Status of Deep Borehole Disposal of High-Level Radioactive Waste in Germany

Abstract

:1. Introduction

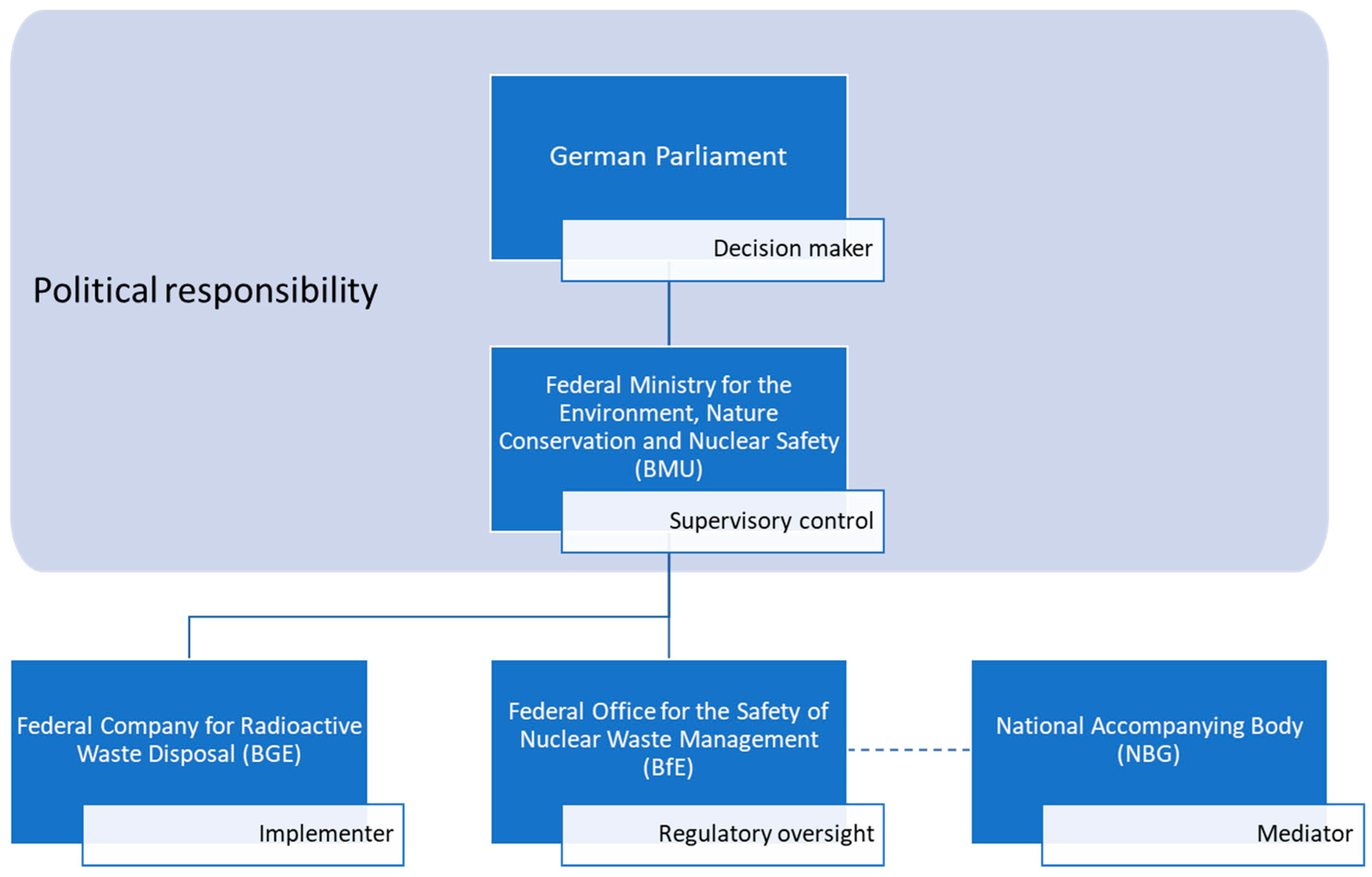

2. Regulatory Framework in Germany as of 2019

2.1. General

2.2. Site Selection Act

2.2.1. Actors in the Site Selection

- German Parliament

- Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (BMU)

- Federal Office for the Safety of Nuclear Waste Management (BfE)

- Federal Company for Radioactive Waste Disposal (BGE)

- National Accompanying Body (NBG)

