Wind Turbine Loads Induced by Terrain and Wakes: An Experimental Study through Vibration Analysis and Computational Fluid Dynamics †

Abstract

1. Introduction

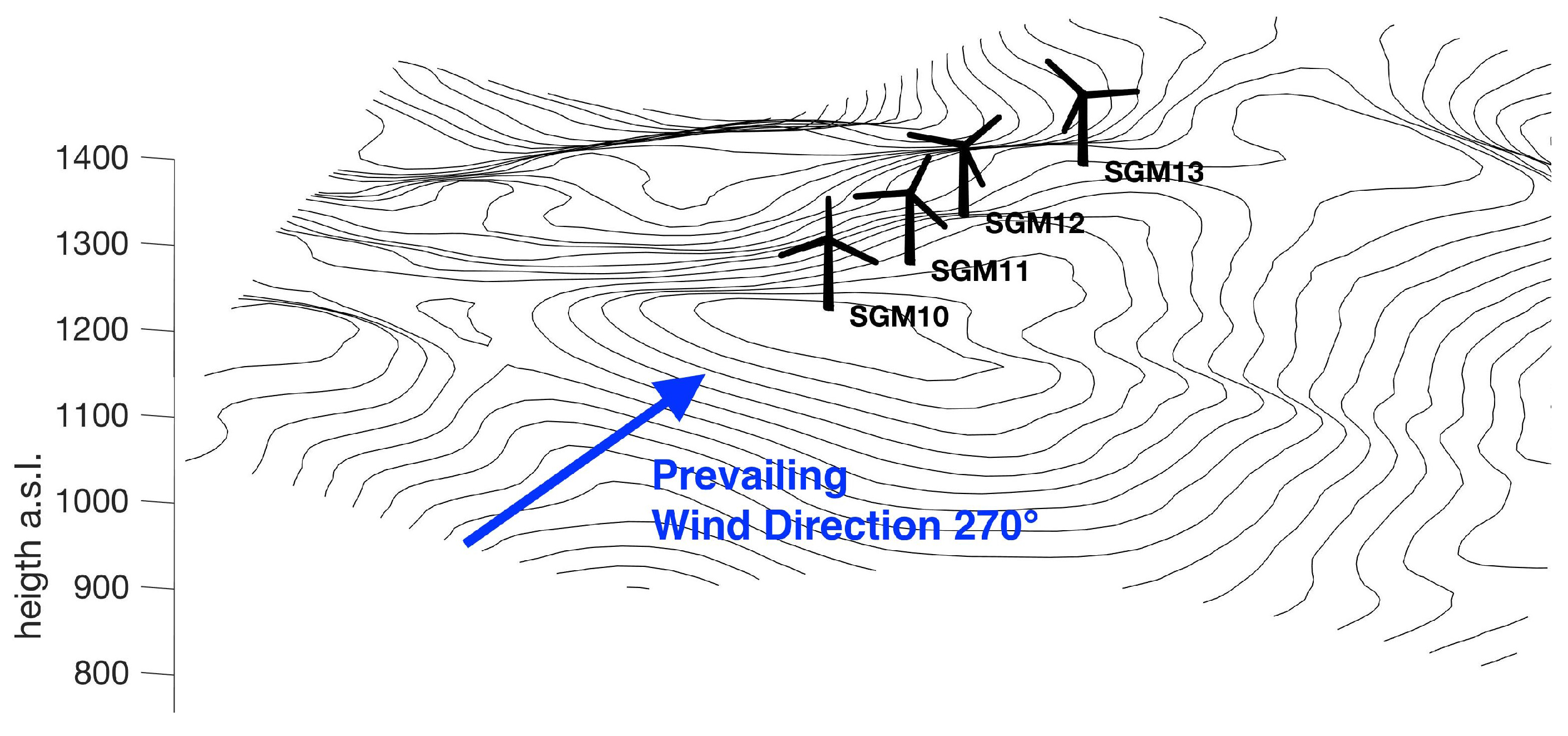

