Thermo-Fluidic Comparison between Sandwich Panels with Tetrahedral Lattice Cores Fabricated by Casting and Metal Sheet Folding

Abstract

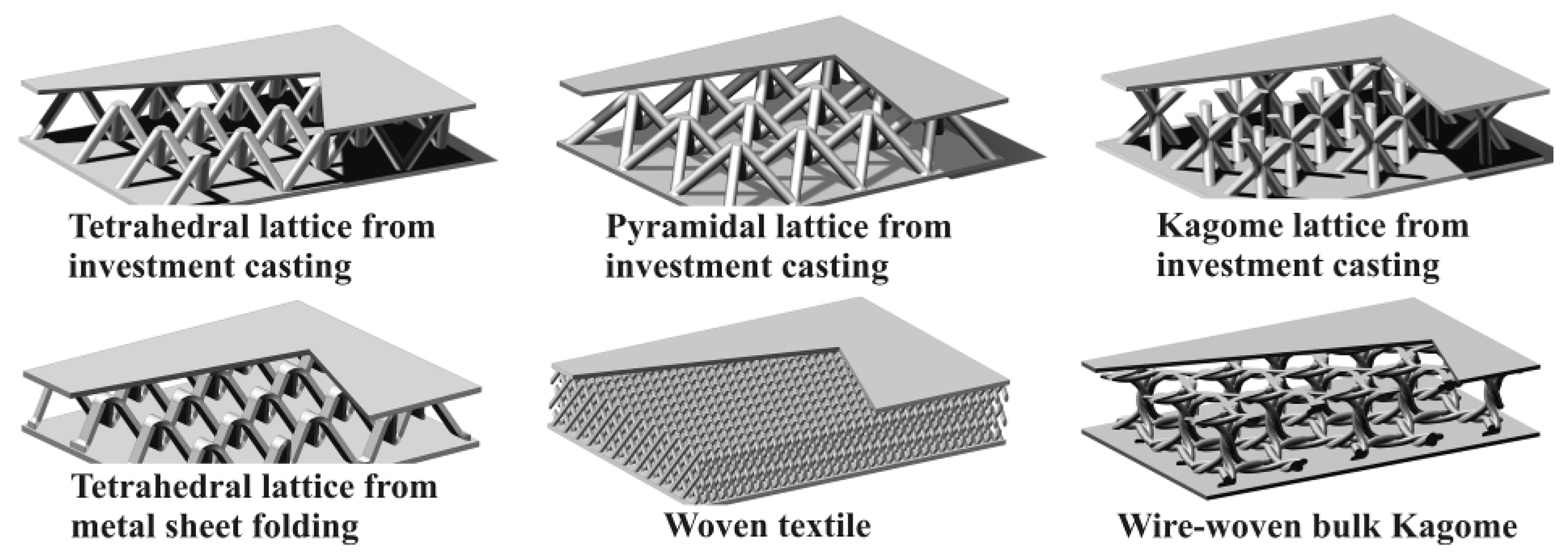

:1. Introduction

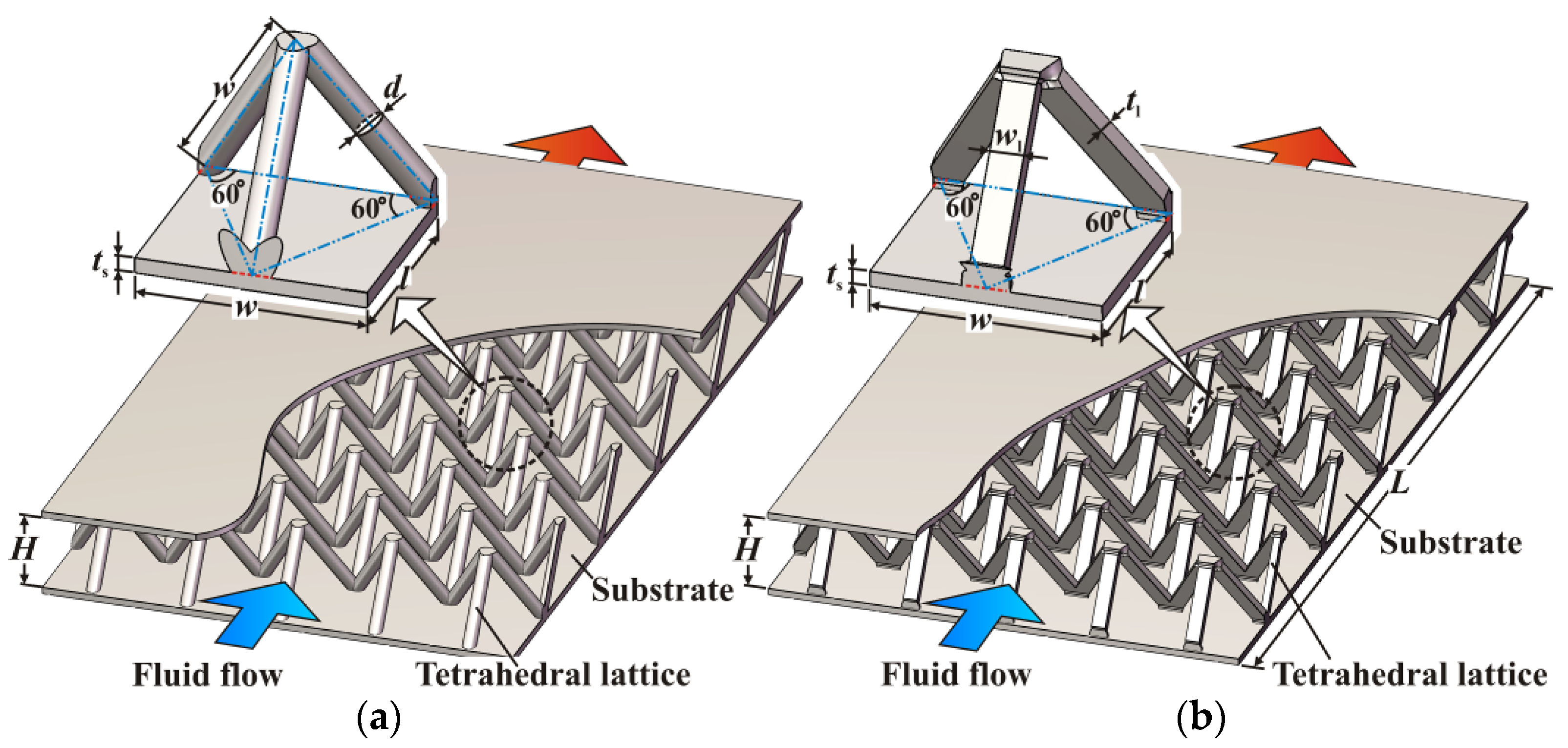

2. Tetrahedral Lattice Cored Sandwich Panels Investigated

3. Details of Numerical Simulation

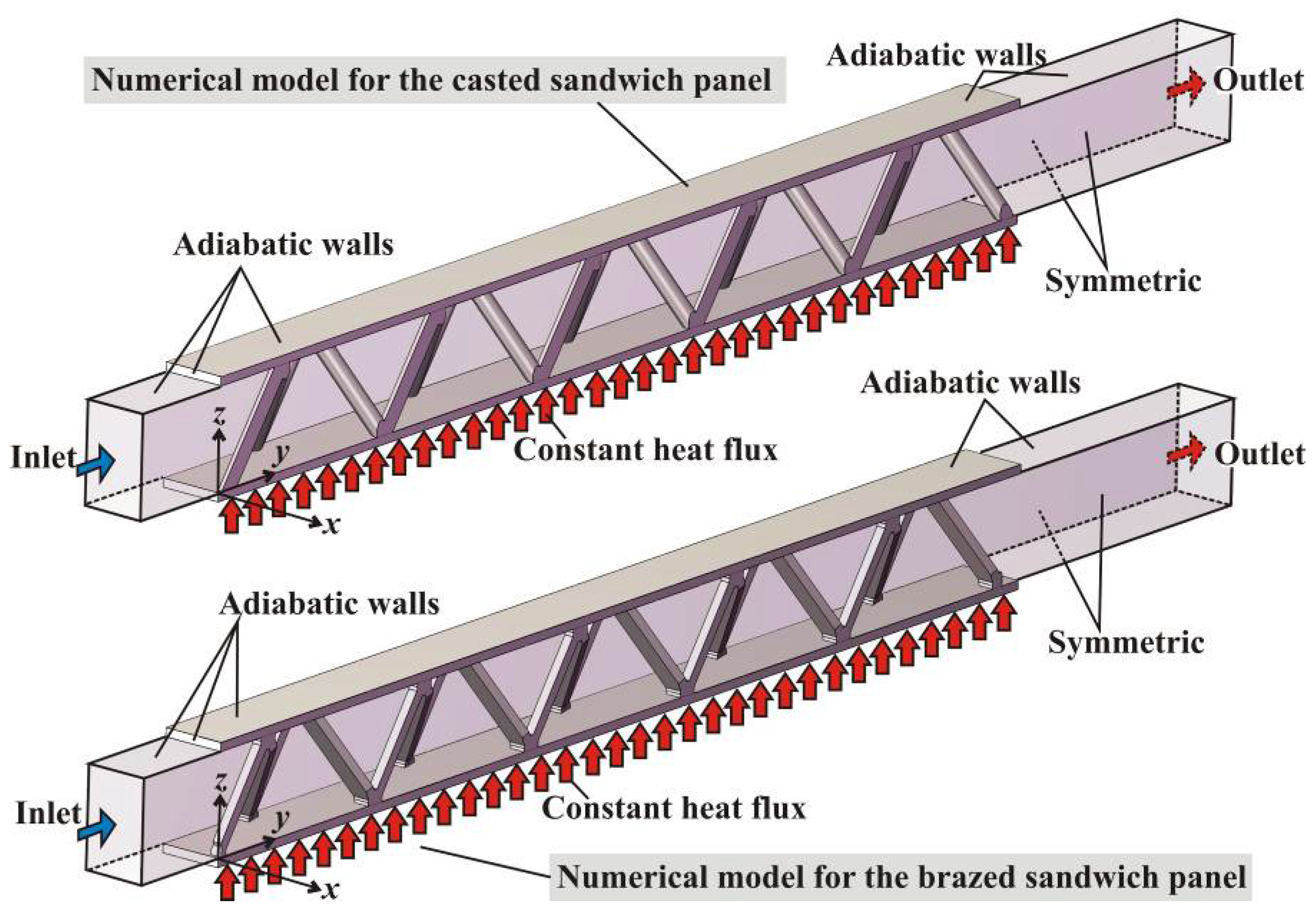

3.1. Computational Domain, Governing Equations and Boundary Conditions

- Continuity equation:

- Momentum equation:

- Energy equations:

- Turbulent kinetic energy equation:

- Turbulent frequency equation:

