A Firefly Algorithm Optimization-Based Equivalent Consumption Minimization Strategy for Fuel Cell Hybrid Light Rail Vehicle

Abstract

1. Introduction

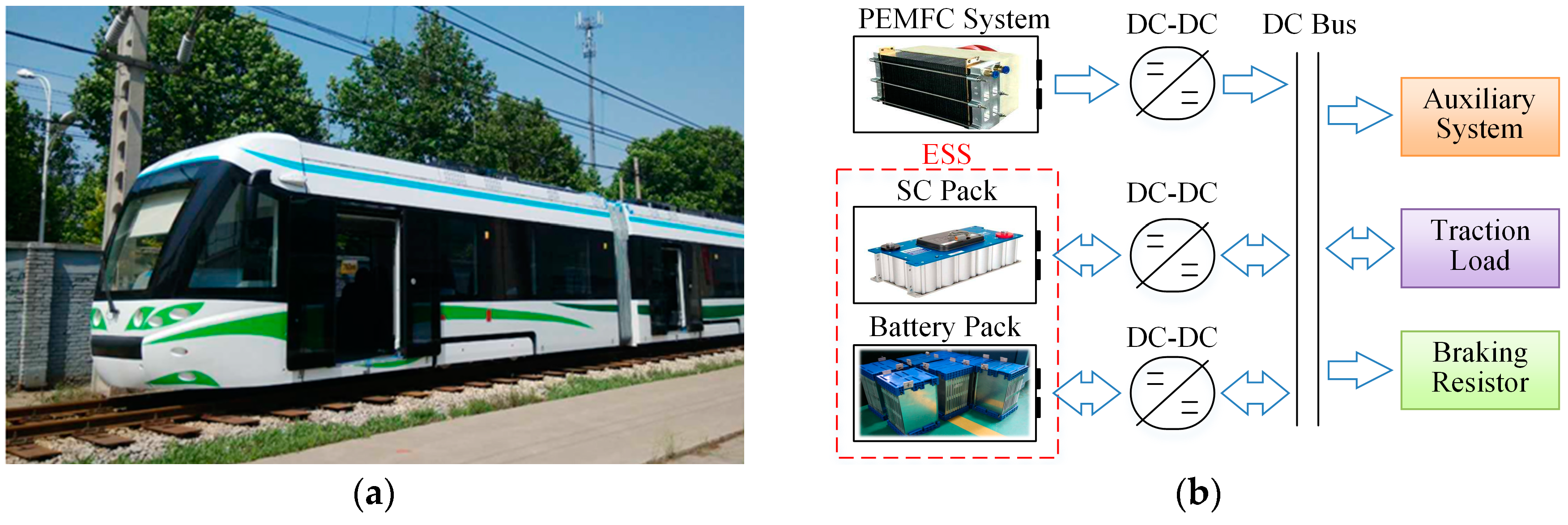

