1. Introduction

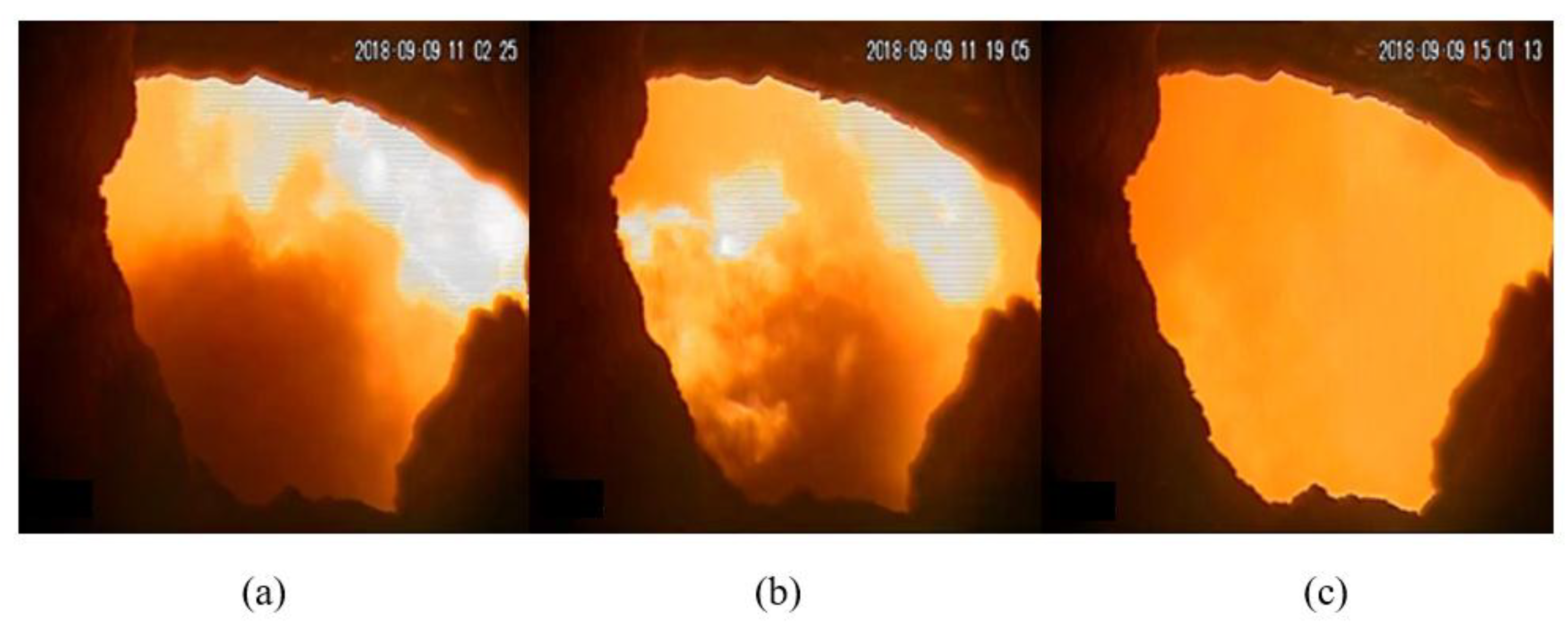

Fossil power plants in China are facing more peak-shaving requests for the growth of renewable energies. Reducing the minimum unit technique output is one of the goals of flexible transformation, which means the boilers in power plants should be operated below the designed minimum output. When the boiler runs in a low load, the changeable quality of coal used in practice makes the combustion unstable, which directly affects the safety and economics of the boiler operation. Hence, the identification of combustion condition has received extensive attention by researchers. Flame visualization and characterization techniques are some of the research tools for understanding the combustion process. Current research mainly includes feature-based machine learning, statistical-based process monitoring, and deep learning methods.

The main steps of feature-based machine learning methods are feature extraction and state classification. However, whether or not the extracted characteristic parameters could represent the combustion condition is dependent on the image processing technology, such as the segmentation algorithm. Machine learning mainly includes artificial neural networks, linear classifiers, and clustering analysis, and tuning the parameters usually takes lot of time. Back propagation (BP) neural network (NN) [

1], wavelet NN [

2], and a method combined with Kohonen’s self-organizing NN and BP [

3] were proposed to predict combustion status based on digital images. For improving the convergence speed and recognition accuracy, Han et al. [

4] proposed an interactive flame image recognition method in which manual evaluation was introduced to the NN. Considering the uncertainty in flame detection, Li et al. [

5] proposed a two-stage fusion structure, combining BP and the Dempster–Shafer (D–S) evidence theory. To analyze the dynamic characters in the flame images, Liu et al. [

