Effect of Ice Shedding on Discharge Characteristics of an Ice-Covered Insulator String during AC Flashover

Abstract

:1. Introduction

2. Experimental Setup and Procedures

3. Flashover Performance on an Ice-Covered Insulator

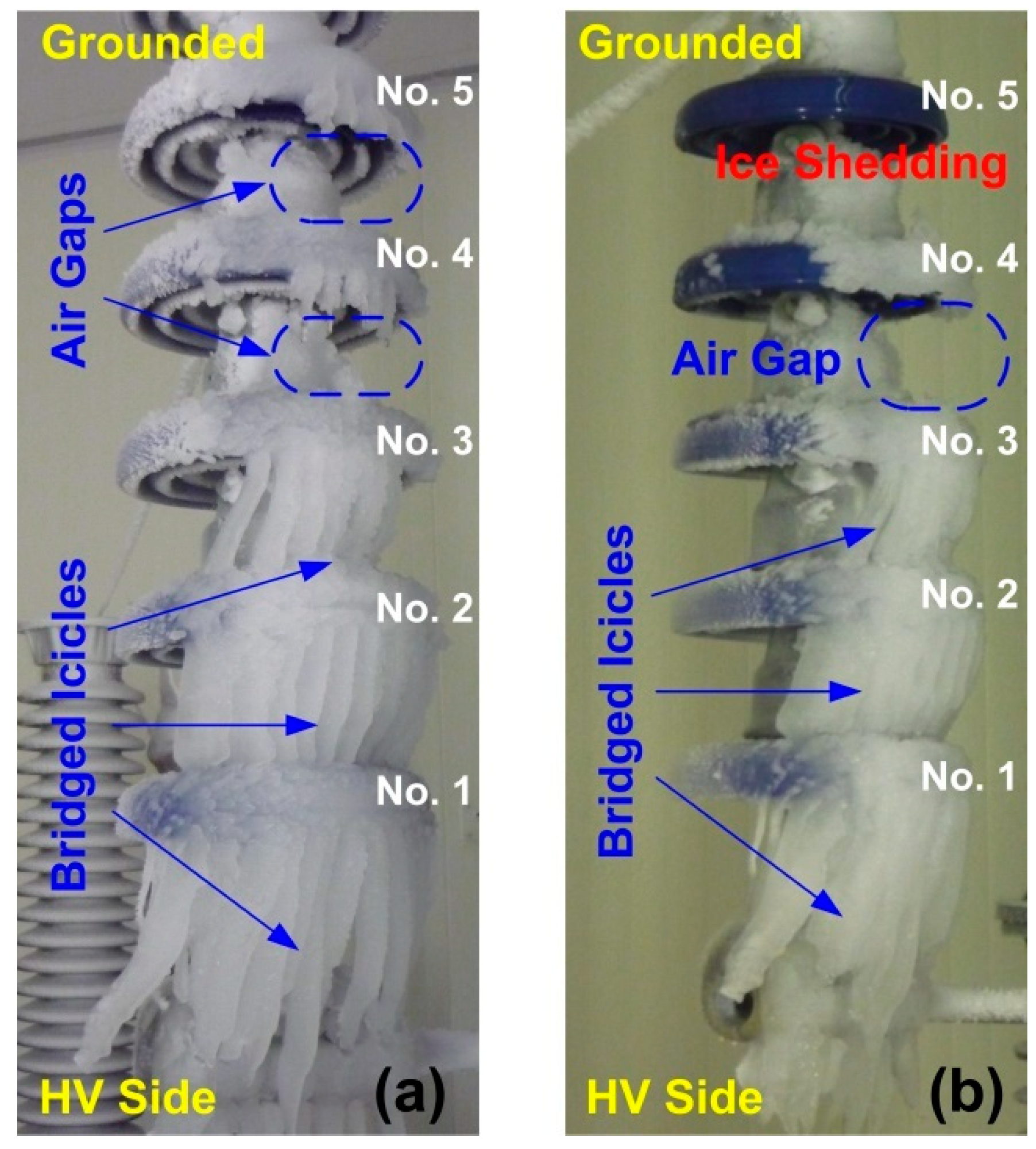

3.1. Icing State of an Ice-Covered Outdoor Insulator