Energy-Saving Analysis of Solar Heating System with PCM Storage Tank

Abstract

:1. Introduction

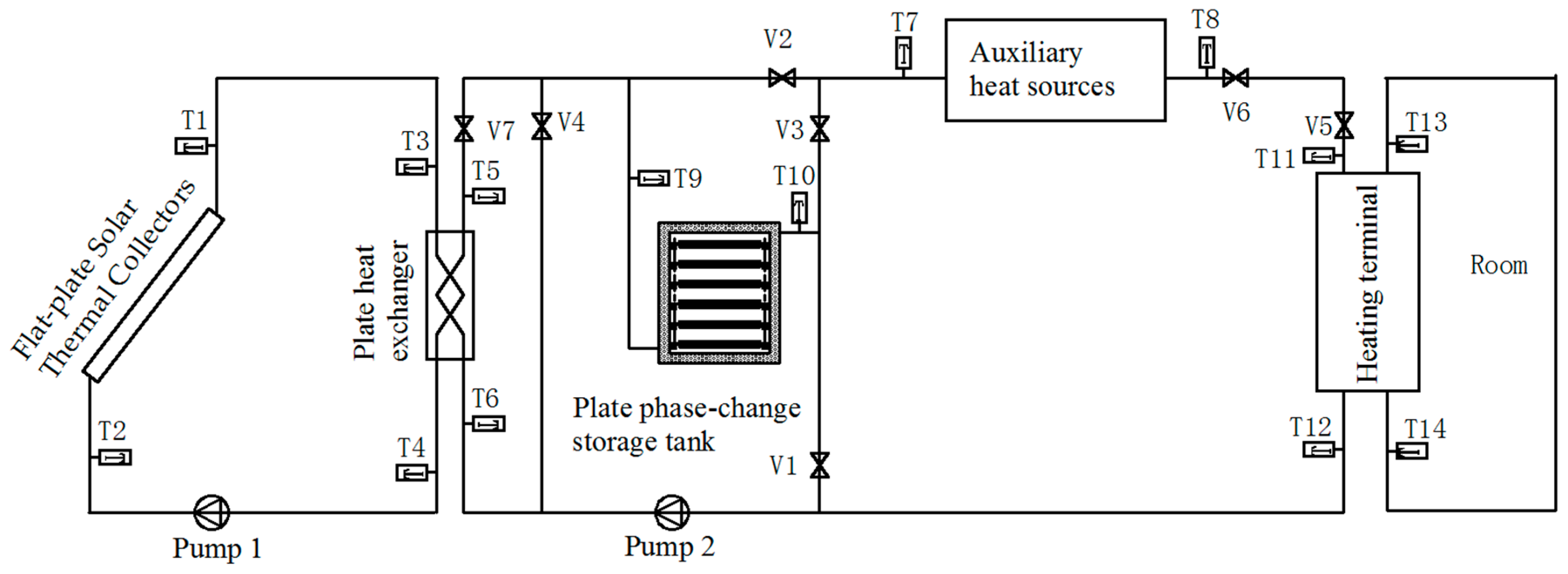

2. Structures and Operation Modes of SHS-PCM

2.1. Structures

2.2. Operation Modes

- Mode 1:

- Natural cooling

- Mode 2:

- Reserve the heat absorbed by the solar collection system in the PCM storage tank when no indoor heating is required.

- Mode 3:

- Directly supply the indoor heating demand using the solar collection system.

- Mode 4:

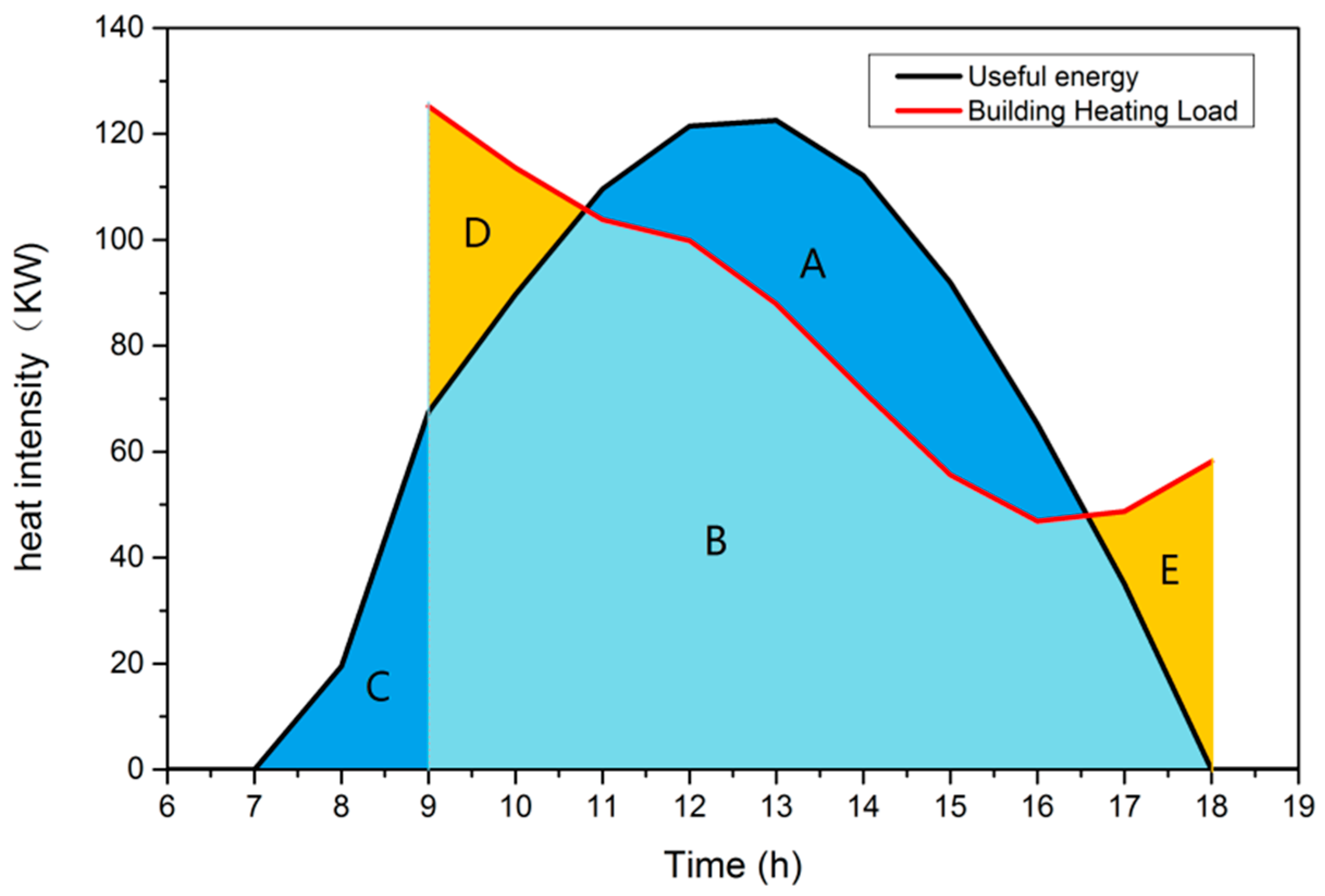

- Supply the heat absorbed by the solar collection system to the rooms, and store excess absorbed heat in the PCM storage tank.

- Mode 5:

- Supply the heat stored in the PCM storage tank to the rooms.

