Numerical Simulation about Reconstruction of the Boundary Layer †

Abstract

:1. Introduction

2. Physical Model and Numerical Method

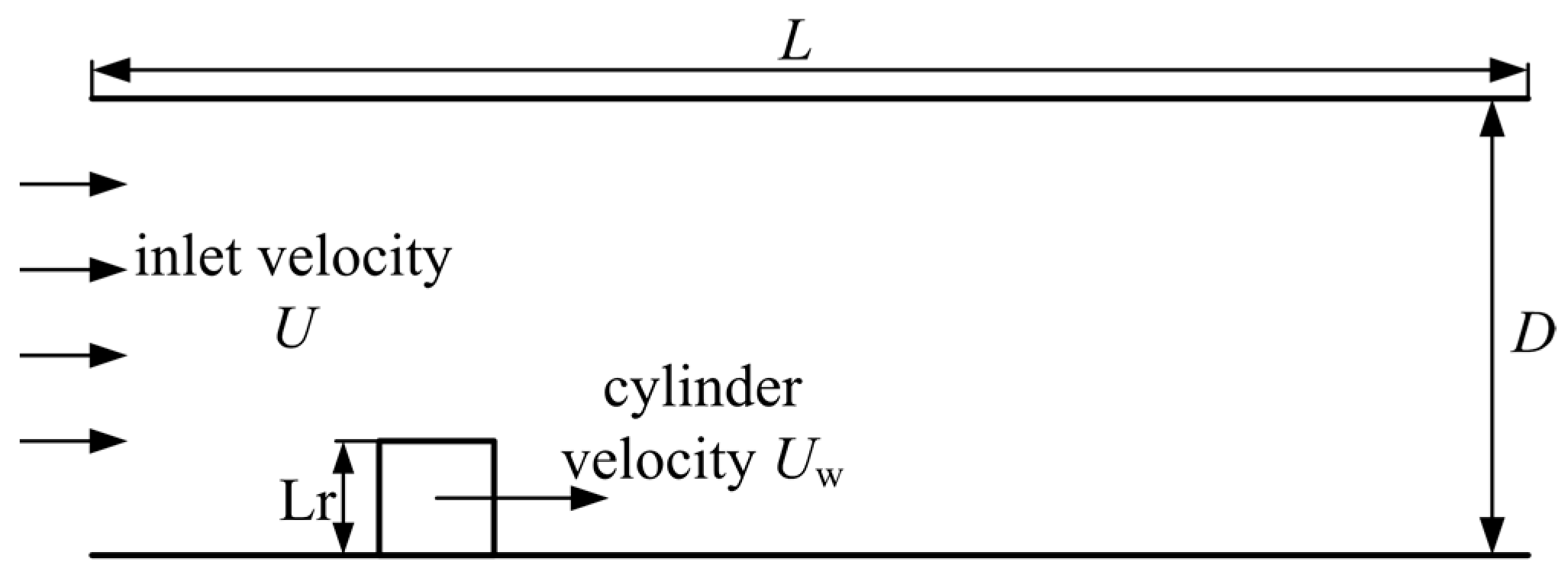

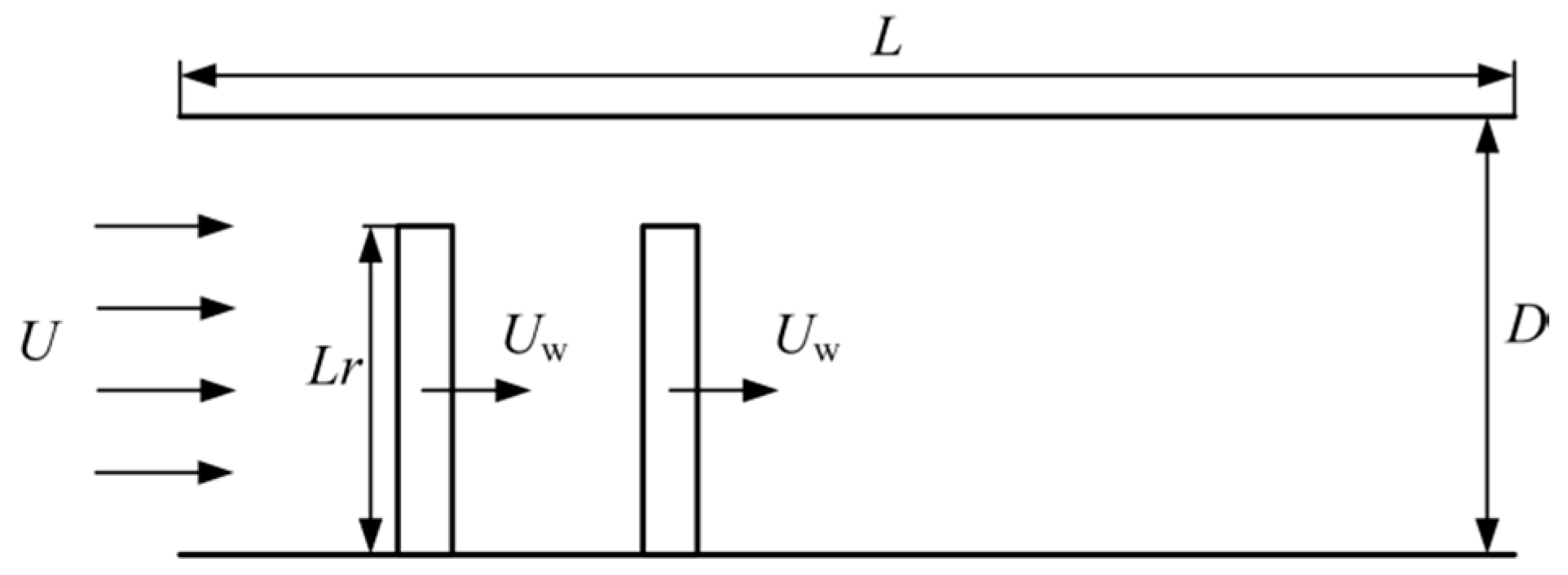

2.1. Physical Model

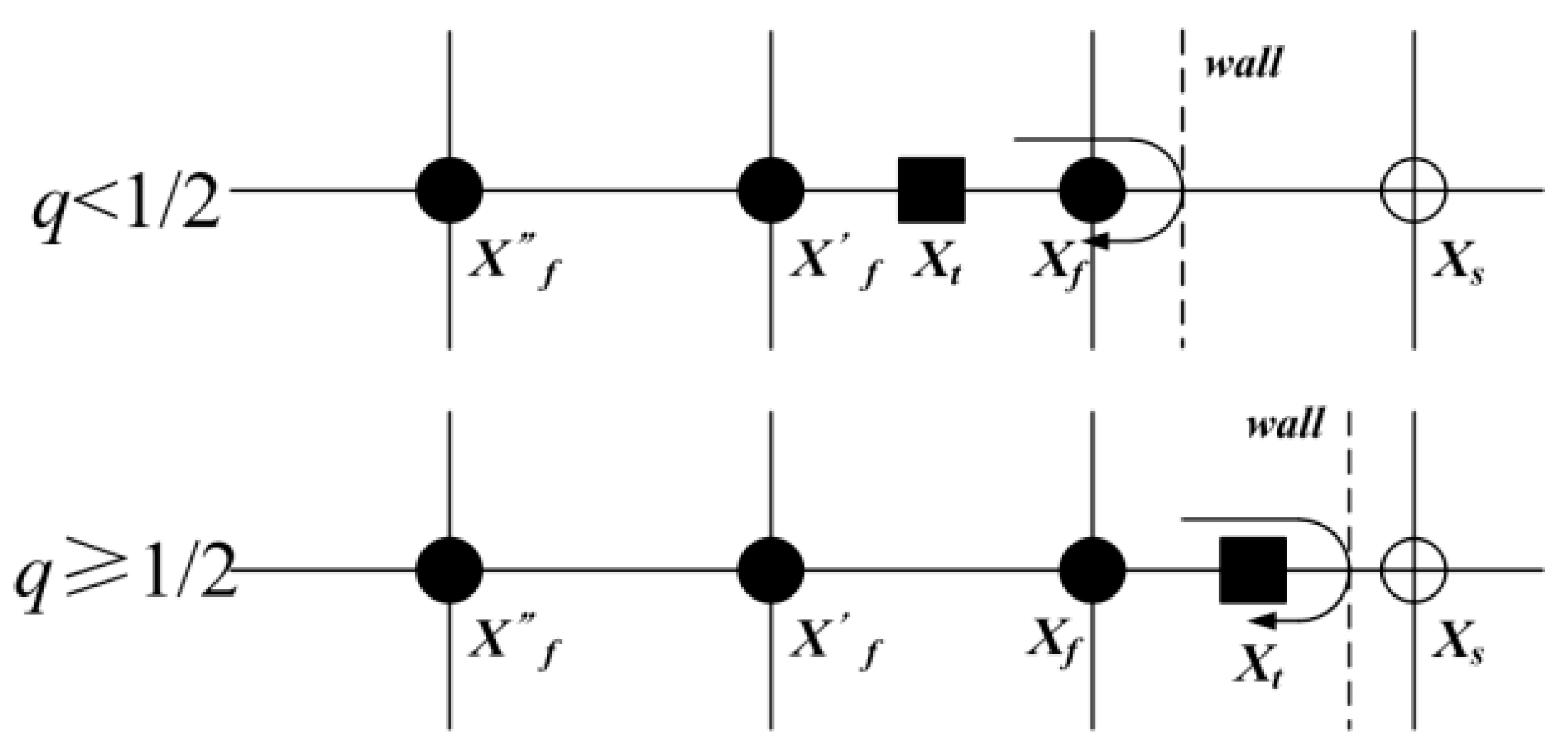

