Efficiency Improvement of a Natural Gas Marine Engine Using a Hybrid Turbocharger

Abstract

1. Introduction

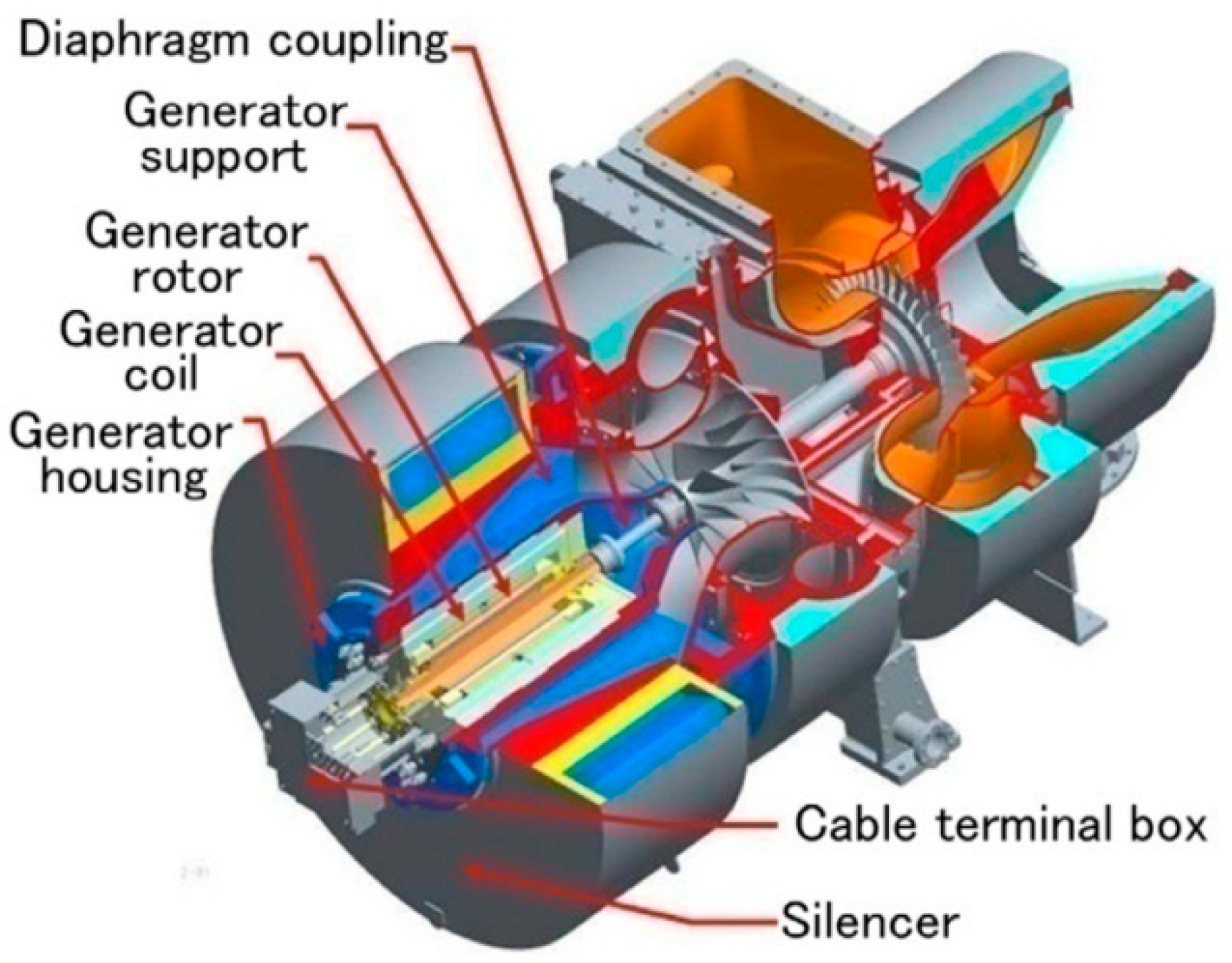

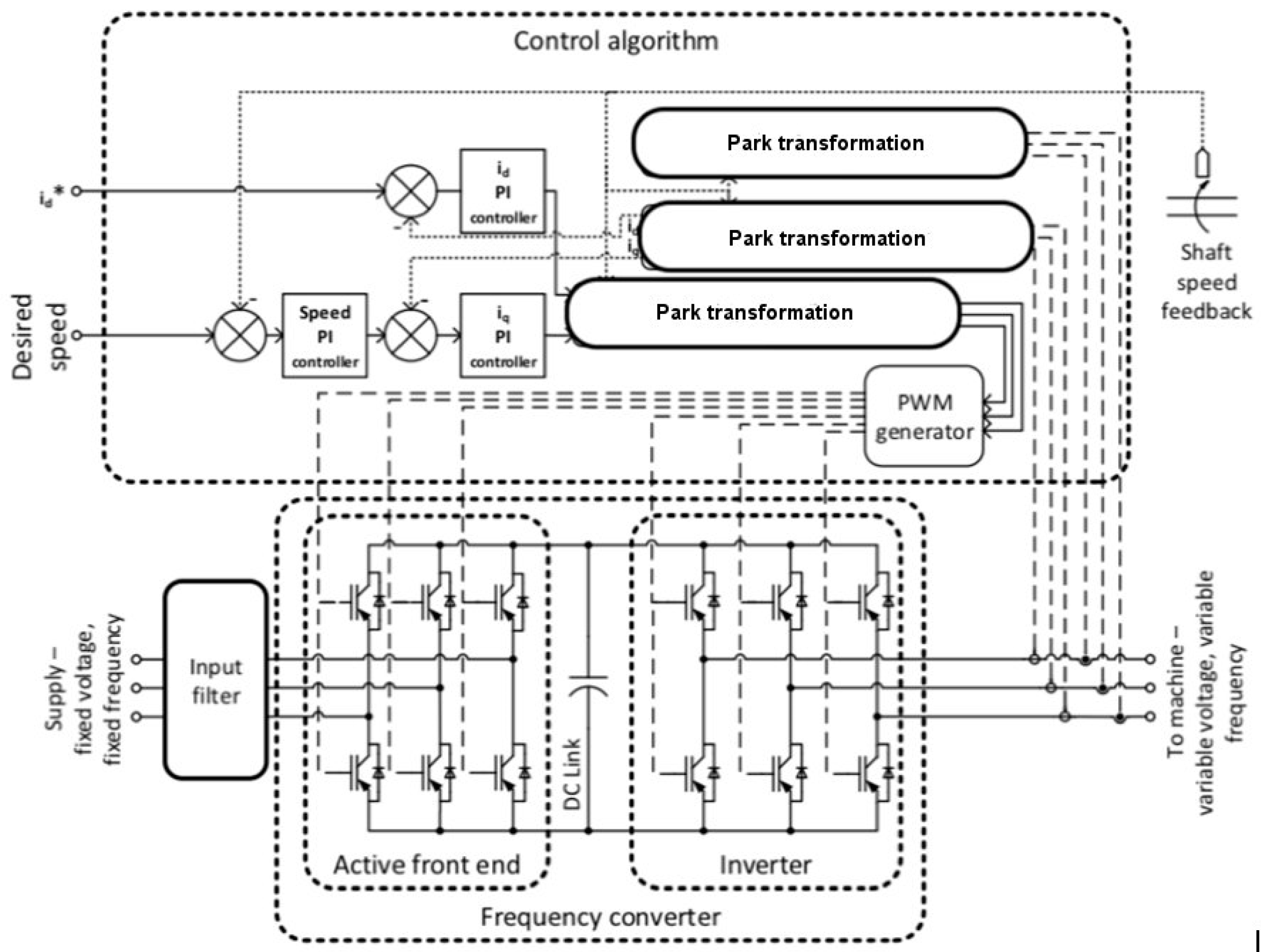

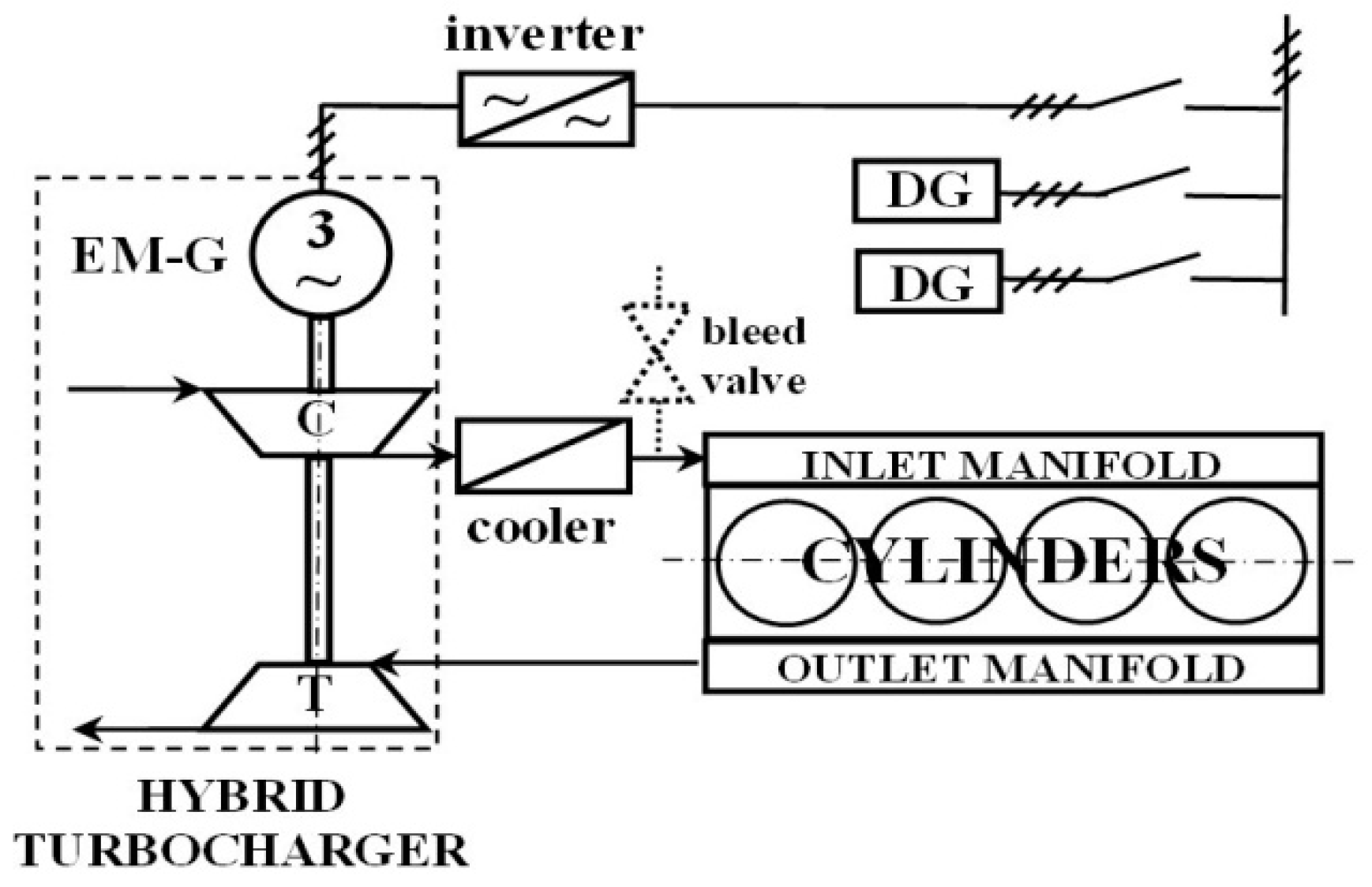

2. Hybrid Turbocharger

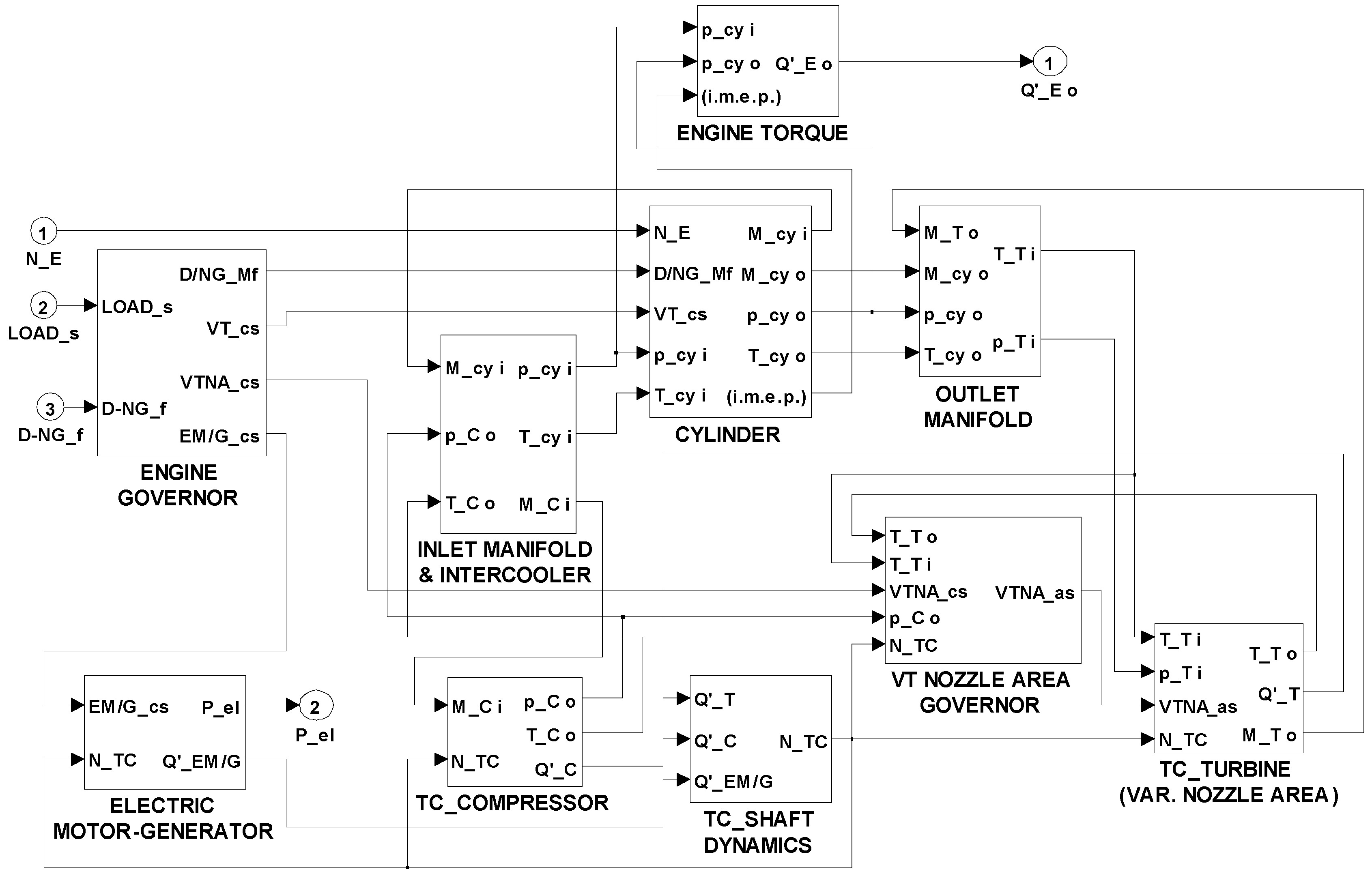

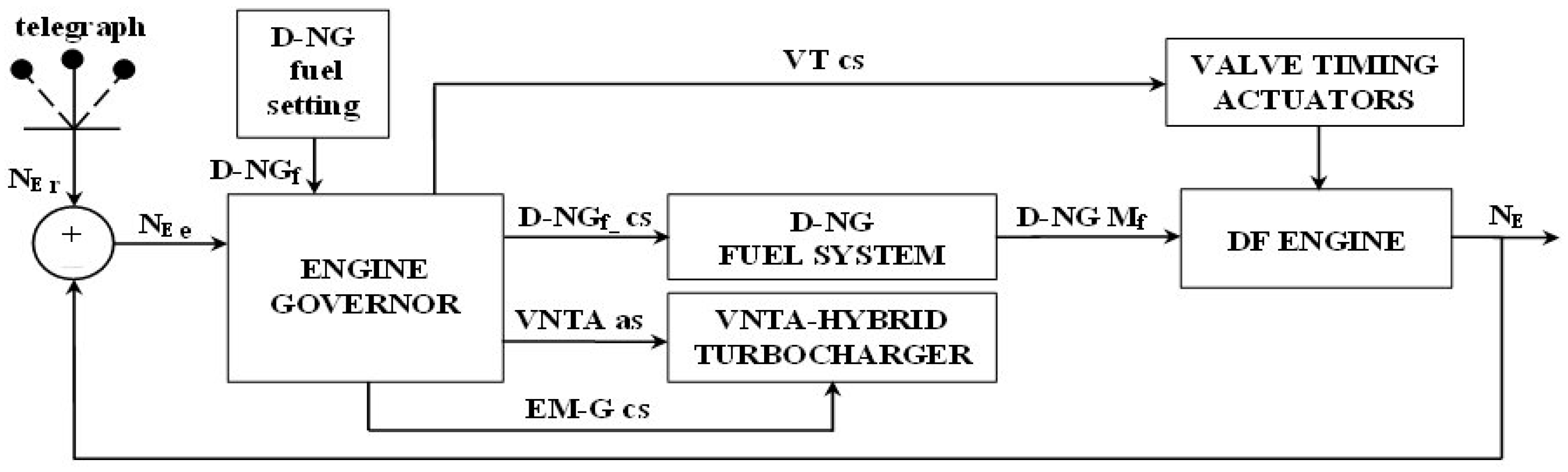

3. Engine Simulator

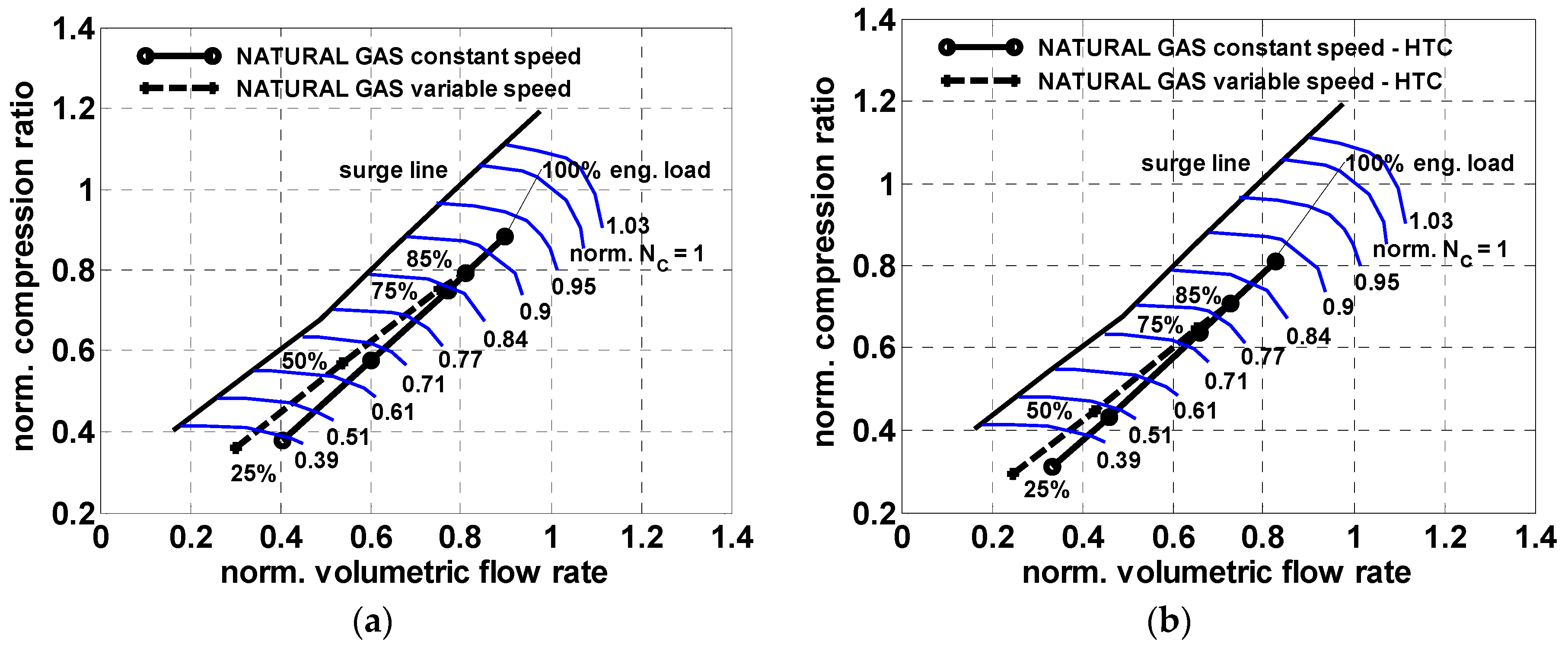

4. Hybrid Turbocharger Implementation

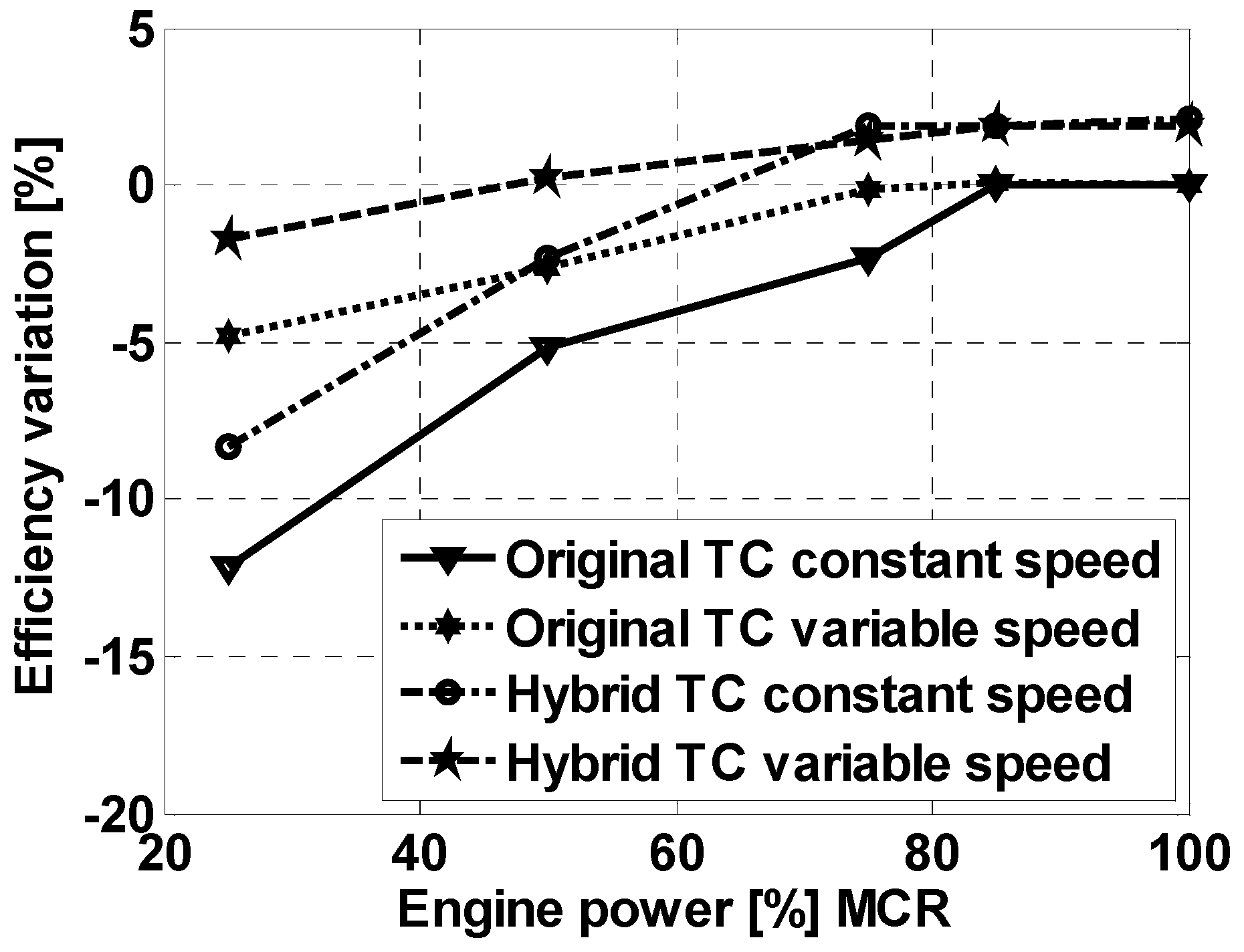

5. Turbochargers Comparison

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| As | actuator signal |

| BSFC | brake specific fuel consumption |

| b.m.e.p. | brake mean effective pressure |

| CC | engine-TC electric motor/generator combined cycle |

| cs | control signal |

| D | heavy fuel oil |

| DG | diesel-generator |

| D-NG | diesel-natural gas |

| E | engine |

| EM-G | turbocharger electric motor-generator |

| FLHV | fuel lower heating value |

| HTC | hybrid turbocharger |

| J | rotor inertia |