3.2. Numerical Methods

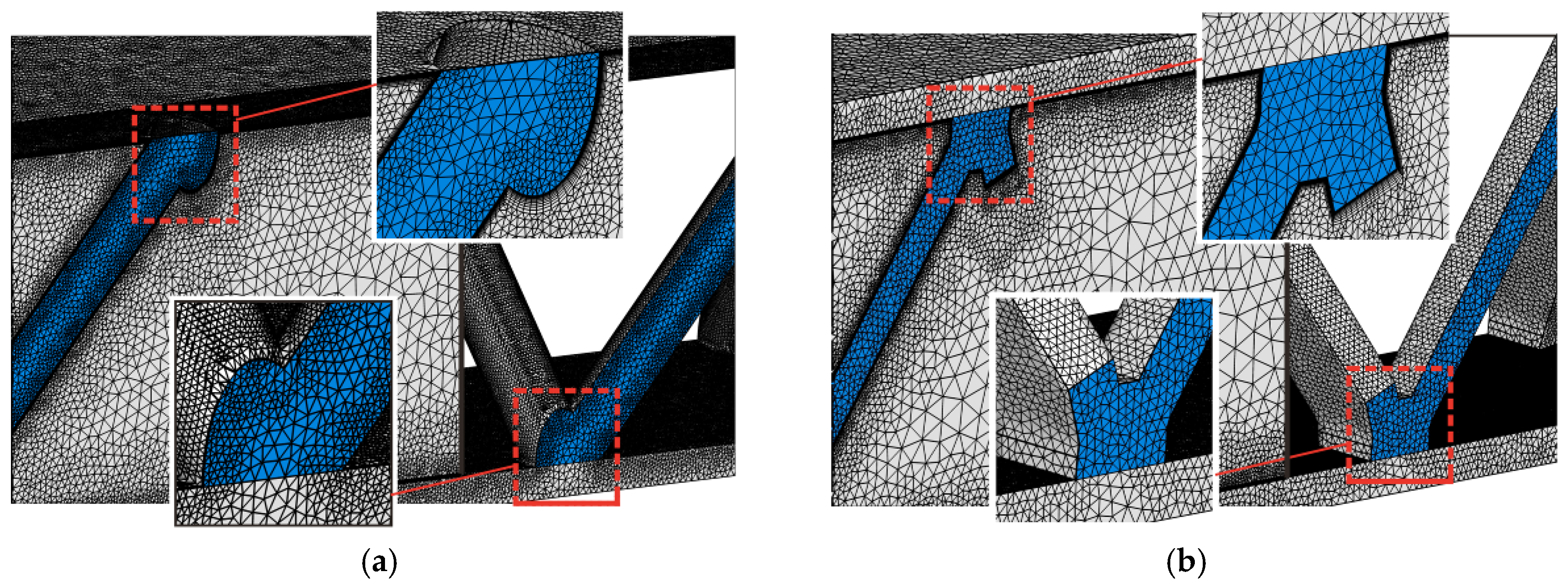

3.3. Mesh Independency

4. Discussion of Results

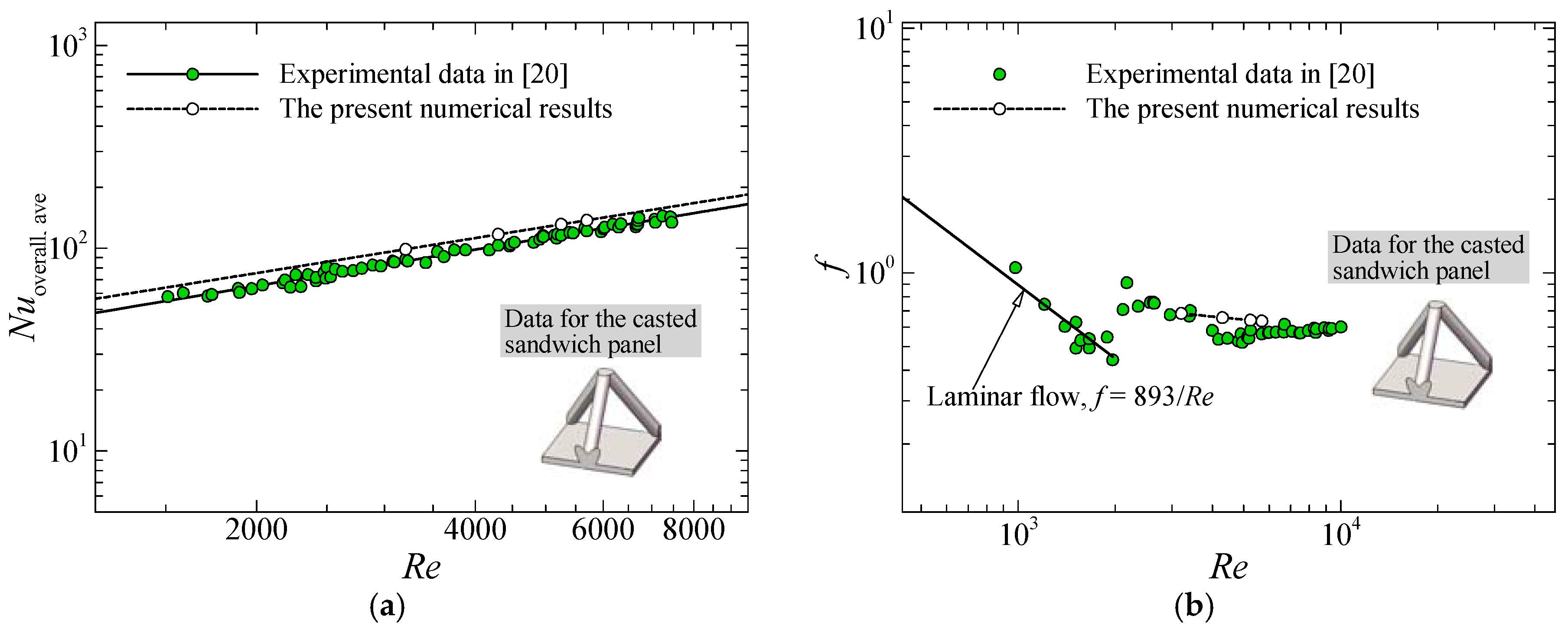

4.1. Validation of the Numerical Model

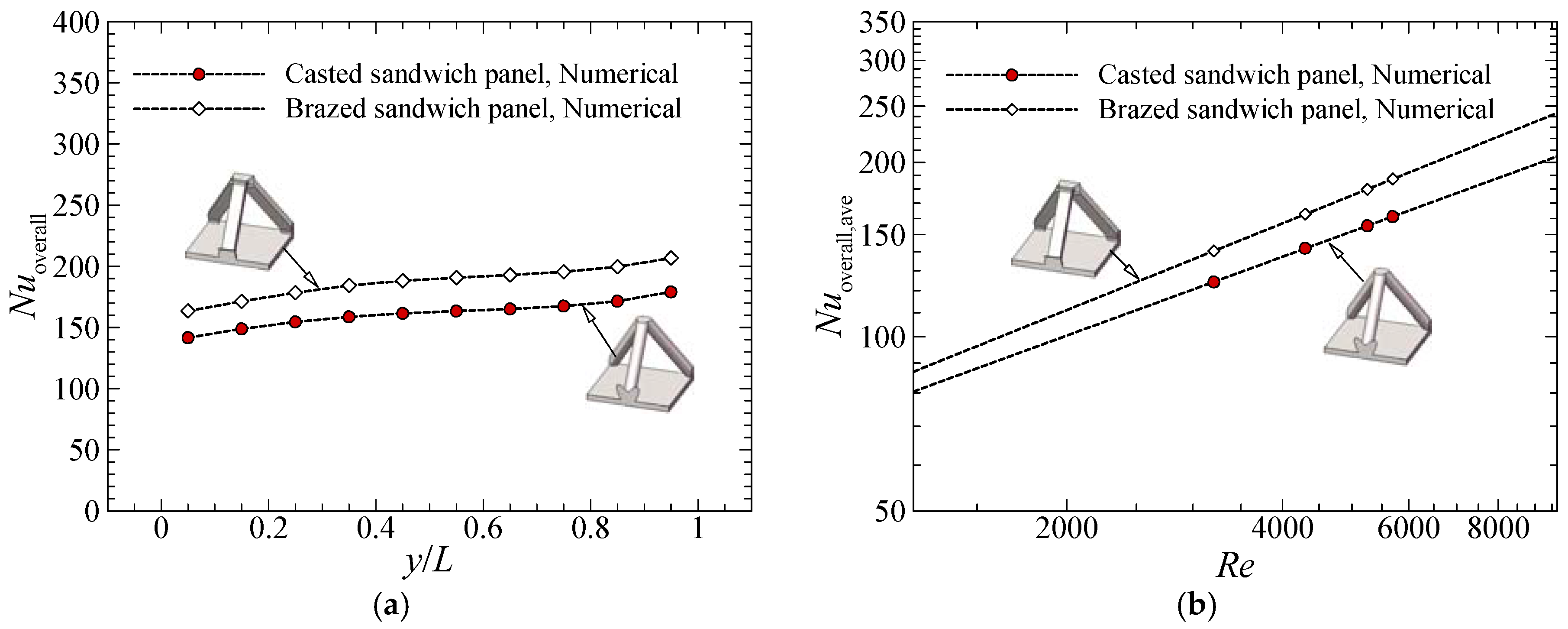

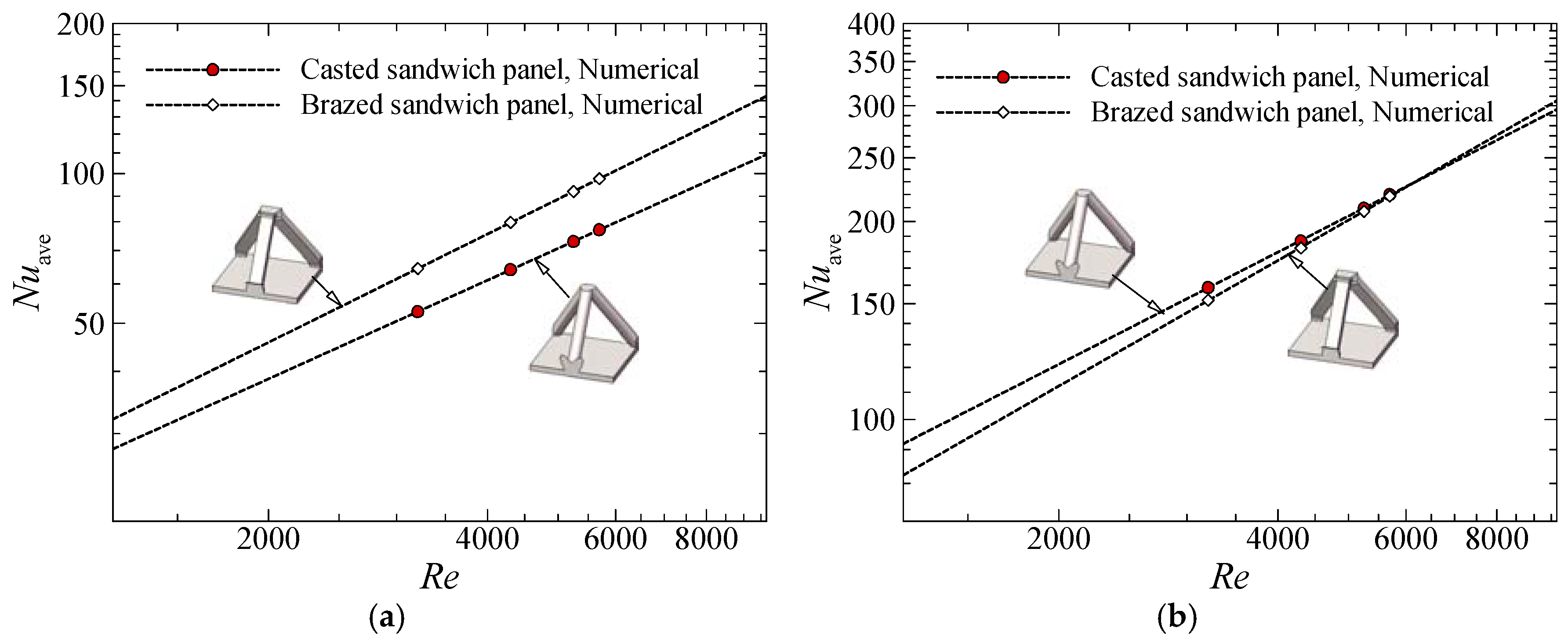

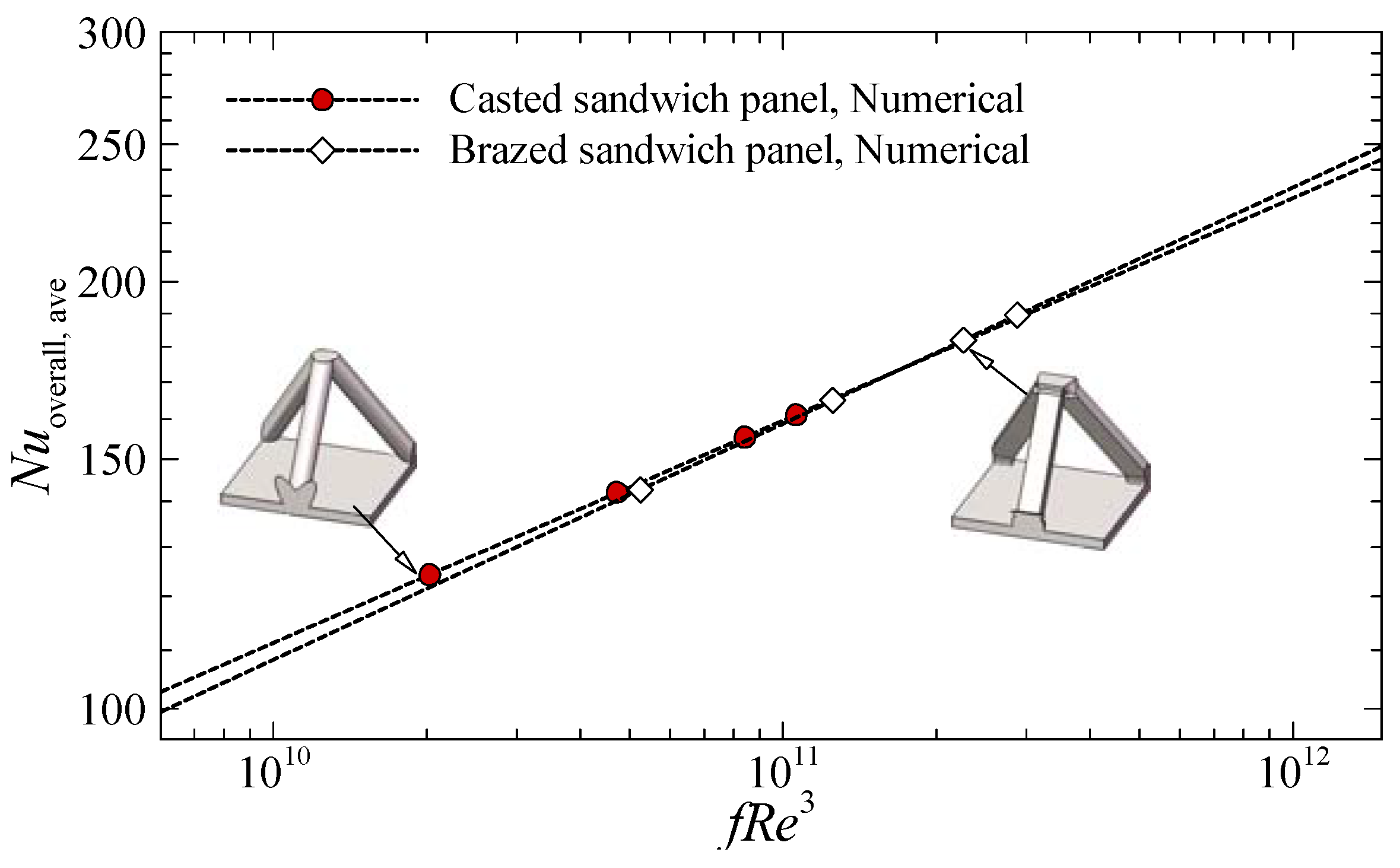

4.2. Comparison of Overall Heat Transfer Characteristics

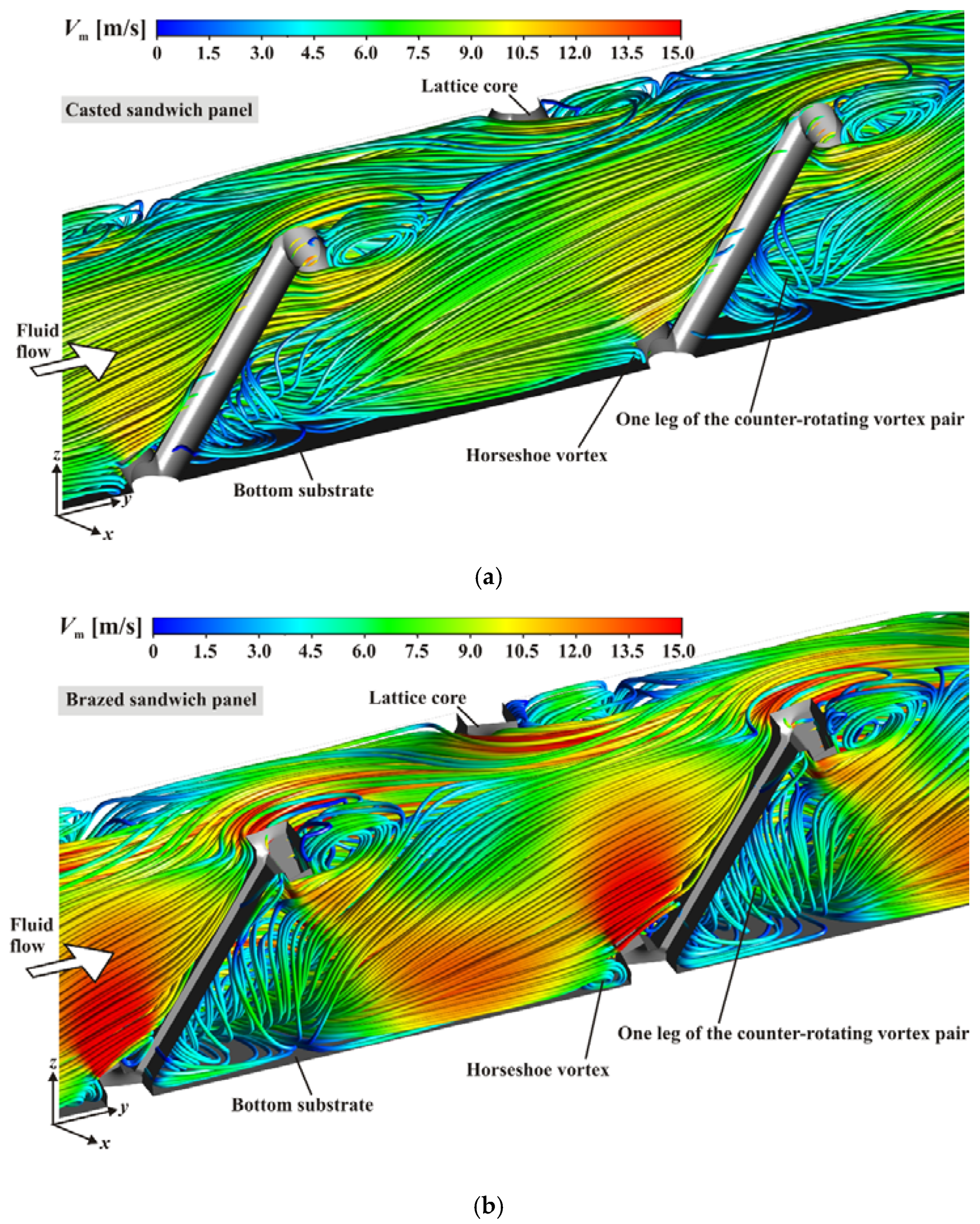

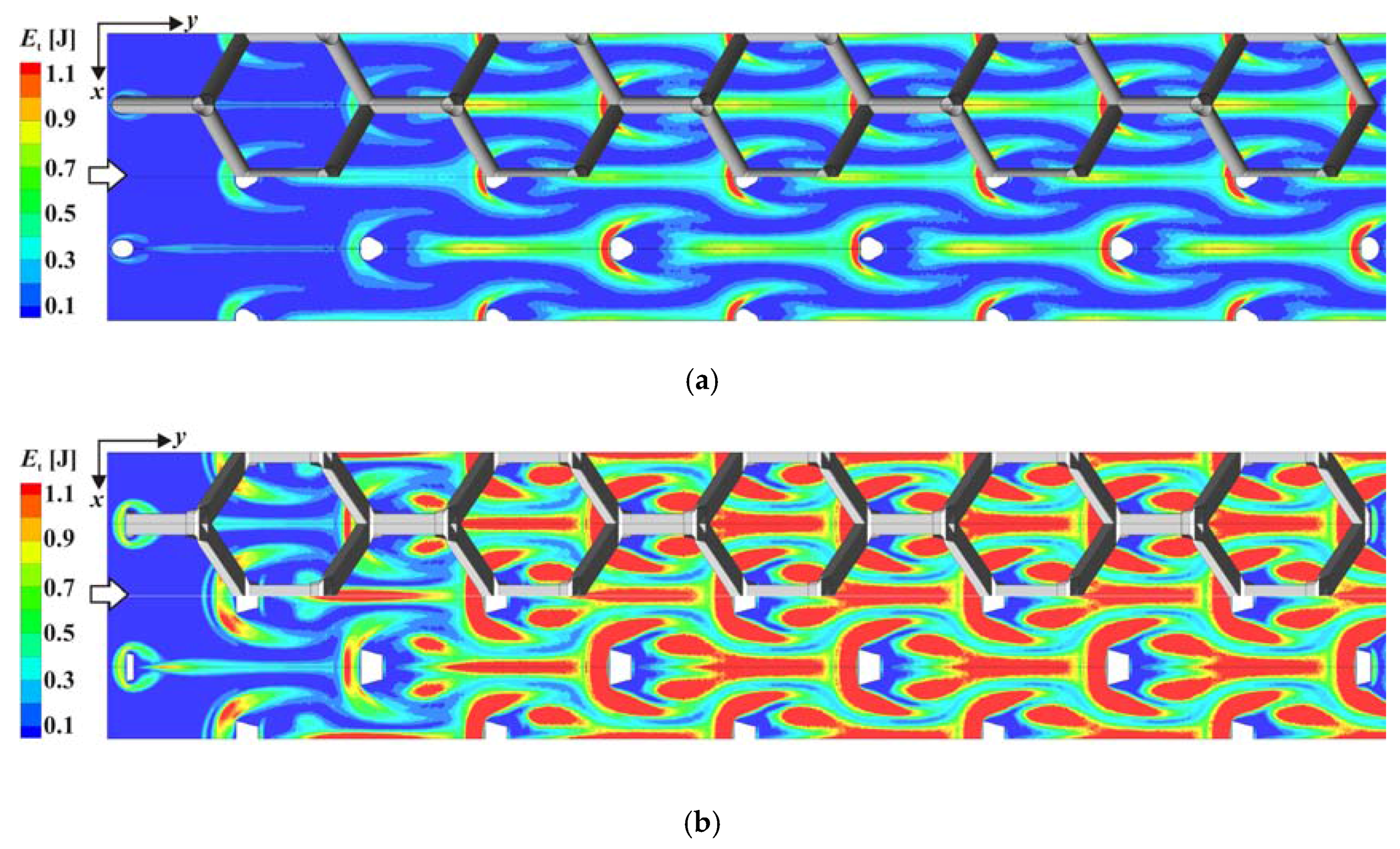

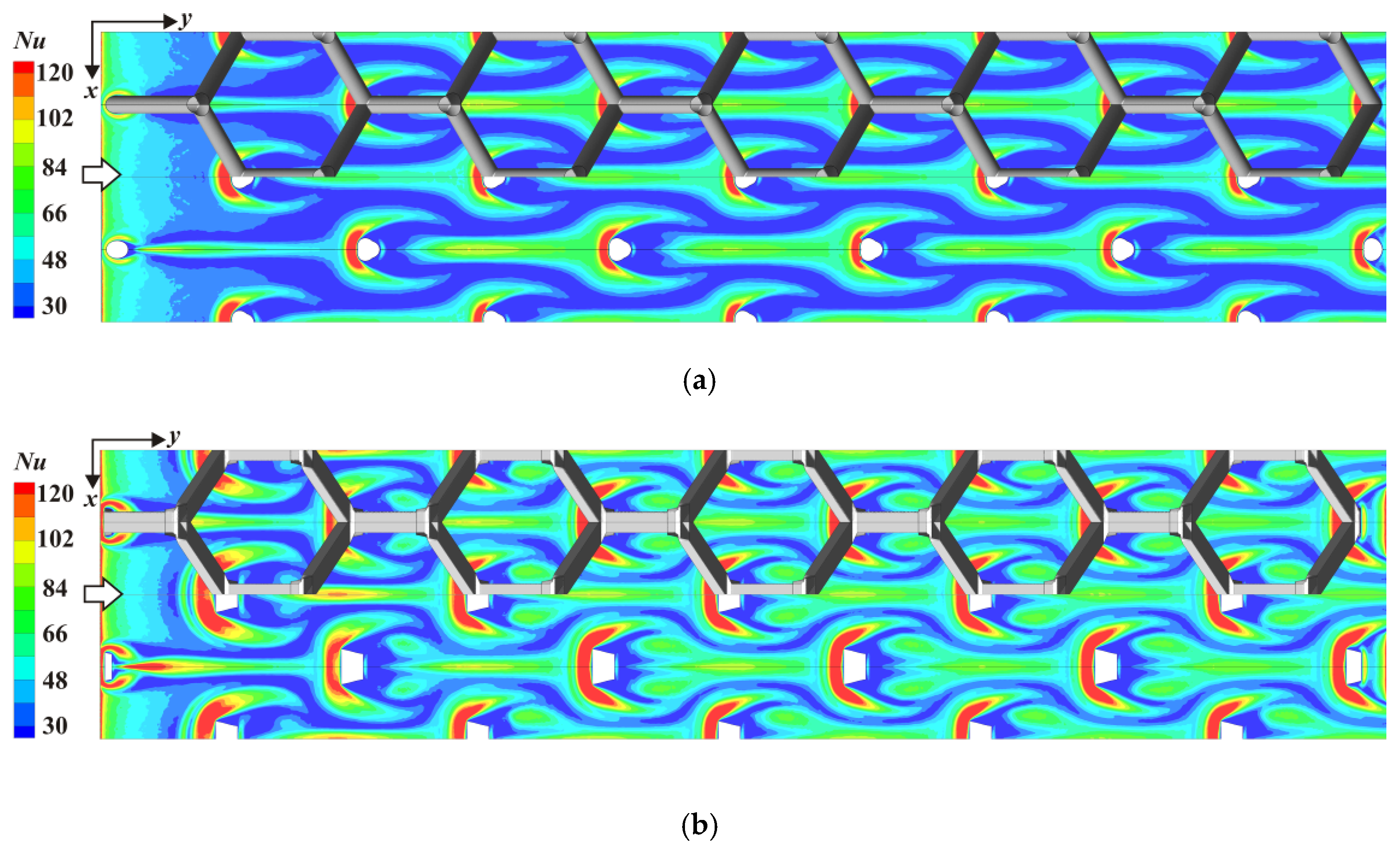

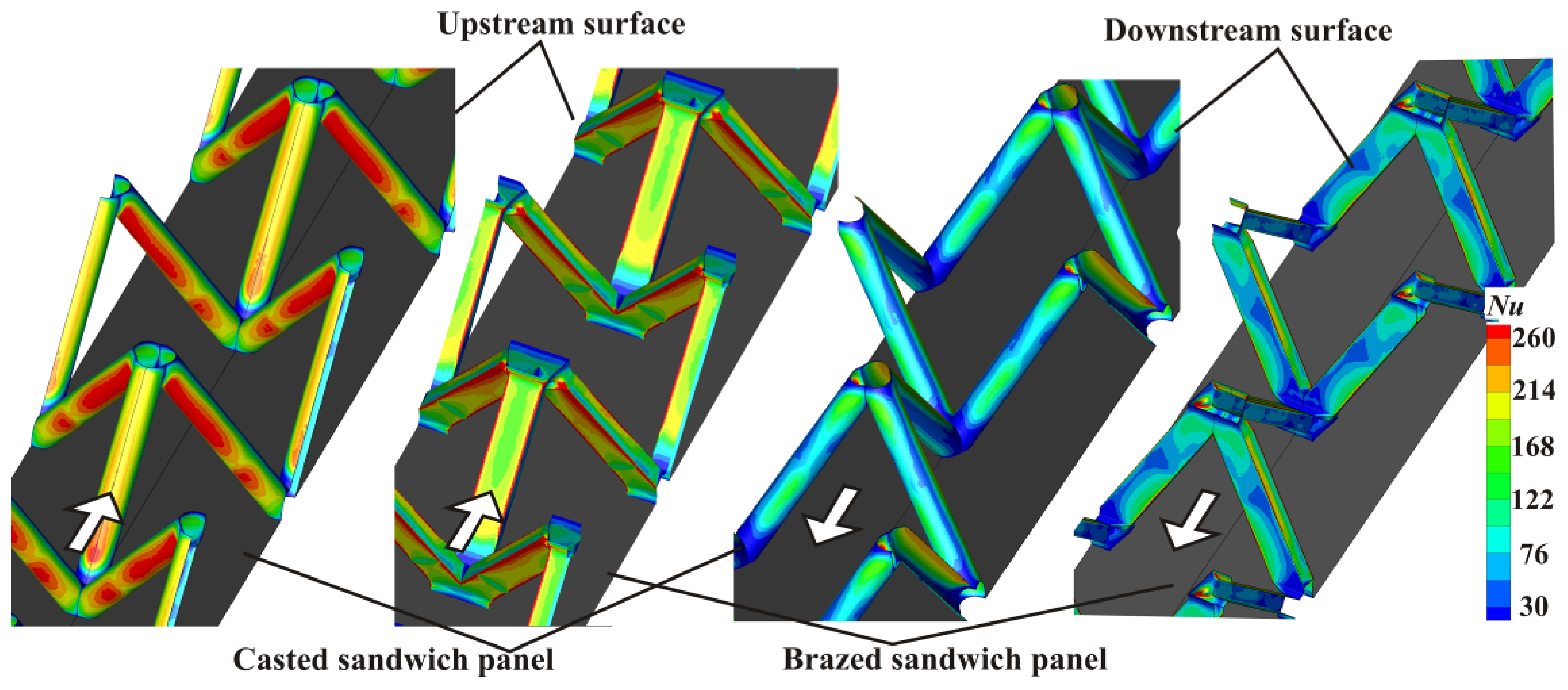

4.3. Comparison of Thermo-Fluidic Mechanisms

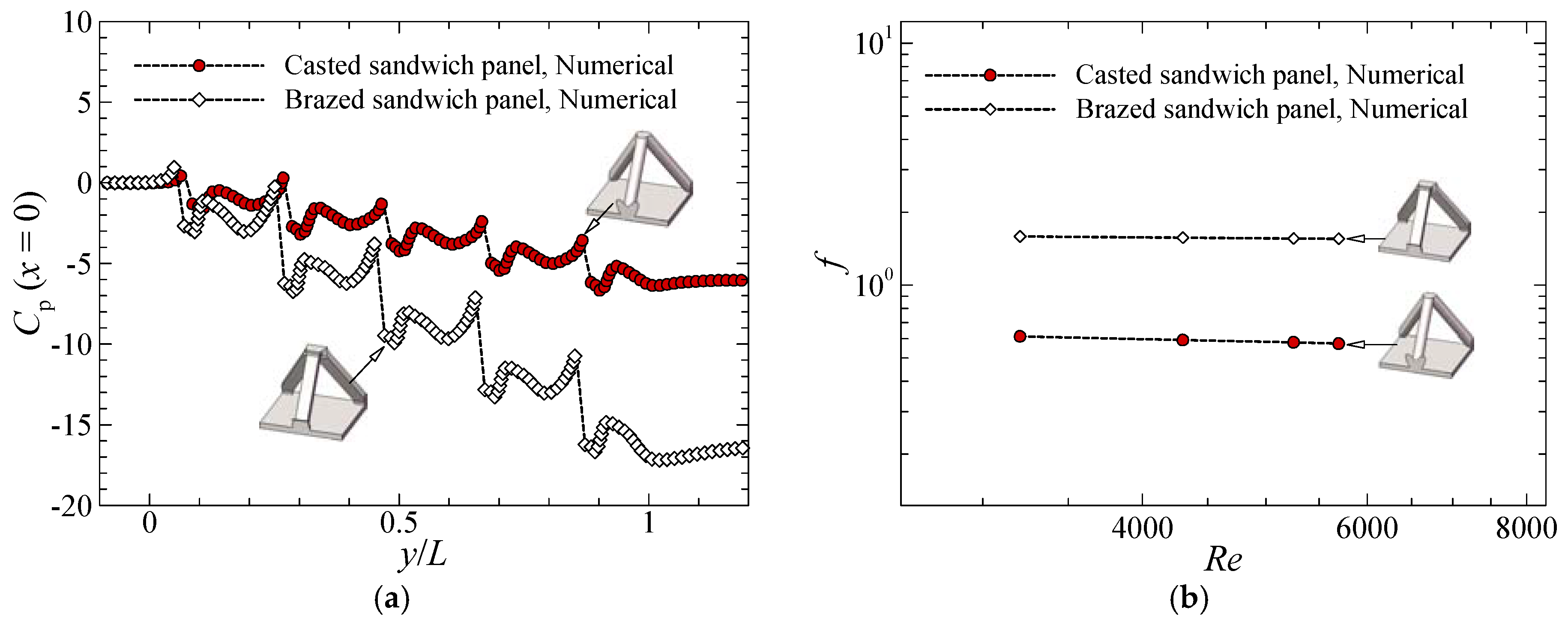

4.4. Comparison of Pressure Drop Characteristics

4.5. Comparison of Overall Thermal Performance

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| a1 | model constant in Equation (6) |

| CDkω | a term defined in Equation (11) |

| Cp | static pressure coefficient |

| cpf | specific heat capacity of fluid (J/(kgK)) |

| d | diameter of the circular ligaments (m) |

| Et | turbulent kinetic energy (J) |