with and without Ice Shedding

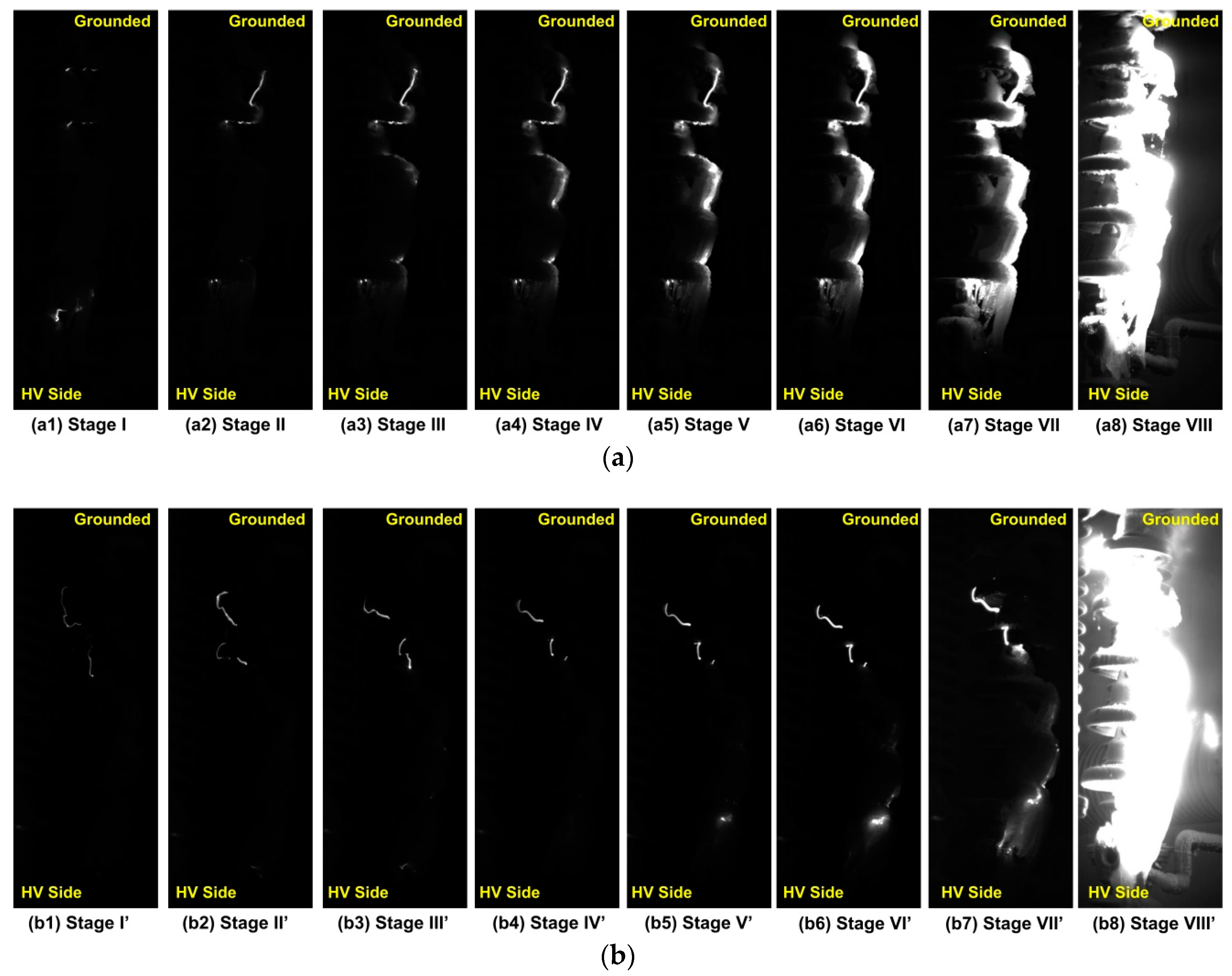

3.2. Flashover Process of Ice-Covered Insulators with and without Ice Shedding

