Experimental Investigation of Performance, Emission and Combustion Characteristics of a Common-Rail Diesel Engine Fuelled with Bioethanol as a Fuel Additive in Coconut Oil Biodiesel Blends

Abstract

1. Introduction

2. Methodology

2.1. Biodiesel Production

2.2. Fuel Properties Test and Analysis

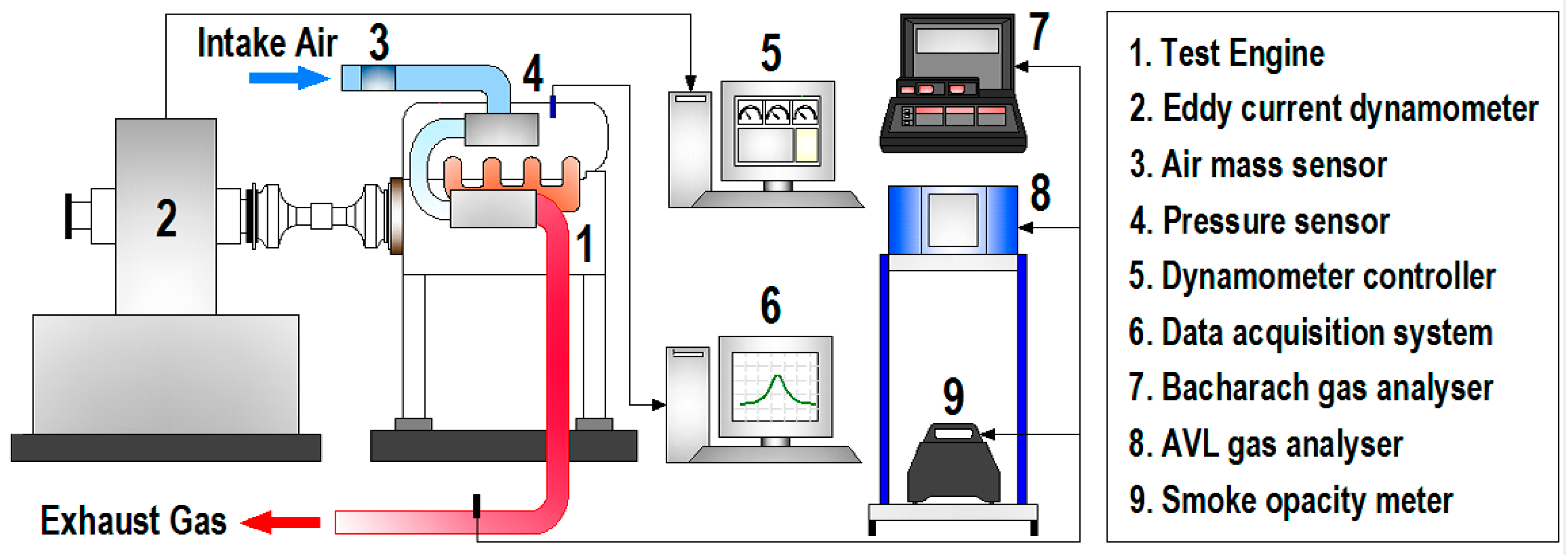