2.2. Lattice Boltzmann Method

3. Results and Discussion

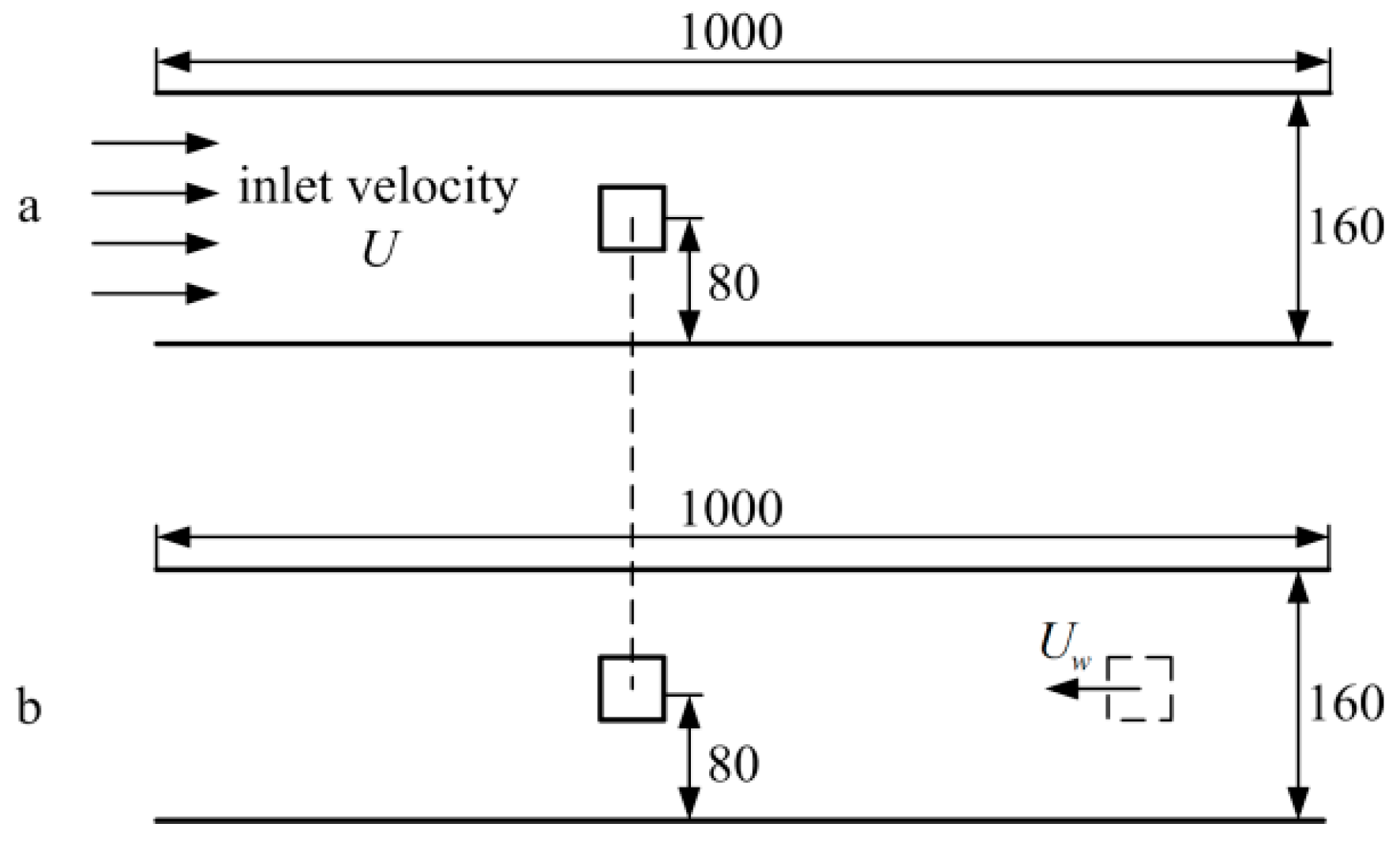

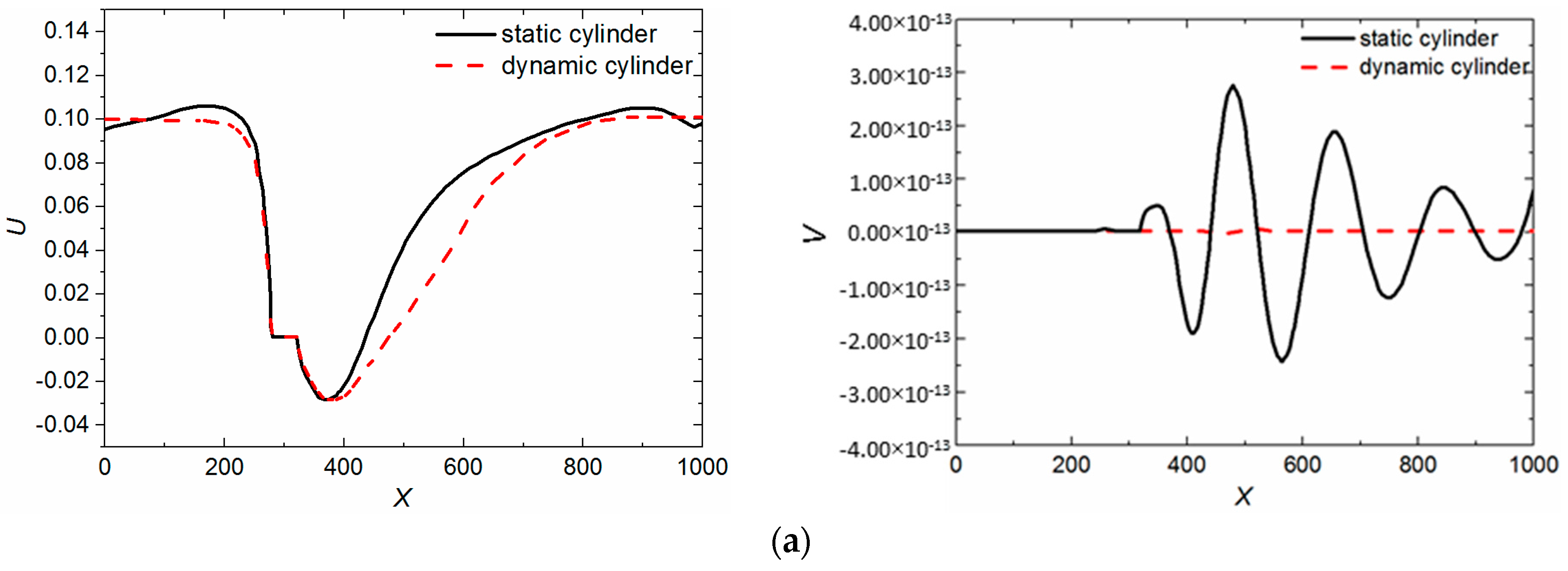

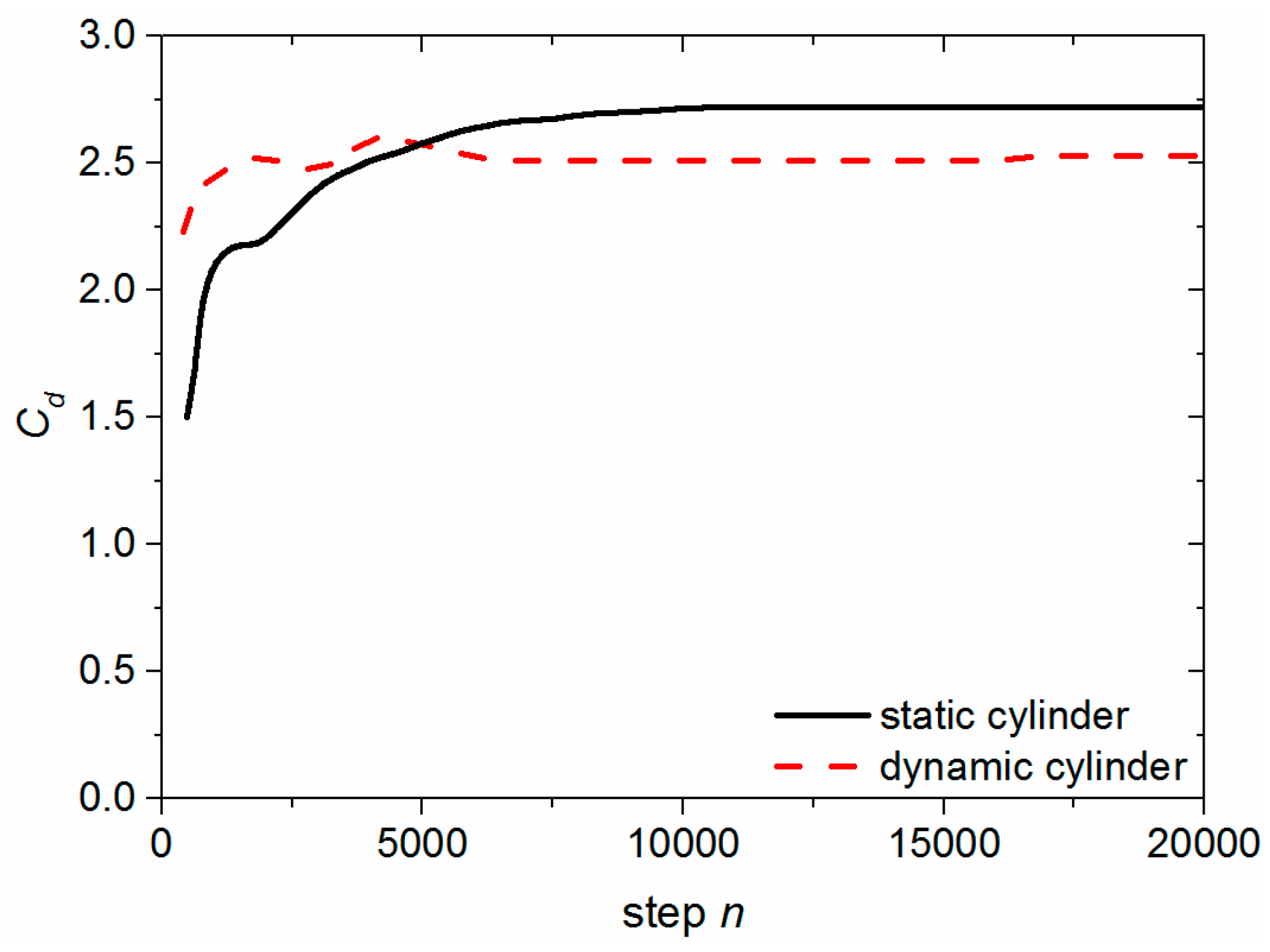

3.1. Model Validation

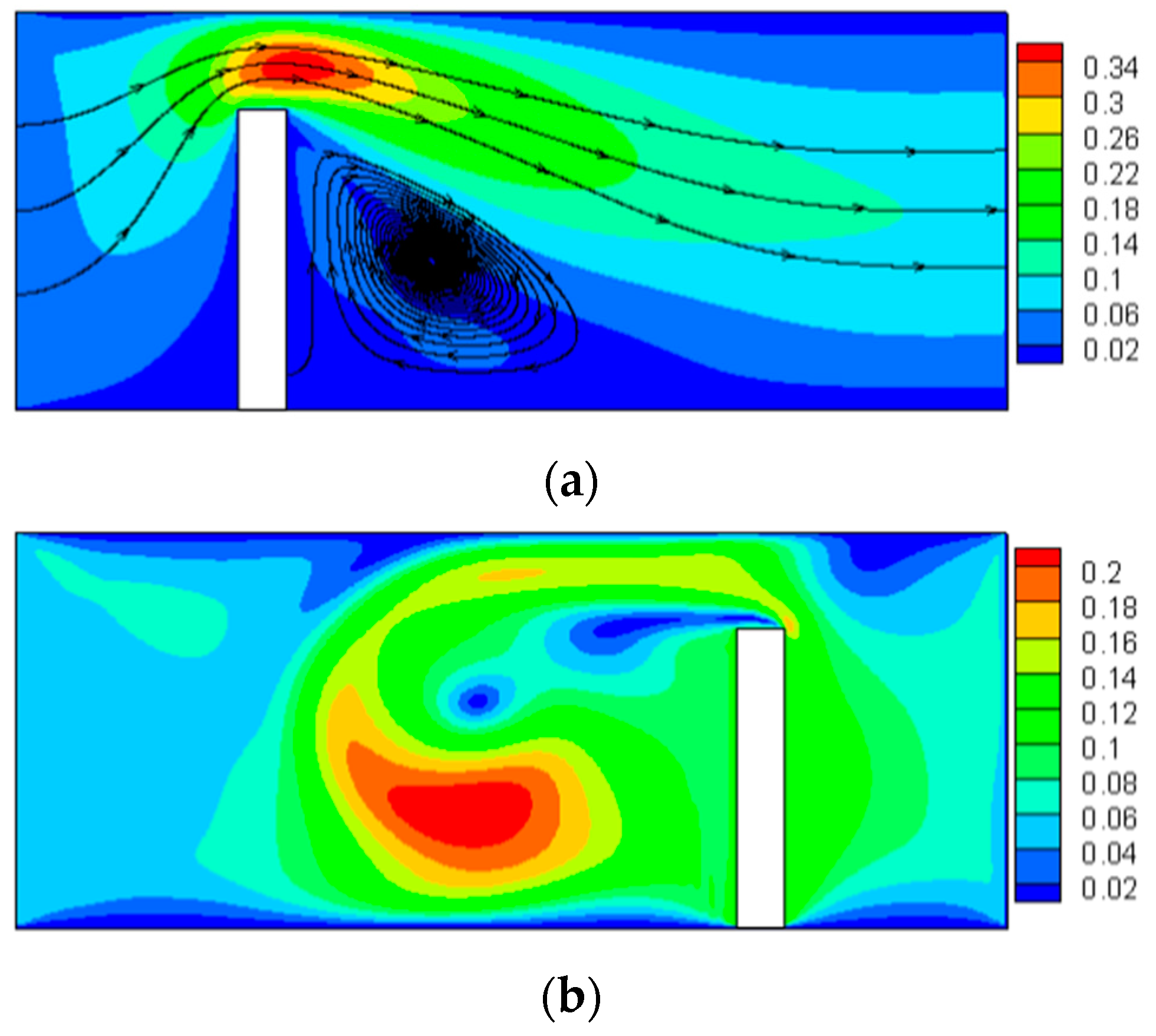

