Power Generation Performance of Building-Integrated Photovoltaic Systems in a Zero Energy Building

Abstract

1. Introduction

2. Overview of the Carbon Zero Building

3. BIPV Systems in the Carbon Zero Building

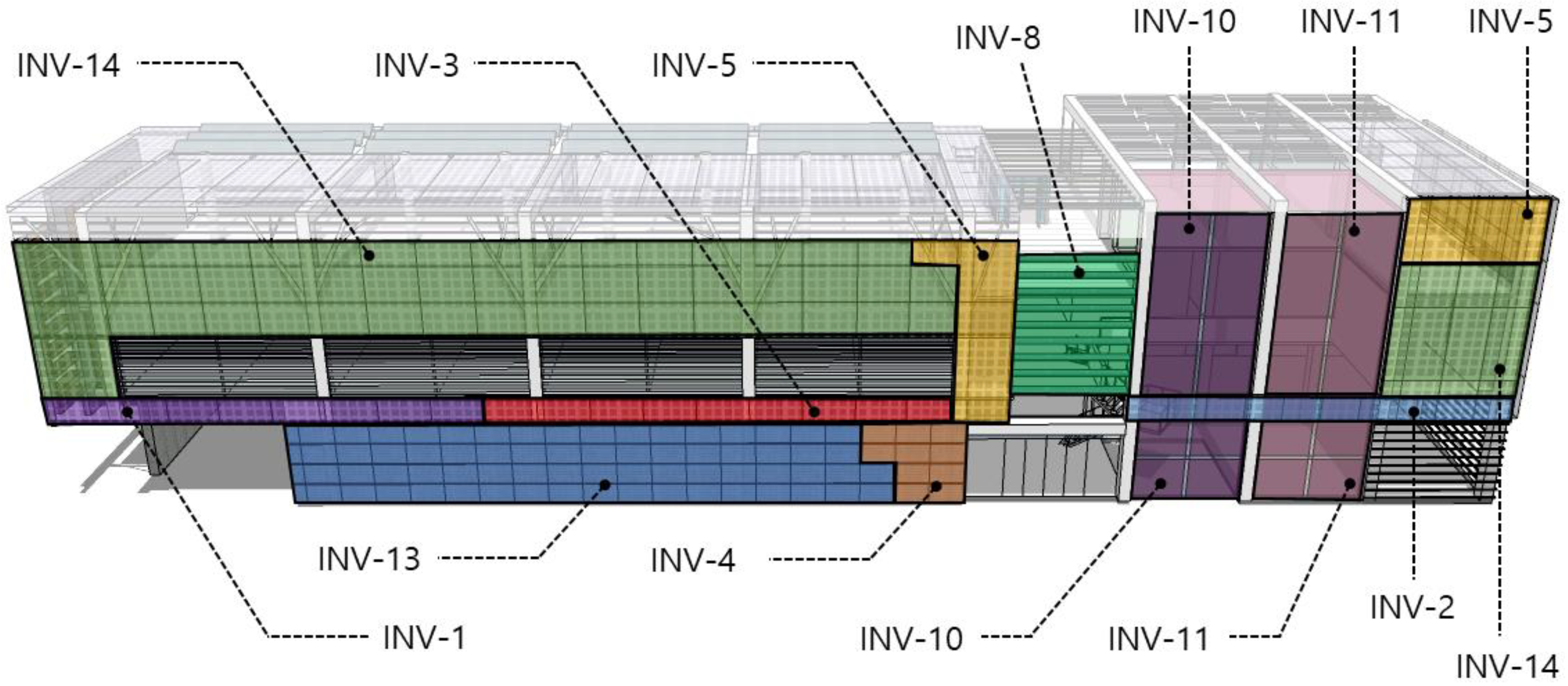

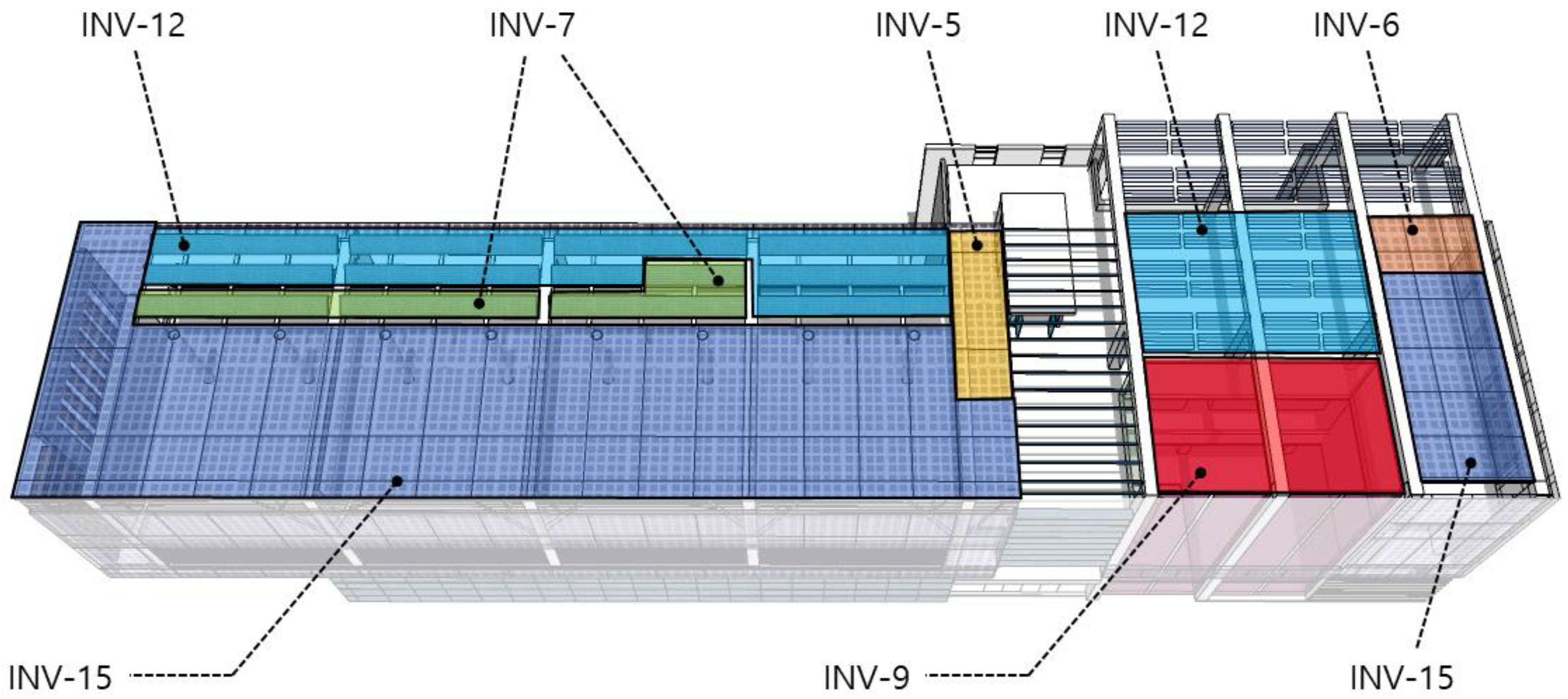

3.1. BIPV Systems

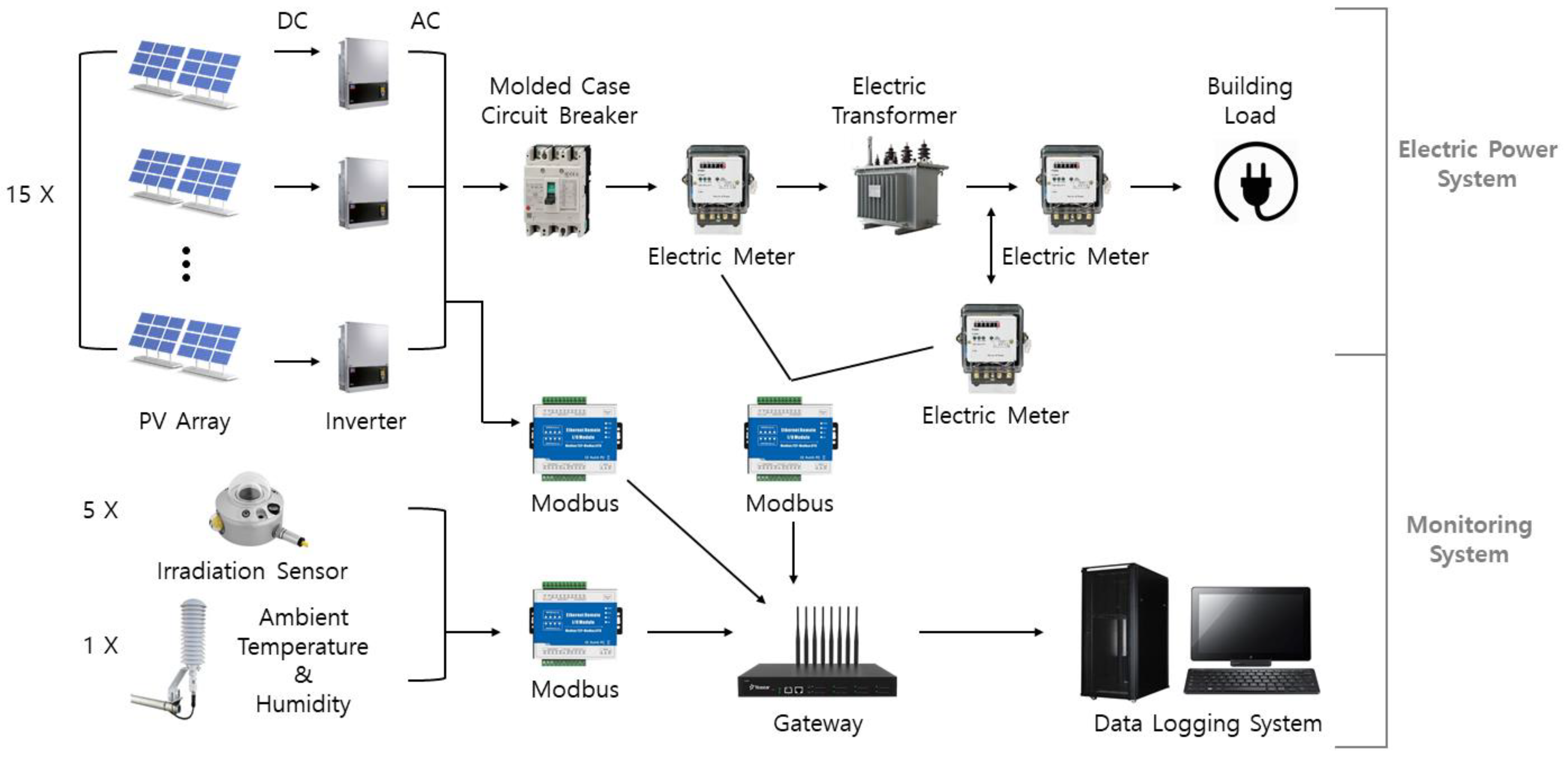

3.2. Monitoring System

4. BIPV System Performance Analysis

4.1. Data Analysis Period

4.2. Data Analysis Method

5. BIPV System Performance Results

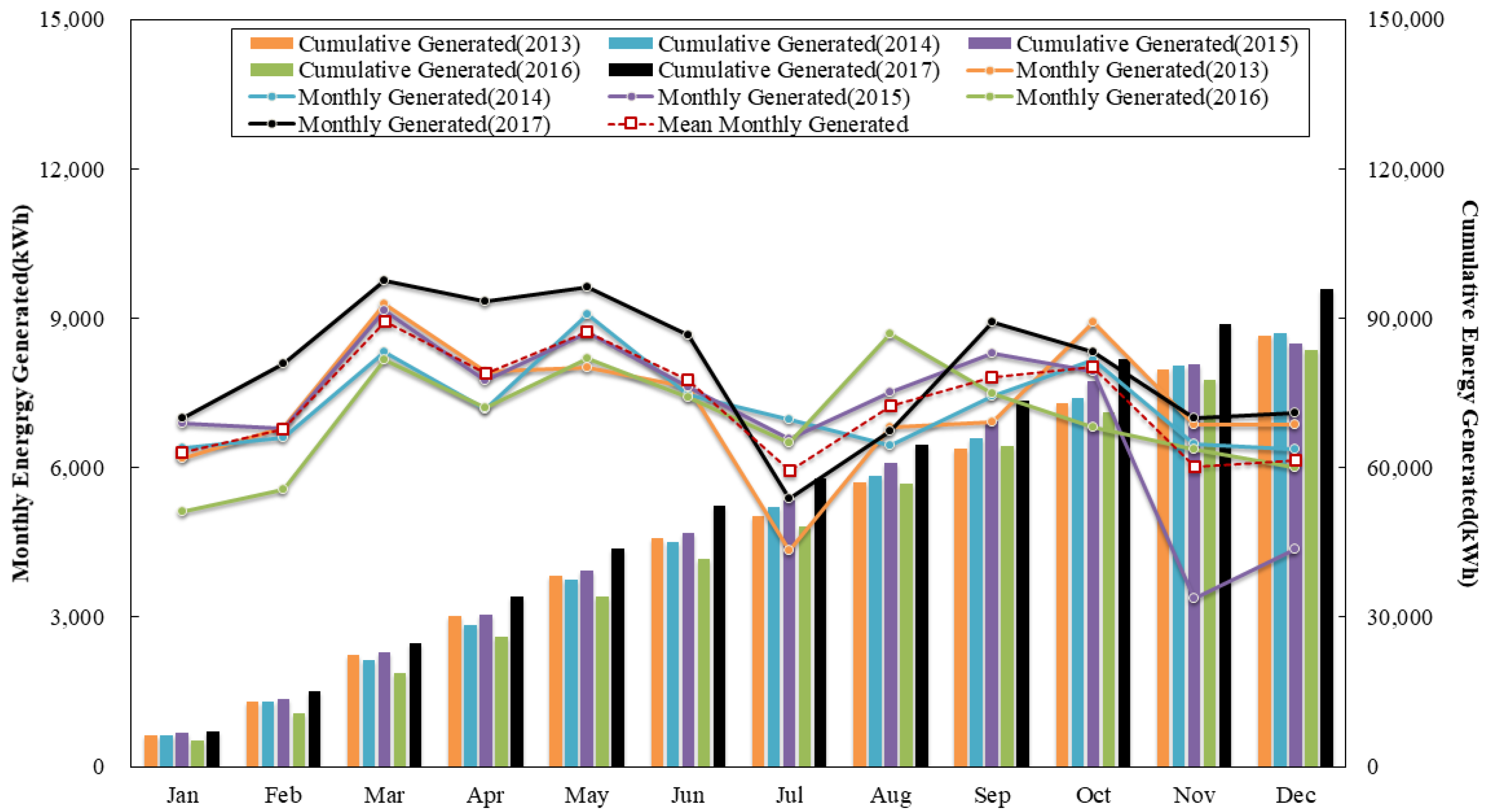

5.1. Total Energy Production of the BIPV Systems

5.2. Comparison between Planned and Actual Energy Production of the BIPV Systems

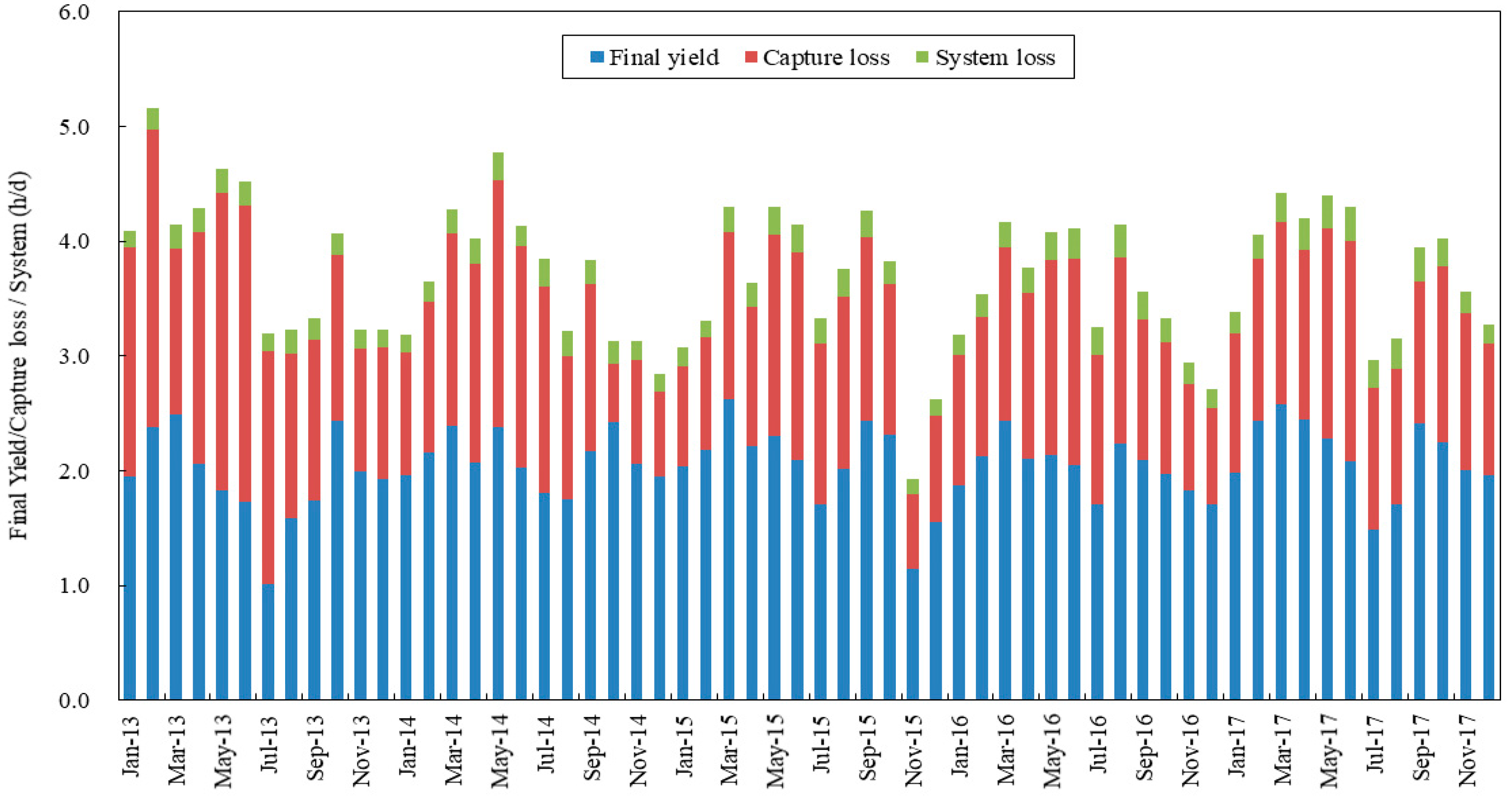

