Experimental Analysis on Flame Flickering of a Swirl Partially Premixed Combustion

Abstract

:1. Introduction

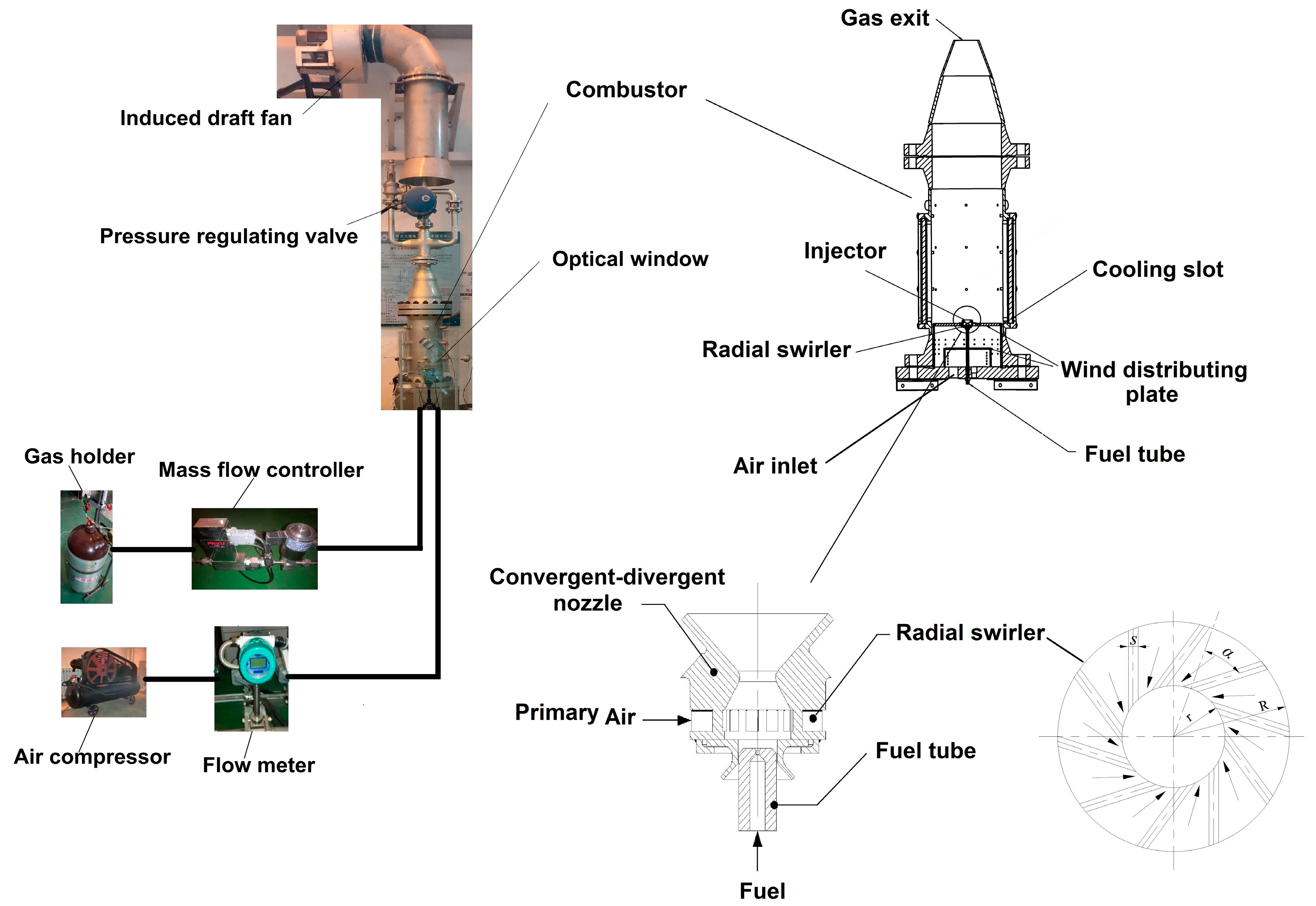

2. Experimental Setup

3. Analysis Technology

3.1. Analysis Parameters

- Mean value l: calculated as Equation (1).

- Flickering weighted average frequency F [29,30]: the flickering spectrum contains multiple frequencies with large amplitudes, as will be displayed in the latter section. Therefore, a comprehensive parameter F is defined to consider the contributions of all components over the entire spectrum. It is a weighted average frequency and can be obtained by Equation (2).where fm is the mth frequency component, that is, fm = mfs/N; fs is the image sampling rate (frame rate); and X(fm) is the DFT (discrete Fourier transformation) calculating result of fm, which is determined by Equation (3).