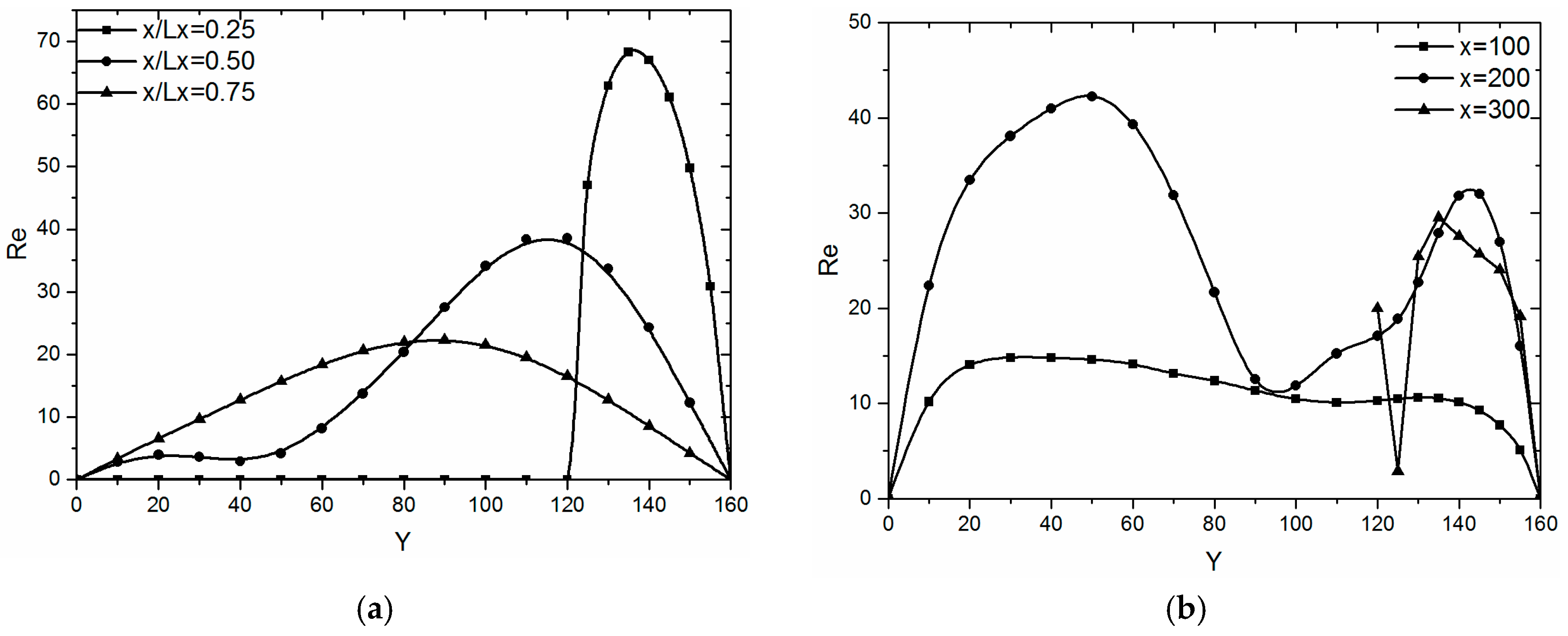

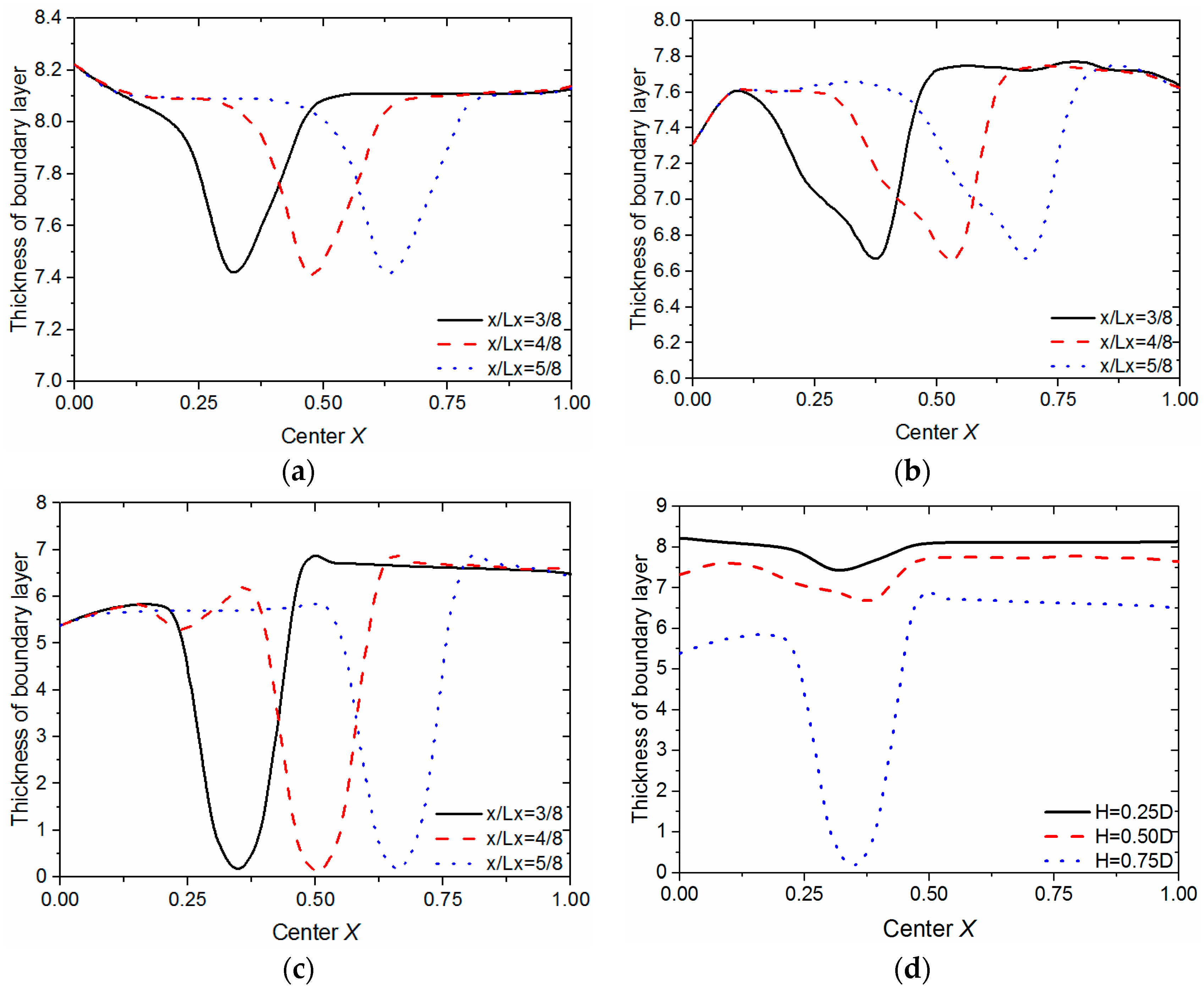

3.2. Effect of Square Cylinder with Different Height on Boundary Layer

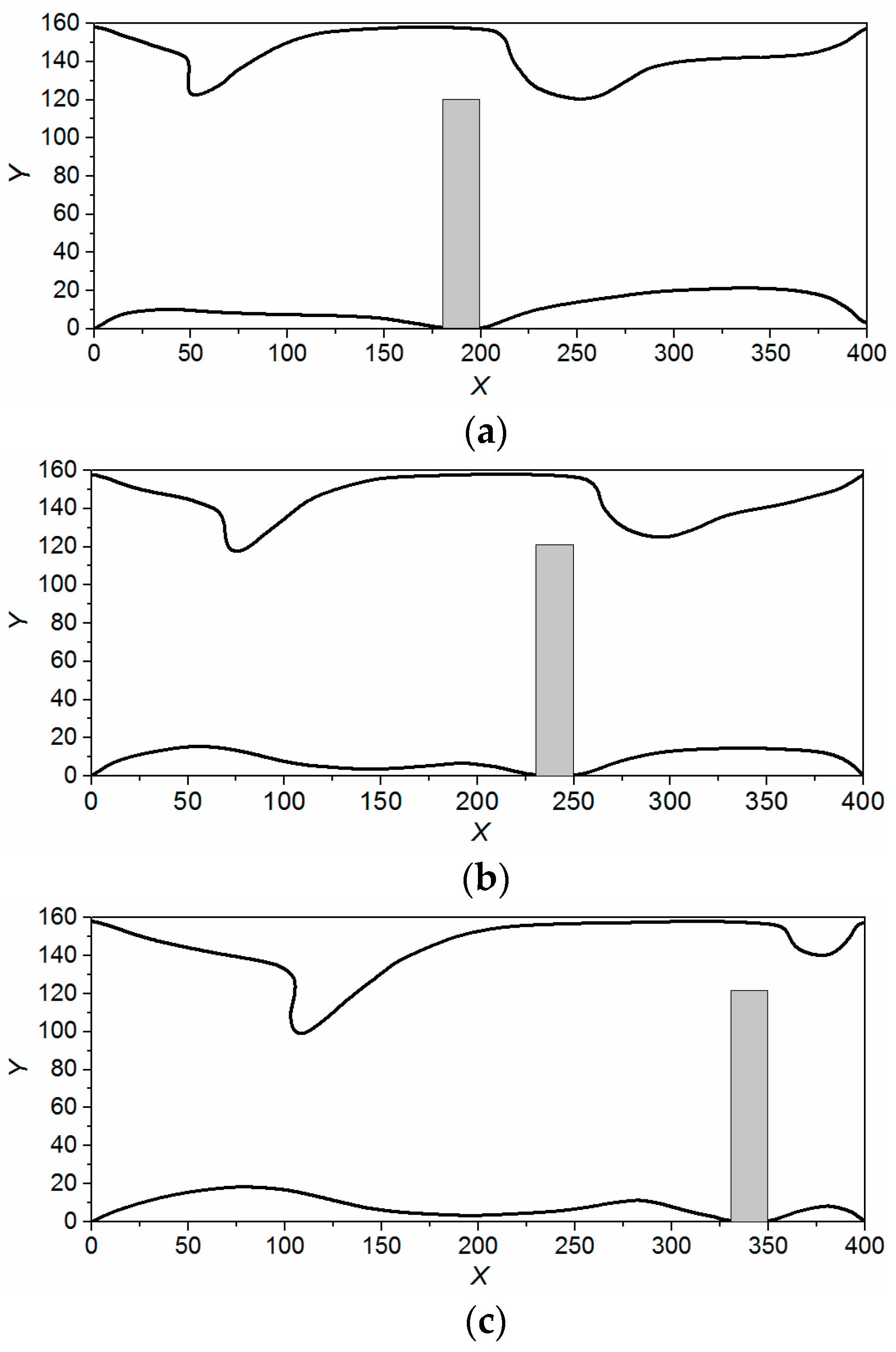

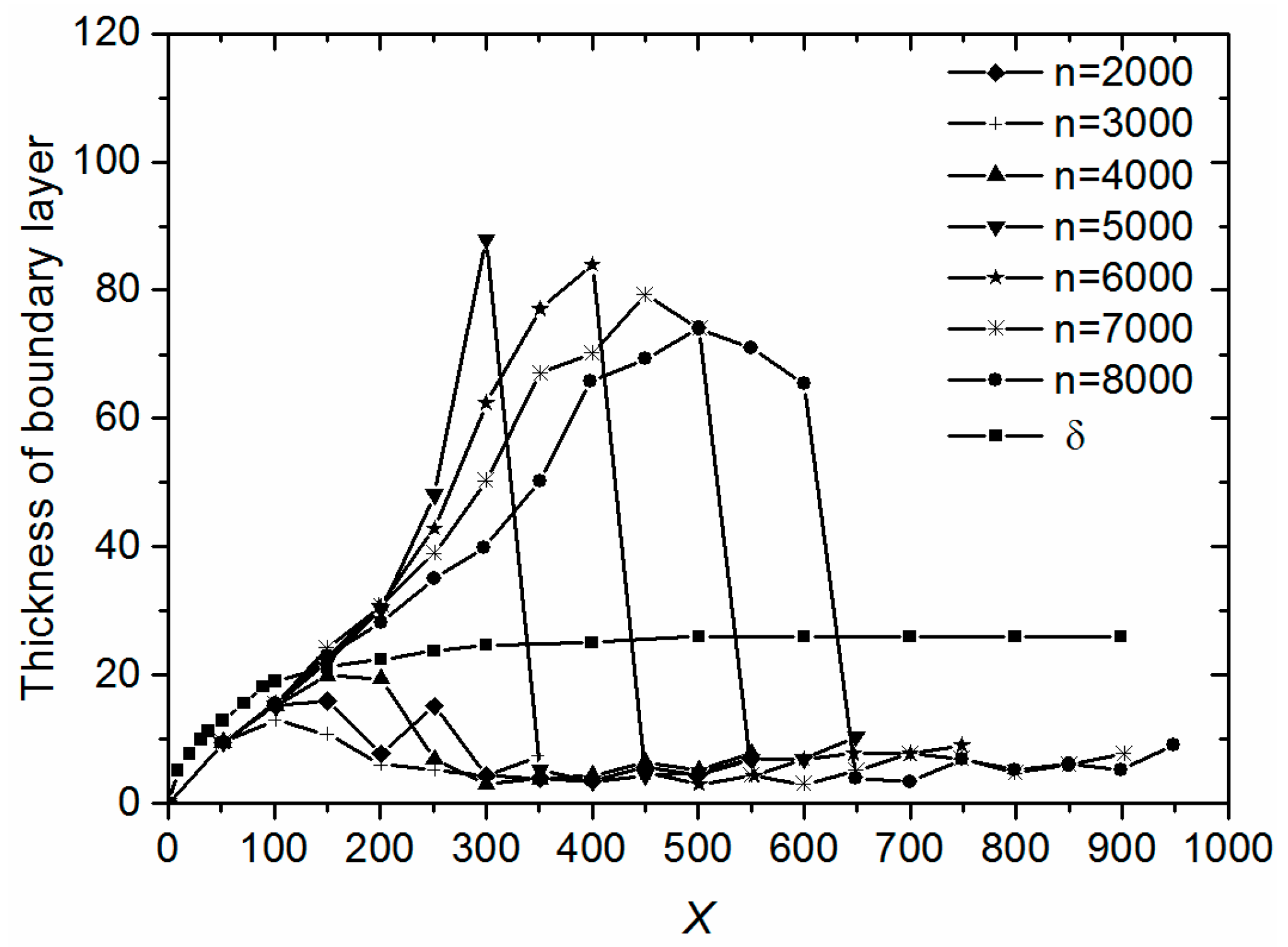

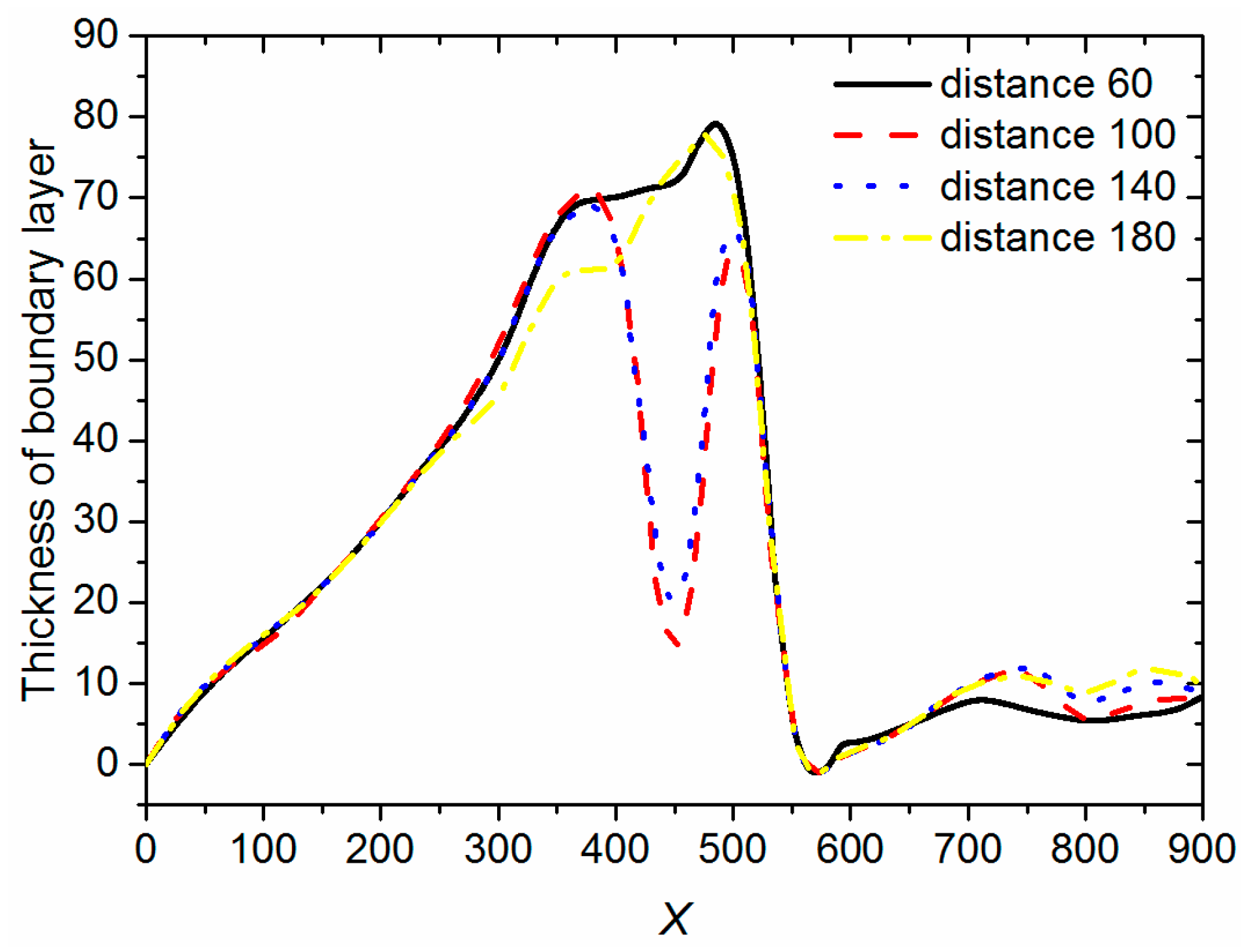