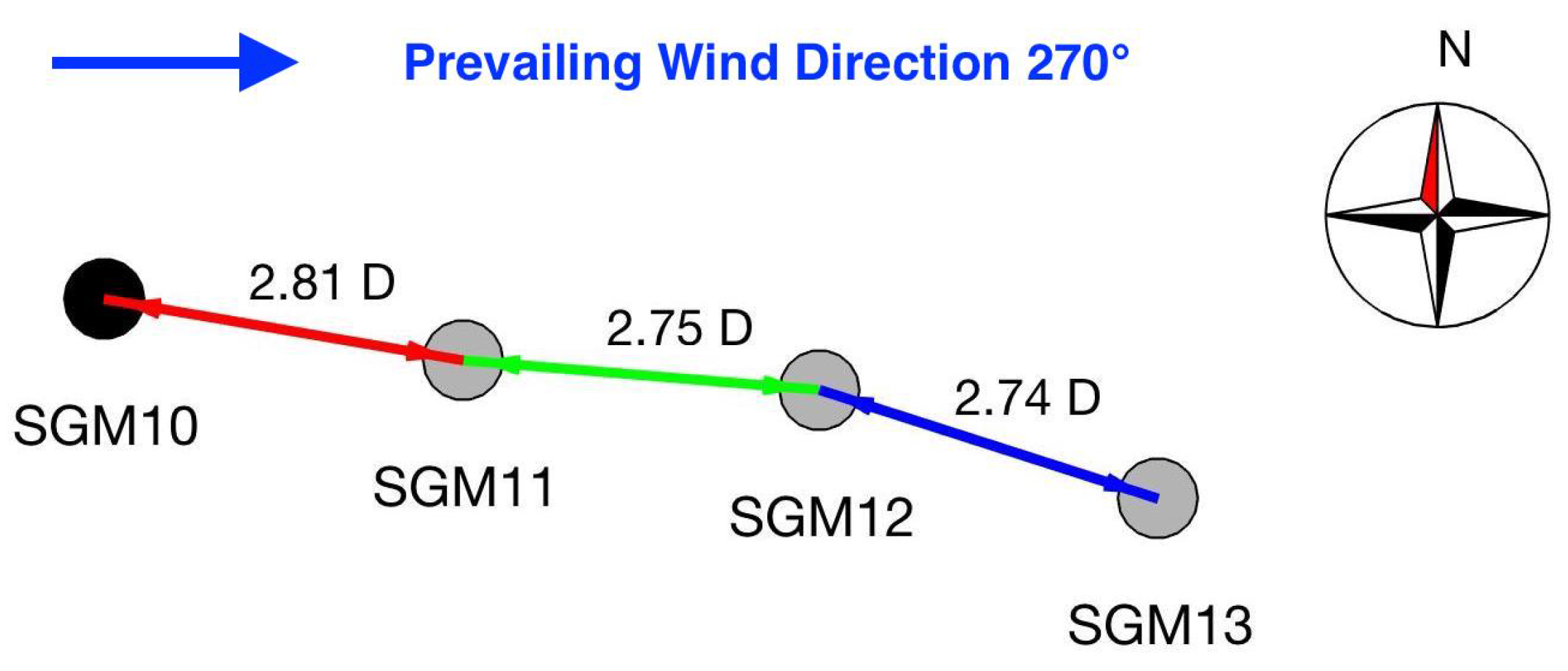

2. The Test Case and the Dataset

3. Experimental and Numerical Methods

