High Performances Design of a Six-Phase Synchronous Reluctance Motor Using Multi-Objective Optimization with Altered Bee Colony Optimization and Taguchi Method

Abstract

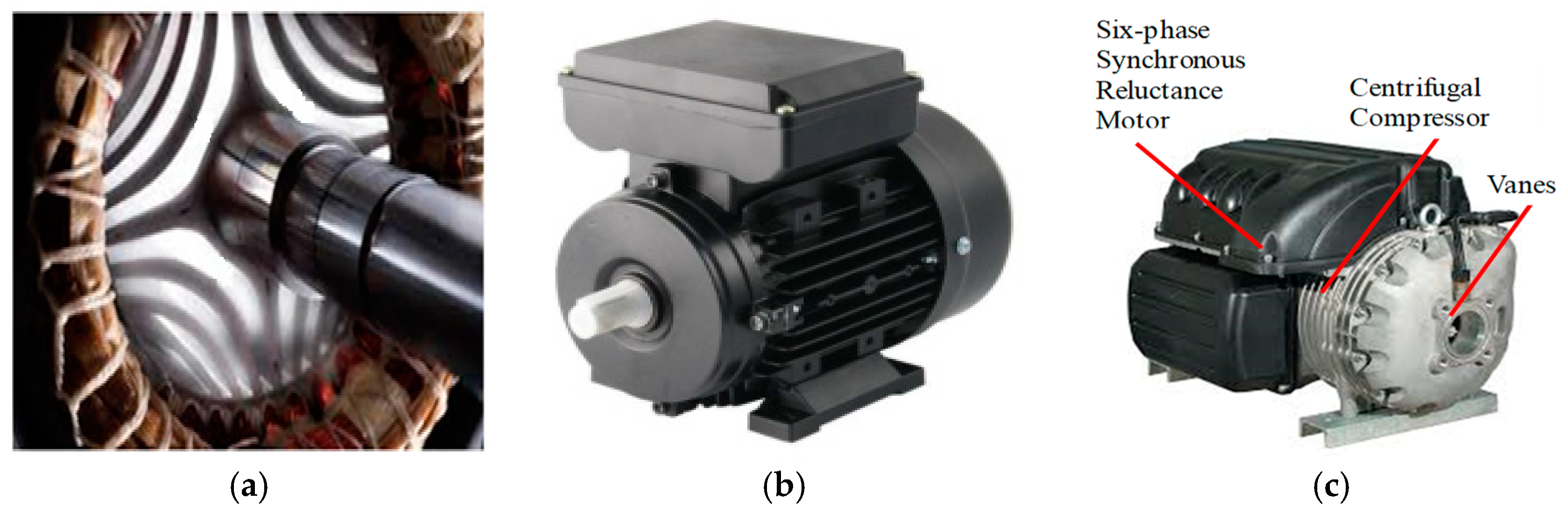

:1. Introduction

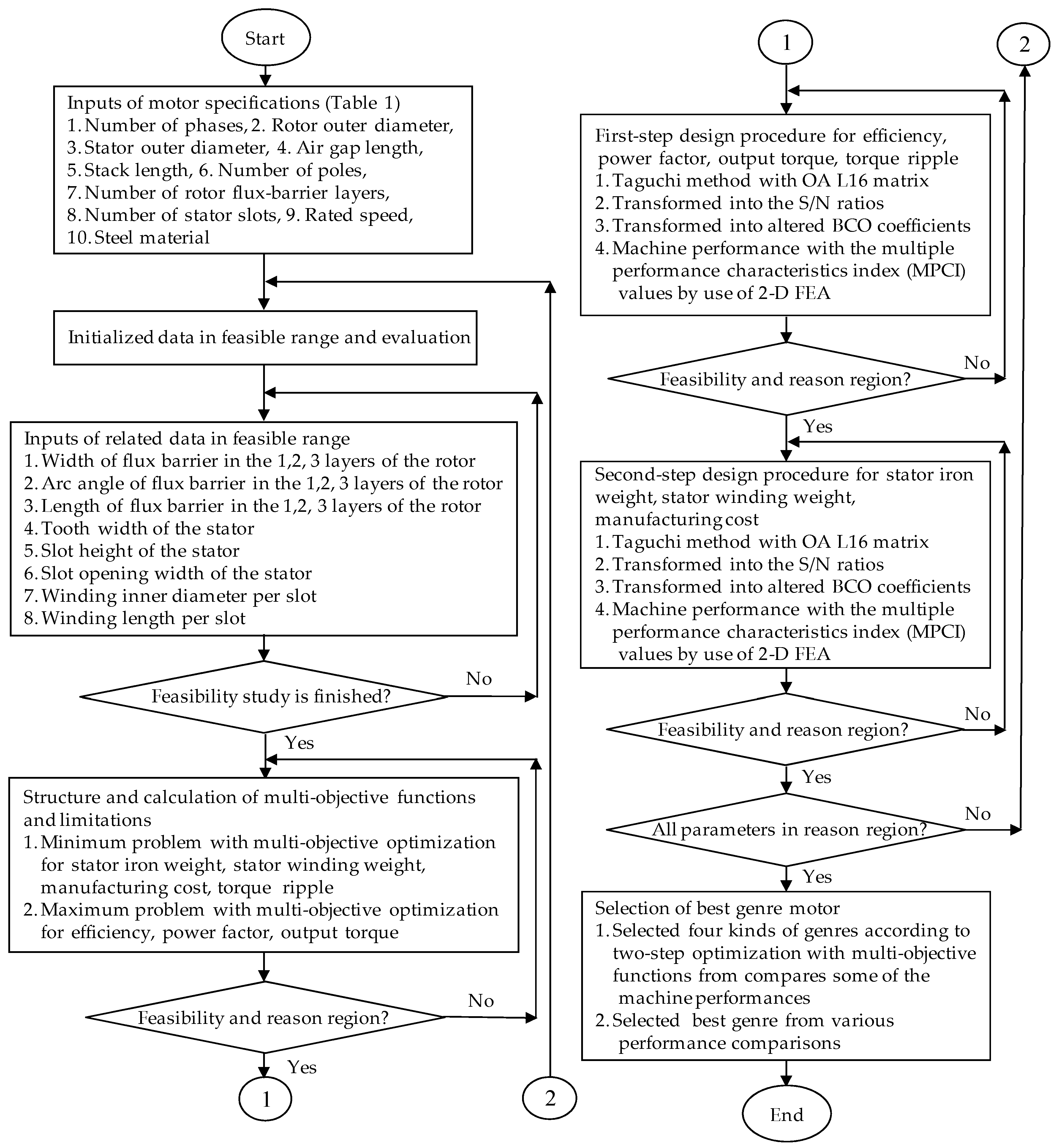