| F1 | non-dimensional blending function defined in Equation (10) |

| F2 | non-dimensional blending function defined in Equation (9) |

| f | friction factor |

| H | height of the lattice core (m) |

| hoverall | overall heat transfer coefficient (W/(m2K)) |

| k | specific turbulent kinetic energy (J/kg) |

| kf | thermal conductivity of fluid (W/(mK)) |

| ks | thermal conductivity of solid (W/(mK)) |

| L | length of the sandwich panel along the flow direction (m) |

| l | length of the unit cell along the flow direction (m) |

| Nu | local Nusselt number |

| Nuave | area-averaged value of local Nusselt number |

| Nuoverall | overall Nusselt number |

| Nuoverall, ave | average overall Nusselt number |

| Pk | production rate of turbulent kinetic energy due to fluid viscosity (J/(m3∙s)) |

| Prt | turbulent Prandtl number |

| p | static pressure (Pa) |

| q’ | heat flux (W/m2) |

| Re | Reynolds number |

| S′ | strain rate defined in Equation (8) (1/s) |

| Tfb | bulk mean fluid temperature corresponding to the central point of each unit cell (K) |

| Tin | inlet fluid temperature (K) |

| Tf | fluid temperature (K) |

| Ts | solid temperature (K) |

| tl | thickness of the rectangular cross-sectioned ligaments (m) |

| ts | thickness of the substrates of the sandwich panel (m) |

| Twm | local substrate temperature corresponding to the central point of each unit cell (K) |

| Um | mean velocity overall channel height at the inlet of the computational domain (m/s) |

| Vi (i =1, 2, 3) | velocity components in Cartesian coordinate system (m/s) |

| Vm | velocity magnitude (m/s) |

| w | width of the unit cell (m) |

| wl | width of the rectangular cross-sectioned ligaments (m) |

| xi | (i = 1, 2, 3) three components of Cartesian coordinate system (m) |

| x, y, z | Cartesian coordinate components (m) |

| yL | distance from the central point of each unit cell to the inlet (m) |

| y+ | dimensionless wall distance |

| y′ | minimum distance between a point to its surrounding solid wall in Equation (9) (m) |