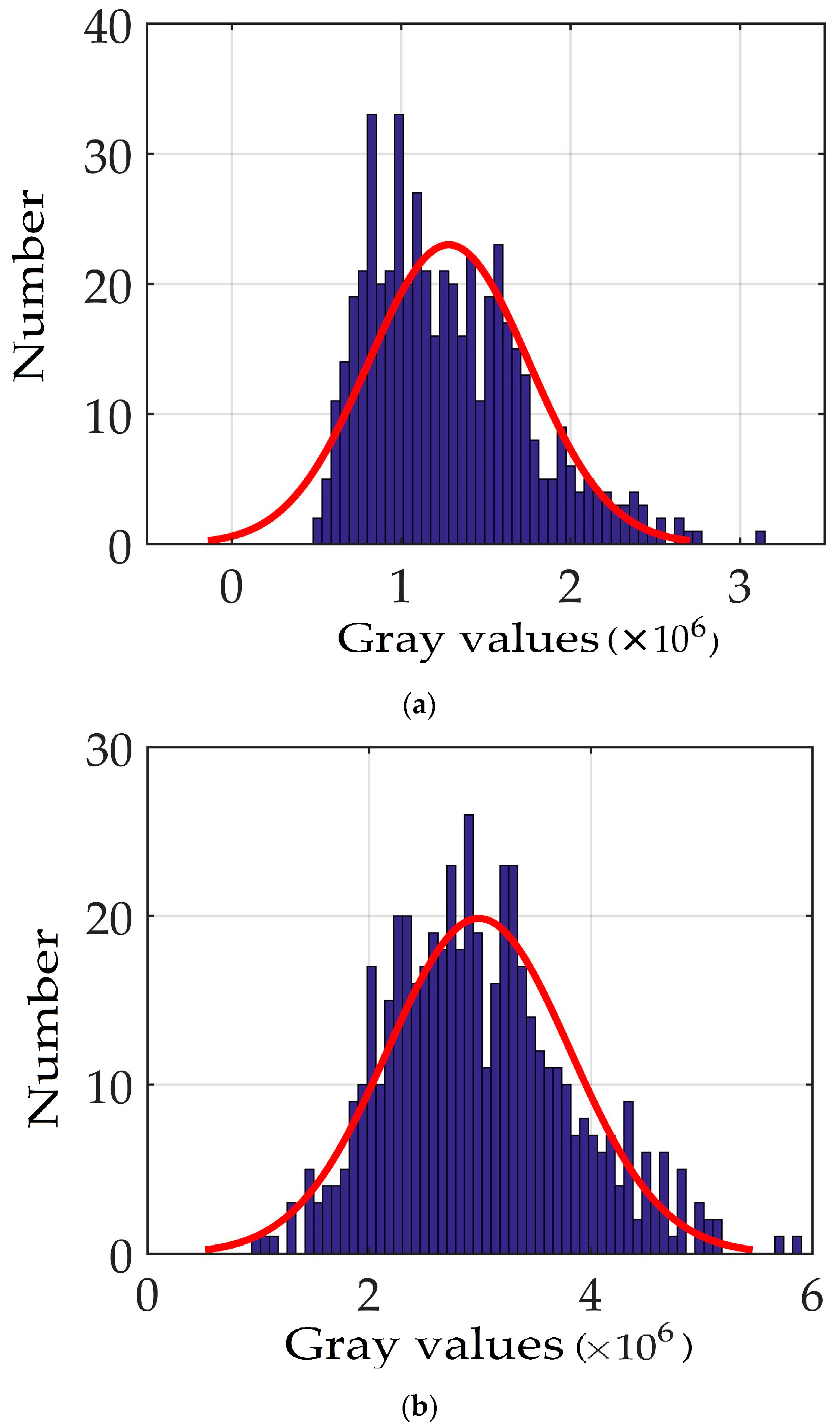

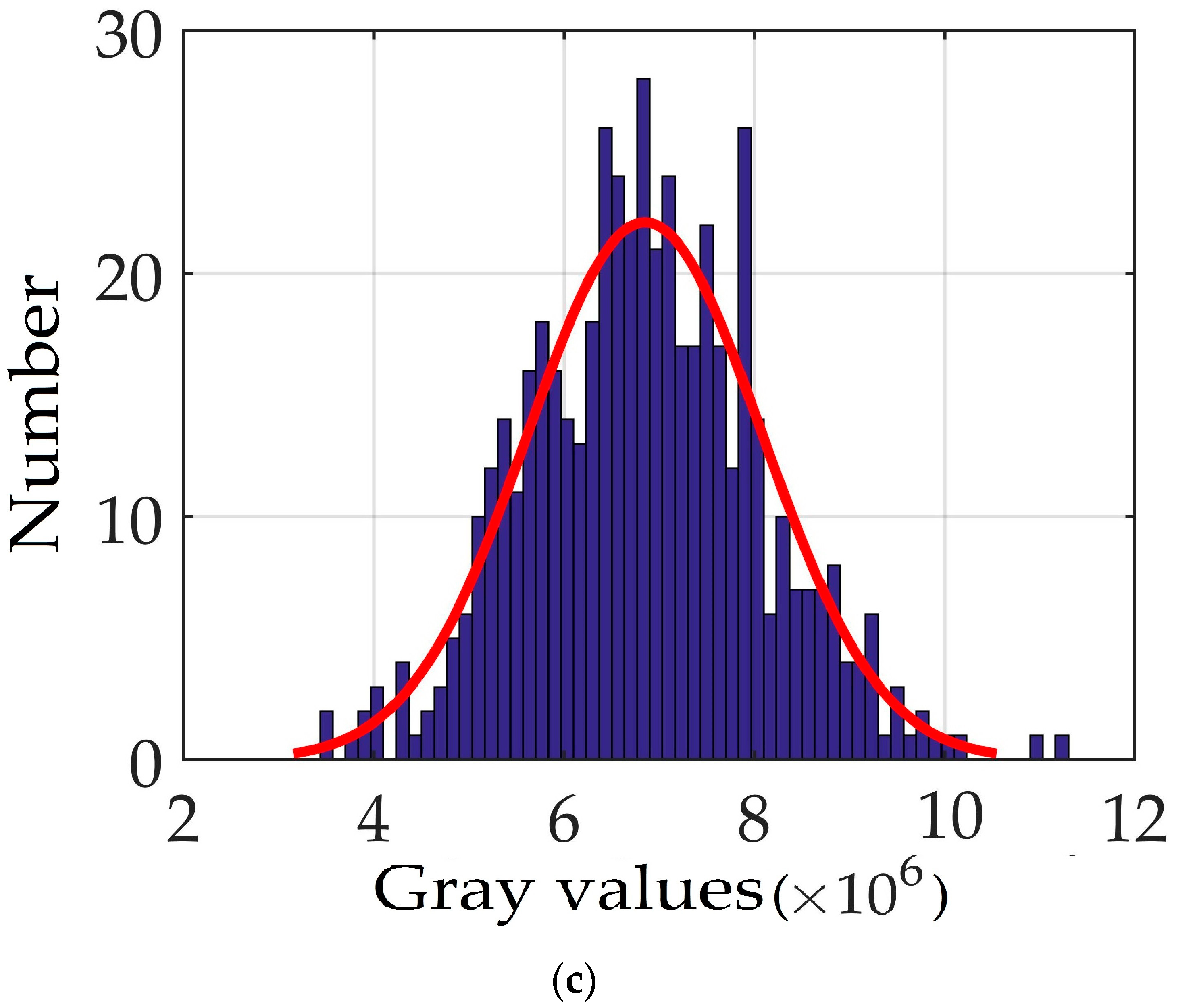

- Flickering coefficient of variation cv: the standard deviation σ is a well-known parameter to evaluate the variability or dispersion within a set of data. In general, a small σ indicates that the values approach the average, while a large σ implies that the data distribute over a large range of values. However, when the comparison is performed within different data groups, the use of σ has an assumption that their mean values are equal (or approximately equal). If the mean values of compared data sets have a significant difference, the σ is not suitable because it will bring large errors. To replace the position of σ under this situation, the coefficient of variation cv is firstly introduced to estimate the oscillation amplitude. The cv is a dimensionless parameter, which is defined as the normalized standard deviation, that is, the σ normalized by mean value, as shown in Equation (4). By employing cv, the effects of diverse mean values can be eliminated. In present investigation, the flame mean luminosity varies considerably under varying mass flow rate of the fuel, and the distribution of mean gray value for a pixel also differs significantly, as exhibited in the latter section. Therefore, the coefficient of variation cv is applied.

- Skewness s: used to evaluate the asymmetry of the probability distribution of a data group around the mean value, which is defined by Equation (5). The s can be 0, positive, or negative. s = 0 indicates that the distribution is perfectly symmetric. s < 0 implies that the number of the values above the mean are larger than that below the mean, and the distribution is said to be left-skewed. On the contrary, s > 0 represents that the number of the values below the mean are larger than that above the mean, and the distribution is said to be right-skewed.

- Kurtosis k: used to describe the ‘peakedness’ of a distribution in comparison with its corresponding normal distribution, as defined by Equation (6). The value of k for normal distribution is 3, k > 3 indicates the shape of the distribution is sharper than normal distribution. A large value of k implies a strong peakedness in distribution values.

3.2. Analysis Methods

- Spatial analysis: for the same pixel in each image, the gray values registered by all pixels constitute a time luminance signal, with a length of N (i.e., the number of image series). For each operating condition, a total of x*y (as mentioned above) time signals are calculated for the oscillation parameters as defined before. The calculation result is an image, which reveals the spatial distribution of flame flickering.