- Mode 6:

- Supply the room heating demands using the PCM storage tank and AHS simultaneously.

- Mode 7:

- Supply the room heating demands using only the AHS.

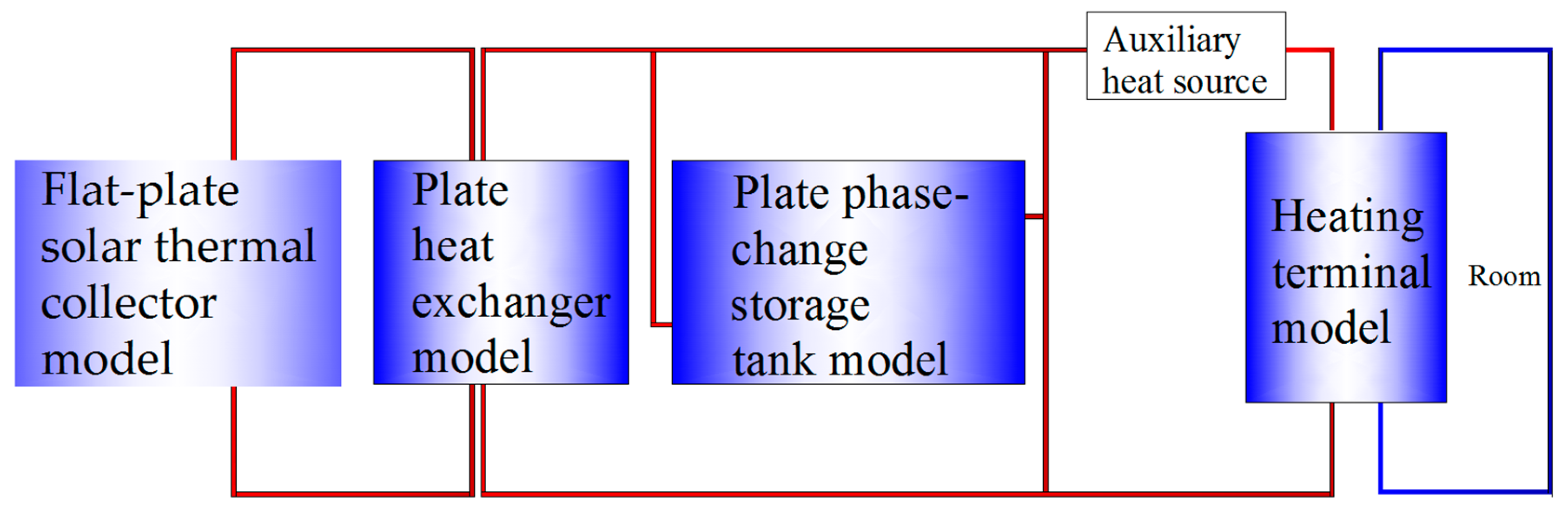

3. Dynamic Simulation Model of System

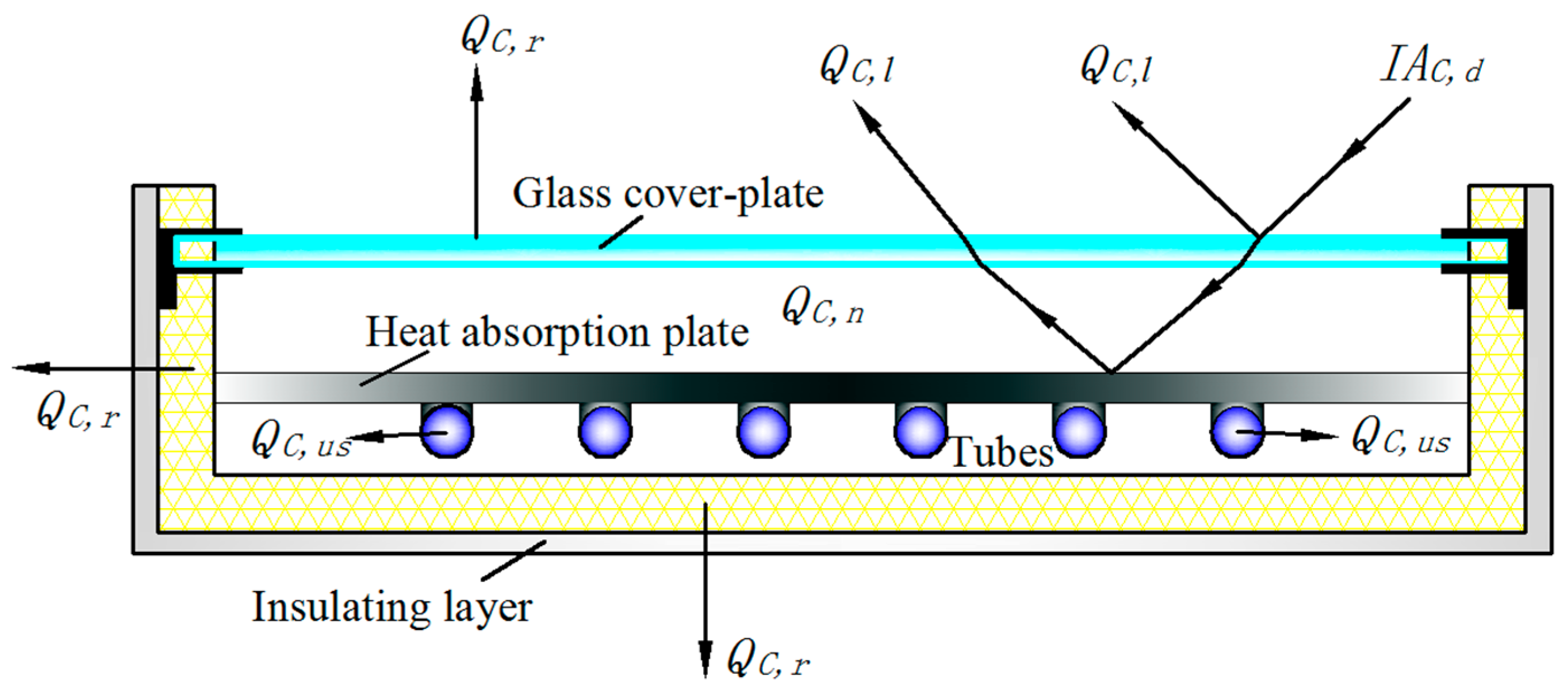

3.1. Model of the Flat-Plate Solar Thermal Collector

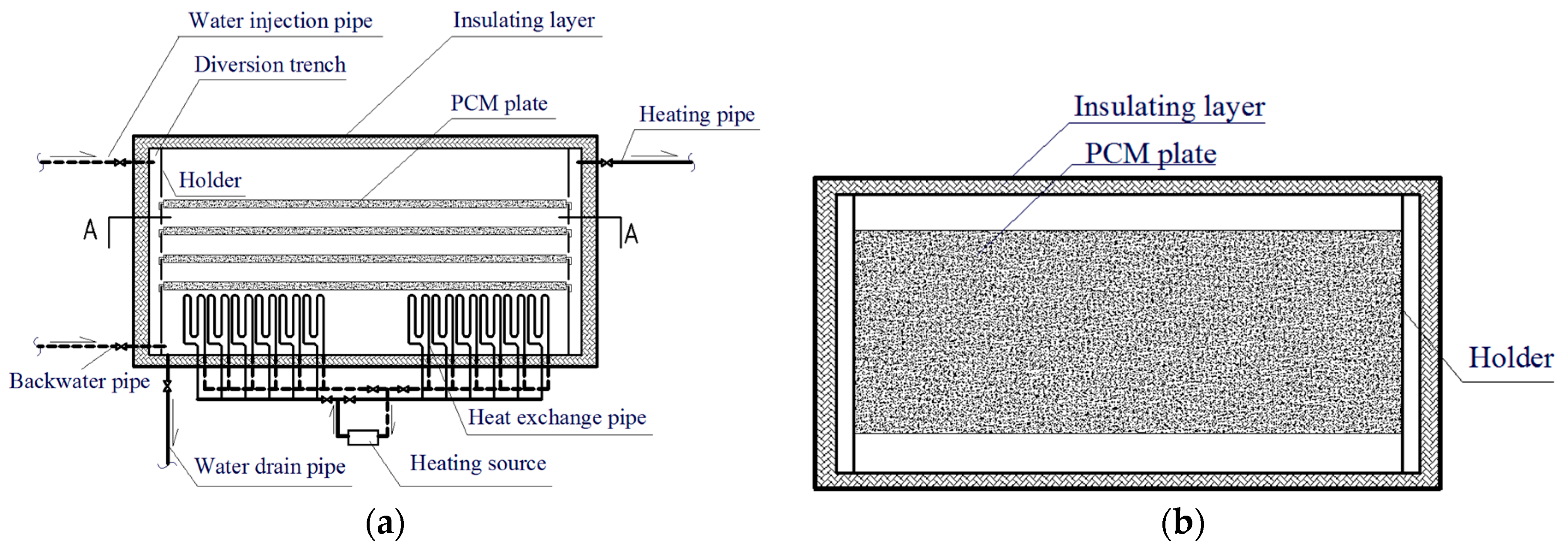

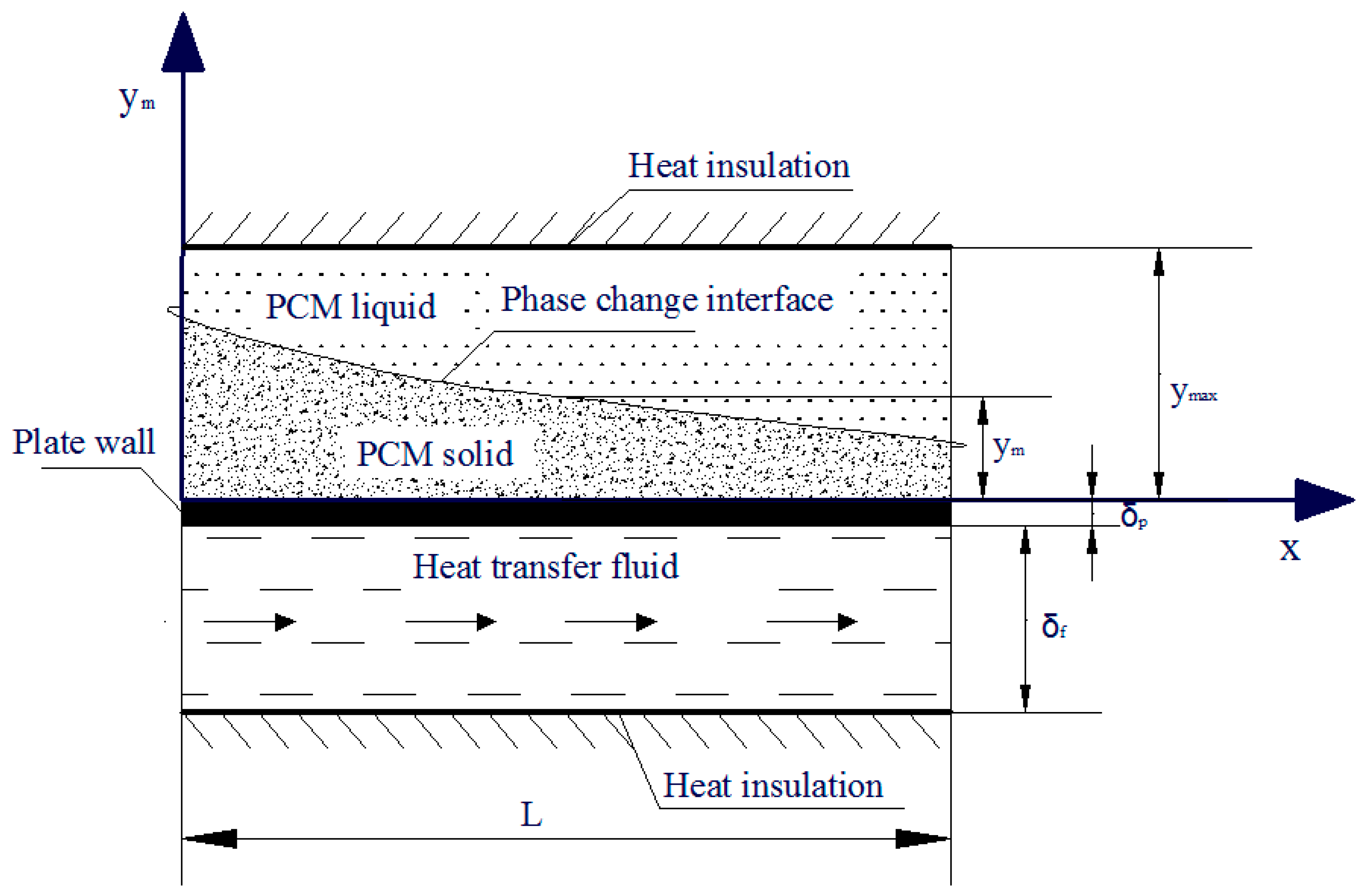

3.2. Model of the PCM Storage Tank

3.3. Model of Plate Heat Exchanger

4. Design Parameter Settings and Methodologies of the Object

5. Results and Discussion

- (1)

- A coupled model of an ordinary water tank was established to analyze the operating conditions of a common water tank and a PCM storage tank combined with SHS, in order to explore how the ordinary water tank and the PCM storage tank contributed to the solar heating system.

- (2)

- Operating conditions with different sizes of heat water storage tanks are compared in order to optimize the selection of the heat water storage tank.

- (3)

- Operating conditions with different terminal forms and different supply and return water temperatures are compared in order to find the best match between the terminal form and the PCM storage tank.