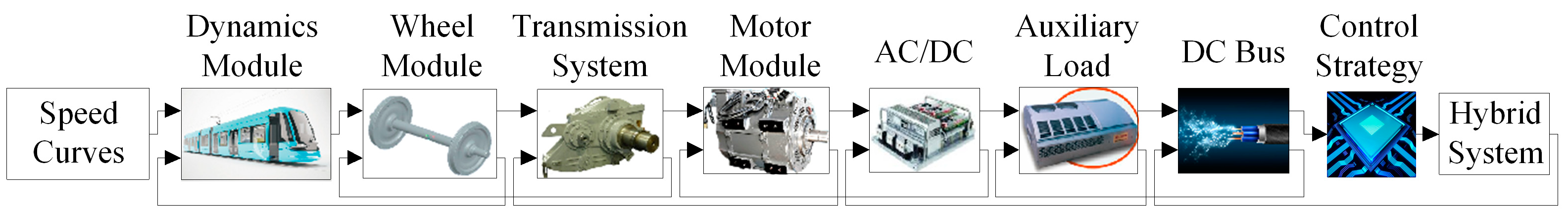

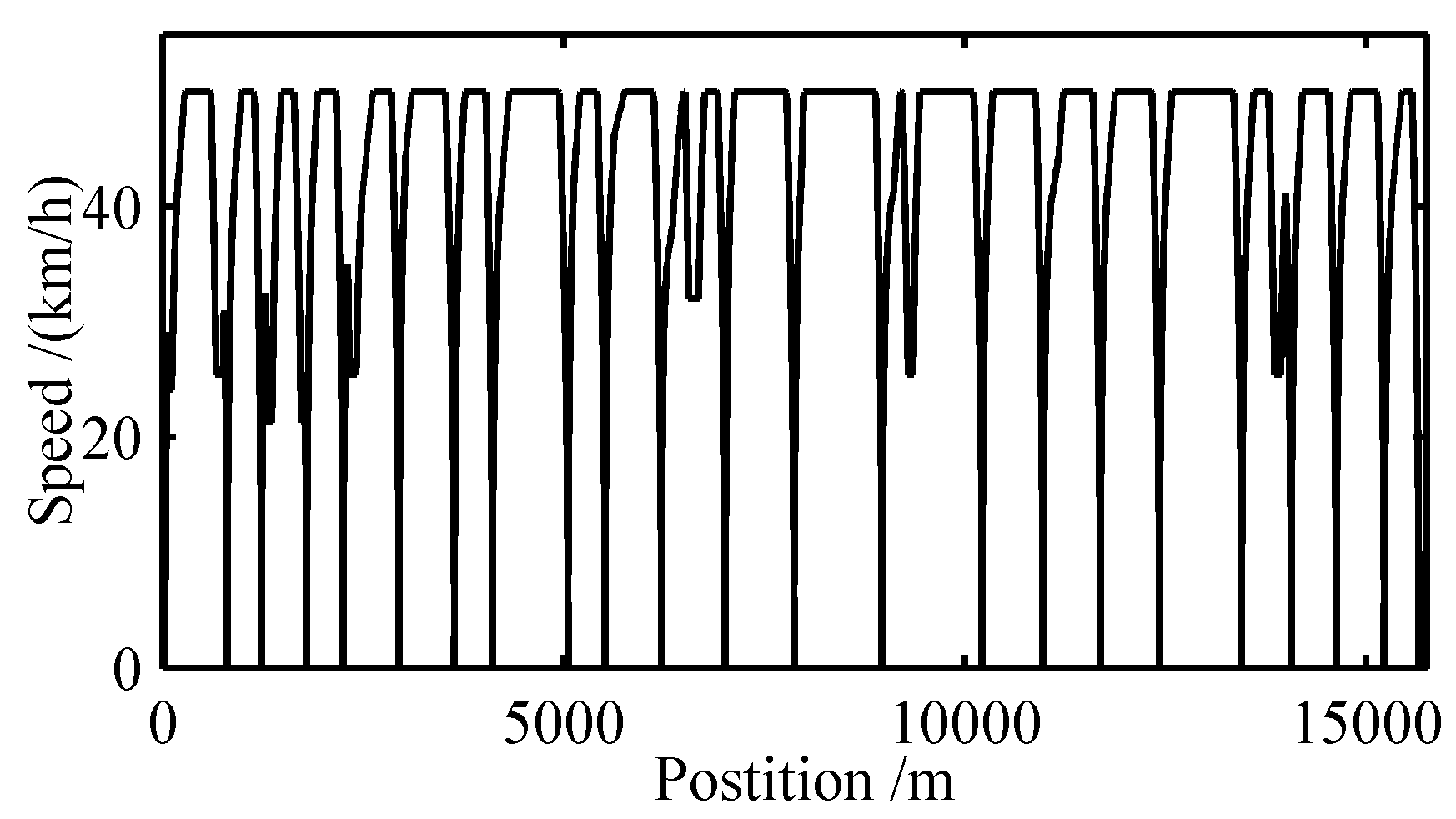

2. Vehicle Modeling

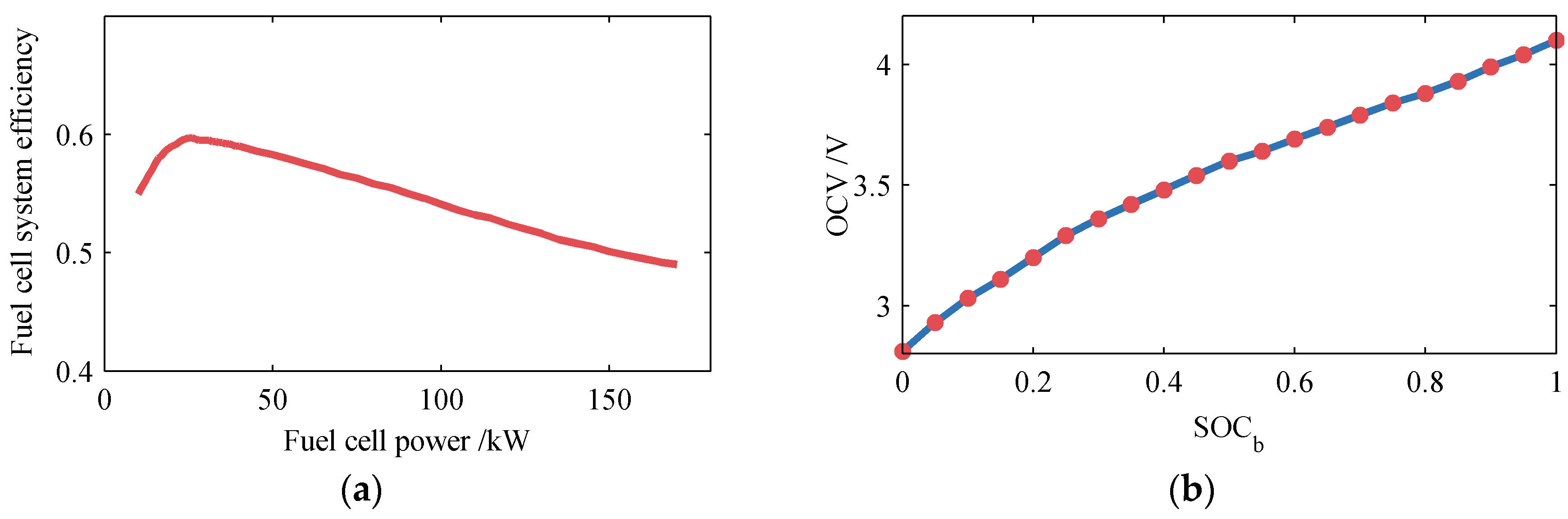

2.1. PEMFC

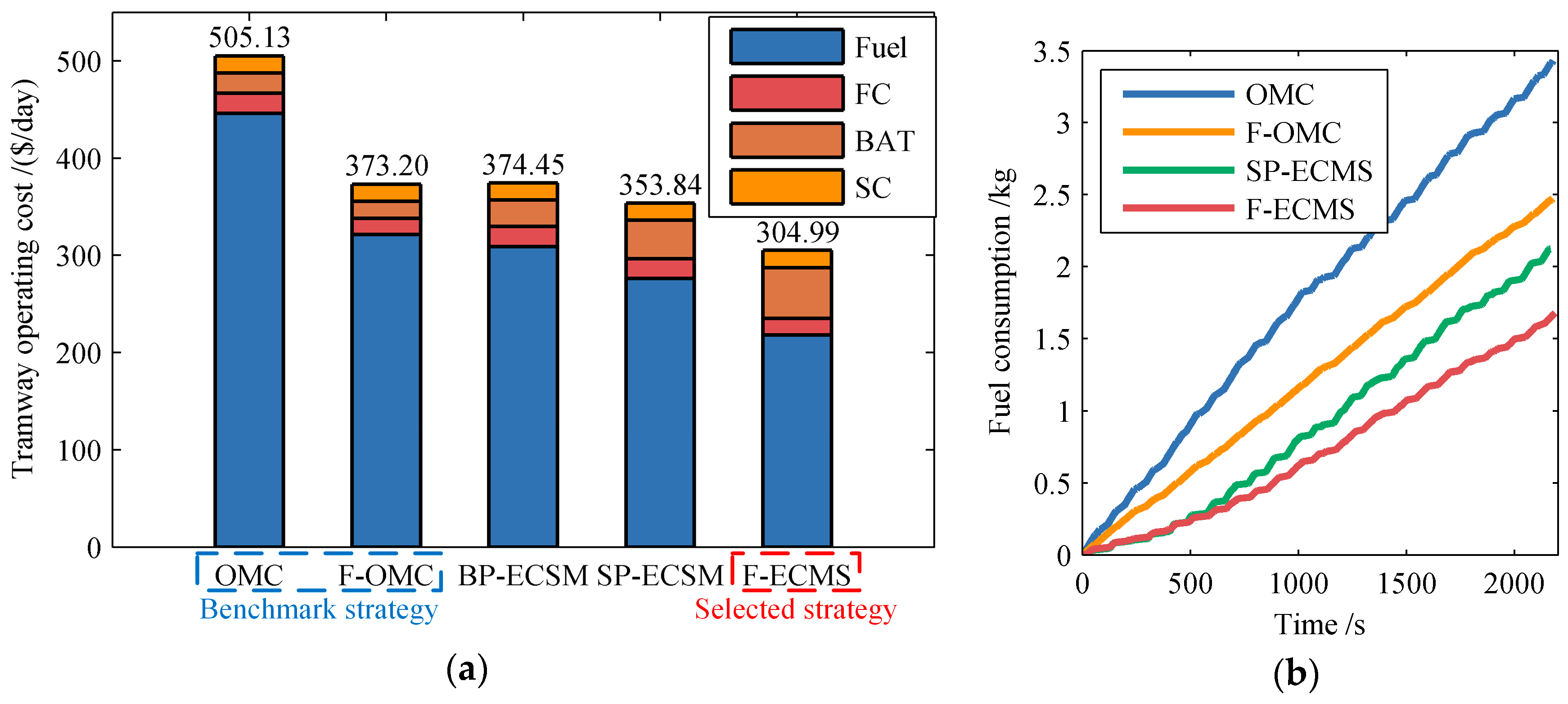