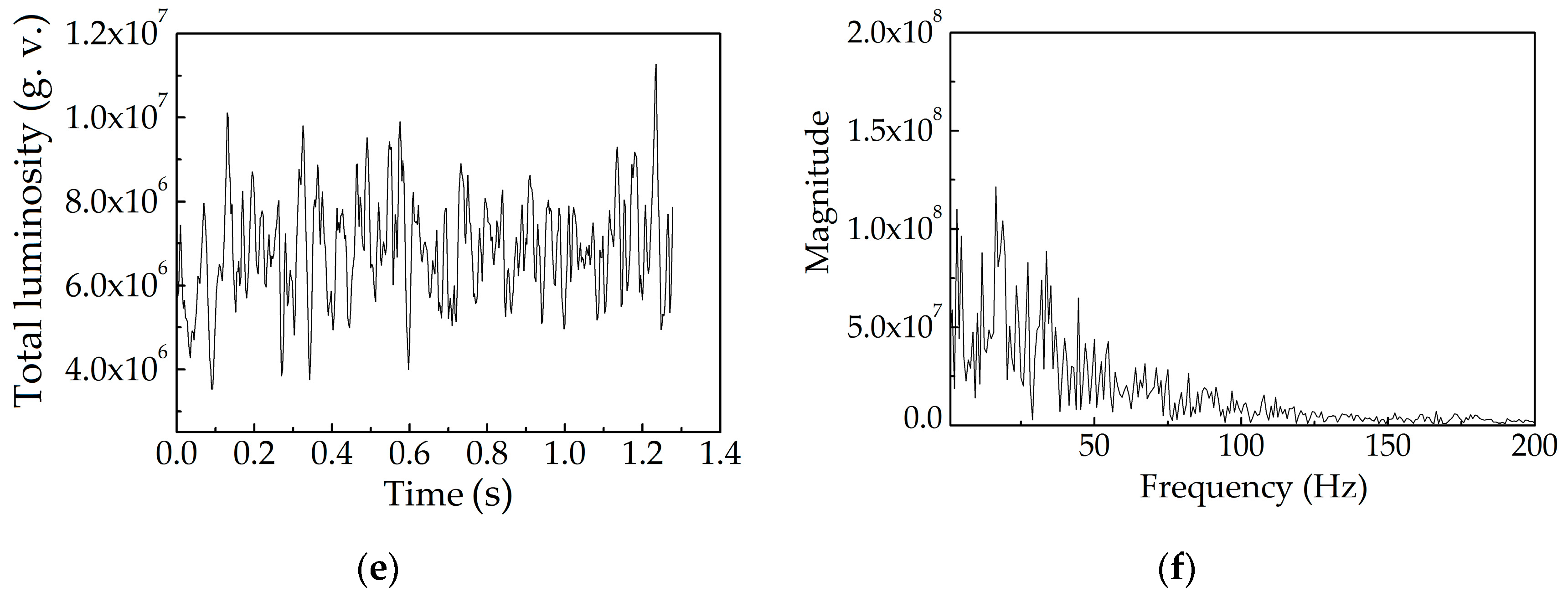

- Global analysis: for each image, the gray values all over an image are summed as a total luminosity, all total luminosities from a series of images make up a global time luminance signal for each case, which is processed to obtain global oscillation information.