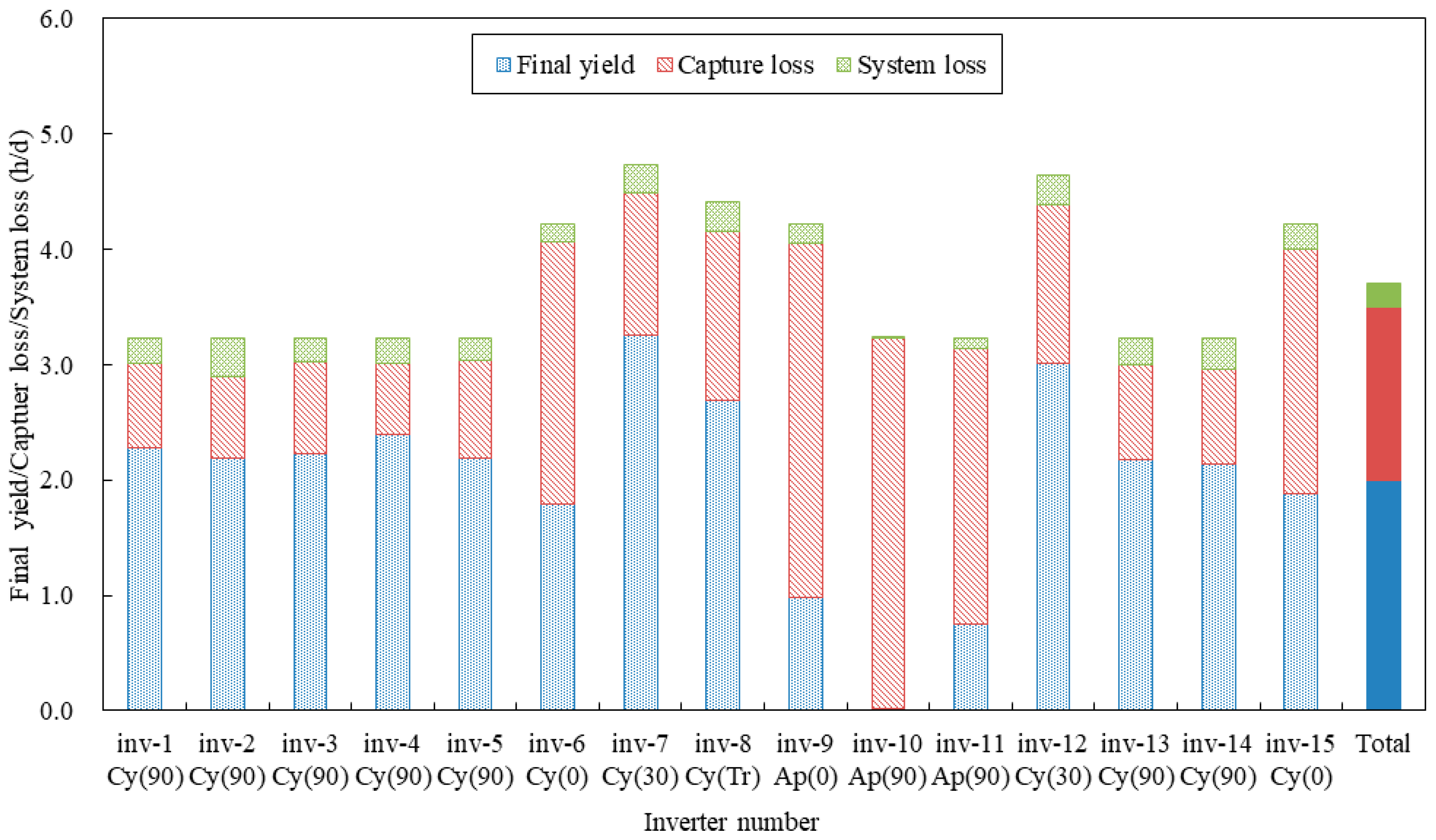

5.3. Yields and Losses of the BIPV Systems

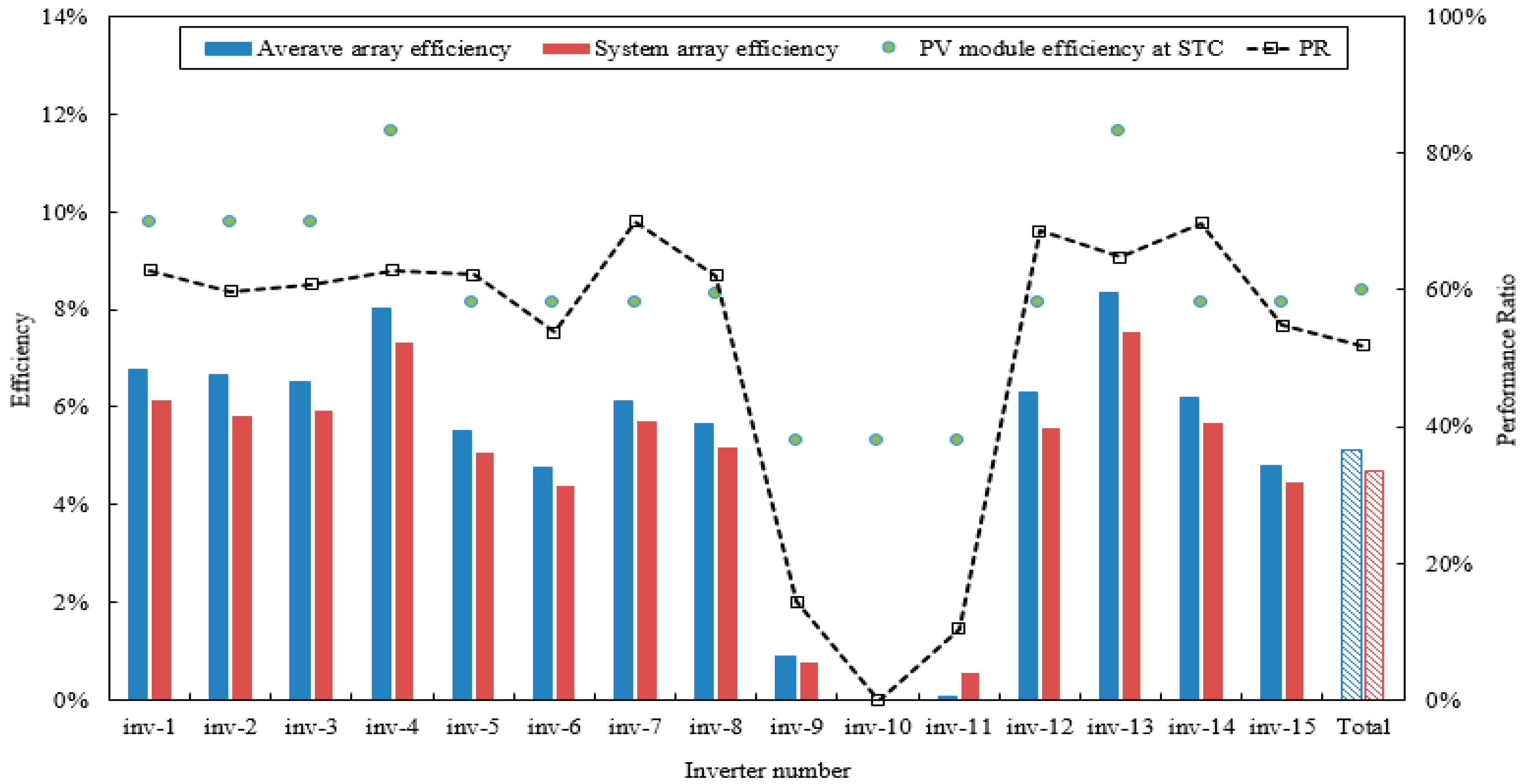

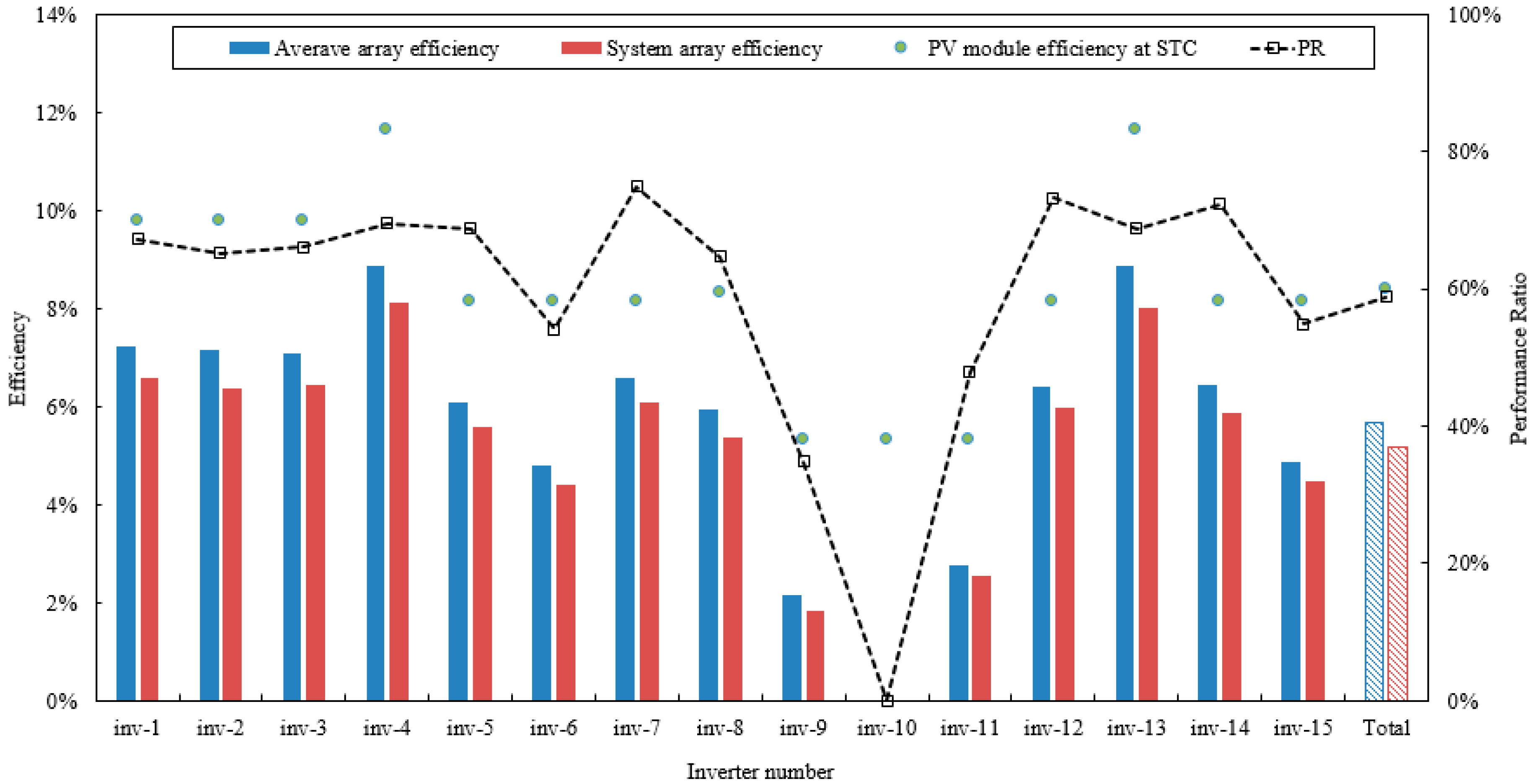

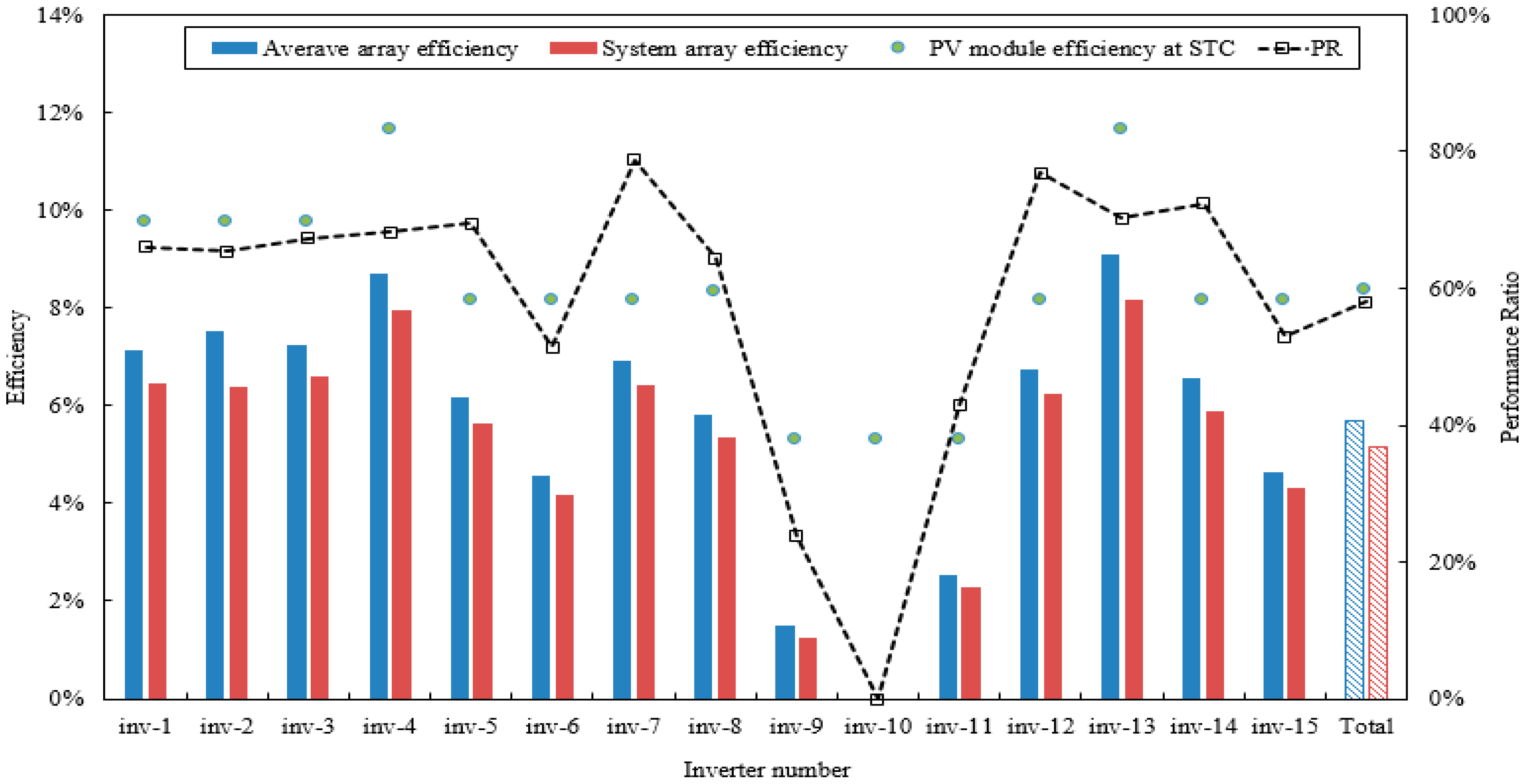

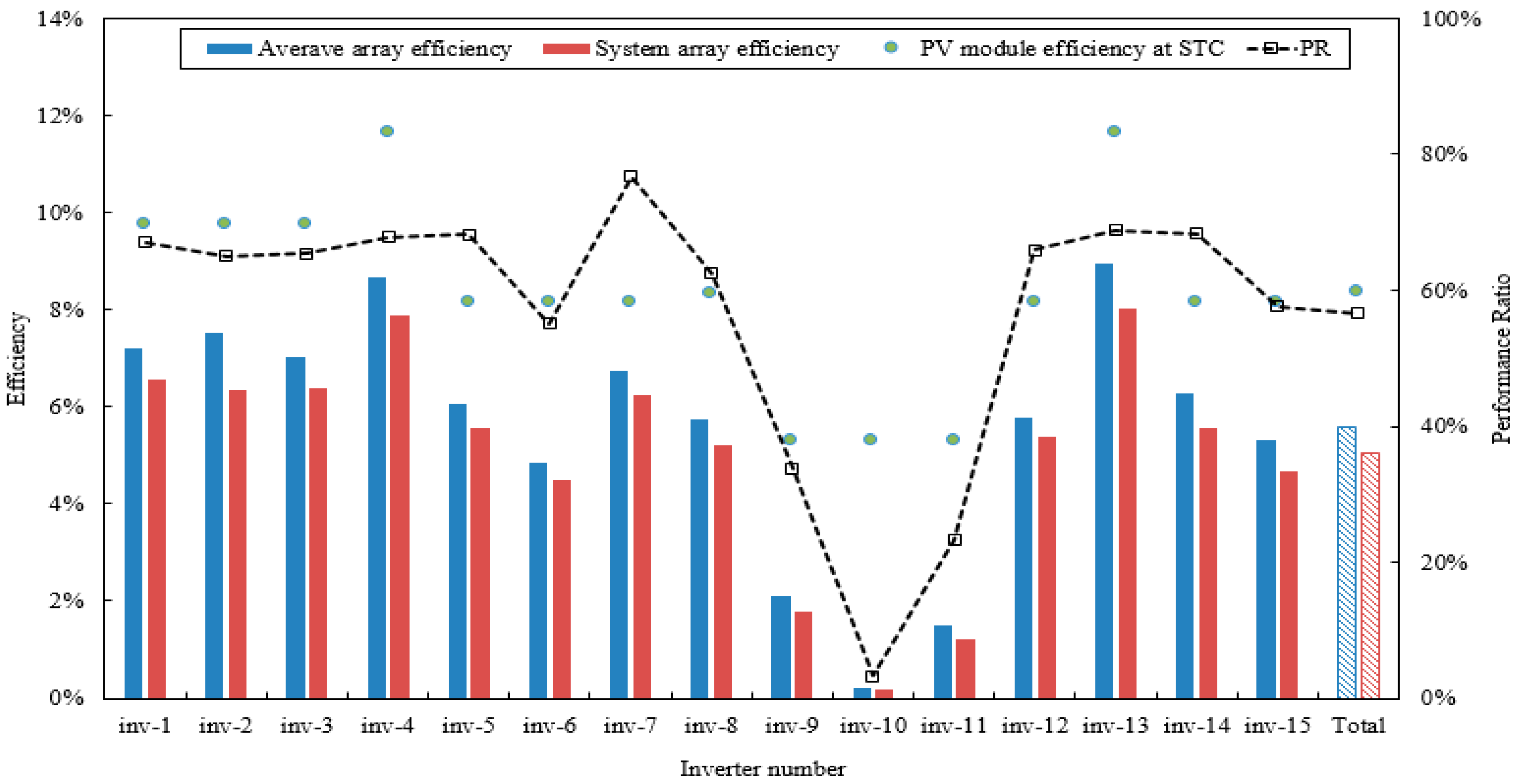

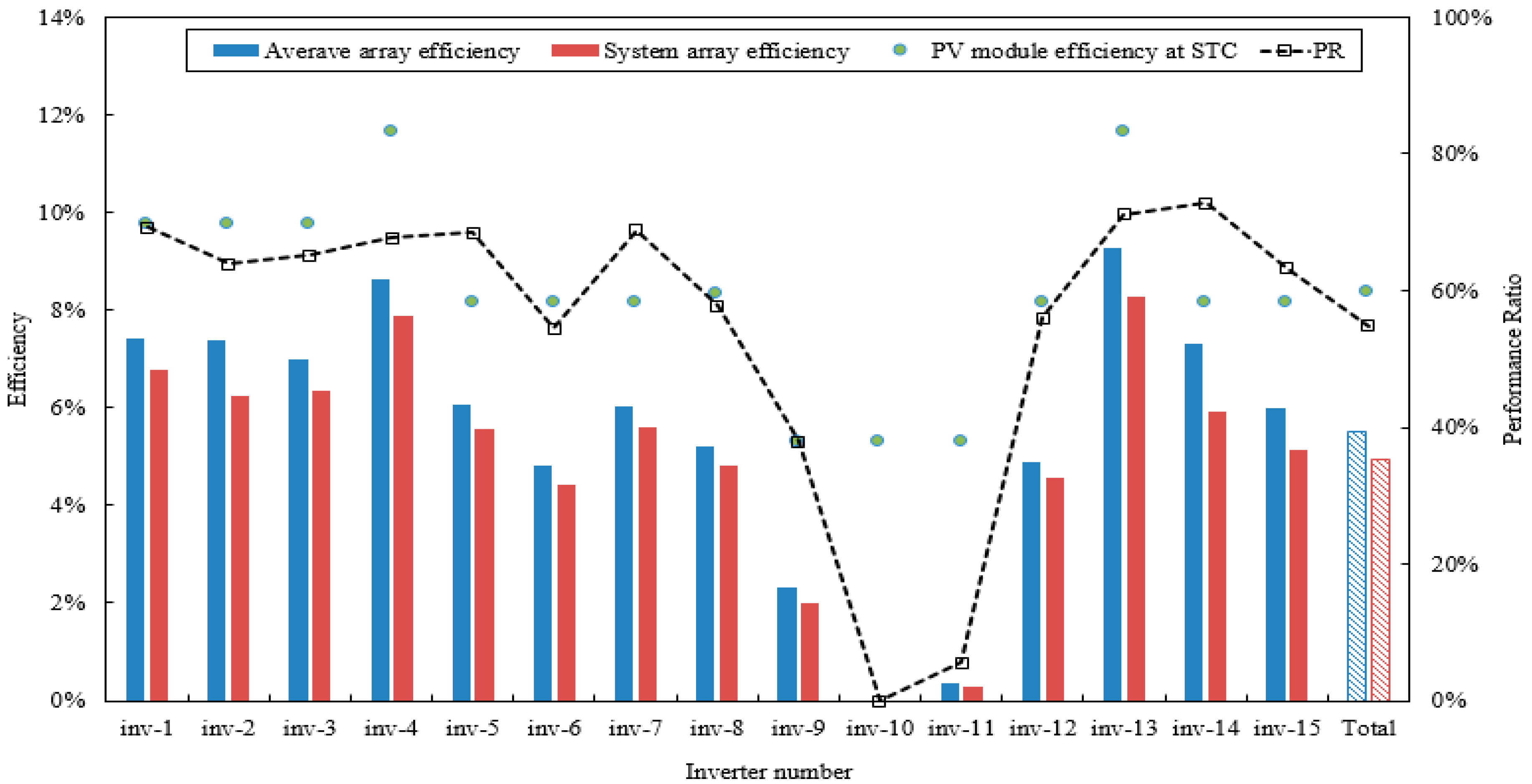

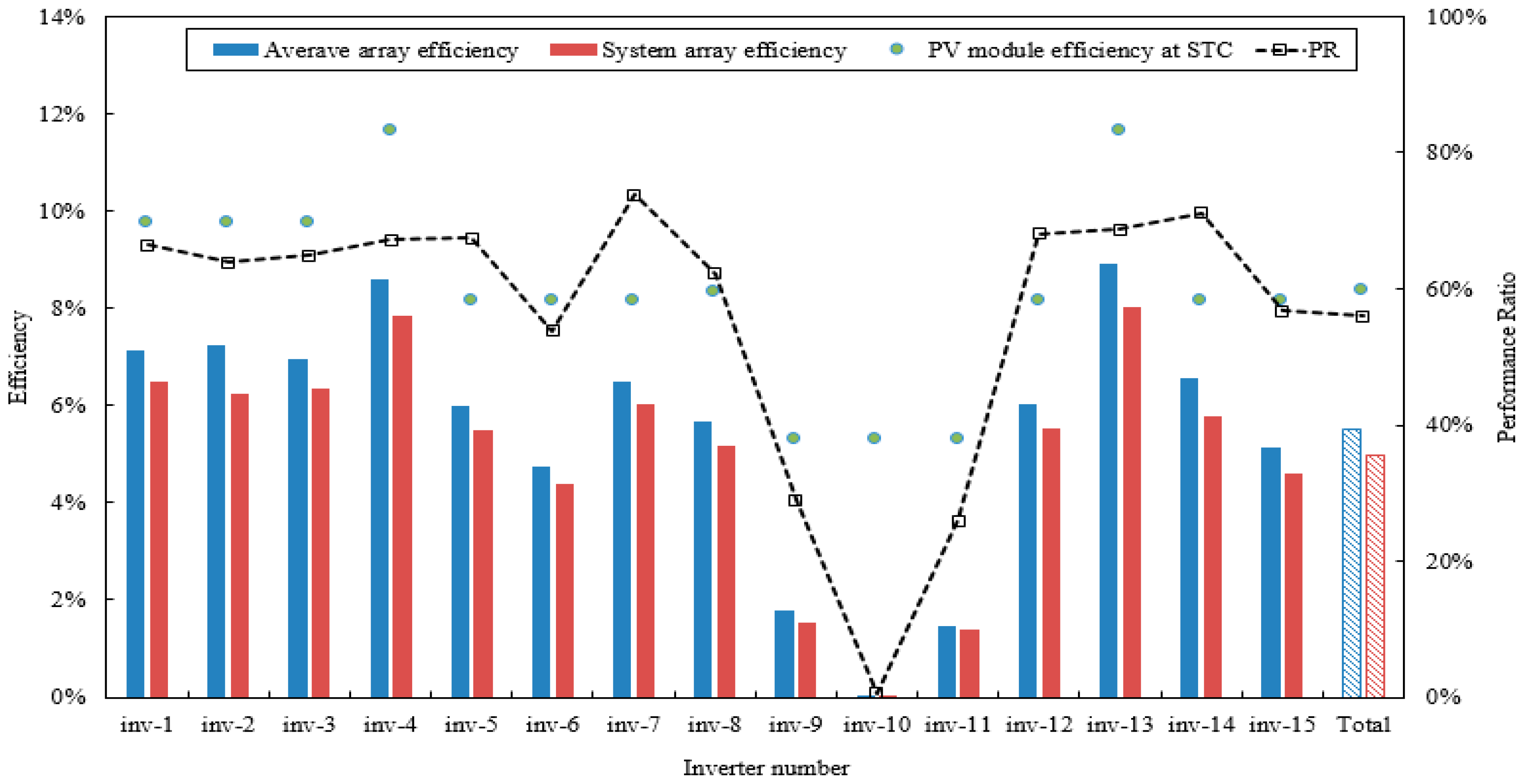

5.4. Efficiency Degradation of the BIPV Systems in the Carbon Zero Building

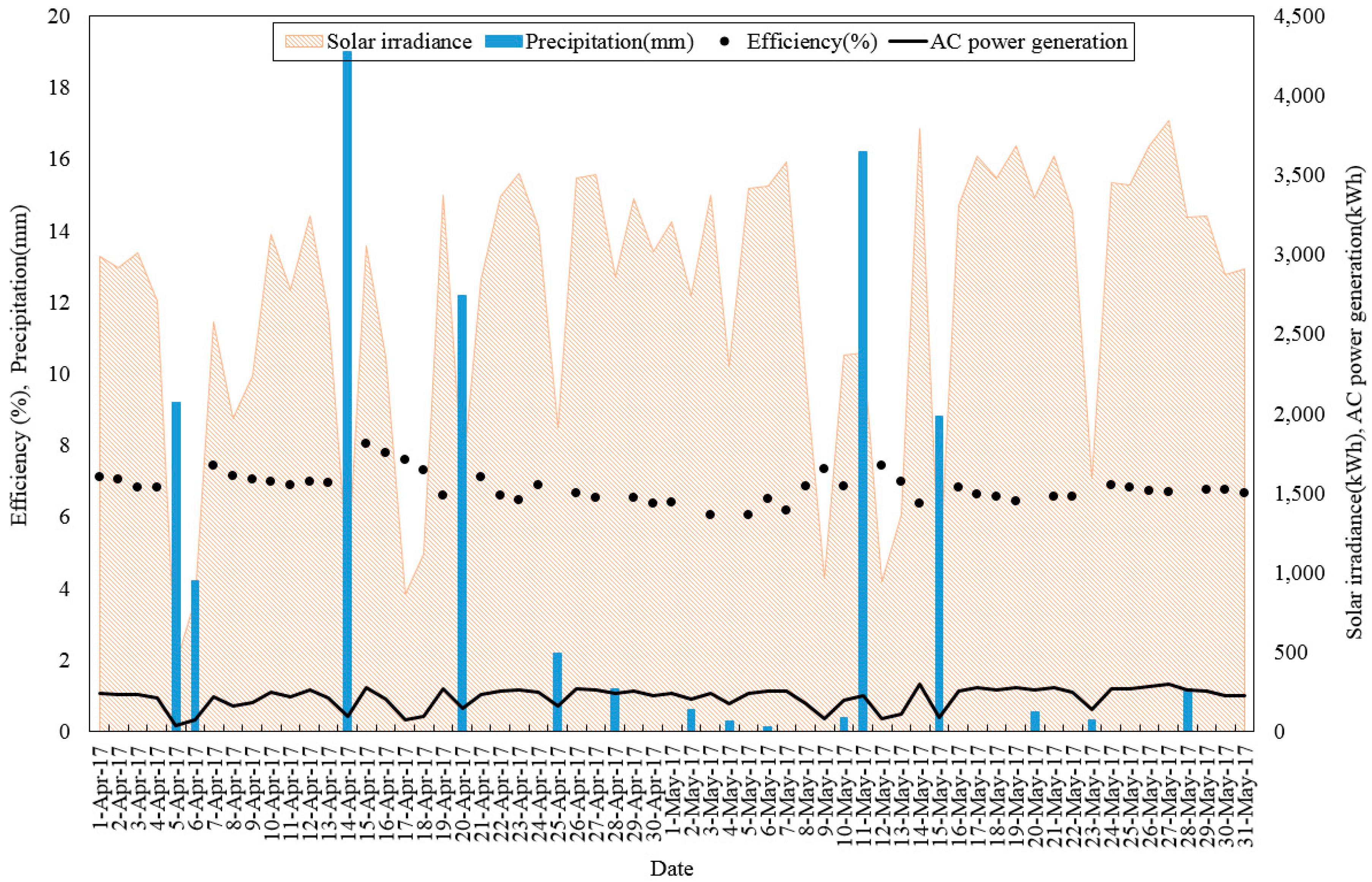

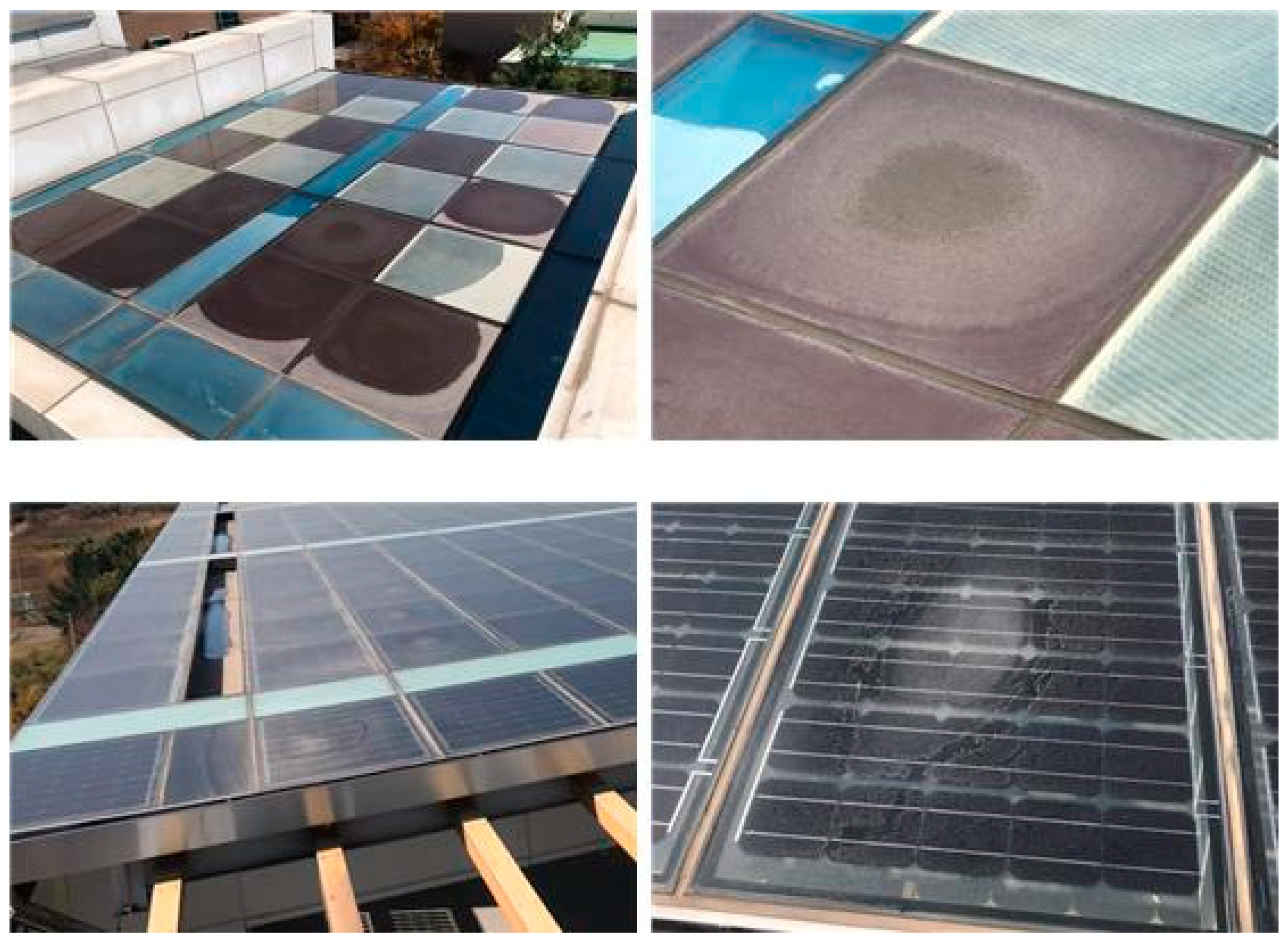

5.4.1. Efficiency Degradation of Horizontal BIPV Modules due to Dust Accumulation

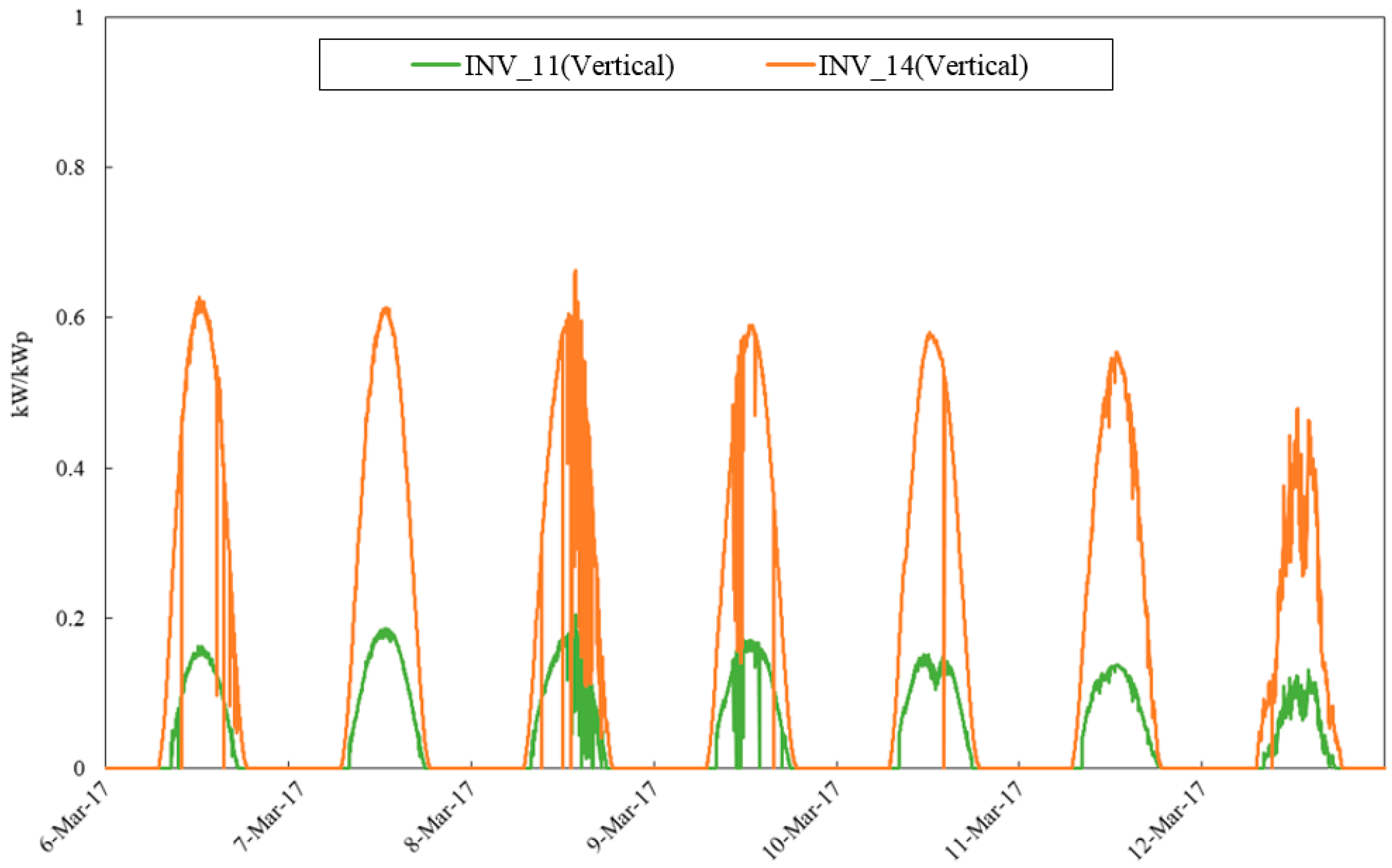

5.4.2. Causes of Output Degradation of the Thin-Film Modules