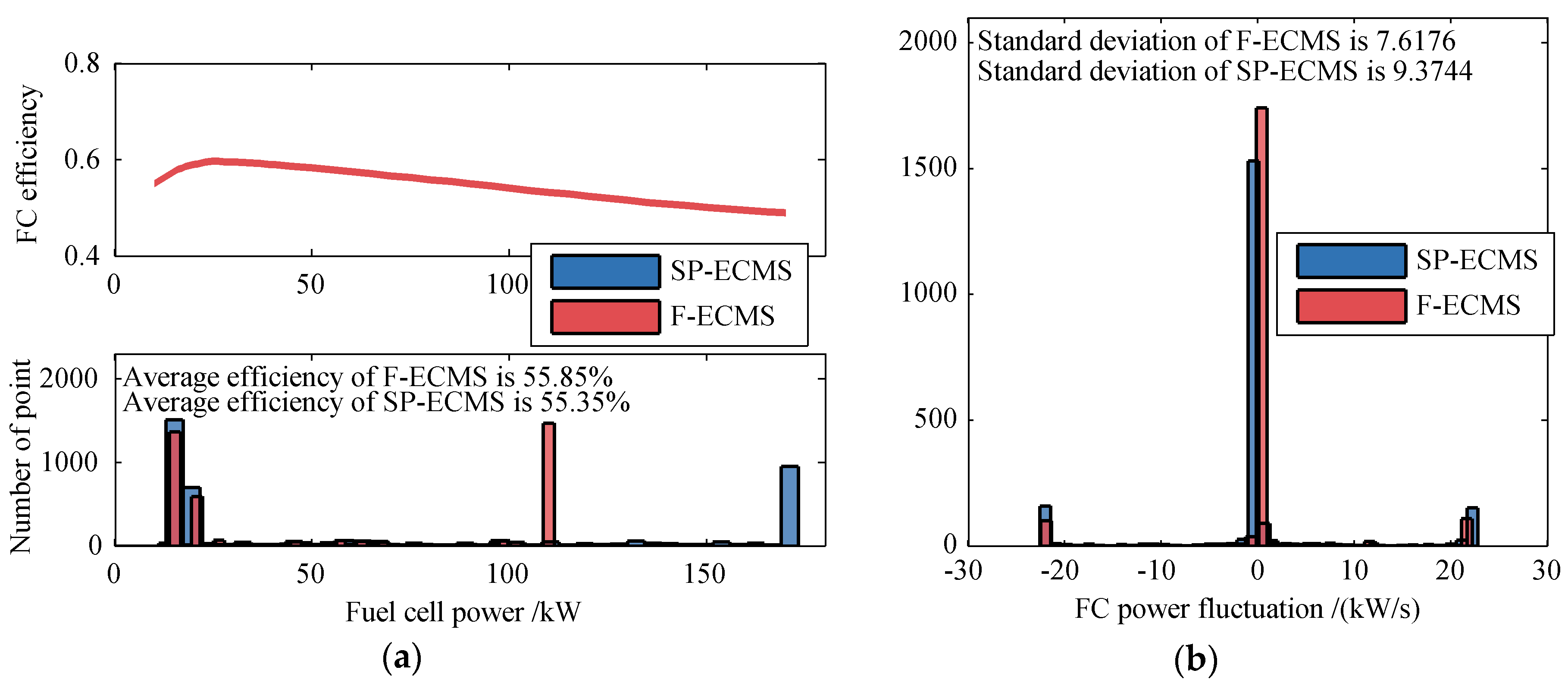

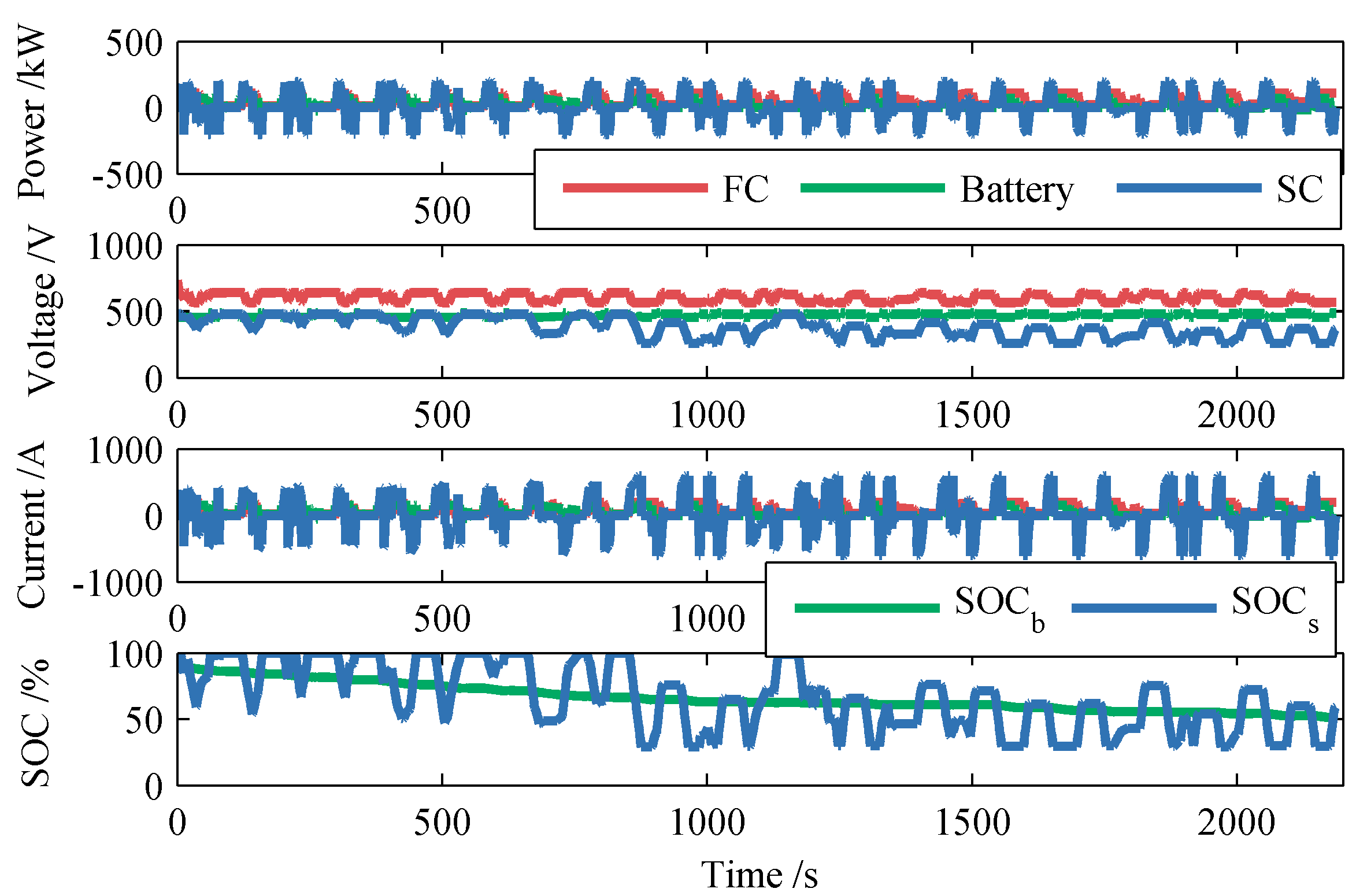

2.2. Battery

2.3. Supercapacitor

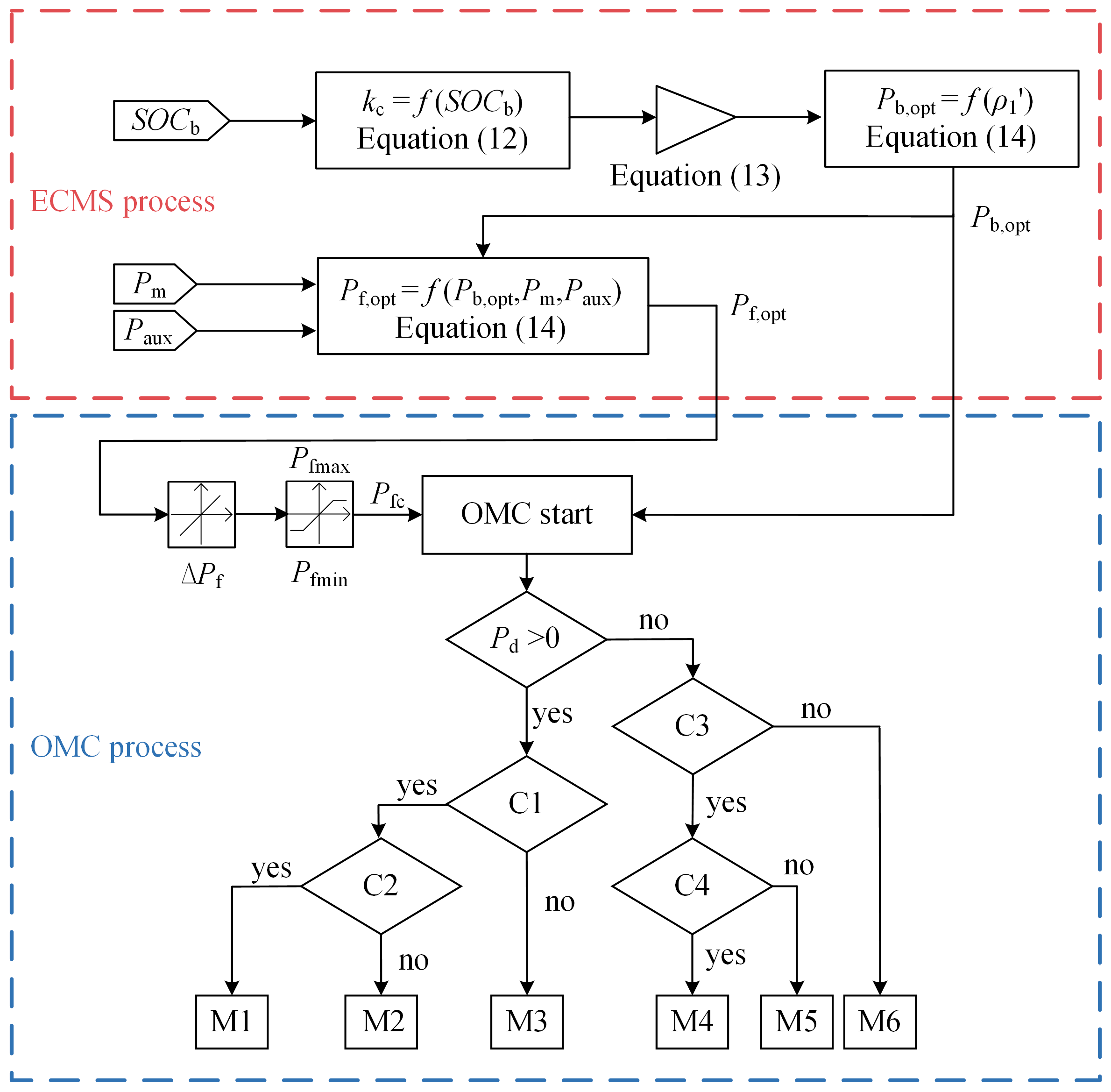

3. Equivalent Consumption Minimization Strategy