4. Time-Frequency Analysis of Leakage Current (LC) during Flashover Process

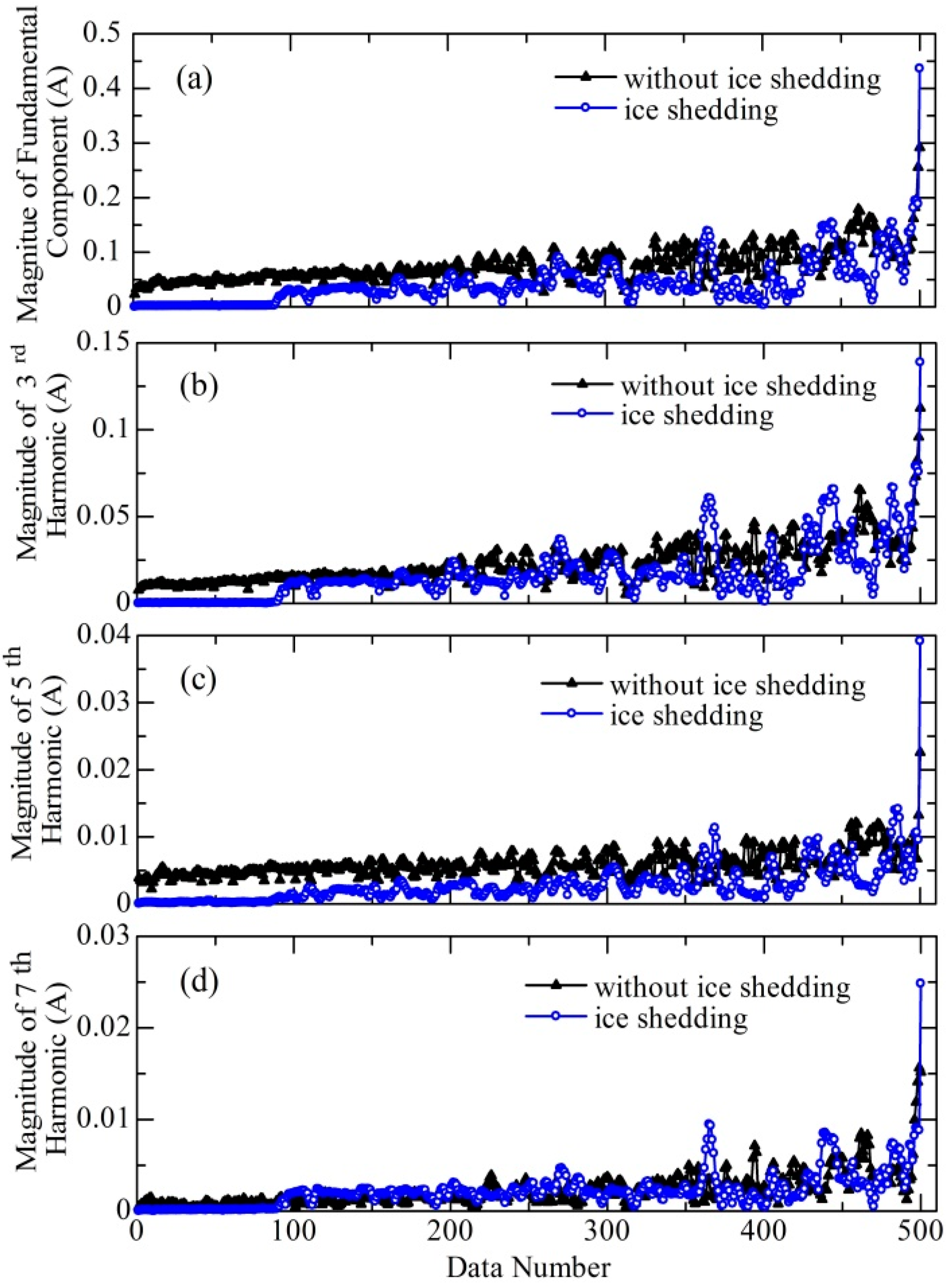

4.1. Temporal Variation of LC Components

