Mechanical and Alkaline Hydrothermal Treated Corn Residue Conversion in to Bioenergy and Biofertilizer: A Resource Recovery Concept

Abstract

:1. Introduction

2. Methodology

2.1. Sample Collection and Feedstock Preparation

2.2. Mechanical Pretreatment

2.3. Alkaline Hydrothermal Pretreatment

2.4. Ultimate Analysis, Proximate Analysis and Higher Heating Value

2.5. Elemental Analysis

2.6. Anaerobic Digestion

2.7. Energy Recovery

3. Results and Discussion

3.1. Proximate and Ultimate Analysis of Corn Residue and AD Inoculum

3.2. Composition of Corn Residue and Its Alkaline Hydrothermal Process Water

3.3. Anaerobic Digestion

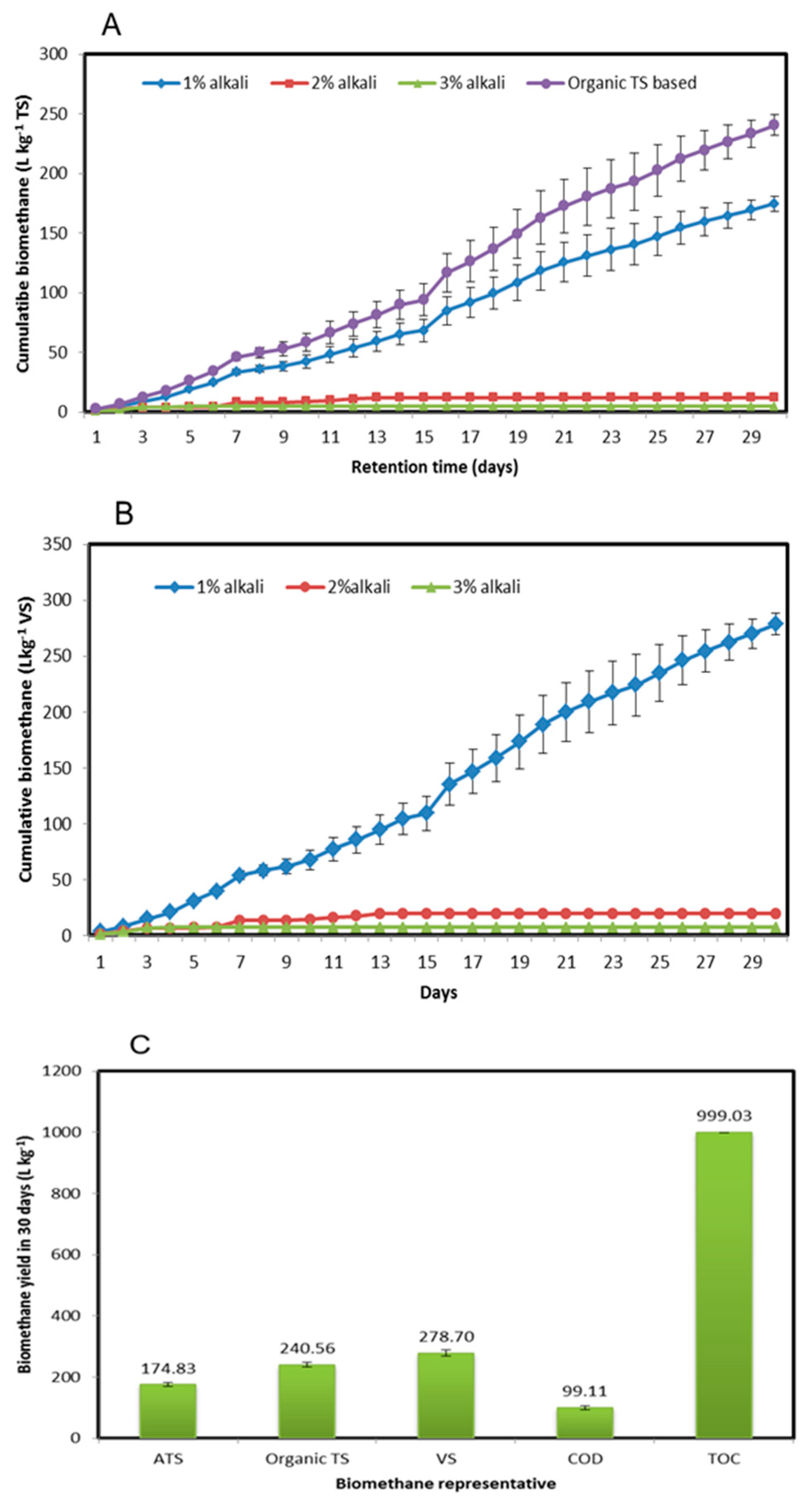

3.3.1. Biomethane Yield from Mechanically Pretreated Corn Residue

3.3.2. Biomethane Yield from Alkaline Hydrothermal Process Water of Corn Residue

3.3.3. Biomethane Yield Comparison between Mechanical and Alkaline Hydrothermal Treated Corn Residue

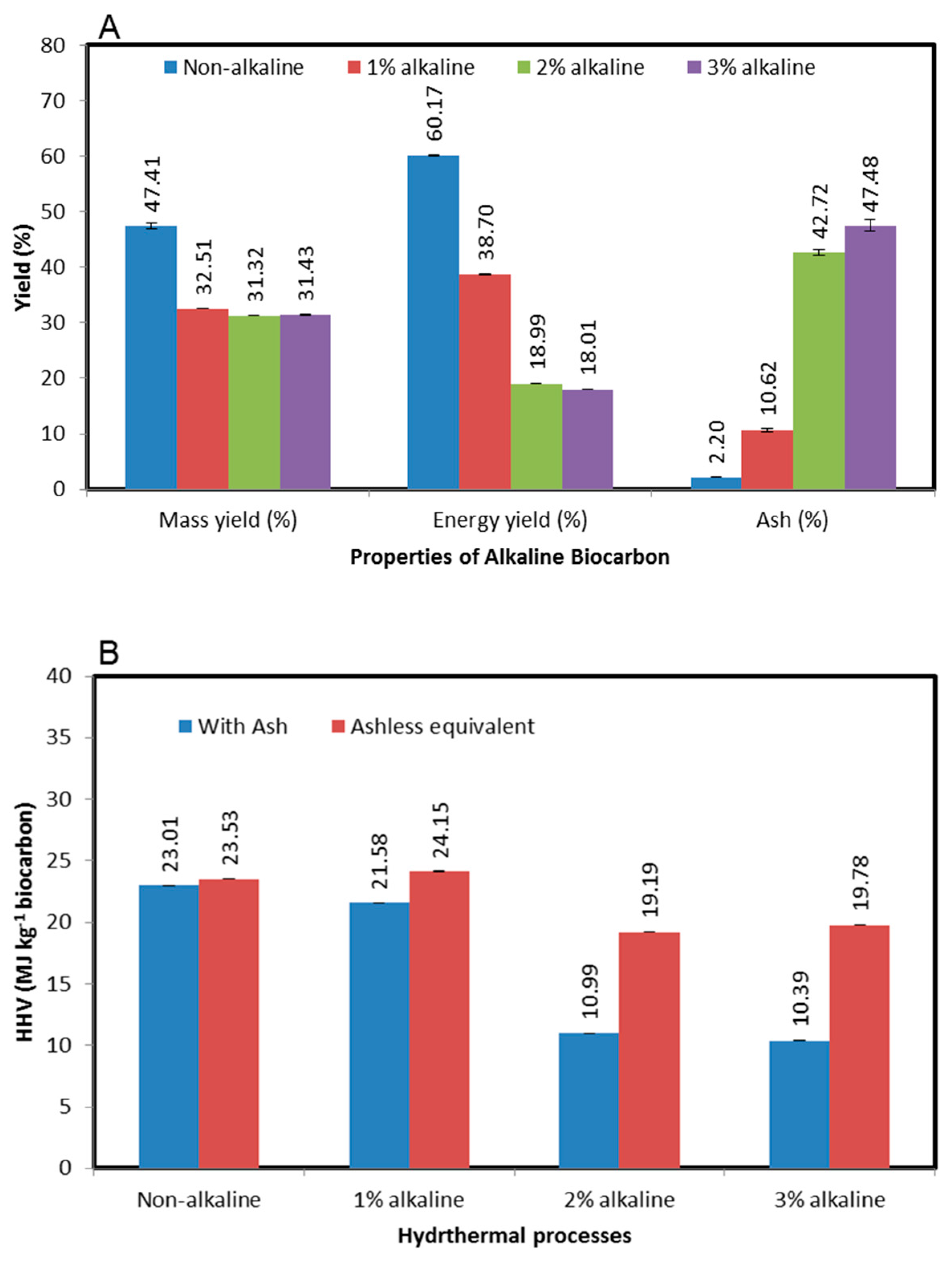

3.4. Biocarbon from Alkaline Hydrothermal Treated Corn Residue

3.5. Hybrid Bioenergy Production

3.6. Energy Recovery

3.7. Nutrient Recivery

3.8. Further Study

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hu, F.; Ragauskas, A. Pretreatment and lignocellulosic chemistry. BioEnergy Res. 2012, 5, 1043–1066. [Google Scholar] [CrossRef]