3.1. Conventional ECMS

3.2. Improved ECMS

4. Optimal Control Strategy

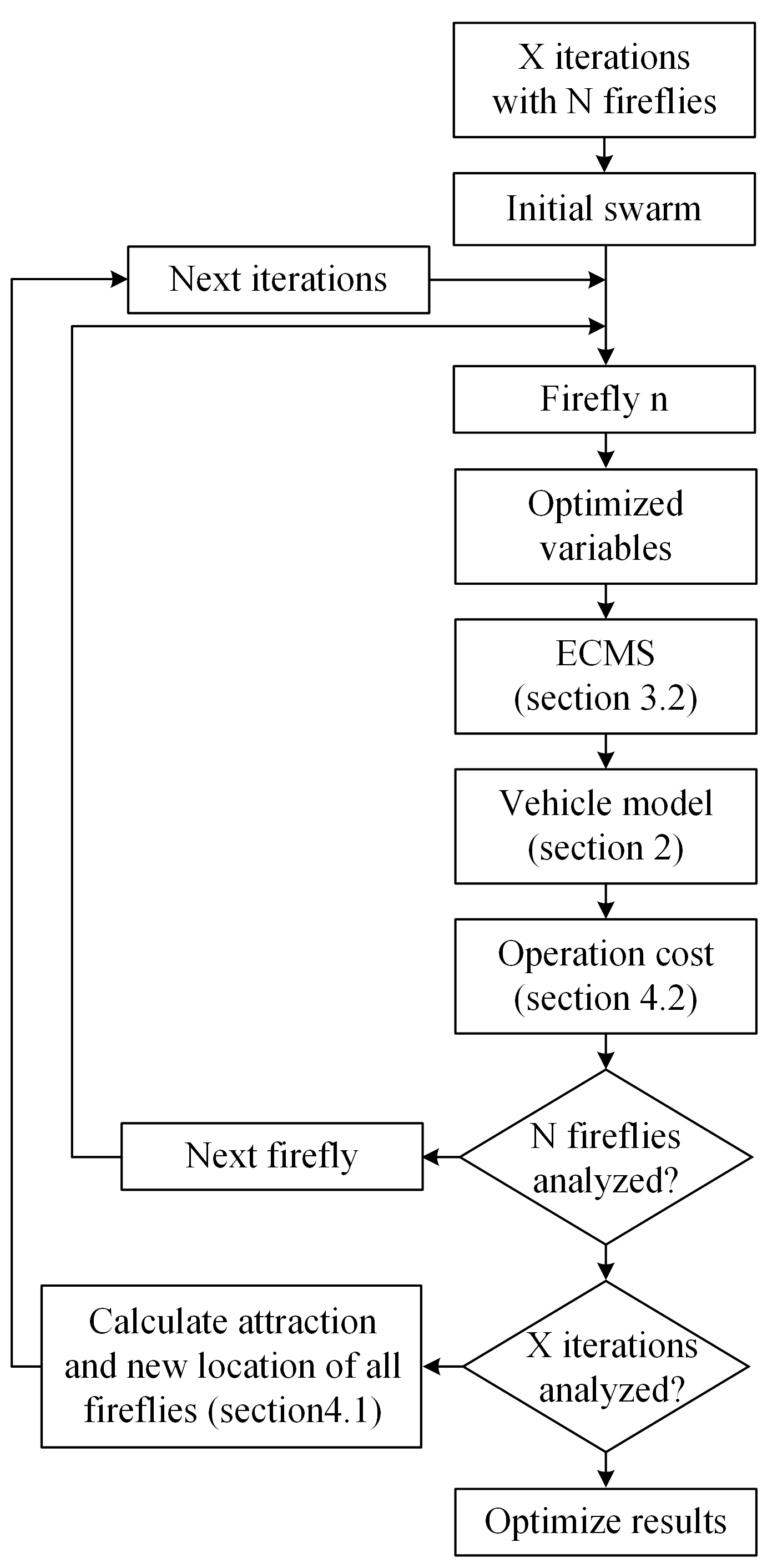

4.1. Firefly Algorithm

4.2. Optimization Objective

4.3. Control Strategy

- Only optimizing the balance factor of F-ECMS can obtain a better result (2.875) than ECMS (2.826).

- Optimizing the balance factor and power limitations can obtain the best result (3.279).