4.2. Ratio of Harmonics to the Fundamental Component

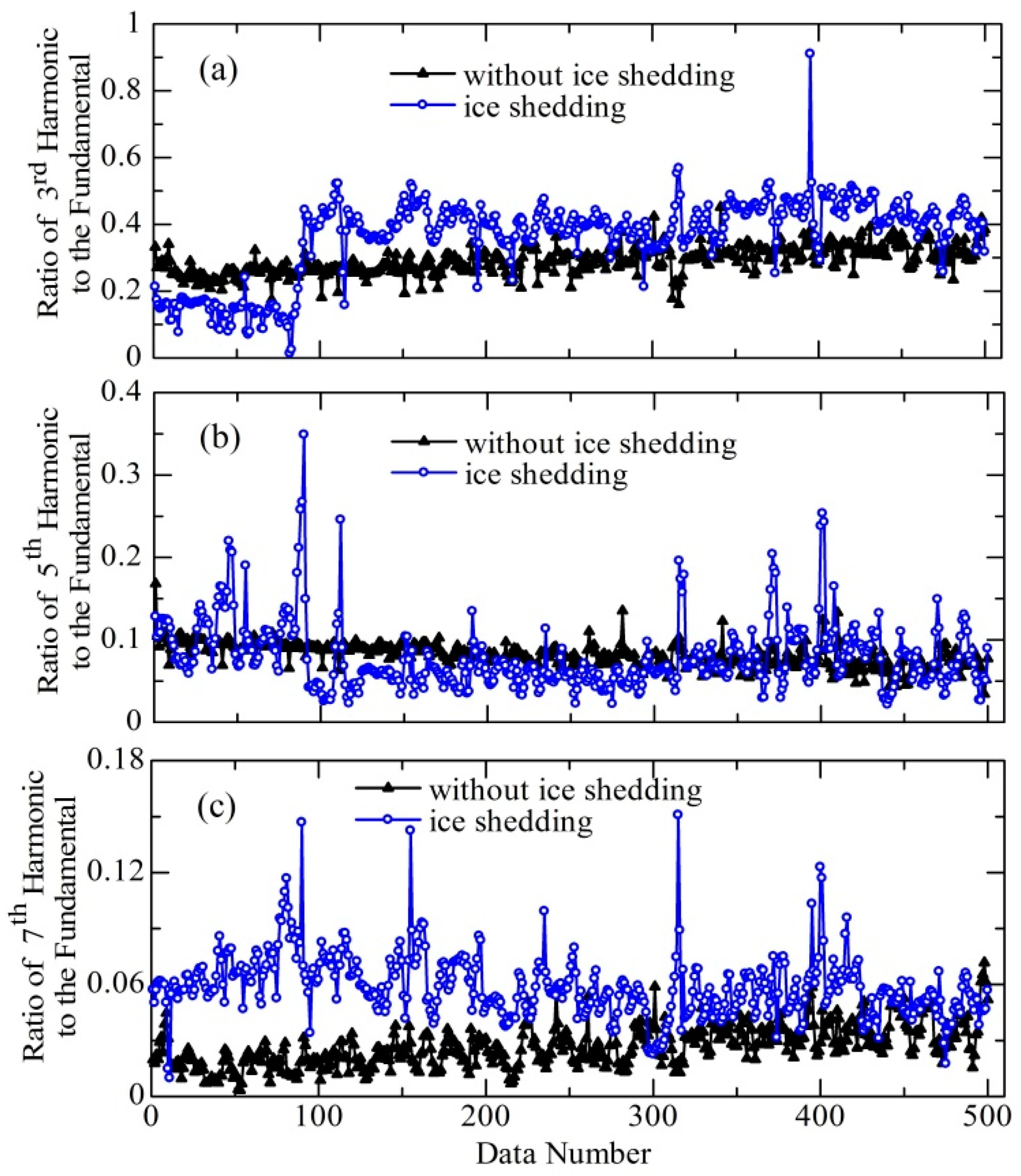

5. Conclusions

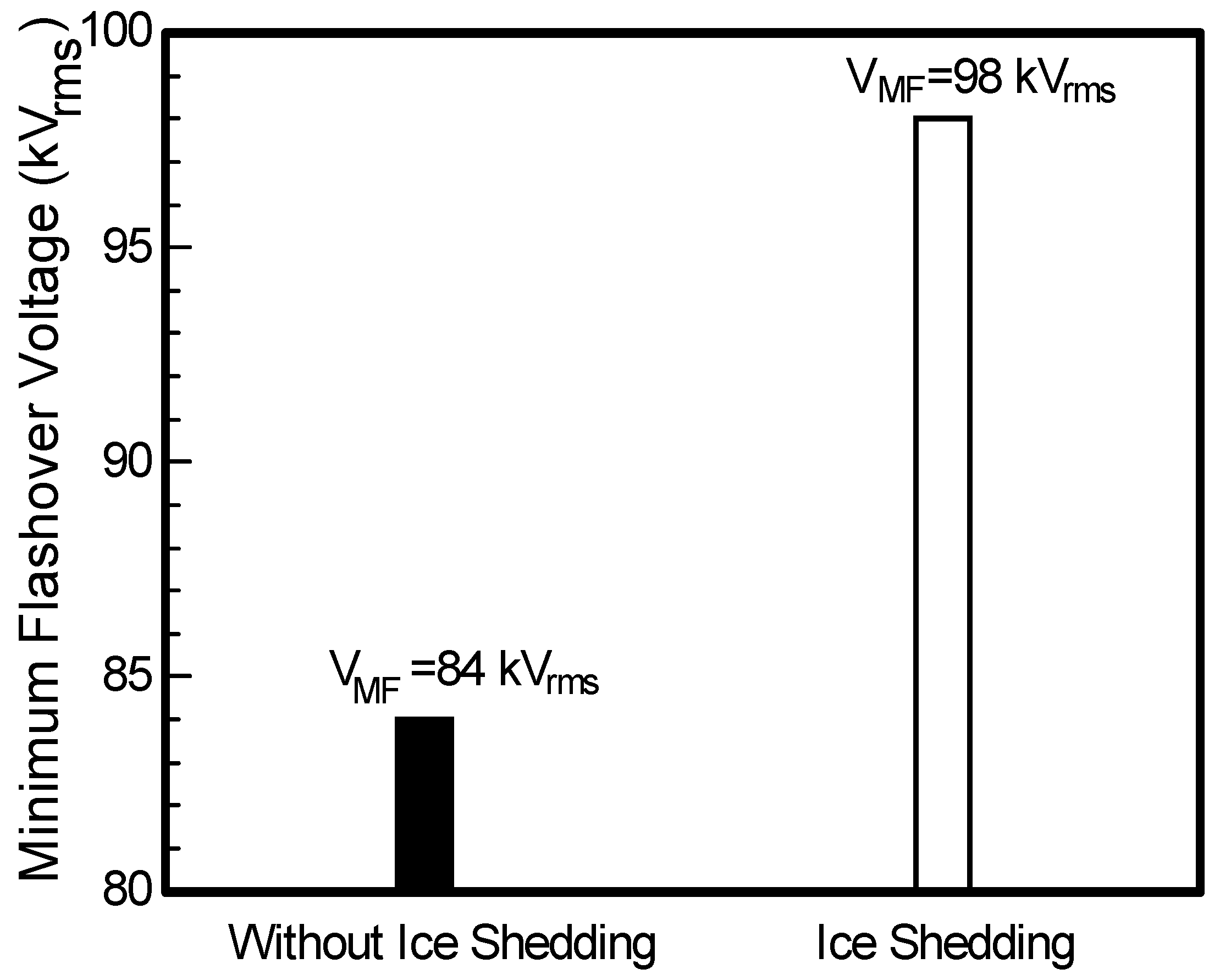

- (1)