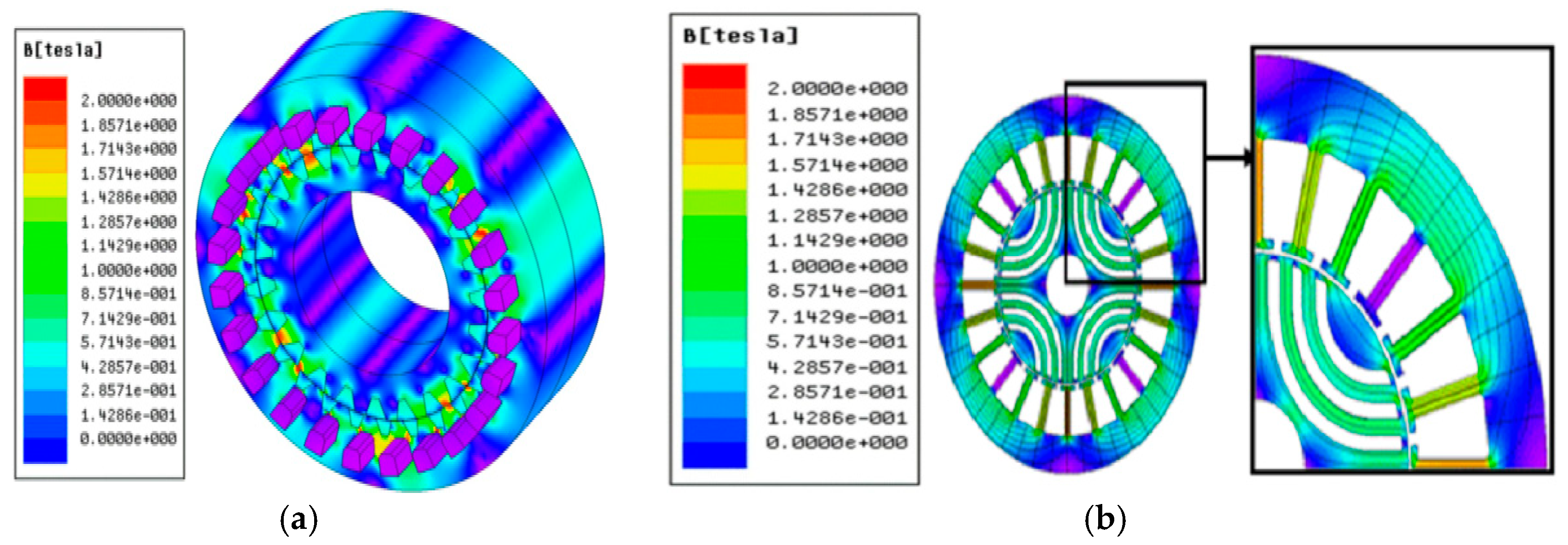

2. Materials and Methods

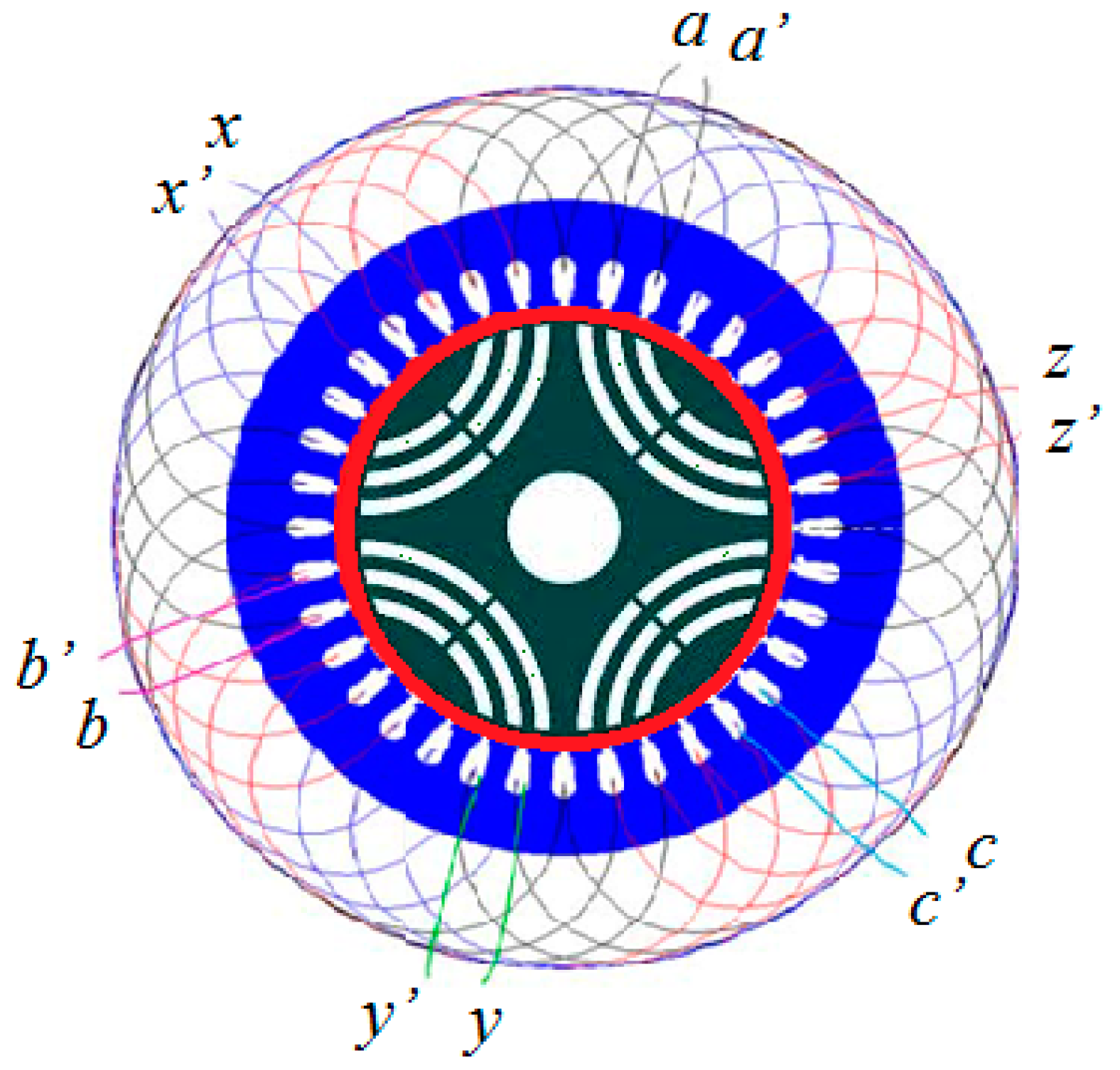

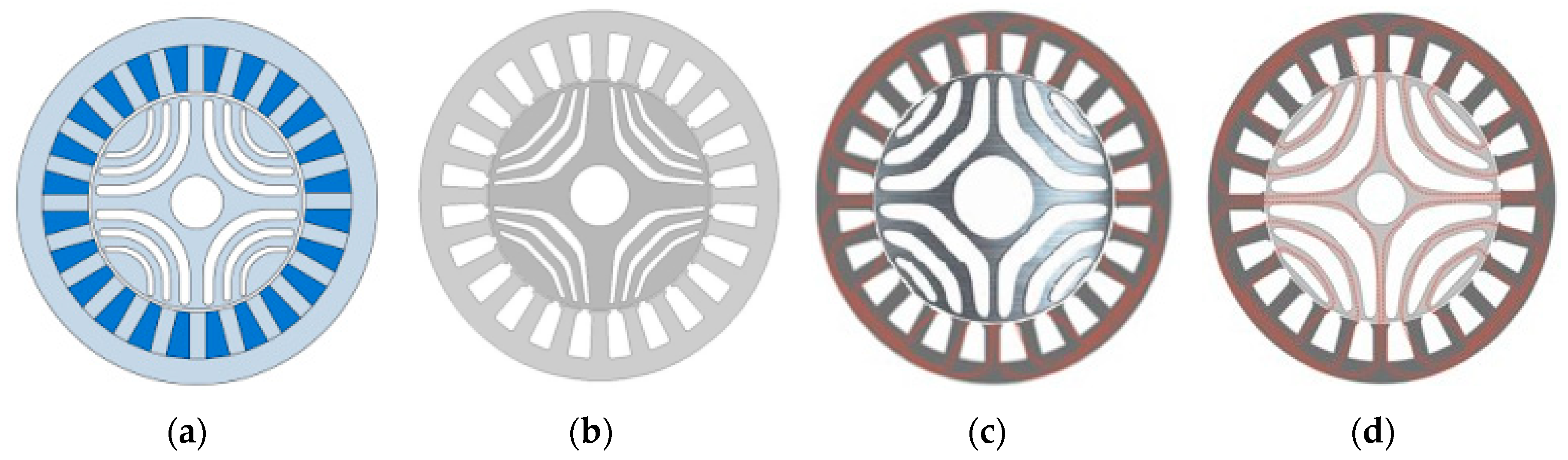

2.1. Initial Design of Six-Phase Synchronous Reluctance Motor

2.2. Optimization Models with Multi-Objective Functions