2.2.2. Phases of the Site Selection Process

- Phase 1: Identification of possible regions

- Phase 2: Exploration from the surface

- Phase 3: Underground explorations and decision for a site

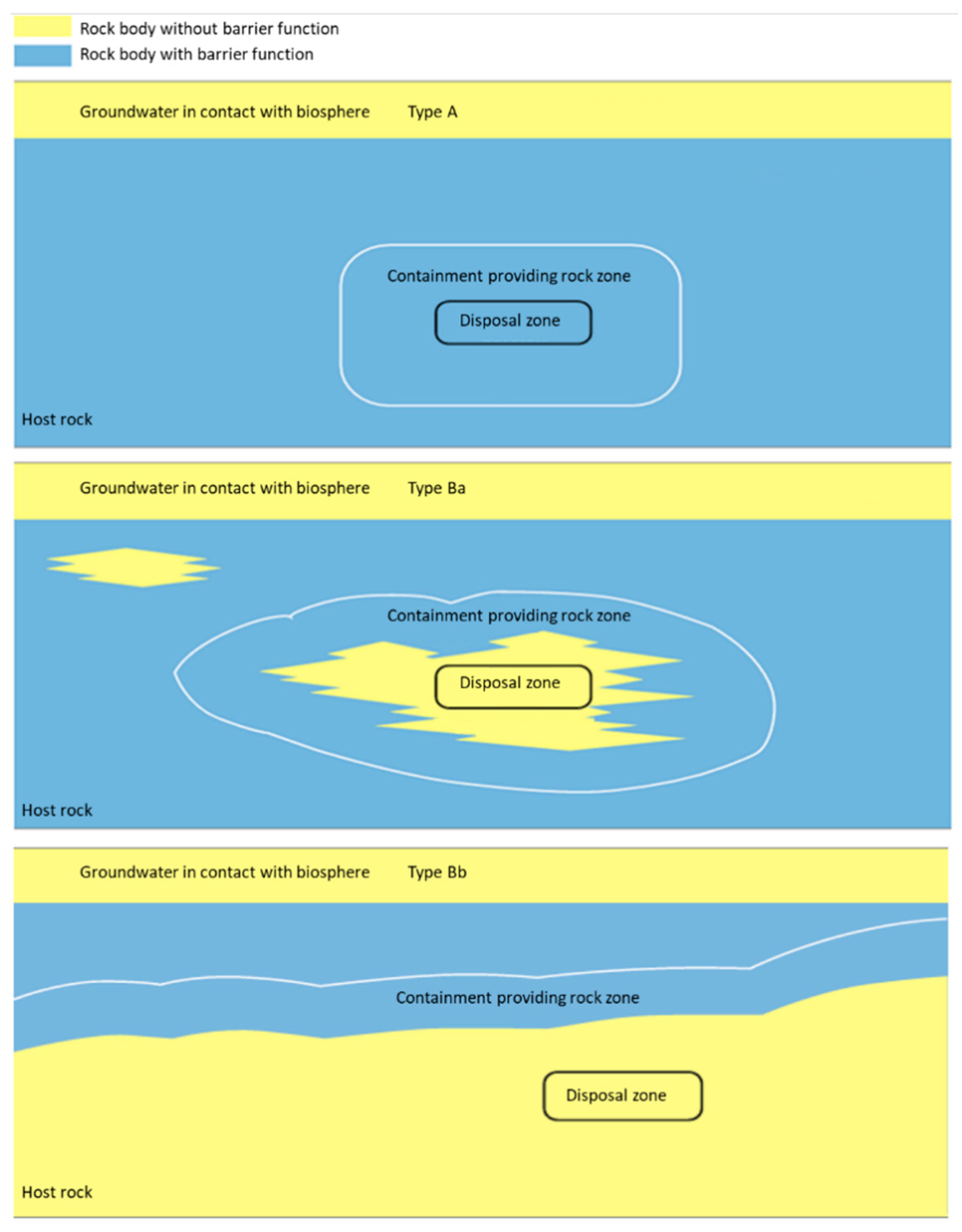

2.2.3. Containment Providing Rock Zone and Deep Borehole Disposal

2.2.4. Requirements, Criteria, Indicators

2.3. Safety Requirements and Safety Analyses

3. Geology in Germany

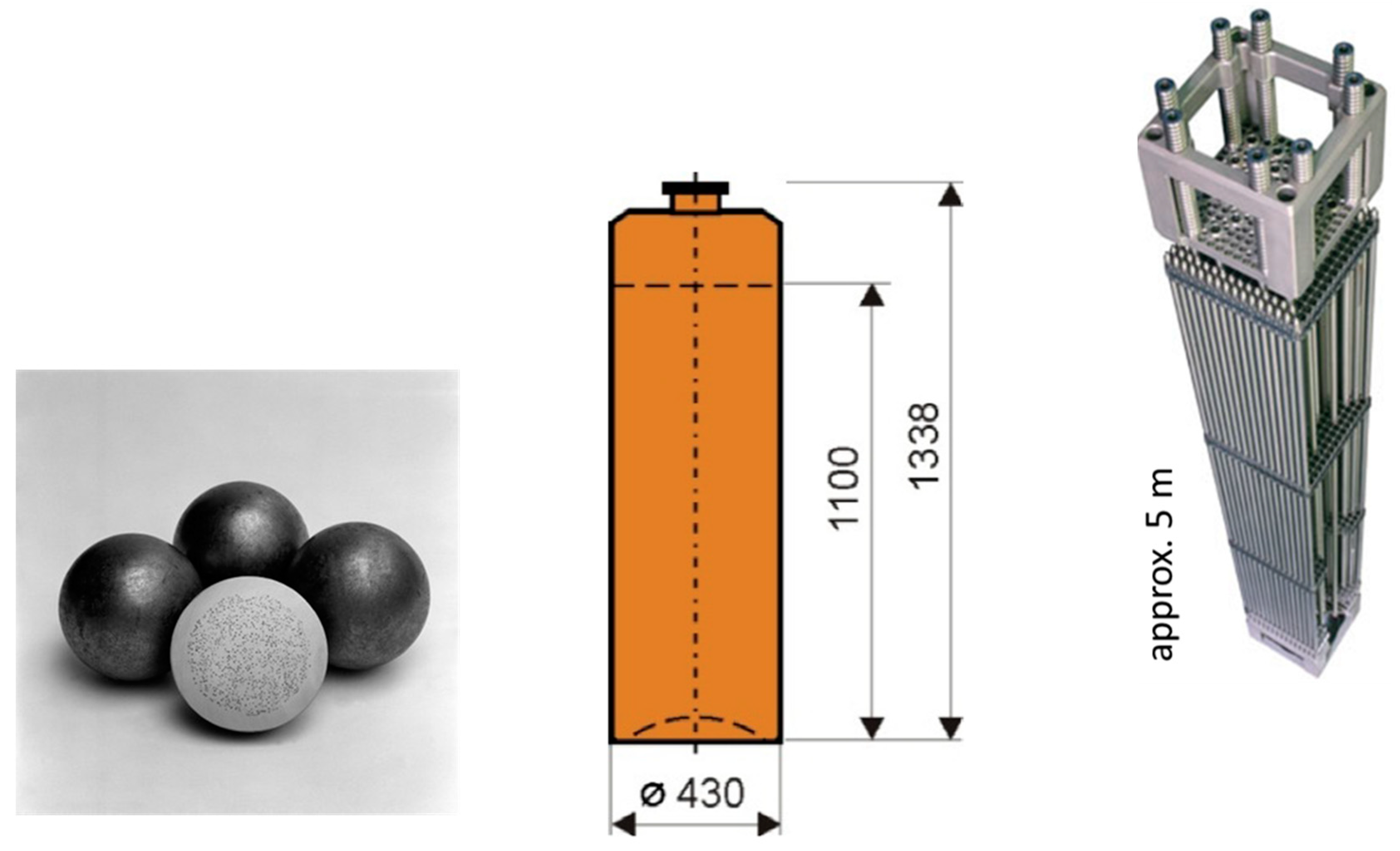

4. Inventory of High Level Radioactive Waste (HLRW) in Germany

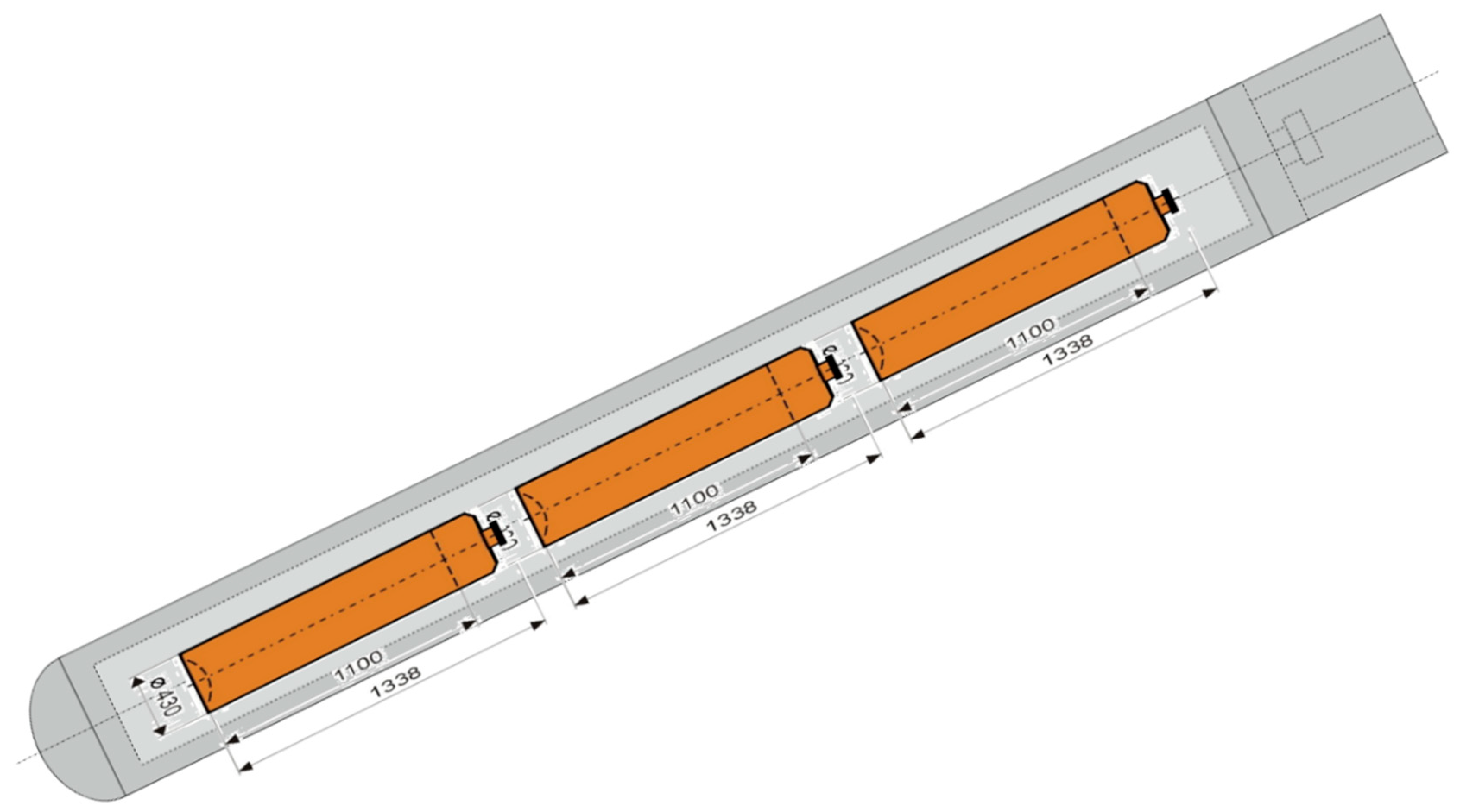

5. Drilling Technology and Its Consequences on the Disposal Concepts

6. Outline of a Concept for Deep Borehole Disposal in Germany

6.1. Safety Concept

- Clay rock: bedded clay which can ensure retardation and containment.

- Salt rock: bedded salt with high sealing capacity and self-sealing ability based on its visco-plastic characteristics.

6.2. Other Aspects for Concepts in Germany