4. Results and Discussion

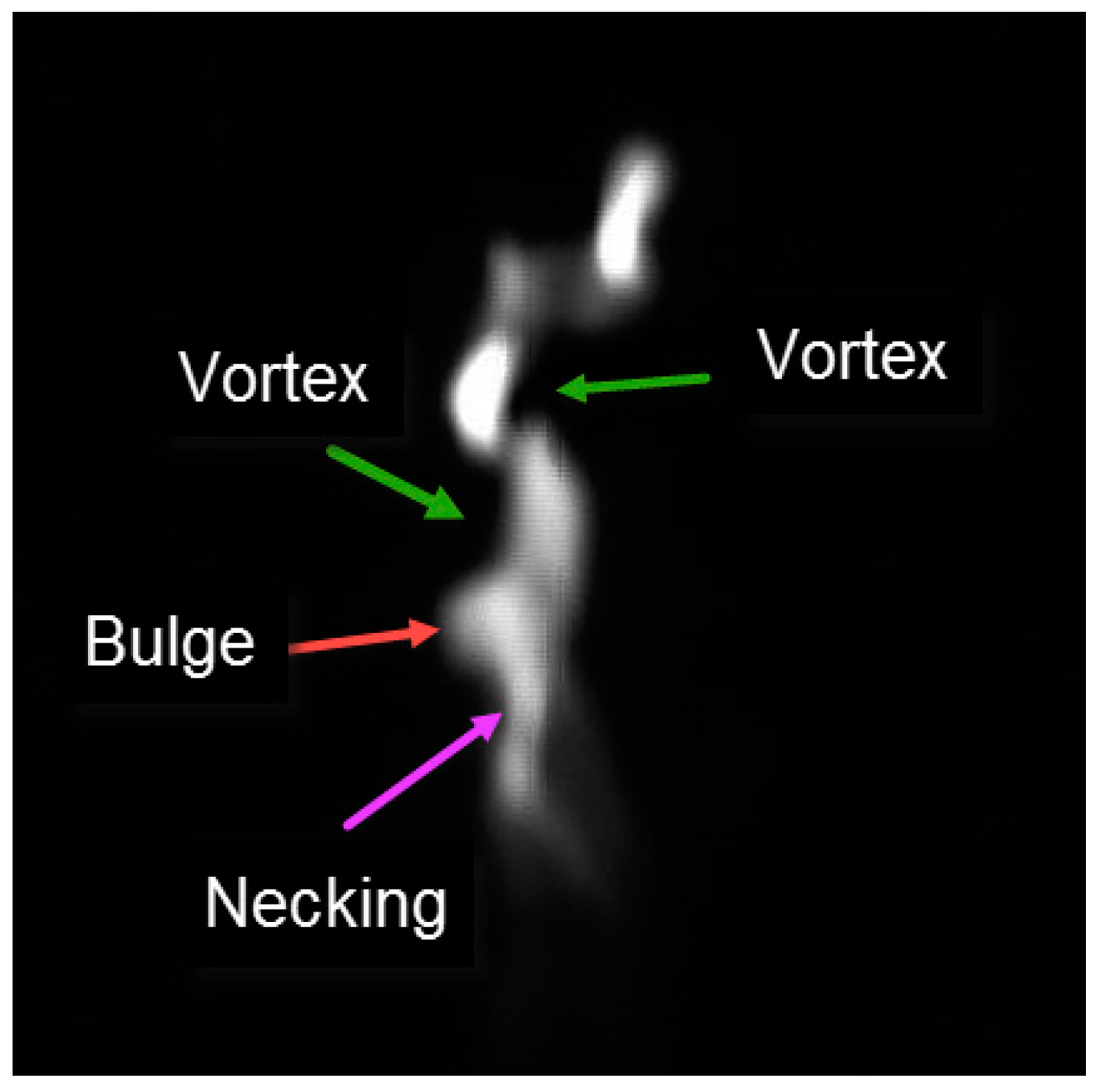

4.1. Flicker Shape

4.2. Spatial Analysis

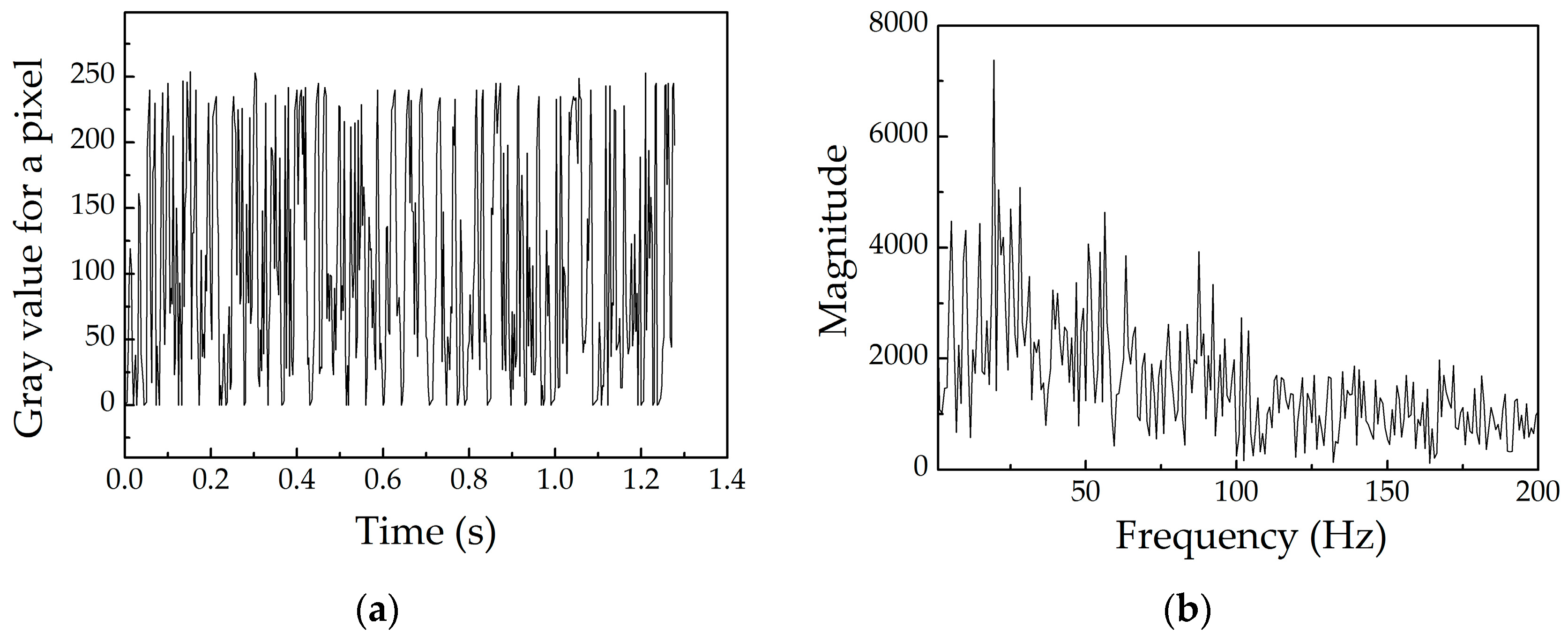

4.2.1. Flickering Signal for a Pixel

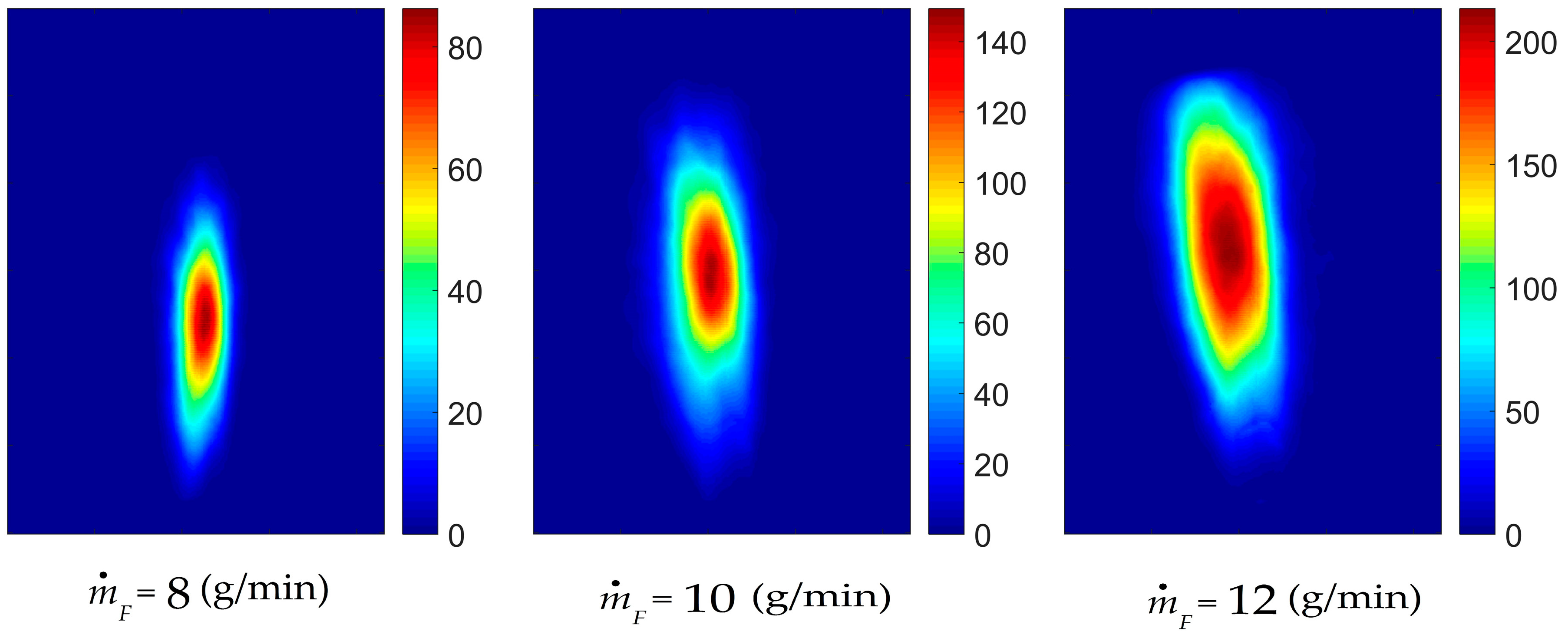

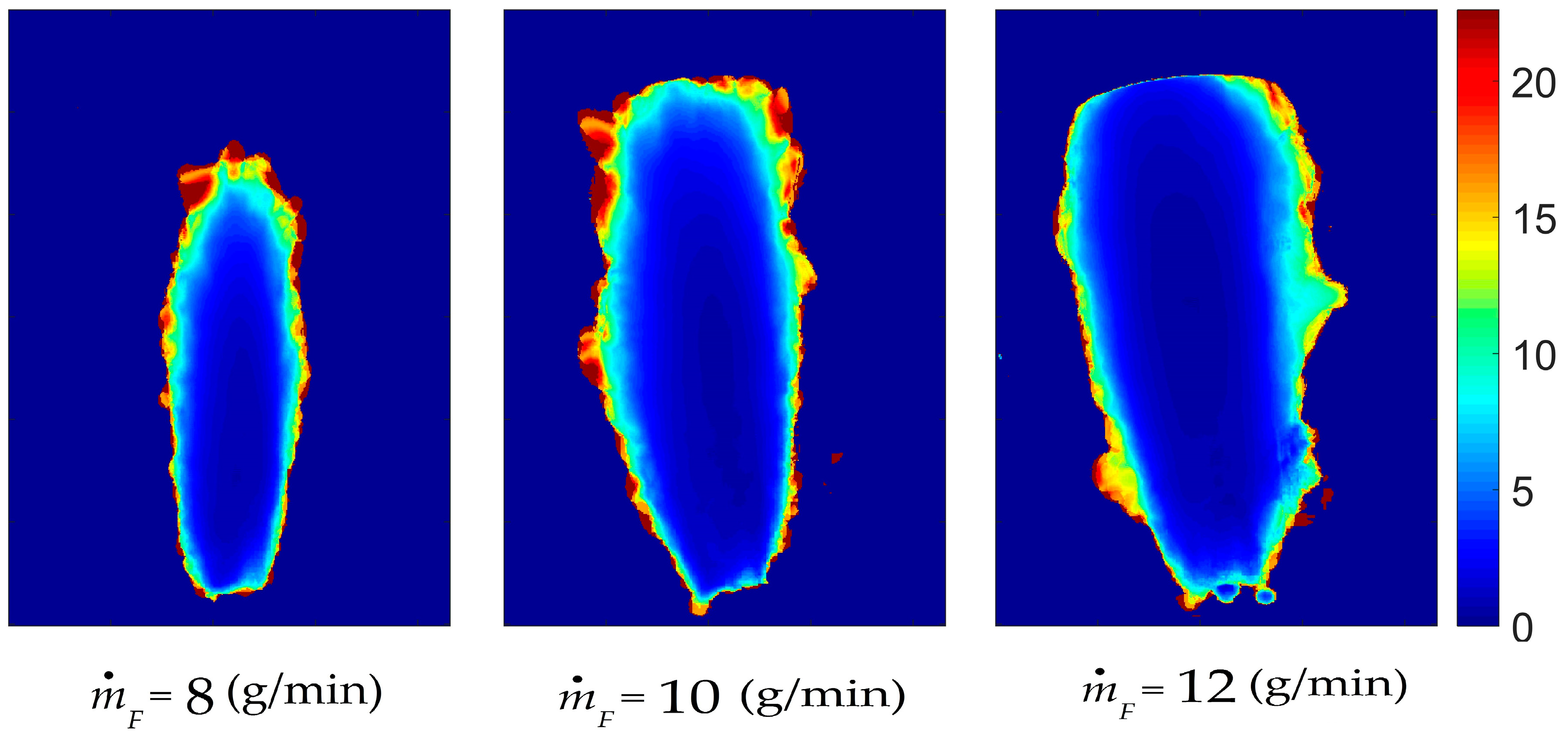

4.2.2. The Distribution of Mean Value

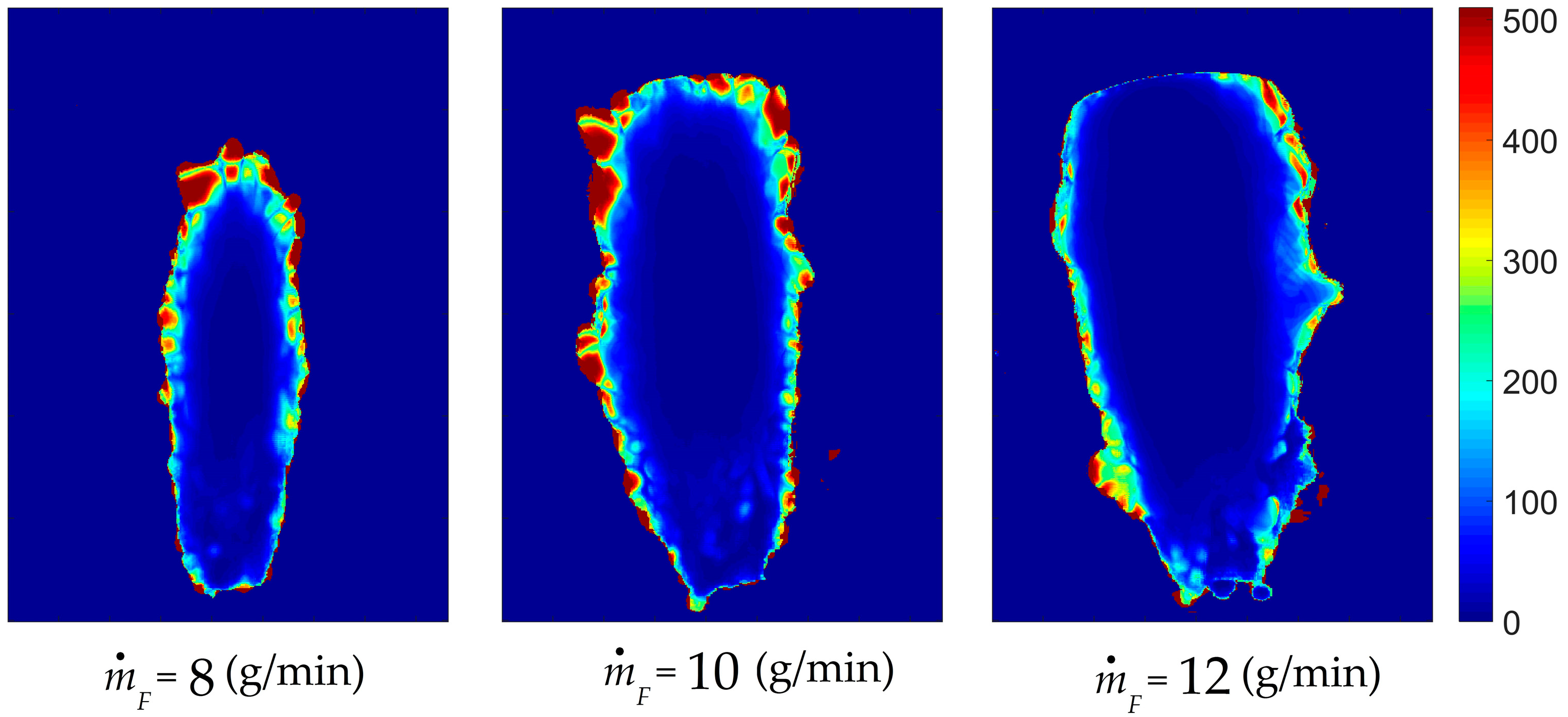

4.2.3. The Distribution of Flickering Weighted Average Frequency

4.2.4. The Distribution of Flickering Coefficient of Variation

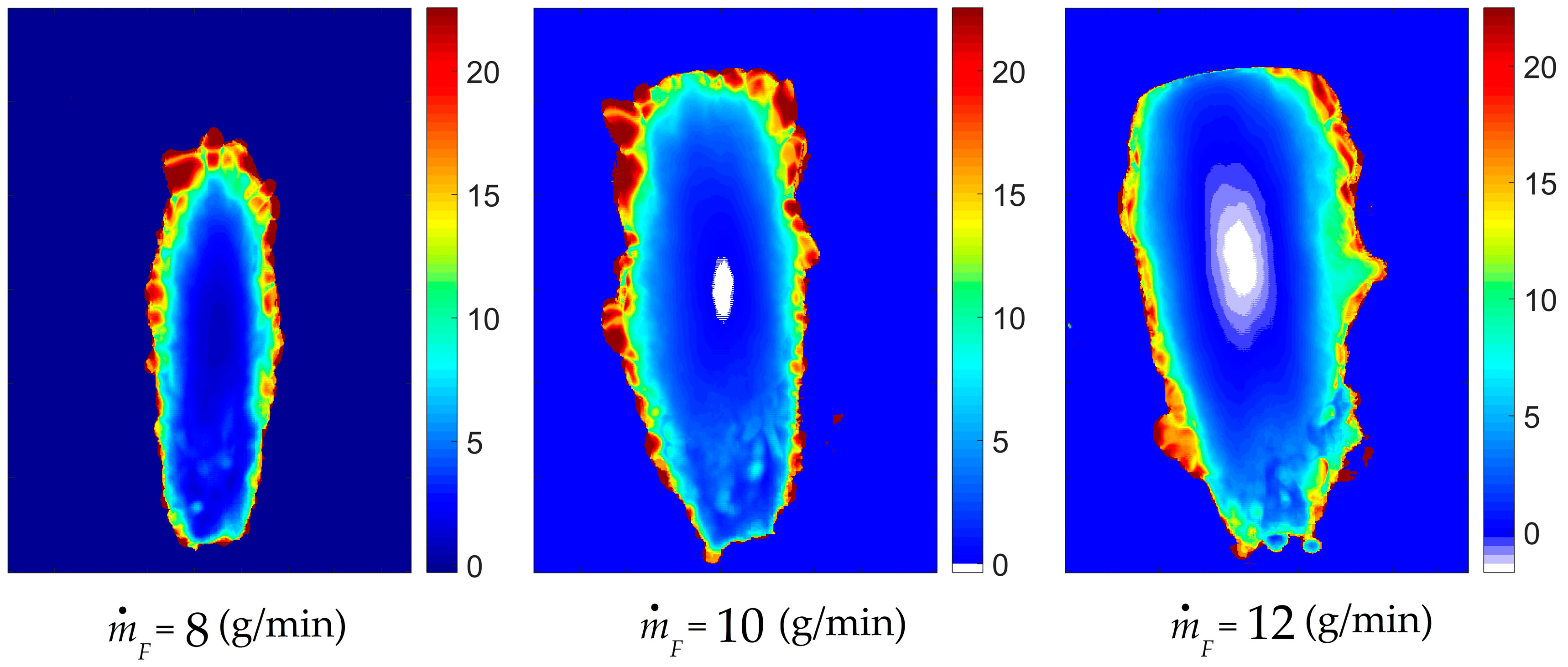

4.2.5. The Distribution of Skewness

4.2.6. The Distribution of Kurtosis

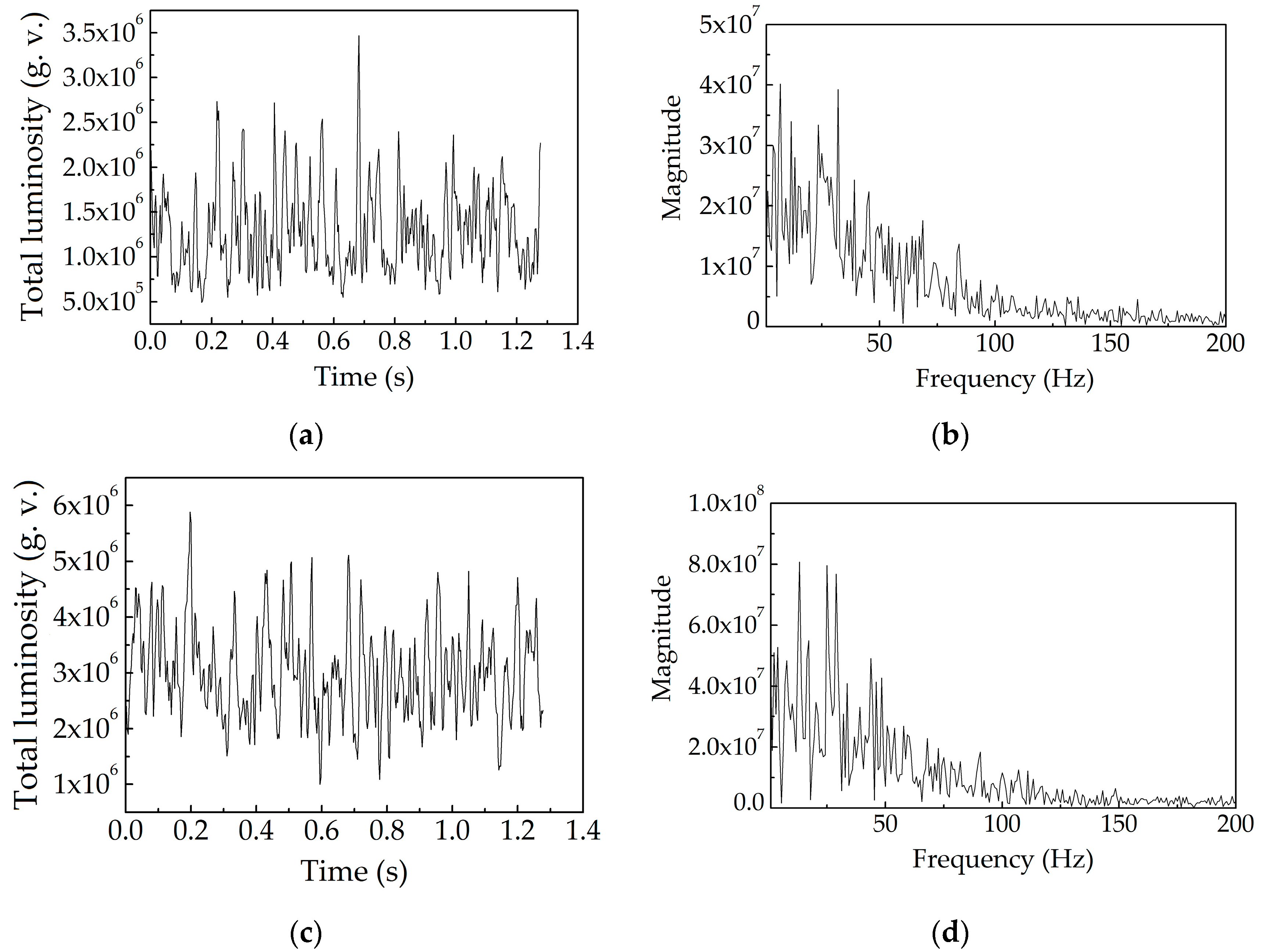

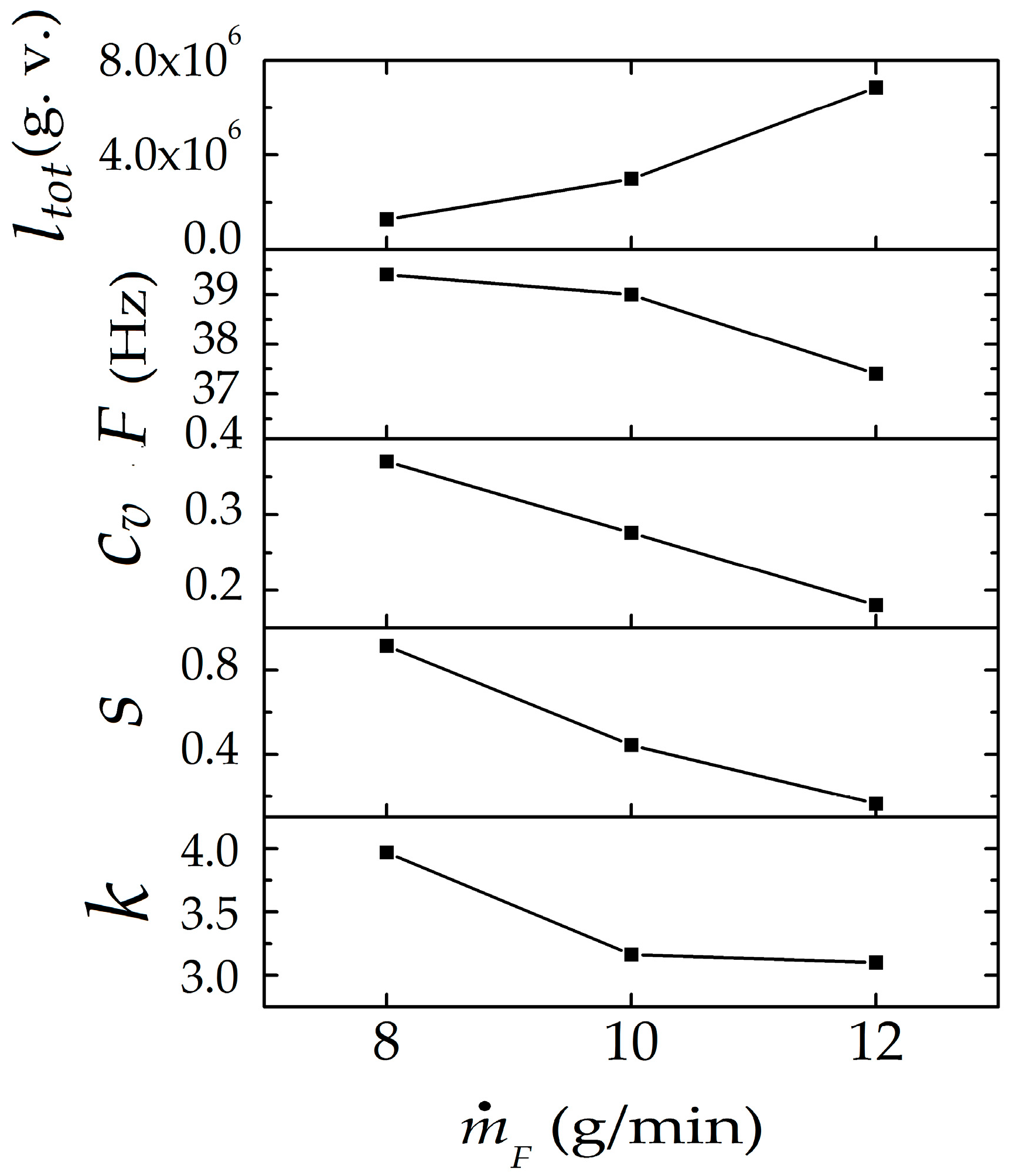

4.3. Global Analysis

5. Conclusions

- From the spatial analysis, the brightest part of flame was located in its core, and the brightness gradually decreased from the inside out. As F increased, high levels of luminosity and its corresponding region were enhanced.

