Review of Wearable Device Technology and Its Applications to the Mining Industry

Abstract

1. Introduction

2. Classification of Wearable Devices

2.1. Smartwatch

2.2. Smart Eyewear

2.3. Fitness Tracker

2.4. Smart Clothing

2.5. Wearable Camera

2.6. Wearable Medical Device

3. Features of Sensors Used in Wearable Devices

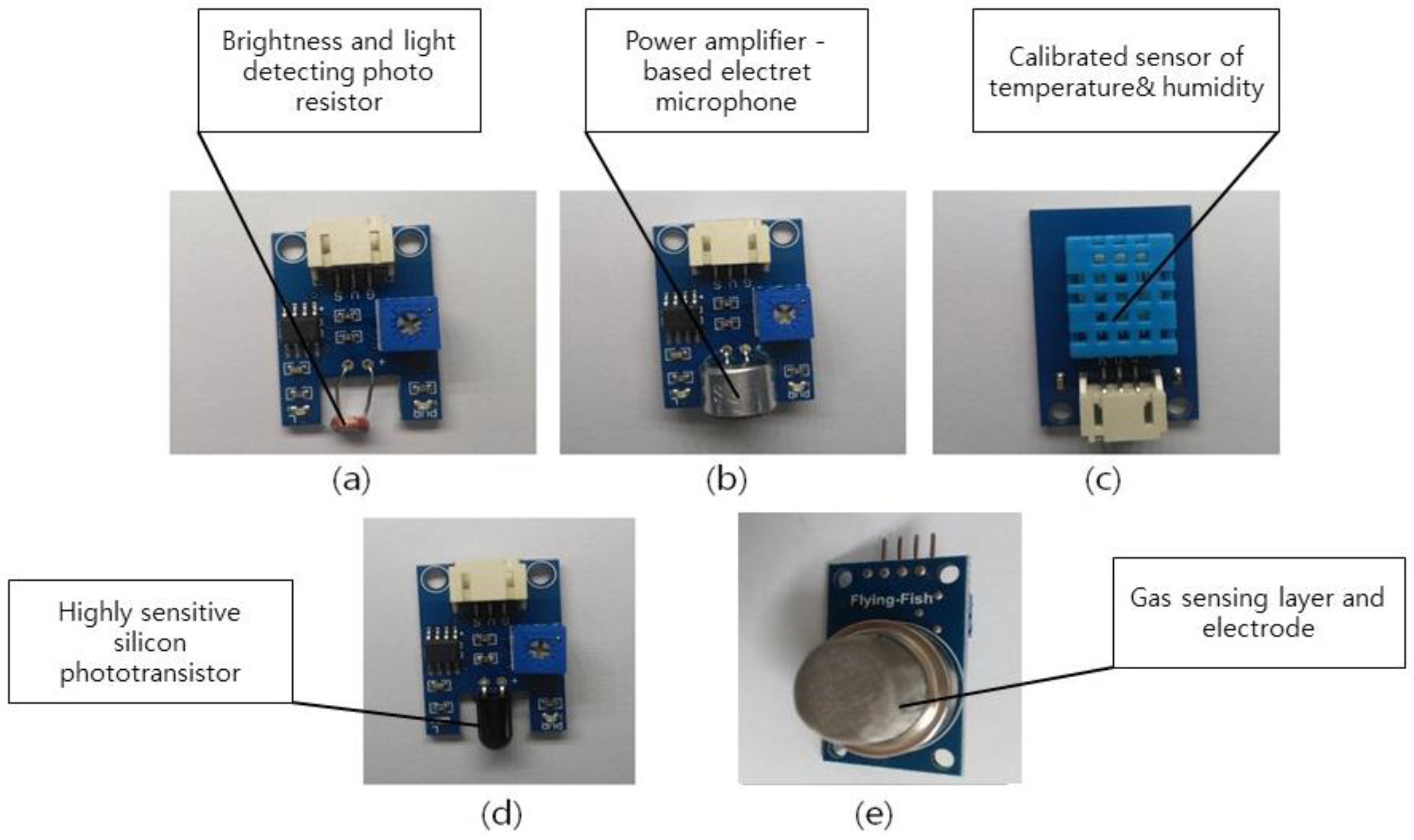

3.1. Environmental Sensors

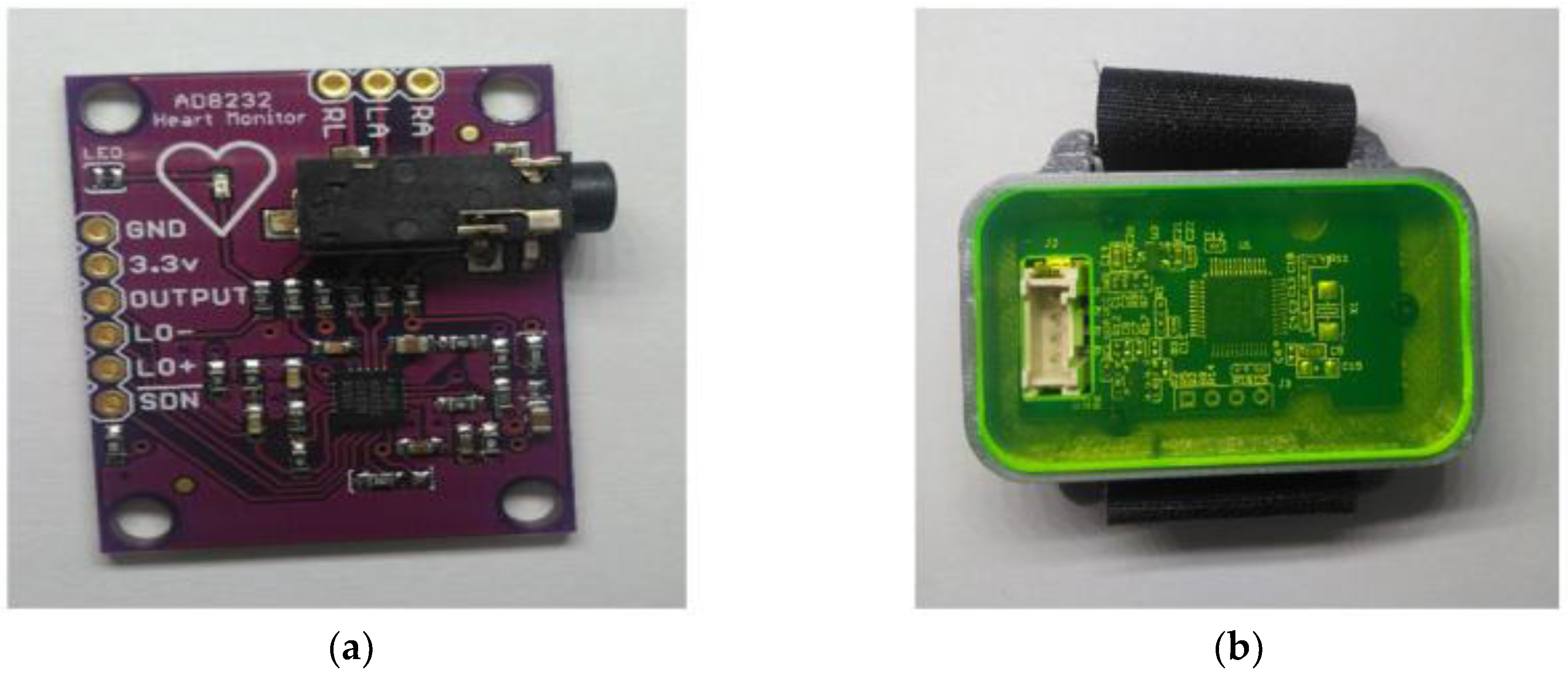

3.2. Biosensors

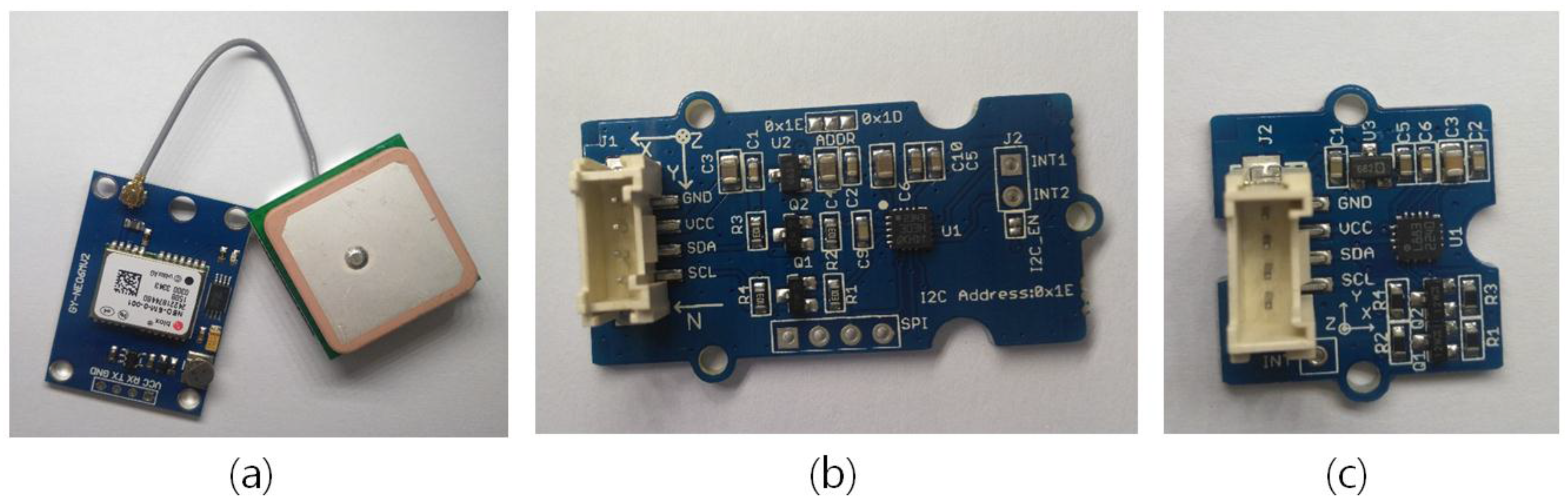

3.3. Position- and Location-Tracking Sensors

3.4. Other Sensors

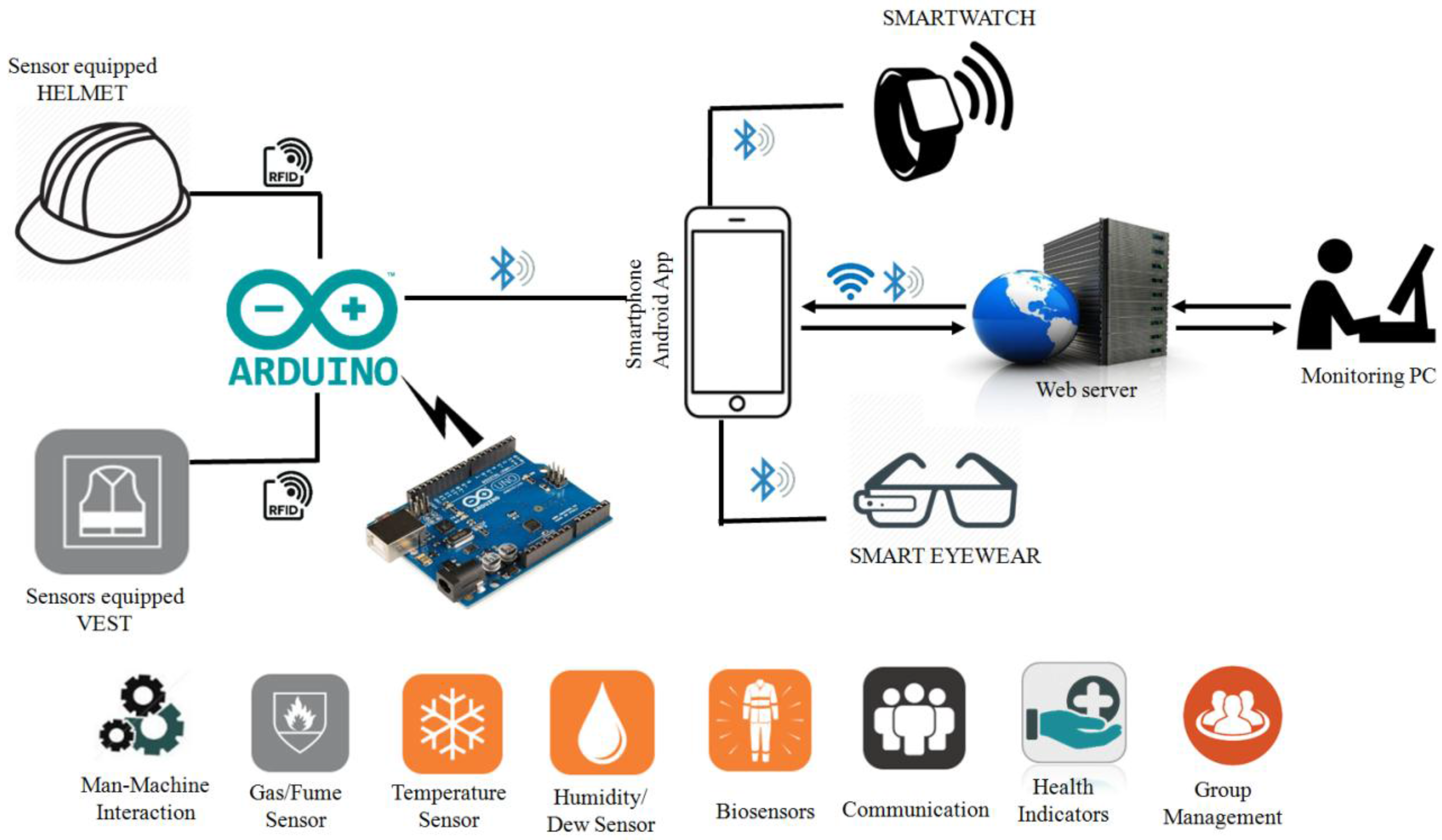

4. Applications of Wearable Devices to the Mining Industry

4.1. Current Applications in the Mining Sector

4.2. Application to Mine Safety Management

- a screen displaying important notifications (the notifications are sent to the glass by mobile phone over Bluetooth);

- the scanning of the situation through the glasses and providing specific guidelines to follow (for example, in site supervision and monitoring conveyor belt operations);