3.3. Double Cylinders Model

4. Conclusions

- (1)

- By comparing the changes of the X-direction velocity component (U) and the Y-direction velocity component (V) and lift and drag in the center of the square cylinder, the conclusion that lattice Boltzmann method has the feasibility and superiority in dealing with moving boundary is obtained.

- (2)

- The boundary layer reconstruction model has been established. It is found that when the square cylinder is present, the fluid boundary layer will be destroyed to enhance the total heat transfer coefficient, which makes the optimization of the heat exchanger possible. At the same time, the thickness of the boundary layer increases as the height of the square cylinder decreases.

- (3)

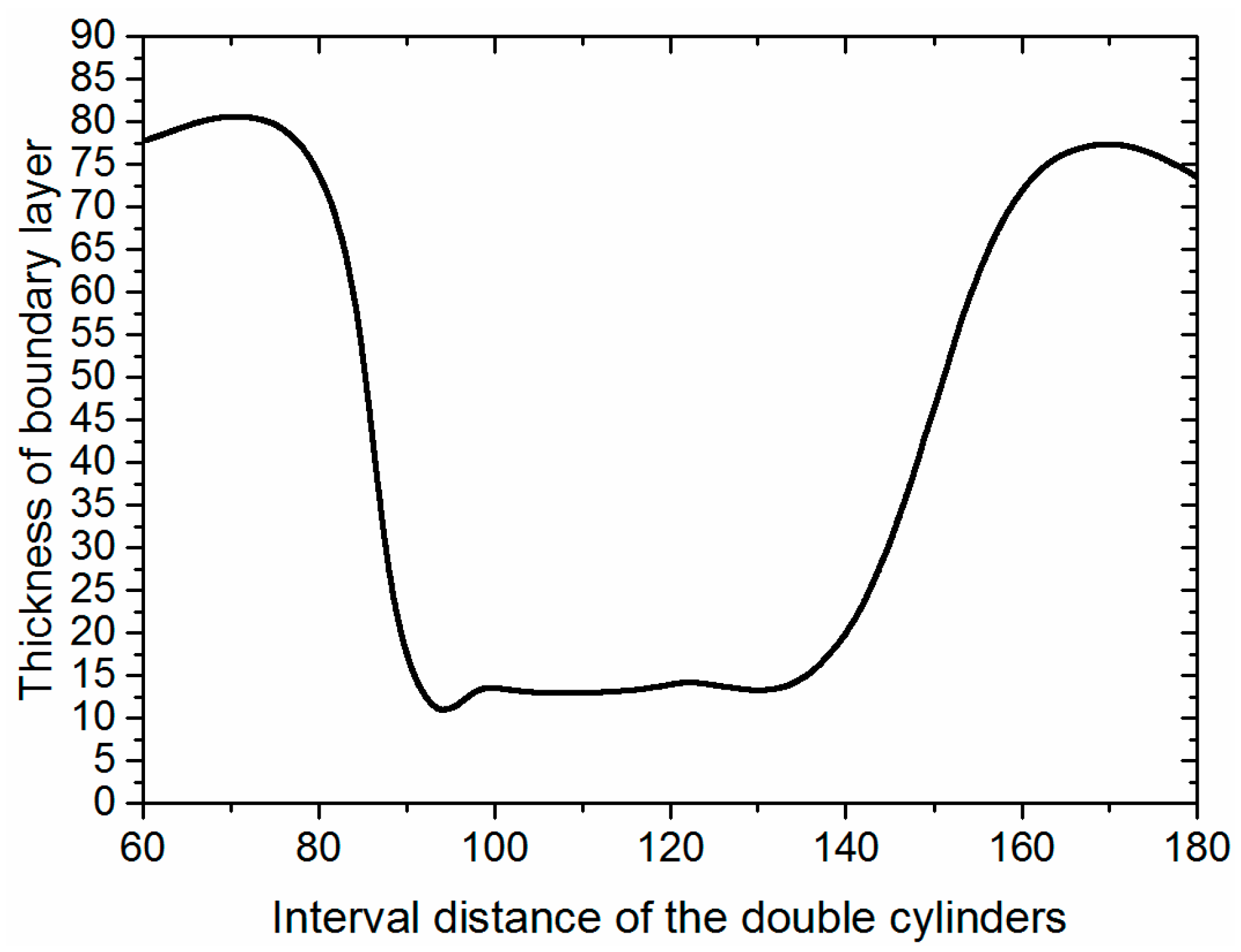

- As the square cylinder passes by, the boundary layer away from the square cylinder will gradually thicken and be reconstructed. Double cylinders are effective to make the boundary layer continuously thin, and there is an optimum interval distance of the cylinders.