- The largest flickering weighted average frequency F mainly lay in the flickering edge, where the velocity of pulsation was the fastest. Meanwhile, F diminished from the flicker outside in, the distribution in interior zone was not continuous, which was composed of many discrete small regions with diverse values of F.

- The coefficient of variation cv was firstly introduced to measure the flickering oscillation amplitude. High levels of cv were also positioned in the flickering edge, where the strongest fluctuation occurs. From the edge outside in, the value of cv sharply declined, and the most part of flickering inner region showed a low magnitude with a smooth distribution.

- Likewise, the largest value of skewness s concentrated on flickering border, where the datasets were the most skewed. Most of the flickering region has a positive value, which implies the major parts are right-skewed. While the negative-s region is also found in the core of the flickering zone, it is left-skewed and corresponds to the brightest parts. As F became larger, the negative-s region was expanded rapidly, which means the flickering region becomes increasingly more left-skewed.

- The distribution of kurtosis k was in accordance with that of the cv, the data groups with large peakedness of probability distribution were situated in the flickering border. While the most flickering area had a low value, where the probability distribution of data sets had a relatively small peakedness.

- From the global analysis, with the increment of F, the global F slightly decreased while the global cv declined uniformly, which means the oscillation amplitude diminished and thus the flame became more stable. The global s linearly reduced and the global k also had a decreasing trend. The decreasing global s indicates the number distribution gradually became symmetric, and the decreasing global k indicates the number distribution progressively became flat. Consequently, the number distribution progressively tends to normal distribution at larger F.