- Disposal zone where containers are supposed to be disposed of

- Retention zone, which is the containment providing rock zone (CPRZ)

- Transfer zone to which the container must pass.

7. Discussion

8. Summary and Conclusions

9. Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chapman, N.; McCombie, C. Principles and Standards for the Disposal of Long-lived Radioactive Wastes; Elsevier Science Limited: Oxford, UK, 2003; ISBN 0080441920. [Google Scholar]

- Ojovan, M.I.; Lee, W.E. An Introduction to Nuclear Waste Immobilisation, 2nd ed.; Elsevier: Kidlington, UK; Oxford, UK; Waltham, MA, USA, 2014; ISBN 9780080993928. [Google Scholar]

- Geological Repository Systems for Safe Disposal of Spent Nuclear Fuels and radioactive Waste, 2nd ed.; Apted, M.J.; Ahn, J. (Eds.) Woodhead Publishing: Cambridge, UK, 2017; ISBN 9780081006528. [Google Scholar]

- International Atomic Energy Agency (IAEA). Scientific and Technical Basis for the Geological Disposal of Radioactive Waste; IAEA: Vienna, Austria, 2003; Technical Report Series STI/DOC/010/413. [Google Scholar]

- International Atomic Energy Agency. Selection of Technical Solutions for the Management of Radioactive Waste; IAEA: Vienna, Austria, 2017; ISBN 9789201047175. [Google Scholar]

- Beswick, A.J. Borehole Construction and Operation for Disposal in Crystalline Rocks. Radwaste Solut. 2017, 24, 28–32. [Google Scholar]

- Gibb, F.G.; Beswick, A.J.; Travis, K.P. Deep borehole disposal of nuclear waste: Engineering challenges. Proc. Inst. Civ. Eng.-Energy 2014, 167, 47–66. [Google Scholar] [CrossRef]

- Arnold, B.W.; Brady, P.V.; Sutton, M.; Travis, K.P.; MacKinnon, R.; Gibb, F.G.F.; Greenberg, H. Deep Borehole Disposal Research: Geological Evaluation, Alternative Wasteforms, and Borehole Seals; SAND2014-17430R; Sandia National Laboratorie: Albuquerque, NM, USA, 2014.