3.1. Tower Vibration Analysis

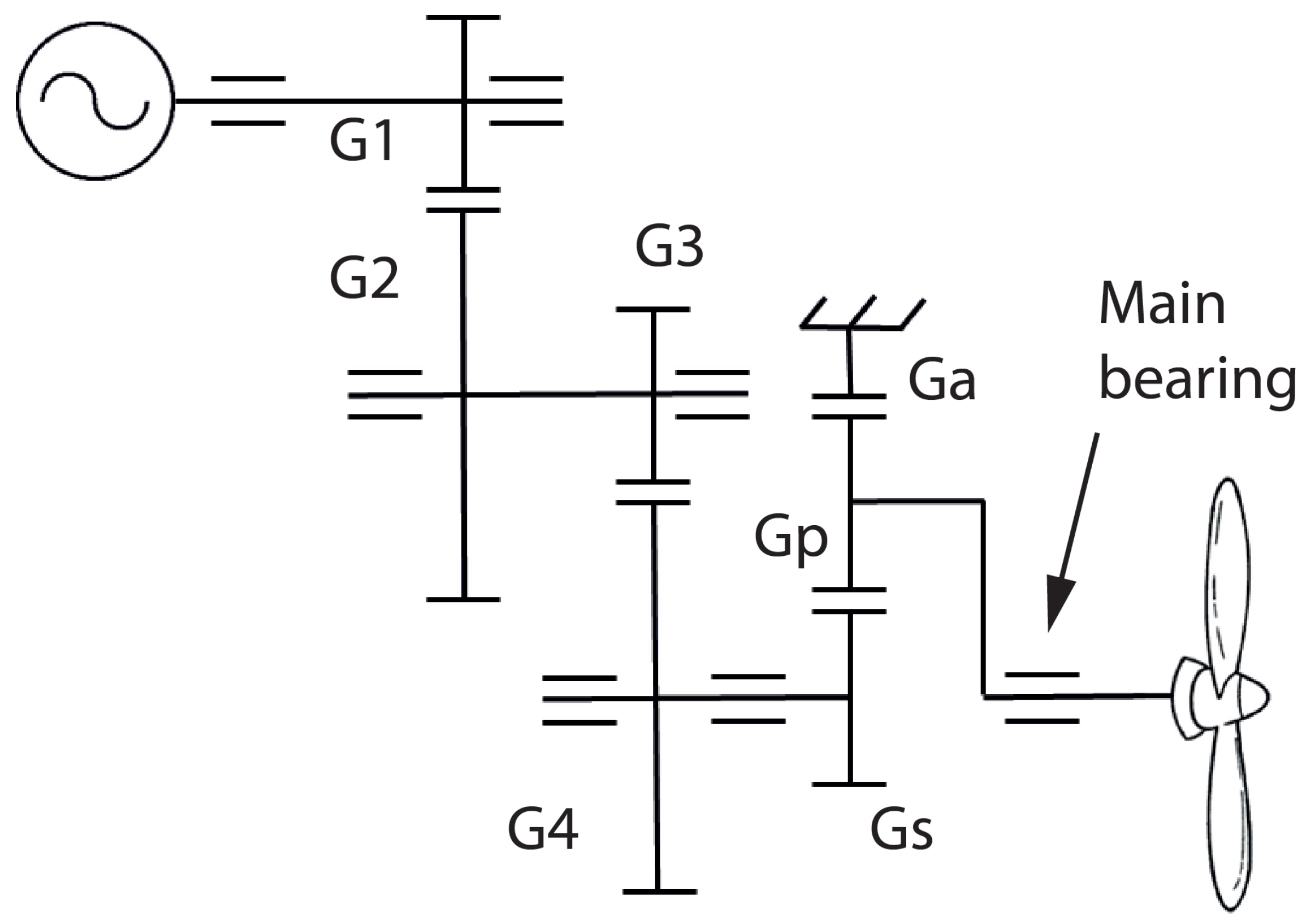

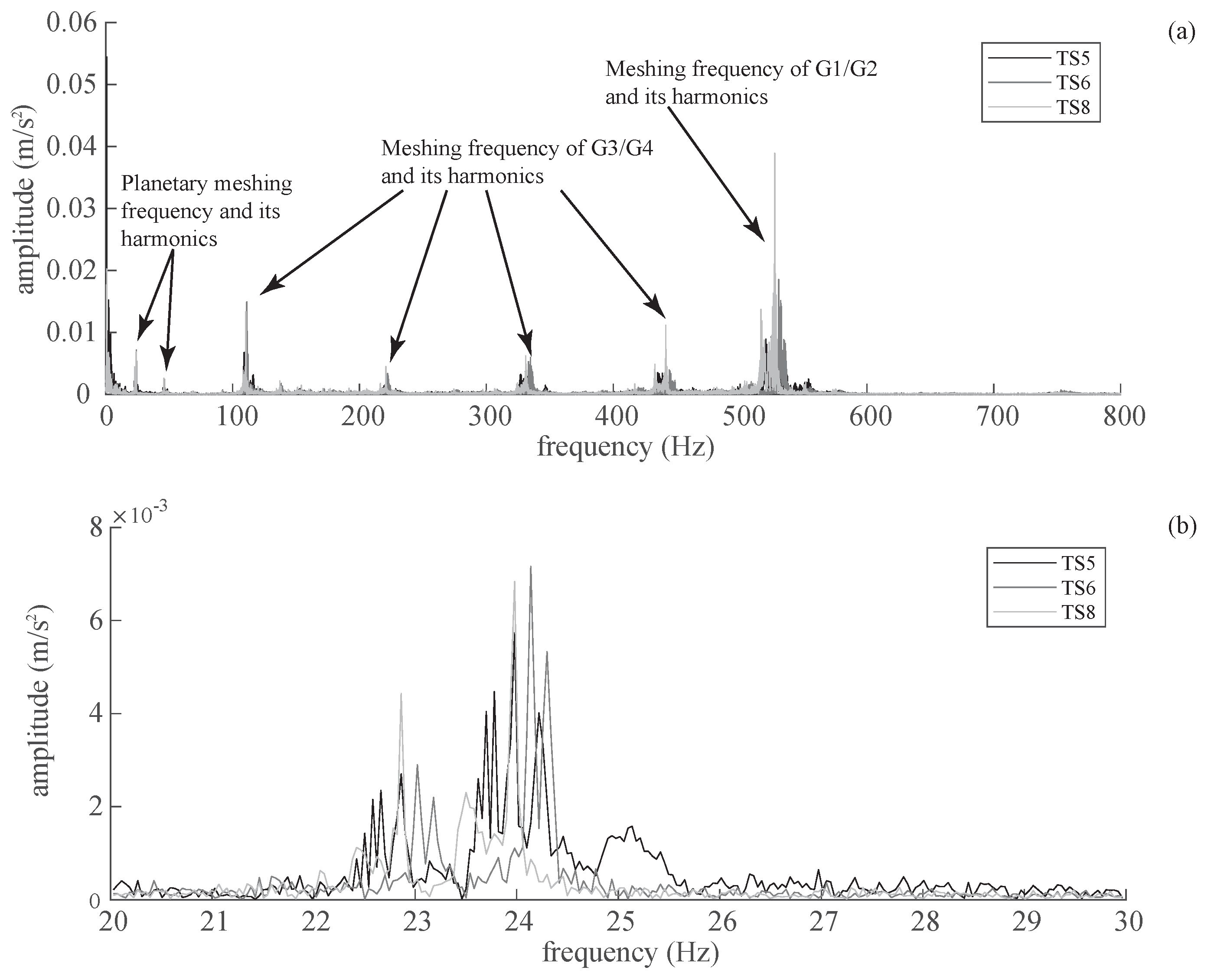