- Graham, R.L.; Nelson, R.; Sheehan, J.; Perlack, R.D.; Wright, L.L. Current and potential US corn stover supplies. Agron. J. 2007, 99, 1–11. [Google Scholar] [CrossRef]

- Wilhelm, W.W.; Johnson, J.M.; Hatfield, J.L.; Voorhees, W.B.; Linden, D.R. Crop and soil productivity response to corn residue removal. Agron. J. 2004, 96, 1–17. [Google Scholar] [CrossRef]

- Statistics Canada. Corn: Canada’s Third Most Valuable Crop. 2017. Available online: http://www.statcan.gc.ca/pub/96-325-x/2014001/article/11913-eng.htm (accessed on 6 February 2017).

- Khan, A.A. Potential to use biomass for bio-energy in Ontario. Guelph Eng. J. 2009, 2, 39–44. [Google Scholar]

- Hewson, D.; Aung, O.; Albion, K.J. Assessment of Agricultural Residuals as a Biomass Fuel for Ontario Power Generation; The University of Western Ontario: London, ON, Canada, 2010. [Google Scholar]

- Minaret, J.; Dutta, A. Comparison of liquid and vapor hydrothermal carbonization of corn husk for the use as a solid fuel. Bioresour. Technol. 2016, 200, 804–811. [Google Scholar] [CrossRef] [PubMed]

- Bacenetti, J.; Sala, C.; Fusi, A.; Fiala, M. Agricultural anaerobic digestion plants: What LCA studies pointed out and what can be done to make them more environmentally sustainable. Appl. Energy 2016, 179, 669–686. [Google Scholar] [CrossRef]

- Wilhelm, W.W.; Johnson, J.M.; Karlen, D.L.; Lightle, D.T. Corn stover to sustain soil organic carbon further constrains biomass supply. Agron. J. 2007, 99, 1665–1667. [Google Scholar] [CrossRef]

- Swan, J.B.; Higgs, R.L.; Baile, T.B.; Wollenhaupt, N.; Paulson, W.H.; Peterson, A.E. Surface residue and in-row treatment effects on long-term no-tillage continuous corn. Agron. J. 1994, 86, 711–718. [Google Scholar] [CrossRef]

- Laird, D.A.; Chang, C.W. Long-term impacts of residue harvesting on soil quality. Soil Tillage Res. 2013, 134, 33–40. [Google Scholar] [CrossRef]

- OFA. Ontario Federation of Agriculture, Consideration for Grading Agricultural Residue. 24 July 2013. Available online: http://www.ofa.on.ca/uploads/userfiles/files/gradingagriculturalresidues-final.pdf (accessed on 3 October 2016).

- Jin, V.L.; Baker, J.M.; Johnson, J.M.; Karlen, D.L.; Lehman, R.M.; Osborne, S.L.; Sauer, T.J.; Stott, D.E.; Varvel, G.E.; Venterea, R.T.; et al. Soil greenhouse gas emissions in response to corn stover removal and tillage management across the US corn belt. BioEnergy Res. 2014, 7, 517–527. [Google Scholar] [CrossRef]

- Sawatdeenarunat, C.; Surendra, K.C.; Takara, D.; Oechsner, H.; Khanal, S.K. Anaerobic digestion of lignocellulosic biomass: Challenges and opportunities. Bioresour. Technol. 2015, 178, 178–186. [Google Scholar] [CrossRef] [PubMed]

- Saha, B.C. Hemicellulose bioconversion. J. Ind. Microbiol. Biotechnol. 2003, 30, 279–291. [Google Scholar] [CrossRef] [PubMed]

- Pu, Y.; Zhang, D.; Singh, P.M.; Ragauskas, A.J. The new forestry biofuels sector. Biofuels Bioprod. Biorefin. 2008, 2, 58–73. [Google Scholar] [CrossRef]