2.3. Two Step Procedures of Optimization Design

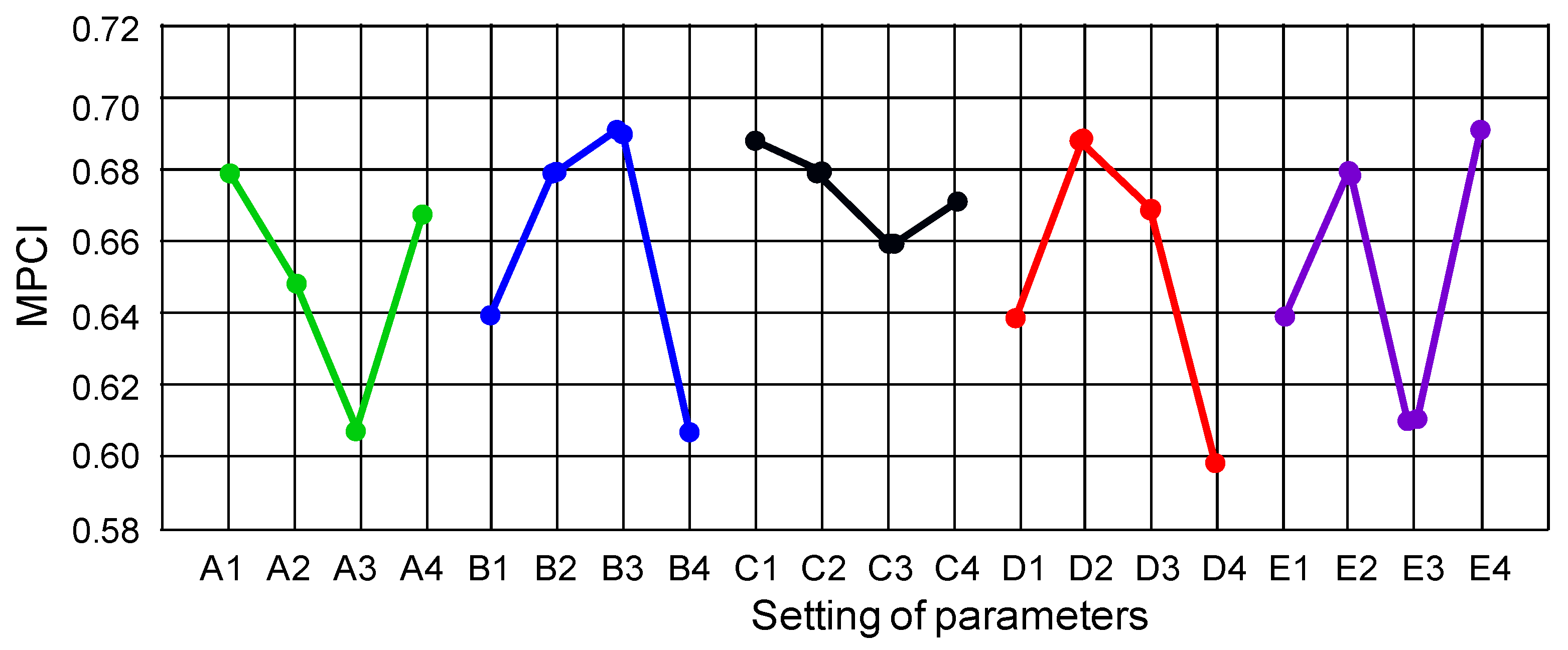

2.3.1. The First-Step Procedure

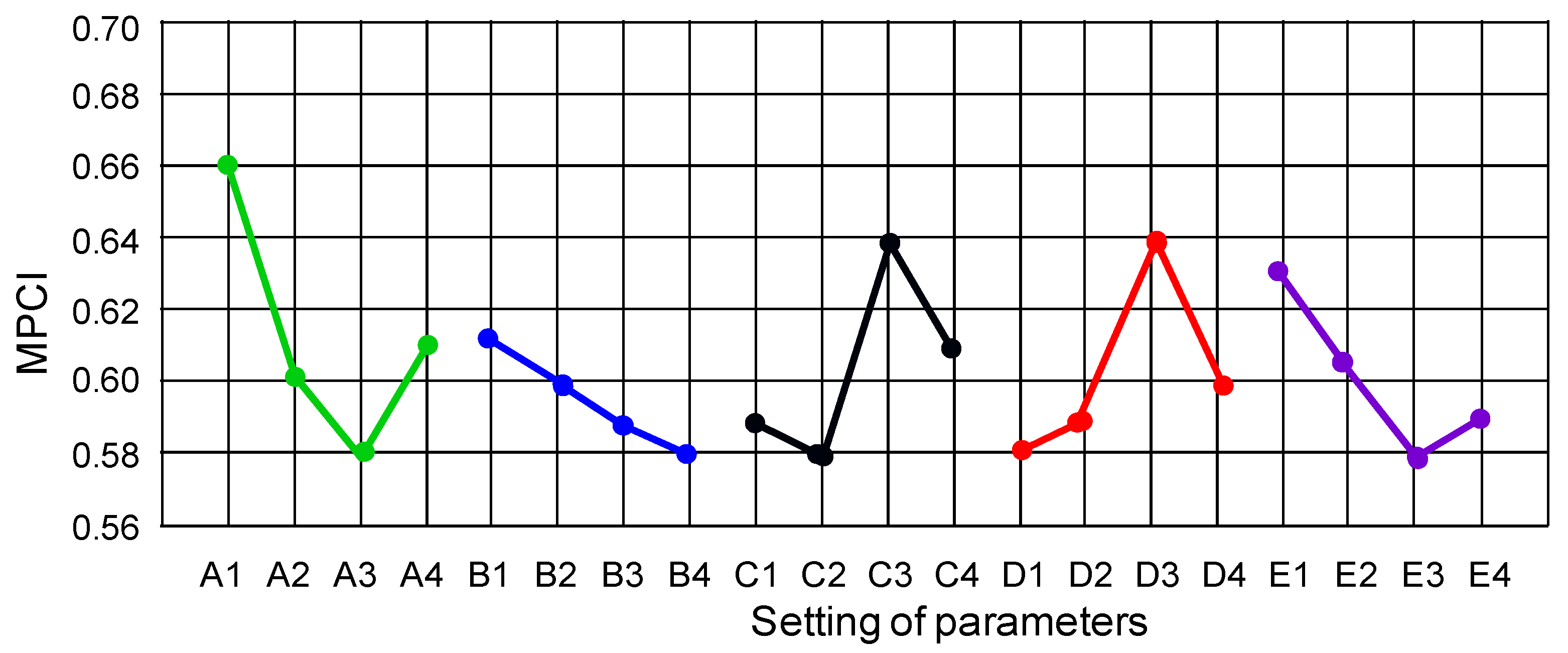

2.3.2. The Second-Step Procedure

3. Results

3.1. Experimental Tests