- using the eyewear as a first-person camera to capture videos and photos for job-related purposes (in cases when there are no smart glasses, a small wearable camera suited for mounting on the helmet can be used for the same purpose);

- using the screen as a navigation display for location (not suitable for underground mines).

4.3. Other Possible Applications

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wrzesińska, N. The use of smart glasses in healthcare—Review. MEDtube Sci. 2015, 3, 31–34. [Google Scholar]

- Choi, B.; Hwang, S.; Lee, S.H. What drives construction workers’ acceptance of wearable technologies in the workplace? Indoor localization and wearable health devices for occupational safety and health. Autom. Constr. 2017, 84, 31–41. [Google Scholar] [CrossRef]

- Audi Uses Wearables in Logistics. Available online: https://www.volkswagenag.com/en/news/2016/11/Audi_Wearables.html (accessed on 5 February 2018).

- TECHZONE360. Available online: http://www.techzone360.com/topics/techzone/articles/2016/06/27 /422510-6-insurance-companies-investing-wearable-technology.htm# (accessed on 20 November 2017).

- Heintzman, N.D. A Digital Ecosystem of Diabetes Data and Technology: Services, Systems, and Tools Enabled by Wearables, Sensors, and Apps. J. Diabetes Sci. Technol. 2016, 10, 35–41. [Google Scholar] [CrossRef] [PubMed]

- Mercer, K.; Giangregorio, L.; Schneider, E.; Chilana, P.; Li, M.; Grindrod, K. Acceptance of Commercially Available Wearable Activity Trackers Among Adults Aged Over 50 and With Chronic Illness: A Mixed-Methods Evaluation. JMIR mHealth uHealth 2016, 4, e7. [Google Scholar] [CrossRef] [PubMed]

- Chiauzzi, E.; Rodarte, C.; DasMahapatra, P. Patient-centered activity monitoring in the self-management of chronic health conditions. BMC Med. 2015, 13, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Chan, M.; Estève, D.; Fourniols, J.-Y.; Escriba, C.; Campo, E. Smart wearable systems: Current status and future challenges. Artif. Intell. Med. 2012, 56, 137–156. [Google Scholar] [CrossRef] [PubMed]

- Motion Metrics Partners with Vandrico to Develop Smartglass Application for Mining|Motion Metrics. Available online: http://www.motionmetrics.com/press/motion-metrics-partners-with-vandrico-to-develop-smartglass-application-for-mining/ (accessed on 1 February 2018).

- Hazarika, P. Implementation of smart safety helmet for coal mine workers. In Proceedings of the 1st IEEE International Conference on Power Electronics, Intelligent Control and Energy Systems, Delhi, India, 4–6 July 2016; pp. 1–3. [Google Scholar] [CrossRef]

- Deloitte Smart Helmet|Wearable Device|Vandrico Inc. Available online: https://vandrico.com/wearables/device/deloitte-smart-helmet (accessed on 1 February 2018).

- Fatigue-Monitoring Solution Implemented at Anglo Coal. Available online: http://www.miningweekly.com/article/fatigue-monitoring-solution-implemented-at-anglo-coal-2017-07-07/rep_id:3650 (accessed on 5 February 2018).