Author Contributions

Funding

Conflicts of Interest

References

- Malalasekera, W.M.G.; Versteeg, H.K.; Gilchrist, K. A Review of Research and an Experimental Study on the Pulsation of Buoyant Diffusion Flames and Pool Fires. Fire Mater. 1996, 20, 261–271. [Google Scholar] [CrossRef]

- Pan, K.L.; Li, C.C.; Juan, W.C.; Yang, J.T. Low-frequency oscillation of a non-premixed flame on a bluff-body burner. Combust. Sci. Technol. 2009, 181, 1217–1230. [Google Scholar] [CrossRef]

- Sahu, K.B.; Kundu, A.; Ganguly, R.; Datta, A. Effects of fuel type and equivalence ratios on the flickering of triple flames. Combust. Flame 2009, 156, 484–493. [Google Scholar] [CrossRef]

- Bahadori, M.Y.; Zhou, L.; Stocker, D.P.; Hegde, U. Functional Dependence of Flame Flicker on Gravitational Level. AIAA J. 2001, 39, 1404–1406. [Google Scholar] [CrossRef]

- Durox, D.; Yuan, T.; Villermaux, E. The Effect of Buoyancy on Flickering in Diffusion Flames. Combust. Sci. Technol. 1997, 124, 277–294. [Google Scholar] [CrossRef]