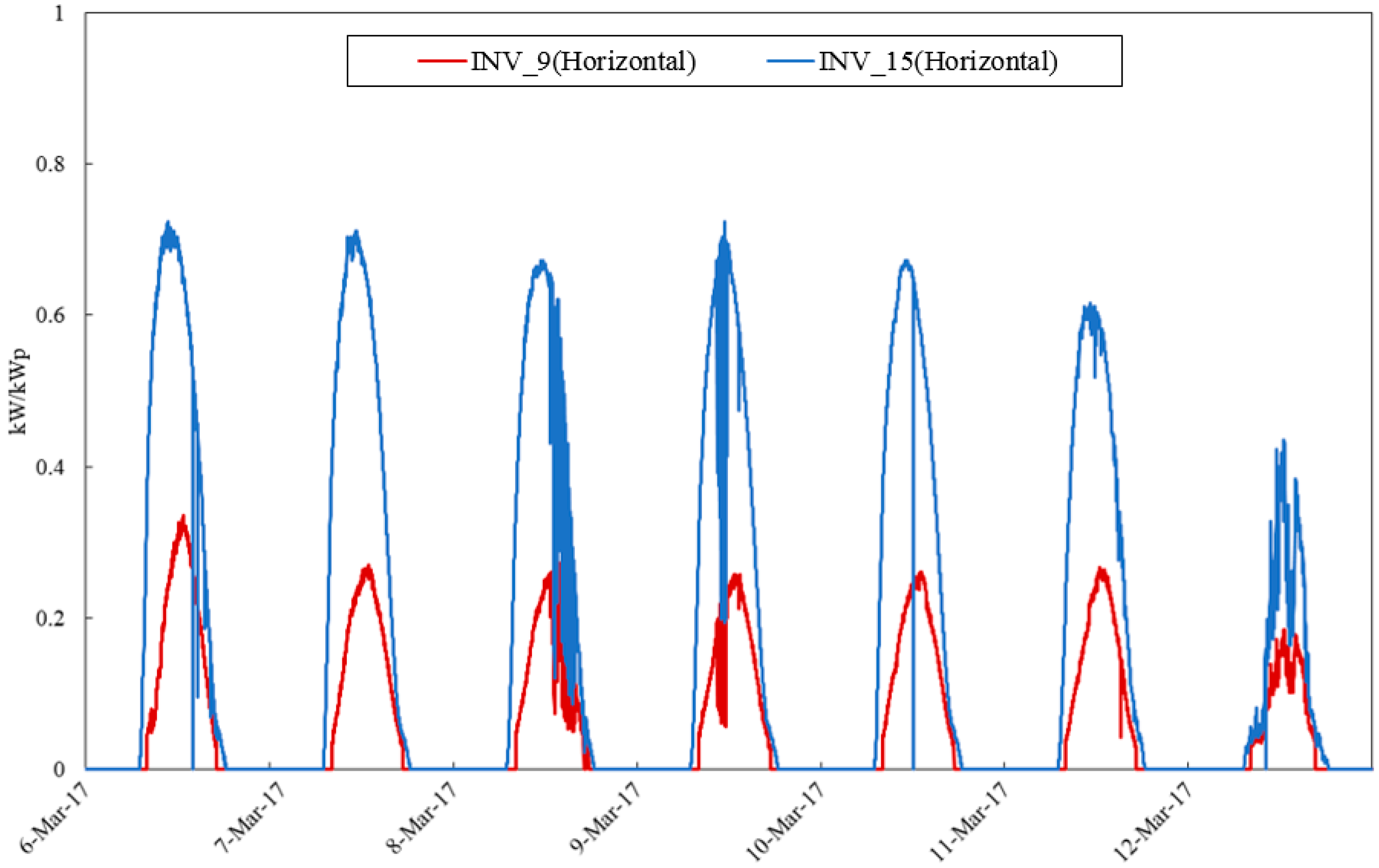

5.5. Energy Production by BIPV Installation Angle

6. Conclusions

- (1)

- Based on simulations, the energy production of the BIPV systems in the Carbon Zero Building was predicted to be 975.2 kWh/kWp. The monitoring results for the five-year period, however, showed that the average annual energy production per kWp was 855.6 kWh/kWp, which was 12.26% lower than the predicted value.

- (2)

- After analyzing the causes of degradation in the measured energy production, it was concluded that the system losses by inverter, which ranged from 0.14 to 0.31 h/d, indicated no significant difference between inverters. Conversely, the capture losses ranged from 0.21 to 1.81 h/d, indicating significant differences.