- Deep Isolation Technical Team. Technology—Deep Isolation. Available online: https://www.deepisolation.com/technology/ (accessed on 22 March 2019).

- Bollingerfehr, W.; Dieterichs, C.; Herold, M.; Kudla, W.; Reich, M.; Rosenzweig, T. Untersuchungen zu Chancen und Risiken der Endlagerung wärmeentwickelnder radioaktiver Abfälle und ausgedienter Brennelemente in Tiefen Bohrlöchern (CREATIEF). Abschlussbericht. 2018. Available online: https://www.tib.eu/suchen/download/?tx_tibsearch_search%5Bdocid%5D=TIBKAT%3A1039255396&cHash=0c55080f07884c822286779dc663cd81#download-mark (accessed on 3 July 2019).

- Bracke, G.; Hurst, S.; Merkel, B.; Müller, B.; Schilling, F. Final disposal in deep boreholes using multiple geological barriers. Digging deeper for safety. In Proceedings of the Workshop Final Disposal in Deep Boreholes Using Multiple Geological Barriers: Digging Deeper for Safety, Berlin, Germany, 5–6 June 2015; Bracke, G., Hurst, S., Merkel, B., Müller, B., Schilling, F., Eds.; Gesellschaft fuer Anlagen-und Reaktorsicherheit mbH: Köln, Germany, 2016. ISBN 978-3-944161-87-7. [Google Scholar]

- Bracke, G. Endlagerkonzept einer tiefen Bohrlochlagerung (Deutschland). In Anforderungen an aktuelle Endlagerkonzepte für unterschiedliche Wirtsgesteinsformationen; Bericht zum Arbeitspaket 1 GRS-471 Anhang 7; Gesellschaft fuer Anlagen-und Reaktorsicherheit mbH: Cologne, Germany, 2017. [Google Scholar]

- Bracke, G.; Charlier, F.; Liebscher, A.; Schilling, F.; Röckel, T. Does Deep Borehole Disposal of HLRW has a Chance in Germany? Atw—Int. Z. für Kernenerg. 2017, 62, 46–53. [Google Scholar]

- Gesetz über die friedliche Verwendung der Kernenergie und den Schutz gegen ihre Gefahren: AtG. In Gesetz über die friedliche Verwendung der Kernenergie und den Schutz gegen ihre Gefahren: Atomgesetz—AtG; Bundesgesetzblatt Teil I: Bonn, Germany, 2018; pp. 1122–1124.

- Arbeitskreis Auswahlverfahren Endlagerstandorte (AkEnd). Auswahlverfahren für Endlagerstandorte. Empfehlungen des AkEnd; Abschlussbericht; Bundesamt für Strahlenschutz (BfS): Köln, Germany, 2002; Available online: https://doris.bfs.de/jspui/handle/urn:nbn:de:0221-201111176633 (accessed on 3 July 2019).

- Gesetz zur Suche und Auswahl eines Standortes für ein Endlager für Wärme entwickelnde radioaktive Abfälle: Standortauswahlgesetz—StandAG. In Gesetz zur Suche und Auswahl eines Standortes für ein Endlager für Wärme entwickelnde radioaktive Abfälle: Standortauswahlgesetz—StandAG; Bundesgesetzblatt Teil I: Bonn, Germany, 2013; pp. 2553–2561.

- Kommission Lagerung hoch radioaktiver Abfallstoffe. Abschlussbericht. Verantwortung für Die Zukunft—Ein Faires und Transparentes Verfahren für Die Auswahl Eines Nationalen Endlagerstandortes; Drucksache der Kommission Lagerung hoch radioaktiver Abfallstoffe K-Drs. 268, 2016. Available online: https://www.bundestag.de/blob/434430/bb37b21b8e1e7e049ace5db6b2f949b2/drs_268-data.pdf (accessed on 24 January 2019).