- Haas, E.J.; Cecala, A.B.; Hoebbel, C.L. Using Dust Assessment Technology to Leverage Mine Site Manager-Worker Communication and Health Behavior: A Longitudinal Case Study. J. Progress. Res. Soc. Sci. 2016, 3, 154–167. [Google Scholar] [PubMed]

- Chatterjee, A.; Aceves, A.; Dungca, R.; Flores, H.; Giddens, K. Classification of wearable computing: A survey of electronic assistive technology and future design. In Proceedings of the 2016 Second International Conference on Research in Computational Intelligence and Communication Networks (ICRCICN), Kolkata, India, 23–25 September 2016; pp. 22–27. [Google Scholar] [CrossRef]

- International Electrotechnical Commission. Available online: http://www.iec.ch/about/brochures/pdf/technology/printed_electronics_lr.pdf (accessed on 20 November 2017).

- Khoa, T.V.A. Wearable Smart Technologies: New Era of Technology. Master’s Thesis, Lapland University of Applied Sciences, Lapland, Finland, 2015. [Google Scholar]

- Parate, A.; Ganesan, D. Detecting Eating and Smoking Behaviors Using Smartwatches. In Mobile Health; Springer: Cham, Switzerland, 2017; pp. 175–201. ISBN 978-3-319-51393-5. [Google Scholar]

- Cadmus-Bertram, L. Using Fitness Trackers in Clinical Research: What Nurse Practitioners Need to Know. J. Nurse Pract. 2017, 13, 34–40. [Google Scholar] [CrossRef] [PubMed]

- Fokkema, T.; Kooiman, T.J.M.; Krijnen, W.P.; Van Der Schans, C.P.; De Groot, M. Reliability and validity of ten consumer activity trackers depend on walking speed. Med. Sci. Sports Exerc. 2017, 49, 793–800. [Google Scholar] [CrossRef] [PubMed]

- Evenson, K.R.; Goto, M.M.; Furberg, R.D. Systematic review of the validity and reliability of consumer-wearable activity trackers. Int. J. Behav. Nutr. Phys. Act. 2015, 12. [Google Scholar] [CrossRef] [PubMed]

- Shih, P.C.; Han, K.; Poole, E.S.; Rosson, M.B.; Carroll, J.M. Use and Adoption Challenges of Wearable Activity Trackers. In Proceedings of the iConference Proceedings 2015, Newport Beach, CA, USA, 24 March 2015; pp. 1–12. [Google Scholar]

- Nelson, E.C.; Verhagen, T.; Noordzij, M.L. Health empowerment through activity trackers: An empirical smart wristband study. Comput. Hum. Behav. 2016, 62, 364–374. [Google Scholar] [CrossRef]

- Wilson, M.; Ramsay, S.; Young, K.J. Engaging Overweight Adolescents in a Health and Fitness Program Using Wearable Activity Trackers. J. Pediatr. Health Care 2017, 31, e25–e34. [Google Scholar] [CrossRef] [PubMed]

- Wearables.com. Available online: http://www.wearables.com/5-wearable-tech-pro-sports-micoach-zebra-catapult/ (accessed on 20 November 2017).

- Hanuska, A.; Chandramohan, B.; Bellamy, L.; Burke, P.; Ramanathan, R.; Balakrishnan, V. Smart Clothing Market Analysis, 2016. Smart-Clothing-Market-Analysis-Report.pdf. Available online: http://scet.berkeley.edu/wp-content/uploads/Smart-Clothing-Market-Analysis-Report.pdf (accessed on 10 February 2018).

- Borges, L.M.; Rente, A.; Velez, F.J.; Salvado, L.R.; Lebres, A.S.; Oliveira, J.M.; Araújo, P.; Ferro, J. Overview of progress in smart-clothing project for health monitoring and sport applications. In Proceedings of the 2008 1st International Symposium on Applied Sciences in Biomedical and Communication Technologies, (ISABEL 2008), Aalborg, Denmark, 25–28 October 2008. [Google Scholar]

- Futuristic Firefighter Suit Has Sensors, Head-up Display—IEEE Spectrum. Available online: https://spectrum.ieee.org/consumer-electronics/portable-devices/futuristic-firefighter-suit-has-sensors-headup-display (accessed on 5 February 2018).