2.3. Engine Setup and Instrumentation

3. Calculations

3.1. Engine Performance

3.2. Heat Release Rate Analysis

4. Results and Discussions

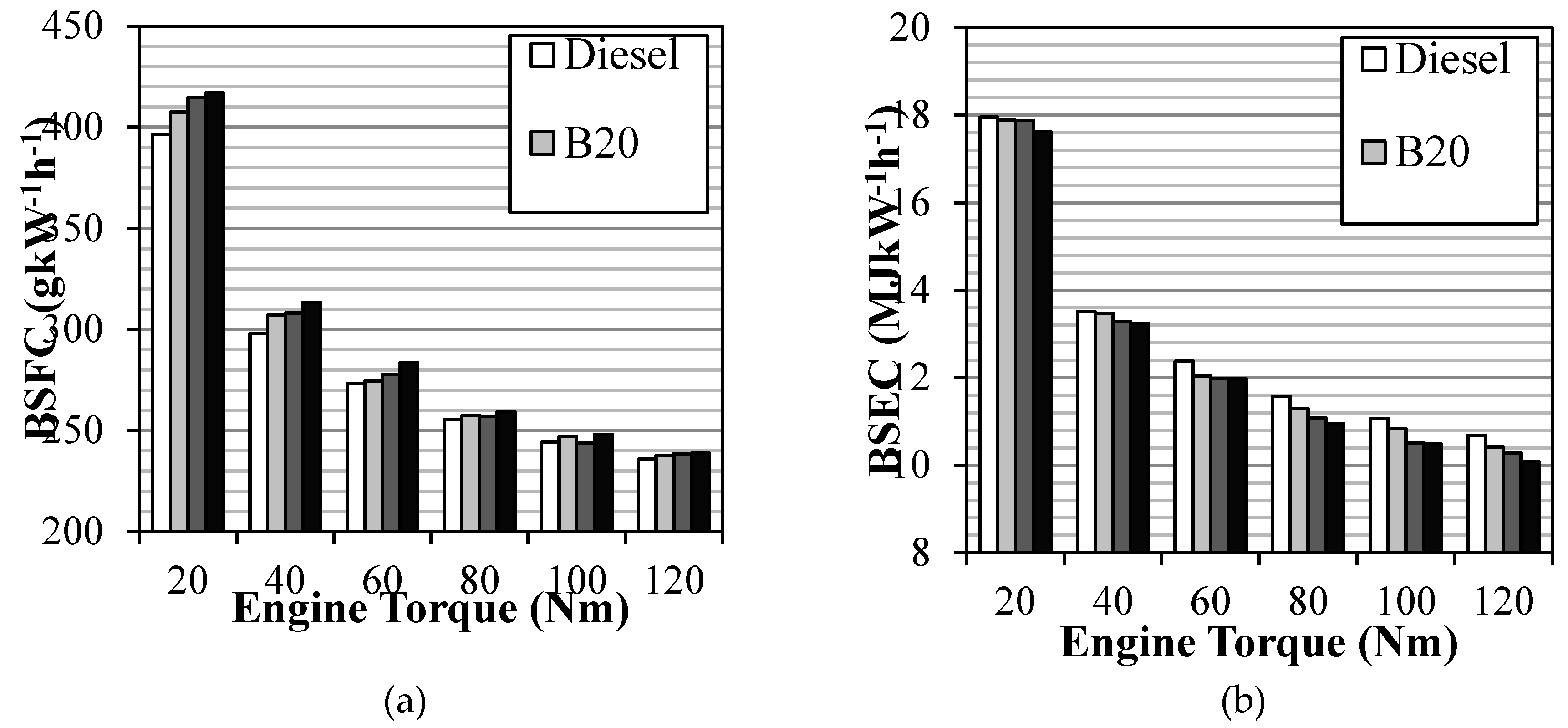

4.1. Engine Performance

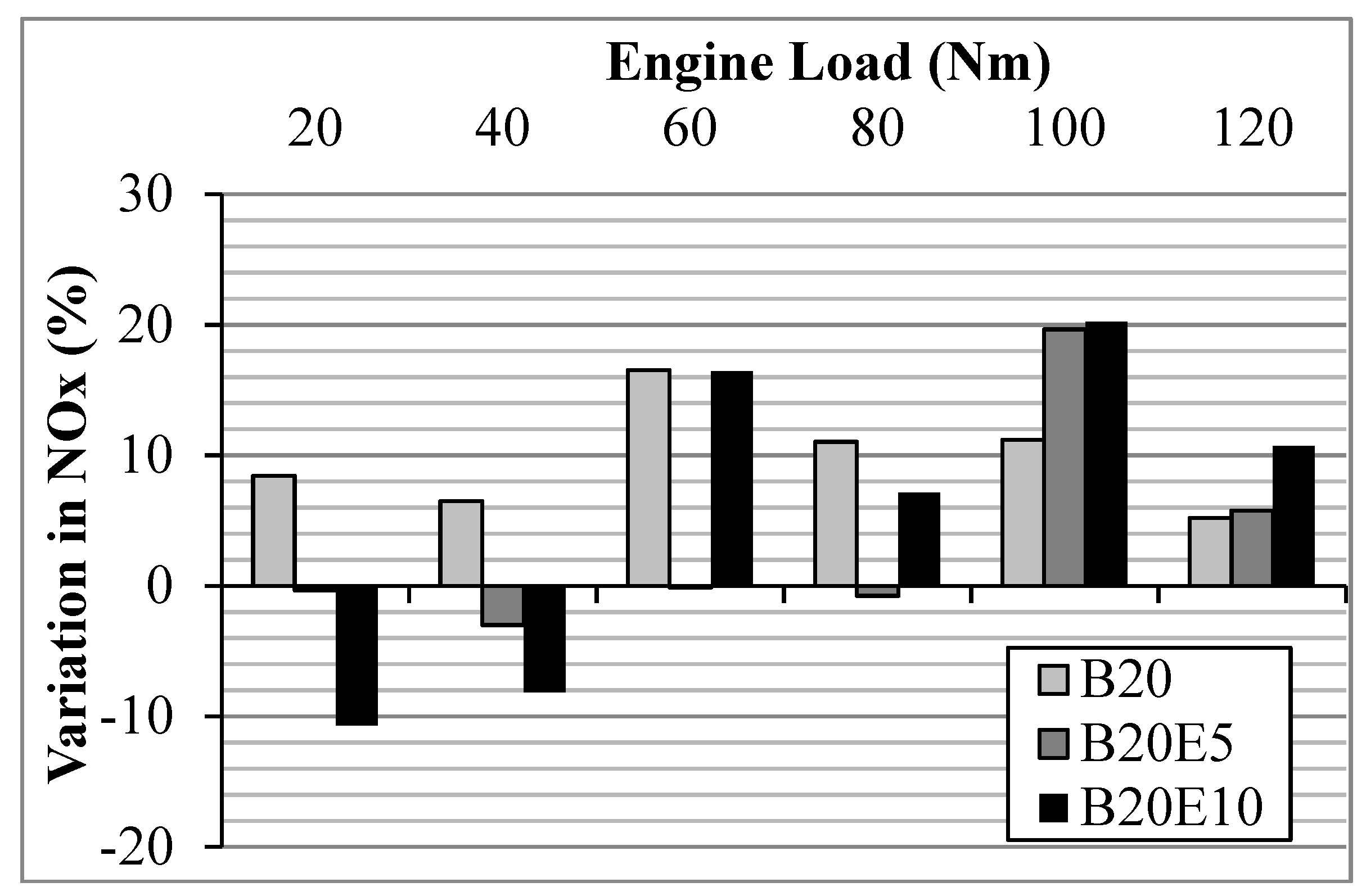

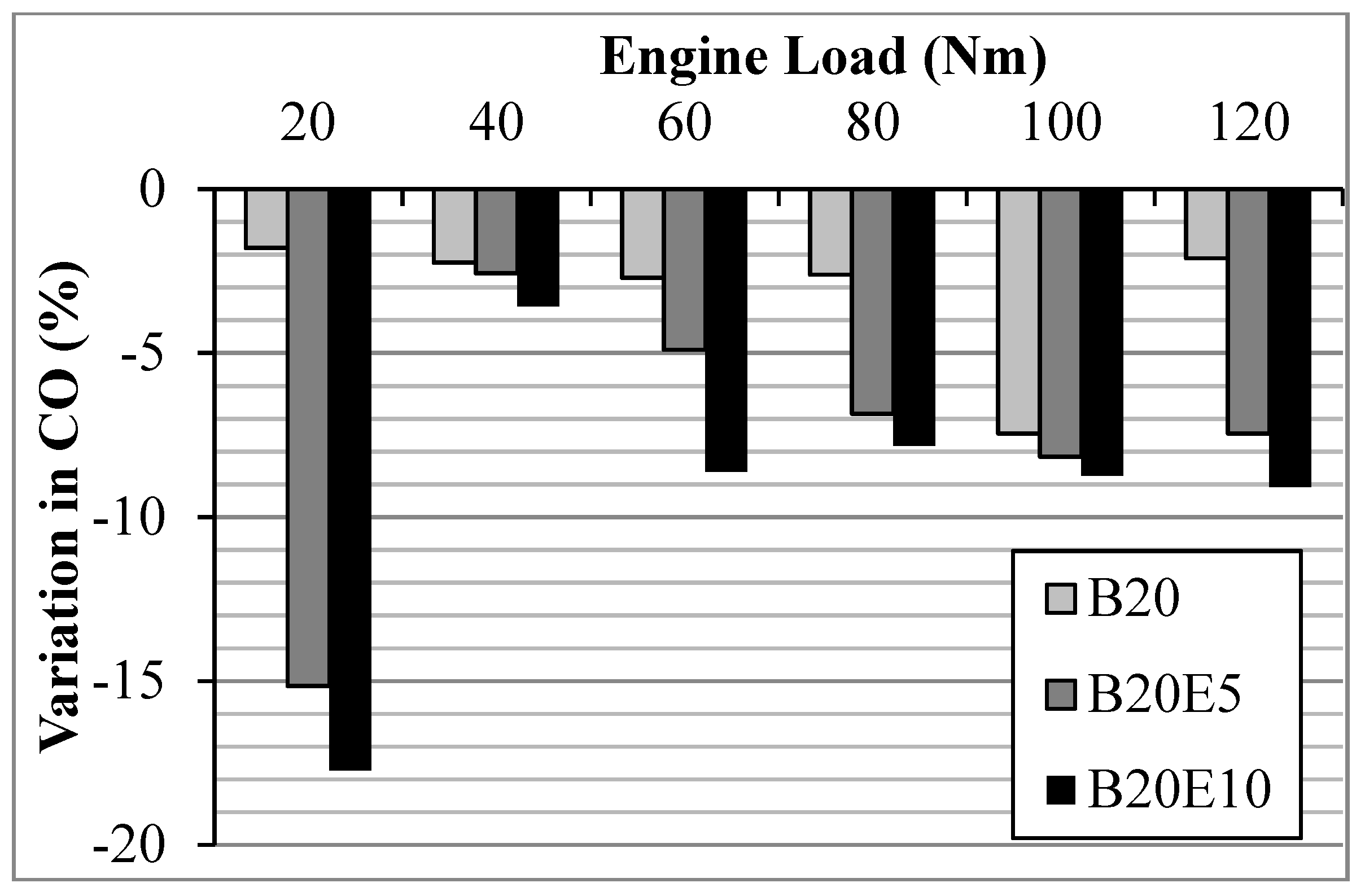

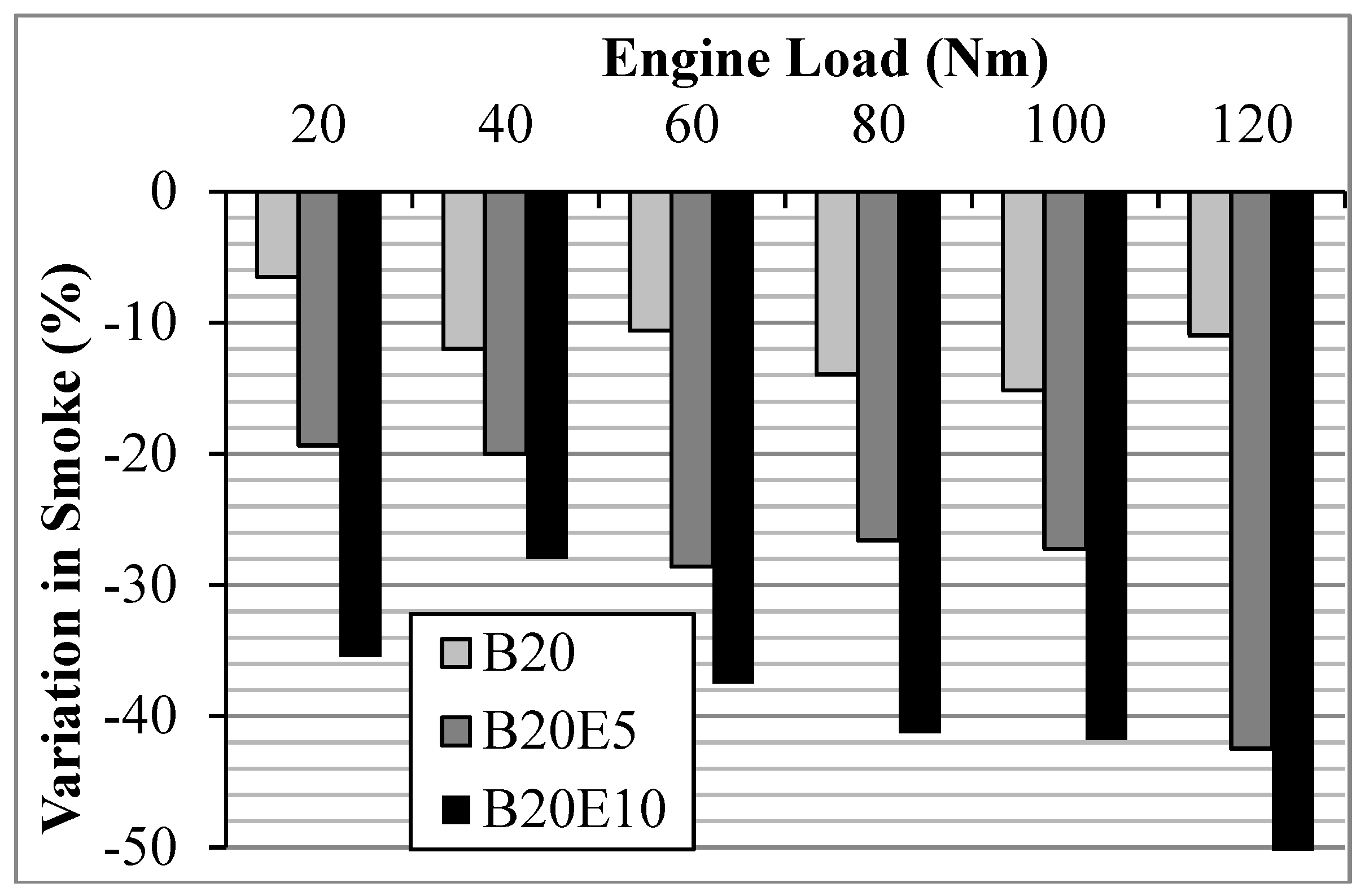

4.2. Exhaust Emissions