- Hamawand, I. Anaerobic digestion process and bio-energy in meat industry: A review and a potential. Renew. Sustain. Energy Rev. 2015, 44, 37–51. [Google Scholar] [CrossRef]

- Zheng, M.; Li, X.; Li, L.; Yang, X.; He, Y. Enhancing anaerobic biogasification of corn stover through wet state NaOH pretreatment. Bioresour. Technol. 2009, 100, 5140–5145. [Google Scholar] [CrossRef] [PubMed]

- Mosier, N.; Wyman, C.; Dale, B.; Elander, R.; Lee, Y.Y.; Holtzapple, M.; Ladisch, M. Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour. Technol. 2005, 96, 673–686. [Google Scholar] [CrossRef] [PubMed]

- Amani, T.; Nosrati, M.; Sreekrishnan, T.R. Anaerobic digestion from the viewpoint of microbiological, chemical, and operational aspects—A review. Environ. Rev. 2010, 18, 255–278. [Google Scholar] [CrossRef]

- Liu, X.; Hiligsmann, S.; Gourdon, R.; Bayard, R. Anaerobic digestion of lignocellulosic biomasses pretreated with Ceriporiopsis subvermispora. J. Environ. Manag. 2017, 193, 154–162. [Google Scholar] [CrossRef] [PubMed]

- Panagiotou, G.; Olsson, L. Effect of compounds released during pretreatment of wheat straw on microbial growth and enzymatic hydrolysis rates. Biotechnol. Bioeng. 2007, 96, 250–258. [Google Scholar] [CrossRef] [PubMed]

- Garrote, G.; Dominguez, H.; Parajo, J.C. Hydrothermal processing of lignocellulosic materials. Eur. J. Wood Wood Prod. 1999, 57, 191–202. [Google Scholar] [CrossRef]

- Negro, M.J.; Manzanares, P.; Oliva, J.M.; Ballesteros, I.; Ballesteros, M. Changes in various physical/chemical parameters of Pinus pinaster wood after steam explosion pretreatment. Biomass Bioenergy 2003, 25, 301–308. [Google Scholar] [CrossRef]

- Ramos, L.P. The chemistry involved in the steam treatment of lignocellulosic materials. Quím. Nova 2003, 26, 863–871. [Google Scholar] [CrossRef]

- Hon, D.N.; Shiraishi, N. Wood and Cellulosic Chemistry, Revised, and Expanded; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Digman, M.F.; Shinners, K.J.; Casler, M.D.; Dien, B.S.; Hatfield, R.D.; Jung, H.J.; Muck, R.E.; Weimer, P.J. Optimizing on-farm pretreatment of perennial grasses for fuel ethanol production. Environ. Sci. Technol. 2010, 101, 5305–5314. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Knierim, B.; Manisseri, C.; Arora, R.; Scheller, H.V.; Auer, M.; Vogel, K.P.; Simmons, B.A.; Singh, S. Comparison of dilute acid and ionic liquid pretreatment of switchgrass: Biomass recalcitrance, delignification and enzymatic saccharification. Bioresour. Technol. 2010, 101, 4900–4906. [Google Scholar] [CrossRef] [PubMed]

- Brown, R.C.; Brown, T.R. Biorenewable Resources: Engineering New Products from Agriculture; John Wiley and Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Zheng, Y.; Zhao, J.; Xu, F.; Li, Y. Pretreatment of lignocellulosic biomass for enhanced biogas production. Prog. Energy Combust. 2014, 42, 35–53. [Google Scholar] [CrossRef]

- Abdi, N.; Hamdache, F.; Belhocine, D.; Grib, H.; Lounici, H.; Piron, D.L.; Mameri, N. Enzymatic saccharification of solid residue of olive mill in a batch reactor. Biochem. Eng. J. 2000, 6, 177–183. [Google Scholar] [CrossRef]

- Carrillo, F.; Lis, M.J.; Colom, X.; López-Mesas, M.; Valldeperas, J. Effect of alkali pretreatment on cellulase hydrolysis of wheat straw: Kinetic study. Process Biochem. 2005, 40, 3360–3364. [Google Scholar] [CrossRef]

- Silverstein, R.A.; Chen, Y.; Sharma-Shivappa, R.R.; Boyette, M.D.; Osborne, J. A comparison of chemical pretreatment methods for improving saccharification of cotton stalks. Bioresour. Technol. 2007, 98, 3000–3011. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Chen, S.; Kafle, G.K. Importance of “weak-base” poplar wastes to process performance and methane yield in solid-state anaerobic digestion. J. Environ. Manag. 2017, 193, 423–429. [Google Scholar] [CrossRef] [PubMed]