- Ice shedding restricts the extension of discharge arcs to the critical length for flashover, leading to VMF enhancement of about 17% from conditions of without ice shedding (VMF = 84 kVrms) to the occurrence of ice shedding (VMF = 98 kVrms).

- (2)

- Compared with a relatively easy initiation and stable occurrence of discharge arcs in shortest air gap on an ice-covered insulator without ice shedding, ice shedding restrains the initiation and formation of discharge arcs across ice-free regions. These arcs are characterized by an unstable propagating path, indeterminate arc shape and longer arc column.

- (3)

- The temporal variation of LC low-frequency components (the fundamental, 3rd, 5th and 7th harmonics) is well related to surface performance of an ice-covered outdoor insulator during AC flashover process, where the fundamental component indicates the melting process of the ice layer and the harmonic components accord with the discharge behaviors across ice-free areas.

- (4)

- Although VMF under ice shedding is higher than that without ice shedding, the fundamental component, 3rd, 5th and 7th harmonics under ice shedding overall show lower values and bigger fluctuation trends with the development of the flashover process.

- (5)

- The ratios of 3rd, 5th and 7th harmonics to the fundamental component are well in accordance with discharge characteristics of ice-covered insulators, where a relatively stable varying tendency can be determined for the without-ice shedding condition, but a significant fluctuation and indeterminate tendency for the ice shedding condition.

Author Contributions

Funding

Conflicts of Interest

References

- Lu, J.Z.; Xie, P.K.; Jiang, Z.L.; Fang, Z.; Wu, W. Voltage distribution and flashover performance of 220 kV composite insulators under different icing conditions. Energies 2018, 11, 632. [Google Scholar] [CrossRef]

- Shu, L.C.; Wang, S.J.; Jiang, X.L.; Hu, Q.; Yang, X.Y.; Yang, S.; Chen, J. Effect of grading ring on ice characteristics and flashover performance of 220 kV composite insulators with different shed configurations. IEEE Trans. Dielectr. Electrl. Insul. 2015, 22, 951–960. [Google Scholar] [CrossRef]

- Hao, Y.P.; Wei, J.; Jiang, X.L.; Yang, L.; Li, L.C.; Wang, J.K.; Li, H.; Li, R.H. Icing condition assessment of in-service glass insulators based on graphical shed spacing and graphical shed overhang. Energies 2018, 11, 318. [Google Scholar] [CrossRef]

- Liu, Y.; Farzaneh, M.; Du, B.X. Investigation on shed icicle characteristics and induced surface discharges along a suspension insulator string during ice accretion. IET Gener. Transm. Distrib. 2017, 11, 1265–1269. [Google Scholar] [CrossRef]

- Deng, Y.; Jia, Z.D.; Jiang, H.; Guan, Z.C.; Zhou, J. Analysis of icicle growth process of composite insulator under energized condition and its impact factors. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 1613–1622. [Google Scholar] [CrossRef]

- Liu, Y.; Du, B.X.; Farzaneh, M. Self-Normalizing multivariate analysis of polymer insulator leakage current under severe fog conditions. IEEE Trans. Power Deliv. 2017, 32, 1279–1286. [Google Scholar] [CrossRef]

- Hara, M.; Phan, C.L. A Study of leakage current of HV insulators under glaze and rime. Can. Electr. Eng. J. 1978, 3, 15–22. [Google Scholar] [CrossRef]