6] selected the relative changes of the ignition position as the inputs of the fuzzy neural network, Zhang et al. [

7] applied the fuzzy theory to fuse the fire detection value and flame characteristics, and Xu et al. [

8] proposed an online fuzzy clustering algorithm to monitor the in-furnace combustion states automatically. In terms of the linear classifiers, the support vector machine (SVM) [

9] and the robust support vector regression machine [

10] are also proposed for their anti-outlier performance. Wu et al. [

11] introduced the Krawtchouk moment and Wang et al. [

12] used Fisher Discriminant Analysis to extract the features, then combined wavelet SVM and k-nearest neighbor (KNN) for combustion state classification. For the sintering process of a rotary kiln, Li et al. [

13] applied the ensemble learner models with the probabilistic neural network (PNN), the NN, the SVM, and extreme learning machine (ELM) classifiers for combustion state recognition and Chen et al. [

14] used SVM and ELM to recognize the temperature condition of a rotary kiln.

On combustion process monitoring, Bai et al. [

15] proposed a principal component analysis (PCA) to extract the characteristics of flame images. Considering the stochastic behavior of time series in the combustion process, Chen et al. [

16] proposed a framework based on multiway principal component analysis (MPCA) and the hidden Markov model (HMM) to establish the probability monitoring chart of oil flame images under a normal combustion state for the combustion transition state sequence tracking. Bai et al. [

17] proposed a multi-condition combustion process monitoring method based on a principal component analysis and random weight network (PCA-RWN).

In recent years, deep learning has received unprecedented attention and development. Its greatest advantage is that it can learn the representative characteristics in data automatically and avoid misleading from hand-crafted features [

18]. It is widely applied in research fields related to feature extraction: Zhou et al. [

19] combined independent subspace analysis (ISA) with a convolutional network to extract the local morphology of the burning image for the rotary kiln sintering process layer by layer and built the word package model to learn its global feature. Yuting et al. [

20] used a deep belief network (DBN) to obtain features in the image of the furnace flame. In combustion state recognition, Wang et al. [

21] proposed a deep learning method based on convolutional neural network (CNN) and deep neural network (DNN) to monitor combustion states and predict the heat release rate.

The studies above were mainly based on supervised learning, that is, the models learn and extract the corresponding features, directly and intentionally, through the information feedback from the labeled images. These labels are often given by researchers through specific experimental conditions or expertise. It’s a time-consuming and laborious task to label the image manually. If mistakes are made in the process of labeling, they would affect the performance of the models. The Kohonen network, proposed by Wei [

2], and a fuzzy immune network algorithm, proposed by Guo et al. [

22], were the attempts to realize the unsupervised learning in the flame monitoring process. However, since the features are extracted by hand-craft, it is hard to determine whether the selected features could improve the optimal recognition performance for combustion state classification.