5.1. Operating Conditions of Different PCM Storage Tanks

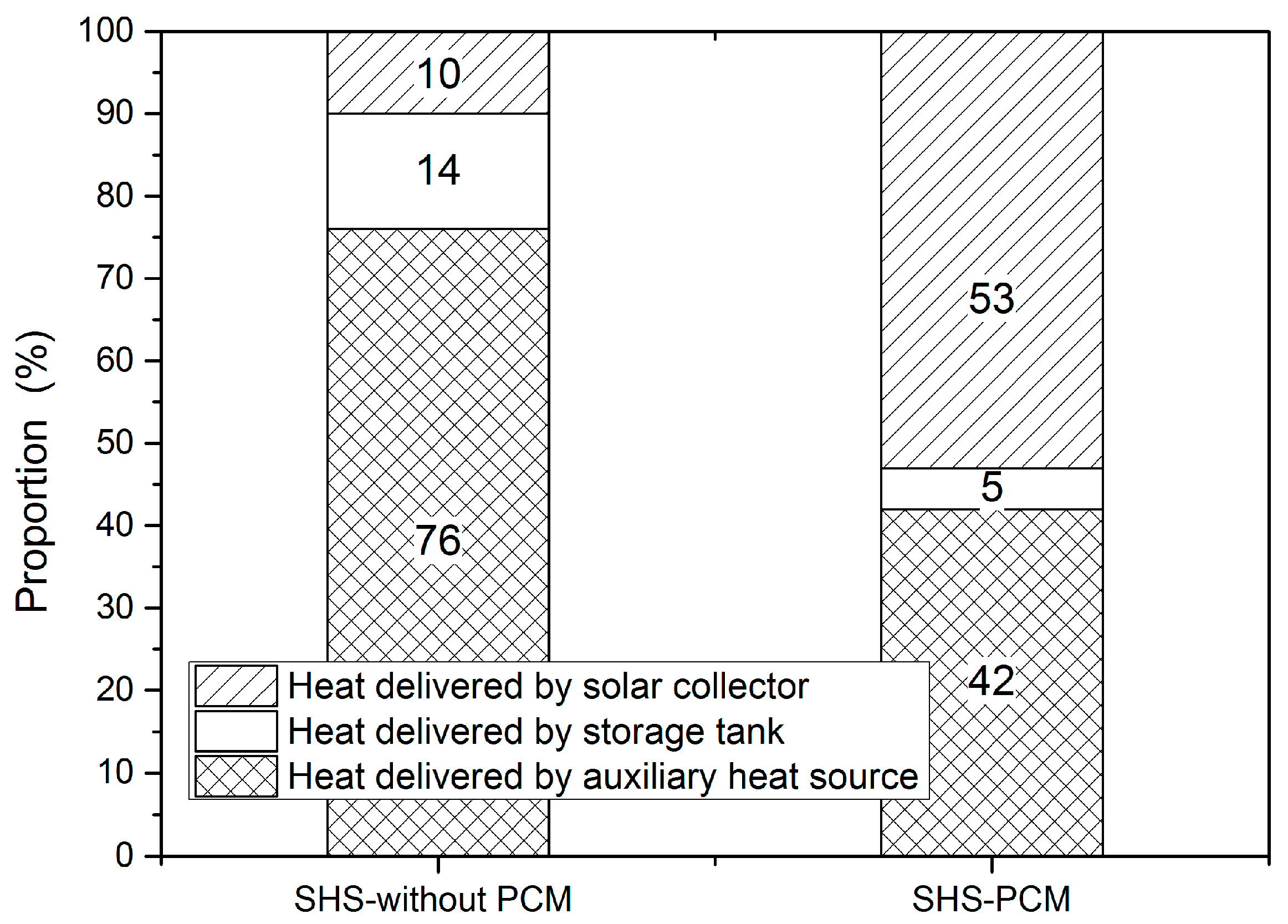

5.1.1. Operating Conditions Comparison between SHS-PCM and SHS-without PCM

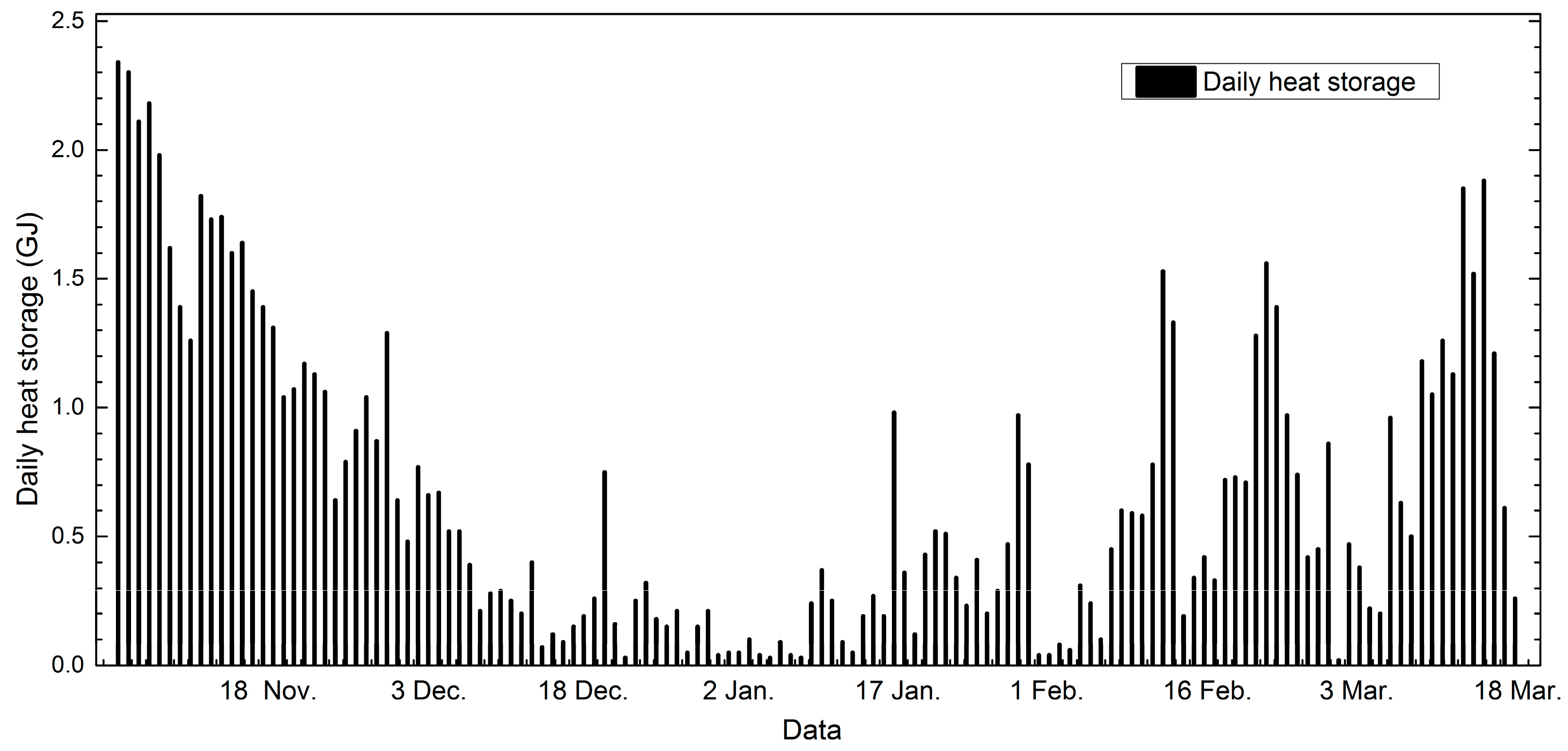

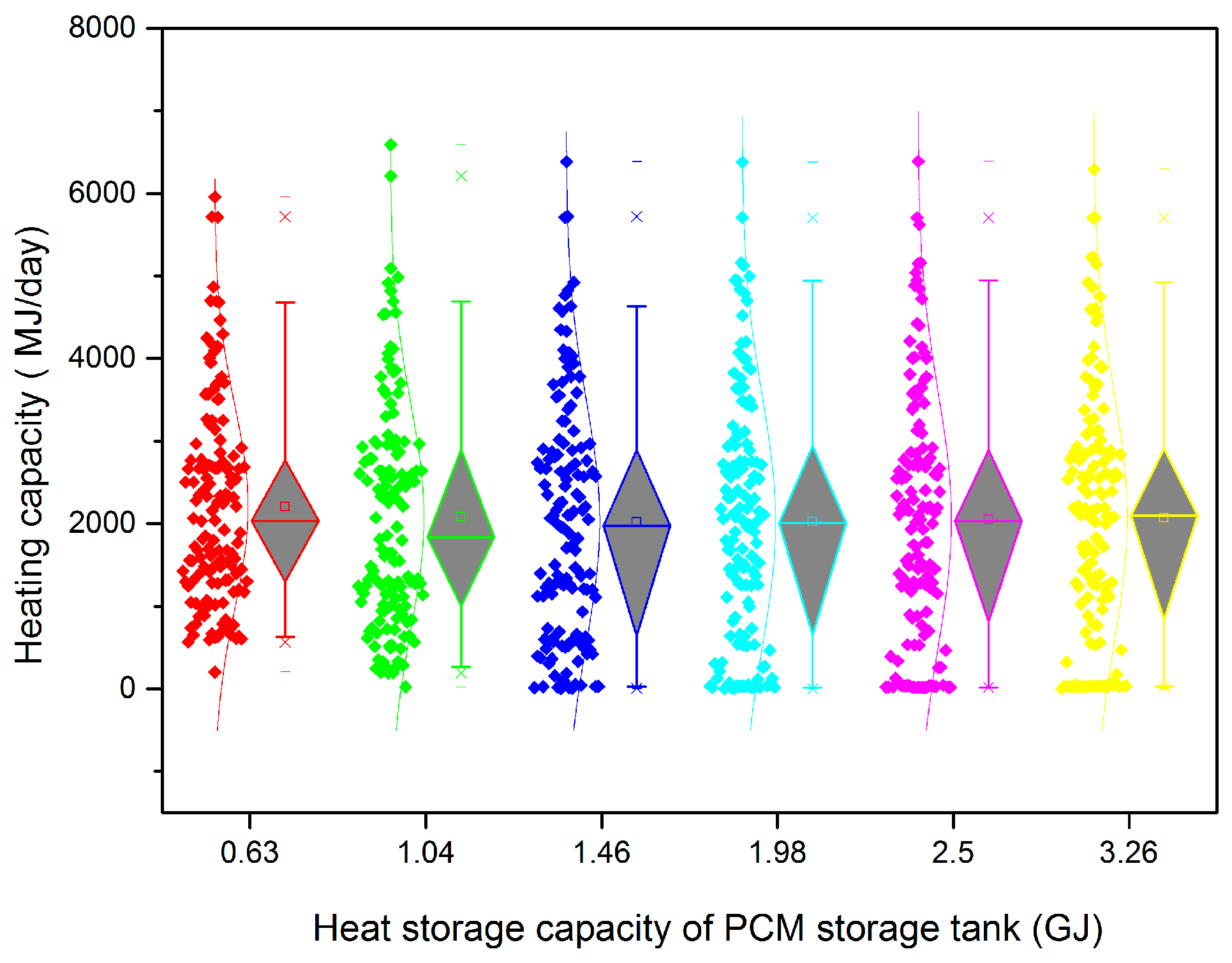

5.1.2. Operating Conditions Comparison with Different Sizes of PCM Storage Tanks

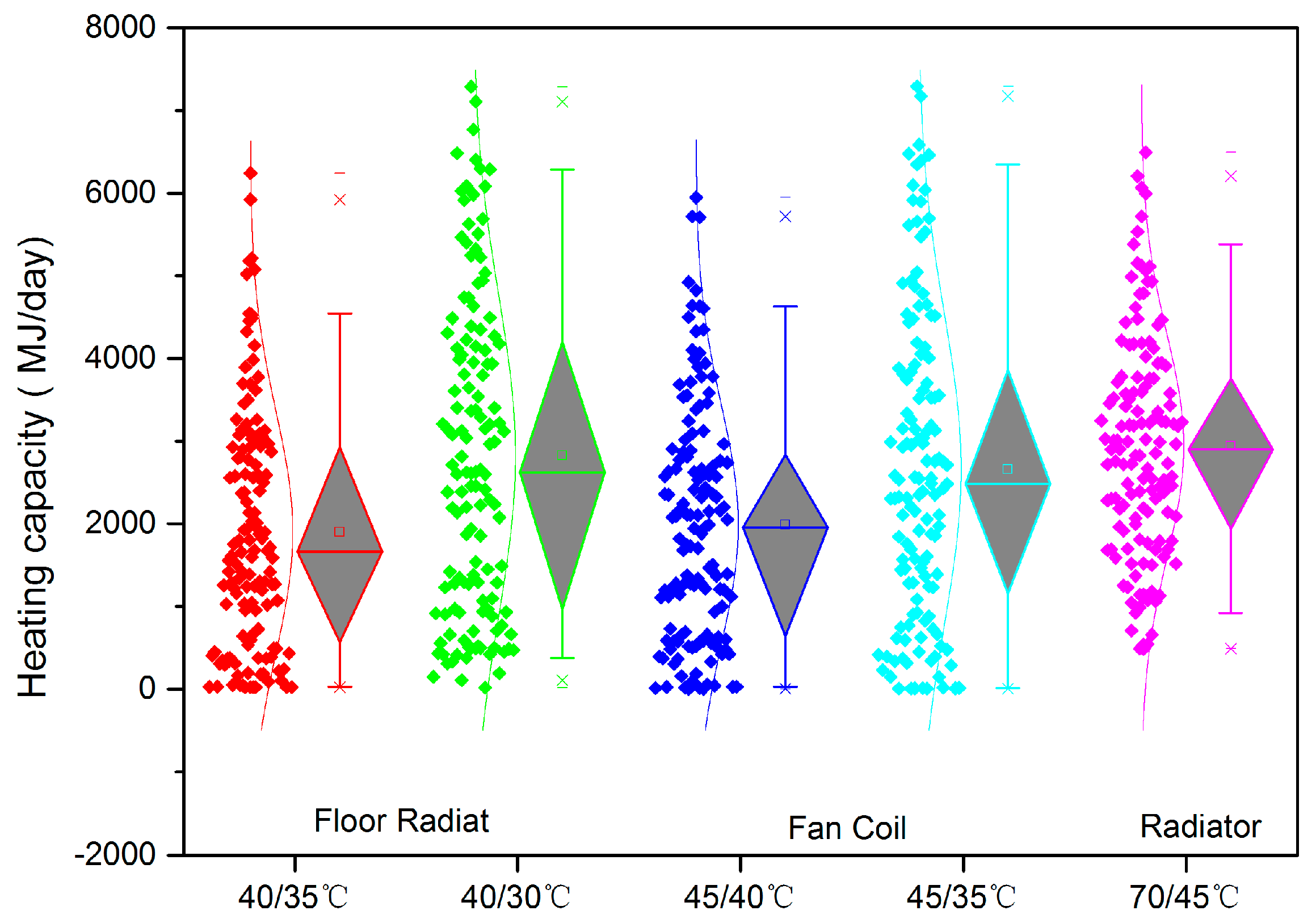

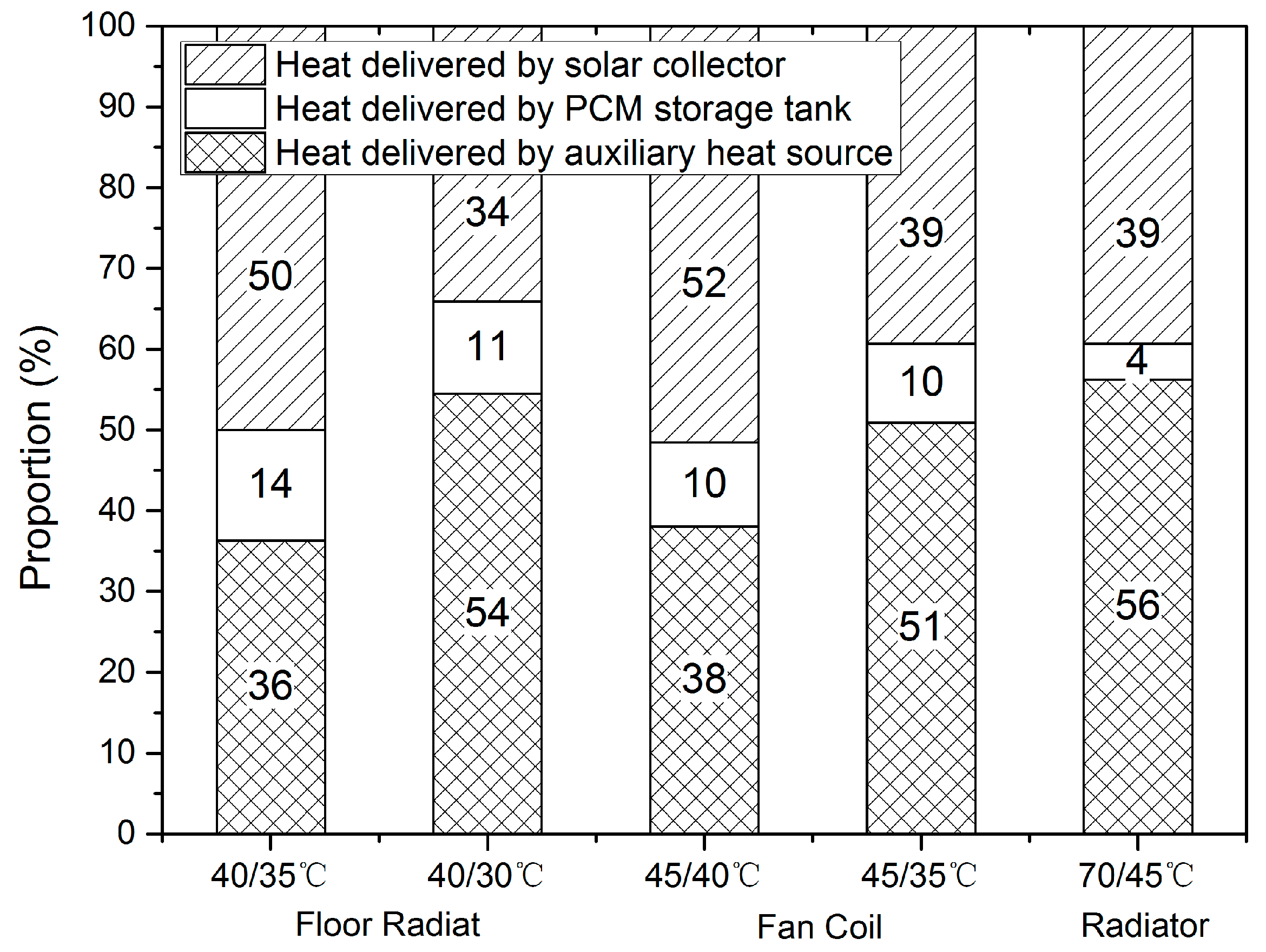

5.2. Operating Conditions of Different Terminal Forms

6. Conclusions

- (1)

- The operating conditions of SHS-without PCM and SHS-PCM were analyzed in order to explore the contribution rate of ordinary water tanks and PCM storage tanks in a solar heating system. The results show that an SHS-PCM system saves 34% more energy than an ordinary water tank heating system. In addition, after the PCM storage tank is adopted, the water tank volume is reduced to 1/5 the size of the ordinary water tank. Because more solar energy is supplied directly from the FSTCs to the indoor terminals and owing to the PCM storage tank’s relatively low contribution to the heating of the terminal, it is necessary to optimize the selection of the PCM storage tank.

- (2)

- Operating conditions with different sizes of PCM storage tanks were compared in order to optimize the selection of the PCM storage tank. The results show that with the increase in heat storage, the heat supply of AHS does not decrease correspondingly; it decreases first, rebalances, and then rises. It is suggested that the design selection parameters of the PCM storage tank should specify a daily heat storage capacity that satisfies 70~80% of the entire heating season.

