 | 3 |

| 3 | 3, 44, 48, 22 | 2 | 25, 36 | 1 | 2, 4, 6, 7 | 3 |

| 4 | 4, 19, 46 | 3 | 10, 11, 38 | 1 | 23, 26, 27, 29 | 4 |

| 5 | 5, 9 | 1 | 29, 45 | 1 | 19, 31, 22, 33 | 3 |

| 6 | 8, 11, 18 | 1 | 9, 12, 16 | 1 | 21, 24, 28, 34 | 3 |

| 7 | 10, 12, 16 | 1 | 8, 30, 32 | 1 | 20, 25, 30, 32 | 2 |

| 8 | 14, 17 | 1 | 19, 37, 34 | 2 | 37, 41,43 | 3 |

| 9 | 13, 20, 23, 26, 40 | 5 | 4, 24, 28, 39 | 2 | 12, 38, 39, 42 | 2 |

| 10 | 21, 30, 38 | 2 | 1, 31, 6, 7, 15, 46 | 3 | 11, 13, 40, 44 | 4 |

| 11 | 24, 28, 31, 39, 34 | 2 | 2, 43, 47, 22 | 2 | 35, 36 | 1 |

| 12 | 25, 29, 32, 35 | 1 | 14, 17 | 1 | 18, 45 | 1 |

| 13 | 36, 41 | 1 | 3, 44, 48, 27, 33 | 3 | 14, 16, 46 | 3 |

| 14 | 42, 45 | 1 | 13, 20, 23, 26, 40 | 5 | 10, 15, 48 | 3 |

| 15 | - | - | - | - | 17, 47 | 2 |

| Material Type | Carbon Emission Coefficient |

|---|---|

| Electric | 0.824 kgCO2e/kW·h |

| Pure cotton fabric | 10.750 kgCO2e/kg |

| Polyester fabric | 25.701 kgCO2e/kg |

| Resin button | 23.806 kgCO2e/kg |

| Sewing thread | 46.287 kgCO2e/kg |

| Woven label | 45.863 kgCO2e/kg |

| Printed label | 45.860 kgCO2e/kg |

| Activity Level | Rest | Sit | Minor Activity | Moderate Activity | Heavy Physical Activity | Extreme Physical Activity |

|---|---|---|---|---|---|---|

| Respiratory volume/L/min | 6.1 | 7.3 | 9.1 | 24.4 | 36.6 | 60.9 |

| Number of Inspectors | 5 | Working Time | 10 h/day | Daily Output | 600 pieces |

| Fabric Width | 144 cm | Fabric Composition | 80% Cotton, 20% Polyester | ||

| Fabric consumption | 160 cm/product | Weight | 150 g/m | Total | 960 m |

| Adhesive lining consumption | 16 cm/product | Weight | 33 g/m | Total | 96 m |

| Sewing thread consumption | 110 m/product | Weight | 0.0323 g/m | Total | 66,000 m |

| Button consumption | 10 capsules/product | Weight | 1 g/capsule | Total | 6000 capsules |

| Trademark consumption | 1 piece/product | Weight | 3 g/piece | Total | 600 pieces |

| Size label consumption | 1 piece/product | Weight | 1 g/piece | Total | 600 pieces |

| Washing label consumption | 1 piece/product | Weight | 1 g/piece | Total | 600 pieces |

| Sewing machines | There are 26 sewing machines in BLP and BLW (seven sets of straight lock stitchers with automatic thread trimmer. One high-speed straight lock stitcher with automatic thread trimmer. Three sets of electric steam irons. Two sets of manually operated machines. One each of: buttonhole stitching machine, button attaching machine, five-thread overlock, trademark shearing, pocket creasing collar turning, upper and lower cutting, shearing collar machine, utility press, fusing press, collar former, shirt collar former, styling press). There are 38 sewing machines in BLG (11 sets of straight lock stitchers with automatic thread trimmer. One high speed straight lock stitcher with automatic thread trimmer. Five sets of electric steam irons. Two sets of manually operated machines. Three sets of buttonhole stitching machines, three sets of button attaching machines. Two sets of five-thread overlock machines. One each of: trademark shearing, pocket creasing, collar turning, upper and lower cutting, shearing collar, utility press, fusing press, collar former, shirt collar former, styling press). | ||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Chen, Y. Carbon Emission Evaluation Based on Multi-Objective Balance of Sewing Assembly Line in Apparel Industry. Energies 2019, 12, 2783. https://doi.org/10.3390/en12142783

Zhang X, Chen Y. Carbon Emission Evaluation Based on Multi-Objective Balance of Sewing Assembly Line in Apparel Industry. Energies. 2019; 12(14):2783. https://doi.org/10.3390/en12142783

Chicago/Turabian StyleZhang, Xujing, and Yan Chen. 2019. "Carbon Emission Evaluation Based on Multi-Objective Balance of Sewing Assembly Line in Apparel Industry" Energies 12, no. 14: 2783. https://doi.org/10.3390/en12142783

APA StyleZhang, X., & Chen, Y. (2019). Carbon Emission Evaluation Based on Multi-Objective Balance of Sewing Assembly Line in Apparel Industry. Energies, 12(14), 2783. https://doi.org/10.3390/en12142783