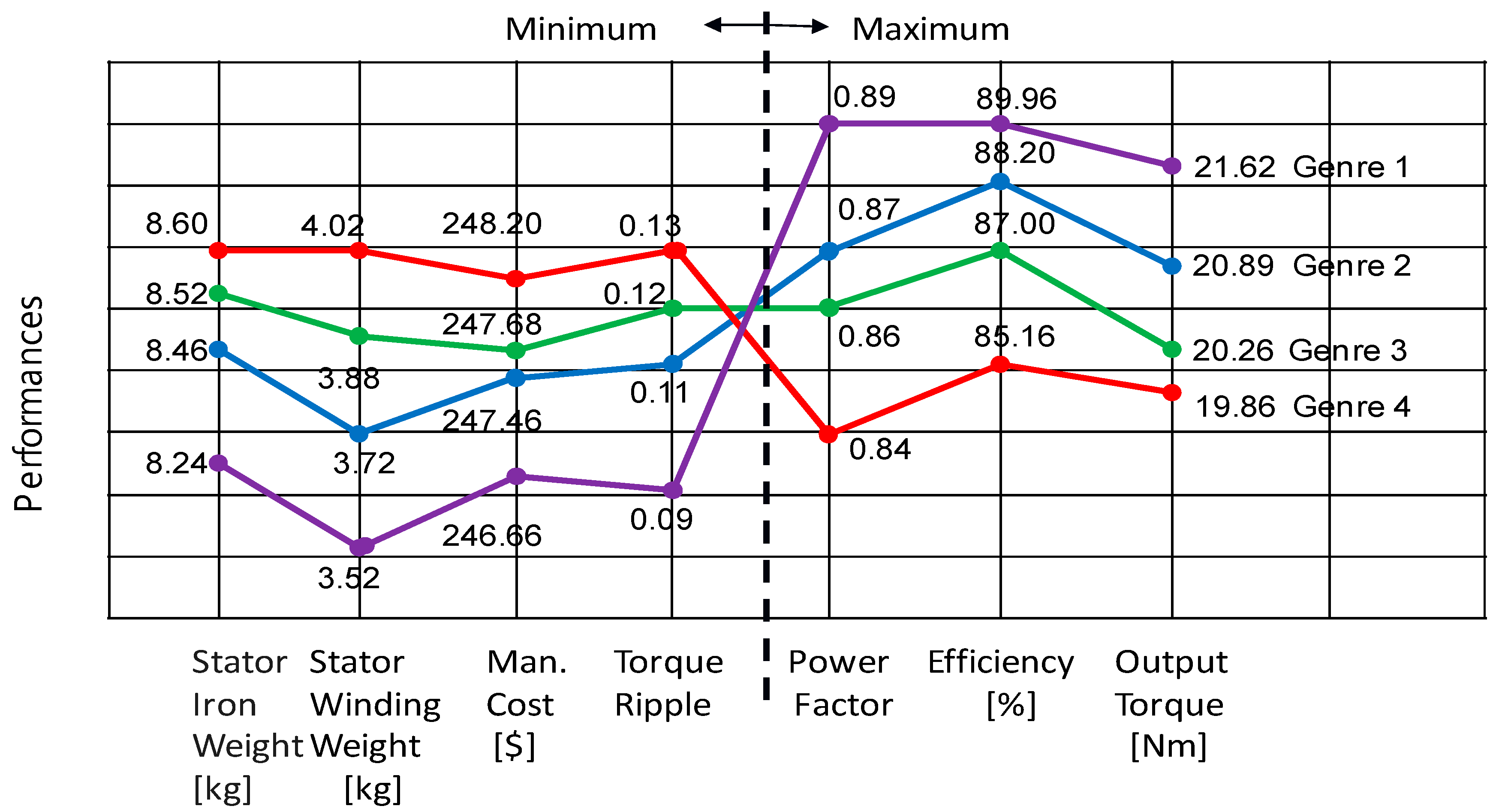

- The weight of iron in Genre 1 is the lowest value as the 8.24 kg.

- The weight of winding in Genre 1 is the lowest value as the 3.52 kg.

- The manufacturing cost in Genre 1 is the lowest value as the $246.66.