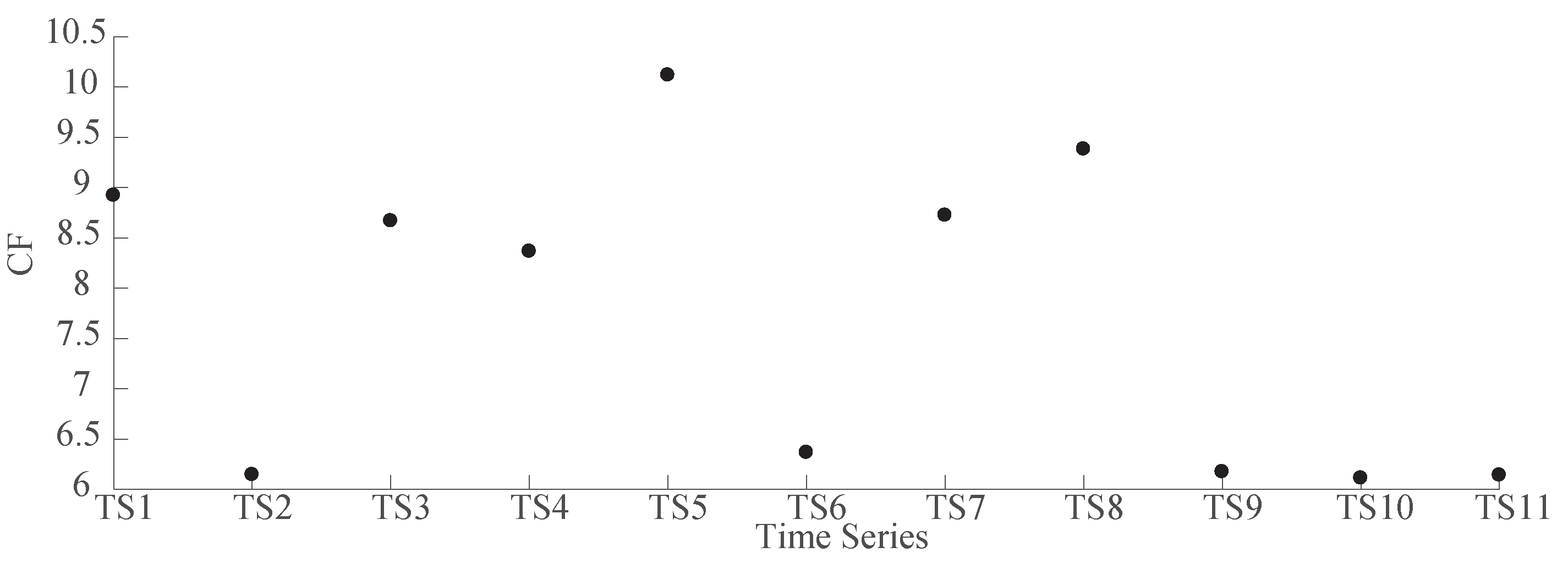

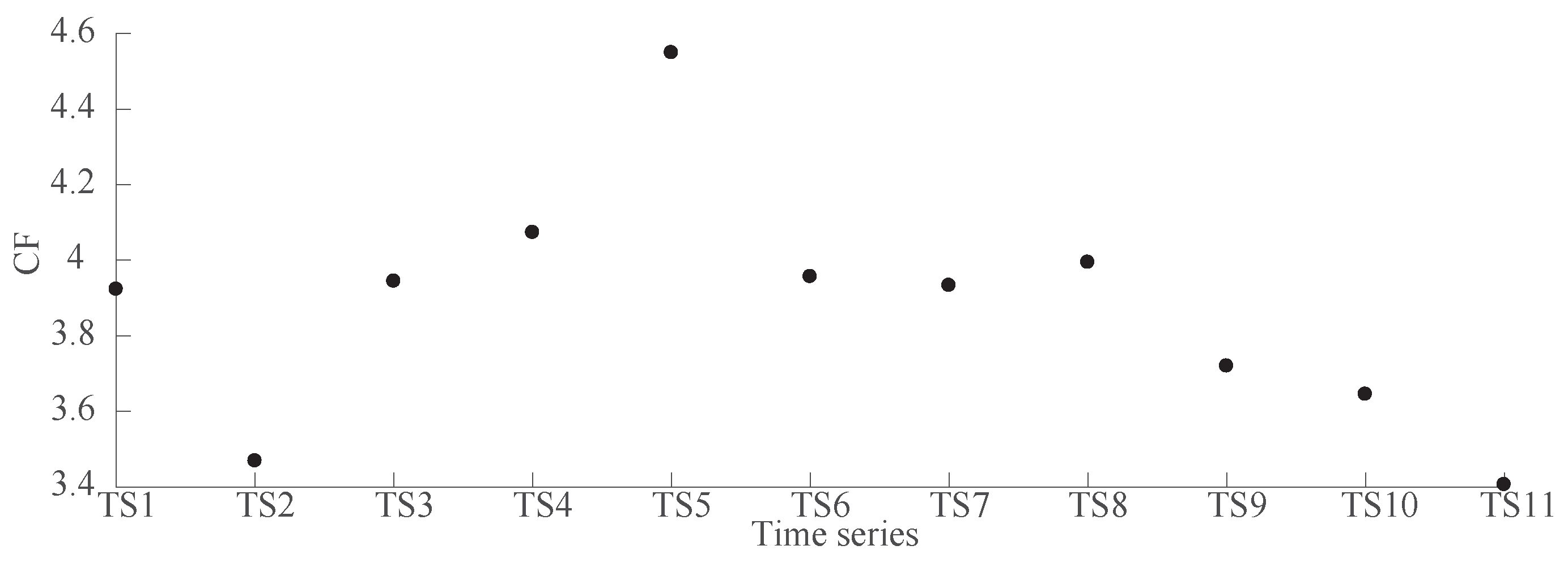