- (3)

- The primary cause of the increase in capture losses was a temporary decrease in the power generation efficiency of the horizontally installed modules due to dust accumulation on the front of the PV modules, which was subsequently removed by precipitation.

- (4)

- The second cause of the increase in capture losses was the fact that the inverters installed in the Carbon Zero Building could not consider the control characteristics of the amorphous modules, leading to a significant decrease in energy production because the same inverters were used for both crystal system modules and amorphous modules.

- (5)

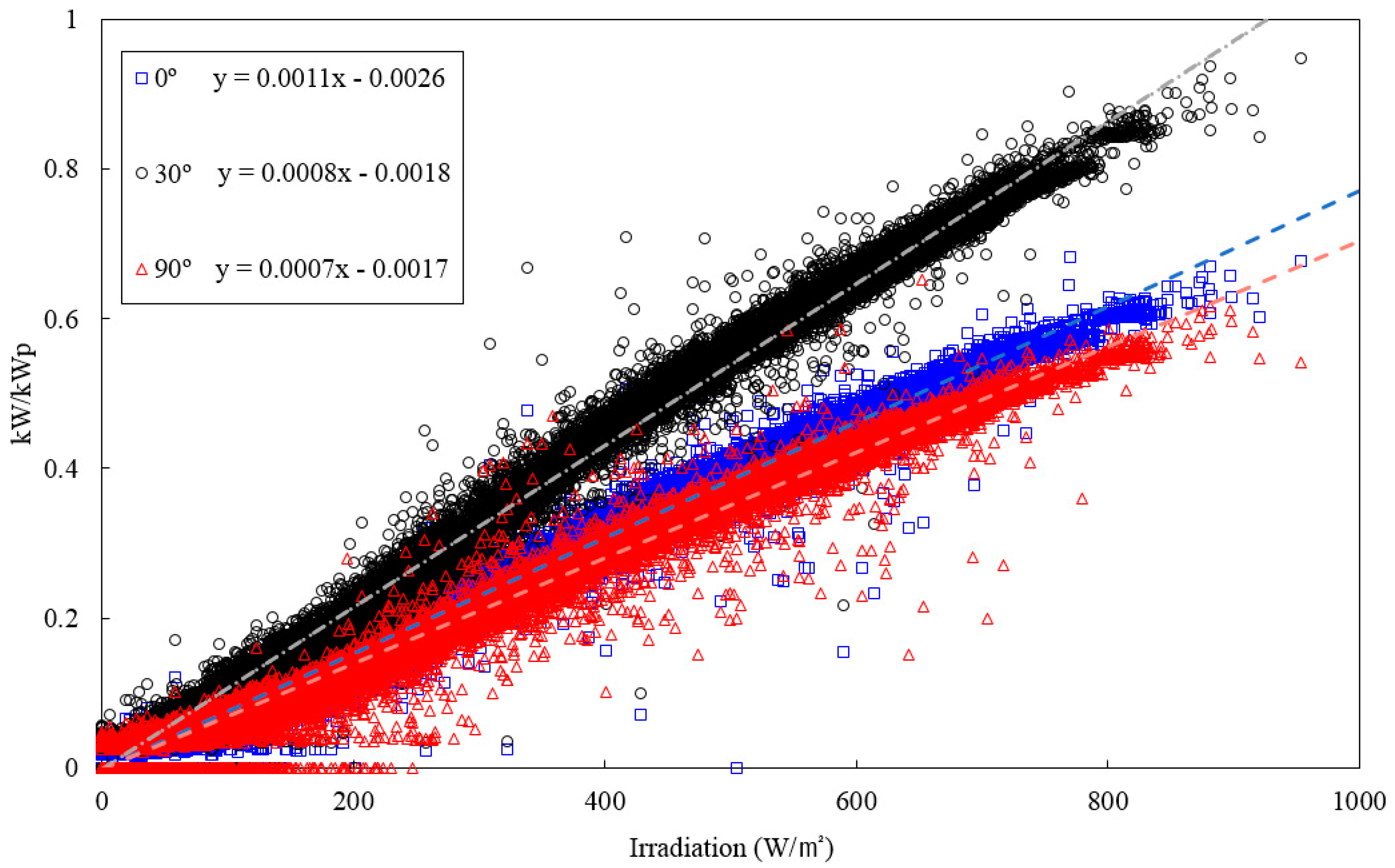