- Gesetz zur Suche und Auswahl eines Standortes für ein Endlager für hochradioaktive Abfälle: Standortauswahlgesetz—StandAG. In Gesetz zur Suche und Auswahl eines Standortes für ein Endlager für hochradioaktive Abfälle: Standortauswahlgesetz—StandAG; Bundesgesetzblatt Teil I: Bonn, Germany, 2017; pp. 2808–2838.

- Gesetz zur Errichtung eines Fonds zur Finanzierung der kerntechnischen Entsorgung (Entsorgungsfondsgesetz-EntsorgFondsG). EntsorgFondsG; Bundesgesetzblatt Teil I: Bonn, Germany, 2017; pp. 114–129.

- Bracke, G.; Weyand, T.; Hartwig-Thurat, E.; Meleshyn, A.; Larue, J.; Fischer-Appelt, K. Untersuchungen zu den “maximalen physikalisch möglichen Temperaturen” gemäß § 27 StandAG im Hinblick auf die Grenztemperatur an der Außenfläche von Abfallbehältern. 1. Statuskonferenz Endlagerung von hochradioaktiven Abfällen, 2018. Available online: https://www.bfe.bund.de/SharedDocs/Downloads/BfE/DE/fachinfo/soa/18110809_Statuskonferenz_Poster_Forschungsvorhaben_BfE.pdf?__blob=publicationFile&v=3 (accessed on 25 June 2019).

- Federal Ministry for the Environment, Nature Conversation and Nuclear Safety (BMU). Safety Requirements Governing the Final Disposal of Heat-Generating Radioactive Waste; Federal Ministry for the Environment, Nature Conversation and Nuclear Safety (BMU): Bonn, Germany, 2010. [Google Scholar]

- Bräuer, V.; Reh, M.; Schulz, P.; Schuster, P.; Sprado, K.-H. Endlagerung stark wärmeentwickelnder radioaktiver Abfälle in tiefen geologischen Formationen Deutschlands.-Untersuchung und Bewertung von Regionen in nichtsalinaren Formationen; Bundesanstalt für Geowissenschaften und Rohstoffe (BGR): Hannover, Germany, 1994; Archiv-Nr.: 112642; 2025039; Tgb.-Nr.: 12437/91. [Google Scholar]

- Jobmann, M.; Becker, D.-A.; Hammer, J.; Jahn, S.; Lommerzheim, A.; Müller-Hoeppe, N.; Noseck, U.; Krone, J.; Weber, J.R.; Weitkamp, A.; et al. Projekt CHRISTA: Machbarkeitsuntersuchung zur Entwicklung einer Sicherheits- und Nachweismethodik für ein Endlager für Wärme entwickelnde radioaktive Abfälle im Kristallingestein in Deutschland TEC-20-2016-AB, 2016. Available online: https://www.dbe-technology.de/fileadmin/user_upload/unterlagen/f_e_berichte/CHRISTA-Projekt_Abschlussbericht.pdf (accessed on 27 March 2018).

- Reinhold, K.; Hammer, J.; Pusch, M. Verbreitung und Eigenschaften flach lagernder Salzschichten in Deutschland (BASAL). Verbreitung, Zusammensetzung und geologische Lagerungsverhältnisse flach lagernder Steinsalzfolgen in Deutschland—Zwischenbericht 9Y2013030000, 2014. Available online: https://www.bgr.bund.de/DE/Themen/Endlagerung/Downloads/Charakterisierung_Wirtsgesteine_geotech_Barrieren/2_Steinsalz/2014-12-10_BGR_Basal_ZB_Verbreitung_Eigenschaften.pdf?__blob=publicationFile&v=3 (accessed on 25 June 2019).

- Hoth, P.; Wirth, H.; Reinhold, K.; Bräuer, V.; Krull, P.; Feldrappe, H. Endlagerung radioaktiver Abfälle in tiefen geologischen Formationen Deutschlands. Untersuchung und Bewertung von Tongesteinsformationen. 2007. Available online: https://www.bgr.bund.de/DE/Themen/Endlagerung/Downloads/Charakterisierung_Wirtsgesteine_geotech_Barrieren/1_Tongestein/2007-04-00_BGR_Tonstudie2007.pdf?__blob=publicationFile&v=6 (accessed on 3 July 2019).

- Schreiber, U.; Jentzsch, G.; Ewert, T. Geologische Potentiale zur Einlagerung von radioaktiven Abfallstoffen unterhalb von stratiformen Salzformationen. Konzeptstudie für ein alternatives Endlagermodell. Material für die Kommission Lagerung hoch radioaktiver Abfallstoffe K-MAT 42, 2015. Available online: https://www.bundestag.de/endlager-archiv/blob/395402/f31ce26e4e7fc8528c956bd5986fce75/kmat_42-data.pdf (accessed on 23 June 2019).