Greek Symbols

| α1–α3 | model constants in Equation (12) |

| β1–β3 | model constants in Equation (12) |

| β′ | model constants in Equation (4) |

| Δp | pressure drop (Pa) |

| σk1–σk3 | model constants in Equation (12) |

| σω1–σω3 | model constants in Equation (12) |

| εB | core porosity of the brazed sandwich panel |

| εC | core porosity of the casted sandwich panel |

| μf | dynamic viscosity of fluid (Pa∙s) |

| μt | turbulent viscosity (Pa∙s) |

| ρf | density of fluid (kg/m3) |

| ρSA, B | core surface area density of the brazed sandwich panel (m2/m3) |

| ρSA, C | core surface area density of the casted sandwich panel (m2/m3) |

| ω | turbulent frequency (1/s) |

References

- Li, H.Y.; Wu, Y.X. Heat transfer characteristics of pin-fin heat sinks cooled by dual piezoelectric fans. Int. J. Therm. Sci. 2016, 110, 26–35. [Google Scholar] [CrossRef]

- Kim, T.H.; Do, K.H.; Kim, S.J. Closed-form correlations of pressure drop and thermal resistance for a plate fin heat sink with uniform air jet impingement. Energy Convers. Manag. 2017, 136, 340–349. [Google Scholar] [CrossRef]