- Therefore, the BIPV systems with an inclination angle of 30° exhibited approximately 57% higher energy production than the vertically (90°) installed systems under the same solar radiation. Furthermore, the horizontal (0°) BIPV systems exhibited up to 14% higher energy production than the vertical BIPV systems.

Author Contributions

Funding

Conflicts of Interest

List of Symbols

| YA | Array yield [h/d] |

| YF | Final yield [h/d] |

| YR | Reference yield [h/d] |

| EDC | Array DC energy output per year [kWh/year] |

| EAC | AC energy output to the grid per year [kWh/year] |

| GI | Reference irradiation (1000 W/m2) |

| HId | Total in-plane irradiation per year [kWh/m2/year] |

| LC | Capture loss [h/d] |

| LS | System loss [h/d] |

| RR | Performance ratio [%] |

| NE | Reference array efficiency [%] |

| A | Area of array [m2] |

| Ntotal | Overall system efficiency [%] |

| TFE | Total facility energy use [kWh/month] |

| FEL | Facility total energy load met by photovoltaic (PV) production [kWh/month] |

| Po | Installed capacity [kWp] |

References

- Global Alliance for Buildings and Construction. Global Status Report; Global Alliance for Buildings and Construction, UN Environment: Paris, France, 2017. [Google Scholar]

- AlAjmi, A.; Abou-Ziyan, H.; Ghoneim, A. Achieving annual and monthly net-zero energy of existing building in hot climate. Appl. Energy 2016, 165, 511–521. [Google Scholar] [CrossRef]

- IEA SHC Task 40. Toward Net Zero Energy Solar Buildings 2010. Available online: http://www.iea-shc.org/task40 (accessed on 20 April 2019).

- NREL. A Common Definition for Zero Energy Buildings; US Department of Energy: Washington, DC, USA, September 2015.

- Pless, S.; Deru, M.; Torcellini, P.; Hayter, S. Procedure for Measuring and Reporting the Performance of Photovoltaic Systems in Buildings; NREL/TP-550-38603: Golden, CO, USA, October 2005. [Google Scholar]

- U.S. Energy Information Administration. International Energy Outlook 2016; U.S. Energy Information Administration: Washington, DC, USA, 2016; pp. 7–10. Available online: https://www.eia.gov/outlooks/ieo/pdf/0484(2016).pdf (accessed on 18 April 2019).