5. Results and Analysis

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yue, M.; Jemei, S.; Gouriveau, R.; Zerhouni, N. Review on Health-Conscious Energy Management Strategies for Fuel Cell Hybrid Electric Vehicles: Degradation Models and Strategies. Int. J. Hydrogen Energy 2019, 44, 6844–6861. [Google Scholar] [CrossRef]

- Hidalgo-Reyes, J.I.; Gomez-Aguilar, J.F.; Escobar-Jimenez, R.F.; Alvarado-Martinez, V.M.; Lopez-Lopez, M.G. Classical and Fractional-order Modeling of Equivalent Electrical Circuits for Supercapacitors and Batteries, Energy Management Strategies for Hybrid Systems and Methods for the State of Charge Estimation: A State of the Art Review. Microelectron. J. 2019, 85, 109–128. [Google Scholar] [CrossRef]

- Hong, Z.; Li, Q.; Han, Y.; Shang, W.; Zhu, Y.; Chen, W. An Energy Management Strategy based on Dynamic Power Factor for Fuel Cell/battery Hybrid Locomotive. Int. J. Hydrogen Energy 2018, 43, 3261–3272. [Google Scholar] [CrossRef]

- Cheng, J.; Yang, G.; Zhang, K.; He, G.; Jia, J.; Yu, H.; Gai, F.; Li, L.; Hao, C.; Zhang, F. Guanidimidazole-quanternized and Cross-linked Alkaline Polymer Electrolyte Membrane for Fuel Cell Application. J. Membr. Sci. 2016, 501, 100–108. [Google Scholar] [CrossRef]

- Kamal, T.; Hassan, S.Z.; Espinosa-Trujillo, M.J.; Li, H.; Flota, M. An Optimal Power Sharing and Power Control Strategy of Photovoltaic/Fuel Cell/Ultra-capacitor Hybrid Power System. J. Renew. Sustain. Energy 2016, 8, 035301. [Google Scholar] [CrossRef]

- Marzougui, H.; Amari, M.; Kadri, A.; Bacha, F.; Ghouili, J. Energy Management of Fuel Cell/Battery/Ultracapacitor in Electrical Hybrid Vehicle. Int. J. Hydrogen Energy 2017, 42, 8857–8869. [Google Scholar] [CrossRef]

- Fathabadi, H. Fuel Cell Hybrid Electric Vehicle (FCHEV): Novel Fuel Cell/SC Hybrid Power Generation System. Energy Convers. Manag. 2018, 156, 192–201. [Google Scholar] [CrossRef]

- Das, H.; Tan, C.; Yatim, A. Fuel Cell Hybrid Electric Vehicles: A Review on Power Conditioning Units and Topologies. Renew. Sustain. Energy Rev. 2017, 76, 268–291. [Google Scholar] [CrossRef]

- Garcia, P.; Fernandez, L.; Torreglosa, J.; Jurado, F. Comparative Study of Four Control Systems for a 400-kW Fuel Cell Battery-Powered Tramway with Two DC/DC Converters. Int. Trans. Electr. Energy Syst. 2013, 23, 1028–1048. [Google Scholar] [CrossRef]

- Behdani, A.; Naseh, M. Power Management and Nonlinear Control of a Fuel Cell-Supercapacitor Hybrid Automotive Vehicle with Working Condition Algorithm. Int. J. Hydrogen Energy 2017, 42, 24347–24357. [Google Scholar] [CrossRef]

- Zhou, D.; Al-Durra, A.; Gao, F.; Ravey, A.; Matraji, I.; Simoes, M. Online Energy Management Strategy of Fuel Cell Hybrid Electric Vehicles Based on Data Fusion Approach. J. Power Sources 2017, 366, 278–291. [Google Scholar] [CrossRef]

- Bauman, J.; Kazerani, M. A Comparative Study of Fuel-Cell-Battery, Fuel-Cell-Ultracapacitor, and Fuel-Cell-Battery-Ultracapacitor Vehicles. IEEE Trans. Veh. Technol. 2008, 57, 760–769. [Google Scholar] [CrossRef]

- Li, Q.; Yang, H.; Han, Y.; Li, M.; Chen, W. A State Machine Strategy Based on Droop Control for an Energy Management System of PEMFC-Battery-Supercapacitor Hybrid Tramway. Int. J. Hydrogen Energy 2016, 41, 16148–16159. [Google Scholar] [CrossRef]

- Peng, F.; Zhao, Y.; Li, X.; Liu, Z.; Chen, W.; Liu, Y.; Zhou, D. Development of Master-Slave Energy Management Strategy Based on Fuzzy Logic Hysteresis State Machine and Differential Power Processing Compensation for a PEMFC-LIB-SC Hybrid Tramway. Appl. Energy 2017, 206, 346–363. [Google Scholar] [CrossRef]

- Ali, A.M.; Soffker, D. Towards Optimal Power Management of Hybrid Electric Vehicles in Real-Time: A Review on Methods, Challenges, and State-of-the-Art Solutions. Energies 2018, 11, 476. [Google Scholar]

- Ahmadi, S.; Bathaee, S.M.T. Multi-Objective Genetic Optimization of the Fuel Cell Hybrid Vehicle Supervisory System: Fuzzy Logic and Operating Mode Control Strategies. Int. J. Hydrogen Energy 2015, 40, 12512–12521. [Google Scholar] [CrossRef]

- Caux, S.; Hankache, W.; Fadel, M.; Hissel, D. On-Line Fuzzy Energy Management for Hybrid Fuel Cell Systems. Int. J. Hydrogen Energy 2010, 35, 2134–2143. [Google Scholar] [CrossRef]

- Bizon, N. Load-Following Mode Control of a Standalone Renewable/Fuel Cell Hybrid Power Source. Energy Convers. Manag. 2014, 77, 763–772. [Google Scholar] [CrossRef]

- Yu, K.; Tan, X.; Yang, H.; Liu, W.; Cui, L.; Liang, Q. Model Predictive Control of Hybrid Electric Vehicles for Improved Fuel Economy. Asian J. Control 2016, 18, 1–14. [Google Scholar] [CrossRef]

- Ayad, M.Y.; Becherif, M.; Henni, A. Vehicle Hybridization with Fuel Cell, Supercapacitors and Batteries by Sliding Mode Control. Renew. Energy 2011, 36, 2627–2634. [Google Scholar] [CrossRef]