- (3)

- Operating conditions observed with different terminal forms and different temperatures of supply and return water were compared in order to find the terminal form that best matches the PCM storage tank. The results show that for different terminal forms and different designed temperatures of supply/return water, the best operational conditions and energy saving capability for SHS-PCM over an entire heating season are provided by floor radiation (40/35 °C), followed by fan coil (45/40 °C), fan coil (45/35 °C), floor radiation (40/30 °C), and radiator (70/45 °C).

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| A | Area, m2 | N | Number |

| Hm | Enthalpy of PCM, kJ/kg | p | Wetted perimeter, m |

| I | Radiant intensity, W/m2 | Q | Quantity of heat, J |

| K | Heat transfer coefficient, W/(m2·°C) | T | Temperature, °C |

| L | Length of PCM plate, m | Δt | Temperature difference, °C |

| l | Length, m | V | Volume, m3 |

| m | Mass flow rate, kg/s | x | x-coordinate, m |

| M | Quality, kg | y | The height of the phase transition interface |

| Cp | Specific heat at constant pressure, J/(kg·K) | ||

| h | Coefficient of convective heat transfer, W/(m2·K) | ||

| Greek symbols | |||

| ρ | Density, kg/m3 | δ | Thickness, m |

| η | Efficiency | εV | Volume fraction |