| IMEP | gross indicated mean effective pressure |

| M | mass flow rate |

| MCR | engine maximum continuous rating |

| N | rotational speed |

| NG | natural gas |

| p | pressure |

| P | power |

| Q’ | shaft torque |

| T | turbine, temperature |

| TC | turbocharger |

| VSI | Voltage Source Inverter |

| VT | engine valve timing |

| VTNA | variable turbine nozzle area |

| β | turbocharger compressor pressure ratio |

| Δ | difference |

| ε | turbocharger turbine expansion pressure ratio |

| η | efficiency |

| Φ | equivalence ratio |

| Subscripts | |

| as | actuator signal |

| C | compressor |

| cs | control signal |

| E | engine |

| EM-G | electric motor-generator |

| e | error |

| el | electric |

| ex gas | exhaust gas |

| f | fuel |

| HTC, HY | hybrid turbocharger |

| i | inlet |

| Mf | fuel mass flow rate |

| o | outlet |

| or | original turbocharger |

| r | required |

| T | turbine, temperature |

| TC | turbocharger |

References

- International Maritime Organization (IMO). Resolution A. 963 (23). IMO Policies and Practices Related to the Reduction of Greenhouse Gas Emissions from Ships. Available online: http://rise.odessa.ua/texts/A963_23e.php3 (accessed on 17 July 2018).

- International Maritime Organization (IMO). Marine Environment Protection Committee (MEPC). Available online: http://www.imo.org/en/KnowledgeCentre/IndexofIMOResolutions/Marine-Environment-Protection-Committee- (accessed on 17 July 2018).

- Marine Environment Protection Committee (MEPC). Resolution, MECP 212 (63/23), Annex 8. 2012. Guidelines to the Method of Calculation of the Attained Energy Efficiency Design Index (EEDI) for New Ships. Available online: http://www.imo.org/en/OurWork/Environment/PollutionPrevention/AirPollution/Documents/212%2863%29.pdf (accessed on 17 July 2018).

- Marine Environment Protection Committee (MEPC). In Proceedings of the International Maritime Organization (IMO), 66th session, London, UK, 31 March–4 April 2014. Available online: http://www.imo.org/en/KnowledgeCentre/IndexofIMOResolutions/Marine-Environment-Protection-Committee-(MEPC)/Pages/default.aspx (accessed on 23 July 2018).