- Teizer, J. Wearable, wireless identification sensing platform: Self-Monitoring Alert and Reporting Technology for Hazard Avoidance and Training (SmartHat). J. Inf. Technol. Constr. 2015, 20, 295–312. [Google Scholar]

- Mayton, B.; Dublon, G.; Palacios, S.; Paradiso, J.A. TRUSS: Tracking Risk with Ubiquitous Smart Sensing. Proc. IEEE Sens. 2012. [Google Scholar] [CrossRef]

- Mohd Rasli, M.K.A.; Madzhi, N.K.; Johari, J. Smart helmet with sensors for accident prevention. In Proceedings of the 2013 International Conference on Electrical, Electronics and System Engineering (ICEESE 2013), Selangor, Malaysia, 4–5 December 2013; pp. 21–26. [Google Scholar] [CrossRef]

- Thakre, K.; Waskar, P.; Sawant, P.; Naik, S.; Chandak, S. Smart Helmet. Int. J. Adv. Res. Comput. Sci. Softw. Eng. 2015, 5, 408–410. [Google Scholar]

- Ozcan, K.; Velipasalar, S. Wearable Camera- and Accelerometer-Based Fall Detection on Portable Devices. IEEE Embed. Syst. Lett. 2016, 8, 6–9. [Google Scholar] [CrossRef]

- Delabrida, S.E.; Dangelo, T.; Oliveira, R.A.R.; Loureiro, A.A.F. Towards a wearable device for monitoring ecological environments. In Proceedings of the 2015 Brazilian Symposium on Computing Systems Engineering (SBESC 2015), Foz do Iguacu, Brazil, 3–6 November 2015; pp. 148–153. [Google Scholar]

- Lymberis, A. Smart wearables for remote health monitoring, from prevention to rehabilitation: Current R&D, future challenges. In Proceedings of the Itab 2003: 4th International Ieee Embs Special Topic Conference on Information Technology Applications in Biomedicine, Conference Proceedings: New Solutions for New Challenges, Birmingham, UK, 24–26 April 2003; pp. 272–275. [Google Scholar] [CrossRef]

- Patel, S.; Park, H.; Bonato, P.; Chan, L.; Rodgers, M. A review of wearable sensors and systems with application in rehabilitation. J. NeuroEng. Rehabil. 2012, 9, 21. [Google Scholar] [CrossRef] [PubMed]

- Jones, K.W. Environmental Sensors. In Sensors Set: A Comprehensive Survey; Göpel, W., Hesse, J., Zemel, J.N., Eds.; Weinheim, Germany, 2008; Volume 8, pp. 451–489. ISBN 9783527620180. [Google Scholar]

- Wild, G.; Hinckley, S. Acousto-ultrasonic optical fiber sensors: Overview and state-of-the-art. IEEE Sens. J. 2008, 8, 1184–1193. [Google Scholar] [CrossRef]

- Yeo, T.L.; Sun, T.; Grattan, K.T.V. Fibre-optic sensor technologies for humidity and moisture measurement. Sens. Actuators A Phys. 2008, 144, 280–295. [Google Scholar] [CrossRef]

- Monošík, R.; Streďanský, M.; Šturdík, E. Biosensors—Classification, characterization and new trends. Acta Chim. Slov. 2012, 5. [Google Scholar] [CrossRef]

- Wang, J. Electrochemical biosensors: Towards point-of-care cancer diagnostics. Biosens. Bioelectron. 2006, 21, 1887–1892. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Peng, D.; Wang, W.; Sharif, H.; Chen, H.H.; Khoynezhad, A. Resource-aware secure ECG healthcare monitoring through body sensor networks. IEEE Wirel. Commun. 2010, 17, 12–19. [Google Scholar] [CrossRef]

- Fletcher, R.R.; Kulkarni, S. Clip-on wireless wearable microwave sensor for ambulatory cardiac monitoring. In Proceedings of the 2010 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, EMBC’10, Buenos Aires, Argentina, 31 August–4 September 2010; pp. 365–369. [Google Scholar]

- Kung, H.T.; Vlah, D. Efficient location tracking using sensor networks. In Proceedings of the 2003 IEEE Wireless Communications and Networking, New Orleans, LA, USA, 16–20 March 2003; Volume 3, pp. 1954–1961. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, L.; Xie, X.; Ma, W.-Y. Mining interesting locations and travel sequences from GPS trajectories. In Proceedings of the 18th International Conference on World Wide Web—WWW ’09, Madrid, Spain, 20–24 April 2009; p. 791. [Google Scholar]

- Liu, X.; Biagioni, J.; Eriksson, J.; Wang, Y.; Forman, G.; Zhu, Y. Mining large-scale, sparse GPS traces for map inference. In Proceedings of the 18th ACM SIGKDD International Conference on Knowledge Discovery and Data Mining—KDD ’12, Beijing, China, 12–16 August 2012; p. 669. [Google Scholar]