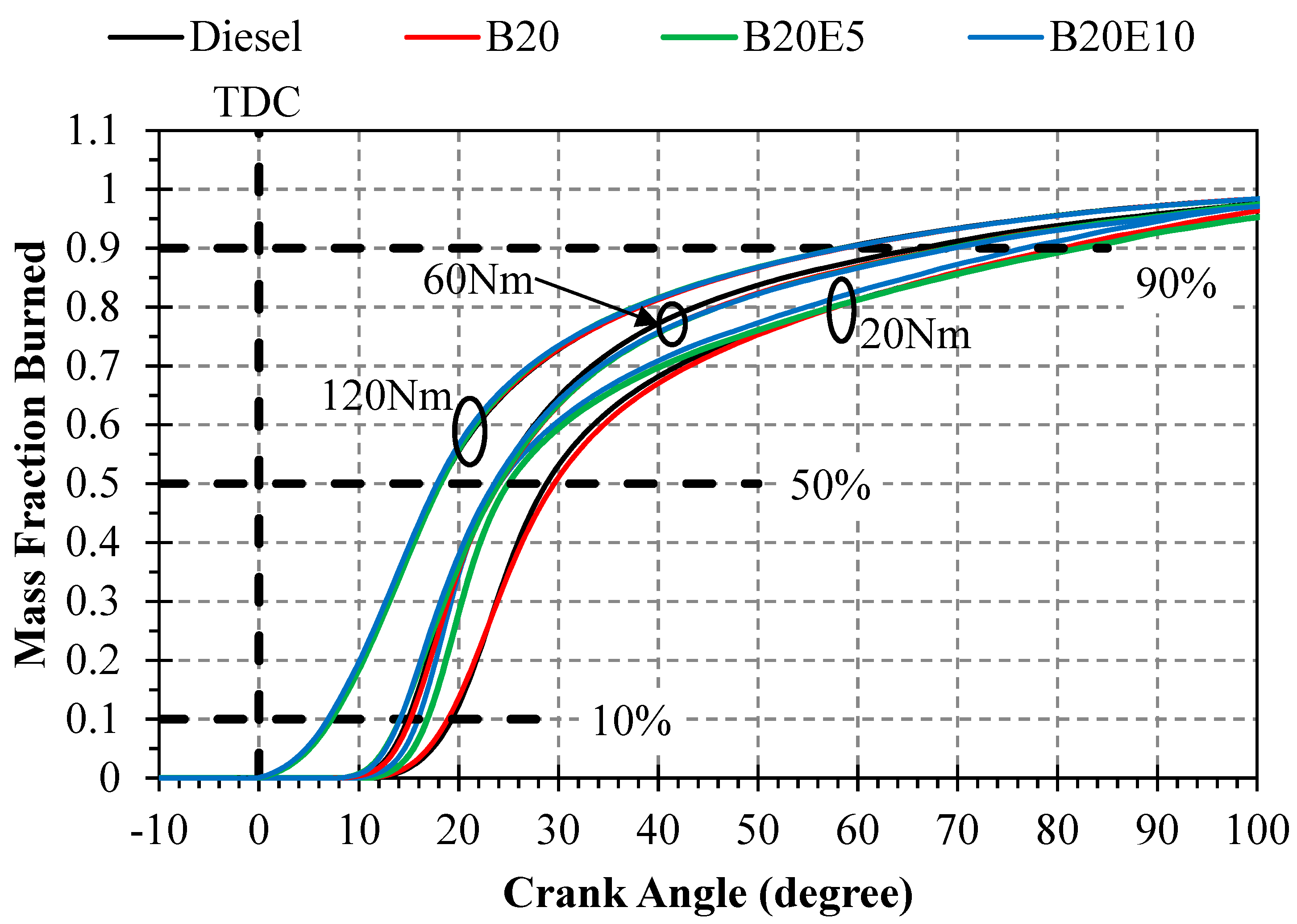

4.3. Combustion Characteristics

5. Conclusions

- An improvement in the BSEC and BTE of the blends at the expense of brake specific fuel consumption (BSFC) can be observed for each bioethanol blend.

- A higher percentage of bioethanol blends causes an increment in NOx across the entire load range, except at low load condition.

- Simultaneous smoke and CO emission reduction from the baseline levels of petroleum diesel fuel can be attained by utilizing all types of fuel blends. Besides, the results showed that B20E10 achieved the highest average reduction of 9.3% and 52% in smoke and CO emissions, respectively, as compared to the baseline diesel.