- International Maritime Organization (IMO). Energy Efficiency Ship Operation. Module 2—Ship Energy Efficiency Regulation and Related Guidelines; IMO: London, UK, January 2016. [Google Scholar]

- Gualeni, P.; Boveri, A.; Silvestro, F.; Margarita, A. Decision Support System for Power generation Management for 110,000-GRT Cruise Ship. Int. J. Marit. Eng. 2016, 158, 163–175. [Google Scholar] [CrossRef]

- Ioannidis, J. Waste Heat recovery from Diesel Engines. In Proceedings of the IMAM 1984 Conference, Athens, Greece; 1984. Available online: http://www.lme.ntua.gr:8080/academic-info-1/prospheromena-mathemata/egkatastaseis-prooses/files/waste_heat_from_diesel_engines.pdf (accessed on 17 July 2018).

- Ioannidis, J. Thermo Efficiency System (TES) for Reduction of Fuel Consumption and CO2 Emission; Aalborg A. G.: Copenhagen, Denmark, 1984. [Google Scholar]

- Schmidt, H. Less Emissions through Waste Heat Recovery. In Proceedings of the Presented at the Green Ship Technology Conference, London, UK, 28–29 April 2004. [Google Scholar]

- Ito, K.; Akagi, S. An Optimal Planning Method for a Marine Heat and Power Generation Plant by Considering its Operational Problem. Energy Res. 1986, 10, 75–85. [Google Scholar] [CrossRef]

- Tien, W.K.; Yeh, R.H.; Hong, J.M. Theoretical Analysis of Cogeneration System for Ships. Energy Convers. Manag. 2007, 48, 1965–1974. [Google Scholar] [CrossRef]

- Dzida, M. On the Possible Increasing of Efficiency of Ship Power Plant with the System Combined of marine Diesel Engine, Gas Turbine and Steam Turbine. Main Engine-Steam Turbine Mode of Cooperation. Pol. Marit. Res. 2009, 16, 47–52. [Google Scholar] [CrossRef]

- Akiliu, B.T.; Gilani, S.I. Mathematical Modelling and Simulation of a Cogeneration Plant. Appl. Therm. Eng. 2010, 30, 2545–2554. [Google Scholar] [CrossRef]

- Dimopopulos, G.G.; Kakalis, N.M.P. An Integrated Modelling framework for the Design Operation and Control of Marine Energy Systems. In Proceedings of the CIMAC Congress, Bergen, Norway, 14–17 June 2010. [Google Scholar]

- Grimmelius, H.; Boonen, E.J.; Nicolai, H.; Stapersma, D. The integration of Mean value First Principle Diesel Engine models in Dynamic Waste Heat and Cooling Load Analysis. In Proceedings of the CIMAC Congress, Bergen, Norway, 14–17 June 2010. Paper No. 280. [Google Scholar]

- Theotokatos, G.; Livanos, G.A. Exhaust gas waste heat recovery in marine propulsion plants. In Proceedings of the 14th International Conference on Maritime Association of Mediterranean (IMAM 2011), Genova, Italy, 13–16 September 2011. [Google Scholar]

- Byung, C.C.; Young, M.K. Thermodynamic analysis of a dual loop heat recovery system with trilateral cycle applied to exhaust gases of internal combustion engine for propulsion of the 6800 TEU container ship. Energy 2013, 58, 404–416. [Google Scholar]

- Benvenuto, G.; Campora, U.; Trucco, A. Optimization of Waste Heat Recovery from the Exhaust Gas of Marine Diesel Engines. J. Eng. Marit. Environ. 2016, 230, 83–94. [Google Scholar] [CrossRef]