- Arai, M.; Sato, H.; Amagai, K. Gravity effects on stability and flickering motion of diffusion flames. Combust. Flame 1999, 118, 293–300. [Google Scholar] [CrossRef]

- Hamins, A.; Yang, J.C.; Kashiwagi, T. An experimental investigation of the pulsation frequency of flames. Symp. Combust. 1992, 24, 1695–1702. [Google Scholar] [CrossRef]

- Cetegen, B.M.; Kasper, K.D. Experiments on the oscillatory behavior of buoyant plumes of helium and helium-air mixtures. Phys. Fluids 1996, 8, 2974–2984. [Google Scholar] [CrossRef]

- Pagni, P.J. Pool vortex shedding frequencies. Appl. Mech. Rev. 1990, 43, 160. [Google Scholar]

- Bejan, A. Predicting the pool fire vortex shedding frequency. J. Heat Transf. 1991, 113, 261–263. [Google Scholar] [CrossRef]

- Yilmaz, N.; Lucero, R.E.; Donaldson, A.B.; Gill, W. Flow characterization of diffusion flame oscillations using particle image velocimetry. Exp. Fluids 2009, 46, 737–746. [Google Scholar] [CrossRef]

- Yilmaz, N.; Donaldson, A.B.; Lucero, R.E. Experimental study of diffusion flame oscillations and empirical correlations. Energy Convers. Manag. 2008, 49, 3287–3291. [Google Scholar] [CrossRef]

- Tang, F.; Hu, L.; Wang, Q.; Ding, Z. Flame pulsation frequency of conduction-controlled rectangular hydrocarbon pool fires of different aspect ratios in a sub-atmospheric pressure. Int. J. Heat Mass Transf. 2014, 76, 447–451. [Google Scholar] [CrossRef]

- Gotoda, H.; Kawaguchi, S.; Saso, Y. Experiments on dynamical motion of buoyancy-induced flame instability under different oxygen concentration in ambient gas. Exp. Therm. Fluid Sci. 2008, 32, 1759–1765. [Google Scholar] [CrossRef]

- Fang, J.; Tu, R.; Guan, J.F.; Wang, J.J.; Zhang, Y.M. Influence of low air pressure on combustion characteristics and flame pulsation frequency of pool fires. Fuel 2011, 90, 2760–2766. [Google Scholar] [CrossRef]

- Wang, Q.; Hu, L.; Tang, F.; Zhang, X.; Delichatsios, M. Characterization and comparison of flame fluctuation range of a turbulent buoyant jet diffusion flame under reduced- and normal pressure atmosphere. Proc. Eng. 2013, 62, 211–218. [Google Scholar] [CrossRef]

- Tao, C.F.; Cai, X.; Wang, X. Experimental Determination of Atmospheric Pressures Effects on Flames from Small Scale Pool Fires. J. Fire Sci. 2013, 31, 387–394. [Google Scholar] [CrossRef]

- Pretrel, H.; Audouin, L. Periodic puffing instabilities of buoyant large-scale pool fires in a confined compartment. J. Fire Sci. 2013, 31, 197–210. [Google Scholar] [CrossRef]

- Chen, X.; Lu, S.; Wang, X.; Liew, K.M.; Li, C.; Zhang, J. Pulsation Behavior of Pool Fires in a Confined Compartment with a Horizontal Opening. Fire Technol. 2016, 52, 515–531. [Google Scholar] [CrossRef]

- Chen, X.; Lu, S.X. On the Analysis of Flame Pulsation and Fire Induced Vent Flow Oscillatory Behaviors in Confined Enclosures with Horizontal Openings. Proc. Eng. 2018, 211, 104–112. [Google Scholar] [CrossRef]

- Kostiuk, L.W.; Cheng, R.K. The coupling of conical wrinkled laminar flames with gravity. Combust. Flame 1995, 103, 27–40. [Google Scholar] [CrossRef]

- Gotoda, H.; Maeda, K.; Ueda, T.; Cheng, R.K. Periodic motion of a Bunsen flame tip with burner rotation. Combust. Flame 2003, 134, 67–79. [Google Scholar] [CrossRef]

- Durox, D.; Baillot, F.; Scouflaire, P.; Prud’homme, R. Some effects of gravity on the behaviour of premixed flames. Combust. Flame 1990, 82, 66–74. [Google Scholar] [CrossRef]

- Fujisawa, N.; Abe, T.; Yamagata, T.; Tomidokoro, H. Flickering characteristics and temperature field of premixed methane/air flame under the influence of co-flow. Energy Convers. Manag. 2014, 78, 374–385. [Google Scholar] [CrossRef]

- Bennett, B.A.V.; McEnally, C.S.; Pfefferle, L.D.; Smooke, M.D.; Colket, M.B. Computational and experimental study of axisymmetric coflow partially premixed ethylene/air flames. Combust. Flame 2001, 127, 2004–2022. [Google Scholar] [CrossRef]

- Xi, Z.; Fu, Z.; Hu, X.; Sabir, S.W.; Jiang, Y. An Experimental Investigation on Flame Pulsation for a Swirl Non-Premixed Combustion. Energies 2018, 11, 1757. [Google Scholar] [CrossRef]

- Samaniego, J.-M.; Egolfopoulos, F.N.; Bowman, C.T. CO2* Chemiluminescence in Premixed Flames. Combust. Sci. Technol. 1995, 109, 183–203. [Google Scholar] [CrossRef]

- Li, M.; Tong, Y.; Klingmann, J.; Thern, M. Impact of vitiation on a swirl-stabilized and premixed methane flame. Energies 2017, 10, 1557. [Google Scholar] [CrossRef]

- Huang, Y.; Yan, Y.; Lu, G.; Reed, A. On-line flicker measurement of gaseous flames by image processing and spectral analysis. Meas. Sci. Technol. 1999, 10, 726–733. [Google Scholar] [CrossRef]

- González-Cencerrado, A.; Peña, B.; Gil, A. Coal flame characterization by means of digital image processing in a semi-industrial scale PF swirl burner. Appl. Energy 2012, 94, 375–384. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xi, Z.; Fu, Z.; Sabir, S.W.; Hu, X.; Jiang, Y.; Zhang, T. Experimental Analysis on Flame Flickering of a Swirl Partially Premixed Combustion. Energies 2018, 11, 2430. https://doi.org/10.3390/en11092430

Xi Z, Fu Z, Sabir SW, Hu X, Jiang Y, Zhang T. Experimental Analysis on Flame Flickering of a Swirl Partially Premixed Combustion. Energies. 2018; 11(9):2430. https://doi.org/10.3390/en11092430

Chicago/Turabian StyleXi, Zhongya, Zhongguang Fu, Syed Waqas Sabir, Xiaotian Hu, Yibo Jiang, and Tao Zhang. 2018. "Experimental Analysis on Flame Flickering of a Swirl Partially Premixed Combustion" Energies 11, no. 9: 2430. https://doi.org/10.3390/en11092430

APA StyleXi, Z., Fu, Z., Sabir, S. W., Hu, X., Jiang, Y., & Zhang, T. (2018). Experimental Analysis on Flame Flickering of a Swirl Partially Premixed Combustion. Energies, 11(9), 2430. https://doi.org/10.3390/en11092430