- Johnson, L. GPS in mining. Min. Mag. 1998, 178, 387–389. [Google Scholar]

- Yin, P.; Ye, M.; Lee, W.C.; Li, Z. Mining GPS data for trajectory recommendation. In Lecture Notes in Computer Science; Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics; Springer: Cham, Switzerland, 2014; Volume 8444 (LNAI), pp. 50–61. [Google Scholar]

- Wahlström, N.; Gustafsson, F. Magnetometer modeling and validation for tracking metallic targets. IEEE Trans. Signal Process. 2014, 62, 545–556. [Google Scholar] [CrossRef]

- Park, K.; Shin, H.; Cha, H. Smartphone-based pedestrian tracking in indoor corridor environments. Pers. Ubiquitous Comput. 2013, 17, 359–370. [Google Scholar] [CrossRef]

- Zhou, H.; Stone, T.; Hu, H.; Harris, N. Use of multiple wearable inertial sensors in upper limb motion tracking. Med. Eng. Phys. 2008, 30, 123–133. [Google Scholar] [CrossRef] [PubMed]

- Yun, X.; Bachmann, E.R. Design, Implementation, and Experimental Results of a Quaternion-Based Kalman Filter for Human Body Motion Tracking. IEEE Trans. Robot. 2006, 22, 1216–1227. [Google Scholar] [CrossRef]

- Baek, J.; Choi, Y.; Lee, C.; Suh, J.; Lee, S. BBUNS: Bluetooth Beacon-Based Underground Navigation System to Support Mine Haulage Operations. Minerals 2017, 7, 228. [Google Scholar] [CrossRef]

- Chisholm, J. Respirable dust and respirable silica concentrations from construction activities. Indoor Built Environ. 1999, 8, 94–106. [Google Scholar] [CrossRef]

- Verma, D.K.; Rajhans, G.S.; Malik, O.P.; Des Tombe, K. Respirable dust and respirable silica exposure in Ontario gold mines. J. Occup. Environ. Hyg. 2014, 11, 111–116. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Zhang, X.; Liu, X. Mine safety information technology in the framework of Digital Mine. Saf. Sci. 2012, 50, 846–850. [Google Scholar] [CrossRef]

- Greenpeace Toxic Tech: The dangerous chemicals in electronic products. Greenpeace Brief. 2014, 7, 1–21.

- Underground Mining Regulations—Occupational Health and Safety Act (Nova Scotia). Available online: https://novascotia.ca/just/regulations/regs/ohsmine.htm#TOC2_190 (accessed on 2 February 2018).

- Mine Safety and Health Administration-MSHA. Available online: https://arlweb.msha.gov/regs/30cfr/ (accessed on 12 January 2018).

- Mines, Quarries, Works and Machinery: Subsidiary Legislation. Government of Botswana, 1978. Available online: https://www.ilo.org/dyn/natlex/docs/ELECTRONIC/12921/94916/F1585757103/BWA12921.pdf (accessed on 17 January 2018).

- Solomon, F.; Katz, E.; Lovel, R. Social dimensions of mining: Research, policy and practice challenges for the minerals industry in Australia. Resour. Policy 2008, 33, 142–149. [Google Scholar] [CrossRef]

- Humphreys, D. Sustainable development: Can the mining industry afford it? Resour. Policy 2001, 27, 1–7. [Google Scholar] [CrossRef]

- Qiuping, W.; Shunbing, Z.; Chunquan, D. Study on Key Technologies of Internet of Things Perceiving Mine. Procedia Eng. 2011, 26, 2326–2333. [Google Scholar] [CrossRef]

- Laurence, D. Establishing a sustainable mining operation: An overview. J. Clean. Prod. 2011, 19, 278–284. [Google Scholar] [CrossRef]