- Benvenuto, G.; Campora, U.; Laviola, M.; Zaccone, R. Comparison of Waste Heat Recovery Systems for the Refitting of a Cruise Ferry. In Proceedings of the NAV 2015, 18th International Conference on Ships and Shipping Research, Lecco, Italy, 24–26 June 2015; pp. 404–415. [Google Scholar]

- Altosole, M.; Benvenuto, G.; Campora, U.; Laviola, M.; Zaccone, R. Simulation and performance comparison between diesel and natural gas engines for marine applications. J. Eng. Marit. Environ. 2017, 231, 690–704. [Google Scholar] [CrossRef]

- Livanos, G.A.; Theotokatos, G.; Patagonis, D.N. Techno-Economical Investigation of Alternative Propulsion Plant for Ferries and RoRo Ships. Energy Convers. Manag. 2014, 79, 640–651. [Google Scholar] [CrossRef]

- Altosole, M.; Campora, U.; Laviola, M.; Zaccone, R. Waste Heat Recovery from Dual-Fuel Marine Engine; Soares, G., Benvenuto, T.G., Eds.; Taylor & Francis Group: London, UK, 2018; ISBN 978-0-8153-7993-5. [Google Scholar]

- Keiichi, S.; Yoshihisa, O. Hybrid Turbocharger with Integrated High Speed Motor-Generator; Technical Review; Mitsubishi Heavy Industries: Tokyo, Japan, 2007; Volume 44, pp. 1–3. [Google Scholar]

- Keiichi, S.; Yoshihisa, O.; Kiyoko, S. Development of Large Marine Hybrid Turbocharger for Generating Electric Power with Exhaust Gas from the Main Engine; Mitsubishi Heavy Industries: Tokyo, Japan, 2010; Volume 47, pp. 53–58. [Google Scholar]

- Yoshihisa, O.; Keiichi, S.; Yukio, Y. Application of a Large Hybrid Turbocharger for Marine Electric-Power Generation; Mitsubishi Heavy Industries: Tokyo, Japan, 2012; Volume 47, pp. 29–33. [Google Scholar]

- Keiichi, S.; Venky, K. Electro-Assist Turbo for Marine Turbocharger Diesel Engines. In Proceedings of the ASME Turbo Expo 2014, Turbine Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014. [Google Scholar] [CrossRef]

- Keiichi, S.; Yoshihisa, O.; Yukio, Y.; Musashi, S. Energy Savings Through Electric-Assist Turbocharger for Marine Diesel Engines; Mitsubishi Heavy Industries: Tokyo, Japan, 2015; Volume 52, pp. 36–41. [Google Scholar]

- World’s First Hybrid Turbocharged Bulk Carrier. The Motor Ship 2011. Available online: http://www.motorship.com/news101/ships-and-shipyards/worlds-first-hybrid-turbocharged-bulk-carrier (accessed on 17 July 2018).

- Benvenuto, G.; Campora, U.; Laviola, M.; Terlizzi, G. Simulation Model of a Dual-Fuel Four Stroke Engine for Low Emission Ship Propulsion Applications. Int. Review Mech. Eng. 2017, 11, 817–824. [Google Scholar] [CrossRef]

- Boveri, A.; D’Agostino, F.; Fidigatti, A.; Ragani, E.; Silvestro, F. Dynamic Modeling of a Supply Vessel Power System for DP3 Protection System. IEEE Trans. Transp. Electrification 2016, 2, 570–579. [Google Scholar] [CrossRef]

- MAN 51/60 DF IMO TIER II/IMO TIER III, Project Guide—Marine, 2015. Available online: https://marine.man-es.com/docs/default-source/shopwaredocuments/man-l51-60df8f6b0c494739478a818ef2765bdbaa92.pdf?sfvrsn=6 (accessed on 17 July 2018).