- An increment in both of the peak in-cylinder pressure and HRR can be observed with the utilization of bioethanol blended fuels at the low engine load, especially for the B20E10 blend. Besides, the combustion process is comparable at the medium and high load for all the tested fuels. In addition, the B20E10 showed shorter combustion duration, which reduced by an average of 1.375 °CA compared to the corresponding baseline diesel.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alptekin, E. Emission, injection and combustion characteristics of biodiesel and oxygenated fuel blends in a common rail diesel engine. Energy 2017, 119, 44–52. [Google Scholar] [CrossRef]

- Owen, N.A.; Inderwildi, O.R.; King, D.A. The status of conventional world oil reserves—Hype or cause for concern? Energy Policy 2010, 38, 4743–4749. [Google Scholar] [CrossRef]

- Augustine, A.; Marimuthu, L.; Muthusamy, S. Performance and Evaluation of DI Diesel Engine by using Preheated Cottonseed Oil Methyl Ester. Procedia Eng. 2012, 38, 779–790. [Google Scholar] [CrossRef]

- Giakoumis, E.G. A statistical investigation of biodiesel physical and chemical properties, and their correlation with the degree of unsaturation. Renew. Energy 2013, 50, 858–878. [Google Scholar] [CrossRef]

- Kumar, M.; Sharma, M.P. Assessment of potential of oils for biodiesel production. Renew. Sustain. Energy Rev. 2015, 44, 814–823. [Google Scholar] [CrossRef]

- Wood, B.M.; Kirwan, K.; Maggs, S.; Meredith, J.; Coles, S.R. Study of combustion performance of biodiesel for potential application in motorsport. J. Clean. Prod. 2015, 93, 167–173. [Google Scholar] [CrossRef]

- Verma, P.; Sharma, M.P.; Dwivedi, G. Potential use of eucalyptus biodiesel in compressed ignition engine. Egypt. J. Pet. 2016, 25, 91–95. [Google Scholar] [CrossRef]

- Demirbas, A. Biodiesel from waste cooking oil via base-catalytic and supercritical methanol transesterification. Energy Convers. Manag. 2009, 50, 923–927. [Google Scholar] [CrossRef]

- Nantha Gopal, K.; Thundil Karupparaj, R. Effect of pongamia biodiesel on emission and combustion characteristics of DI compression ignition engine. Ain Shams Eng. J. 2015, 6, 297–305. [Google Scholar] [CrossRef]

- Dhar, A.; Agarwal, A.K. Performance, emissions and combustion characteristics of Karanja biodiesel in a transportation engine. Fuel 2014, 119, 70–80. [Google Scholar] [CrossRef]

- Balamurugan, T.; Arun, A.; Sathishkumar, G.B. Biodiesel derived from corn oil—A fuel substitute for diesel. Renew. Sustain. Energy Rev. 2018, 94, 772–778. [Google Scholar] [CrossRef]

- Liaquat, A.M.; Masjuki, H.H.; Kalam, M.A.; Rizwanul Fattah, I.M. Impact of biodiesel blend on injector deposit formation. Energy 2014, 72, 813–823. [Google Scholar] [CrossRef]

- Imdadul, H.K.; Rashed, M.M.; Shahin, M.M.; Masjuki, H.H.; Kalam, M.A.; Kamruzzaman, M.; Rashedul, H.K. Quality improvement of biodiesel blends using different promising fuel additives to reduce fuel consumption and NO emission from CI engine. Energy Convers. Manag. 2017, 138, 327–337. [Google Scholar] [CrossRef]

- Mat Yasin, M.H.; Mamat, R.; Yusop, A.F.; Rahim, R.; Aziz, A.; Shah, L.A. Fuel Physical Characteristics of Biodiesel Blend Fuels with Alcohol as Additives. Procedia Eng. 2013, 53, 701–706. [Google Scholar] [CrossRef]

- Mat Yasin, M.H.; Yusaf, T.; Mamat, R.; Fitri Yusop, A. Characterization of a diesel engine operating with a small proportion of methanol as a fuel additive in biodiesel blend. Appl. Energy 2014, 114, 865–873. [Google Scholar] [CrossRef]

- Labeckas, G.; Slavinskas, S.; Mažeika, M. The effect of ethanol–diesel–biodiesel blends on combustion, performance and emissions of a direct injection diesel engine. Energy Convers. Manag. 2014, 79, 698–720. [Google Scholar] [CrossRef]

- Atmanlı, A.; İleri, E.; Yüksel, B. Experimental investigation of engine performance and exhaust emissions of a diesel engine fueled with diesel–n-butanol–vegetable oil blends. Energy Convers. Manag. 2014, 81, 312–321. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Gnatowska, R.; Nowak, Ł. Comparative Analysis of the Combustion Stability of Diesel-Methanol and Diesel-Ethanol in a Dual Fuel Engine. Energies 2019, 12, 971. [Google Scholar] [CrossRef]

- Niculescu, R.; Clenci, A.; Iorga-Siman, V. Review on the Use of Diesel–Biodiesel–Alcohol Blends in Compression Ignition Engines. Energies 2019, 12, 1194. [Google Scholar] [CrossRef]

- Sayin, C. Engine performance and exhaust gas emissions of methanol and ethanol–diesel blends. Fuel 2010, 89, 3410–3415. [Google Scholar] [CrossRef]

- Tian, W.; Chu, Y.; Han, Z.; Wang, X.; Yu, W.; Wu, X. Experimental Study of the Effect of Intake Oxygen Concentration on Engine Combustion Process and Hydrocarbon Emissions with N-Butanol-Diesel Blended Fuel. Energies 2019, 12, 1310. [Google Scholar] [CrossRef]