| β | Heat resistance of dimensionless number | ||

| Subscripts | |||

| C | Solar thermal collector | max | Maximum |

| e | Load | n | Internal energy |

| ev | Environment | o | Outlet |

| f | Fluid | p | Wall of encapsulated version |

| g | Heat collection medium | pp | PCM plate |

| h | Plate heat exchanger | r | Thermal energy |

| hp | Heat storage tank | S | Auxiliary heat source |

| I | Radiation | s | Solid |

| in | Inlet | us | Useful energy |

| l | Luminous energy | W | Water |

| m | PCM | V | Volume |

| Abbreviations | |||

| AHS | Auxiliary Heat Source | PCM | Phase change material |

| FSTC | Flat-plate Solar Thermal Collector | PCTSS | Phase change thermal storage system |

| HTF | Heat transfer fluid | SCS | solar collection system |

| IHS | Indoor heating system | SDHW | Solar domestic hot water |

| LHS | Latent heat storage | SHS-PCM | Solar heating system with PCM storage tank |

| LTES | Latent thermal energy storage | TES | Thermal energy storage |

References

- Zhou, Z.H.; Zhang, Z.M.; Zuo, J.; Huang, K.; Zhang, L.Y. Phase change materials for solar thermal energy storage in residential buildings in cold climate. Renew. Sustain. Energy Rev. 2015, 48, 692–703. [Google Scholar] [CrossRef]

- Ouyang, L.P.; Sun, L.L.; Yuan, Y.P.; Cao, X.L.; Xiang, B. Optimum connection modes for photovoltaic thermal collectors in different radiation zones of China. Appl. Therm. Eng. 2017, 122, 661–672. [Google Scholar] [CrossRef]