Acknowledgements

Author Contributions

Conflicts of Interest

References

- Shirvan, K.M.; Mamourian, M.; Mirzakhanlari, S.; Ellahi, R.; Vafai, K. Numerical investigation and sensitivity analysis of effective parameters on combined heat transfer performance in a porous solar cavity receiver by response surface methodology. Int. J. Heat Mass Tranf. 2017, 105, 811–825. [Google Scholar] [CrossRef]

- Shirvan, K.M.; Ellahi, R.; Mirzakhanlari, S.; Mamourian, M. Enhancement of heat transfer and heat exchanger effectiveness in a double pipe heat exchanger filled with porpous media: Numerical simulation and sensitivity analysis of turbulent fluid flow. Appl. Therm. Eng. 2016, 109, 761–774. [Google Scholar] [CrossRef]

- Sheikholesmi, M.; Zia, Z.Q.M.; Ellahi, R. Influence of induced magnetic field on free convection of nanofluid considering Koo-Kleinstreuer-Li(KKL) correlation. Appl. Sci. 2016, 6, 324. [Google Scholar] [CrossRef]

- Shirvan, K.M.; Mamourian, M.; Ellahi, R. Numerical investigation and optimization of mixed convection in ventilated square cavity filled with nanofluid of different Inlet and outlet port. Int. J. Numer. Methods Heat Fluid Flow 2017, 27, 2053–2069. [Google Scholar] [CrossRef]

- Kandelousi, M.S.; Ellahi, R. Simulation of ferrofluid flow for magnetic drug targeting using the lattice Boltzmann method. Zeitschrift für Naturforschung A 2015, 70, 115–124. [Google Scholar] [CrossRef]

- Shirvan, K.M.; Mamourian, M.; Mirzakhanlari, S.; Ellahi, R. Numerical investigation of heat exchanger dffectiveness in a double pipe heat exchanger filled with nanofluid: A sensitivity analysis by response surface methodology. Powder Technol. 2017, 313, 99–111. [Google Scholar] [CrossRef]

- Pasquetti, R.; Bwemba, R.; Cousin, L. A pseudo-penalization method for high Reynoles number unsteady flows. Appl. Numer. Math. 2008, 58, 946–954. [Google Scholar] [CrossRef]

- Kim, D.K. Thermal optimization of branched-fin heat sinks subject to a parallel flow. Int. J. Heat Mass Tranf. 2014, 77, 278–287. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, Z.; Wang, H. Numerical simulation of low-Reynolds number flows part two tandem cylinders of different diameters. Water Sci. Eng. 2013, 6, 433–445. [Google Scholar]

- Shirvan, K.M.; Mamourian, M.; Mirzakhanlari, S.; Rahimi, A.B.; Ellahi, R. Numerical study of surface radiation and combined natural convection heat transfer in a solar cavity receiver. Int. J. Numer. Methods Heat Fluid Flow 2017, 27, 2385–2399. [Google Scholar] [CrossRef]

- Saha, A.K.; Acharya, S. Parametric study of unsteady flow and heat transfer in a pin-fin heat exchanger. Int. J. Heat Mass Tranf. 2003, 46, 3815–3830. [Google Scholar] [CrossRef]

- Sharman, B.; Lien, F.S.; Davidson, L.; Norberg, C. Numerical predictions of low Reynolds number flows over two tandem circular cylinders. Int. J. Numer. Methods Fluids 2005, 47, 423–447. [Google Scholar] [CrossRef]

- Rashidi, S.; Esfahani, J.A.; Ellahi, R. Convective heat transfer and particle motion in an obstructed duct with two side by side obstacles by means of DPM model. Appl. Sci. 2017, 7, 431. [Google Scholar] [CrossRef]

- Lu, J.; Han, H.; Shi, B. A numerical study of fluid flow passes two heated/cooled square cylinders in a tandem arrangement via lattice Boltzmann method. Int. J. Heat Mass Tranf. 2012, 55, 3909–3920. [Google Scholar] [CrossRef]

- Kotcioglu, I.; Caliskan, S.; Baskaya, S. Experimental study on the heat transfer and pressure drop of a cross flow heat exchanger with different pin-fin arrays. Heat Mass Transf. 2011, 47, 1133–1142. [Google Scholar] [CrossRef]

- Shi, Z.; Dong, T. Entropy generation and optimization of laminar convective heat transfer and fluid flow in a microchannel with staggered arrays of pin fin structure with tip clearance. Energy Convers. Manag. 2015, 94, 493–504. [Google Scholar] [CrossRef]

- Chang, S.; Chen, C.; Cheng, S. Analysis of convective heat transfer improved impeller stirred tanks by the lattice Boltzmann method. Int. J. Heat Mass Tranf. 2015, 87, 568–575. [Google Scholar] [CrossRef]

- Agrawal, S.; Terrence, W.S.; North, M.; Bissell, D.; Cui, T. Heat transfer augmentation of a channel flow by active agitation and surface mounted cylindrical pin fins. Int. J. Heat Mass Tranf. 2015, 87, 557–567. [Google Scholar] [CrossRef]

- Yoon, H.S.; Chun, H.H.; Kim, J.H.; RyongPark, I.L. Flow characteristics of two rotating side-by-side circular cylinder. Comput. Fluids 2009, 38, 466–474. [Google Scholar] [CrossRef]

- Yan, Y.Y.; Zu, Y.Q. Numerical simulation of heat transfer and fluid flow past a rotating isothermal cylinder—A LBM approach. Int. J. Heat Mass Tranf. 2008, 51, 2519–2536. [Google Scholar] [CrossRef]

- Bhatnagar, P.L.; Gross, E.P.; Krook, M. A model for collision processes in gases. I. small amplitude processes in charged and neutral one-component systems. Phys. Rev. 1954, 94, 511–524. [Google Scholar] [CrossRef]

- He, X.Y.; Luo, L.S. Lattice Boltzmann model for the incompressible Navier-Stokes equation. J. Stat. Phys. 1997, 88, 927–944. [Google Scholar] [CrossRef]

- Qian, Y.H.; Dhumieres, D.; Lallemand, P. Lattice BGK models for Navier-Stokes equation. Europhys. Lett. 1992, 17, 479. [Google Scholar] [CrossRef]

- Bouzidi, M.; Firdaouss, M.; Lallemand, P. Momentum transfer of a Boltzmann-lattice fluid with boundaries. Phys. Fluids 2001, 13, 3452–3459. [Google Scholar] [CrossRef]

- Lallemand, P.; Luo, L.S. Lattice Boltzmann method for moving boundaries. J. Comput. Phys. 2003, 184, 406–421. [Google Scholar] [CrossRef]

- Ladd, A. Numerical simulations of particulate suspensions via a discretized Boltzmann equation Part 2. Numerical results. J. Fluid Mech. 1999, 271, 311–339. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Li, C.; Wu, Y.; Liu, C.; Yuan, H.; Mei, N. Numerical Simulation about Reconstruction of the Boundary Layer. Energies 2017, 10, 2074. https://doi.org/10.3390/en10122074

Li Y, Li C, Wu Y, Liu C, Yuan H, Mei N. Numerical Simulation about Reconstruction of the Boundary Layer. Energies. 2017; 10(12):2074. https://doi.org/10.3390/en10122074

Chicago/Turabian StyleLi, Yan, Chuan Li, Yajie Wu, Cong Liu, Han Yuan, and Ning Mei. 2017. "Numerical Simulation about Reconstruction of the Boundary Layer" Energies 10, no. 12: 2074. https://doi.org/10.3390/en10122074

APA StyleLi, Y., Li, C., Wu, Y., Liu, C., Yuan, H., & Mei, N. (2017). Numerical Simulation about Reconstruction of the Boundary Layer. Energies, 10(12), 2074. https://doi.org/10.3390/en10122074