- Birgersson, L. The barriers in the KBS-3 repository in Forsmark. SKB Public Report No. 1520261, 2015. Available online: http://www.skb.se/wp-content/uploads/2016/01/D-The-barriers-in-the-KBS-3-repository-in-Forsmark.pdf (accessed on 16 November 2017).

- Bracke, G.; Fischer-Appelt, K. Methodological approach to a safety analysis of radioactive waste disposal in rock salt: An example. Prog. Nucl. Energy 2015, 84, 79–88. [Google Scholar] [CrossRef]

- Peiffer, F.; McStocker, B.; Gründler, D.; Ewig, F.; Thomauske, B.; Havenith, A.; Kettler, J. Abfallspezifikation und Mengengerüst. In Basis Ausstieg aus der Kernenergienutzung (Juli 2011). Bericht zum Arbeitspaket 3, Vorläufige Sicherheitsanalyse für den Standort Gorleben; Gesellschaft für Anlagen—und Reaktorsicherheit (GRS) mbH: Köln, Germany, 2011; ISBN 978-3-939355-54-0. [Google Scholar]

- Federal Ministry for the Environment, Nature Conversation, Building and Nuclear Safety (BMUB). Joint Convention on the Safety of Spent Fuel Management and on the Safety of Radioactive Waste Management. In Report of the Federal Republic of Germany for the Sixth Review Meeting; Federal Ministry for the Environment, Nature Conversation, Building and Nuclear Safety (BMUB): Bonn, Germany, 2018. [Google Scholar]

- Bundesministerium für Umwelt, Naturschutz, Bau und Reaktorsicherheit (BMUB). Verzeichnis radioaktiver Abfälle. Bestand zum 31. Dezember 2017 und Prognose; Bundesministerium für Umwelt, Naturschutz, Bau und Reaktorsicherheit (BMUB): Bonn, Germany, 2018. [Google Scholar]

- Ewing, R.C.; Bahr, J.M.; Becker, S.M.; Brantley, S.L.; Croff, A.G.; Foufoula-Georgiou, E.; Frankel, G.S.; Nozick, L.K.; Peddicord, K.L.; Turinsky, P.J.; et al. Technical Evaluation of the U.S. Department of Energy Deep Borehole Disposal Research and Development Program. A Report to the U.S. Congress and the Secretary of Energy, 2016. Available online: https://www.nwtrb.gov/docs/default-source/reports/dbd_final.pdf?sfvrsn=7 (accessed on 25 June 2019).

- Hardin, E.L. Deep Borehole Field Test. Requirements and Controlled Assumptions; SANDIA Report SAND2015-6009, 2015. Available online: https://prod-ng.sandia.gov/techlib-noauth/access-control.cgi/2015/156009.pdf (accessed on 24 June 2019).

- Rigali, M.J.; Hardin, E.L.; Stein, E.R.; Su, J.C. Large Diameter Deep Borehole Disposal Concept for HLW Glass. In Proceedings of the International High-Level Radioactive Waste Management Conference, Charlotte, NC, USA, 9–13 April 2017; pp. 536–546. [Google Scholar]

- Heidelberger, C.A. Energy Dept. Cancels Deep Borehole Field Test. Available online: https://dakotafreepress.com/2017/05/23/energy-dept-cancels-deep-borehole-field-test/ (accessed on 24 June 2019).

- Bracke, G.; Charlier, F.; Geckeis, H.; Harms, U.; Heidbach, O.; Kienzler, B.; Liebscher, A.; Müller, B.; Prevedel, B.; Röckel, T. Tiefe Bohrlöcher; Gesellschaft für Anlagen- und Reaktorsicherheit (GRS) gGmbH: Köln, Germany, 2016; ISBN 9783946607052. [Google Scholar]

- Bracke, G.; Charlier, F.; Liebscher, A.; Schilling, F.; Röckel, T. About the Possibility of Disposal of HLRW in Deep Boreholes in Germany. Geosciences 2017, 7, 58. [Google Scholar] [CrossRef]

- Fonds zur Finanzierung der kerntechnischen Entsorgung. Available online: http://www.entsorgungsfonds.de/ (accessed on 23 June 2019).

- Arnold, B.W.; Brady, P.V.; Bauer, S.J.; Herrick, C.; Pye, S.; Finger, J. Reference Design and Operations for Deep Borehole Disposal of High.-Level Radioactive Waste SAND2011-6749, 2011. Available online: https://prod-ng.sandia.gov/techlib-noauth/access-control.cgi/2011/116749.pdf (accessed on 25 June 2019).