- Yuan, Y.P.; Ouyang, L.P.; Sun, L.L.; Cao, X.L.; Xiang, B.; Zhang, X.X. Effect of connection mode and mass flux on the energy output of a PVT hot water system. Sol. Energy 2017, 158, 285–294. [Google Scholar] [CrossRef]

- Sun, L.L.; Li, M.; Yuan, Y.P.; Cao, X.L.; Lei, B.; Yu, N.Y. Effect of tilt angle and connection mode of PVT modules on the energy efficiency of a hot water system for high-rise residential buildings. Renew. Energy 2016, 93, 291–301. [Google Scholar] [CrossRef]

- Yuan, Y.P.; Gao, X.K.; Wu, H.W.; Zhang, Z.J.; Cao, X.L.; Sun, L.L.; Yu, N.Y. Coupled cooling method and application of latent heat thermal energy storage combined with pre-cooling of envelope: Method and model development. Energy 2017, 119, 817–833. [Google Scholar] [CrossRef]

- Yuan, Y.P.; Zhang, N.; Li, T.Y.; Cao, X.L.; Long, W.Y. Thermal performance enhancement of palmitic-stearic acid by adding graphene nanoplatelets and expanded graphite for thermal energy storage: A comparative study. Energy 2016, 97, 488–497. [Google Scholar] [CrossRef]

- Kenisarin, M.; Mahkamov, K. Solar energy storage using phase change materials. Renew. Sustain. Energy Rev. 2007, 11, 1913–1965. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Qiu, F.; Yang, W.S.; Zhao, X.D. Applications of solar water heating system with phase change material. Renew. Sustain. Energy Rev. 2015, 52, 645–652. [Google Scholar] [CrossRef]

- Liu, M.; Belusko, M.; Steven Tay, N.H.; Bruno, F. Impact of the heat transfer fluid in a flat plate phase change thermal storage unit for concentrated solar tower plants. Sol. Energy 2014, 101, 220–231. [Google Scholar] [CrossRef]

- Xiang, B.; Cao, X.; Yuan, Y.; Sun, L.; Wu, H.; Haghighat, F. A novel hybrid energy system combined with solar-road and soil-regenerator: Dynamic model and operational performance. Energy Convers. Manag. 2018, 156, 376–387. [Google Scholar] [CrossRef]

- Saxena, A.; Varun; El-Sebaii, A.A. A thermodynamic review of solar air heaters. Renew. Sustain. Energy Rev. 2015, 43, 863–890. [Google Scholar] [CrossRef]

- Bouadila, S.; Fteti, M.; Oueslati, M.M.; Guizani, A.; Farhat, A. Enhancement of latent heat storage in a rectangular cavity: Solar water heater case study. Energy Convers. Manag. 2014, 78, 904–912. [Google Scholar] [CrossRef]

- Mahfuz, M.H.; Anisur, M.R.; Kibria, M.A.; Saidur, R.; Metselaar, I.H.S.C. Performance investigation of thermal energy storage system with Phase Change Material (PCM) for solar water heating application. Int. Commun. Heat Mass Transf. 2014, 57, 132–139. [Google Scholar] [CrossRef]

- Agyenim, F.; Hewitt, N.; Eames, P.; Smyth, M. A review of materials, heat transfer and phase change problem formulation for latent heat thermal energy storage systems (LHTESS). Renew. Sustain. Energy Rev. 2010, 14, 615–628. [Google Scholar] [CrossRef]

- Xu, H.X.; Sze, J.Y.; Romagnoli, A.; Py, X. Selection of Phase Change Material for Thermal Energy Storage in Solar Air Conditioning Systems. Energy Procedia 2017, 105, 4281–4288. [Google Scholar] [CrossRef]

- Zheng, L.; Zhang, W.; Liang, F. A review about phase change material cold storage system applied to solar-powered air-conditioning system. Adv. Mech. Eng. 2017, 9, 1–20. [Google Scholar] [CrossRef]

- Cao, X.; Yuan, Y.; Xiang, B.; Sun, L.; Zhang, X. Numerical investigation on optimal number of longitudinal fins in horizontal annular phase change unit at different wall temperatures. Energy Build. 2018, 158, 384–392. [Google Scholar] [CrossRef]

- Belmonte, J.F.; Eguía, P.; Molina, A.E.; Almendros-Ibáñez, J.A.; Salgado, R. A simplified method for modeling the thermal performance of storage tanks containing PCMs. Appl. Therm. Eng. 2016, 95, 394–410. [Google Scholar] [CrossRef]

- Zhang, S.M.; Zhang, L.Y.; Yang, X.H.; Yu, X.L.; Duan, F.; Jin, L.W.; Meng, X.Z. Experimental Investigation of a Spiral Tube Embedded Latent Thermal Energy Storage Tank Using Paraffin as PCM. Energy Procedia 2017, 105, 4543–4548. [Google Scholar] [CrossRef]

- Meng, Z.N.; Zhang, P. Experimental and numerical investigation of a tube-in-tank latent thermal energy storage unit using composite PCM. Appl. Energy 2017, 190, 524–539. [Google Scholar] [CrossRef]

- Lu, S.L.; Zhang, T.S.; Chen, Y.F. Study on the Performance of Heat Storage and Heat Release of Water Storage Tank with PCMs. Energy Build. 2017, 158, 1770–1780. [Google Scholar] [CrossRef]

- Senthil Kumar, G.; Nagarajan, D.; Chidambaram, L.A.; Kumaresan, V.; Ding, Y.; Velraj, R. Role of PCM addition on stratification behaviour in a thermal storage tank—An experimental study. Energy 2016, 115, 1168–1178. [Google Scholar] [CrossRef]

- Talmatsky, E.; Kribus, A. PCM storage for solar DHW: An unfulfilled promise? Sol. Energy 2008, 82, 861–869. [Google Scholar] [CrossRef]

- Najafian, A.; Haghighat, F.; Moreau, A. Integration of PCM in domestic hot water tanks: Optimization for shifting peak demand. Energy Build. 2015, 106, 59–64. [Google Scholar] [CrossRef]

- Haillot, D.; Franquet, E.; Gibout, S.; Bedecarrats, J.P. Optimization of solar DHW system including PCM media. Appl. Energy 2013, 109, 470–475. [Google Scholar] [CrossRef]

- Padovan, R.; Manzan, M. Genetic optimization of a PCM enhanced storage tank for Solar Domestic Hot Water Systems. Sol. Energy 2014, 103, 563–573. [Google Scholar] [CrossRef]

- Kaygusuz, K.; Ayhan, T. Experimental and theoretical investigation of combined solar heat pump system for residential heating. Energy Convers. Manag. 1999, 40, 1377–1396. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, C.; Jiao, H.; Wang, W.J.; Shao, Z.Y.; Qi, D.W.; Wang, R. Thermal Performance of New Hybrid Solar Energy-phase Change Storage-floor Radiant Heating System. Procedia Eng. 2016, 146, 89–99. [Google Scholar] [CrossRef]

- Zhao, J.; Ji, Y.; Yuan, Y.; Zhang, Z.; Lu, J. Seven Operation Modes and Simulation Models of Solar Heating System with PCM Storage Tank. Energies 2017, 10. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Design Code for Heating Ventilation and Air Conditioning of Civil Buildings; China Architecture & Building Press: Beijing, China, 2012; GB 50736-2012.