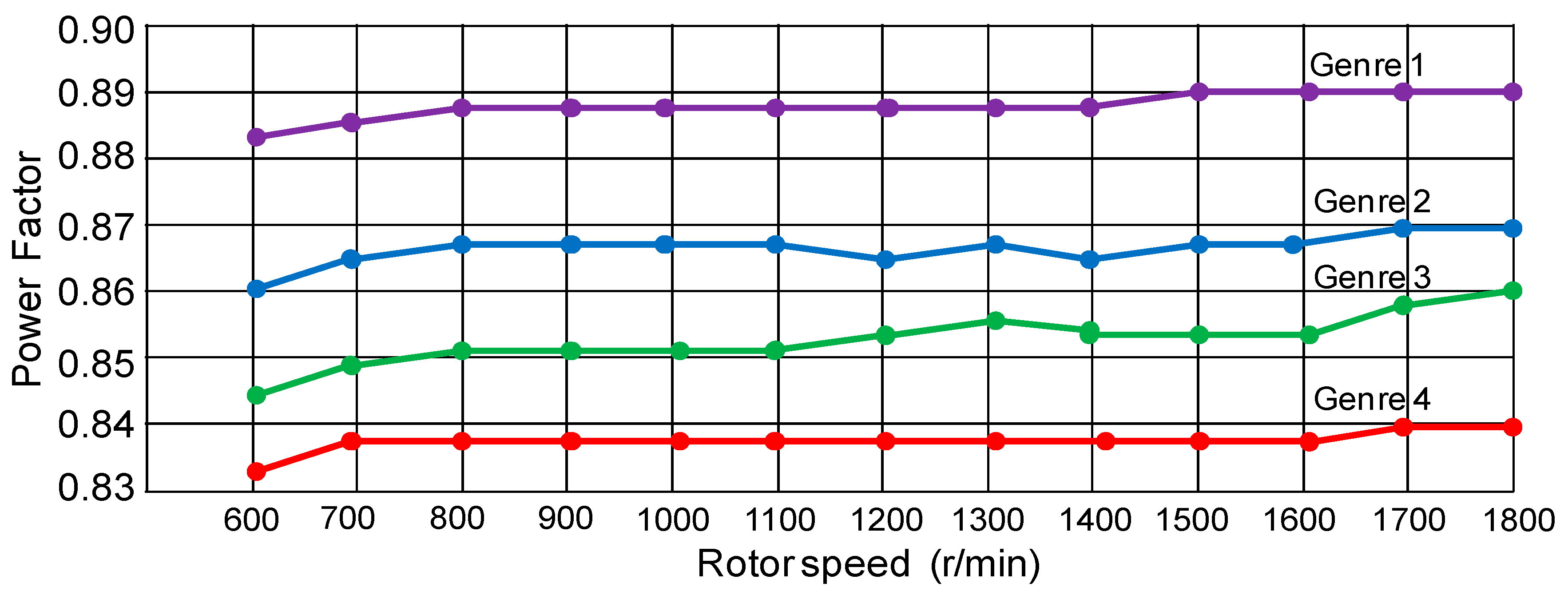

- The power factor in Genre 1 is the highest value as the 0.89.

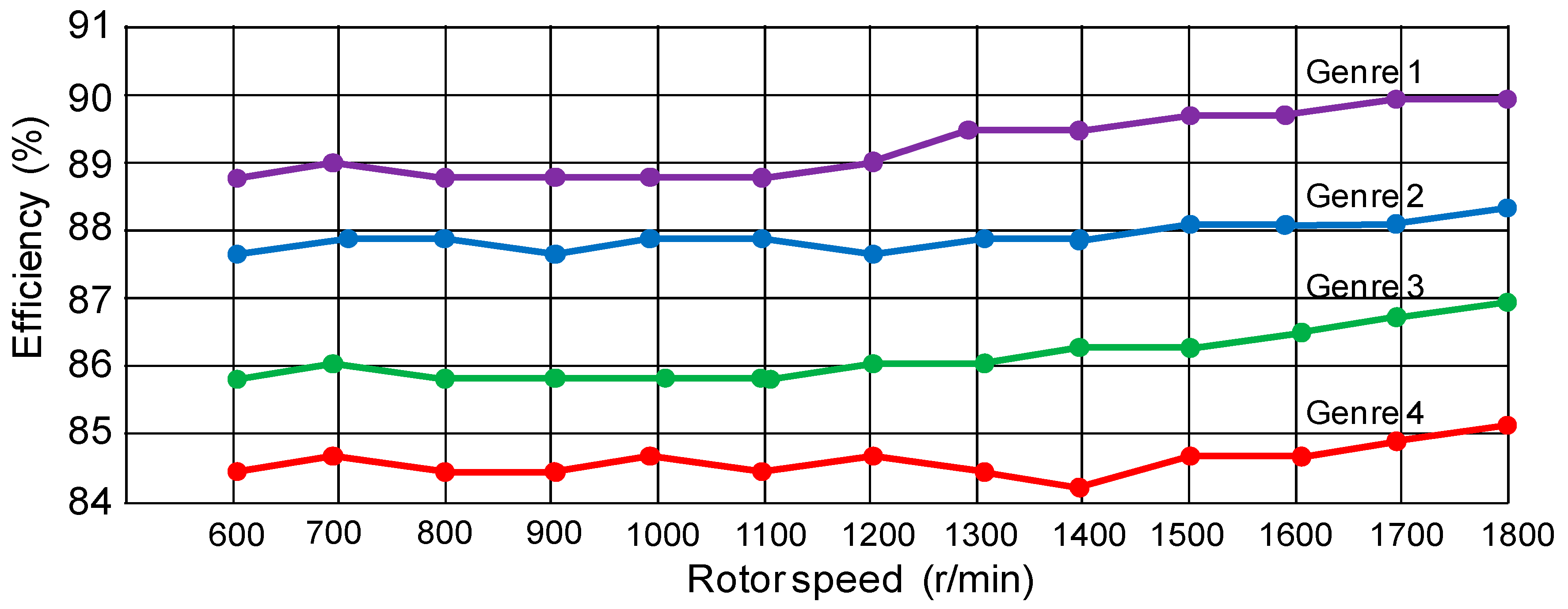

- The efficiency in Genre 1 is the highest value as the 89.96%.

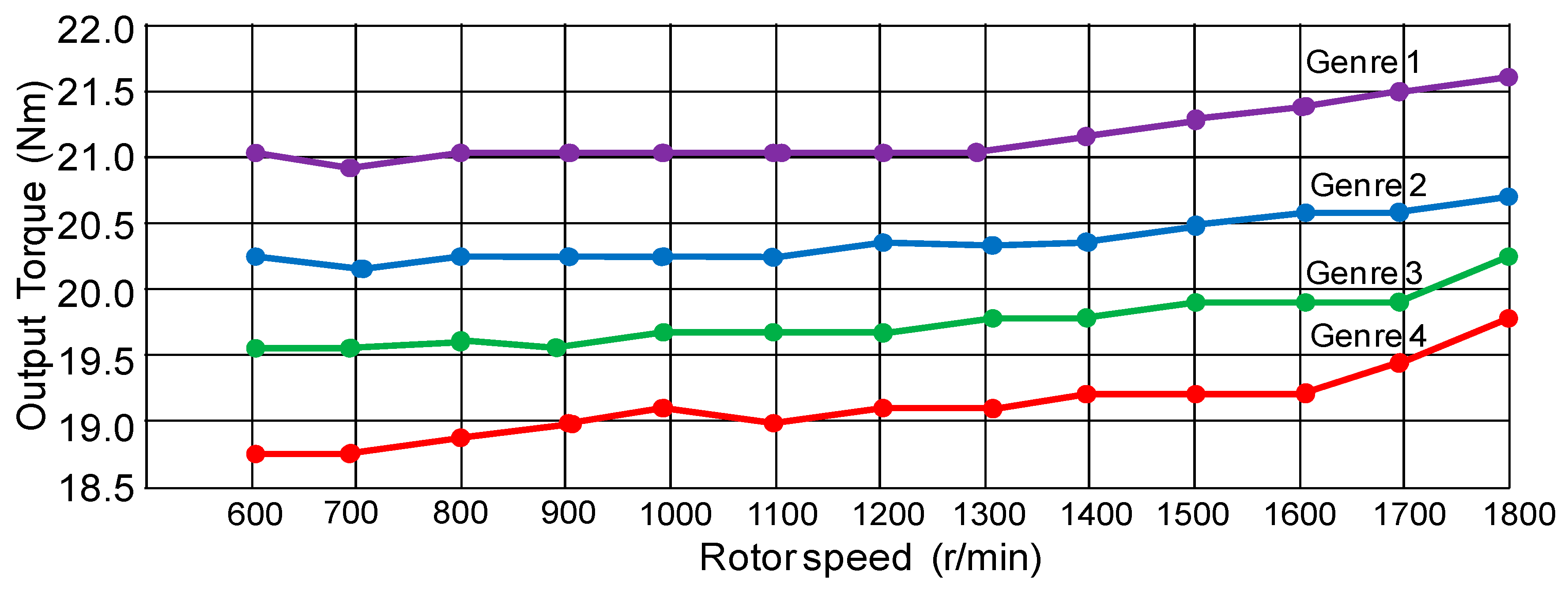

- The output torque in Genre 1 is highest value as the 21.62 Nm.