- Kambo, H.S. Energy Densification of Lignocellulosic Biomass via Hydrothermal Carbonization and Torrefaction. Master’s Thesis, University of Guelph, Guelph, ON, Canada, 2014. [Google Scholar]

- Chandra, R.; Takeuchi, H.; Hasegawa, T. Methane production from lignocellulosic agricultural crop wastes: A review in context to second generation of biofuel production. Renew. Sustain. Energy Rev. 2012, 16, 1462–1476. [Google Scholar] [CrossRef]

- Wirth, B.; Mumme, J. Anaerobic digestion of waste water from hydrothermal carbonization of corn silage. Appl. Bioenergy 2014, 1, 1–10. [Google Scholar] [CrossRef]

- Libra, J.A.; Ro, K.S.; Kammann, C.; Funke, A.; Berge, N.D.; Neubauer, Y.; Titirici, M.M.; Fühner, C.; Bens, O.; Kern, J.; et al. Hydrothermal carbonization of biomass residuals: A comparative review of the chemistry, processes and applications of wet and dry pyrolysis. Biofuels 2011, 2, 71–106. [Google Scholar] [CrossRef]

- Barakat, A.; Monlau, F.; Steyer, J.P.; Carrere, H. Effect of lignin-derived and furan compounds found in lignocellulosic hydrolysates on biomethane production. Bioresour. Technol. 2012, 104, 90–99. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.; Ding, W.; Bi, J.; Mehryar, E.; Talha, Z.A.; Huang, H. Methane enhancement through oxidative cleavage and alkali solubilization pre-treatments for corn stover with anaerobic activated sludge. Bioresour. Technol. 2016, 200, 405–412. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhang, R.; Siddhu, M.A.; He, Y.; Wang, W.; Li, Y.; Chen, C.; Liu, G. Enhancing methane production of corn stover through a novel way: Sequent pretreatment of potassium hydroxide and steam explosion. Bioresour. Technol. 2015, 181, 345–350. [Google Scholar] [CrossRef] [PubMed]

- Tchobanoglous, G.; Stensel, H.D.; Tsuchihashi, R.; Burton, F. Wastewater Engineering: Treatment and Resource Recovery, 4th ed.; McGraw Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Thomsen, M.; Seghetta, M.; Mikkelsen, M.H.; Gyldenkærne, S.; Becker, T.; Caro, D.; Frederiksen, P. Comparative life cycle assessment of biowaste to resource management systems—A Danish case study. J. Clean. Prod. 2017, 142, 4050–4058. [Google Scholar] [CrossRef]

- Ontario, 2016. Resource Recovery and Circular Economy Act, 2016. The Ontario Government, Canada. Available online: http://www.downloads.ene.gov.on.ca/envision/env_reg/er/documents/2016/012-9356.pdf (accessed on 2 May 2017).

- WRAP. WRAP and the Circular Economy. Waste and Resources Action Programme, Oxon, UK. 2017. Available online: http://www.wrap.org.uk/about-us/about/wrap-and-circular-economy (accessed on 2 May 2017).

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Lizotte, P.L.; Savoie, P. Spring harvest of corn stover for animal bedding with a self-loading wagon. Appl. Eng. Agric. 2013, 29, 25–31. [Google Scholar] [CrossRef]

- Hoskinson, R.L.; Karlen, D.L.; Birrell, S.J.; Radtke, C.W.; Wilhelm, W.W. Engineering, nutrient removal, and feedstock conversion evaluations of four corn stover harvest scenarios. Biomass Bioenergy 2007, 31, 126–136. [Google Scholar] [CrossRef]

- Sawyer, J.E.; Mallarino, A.P. Nutrient removal when harvesting corn stover. In Integrated Crop Management News; Iowa State University: Ames, IA, USA, 2008. [Google Scholar]

- Kumagai, S.; Ota, M.; Nakano, S.; Hayashi, N.; Sakaki, T. Solubilization and saccharification of barley straw by hot-compressed water treatment. Jpn. J. Food Eng. 2008, 9, 115–119. [Google Scholar]

- Kumagai, S.; Hirajima, T. Effective Utilization of Moso-Bamboo (Phyllostachys heterocycla) with Hot-Compressed Water. In Application of Hydrothermal Reactions to Biomass Conversion; Springer: Berlin/Heidelberg, Germany, 2014; pp. 155–170. [Google Scholar]