- Manzetti, S.; Andersen, O. A review of emission products from bioethanol and its blends with gasoline. Background for new guidelines for emission control. Fuel 2015, 140, 293–301. [Google Scholar] [CrossRef]

- Lennartsson, P.R.; Erlandsson, P.; Taherzadeh, M.J. Integration of the first and second generation bioethanol processes and the importance of by-products. Bioresour. Technol. 2014, 165, 3–8. [Google Scholar] [CrossRef]

- Ziolkowska, J.R. Prospective technologies, feedstocks and market innovations for ethanol and biodiesel production in the US. Biotechnol. Rep. 2014, 4, 94–98. [Google Scholar] [CrossRef]

- Aditiya, H.B.; Mahlia, T.M.I.; Chong, W.T.; Nur, H.; Sebayang, A.H. Second generation bioethanol production: A critical review. Renew. Sustain. Energy Rev. 2016, 66, 631–653. [Google Scholar] [CrossRef]

- Gronchi, N.; Favaro, L.; Cagnin, L.; Brojanigo, S.; Pizzocchero, V.; Basaglia, M.; Casella, S. Novel Yeast Strains for the Efficient Saccharification and Fermentation of Starchy By-Products to Bioethanol. Energies 2019, 12, 714. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Papagiannakis, R.G.; Kyritsis, D.C. Combustion heat release analysis of ethanol or n-butanol diesel fuel blends in heavy-duty DI diesel engine. Fuel 2011, 90, 1855–1867. [Google Scholar] [CrossRef]

- Guido, C.; Beatrice, C.; Napolitano, P. Application of bioethanol/RME/diesel blend in a Euro5 automotive diesel engine: Potentiality of closed loop combustion control technology. Appl. Energy 2013, 102, 13–23. [Google Scholar] [CrossRef]

- Lapuerta, M.; Armas, O.; Herreros, J.M. Emissions from a diesel–bioethanol blend in an automotive diesel engine. Fuel 2008, 87, 25–31. [Google Scholar] [CrossRef]

- Chen, H.; Shi-Jin, S.; Jian-Xin, W. Study on combustion characteristics and PM emission of diesel engines using ester–ethanol–diesel blended fuels. Proc. Combust. Inst. 2007, 31, 2981–2989. [Google Scholar] [CrossRef]

- Corro, G.; Ayala, E. Bioethanol and diesel/bioethanol blends emissions abatement. Fuel 2008, 87, 3537–3542. [Google Scholar] [CrossRef]

- Yilmaz, N.; Atmanli, A.; Vigil, F.M. Quaternary blends of diesel, biodiesel, higher alcohols and vegetable oil in a compression ignition engine. Fuel 2018, 212, 462–469. [Google Scholar] [CrossRef]

- Yilmaz, N. Comparative analysis of biodiesel–ethanol–diesel and biodiesel–methanol–diesel blends in a diesel engine. Energy 2012, 40, 210–213. [Google Scholar] [CrossRef]

- Yasin, M.H.M.; Mamat, R.; Yusop, A.F.; Aziz, A.; Najafi, G. Comparative Study on Biodiesel-methanol-diesel Low Proportion Blends Operating with a Diesel Engine. Energy Procedia 2015, 75, 10–16. [Google Scholar] [CrossRef]

- Tan, Y.H.; Abdullah, M.O.; Nolasco-Hipolito, C.; Zauzi, N.S.A.; Abdullah, G.W. Engine performance and emissions characteristics of a diesel engine fueled with diesel-biodiesel-bioethanol emulsions. Energy Convers. Manag. 2017, 132, 54–64. [Google Scholar] [CrossRef]

- Zhang, Z.-H.; Balasubramanian, R. Influence of butanol–diesel blends on particulate emissions of a non-road diesel engine. Fuel 2014, 118, 130–136. [Google Scholar] [CrossRef]

- Karabektas, M.; Hosoz, M. Performance and emission characteristics of a diesel engine using isobutanol–diesel fuel blends. Renew. Energy 2009, 34, 1554–1559. [Google Scholar] [CrossRef]

- Senthil, R.; Silambarasan, R. Annona: A new biodiesel for diesel engine: A comparative experimental investigation. J. Energy Inst. 2015, 88, 459–469. [Google Scholar] [CrossRef]

- Gad, M.S.; El-Araby, R.; Abed, K.A.; El-Ibiari, N.N.; El Morsi, A.K.; El-Diwani, G.I. Performance and emissions characteristics of C.I. engine fueled with palm oil/palm oil methyl ester blended with diesel fuel. Egypt. J. Pet. 2018, 27, 215–219. [Google Scholar] [CrossRef]

- Masum, B.M.; Masjuki, H.H.; Kalam, M.A.; Rizwanul Fattah, I.M.; Palash, S.M.; Abedin, M.J. Effect of ethanol–gasoline blend on NOx emission in SI engine. Renew. Sustain. Energy Rev. 2013, 24, 209–222. [Google Scholar] [CrossRef]

- How, H.G.; Masjuki, H.H.; Kalam, M.A.; Teoh, Y.H. An investigation of the engine performance, emissions and combustion characteristics of coconut biodiesel in a high-pressure common-rail diesel engine. Energy 2014, 69, 749–759. [Google Scholar] [CrossRef]

- Teoh, Y.H.; Masjuki, H.H.; Kalam, M.A.; How, H.G. Effect of injection timing and EGR on engine-out-responses of a common-rail diesel engine fueled with neat biodiesel. RSC Adv. 2015, 5, 96080–96096. [Google Scholar] [CrossRef]

- Senthil, R.; Sivakumar, E.; Silambarasan, R. Effect of di ethyl ether on the performance and emission characteristics of a diesel engine using biodiesel–eucalyptus oil blends. RSC Adv. 2015, 5, 54019–54027. [Google Scholar] [CrossRef]