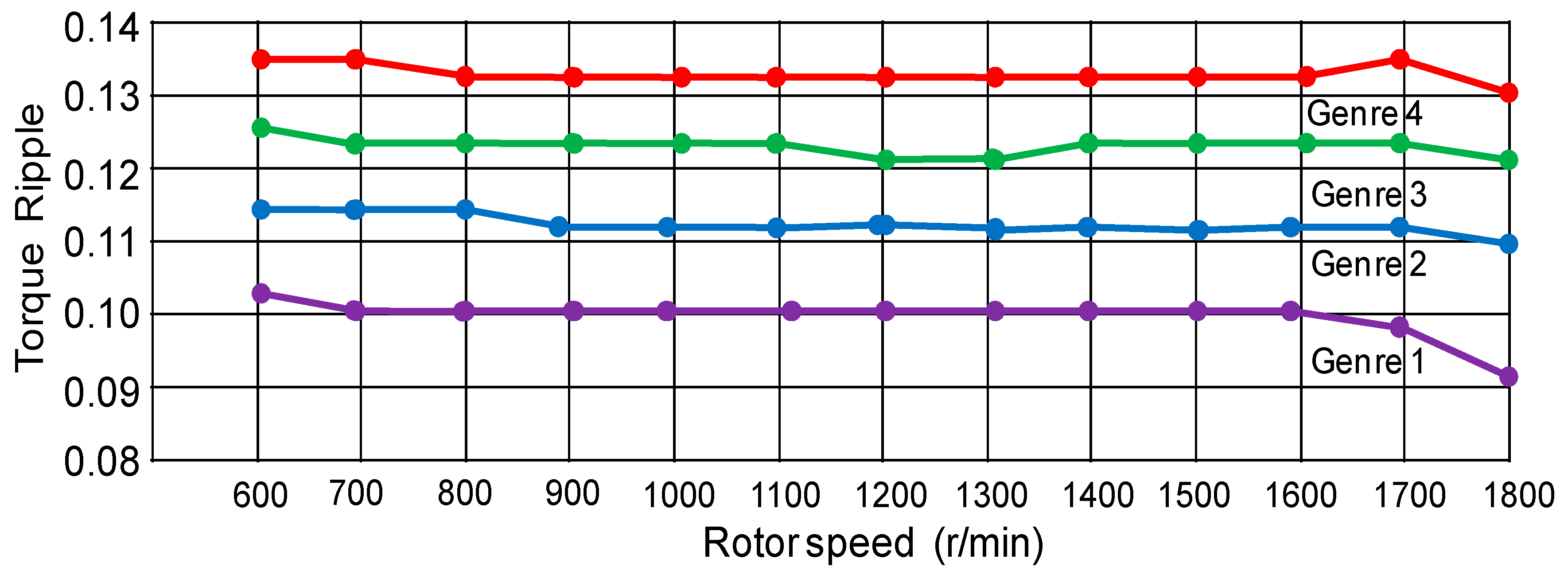

- The torque ripple in Genre 1 is lowest value as the 0.09.

3.2. Experimental Results

4. Discussions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Leon, J.I.; Lopez, O.; Franquelo, L.G.; Doval-Gandoy, J.; Vazquez, S.; Alvarez, J.; Freijedo, F.D. Multilevel multiphase feedforward spacevector modulation technique. IEEE Trans. Ind. Electron. 2010, 57, 2066–2075. [Google Scholar] [CrossRef]

- Apsley, J.M.; Gonzalez-Villasenor, A.; Barnes, M.; Smith, A.C.; Williamson, S.; Schuddebeurs, J.D.; Norman, P.J.; Booth, C.D.; Burt, G.M.; McDonald, J.R. Propulsion drive models for full electric marine propulsion systems. IEEE Trans. Ind. Appl. 2009, 45, 676–684. [Google Scholar] [CrossRef]

- Kim, Y.H.; Lee, J.H. Optimum design criteria of an ALA-SynRM for the maximum torque density and power factor improvement. Int. J. Appl. Electromagn. Mech. 2017, 53 (Suppl. 2), 279–288. [Google Scholar] [CrossRef]

- Chai, W.; Zhao, W.; Kwon, B. Optimal design of wound field synchronous reluctance machines to improve torque by increasing the saliency ratio. IEEE Trans. Magn. 2017, 53. [Google Scholar] [CrossRef]

- Wang, T.; Fang, F.; Wu, X.; Jiang, X. Novel filter for stator harmonic currents reduction in six-step converter fed multiphase induction motor drives. IEEE Trans. Power Electron. 2013, 28, 498–506. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, J.; Wang, X.; Wang, Q.; Liu, X.; Luo, Y. A design method for cage induction motors with non-skewed rotor bars. IEEE Trans. Magn. 2014, 50, 7019004. [Google Scholar]

- Fathy, M.N.I.; Sergeant, P.; Rashad, E. Simple design approach for low torque ripple and high output torque synchronous reluctance motors. Energies 2016, 9, 942. [Google Scholar]

- Fathy, M.N.I.; Sergeant, P.; Rashad, E. Performance comparison of conventional synchronous reluctance machines and PM-assisted types with combined star–delta winding. Energies 2017, 10, 1500. [Google Scholar]

- Artetxe, G.; Paredes, J.; Prieto, B.; Martinez-Iturralde, M.; Elosegui, I. Optimal pole number and winding designs for low speed–high torque synchronous reluctance machines. Energies 2018, 11, 128. [Google Scholar] [CrossRef]

- Mittelstedt, M.; Hansen, C.; Mertiny, P. Design and multi-objective optimization of fiber-reinforced polymer composite flywheel rotors. Appl. Sci. 2018, 8, 1256. [Google Scholar] [CrossRef]

- Anwar, N.; Deng, H. A hybrid metaheuristic for multi-objective scientific workflow scheduling in a cloud environment. Appl. Sci. 2018, 8, 538. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, X.; Chen, J. Wind power forecasting using multi-objective evolutionary algorithms for wavelet neural network-optimized prediction intervals. Appl. Sci. 2018, 8, 185. [Google Scholar] [CrossRef]