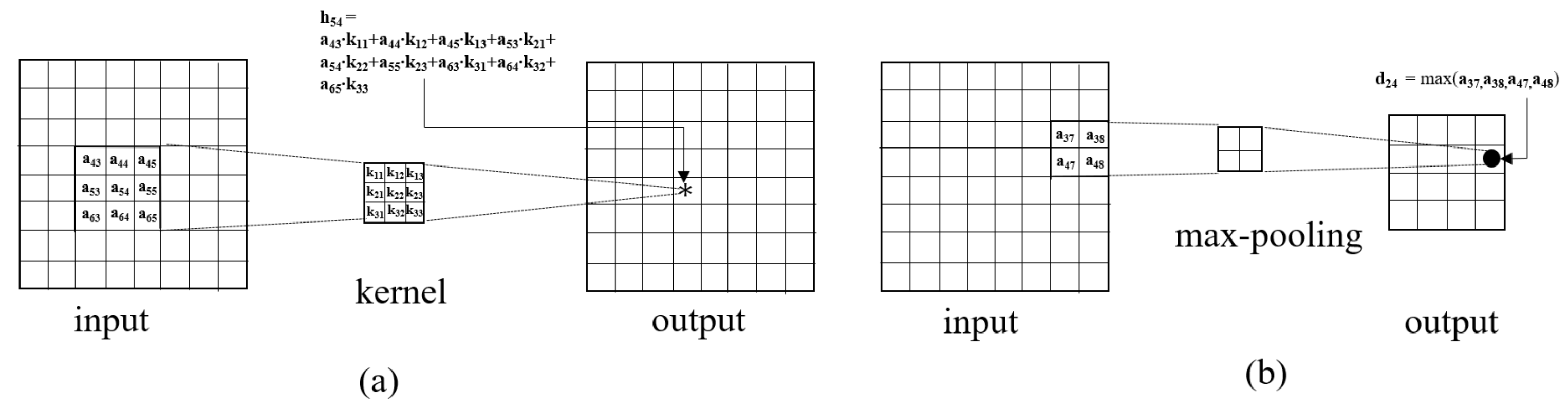

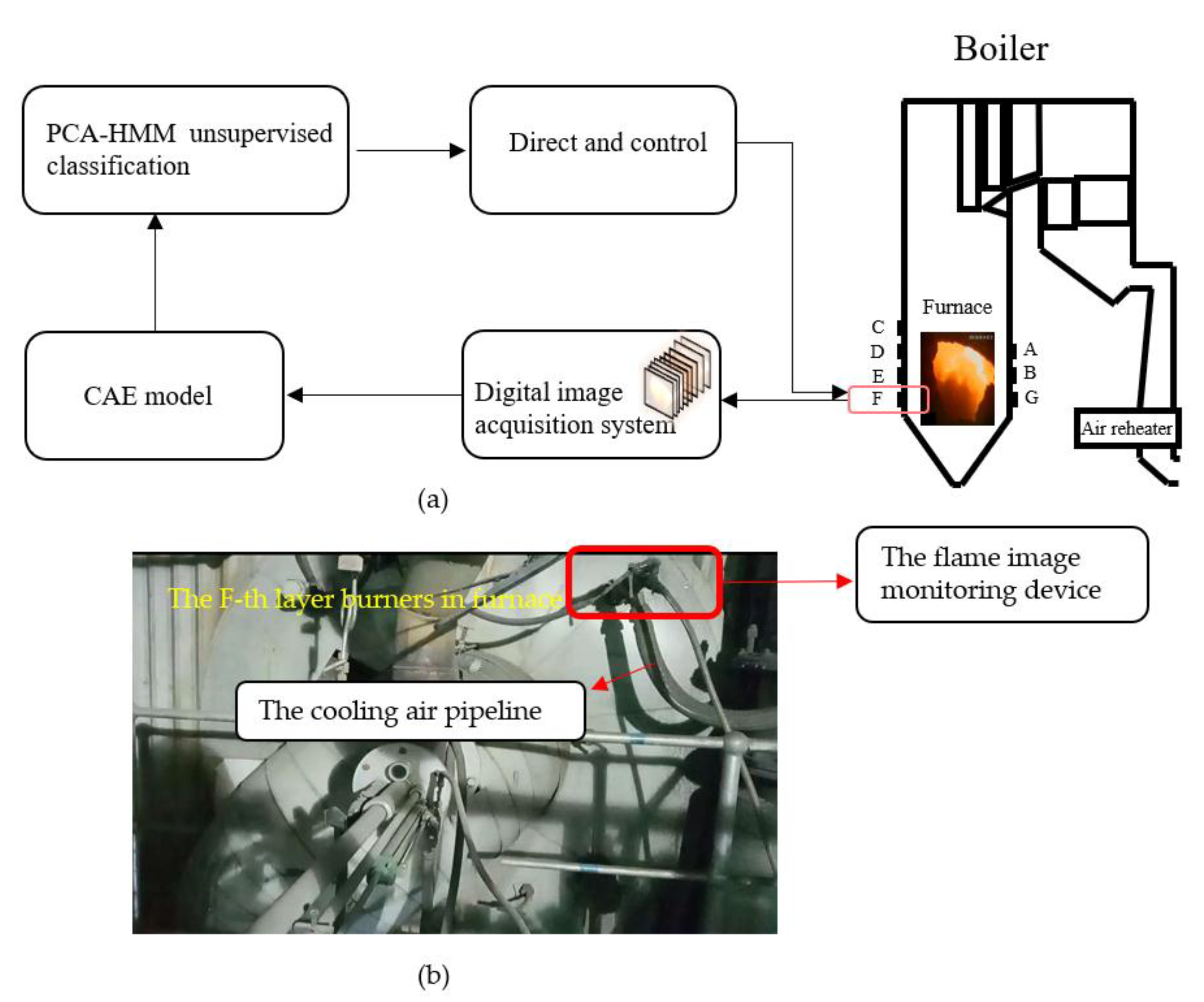

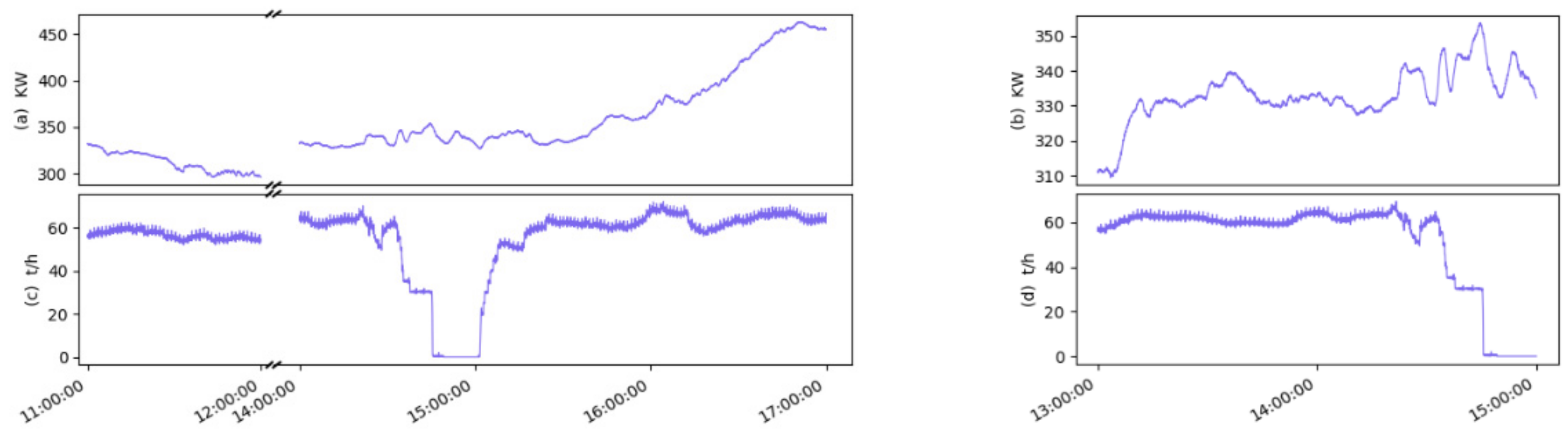

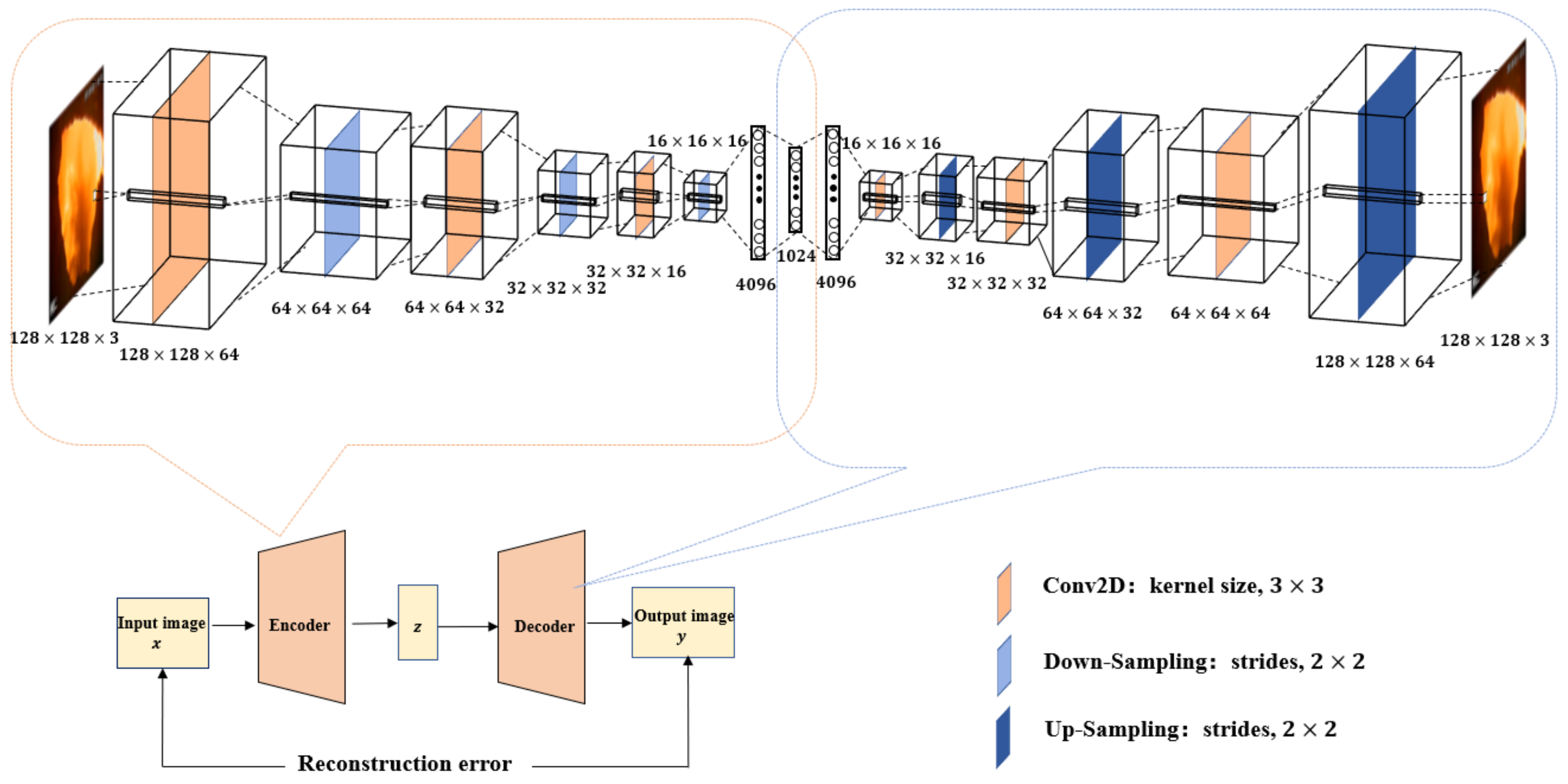

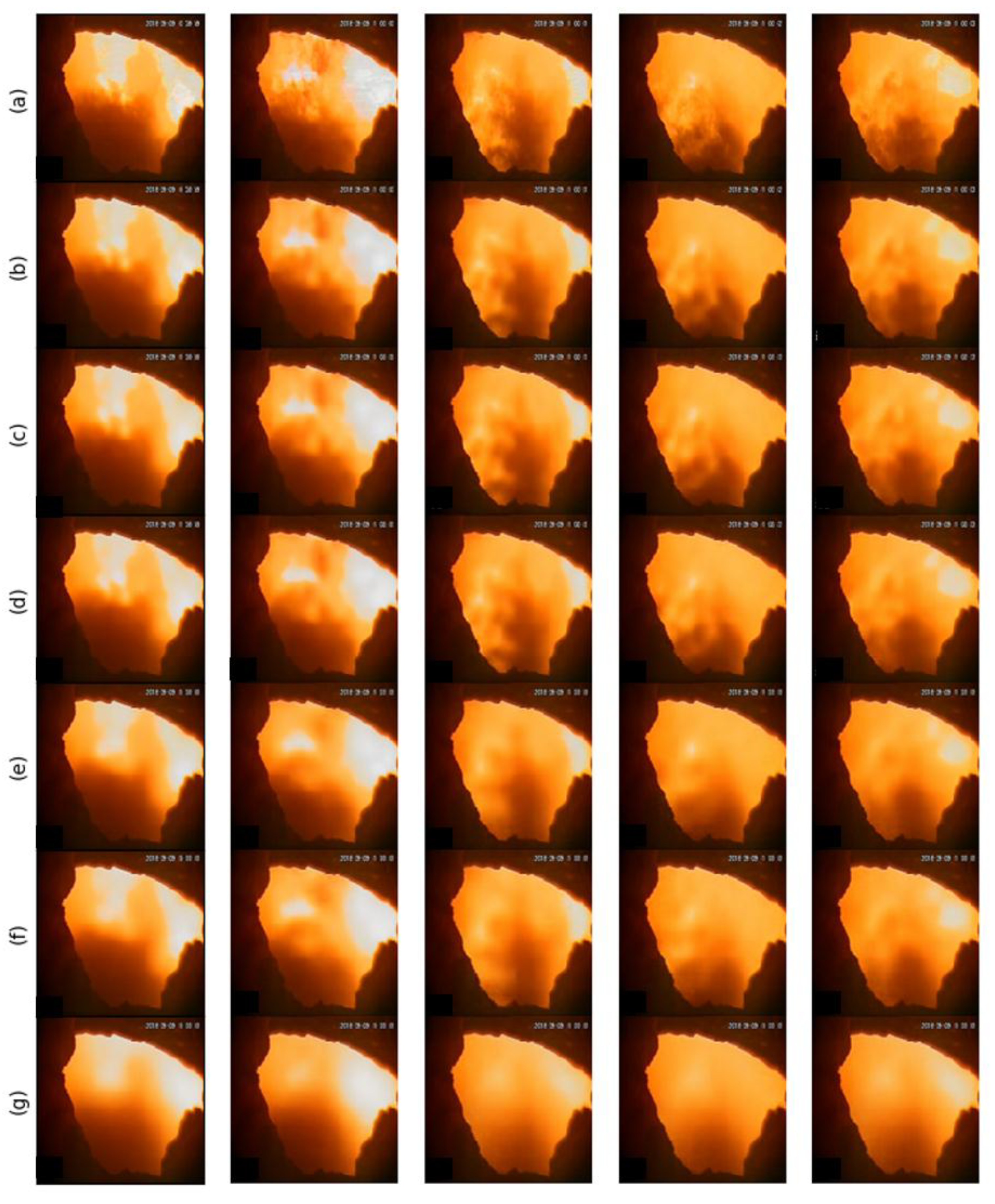

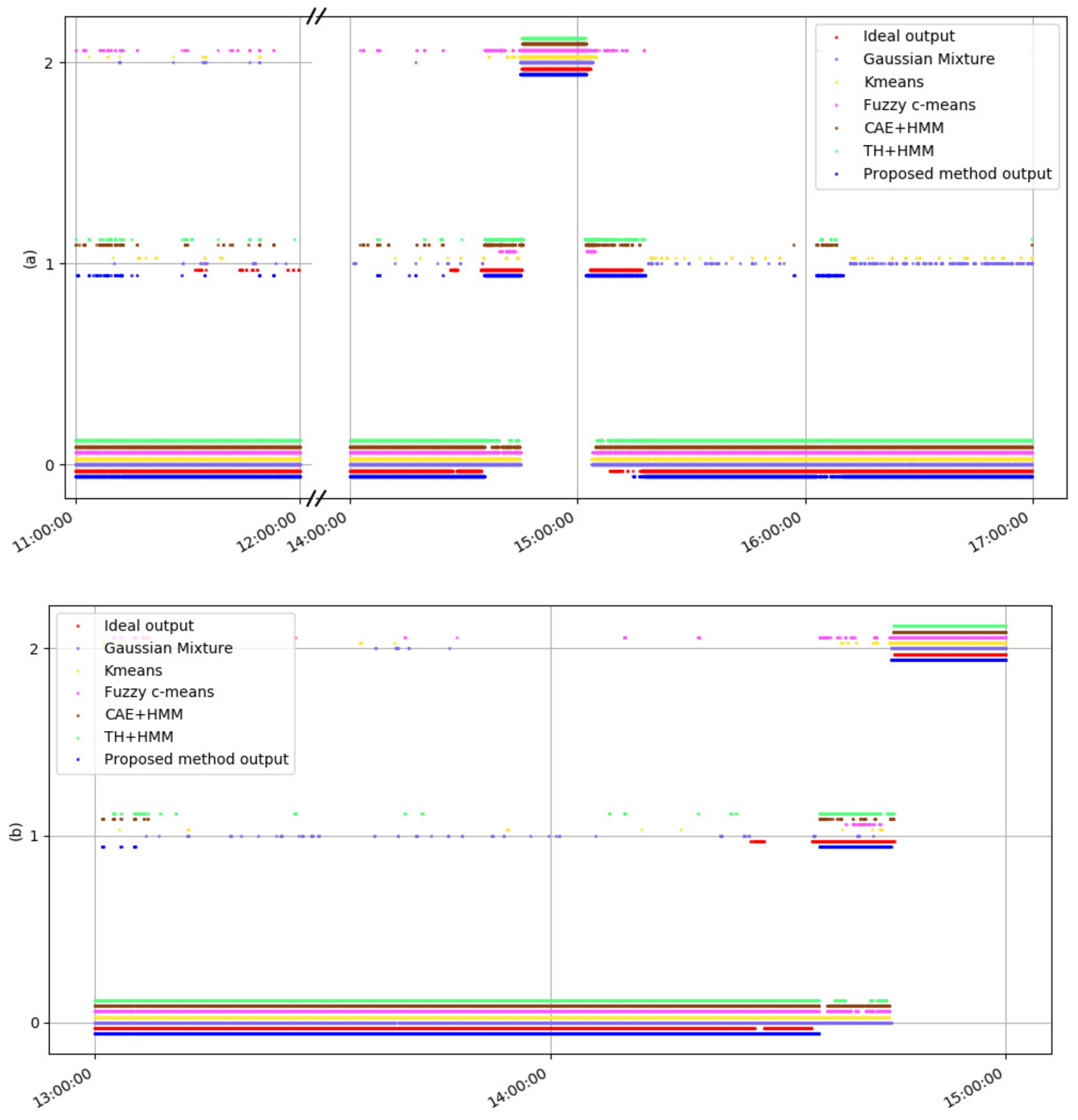

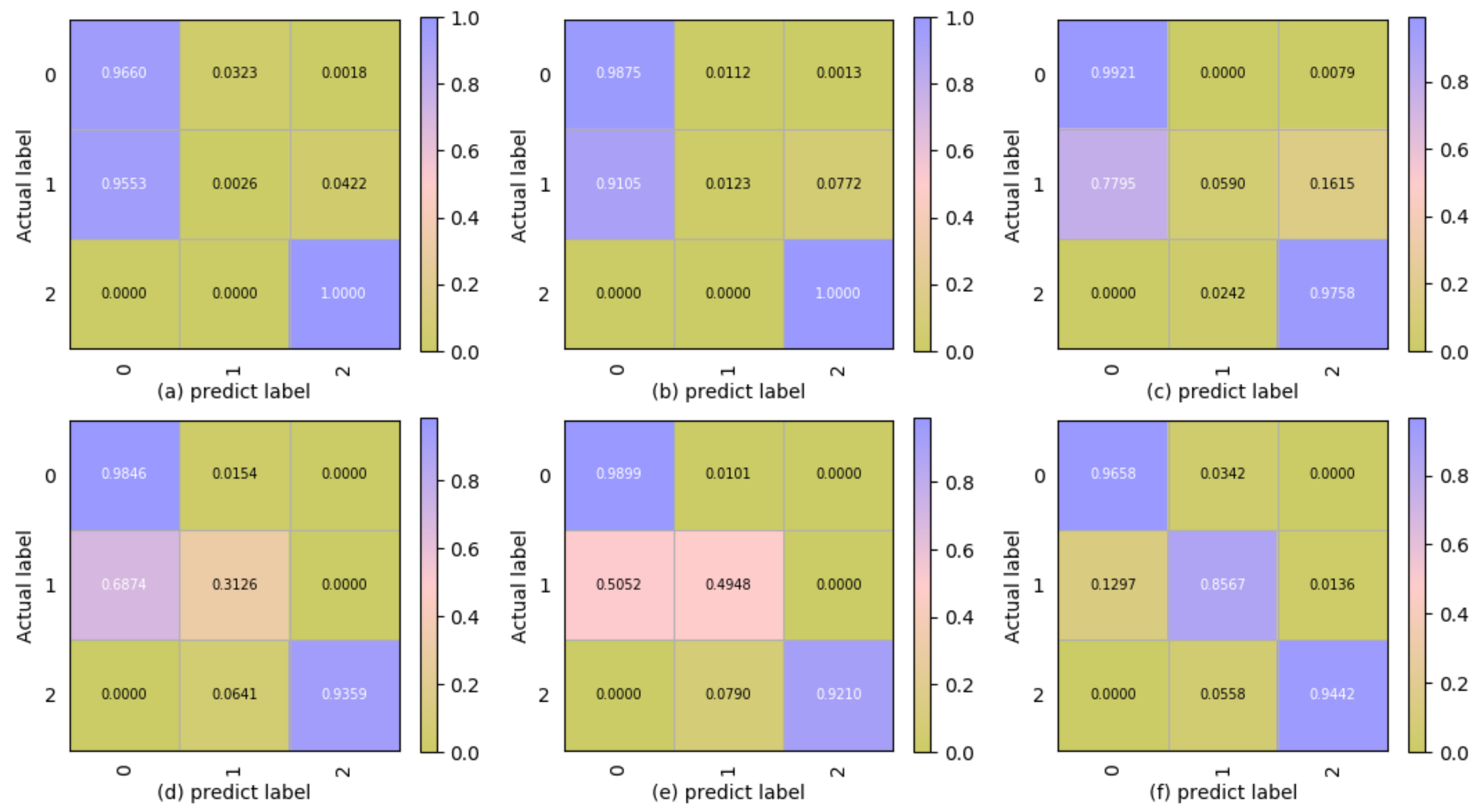

In this paper, we propose an unsupervised classification framework based on the convolutional auto-encoder (CAE), principal component analysis (PCA), and the hidden Markov model (HMM) for pulverized coal combustion status recognition with the uniformly spaced flame images. The effective characteristics of the flame images are retrieved with the CAE and then further compressed with PCA to obtain a set of orthogonal data. The hidden Markov model is built on the orthogonal data and applied to new flame images for combustion status recognition. In the framework, the CAE is applied to extract features from the flame images directly, which simplifies the whole feature extraction process compared with the hand-craft method; PCA is introduced to disentangle the latent space, in which the data exists as relevant relationships in a good representation subspace, to make the different features independent of each other; HMM is applied to capture the dynamic temporal behaviors, which are effective for combustion condition recognition. In this paper, six different compression dimensions of the latent variable z in the CAE model are compared to select the appropriate compress parameter. The framework is then tested with the flame images from a 660 MW thermal power plant and compared with other methods, including the CAE + Gaussian mixture model (GMM), CAE + Kmean, the CAE + fuzzy c-mean method, CAE + HMM, and the traditional handcraft feature extraction method (TH) + HMM, to verify the effectiveness of the proposed framework.