- Goering, C. Engine heat release via spread sheet. Trans. ASAE 1998, 41, 1249. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Yilmaz, N.; Atmanli, A. Experimental assessment of a diesel engine fueled with diesel-biodiesel-1-pentanol blends. Fuel 2017, 191, 190–197. [Google Scholar] [CrossRef]

- Can, Ö.; Öztürk, E.; Yücesu, H.S. Combustion and exhaust emissions of canola biodiesel blends in a single cylinder DI diesel engine. Renew. Energy 2017, 109, 73–82. [Google Scholar] [CrossRef]

- Srithar, K.; Arun Balasubramanian, K.; Pavendan, V.; Ashok Kumar, B. Experimental investigations on mixing of two biodiesels blended with diesel as alternative fuel for diesel engines. J. King Saud Univ. Eng. Sci. 2017, 29, 50–56. [Google Scholar] [CrossRef]

- Yang, K.; Wei, L.; Cheung, C.S.; Tang, C.; Huang, Z. The effect of pentanol addition on the particulate emission characteristics of a biodiesel operated diesel engine. Fuel 2017, 209, 132–140. [Google Scholar] [CrossRef]

- Imtenan, S.; Masjuki, H.H.; Varman, M.; Kalam, M.A.; Arbab, M.I.; Sajjad, H.; Ashrafur Rahman, S.M. Impact of oxygenated additives to palm and jatropha biodiesel blends in the context of performance and emissions characteristics of a light-duty diesel engine. Energy Convers. Manag. 2014, 83, 149–158. [Google Scholar] [CrossRef]

- Prbakaran, B.; Viswanathan, D. Experimental investigation of effects of addition of ethanol to bio-diesel on performance, combustion and emission characteristics in CI engine. Alex. Eng. J. 2018, 57, 383–389. [Google Scholar] [CrossRef]

- Imdadul, H.K.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Alabdulkarem, A.; Rashed, M.M.; Teoh, Y.H.; How, H.G. Higher alcohol–biodiesel–diesel blends: An approach for improving the performance, emission, and combustion of a light-duty diesel engine. Energy Convers. Manag. 2016, 111, 174–185. [Google Scholar] [CrossRef]

- Babu, D.; Anand, R. Effect of biodiesel-diesel-n-pentanol and biodiesel-diesel- n -hexanol blends on diesel engine emission and combustion characteristics. Energy 2017, 133, 761–776. [Google Scholar] [CrossRef]

- Dhanasekaran, R.; Krishnamoorthy, V.; Rana, D.; Saravanan, S.; Nagendran, A.; Rajesh Kumar, B. A sustainable and eco-friendly fueling approach for direct-injection diesel engines using restaurant yellow grease and n-pentanol in blends with diesel fuel. Fuel 2017, 193, 419–431. [Google Scholar] [CrossRef]

- Wei, L.; Cheung, C.S.; Huang, Z. Effect of n-pentanol addition on the combustion, performance and emission characteristics of a direct-injection diesel engine. Energy 2014, 70, 172–180. [Google Scholar] [CrossRef]

- Liaquat, A.M.; Masjuki, H.H.; Kalam, M.A.; Fattah, I.M.R.; Hazrat, M.A.; Varman, M.; Mofijur, M.; Shahabuddin, M. Effect of Coconut Biodiesel Blended Fuels on Engine Performance and Emission Characteristics. Procedia Eng. 2013, 56, 583–590. [Google Scholar] [CrossRef]

- Chen, K.-H.; Chao, Y.-C. Characterization of Performance of Short Stroke Engines with Valve Timing for Blended Bioethanol Internal Combustion. Energies 2019, 12, 759. [Google Scholar] [CrossRef]

- Fang, Q.; Fang, J.; Zhuang, J.; Huang, Z. Effects of ethanol–diesel–biodiesel blends on combustion and emissions in premixed low temperature combustion. Appl. Therm. Eng. 2013, 54, 541–548. [Google Scholar] [CrossRef]

- Yilmaz, N.; Atmanli, A. Experimental evaluation of a diesel engine running on the blends of diesel and pentanol as a next generation higher alcohol. Fuel 2017, 210, 75–82. [Google Scholar] [CrossRef]

- Yilmaz, N.; Atmanli, A.; Trujillo, M. Influence of 1-pentanol additive on the performance of a diesel engine fueled with waste oil methyl ester and diesel fuel. Fuel 2017, 207, 461–469. [Google Scholar] [CrossRef]

- Yilmaz, N.; Vigil, F.M.; Burl Donaldson, A.; Darabseh, T. Investigation of CI engine emissions in biodiesel–ethanol–diesel blends as a function of ethanol concentration. Fuel 2014, 115, 790–793. [Google Scholar] [CrossRef]

- Atmanli, A. Effects of a cetane improver on fuel properties and engine characteristics of a diesel engine fueled with the blends of diesel, hazelnut oil and higher carbon alcohol. Fuel 2016, 172, 209–217. [Google Scholar] [CrossRef]

- Baskar, P.; Senthilkumar, A. Effects of oxygen enriched combustion on pollution and performance characteristics of a diesel engine. Eng. Sci. Technol. Int. J. 2016, 19, 438–443. [Google Scholar] [CrossRef]

- Teoh, Y.H.; Masjuki, H.H.; Kalam, M.A.; Amalina, M.A.; How, H.G. Impact of waste cooking oil biodiesel on performance, exhaust emission and combustion characteristics in a light-duty diesel engine. SAE Tech. Pap. 2013. [Google Scholar] [CrossRef]

- How, H.G.; Teoh, Y.H.; Masjuki, H.H.; Kalam, M.A. Impact of coconut oil blends on particulate-phase PAHs and regulated emissions from a light duty diesel engine. Energy 2012, 48, 500–509. [Google Scholar] [CrossRef]