- Ferrari, L.; Barbato, M.; Esser, B.; Petkov, I.; Kuhn, M.; Gianella, S.; Barcena, J.; Jimenez, C.; Francesconi, D.; Liedtke, V.; et al. Sandwich structured ceramic matrix composites with periodic cellular ceramic cores: An active cooled thermal protection for space vehicles. Compos. Struct. 2016, 154, 61–68. [Google Scholar] [CrossRef]

- Song, J.W.; Sun, B. Coupled numerical simulation of combustion and regenerative cooling in LOX/Methane rocket engines. Appl. Therm. Eng. 2016, 106, 762–773. [Google Scholar] [CrossRef]

- Feng, S.S.; Li, M.Z.; Joo, J.H.; Kang, K.J.; Kim, T.; Lu, T.J. Thermomechanical properties of brazed wire-woven bulk Kagome cellular metals for multifunctional applications. J. Therm. Heat Transf. 2012, 26, 66–74. [Google Scholar] [CrossRef]

- Yan, H.B.; Zhang, Q.C.; Lu, T.J. An X-type lattice cored ventilated brake disc with enhanced cooling performance. Int. J. Heat Mass Transf. 2015, 80, 458–468. [Google Scholar] [CrossRef]

- Yan, H.B.; Mew, T.; Lee, M.G.; Kang, K.J.; Lu, T.J.; kienhöfer, F.W.; Kim, T. Thermofluidic characteristics of a porous ventilated brake disk. ASME J. Heat Transf. 2015, 137, 022601. [Google Scholar] [CrossRef]

- Maloney, K.J.; Fink, K.D.; Schaedler, T.A.; Kolodziejska, J.A.; Jacobsen, A.J.; Roper, C.S. Multifunctional heat exchangers derived from three-dimensional micro-lattice structures. Int. J. Heat Mass Transf. 2012, 55, 2486–2493. [Google Scholar] [CrossRef]

- Wadley, H.N.G. Multifunctional periodic cellular metals. Philos. Trans. R. Soc. A 2006, 364, 31–68. [Google Scholar] [CrossRef] [PubMed]

- Wadley, H.N.G.; Fleck, N.A.; Evans, A.G. Fabrication and structural performance of periodic cellular metal sandwich structures. Compos. Sci. Technol. 2003, 63, 2331–2343. [Google Scholar] [CrossRef]

- Wei, K.; He, R.J.; Cheng, X.M.; Pei, Y.M.; Zhang, R.B.; Fang, D.N. Fabrication and heat transfer characteristics of C/SiC pyramidal core lattice sandwich panel. Appl. Therm. Eng. 2015, 81, 10–17. [Google Scholar] [CrossRef]