- Jiang, X.L.; Wang, Q.L.; Zhang, Z.J.; Hu, J.L.; Hu, Q.; Zhu, C.Z. Ion migration in the process of water freezing under alternating electric field and its impact on insulator flashover. Energies 2017, 10, 61. [Google Scholar] [CrossRef]

- Farokhi, S.; Farzaneh, M.; Fofana, I. Experimental investigation of the process of arc propagation over an ice surface. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 458–464. [Google Scholar] [CrossRef]

- Fofana, I.; Farzaneh, M.; Hemmatjou, H.; Volat, C. Study of discharge in air from the tip of an icicle. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 730–740. [Google Scholar] [CrossRef]

- Arshad, M.; Nekahi, A.; McMeekin, S.G.; Farzaneh, M. Flashover characteristics of silicone rubber sheets under various environmental conditions. Energies 2016, 9, 683. [Google Scholar] [CrossRef]

- Jiang, X.L.; Dong, B.B.; Zhang, Z.J.; Yin, F.H.; Shu, L.C. Effect of shed configuration on DC flashover performance of ice-covered 110 kV composite insulators. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 699–705. [Google Scholar] [CrossRef]

- Hu, J.L.; Jiang, X.L.; Yin, F.H.; Zhang, Z.J. DC flashover performance of ice-covered composite insulators with parallel air gaps. Energies 2015, 8, 4983–4999. [Google Scholar] [CrossRef]

- Farzaneh, M.; Kiernicki, J. Flashover performance of IEEE standard insulators under ice conditions. IEEE Trans. Power Deliv. 1997, 12, 1602–1613. [Google Scholar] [CrossRef]

- Nekahi, A.; Farokhi, S.; Farzaneh, M.; Stewart, B.G. Arc energy and temperature during its propagation over ice-covered surfaces. IEEE Trans. Plasma Sci. 2014, 42, 114–119. [Google Scholar] [CrossRef]

- Farzaneh, M.; Zhang, J. A multi-arc model for predicting AC critical flashover voltage of ice-covered insulators. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 1401–1409. [Google Scholar] [CrossRef]

- Farzaneh, M.; Zhang, J.; Chaarani, R.; Fikke, S.M. Critical conditions of AC arc propagation on ice surfaces. In Proceedings of the IEEE International Symposium on Electrical Insulation, Anaheim, CA, USA, 2–5 April 2000. [Google Scholar]

- Farzaneh, M.; Volat, C.; Zhang, J. Role of air gaps on AC withstand voltage of an ice-covered insulator string. IEEE Trans. Dielectr. Electr. Insul. 2007, 13, 1350–1357. [Google Scholar] [CrossRef]

- Volat, C.; Farzaneh, M. Three-dimensional modeling of potential and electric-field distributions along an EHV ceramic post insulator covered with ice—Part I: Simulations of a melting period. IEEE Trans. Power Deliv. 2005, 20, 2006–2013. [Google Scholar] [CrossRef]

- Volat, C.; Farzaneh, M. Three-dimensional modeling of potential and electric-field distributions along an EHV ceramic post insulator covered with ice—Part II: Effect of air gaps and partial arcs. IEEE Trans. Power Deliv. 2005, 20, 2014–2021. [Google Scholar] [CrossRef]

- Wang, Y.X.; Jiang, X.L.; Fan, S.H.; Meng, Z.G. Asynchronism of ice shedding from the de-iced conductor based on heat transfer. IET Sci. Meas. Technol. 2016, 10, 389–395. [Google Scholar]

- Jiang, X.L.; Fan, S.H.; Zhang, Z.J.; Sun, C.X.; Shu, L.C. Simulation and experimental investigation of DC ice-melting process on an iced conductor. IEEE Trans. Power Deliv. 2010, 25, 919–929. [Google Scholar] [CrossRef]