- Dhinesh, B.; Annamalai, M. A study on performance, combustion and emission behaviour of diesel engine powered by novel nano nerium oleander biofuel. J. Clean. Prod. 2018, 196, 74–83. [Google Scholar] [CrossRef]

- Rajesh Kumar, B.; Saravanan, S. Effects of iso-butanol/diesel and n-pentanol/diesel blends on performance and emissions of a DI diesel engine under premixed LTC (low temperature combustion) mode. Fuel 2016, 170, 49–59. [Google Scholar] [CrossRef]

- Emiroğlu, A.O.; Şen, M. Combustion, performance and exhaust emission characterizations of a diesel engine operating with a ternary blend (alcohol-biodiesel-diesel fuel). Appl. Therm. Eng. 2018, 133, 371–380. [Google Scholar] [CrossRef]

- Özener, O.; Yüksek, L.; Ergenç, A.T.; Özkan, M. Effects of soybean biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 2014, 115, 875–883. [Google Scholar] [CrossRef]

- Zheng, Z.; Wang, X.; Zhong, X.; Hu, B.; Liu, H.; Yao, M. Experimental study on the combustion and emissions fueling biodiesel/n-butanol, biodiesel/ethanol and biodiesel/2,5-dimethylfuran on a diesel engine. Energy 2016, 115, 539–549. [Google Scholar] [CrossRef]

- Alptekin, E. Evaluation of ethanol and isopropanol as additives with diesel fuel in a CRDI diesel engine. Fuel 2017, 205, 161–172. [Google Scholar] [CrossRef]

- Song, H.; Quinton, K.; Peng, Z.; Zhao, H.; Ladommatos, N. Effects of Oxygen Content of Fuels on Combustion and Emissions of Diesel Engines. Energies 2016, 9, 28. [Google Scholar] [CrossRef]

- Gharehghani, A.; Mirsalim, M.; Hosseini, R. Effects of waste fish oil biodiesel on diesel engine combustion characteristics and emission. Renew. Energy 2017, 101, 930–936. [Google Scholar] [CrossRef]

- Qi, D.H.; Yang, K.; Zhang, D.; Chen, B. Combustion and emission characteristics of diesel-tung oil-ethanol blended fuels used in a CRDI diesel engine with different injection strategies. Appl. Therm. Eng. 2017, 111, 927–935. [Google Scholar] [CrossRef]

| Properties | Unit | Diesel | Coconut Biodiesel | Bioethanol | Test Method |

|---|---|---|---|---|---|

| Kinematic viscosity @ 40 °C | mm2s−1 | 3.51 | 4.1 | 1.08 | D445 |

| Density @ 15 °C | kgm−3 | 851.9 | 886.2 | 794.0 | D127 |

| Calorific value | MJkg−1 | 45.31 | 38.1 | 29.0 | D240 |

| Flash point | °C | 71.5 | 115.5 | 14 | D93 |

| Cetane number | - | 52 | 55.9 | 5–8 | D6890 |

| Carbon | wt.% | 88 | 78 | 52 | D5291 |

| Hydrogen | wt.% | 13 | 12 | 13 | D5292 |

| Oxygen | wt.% | 0 | 11 | 35 | D5293 |

| Fuels | Unit | B20 | B20E5 | B20E10 | Test Method |

|---|---|---|---|---|---|

| Diesel | %(v/v) | 80 | 75 | 70 | - |

| Methyl ester | %(v/v) | 20 | 20 | 20 | - |

| Bioethanol | %(v/v) | 0 | 5 | 10 | - |

| Kinematic viscosity @ 40 °C | mm2s−1 | 3.74 | 3.33 | 2.98 | D445 |

| Density @ 15 °C | kgm−3 | 859.6 | 856 | 852.1 | D127 |

| Calorific value | MJkg−1 | 43.89 | 43.12 | 42.25 | D240 |

| Engine Type | Diesel, Direct Injection, Turbocharged |

|---|---|

| Number of cylinders | 4 |

| Number of valves per cylinder | 2 |

| Bore | 76.0 mm |

| Stroke | 80.5 mm |

| Maximum power | 48 kW @ 4000 rpm |

| Maximum torque | 160 Nm @ 2000 rpm |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teoh, Y.H.; Yu, K.H.; How, H.G.; Nguyen, H.-T. Experimental Investigation of Performance, Emission and Combustion Characteristics of a Common-Rail Diesel Engine Fuelled with Bioethanol as a Fuel Additive in Coconut Oil Biodiesel Blends. Energies 2019, 12, 1954. https://doi.org/10.3390/en12101954

Teoh YH, Yu KH, How HG, Nguyen H-T. Experimental Investigation of Performance, Emission and Combustion Characteristics of a Common-Rail Diesel Engine Fuelled with Bioethanol as a Fuel Additive in Coconut Oil Biodiesel Blends. Energies. 2019; 12(10):1954. https://doi.org/10.3390/en12101954

Chicago/Turabian StyleTeoh, Y.H., K.H. Yu, H.G. How, and H.-T. Nguyen. 2019. "Experimental Investigation of Performance, Emission and Combustion Characteristics of a Common-Rail Diesel Engine Fuelled with Bioethanol as a Fuel Additive in Coconut Oil Biodiesel Blends" Energies 12, no. 10: 1954. https://doi.org/10.3390/en12101954

APA StyleTeoh, Y. H., Yu, K. H., How, H. G., & Nguyen, H.-T. (2019). Experimental Investigation of Performance, Emission and Combustion Characteristics of a Common-Rail Diesel Engine Fuelled with Bioethanol as a Fuel Additive in Coconut Oil Biodiesel Blends. Energies, 12(10), 1954. https://doi.org/10.3390/en12101954