- Freeze, G.A.; Stein, E.; Brady, P.V. Post-Closure Performance Assessment for Deep Borehole Disposal of Cs/Sr Capsules. Energies 2019, 12, 1980. [Google Scholar] [CrossRef]

| Requirement | Comments by the Authors Regarding DBD | |

|---|---|---|

| 1. | No or slow transport with groundwater in the CPRZ | Achievable |

| 2. | Favorable configuration of rock body, host rock and CPRZ | Achievable |

| 3. | Good spatial characterization | Tools to characterize host rock properties are available for greater depths but may pose a larger effort compared to lower depth. The volume of rock to be characterized for a CPRZ for DBD may be lower than for a repository depending on the concept. |

| 4. | Good predictability of the long-term stability of favorable conditions | Achievable |

| Requirement | Comment by the Author Regarding DBD | |

|---|---|---|

| 1. | Favorable rock mechanics | Achievable |

| 2. | Low tendency to generation of groundwater flows in host rock and CPRZ | Achievable |

| Requirement | Comment Regarding DBD | |

|---|---|---|

| 1. | Protective composition of overlying rocks | Achievable |

| 2. | Good conditions to avoid or minimize gas generation | The draft concept for container and casing is using steel, which will inevitably lead to gas generation. Gas generation may be minimized or slowed down by choice of suitable borehole fluid or cementation of containers. A future concept may also minimize the use of steel or may provide physical gas traps. Gas generation cannot be completely avoided. |

| 3. | Good temperature compatibility | The temperature in the disposal zone will be higher than 100 °C due to the depth. Any safety analyses must consider the temperatures and its compatibility for DBD. |

| 4. | High radionuclide retention capability of CPRZ | Achievable |

| 5. | Favorable hydrochemistry | Achievable |

| Concept # | 1 * [10] | 2 [10] | 3 [36,37] |

|---|---|---|---|

| Diameter of borehole | 17.5″/44.5 cm | 35.4″/90 cm | 29.5″/75 cm |

| Maximum depth of borehole | 5000 m | 5000 m | 3500 m |

| Disposal zone | 3000–5000 m | 3000–5000 m | 1500–3500 m |

| Space for cementation | 44.5 mm | 44 mm | 25 mm |

| Outer diameter of casing | 14″/356 mm | 32″/812 mm | 27.6″/700 mm |

| Wall thickness of casing | 21.6 mm | 63.5 mm | 62.5 mm |

| Space between casing and container | 24 mm | 25 mm | 25 mm |

| Outer diameter of container | 265 mm | 635 mm | 525 mm |

| Inner diameter of container | 175 mm | 435 mm | 435 mm |

| Wall thickness of container | 45 mm | 100 mm | 45 mm |

| Length of container | 5.6 m | 5.6 m | 5.6 m |

| Number of containers | 27,000 | 11,000 | 11,000 |

| Number of containers per borehole | 180 | 356 | 356 |

| Minimum number of boreholes | 150 | 31 | 31 |

| Task | Number | Costs | Sum |

|---|---|---|---|

| Feasibility Demonstration | 1 | 500 Mio €/each | 0.50 billion € |

| Site Selection and Exploration | 5 | 200 Mio €/each | 1.00 billion € |

| Borehole | 35 | 50 Mio €/each | 1.75 billion € |

| Containers | 11,000 | 0.1 Mio €/each | 1.10 billion € |

| Reconditioning | 1 | 1 Billion € | 1.00 billion € |

| Installation and Operating Costs | 35/2 years | 50 Mio €/each | 3.50 billion € |

| Licensing/safety analyses | 35 | 5 Mio € /each | 0.175 billion € |

| Total | - | - | 9.025 billion € |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bracke, G.; Kudla, W.; Rosenzweig, T. Status of Deep Borehole Disposal of High-Level Radioactive Waste in Germany. Energies 2019, 12, 2580. https://doi.org/10.3390/en12132580

Bracke G, Kudla W, Rosenzweig T. Status of Deep Borehole Disposal of High-Level Radioactive Waste in Germany. Energies. 2019; 12(13):2580. https://doi.org/10.3390/en12132580

Chicago/Turabian StyleBracke, Guido, Wolfram Kudla, and Tino Rosenzweig. 2019. "Status of Deep Borehole Disposal of High-Level Radioactive Waste in Germany" Energies 12, no. 13: 2580. https://doi.org/10.3390/en12132580

APA StyleBracke, G., Kudla, W., & Rosenzweig, T. (2019). Status of Deep Borehole Disposal of High-Level Radioactive Waste in Germany. Energies, 12(13), 2580. https://doi.org/10.3390/en12132580