4. Conclusions

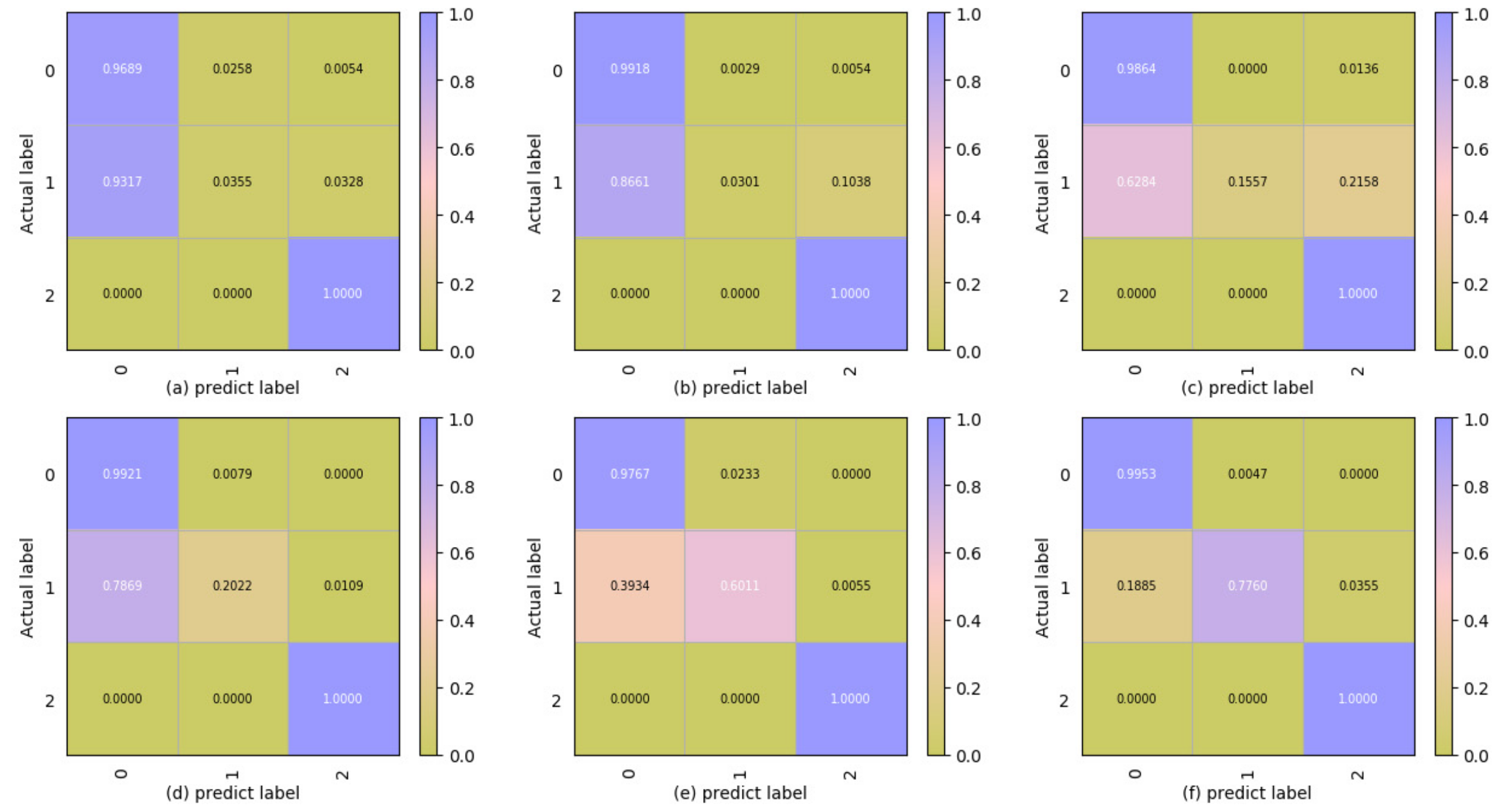

In this study, an unsupervised framework combined CAE, PCA, and HMM is proposed to classify the coal combustion status. First, we tested the influence of latent representation variables () in CAE with different dimensions on coal combustion adjustment experiment results, and was selected as the suitable parameter, which made the CAE contain the useful and sufficient features to closely reconstruct the input data. PCA was then applied to compress and de-nose the latent representation and to ensure that the vector components in the latent representation were independent and the computing was efficient. Finally, we adopted the HMM to learn and capture the sequence correlation in the combustion process.

In order to verify the effectiveness of the model, the coal rate was selected as the classification criteria of the combustion state, according to the combustion theory. The classification accuracy of the proposed framework on the training data and testing data were 95.25% and 97.36%, respectively. In particular, the proposed framework had better performance in recognising the semi-stable state (85.67% for the training samples and 77.60% for the testing samples), which is important for adjusting the combustion state in advance to avoid unstable combustion. It can therefore be concluded that the proposed framework not only simplifies the feature extraction process compared with manual image processing, but also provides an effective means for classifying the flame combustion status in an unsupervised way.