- Farzaneh, M.; Zhang, J.; Chen, X. Modeling of the AC arc discharge on ice surfaces. IEEE Trans. Power Deliv. 1997, 12, 325–338. [Google Scholar] [CrossRef]

- Volat, C.; Meghnefi, F.; Farzaneh, M.; Ezzaidi, H. Monitoring leakage current of ice-covered station post insulator using artificial neural networks. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 443–450. [Google Scholar] [CrossRef]

- El-Hag, A.H.; Jayaram, S.H.; Cherney, E.A. Fundamental and low frequency harmonic components of leakage current as a diagnostic tool to study aging of RTV and HTV silicone rubber in salt-fog. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 128–136. [Google Scholar] [CrossRef]

- Suda, T. Frequency characteristics of leakage current waveforms of a string of suspension insulators. IEEE Trans. Power Deliv. 2005, 20, 481–487. [Google Scholar]

- Jiang, X.L.; Shi, Y.; Sun, C.X.; Zhang, Z.J. Evaluating the safety condition of porcelain insulators by the time and frequency characteristics of LC based on artificial pollution tests. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 481–489. [Google Scholar] [CrossRef]

- Chen, W.G.; Wang, W.P.; Xia, Q.; Luo, B.; Li, L.C. Insulator contamination forecasting based on fractal analysis of leakage current. Energies 2012, 5, 2594–2607. [Google Scholar] [CrossRef]

- Liu, Y.; Farzaneh, M.; Du, B.X. Using chaotic features of leakage current for monitoring dynamic behavior of surface discharges on an ice-covered insulator. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2607–2615. [Google Scholar] [CrossRef]

- Kordkheili, H.H.; Abravesh, H.; Tabasi, M.; Dakhem, M.; Abravesh, M.M. Determining the probability of flashover occurrence in composite insulators by using leakage current harmonic components. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 502–512. [Google Scholar] [CrossRef]

- Tavares, M.; Talaisys, J.; Camara, A. Voltage harmonic content of long artificially generated electrical arc in out-door experiment at 500kV towers. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1005–1014. [Google Scholar] [CrossRef]

- Liu, Y.; Farzaneh, M.; Du, B.X. Nonlinear characteristics of leakage current for flashover monitoring of ice-covered suspension insulators. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1242–1250. [Google Scholar] [CrossRef]

- Bashir, N.; Ahmad, H. Odd harmonics and third to fifth harmonic ratios of leakage currents as diagnostic tools to study the ageing of glass insulators. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 819–832. [Google Scholar] [CrossRef]

- Pylarinos, D.; Theofilatos, K.; Siderakis, K.; Thalassinakis, E.; Vitellas, I.; Alexandridis, A.T.; Pyrgioti, E. Investigation and classification of field leakage current waveforms. IEEE Trans. Dielectr. Electrl. Insul. 2012, 19, 2111–2118. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Zhou, M.; Luo, Y.; Wang, G.; Jia, L. Effect of Ice Shedding on Discharge Characteristics of an Ice-Covered Insulator String during AC Flashover. Energies 2018, 11, 2440. https://doi.org/10.3390/en11092440

Li X, Zhou M, Luo Y, Wang G, Jia L. Effect of Ice Shedding on Discharge Characteristics of an Ice-Covered Insulator String during AC Flashover. Energies. 2018; 11(9):2440. https://doi.org/10.3390/en11092440

Chicago/Turabian StyleLi, Xiangxin, Ming Zhou, Yazhou Luo, Gang Wang, and Lin Jia. 2018. "Effect of Ice Shedding on Discharge Characteristics of an Ice-Covered Insulator String during AC Flashover" Energies 11, no. 9: 2440. https://doi.org/10.3390/en11092440

APA StyleLi, X., Zhou, M., Luo, Y., Wang, G., & Jia, L. (2018). Effect of Ice Shedding on Discharge Characteristics of an Ice-Covered Insulator String during AC Flashover. Energies, 11(9), 2440. https://doi.org/10.3390/en11092440