- Mathur, V.K. How well do we know Pareto optimality. J. Econ. Educ. 1991, 22, 172–178. [Google Scholar] [CrossRef]

- Kanbur, R. Pareto’s revenge. J. Soc. Econ. Dev. 2005, 7, 1–11. [Google Scholar]

- Barr, N. The Relevance of Efficiency to Different Theories of Society. In Economics of the Welfare State; Oxford University Press: Oxford, UK, 2012; pp. 46–51. [Google Scholar]

- Huang, Y.; Wang, H.; Khajepour, A.; Li, B.; Ji, J.; Zhao, K.; Hu, C. A review of power management strategies and component sizing methods for hybrid vehicles. Renew. Sustain. Energy Rev. 2018, 96, 132–144. [Google Scholar] [CrossRef]

- Karaboga, D.; Basturk, B. On the performance of artificial bee colony (ABC) algorithm. Appl. Soft Comput. 2008, 8, 687–697. [Google Scholar] [CrossRef]

- Lin, C.H. Modelling and control of six-phase induction motor servo-driven continuously variable transmission system using blend modified recurrent Gegenbauer orthogonal polynomial neural network control system and amended artificial bee colony optimization. Int. J. Numer. Model. 2016, 29, 915–942. [Google Scholar] [CrossRef]

- Hwang, C.C.; Chang, C.M.; Liu, C.T. A fuzzy-based Taguchi method for multi-objective design of PM motors. IEEE Trans. Magn. 2013, 49, 2153–2156. [Google Scholar] [CrossRef]

- Lin, C.H.; Hwang, C.C. Multiobjective optimization design for a six-phase copper rotor induction motor mounted with a Scroll compressor. IEEE Trans. Magn. 2016, 52, 9401604. [Google Scholar] [CrossRef]

- Yamazaki, K.; Suzuki, A.; Ohto, M.; Takakura, T.; Nakagawa, S. Equivalent circuit modeling of induction motors considering stray load loss and harmonic torques using finite element method. IEEE Trans. Magn. 2011, 47, 986–989. [Google Scholar] [CrossRef]

- Ahn, J.; Lee, D.; Park, G.J.; Kim, Y.J.; Kim, J.; Jung, S.Y. Numerical design compatibility of induction motor with respect to voltage and current sources. IEEE Trans. Magn. 2014, 50, 7019104. [Google Scholar] [CrossRef]

- Hwang, C.C.; Chang, C.M.; Hung, S.S.; Liu, C.T. Design of high performance flux switching PM machines with concentrated windings. IEEE Trans. Magn. 2014, 50, 4002404. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Number of phases | 6 (phase a, phase b, phase c, phase x, phase y, phase z) |

| Rotor outer diameter [mm] | 82 |

| Stator outer diameter [mm] | 134 |

| Air gap length [mm] | 0.5 |

| Stack length [mm] | 84 |

| Number of poles | 4 |

| Number of rotor flux-barrier layers | 3 |

| Number of stator slots | 24 |

| Rated speed [r/min] | 1800 |

| Rated power output [kW] | 4 |

| Steel material | 50CS600 |

| No. | Control Factor | Efficiency η | Power Factor φ | Torque Ripple γ | Output Torque τ | ||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | [%] | - | - | [Nm] | |

| 1 | 1 | 1 | 1 | 1 | 1 | 77.63 | 0.81 | 0.21 | 18.60 |

| 2 | 1 | 2 | 2 | 2 | 2 | 78.15 | 0.82 | 0.16 | 18.71 |

| 3 | 1 | 3 | 3 | 3 | 3 | 80.10 | 0.79 | 0.20 | 18.94 |

| 4 | 1 | 4 | 4 | 4 | 4 | 80.63 | 0.82 | 0.17 | 19.20 |

| 5 | 2 | 1 | 2 | 3 | 4 | 87.00 | 0.86 | 0.12 | 19.86 |

| 6 | 2 | 2 | 1 | 4 | 3 | 80.20 | 0.81 | 0.18 | 19.24 |

| 7 | 2 | 3 | 4 | 1 | 2 | 78.21 | 0.80 | 0.24 | 18.12 |

| 8 | 2 | 4 | 3 | 2 | 1 | 89.96 | 0.89 | 0.09 | 21.62 |

| 9 | 3 | 1 | 3 | 4 | 2 | 77.04 | 0.78 | 0.27 | 18.46 |

| 10 | 3 | 2 | 4 | 3 | 1 | 85.16 | 0.84 | 0.13 | 20.26 |

| 11 | 3 | 3 | 1 | 2 | 4 | 80.82 | 0.79 | 0.23 | 19.28 |

| 12 | 3 | 4 | 2 | 1 | 3 | 78.70 | 0.81 | 0.19 | 18.61 |

| 13 | 4 | 1 | 4 | 2 | 3 | 78.70 | 0.79 | 0.20 | 18.62 |

| 14 | 4 | 2 | 3 | 1 | 4 | 88.20 | 0.87 | 0.11 | 20.81 |

| 15 | 4 | 3 | 2 | 4 | 1 | 80.20 | 0.81 | 0.25 | 19.18 |

| 16 | 4 | 4 | 1 | 3 | 2 | 79.46 | 0.80 | 0.19 | 18.93 |

| No. | S/N Ratio | Altered BCO Coefficient | MPCI | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Efficiency η | Power Factor φ | Torque Ripple γ | Output Torque τ | Efficiency η | Power Factor φ | Torque Ripple γ | Output Torque τ | ||