- Zhang, W.; Li, J.; Xu, L.; Ouyang, M. Optimization for a Fuel Cell/Battery/Capacity Tram with Equivalent Consumption Minimization Strategy. Energy Convers. Manag. 2017, 134, 59–69. [Google Scholar] [CrossRef]

- Hu, Z.; Li, J.; Xu, L.; Song, Z.; Fang, C.; Ouyang, M.; Dou, G.; Kou, G. Multi-Objective Energy Management Optimization and Parameter Sizing for Proton Exchange Membrane Hybrid Fuel Cell Vehicles. Energy Convers. Manag. 2016, 129, 108–121. [Google Scholar] [CrossRef]

- Xu, L.; Yang, F.; Li, J.; Ouyang, M.; Hua, J. Real Time Optimal Energy Management Strategy Targeting at Minimizing Daily Operation Cost for a Plug-in Fuel Cell City Bus. Int. J. Hydrogen Energy 2012, 37, 15380–15392. [Google Scholar] [CrossRef]

- Li, M.; Li, M.; Han, G.; Liu, N.; Zhang, Q.; Wang, Y. Optimization Analysis of the Energy Management Strategy of the New Energy Hybrid 100% Low-Floor Tramcar Using a Genetic Algorithm. Appl. Sci. 2018, 8, 1144. [Google Scholar] [CrossRef]

- Olivier, J.C.; Wasselynck, G.; Chevalier, S.; Auvity, B.; Josset, C.; Trichet, D.; Squadrito, G.; Bernard, N. Multiphysics Modeling and Optimization of the Driving Strategy of a Light Duty Fuel Cell Vehicle. Int. J. Hydrogen Energy 2017, 42, 26943–26955. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, J.; Zhang, J.; Song, P.; Li, M. Optimal Energy Management of a Fuel Cell-Battery-Supercapacitor-Powered Hybrid Tramway Using a Multi-Objective Approach. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2019. [Google Scholar] [CrossRef]

- Zhang, F.; Xu, K.; Li, L.; Langari, R. Comparative Study of Equivalent Factor Adjustment Algorithm for Equivalent Consumption Minimization Strategy for HEVs. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 27–30 August 2018. [Google Scholar]

- Li, H.; Ravey, A.; N’Diaye, A.; Djerdir, A. A Novel Equivalent Consumption Minimization Strategy for Hybrid Electric Vehicle Powered by Fuel Cell, Battery and Supercapacitor. J. Power Sources 2018, 395, 262–270. [Google Scholar] [CrossRef]

- Lin, X.; Feng, Q.; Mo, L.; Li, H. Optimal Adaptation Equivalent Factor of Energy Management Strategy for Plug-in CVT HEV. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2019, 233, 877–889. [Google Scholar] [CrossRef]

- Torreglosa, J.P.; Jurado, F.; Garcia, P.; Fernandez, L.M. Hybrid Fuel Cell and Battery Tramway Control Based on an Equivalent Consumption Minimization Strategy. Control Eng. Pract. 2011, 19, 1182–1194. [Google Scholar] [CrossRef]

- Zhang, G.; Li, Q.; Han, Y.; Meng, X.; Chen, W. Study on Equivalent Consumption Minimization Strategy Based on Operation Mode and DDOH for Fuel Cell Hybrid Tramway. Proc. CSEE 2018, 23, 6905–6914. [Google Scholar]

- Garcia, P.; Torreglosa, J.P.; Fernandez, L.M.; Jurado, F. Viability Study of a FC-Battery-SC Tramway Controlled by Equivalent Consumption Minimization Strategy. Int. J. Hydrogen Energy 2012, 37, 9368–9382. [Google Scholar] [CrossRef]

- Yan, Y.; Li, Q.; Chen, W.; Su, B.; Liu, J.; Ma, L. Optimal Energy Management and Control in Multimode Equivalent Energy Consumption of Fuel Cell/Supercapacitor of Hybrid Electric Tram. IEEE Trans. Ind. Electron. 2019, 66, 6065–6076. [Google Scholar] [CrossRef]

- Han, Y.; Li, Q.; Wang, T.; Chen, W.; Ma, L. Multisource Coordination Energy Management Strategy Based on SOC Consensus for a PEMFC–Battery–Supercapacitor Hybrid Tramway. IEEE Trans. Veh. Technol. 2018, 67, 296–305. [Google Scholar] [CrossRef]

- Yang, J.; Xu, X.; Peng, Y.; Zhang, J.; Song, P. Modeling and Optimal Energy Management Strategy for a Catenary-Battery-Ultracapacitor Based Hybrid Tramway. Energy 2019, 183, 1123–1135. [Google Scholar] [CrossRef]

- Yang, J.; Song, P.; Zhang, J.; Wang, G.; Zhang, H. Research on Simulation System of Hybrid Modern Tramway. J. Mech. Eng. 2017, 53, 161–168. [Google Scholar] [CrossRef]

- Niu, Q.; Zhang, H.; Li, K. An Improved TLBO with Elite Strategy for Parameters Identification of PEM Fuel Cell and Solar Cell Models. Int. J. Hydrogen Energy 2014, 39, 3837–3854. [Google Scholar] [CrossRef]

- Li, Q.; Wang, T.; Dai, C.; Chen, W.; Ma, L. Power Management Strategy Based on Adaptive Droop Control for a Fuel Cell-Battery-Supercapacitor Hybrid Tramway. IEEE Trans. Veh. Technol. 2018, 67, 5658–5670. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, J.; Song, P.; Chen, Y.; Wang, G. Research on Modeling and Operation Control of Fuel Cell Hybrid Train. J. China Railw. Soc. 2017, 39, 40–47. [Google Scholar]

- Tremblay, O.; Dessaint, L. Experimental Validation of a Battery Dynamic Model for EV Applications. World Electr. Veh. J. 2009, 3, 1–10. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Stoller, M.; Ganesh, K.; Cai, W.; Ferreira, P.; Pirkle, A.; Wallace, R.; Cychosz, k.; Thommes, M.; et al. Carbon-Based Supercapacitors Produced by Activation of Graphene. Science 2011, 332, 1537–1541. [Google Scholar] [CrossRef]