- Reza, M.T.; Wirth, B.; Lüder, U.; Werner, M. Behavior of selected hydrolyzed and dehydrated products during hydrothermal carbonization of biomass. Bioresour. Technol. 2014, 169, 352–361. [Google Scholar] [CrossRef] [PubMed]

- Teater, C.; Yue, Z.; MacLellan, J.; Liu, Y.; Liao, W. Assessing solid digestate from anaerobic digestion as feedstock for ethanol production. Bioresour. Technol. 2011, 102, 1856–1862. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Yan, W.; Sheng, K.; Sanati, M. Comparison of high-solids to liquid anaerobic co-digestion of food waste and green waste. Bioresour. Technol. 2014, 154, 215–221. [Google Scholar] [CrossRef] [PubMed]

- Golkowska, K.; Greger, M. Thermophilic digestion of cellulose at high-organic loading rates. Eng. Life Sci. 2010, 10, 600–606. [Google Scholar] [CrossRef]

- Zheng, J.L.; Zhu, M.Q.; Wu, H.T. Alkaline hydrothermal liquefaction of swine carcasses to bio-oil. Waste Manag. 2015, 43, 230–238. [Google Scholar] [CrossRef] [PubMed]

- Anastasakis, K.; Ross, A.B. Hydrothermal liquefaction of four brown macro-algae commonly found on the UK coasts: An energetic analysis of the process and comparison with bio-chemical conversion methods. Fuel 2015, 139, 546–553. [Google Scholar] [CrossRef]

- Cox, J.L.; Hallen, R.T.; Lilga, M.A. Thermochemical nitrate destruction. Environ. Sci. Technol. 1994, 28, 423–428. [Google Scholar] [CrossRef] [PubMed]

- Marchand, L. Cost Assessment for Cornstalk Supply Chain for Bioprocessing Purses. 2015. Prepared for: Ontario Federation of Agriculture (OFA). Available online: https://www.google.ca (accessed on 2 October 2016).

- Hoekman, S.K.; Broch, A.; Robbins, C.; Zielinska, B.; Felix, L. Hydrothermal carbonization (HTC) of selected woody and herbaceous biomass feedstocks. Biomass Convers. Biorefin. 2013, 3, 113–126. [Google Scholar] [CrossRef]

- Reza, M.T.; Uddin, M.H.; Lynam, J.G.; Hoekman, S.K.; Coronella, C.J. Hydrothermal carbonization of loblolly pine: Reaction chemistry and water balance. Biomass Convers. Biorefin. 2014, 4, 311–321. [Google Scholar] [CrossRef]

- Weingarten, R.; Conner, W.C.; Huber, G.W. Production of levulinic acid from cellulose by hydrothermal decomposition combined with aqueous phase dehydration with a solid acid catalyst. Energy Environ. Sci. 2012, 5, 7559–7574. [Google Scholar] [CrossRef]

- Becker, R.; Dorgerloh, U.; Paulke, E.; Mumme, J.; Nehls, I. Hydrothermal carbonization of biomass: Major organic components of the aqueous phase. Chem. Eng. Technol. 2014, 37, 511–518. [Google Scholar] [CrossRef]

- Antal, M.J.; Leesomboon, T.; Mok, W.S.; Richards, G.N. Mechanism of formation of 2-furaldehyde from D-xylose. Carbohydr. Res. 1991, 217, 71–85. [Google Scholar] [CrossRef]

- Xiao, L.P.; Shi, Z.J.; Xu, F.; Sun, R.C. Hydrothermal carbonization of lignocellulosic biomass. Bioresour. Technol. 2012, 118, 619–623. [Google Scholar] [CrossRef] [PubMed]

- Jin, F.; Zhou, Z.; Moriya, T.; Kishida, H.; Higashijima, H.; Enomoto, H. Controlling hydrothermal reaction pathways to improve acetic acid production from carbohydrate biomass. Environ. Sci. Technol. 2005, 39, 1893–1902. [Google Scholar] [CrossRef] [PubMed]

- Ishiguro, M.; Endo, T. Addition of alkali to the hydrothermal–mechanochemical treatment of Eucalyptus enhances its enzymatic saccharification. Bioresour. Technol. 2014, 153, 322–326. [Google Scholar] [CrossRef] [PubMed]