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Code for Solar Heating System; China Architecture & Building Press: Beijing, China, 2009; GB 50495-2009.

| Mode | Detail | Flat-Plate Solar Thermal Collectors (FSTCs) | PCM Storage Tank | Auxiliary Heat Source (AHS) | Operation |

|---|---|---|---|---|---|

| Mode 1 | Natural cooling | Off | Off | Off | All valves closed |

| Mode 2 | FSTCs for PCM storage tank | On | On | Off | Valves V7 and V1 opened; Pumps 1 and 2 on |

| Mode 3 | FSTCs for indoor heating | On | Off | Off | Valves V7, V2, V6, and V5 opened; Pumps 1 and 2 on |

| Mode 4 | FSTCs for PCM storage tank and indoor heating | On | On | Off | Valves V7, V1, V2. V6, and V5 opened; Pumps 1 and 2 on |

| Mode 5 | PCM storage tank for indoor heating | Off | On | Off | Valves V3, V6, V5, and V4 opened; Pump 2 on |

| Mode 6 | PCM storage tank and AHS for indoor heating | Off | On | On | Valves V3, V6, V5, V4 opened; Pump 2 on; AHS on |

| Mode 7 | AHS for indoor heating | Off | Off | On | Valves V6, V5, V4, and V2 opened; Pump 2 on; AHS on |

| Architecture Type: Public Buildings | Floor Radiation | Fan Coil | Radiator | ||||

|---|---|---|---|---|---|---|---|

| Condition 1 | Condition 2 | Condition 3 | Condition 4 | Condition 5 | |||

| Supply and return temperature of fluid 3 | Te,in/Te,o | °C | 40/35 | 40/30 | 45/40 | 45/35 | 70/45 |

| Design temperature difference of plate heat exchanger | - | °C | 5 | 10 | 5 | 10 | 25 |

| Supply and return temperature of fluid 1 | TC,in/TC,o | °C | 45/40 | 50/40 | 50/45 | 55/45 | 120/70 |

| Collector type | FSTC | FSTC | FSTC | FSTC | Concentrating solar collector | ||

| Heat transfer fluid of the collector side | water-glycol | water-glycol | water-glycol | water-glycol | heat conducting oil | ||

| Heat transfer coefficient | Kh | W/(m2 °C) | 4124 | 4631 | 4124 | 4631 | 1996 |

| Area of the plate heat exchanger | Ah | m2 | 15.5 | 6.4 | 15 | 6.4 | 5.2 |

| Area of single plate heat collector | AC | m2 | 2.23 | 2.23 | 2.23 | 2.23 | - |

| Number of heat collectors | NC | - | 88 | 88 | 88 | 88 | 88 |

| Total flow of fluid 1 | mf1 | kg/s | 10.85 | 5.3 | 10.55 | 5.16 | 1.39 |

| Total flow of fluid 2 | mf2 | kg/s | 9.45 | 4.62 | 9.26 | 4.53 | 1.54 |

| Specific heat of fluid 1 | Cpf1 | J/(kg·K) | 3635 | 3635 | 3666 | 3666 | 2302 |

| Specific heat of fluid 2 | Cpf2 | J/(kg·K) | 4174 | 4174 | 4174 | 4174 | 4179 |

| Solution density of fluid 1 | ρf1 | kg/m3 | 1042 | 1042 | 1037 | 1037 | 850 |

| Solution density of fluid 2 | ρf2 | kg/m3 | 992.2 | 992.2 | 990 | 990 | 983 |

| Volume of PCM storage tank | Vhp | m3 | 3 × 2.5 × 1.9 | 3 × 2.5 × 1.9 | 3 × 2.5 × 2 | 3 × 2.5 × 2 | 3 × 2.5 × 1.6 |

| PCM materials | Lauric acid | Lauric acid | paraffin | paraffin | hydrated salts | ||

| Phase-transition temperature | Tm | °C | 43 | 43 | 47 | 47 | 72 |

| Volume of PCM plate | Vpp | m × m × m | 3 × 2.5 × 0.08 | 3 × 2.5 × 0.08 | 3 × 2.5 × 0.08 | 3 × 2.5 × 0.08 | 3 × 2.5 × 0.08 |

| Number of PCM plates | Npp | - | 14 | 14 | 14 | 14 | 12 |

| AHS | - | air-cooled heat pump | air-cooled heat pump | air-cooled heat pump | air-cooled heat pump | Gas fired boiler | |

| Nomenclature | Units | Ordinary Water Tank | PCM Storage Tank | |

|---|---|---|---|---|

| Heat storage capacity | Qm | GJ | 0.63 | 0.63 |

| Volume of tank | Vhp | m3 | 3 × 2.5 × 4 | 3 × 2.5 × 0.8 |

| Volume of PCM plate | Vpp | m3 | - | 3 × 2.5 × 0.08 |

| Number of PCM plates | Npp | - | 6 | |

| PCM materials | paraffin | |||

| Phase-transition temperature | Tm | °C | - | 47 |

| Terminal form | fan coil | fan coil | ||

| Supply and return heating temperature | Te,in/Te,o | °C | 45/40 | 45/40 |

| Daily Heat Storage/GJ | Days/Day | Percentage of Days/% | Plate Volume/m3 | Plate Number/Block | Tank Volume/m3 | Actual Heat Storage/GJ |

|---|---|---|---|---|---|---|

| 0 | 5 | 4 | - | - | - | - |

| 0.5 | 31 | 23 | - | - | - | - |

| 0.63 | 47 | 35 | 3 × 2.5 × 0.08 | 6 | 3 × 2.5 × 0.8 | 0.63 |

| 1 | 72 | 53 | 3 × 2.5 × 0.08 | 10 | 3 × 2.5 × 1.3 | 1.04 |

| 1.5 | 97 | 71 | 3 × 2.5 × 0.08 | 14 | 3 × 2.5 × 2 | 1.46 |

| 2 | 114 | 84 | 3 × 2.5 × 0.08 | 19 | 3 × 2.5 × 2.5 | 1.98 |

| 2.5 | 128 | 94 | 3 × 2.5 × 0.08 | 24 | 3 × 2.5 × 3.2 | 2.5 |

| 3 | 133 | 98 | - | - | - | - |

| 3.26 | 136 | 100 | 3 × 2.5 × 0.08 | 26 | 3 × 3 × 2.5 | 3.26 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Ji, Y.; Yuan, Y.; Zhang, Z.; Lu, J. Energy-Saving Analysis of Solar Heating System with PCM Storage Tank. Energies 2018, 11, 237. https://doi.org/10.3390/en11010237

Zhao J, Ji Y, Yuan Y, Zhang Z, Lu J. Energy-Saving Analysis of Solar Heating System with PCM Storage Tank. Energies. 2018; 11(1):237. https://doi.org/10.3390/en11010237

Chicago/Turabian StyleZhao, Juan, Yasheng Ji, Yanping Yuan, Zhaoli Zhang, and Jun Lu. 2018. "Energy-Saving Analysis of Solar Heating System with PCM Storage Tank" Energies 11, no. 1: 237. https://doi.org/10.3390/en11010237

APA StyleZhao, J., Ji, Y., Yuan, Y., Zhang, Z., & Lu, J. (2018). Energy-Saving Analysis of Solar Heating System with PCM Storage Tank. Energies, 11(1), 237. https://doi.org/10.3390/en11010237