- Ehsani, M.; Gao, Y.; Emadi, A. Modern Electric, Hybrid Electric, and Fuel Cell Vehicles: Fundamentals, Theory, and Design, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2010; pp. 331–333. [Google Scholar]

- Herrera, V.; Milo, A.; Gaztanaga, H.; Etxeberria-Otadui, I.; Villarreal, I.; Camblong, H. Adaptive Energy Management Strategy and Optimal Sizing Applied on a Battery-Supercapacitor Based Tramway. Appl. Energy 2016, 169, 831–845. [Google Scholar] [CrossRef]

- Herrera, V.; Gaztanaga, H.; Milo, A.; Saez-de-Ibarra, A.; Etxeberria-Otadui, I.; Nieva, T. Optimal Energy Management and Sizing of a Battery-Supercapacitor-Based Light Rail Vehicle with a Multiobjective Approach. IEEE. Trans. Ind. Appl. 2016, 52, 3367–3377. [Google Scholar] [CrossRef]

- Paganelli, G.; Delprat, S.; Guerra, T.M.; Rimaux, J.; Santin, J.J. Equivalent Consumption Minimization Strategy for Parallel Hybrid Powertrains. In Proceedings of the IEEE 55th Vehicular Technology Conference, Birmingham, AL, USA, 6–9 May 2002. [Google Scholar]

- Xu, L.; Li, J.; Hua, J.; Li, X.; Ouyang, M. Adaptive Supervisory Control Strategy of a Fuel Cell/Battery-Powered City Bus. J. Power Sources 2009, 194, 360–368. [Google Scholar] [CrossRef]

- Garcia, P.; Fernandez, L.M.; Torreglosa, J.P.; Jurado, F. Operation Mode Control of a Hybrid Power System Based on Fuel Cell/Battery/Ultracapacitor for an Electric Tramway. Comput. Electr. Eng. 2013, 39, 1993–2004. [Google Scholar] [CrossRef]

- Yang, X. Firefly algorithms for multimodal optimization. In Proceedings of the International Symposium on Stochastic Algorithms, Sapporo, Japan, 26–28 October 2009. [Google Scholar]

- Chaurasia, G.S.; Singh, A.K.; Agrawal, S.; Sharma, N.K. A Meta-Heuristic Firefly Algorithm Based Smart Control Strategy and Analysis of a Grid Connected Hybrid Photovoltaic/Wind Distributed Generation System. Sol. Energy 2017, 150, 265–274. [Google Scholar] [CrossRef]

- Wang, D.; Luo, H.; Grunder, O.; Lin, Y.; Guo, H. Multi-Step Ahead Electricity Price Forecasting Using a Hybrid Model Based on Two-Layer Decomposition Technique and BP Neural Network Optimized by Firefly Algorithm. Appl. Energy 2017, 190, 390–407. [Google Scholar] [CrossRef]

- Bahadormanesh, N.; Rahat, S.; Yarali, M. Constrained Multi-Objective Optimization of Radial Expanders in Organic Rankine Cycles by Firefly Algorithm. Energy Convers. Manag. 2017, 148, 1179–1193. [Google Scholar] [CrossRef]

- Yang, J.; Xu, X.; Zhang, J.; Song, P. Multi-objective Optimization of Energy Management Strategy for Fuel Cell Tram. J. Mech. Eng. 2018, 22, 153–159. [Google Scholar] [CrossRef]

| Condition/Mode | BP-ECMS | SP-ECMS |

|---|---|---|

| C1 | ||

| C2 | ||

| C3 | ||

| C4 | ||

| M1 | , | , |

| M2 | , | , |

| M3 | , | , |

| M4 | , | , |

| M5 | , , | , , |

| M6 | , | , |

| Power source | Parameter | Value |

|---|---|---|

| PEMFC | Maximum power (kW) | 170 |

| Rated voltage (V) | 540 | |

| Maximum current (A) | 320 | |

| Cell number | 735 | |

| Battery cell | Rated voltage (V) | 3.2 |

| Rated capacity (Ah) | 40 | |

| Operating voltage (V) | 2.5–3.8 | |

| Operating temperature (K) | 253–318 | |

| SC cell | Rated voltage (V) | 2.7 |

| Rated capacity (F) | 3000 | |

| Maximum current (A) | 210 | |

| Operating temperature (K) | 233–335 |

| Indicators | OMC | F-OMC | SP-ECMS |

|---|---|---|---|

| Methods | Introduces ECMS and FA | Introduces ECMS | Optimized by FA |

| Operating cost | Save 39.62% | Save 18.28% | Save 13.81% |

| Fuel consumption | Save 51.02% | Save 31.98% | Save 20.75% |

| FC system efficiency | Improve 3.34% | Improve 0.88% | Improve 0.5% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Yang, J.; Zhang, J.; Song, P.; Xu, X. A Firefly Algorithm Optimization-Based Equivalent Consumption Minimization Strategy for Fuel Cell Hybrid Light Rail Vehicle. Energies 2019, 12, 2665. https://doi.org/10.3390/en12142665

Zhang H, Yang J, Zhang J, Song P, Xu X. A Firefly Algorithm Optimization-Based Equivalent Consumption Minimization Strategy for Fuel Cell Hybrid Light Rail Vehicle. Energies. 2019; 12(14):2665. https://doi.org/10.3390/en12142665

Chicago/Turabian StyleZhang, Han, Jibin Yang, Jiye Zhang, Pengyun Song, and Xiaohui Xu. 2019. "A Firefly Algorithm Optimization-Based Equivalent Consumption Minimization Strategy for Fuel Cell Hybrid Light Rail Vehicle" Energies 12, no. 14: 2665. https://doi.org/10.3390/en12142665

APA StyleZhang, H., Yang, J., Zhang, J., Song, P., & Xu, X. (2019). A Firefly Algorithm Optimization-Based Equivalent Consumption Minimization Strategy for Fuel Cell Hybrid Light Rail Vehicle. Energies, 12(14), 2665. https://doi.org/10.3390/en12142665