- Ishiguro, M.; Endo, T. Effect of the addition of calcium hydroxide on the hydrothermal–mechanochemical treatment of Eucalyptus. Bioresour. Technol. 2015, 177, 298–301. [Google Scholar] [CrossRef] [PubMed]

- De Souza, R.L.; Yu, H.; Rataboul, F.; Essayem, N. 5-Hydroxymethylfurfural (5-HMF) production from hexoses: Limits of heterogeneous catalysis in hydrothermal conditions and potential of concentrated aqueous organic acids as reactive solvent system. Challenges 2012, 3, 212–232. [Google Scholar] [CrossRef]

- He, Y.; Pang, Y.; Liu, Y.; Li, X.; Wang, K. Physicochemical characterization of rice straw pretreated with sodium hydroxide in the solid state for enhancing biogas production. Energy Fuels 2008, 22, 2775–2781. [Google Scholar] [CrossRef]

- He, Y.; Pang, Y.; Li, X.; Liu, Y.; Li, R.; Zheng, M. Investigation on the changes of main compositions and extractives of rice straw pretreated with sodium hydroxide for biogas production. Energy Fuels 2009, 23, 2220–2224. [Google Scholar] [CrossRef]

- Cara, C.; Ruiz, E.; Ballesteros, I.; Negro, M.J.; Castro, E. Enhanced enzymatic hydrolysis of olive tree wood by steam explosion and alkaline peroxide delignification. Process Biochem. 2006, 41, 423–429. [Google Scholar] [CrossRef]

- Kambo, H.S.; Dutta, A. Comparative evaluation of torrefaction and hydrothermal carbonization of lignocellulosic biomass for the production of solid biofuel. Energy Convers. Manag. 2015, 105, 746–755. [Google Scholar] [CrossRef]

- Nakason, K.; Panyapinyopol, B.; Kanokkantapong, V.; Viriya-empikul, N.; Kraithong, W.; Pavasant, P. Hydrothermal carbonization of unwanted biomass materials: Effect of process temperature and retention time on hydrochar and liquid fraction. J. Energy Inst. 2017, 11, 1–11. [Google Scholar] [CrossRef]

- Akhtar, J.; Amin, N.A. A review on process conditions for optimum bio-oil yield in hydrothermal liquefaction of biomass. Renew Sustain. Energy Rev. 2011, 15, 1615–1624. [Google Scholar] [CrossRef]

- Tian, C.; Li, B.; Liu, Z.; Zhang, Y.; Lu, H. Hydrothermal liquefaction for algal biorefinery: A critical review. Renew Sustain. Energy Rev. 2014, 38, 933–950. [Google Scholar] [CrossRef]

- Engineering ToolBox, Fuels-Higher Calorific Values. Available online: http://www.engineeringtoolbox.com/fuels-higher-calorific-values-d_169.html (accessed on 19 January 2017).

- Zhang, R.; El-Mashad, H.M.; Hartman, K.; Wang, F.; Liu, G.; Choate, C.; Gamble, P. Characterization of food waste as feedstock for anaerobic digestion. Bioresour. Technol. 2007, 98, 929–935. [Google Scholar] [CrossRef] [PubMed]

- Lusk, P. Methane Recovery from Animal Manures the Current Opportunities Casebook; National Renewable Energy Lab.: Golden, CO, USA, 1998.

- Pang, Y.Z.; Liu, Y.P.; Li, X.J.; Wang, K.S.; Yuan, H.R. Improving biodegradability and biogas production of corn stover through sodium hydroxide solid state pretreatment. Energy Fuels 2008, 22, 2761–2766. [Google Scholar] [CrossRef]

| Parameter | Unit | Value | |

|---|---|---|---|

| Corn Residue | Inoculum (AD Digestate) | ||

| TS | % (wet basis, wb) | 53.28 ± 0.11 | 3.54 ± 0.47 |

| Volatile solid (VS) | % (dry basis, db) | 84.79 ± 2.23 | 40.89 ± 0.42 |

| Ash content | % (db) | 2.34 ± 0.06 | 38.56 ± 0.16 |

| Fixed carbon (FC) | % (db) | 12.86 ± 2.18 | 20.15 ± 0.27 |

| Higher heating value (HHV) | MJ kg−1 (db) | 18.13 ± 0.06 | 14.698 ± 0.12 |

| C | % (db) | 45.29 ± 0.12 | 26.98 ± 0.40 |

| H | % (db) | 5.77 ± 0.13 | 3.56 ± 0.07 |

| N | % (db) | 0.88 ± 0.97 | 3.26 ± 0.13 |

| S | % (db) | Not detected | 0.21 ± 0.18 |

| O | % (db) | 48.08 ± 0.30 | 65.99 ± 0.33 |

| Name of AD Substrate | pH of AD Substrate | TS in AD Substrate (%) wb | VS in AD Substrate (%TS) | Total VFA in AD Substrate (%TS) | COD in TS (g kg−1) | TOC in TS (g kg−1) | TKN in TS (g kg−1) | C/N Ratio |