- Wittkopf, S.; Valliappan, S.; Liu, L.; Seng Ang, K.; Chye, S.; Cheng, J. Analytical performance monitoring of a 142.5 kWp grid-connected rooftop BIPV system in Singapore. Renew Energy 2012, 47, 9–20. [Google Scholar] [CrossRef]

- Yoon, J.H.; Song, J.; Lee, S.J. Practical application of building integrated photovoltaic (BIPV) system using transparent amorphous silicon thin-film PV module. Solar Energy 2011, 85, 723–733. [Google Scholar] [CrossRef]

- Sasitharanuwat, A.; Rakwichian, W.; Ketjoy, N.; Yammen, S. Performance evaluation of a 10 kWp PV power system prototype for isolated building in Thailand. Renew Energy 2006, 32, 1288–1300. [Google Scholar] [CrossRef]

- Yoon, J.H.; Song, J.; Lee, S.J. Heating and Cooling Performance of Office Buildings with a-Si BIPV Windows Considering Operating Conditions in Temperate Climates: The Case of Korea. Sustainability 2018, 10, 4856. [Google Scholar]

- Broeck, G.V.D.; Parys, W.; Goverde, H.; Putten, S.V.D.; Poortmans, J.; Driesen, J.; Baert, K. Experimental analysis of the performance of facade-integrated BIPV in different configurations. In Proceedings of the 32nd European Photovoltaic Solar Energy Conference and Exhibition, Munich, Germany, 20–24 June 2016; pp. 1–5. [Google Scholar]

- Gross, M.A.; Martin, S.O.; Pearsall, N.M. Estimation of output enhancement of a partially shaded BIPV array by the use of AC modules. In Proceedings of the Conference Record of the Twenty Sixth IEEE Photovoltaic Specialists Conference, Anaheim, CA, USA, 29 September–3 October 1997; pp. 1381–1384. [Google Scholar]

- Zomer, C.; Nobre, A.; Cassatella, P.; Reindl, T.; Rüther, R. The balance between aesthetics and performance in building-intecgrated photovoltaics in the tropics. Prog. Photovolt. Res. Appl. 2014, 22, 744–756. [Google Scholar] [CrossRef]

- IEC 61724-1:2017. Photovoltaic System Performance Monitoring—Guidelines for Measurement, Data Exchange and Analysis; IEC Standard; IEC: Geneva, Switzerland, 2017. [Google Scholar]

- Alonso, R.; Román, E.; Elorduizapatarietxe, S.; Ibanez, P.; Apinaniz, S. Experimental Results of Intelligent PV Module for Grid-Connected PV Systems. In Proceedings of the 21st European Photovoltaic Solar Energy Conference and Exhibition, Dresden, Germany, 4–8 September 2006; Volume 53, p. 2297. [Google Scholar]

- Walker, G.R.; Pierce, J.C. PhotoVoltaic DC-DC module integrated converter for novel cascaded and bypass grid connection topologies—Design and optimisation. In Proceedings of the PESC Record—IEEE Annual Power Electronics Specialists Conference, Jeju, Korea, 18–22 June 2006; pp. 1–7. [Google Scholar]

- Dong, M.; Dong, H.; Wang, L.; Yang, J.; Li, L.; Wang, Y. A Simple Open-Circuit Detection Strategy for a Single-Phase Grid-Connected PV Inverter Fed from Power Optimizers. IEEE Trans. Power Electron. 2018, 33, 2798–2802. [Google Scholar] [CrossRef]

- Liu, B.; Duan, S.; Cai, T. Photovoltaic DC-building-module-based BIPV system-concept and design considerations. IEEE Trans. Power Electron. 2011, 26, 1418–1429. [Google Scholar] [CrossRef]

- Kasper, M.; Ritz, M.; Bortis, D.; Kolar, J.W. PV Panel-Integrated High Step-up High Efficiency Isolated GaN DC-DC Boost Converter. In Proceedings of the Telecommunications Energy Conference ‘Smart Power and Efficiency’ (INTELEC), Hamburg, Germany, 13–17 October 2013; pp. 602–608. [Google Scholar]

- Mamarelis, E.; Petrone, G.; Sahan, B.; Lempidis, G.; Spagnuolo, G.; Zacharias, P. What is the best dc/dc converter for an AC module Experimental analysis of two interesting solutions. In Proceedings of the ISIE 2011: 2011 IEEE International Symposium on Industrial Electronics, Gdansk, Poland, 27–30 June 2011; pp. 1759–1764. [Google Scholar]

- Simon, R.; Mauricio, D.V.; Giel, V.D.B.; Johan, D. Review on Building-Integrated Photovoltaics Electrical System Requirements and Module-Integrated Converter Recommendations. Energies 2019, 12, 1532. [Google Scholar]

| Floor | Facility | Use | Area (m2) |

|---|---|---|---|

| Underground floor | Public facility | Machine room, electricity room, generator room, control room | 521.6 |

| 1st floor | Promotion facility | Exhibition room | 280.7 |

| International conference room | 431.4 | ||

| Information room, situation room | 18.0 | ||

| Warehouse | 11.3 | ||

| Public facility | Rest room | 22.6 | |

| Hall | 138.3 | ||

| EV | 28.3 | ||

| Wind-proof room | |||

| 2nd floor | Research facility | Laboratory | 412.1 |

| Data center | 42.7 | ||

| Large meeting room | 92.0 | ||

| Small meeting room | 22.8 | ||

| Data storage room | 56.1 | ||

| Lounges (male and female) | 30.4 | ||

| Public facility | Rest room | 22.6 | |

| Hall | 153.6 | ||

| EV | 164.9 | ||

| Hallway | |||

| Staircase | |||

| Total floor area | 2449.2 | ||

| Type | Polycrystal | Amorphous | |||

|---|---|---|---|---|---|

| Voc | 7.6 | 25.5 | 30.6 | 34.5 | 91.8 |

| Vmp | 5.3 | 17.8 | 21 | 26.1 | 66 |

| Isc | 8.92 | 8.92 | 8.92 | 8.92 | 1.09 |

| Imo | 8.17 | 8.17 | 8.17 | 8.17 | 0.75 |

| Efficiency (%) | 8.32 | 8.14 | 9.77 | 11.65 | 5.3 |

| Capacity (W) | 43 | 145 | 171 | 213 | 50 |

| Number of photovoltaic (PV) Cells | 12 | 40 | 48 | 54 | - |

| Module quantity | 32 | 590 | 37 | 76 | 136 |

| Inverter Number | Module Type | Tilt Angles | Module Area (m2) | Module Capacity (Wp) | Module Quantity | Total Area (m2) | Total Capacity (kWp) | Inverter Capacity (kWp) |

|---|---|---|---|---|---|---|---|---|

| INV_1 | Glass to Glass | 90 | 1.84 | 171 | 12 | 22.08 | 2.052 | 3 |

| INV_2 | 90 | 1.84 | 171 | 12 | 22.08 | 2.052 | 3 | |

| INV_3 | 90 | 1.84 | 171 | 13 | 23.92 | 2.223 | 3 | |

| INV_4 | 90 | 1.77 | 213 | 10 | 17.7 | 2.13 | 3 | |

| INV_5 | Glass to Glass | 0 | 1.41 | 145 | 18 | 25.38 | 2.61 | 3 |

| INV_6 | 0 | 1.41 | 145 | 18 | 25.38 | 2.61 | 3 | |

| INV_7 | Glass to Tedlar/crystal | 30 | 1.41 | 145 | 16 | 22.56 | 2.32 | 3 |

| INV_8 | Tracking | 0.53 | 43 | 32 | 16.96 | 1.376 | 3 | |

| INV_9 | Amorphous | 0 | 0.93 | 50 | 32 | 29.76 | 1.6 | 3 |

| INV_10 | 90 | 0.93 | 50 | 52 | 48.36 | 2.6 | 3 | |

| INV_11 | 90 | 0.93 | 50 | 52 | 48.36 | 2.6 | 3 | |

| INV_12 | Glass to Tedlar/crystal | 30 | 1.41 | 145 | 70 | 98.7 | 10.15 | 11 |

| INV_13 | 90 | 1.77 | 213 | 66 | 116.82 | 14.058 | 15 | |

| INV_14 | Glass to Glass | 90 | 1.41 | 145 | 160 | 225.6 | 23.2 | 25 |

| INV_15 | 0 | 1.41 | 145 | 308 | 434.28 | 44.66 | 45 | |

| Total | - | - | - | - | 871 | 1177.94 | 116.241 | 129 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, W.J.; Joo, H.J.; Park, J.-W.; Kim, S.-k.; Lee, J.-B. Power Generation Performance of Building-Integrated Photovoltaic Systems in a Zero Energy Building. Energies 2019, 12, 2471. https://doi.org/10.3390/en12132471

Choi WJ, Joo HJ, Park J-W, Kim S-k, Lee J-B. Power Generation Performance of Building-Integrated Photovoltaic Systems in a Zero Energy Building. Energies. 2019; 12(13):2471. https://doi.org/10.3390/en12132471

Chicago/Turabian StyleChoi, Won Jun, Hong Jin Joo, Jae-Wan Park, Sang-kyun Kim, and Jae-Bum Lee. 2019. "Power Generation Performance of Building-Integrated Photovoltaic Systems in a Zero Energy Building" Energies 12, no. 13: 2471. https://doi.org/10.3390/en12132471

APA StyleChoi, W. J., Joo, H. J., Park, J.-W., Kim, S.-k., & Lee, J.-B. (2019). Power Generation Performance of Building-Integrated Photovoltaic Systems in a Zero Energy Building. Energies, 12(13), 2471. https://doi.org/10.3390/en12132471