- Worrall, R.; Neil, D.; Brereton, D.; Mulligan, D. Towards a sustainability criteria and indicators framework for legacy mine land. J. Clean. Prod. 2009, 17, 1426–1434. [Google Scholar] [CrossRef]

| Type | Properties | Capabilities | Applications |

|---|---|---|---|

| Smartwatch | -low operating power -user-friendly interface with both touch and voice commands | -displays specific information -payment -fitness/activity tracking -communication -navigation | -business, administration -marketing, insurance -professional sport, training -education -infotainment |

| Smart eyewear | -controlled by touching the screen, head movement, voice command, and hand shake -low operating power -sends sound directly to the ear | -visualization -language interpretation -communication -task coordination | -surgery -aerospace and defense -logistics -education -infotainment |

| Fitness tracker | -high accuracy -waterproof -lightweight -wireless communication | -physiological wellness -navigation -fitness/activity tracking -heart rate monitor | -fitness -healthcare -professional sport -outdoor/indoor sport |

| Smart clothing | -no visual interaction with user via display or screen -data are obtained by body sensors and actuators | -heart rate, daily activities, temperature, and body position tracking -heating or cooling the body automatic payment | -professional sport-fitness -medicine -military -logistics |

| Wearable camera | -making first-person capture attachable on clothes or body -smaller dimensions -night vision | -captures real-time first-person photos and videos -live streaming -fitness/activity tracking | -defense -fitness -industry -education |

| Wearable medical device | -pain management -physiological tracking -glucose monitoring -sleep monitoring -brain activity monitoring | -cardiovascular diseases -physiological disorders -chronic diseases; diabetes -surgery -neuroscience -dermatology -rehabilitation | -fitness -cardiovascular medicine -psychiatry -surgery -oncology -dermatology -respirology |

| Wearable Device | Sensor | Application | |||||

|---|---|---|---|---|---|---|---|

| S.W. 1 | S.E. 2 | W.C. 3 | S.C. 4 | F.T. 5 | M.W.D. 6 | ||

| ∆ | ∆ | ∆ | IMU 7 sensor, control sensor, IR 8 sensor | mining equipment management | |||

| ∆ | ∆ | ∆ | camera sensor, navigation module, accelerometer, speed sensor, magnetometer, position sensor | transport and logistics management | |||

| ∆ | ∆ | ∆ | proximity/motion sensor, ultrasonic sensor, IR sensor, camera sensor | process monitoring & reporting | |||

| ∆ | ∆ | ∆ | camera sensor, control sensor, navigation module, IMU sensor | site supervision | |||

| ∆ | ∆ | ∆ | supply chain management | ||||

| ∆ | ∆ | ∆ | task achievement monitoring | ||||

| ∆ | ∆ | conveyor belt monitoring | |||||

| ∆ | ∆ | ∆ | camera sensor, IMU sensor, navigation module | labor education and training | |||

| ∆ | ∆ | ∆ | emergency preparedness | ||||

| ∆ | ∆ | ∆ | communication module, camera sensor | communication & data management | |||

| ∆ | ∆ | ∆ | camera sensor, motion/proximity sensor, temperature sensor, humidity sensor, gas sensor, air pressure sensor, radiation sensor | risk and change management | |||

| ∆ | ∆ | ∆ | operational safety monitoring | ||||

| ∆ | ∆ | ∆ | ∆ | mine rescue training/operations | |||

| ∆ | ∆ | ∆ | pulse rate sensor, ECG 9 sensor, EEG 10 sensor, body temperature sensor, sound sensor, blood pressure sensor, glucose level sensor, exhalation sensor | occupational health monitoring | |||

| ∆ | ∆ | ∆ | occupational disease prevention | ||||

| ∆ | ∆ | camera sensor, dust sensor, humidity sensor | dust monitoring | ||||

| ∆ | ∆ | camera sensor, sound sensor | noise monitoring | ||||

| ∆ | ∆ | temperature sensor, gas/fume sensor, humidity sensor, exhalation sensor | air flow monitoring (ventilation) | ||||

| ∆ | ∆ | ∆ | light sensor, camera sensor, control sensor | facility management (lights, pump etc.) | |||

| ∆ | ∆ | mine equipment service and maintenance | |||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mardonova, M.; Choi, Y. Review of Wearable Device Technology and Its Applications to the Mining Industry. Energies 2018, 11, 547. https://doi.org/10.3390/en11030547

Mardonova M, Choi Y. Review of Wearable Device Technology and Its Applications to the Mining Industry. Energies. 2018; 11(3):547. https://doi.org/10.3390/en11030547

Chicago/Turabian StyleMardonova, Mokhinabonu, and Yosoon Choi. 2018. "Review of Wearable Device Technology and Its Applications to the Mining Industry" Energies 11, no. 3: 547. https://doi.org/10.3390/en11030547

APA StyleMardonova, M., & Choi, Y. (2018). Review of Wearable Device Technology and Its Applications to the Mining Industry. Energies, 11(3), 547. https://doi.org/10.3390/en11030547