| [%] | - | - | [Nm] | [%] | - | - | [Nm] | ||

| 1 | 21.8 | 15.6 | −1.61 | 7.28 | 0.79 | 0.86 | −0.58 | 0.73 | 0.64 |

| 2 | 21.4 | 18.1 | −1.82 | 7.68 | 0.82 | 0.78 | −0.64 | 0.77 | 0.68 |

| 3 | 22.6 | 19.1 | −1.88 | 6.86 | 0.59 | 0.81 | −0.59 | 0.88 | 0.62 |

| 4 | 21.7 | 19.6 | −1.68 | 6.85 | 0.64 | 0.68 | −0.58 | 0.95 | 0.56 |

| 5 | 22.7 | 15.2 | −1.29 | 8.86 | 0.75 | 0.87 | −0.69 | 0.76 | 0.65 |

| 6 | 21.8 | 15.8 | −1.56 | 8.78 | 0.69 | 0.69 | −0.52 | 0.84 | 0.62 |

| 7 | 21.4 | 15.2 | −1.54 | 9.10 | 0.59 | 0.58 | −0.67 | 0.66 | 0.64 |

| 8 | 21.5 | 18.2 | −1.33 | 8.87 | 0.56 | 0.79 | −0.55 | 0.78 | 0.68 |

| 9 | 22.7 | 16.7 | −1.64 | 8.62 | 0.52 | 0.74 | −0.48 | 0.88 | 0.60 |

| 10 | 22.8 | 19.8 | −1.68 | 8.82 | 0.82 | 0.82 | −0.95 | 0.69 | 0.67 |

| 11 | 21.8 | 16.9 | −1.59 | 8.70 | 0.84 | 0.71 | −0.64 | 0.78 | 0.69 |

| 12 | 22.5 | 15.9 | −1.49 | 8.94 | 0.82 | 0.66 | −0.59 | 0.66 | 0.61 |

| 13 | 22.4 | 16.8 | −1.76 | 8.36 | 0.81 | 0.72 | −0.48 | 0.67 | 0.67 |

| 14 | 21.8 | 17.5 | −1.58 | 8.92 | 0.71 | 0.85 | −0.57 | 0.73 | 0.66 |

| 15 | 22.4 | 15.3 | −1.69 | 8.86 | 0.72 | 0.83 | −0.67 | 0.83 | 0.60 |

| 16 | 21.3 | 18.8 | −1.94 | 8.68 | 0.68 | 0.89 | −0.63 | 0.76 | 0.58 |

| No. | Control Factor | Stator Iron Weight | Stator Winding Weight | Manufacturing Cost | ||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | [kg] | [kg] | [$] | |

| 1 | 1 | 1 | 1 | 1 | 1 | 9.88 | 4.96 | 258.20 |

| 2 | 1 | 2 | 2 | 2 | 2 | 9.46 | 4.44 | 257.61 |

| 3 | 1 | 3 | 3 | 3 | 3 | 9.22 | 4.64 | 252.82 |

| 4 | 1 | 4 | 4 | 4 | 4 | 9.02 | 5.02 | 253.96 |

| 5 | 2 | 1 | 2 | 3 | 4 | 8.73 | 5.04 | 249.12 |

| 6 | 2 | 2 | 1 | 4 | 3 | 9.00 | 4.44 | 249.38 |

| 7 | 2 | 3 | 4 | 1 | 2 | 8.92 | 4.22 | 248.68 |

| 8 | 2 | 4 | 3 | 2 | 1 | 8.46 | 3.72 | 247.46 |

| 9 | 3 | 1 | 3 | 4 | 2 | 8.84 | 4.08 | 249.18 |

| 10 | 3 | 2 | 4 | 3 | 1 | 8.60 | 4.02 | 248.20 |

| 11 | 3 | 3 | 1 | 2 | 4 | 8.66 | 4.98 | 248.98 |

| 12 | 3 | 4 | 2 | 1 | 3 | 8.70 | 4.68 | 248.86 |

| 13 | 4 | 1 | 4 | 2 | 3 | 8.24 | 3.52 | 246.66 |

| 14 | 4 | 2 | 3 | 1 | 4 | 8.52 | 3.88 | 247.68 |

| 15 | 4 | 3 | 2 | 4 | 1 | 9.20 | 4.31 | 248.58 |

| 16 | 4 | 4 | 1 | 3 | 2 | 9.36 | 4.20 | 249.96 |

| No. | S/N Ratio | Altered BCO Coefficient | MPCI | ||||

|---|---|---|---|---|---|---|---|

| Stator Iron Weight | Stator Winding Weight | Manufacturing Cost | Stator Iron Weight | Stator Winding Weight | Manufacturing Cost | ||

| [kg] | [kg] | [$] | [kg] | [kg] | [$] | ||

| 1 | 16.40 | 19.64 | 39.82 | 0.58 | 0.76 | 0.860 | 0.66 |

| 2 | 16.18 | 18.86 | 39.91 | 0.48 | 0.68 | 0.899 | 0.68 |

| 3 | 17.94 | 18.96 | 39.94 | 0.72 | 0.56 | 0.956 | 0.69 |

| 4 | 17.66 | 17.88 | 38.92 | 0.68 | 0.50 | 0.976 | 0.67 |

| 5 | 17.24 | 16.88 | 39.20 | 0.58 | 0.62 | 0.804 | 0.64 |

| 6 | 16.12 | 17.82 | 38.82 | 0.62 | 0.66 | 0.692 | 0.60 |

| 7 | 17.78 | 17.43 | 38.96 | 0.58 | 0.56 | 0.724 | 0.61 |

| 8 | 16.88 | 18.86 | 38.88 | 0.54 | 0.66 | 0.787 | 0.63 |

| 9 | 16.86 | 16.61 | 38.96 | 0.50 | 0.62 | 0.868 | 0.68 |

| 10 | 16.29 | 18.28 | 39.08 | 0.82 | 0.52 | 0.972 | 0.69 |

| 11 | 16.04 | 18.96 | 37.88 | 0.60 | 0.56 | 0.646 | 0.59 |

| 12 | 16.02 | 16.66 | 38.68 | 0.52 | 0.62 | 0.624 | 0.58 |

| 13 | 15.76 | 15.88 | 38.48 | 0.48 | 0.74 | 0.656 | 0.61 |

| 14 | 17.12 | 16.86 | 38.96 | 0.70 | 0.52 | 0.738 | 0.64 |

| 15 | 16.18 | 19.86 | 38.86 | 0.60 | 0.54 | 0.798 | 0.63 |

| 16 | 16.96 | 15.62 | 38.44 | 0.58 | 0.60 | 0.849 | 0.66 |

| Configuration | Genre 1 | Genre 2 | Genre 3 | Genre 4 |

|---|---|---|---|---|

| Stator Iron Weight [kg] | 8.24 | 8.46 | 8.52 | 8.60 |

| Stator Winding Weight [kg] | 3.52 | 3.72 | 3.88 | 4.02 |

| Manufacturing Cost [$] | 246.66 | 247.46 | 247.68 | 248.20 |

| Power Factor [−] | 0.89 | 0.87 | 0.86 | 0.84 |

| Efficiency [%] | 89.96 | 88.20 | 87.00 | 85.16 |

| Torque Ripple [−] | 0.09 | 0.11 | 0.12 | 0.13 |

| Output Torque [Nm] | 21.62 | 20.81 | 20.26 | 19.86 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, C.-H.; Hwang, C.-C. High Performances Design of a Six-Phase Synchronous Reluctance Motor Using Multi-Objective Optimization with Altered Bee Colony Optimization and Taguchi Method. Energies 2018, 11, 2716. https://doi.org/10.3390/en11102716

Lin C-H, Hwang C-C. High Performances Design of a Six-Phase Synchronous Reluctance Motor Using Multi-Objective Optimization with Altered Bee Colony Optimization and Taguchi Method. Energies. 2018; 11(10):2716. https://doi.org/10.3390/en11102716

Chicago/Turabian StyleLin, Chih-Hong, and Chang-Chou Hwang. 2018. "High Performances Design of a Six-Phase Synchronous Reluctance Motor Using Multi-Objective Optimization with Altered Bee Colony Optimization and Taguchi Method" Energies 11, no. 10: 2716. https://doi.org/10.3390/en11102716

APA StyleLin, C.-H., & Hwang, C.-C. (2018). High Performances Design of a Six-Phase Synchronous Reluctance Motor Using Multi-Objective Optimization with Altered Bee Colony Optimization and Taguchi Method. Energies, 11(10), 2716. https://doi.org/10.3390/en11102716