|---|---|---|---|---|---|---|---|---|

| CR | 6.50 | 5.00 | 84.79 ± 2.23 | 17.65± 0.45 | 2087 ± 8 | 450.00 | 9.75 ± 0.15 | 46.15 |

| Non-alkaline HTPW | 3.83 | 1.48 | 73.02 ± 0.96 | 23.78 | 1776 ± 3 | 367.57 | 8.67 | 42.40 |

| 1% NaOH AHTPW | 6.10 | 3.55 ± 0.03 | 62.73 ± 0.87 | 34.46± 0.28 | 1764 ± 12 | 175.93 | 4.72 ± 0.09 | 37.27 |

| 2% NaOH AHTPW | 9.00 | 4.79 ± 0.10 | 58.85 ± 0.07 | 36.50± 0.24 | 1226 ± 26 | 312.04 | 6.99 ± 0.15 | 44.64 |

| 3% NaOH AHTPW | 9.80 | 5.27 ± 0.09 | 54.33 ± 1.09 | 36.50± 0.02 | 1171 ± 16 | 286.22 | 6.28 ± 0.12 | 45.58 |

| Inoculum (food waste AD digestate) | 8.22 | 3.54 | 40.89 ± 0.42 | 4.27 ± 0.34 | 975 ± 2.82 | 266.95 (TC = 629) | 59.32 | 11 |

| Bio-Carbon Name | C (% of TS) | H (% of TS) | N (% of TS) | S (% of TS) | O (% of TS) | HHV Dry Ash Free (MJ kg−1) |

|---|---|---|---|---|---|---|

| Non-alkaline | 56.83 ± 0.31 | 5.87 ± 0.08 | 1.35 ± 0.01 | 0.18 ± 0.01 | 35.77 ± 0.32 | 23.53 ± 0.12 |

| 1% alkaline | 57.76 ± 0.28 | 5.88 ± 0.01 | 1.21 ± 0.01 | 0.14 ± 00 | 35.01 ± 0.25 | 24.14 ± 0.15 |

| Name of Nutrient | Digestate Type | ||

|---|---|---|---|

| Raw Corn Residue (gkg−1 TS) | HTPW (gkg−1 TS) | AHTPW (gkg−1 TS) | |

| Nitrogen (N) | 16.62 ± 0.08 | 17.75 | 4.72 ± 0.09 |

| Phosphorus (P) | 1.51 ± 0.14 | 0.39 | 0.26 ± 0.14 |

| Potassium (K) | 26.00 | 16.22 | 6.74 |

| Sulfur (S) | 45.49 ± 1.85 | 19.07 | 9.46 ± 1.85 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paul, S.; Dutta, A.; Defersha, F. Mechanical and Alkaline Hydrothermal Treated Corn Residue Conversion in to Bioenergy and Biofertilizer: A Resource Recovery Concept. Energies 2018, 11, 516. https://doi.org/10.3390/en11030516

Paul S, Dutta A, Defersha F. Mechanical and Alkaline Hydrothermal Treated Corn Residue Conversion in to Bioenergy and Biofertilizer: A Resource Recovery Concept. Energies. 2018; 11(3):516. https://doi.org/10.3390/en11030516

Chicago/Turabian StylePaul, Subhash, Animesh Dutta, and Fantahun Defersha. 2018. "Mechanical and Alkaline Hydrothermal Treated Corn Residue Conversion in to Bioenergy and Biofertilizer: A Resource Recovery Concept" Energies 11, no. 3: 516. https://doi.org/10.3390/en11030516

APA StylePaul, S., Dutta, A., & Defersha, F. (2018). Mechanical and Alkaline Hydrothermal Treated Corn Residue Conversion in to Bioenergy and Biofertilizer: A Resource Recovery Concept. Energies, 11(3), 516. https://doi.org/10.3390/en11030516