- Hoffmann, F. Heat Transfer Performance and Pressure Drop of Kagome Core Metal Truss Panels. Master’s Thesis, University of Cambridge, Cambridge, UK, 2002. [Google Scholar]

- Tian, J.; Lu, T.J.; Hodson, H.P.; Queheillalt, D.T.; Wadley, H.N.G. Cross flow heat exchange of textile cellular metal core sandwich panels. Int. J. Heat Mass Transf. 2007, 50, 2521–2536. [Google Scholar] [CrossRef]

- Kang, K.J. Wire-woven cellular metals: The present and future. Prog. Mater. Sci. 2015, 69, 213–307. [Google Scholar] [CrossRef]

- Pingle, S.M.; Fleck, N.A.; Deshpande, V.S.; Wadley, H.N.G. Collapse mechanism maps for the hollow pyramidal core of a sandwich panel under transverse shear. Int. J. Solids Struct. 2011, 48, 3417–3430. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Fleck, N.A.; Ashby, M.F. Effective properties of the octet-truss lattice material. J. Mech. Phys. Solids 2001, 49, 1747–1769. [Google Scholar] [CrossRef]

- Zhang, Q.C.; Han, Y.J.; Chen, C.Q.; Lu, T.J. Ultralight X-type lattice sandwich structure (I): Concept, fabrication and experimental characterization. Sci. China Ser. E Technol. Sci. 2009, 52, 2147–2154. [Google Scholar] [CrossRef]

- Yan, H.B.; Zhang, Q.C.; Lu, T.J.; Kim, T. A lightweight X-type metallic lattice in single-phase forced convection. Int. J. Heat Mass Transf. 2015, 83, 273–283. [Google Scholar] [CrossRef]

- Kim, T.; Hodson, H.P.; Lu, T.J. Contribution of vortex structures and flow separation to local and overall pressure and heat transfer characteristics in an ultralightweight lattice material. Int. J. Heat Mass Transf. 2005, 48, 4243–4264. [Google Scholar] [CrossRef]

- Kim, T.; Zhao, C.Y.; Lu, T.J.; Hodson, H.P. Convective heat dissipation with lattice-frame materials. Mech. Mater. 2004, 36, 767–780. [Google Scholar] [CrossRef]

- Kim, T.; Hodson, H.P.; Lu, T.J. Fluid-flow and endwall heat-transfer characteristics of an ultralight lattice-frame material. Int. J. Heat Mass Transf. 2004, 47, 1129–1140. [Google Scholar] [CrossRef]

- Kim, T.; Hodson, H.P.; Lu, T.J. Pressure loss and heat transfer mechanisms in a lattice-frame structured heat exchanger. IMechE J. Mech. Eng. Sci. 2004, 218, 1321–1336. [Google Scholar] [CrossRef]

- Gao, L.; Sun, Y.G. Thermal control of composite sandwich structure with lattice truss cores. J. Therm. Heat Transf. 2015, 29, 47–54. [Google Scholar] [CrossRef]

- Gao, L.; Sun, Y.G. Fluid flow and heat transfer characteristics of composite lattice core sandwich structures. J. Therm. Heat Transf. 2014, 28, 258–269. [Google Scholar] [CrossRef]

- Joo, J.H.; Kang, K.J.; Kim, T.; Lu, T.J. Forced convective heat transfer in all metallic wire-woven bulk Kagome sandwich panels. Int. J. Heat Mass Transf. 2011, 54, 5658–5662. [Google Scholar] [CrossRef]

- Zhao, L.Y.; Ryan, S.M.; Ortega, J.K.; Ha, S.; Sharp, K.W.; Guest, J.K.; Hemker, K.J.; Weihs, T.P. Experimental investigation of 3D woven Cu lattices for heat exchanger applications. Int. J. Heat Mass Transf. 2016, 96, 296–311. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Menter, F.R.; Kuntz, M.; Langtry, R. Ten years of industrial experience with the SST turbulence model. In Turbulence Heat and Mass Transfer; Hanjalić, K., Nagano, Y., Tummers, M., Eds.; Begell House Inc.: Danbury, PA, USA, 2003; Volume 4, pp. 625–632. [Google Scholar]

- CFX 14.0. ANSYS CFX Solver Theory Guide; ANSYS Inc.: Canonsburg, DC, USA, 2012. [Google Scholar]

- Kim, T. Fluid-Flow and Heat-Transfer in a Lattice-Frame Material. Ph.D. Dissertation, University of Cambridge, Cambridge, UK, 2004. [Google Scholar]

- Tian, J.; Kim, T.; Lu, T.J.; Honson, H.P.; Queheillalt, D.T.; Sypeck, D.J.; Wadley, H.N.G. The effects of topology upon fluid-flow and heat-transfer within cellular copper structures. Int. J. Heat Mass Transf. 2004, 47, 3171–3186. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|

| d | 1.80 mm | tl | 1.13 mm | εB | 0.953 |

| H | 11.6 mm | ts | 1.00 mm | εC | 0.953 |

| l | 12.7 mm | w | 14.7 mm | ρSA, B | 113.7 m2/m3 |

| L | 127 mm | wl | 2.16 mm | ρSA, C | 98.1 m2/m3 |

| Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|

| α1 | 0.556 | β1 | 0.075 | σk1 | 0.85 |

| α2 | 0.44 | β2 | 0.0828 | σk2 | 1.0 |

| σω1 | 0.5 | a1 | 0.31 | Prt | 0.9 |

| σω2 | 0.856 | β′ | 0.09 | - | - |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Specific heat of air, cpf | 1006 J/(kgK) | Thermal conductivity of solid, ks | 150.84 W/(mK) |

| Thermal conductivity of air, kf | 0.0242 W/(mK) | Applied heat flux, q″ | 8000 W/m2 |

| Dynamic viscosity of air, μf | 1.79×10−5 Pa∙s | Inlet air temperature, Tin | 298.15 K |

| Density of air, ρf | 1.225 kg/m3 | Reynolds number, Re | 3209–5700 |

| Total Elements | Nuoverall | f |

|---|---|---|

| 7,649,638 | 134.2891 | 0.6217 |

| 13,666,657 | 137.4246 | 0.6363 |

| 18,690,337 | 137.6380 | 0.6401 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Jin, X.; Xie, G.; Yan, H. Thermo-Fluidic Comparison between Sandwich Panels with Tetrahedral Lattice Cores Fabricated by Casting and Metal Sheet Folding. Energies 2017, 10, 906. https://doi.org/10.3390/en10070906

Zhang X, Jin X, Xie G, Yan H. Thermo-Fluidic Comparison between Sandwich Panels with Tetrahedral Lattice Cores Fabricated by Casting and Metal Sheet Folding. Energies. 2017; 10(7):906. https://doi.org/10.3390/en10070906

Chicago/Turabian StyleZhang, Xiaoqing, Xin Jin, Gongnan Xie, and Hongbin Yan. 2017. "Thermo-Fluidic Comparison between Sandwich Panels with Tetrahedral Lattice Cores Fabricated by Casting and Metal Sheet Folding" Energies 10, no. 7: 906. https://doi.org/10.3390/en10070906

APA StyleZhang, X., Jin, X., Xie, G., & Yan, H. (2017). Thermo-Fluidic Comparison between Sandwich Panels with Tetrahedral Lattice Cores Fabricated by Casting and Metal Sheet Folding. Energies, 10(7), 906. https://doi.org/10.3390/en10070906