| Engine Parameters | D/NG |

|---|---|

| Engine length (mm) | 10,254 |

| Height (mm) | 5517 |

| Width (mm) | 4713 |

| Dry weight (t) | 189 |

| cylinders number (V) | 12 |

| bore (mm) | 510 |

| stroke (mm) | 600 |

| brake power (kW) | 12,000 |

| speed (rpm) | 514 |

| (b.m.e.p.) (bar) | 19.1 |

| BSFC [g/kWh] | 189/157 |

| charge air pressure (barg) | 4.29/3.77 |

| Line | Engine Parameters | Engine Loads | ||||

|---|---|---|---|---|---|---|

| 1 | Engine power (% of MCR) | 100 | 85 | 75 | 50 | 25 |

| 2 | Engine power (kW) | 12,000 | 10,260 | 9000 | 6000 | 3000 |

| 3 | EM/G electric power (kW) | 531 | 600 | 716 | 600 | 374 |

| 4 | EM/G el. pow. (% of E pow.) | 4.42 | 5.85 | 7.95 | 10.00 | 12.47 |

| 5 | NTC (Δ%) | −6.31 | −7.96 | −11.78 | −22.01 | −49.65 |

| 6 | βC (Δ%) | −9.57 | −9.09 | −15.18 | −18.75 | −25.46 |

| 7 | Compressore temp. (Δ%) | −3.84 | −4.22 | −5.46 | −6.52 | −6.89 |

| 8 | Compr. M air (Δ%) | −6.32 | −10.04 | −10.70 | −9.45 | −7.31 |

| 9 | Compr. efficiency (Δ%) | −0.12 | 0.65 | 1.60 | 0.97 | 1.06 |

| 10 | εT (Δ%) | 0.22 | 1.17 | 0.58 | 2.62 | 8.42 |

| 11 | Turbinei pressure (Δ%) | 0.21 | 0.39 | 0.61 | 0.25 | 0.32 |

| 12 | Turbinei temp. (Δ%) | −0.12 | −0.17 | −0.34 | −0.21 | −0.58 |

| 13 | Turbine efficiency (Δ%) | 0.00 | 0.01 | 0.01 | −0.01 | 0.01 |

| 14 | Cylinder inlet air mass (Δ%) | 0.01 | −0.01 | 0.01 | 0.01 | 0.01 |

| 15 | Cylinder inlet air temp. (Δ%) | −0.51 | −0.68 | −0.61 | −0.29 | −0.79 |

| 16 | Cylinder exh. gas mass (Δ%) | 0.01 | 0.02 | 0.01 | 0.02 | 0.02 |

| 17 | Engine IMEP (Δ%) | −0.02 | −0.02 | −0.03 | −0.01 | −0.02 |

| 18 | Orig. TC engine eff. (ΔηE%) | −0.01 | −0.01 | 0.01 | −0.01 | 0.02 |

| 19 | HTC engine eff. (ΔηE HTC%) | 2.10 | 4.20 | 3.72 | 2.90 | 2.81 |

| Line | Engine Parameters | Engine Loads | ||||

|---|---|---|---|---|---|---|

| 1 | Engine power (% of MCR) | 100 | 85 | 75 | 50 | 25 |

| 2 | Engine power (kW) | 12,000 | 10,260 | 9000 | 6000 | 3000 |

| 3 | Engine speed (rpm) | 514 | 514 | 501 | 462 | 402 |

| 4 | EM/G electric power (kW) | 490 | 542 | 562 | 567 | 241 |

| 5 | EM/G el. pow. (% of E pow.) | 4.08 | 5.28 | 6.24 | 9.45 | 8.03 |

| 6 | NTC (Δ%) | –6.74 | –8.00 | –10.64 | –17.55 | –38.94 |

| 7 | βC (Δ%) | –9.57 | –6.67 | –15.63 | –19.91 | –27.03 |

| 8 | Compressore temp. (Δ%) | –3.85 | –4.44 | –5.67 | –5.52 | –6.76 |

| 9 | Compr. M air (Δ%) | –8.92 | –10.42 | –13.06 | –15.69 | –18.47 |

| 10 | Compr. efficiency (Δ%) | 0.12 | 1.60 | 1.71 | 1.29 | 2.02 |

| 11 | εT (Δ%) | 0.21 | 1.18 | 0.58 | 2.43 | 3.29 |

| 12 | Turbinei pressure (Δ%) | 0.22 | 0.16 | 0.53 | 0.34 | 0.27 |

| 13 | Turbinei temp. (Δ%) | –0.14 | –0.16 | –0.39 | –0.26 | –0.45 |

| 14 | Turbine efficiency (Δ%) | 0.00 | –0.01 | 0.00 | 0.01 | 0.01 |

| 15 | Cylinder inlet air mass (Δ%) | 0.01 | 0.02 | 0.01 | –0.01 | 0.01 |

| 16 | Cylinder air temp. (Δ%) | –0.55 | –0.63 | –0.59 | –0.43 | –0.66 |

| 17 | Cylinder exh. gas mass (Δ%) | 0.01 | –0.01 | 0.01 | –0.01 | 0.02 |

| 18 | Engine IMEP (Δ%) | –0.01 | –0.03 | –0.01 | –0.02 | –0.02 |

| 19 | Orig. TC engine eff. (ΔηE%) | –0.01 | –0.02 | 0.01 | –0.01 | 0.02 |

| 20 | HTC engine eff. (ΔηE HTC%) | 1.93 | 3.71 | 2.79 | 2.68 | 1.93 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Altosole, M.; Benvenuto, G.; Campora, U.; Silvestro, F.; Terlizzi, G. Efficiency Improvement of a Natural Gas Marine Engine Using a Hybrid Turbocharger. Energies 2018, 11, 1924. https://doi.org/10.3390/en11081924

Altosole M, Benvenuto G, Campora U, Silvestro F, Terlizzi G. Efficiency Improvement of a Natural Gas Marine Engine Using a Hybrid Turbocharger. Energies. 2018; 11(8):1924. https://doi.org/10.3390/en11081924

Chicago/Turabian StyleAltosole, Marco, Giovanni Benvenuto, Ugo Campora, Federico Silvestro, and Giulio Terlizzi. 2018. "Efficiency Improvement of a Natural Gas Marine Engine Using a Hybrid Turbocharger" Energies 11, no. 8: 1924. https://doi.org/10.3390/en11081924

APA StyleAltosole, M., Benvenuto, G., Campora, U., Silvestro, F., & Terlizzi, G. (2018). Efficiency Improvement of a Natural Gas Marine Engine Using a Hybrid Turbocharger. Energies, 11(8), 1924. https://doi.org/10.3390/en11081924