3.2. Gearbox Vibration Analysis

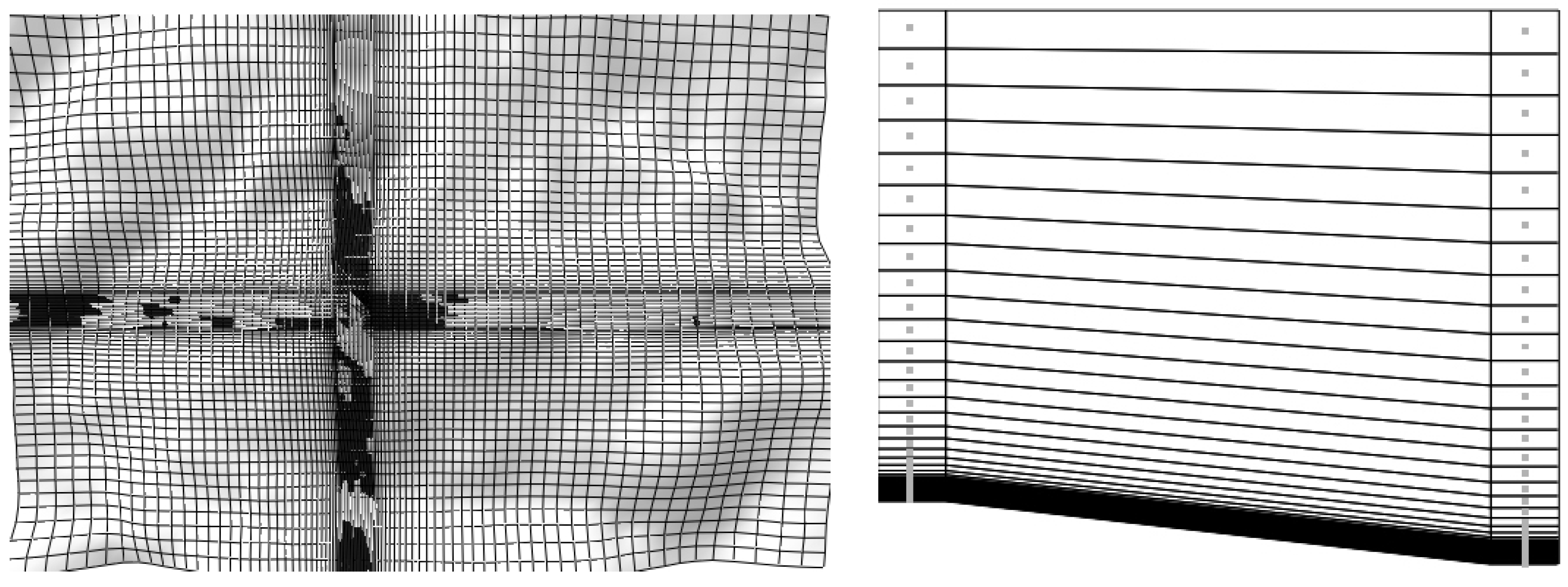

3.3. The CFD Model

4. Results

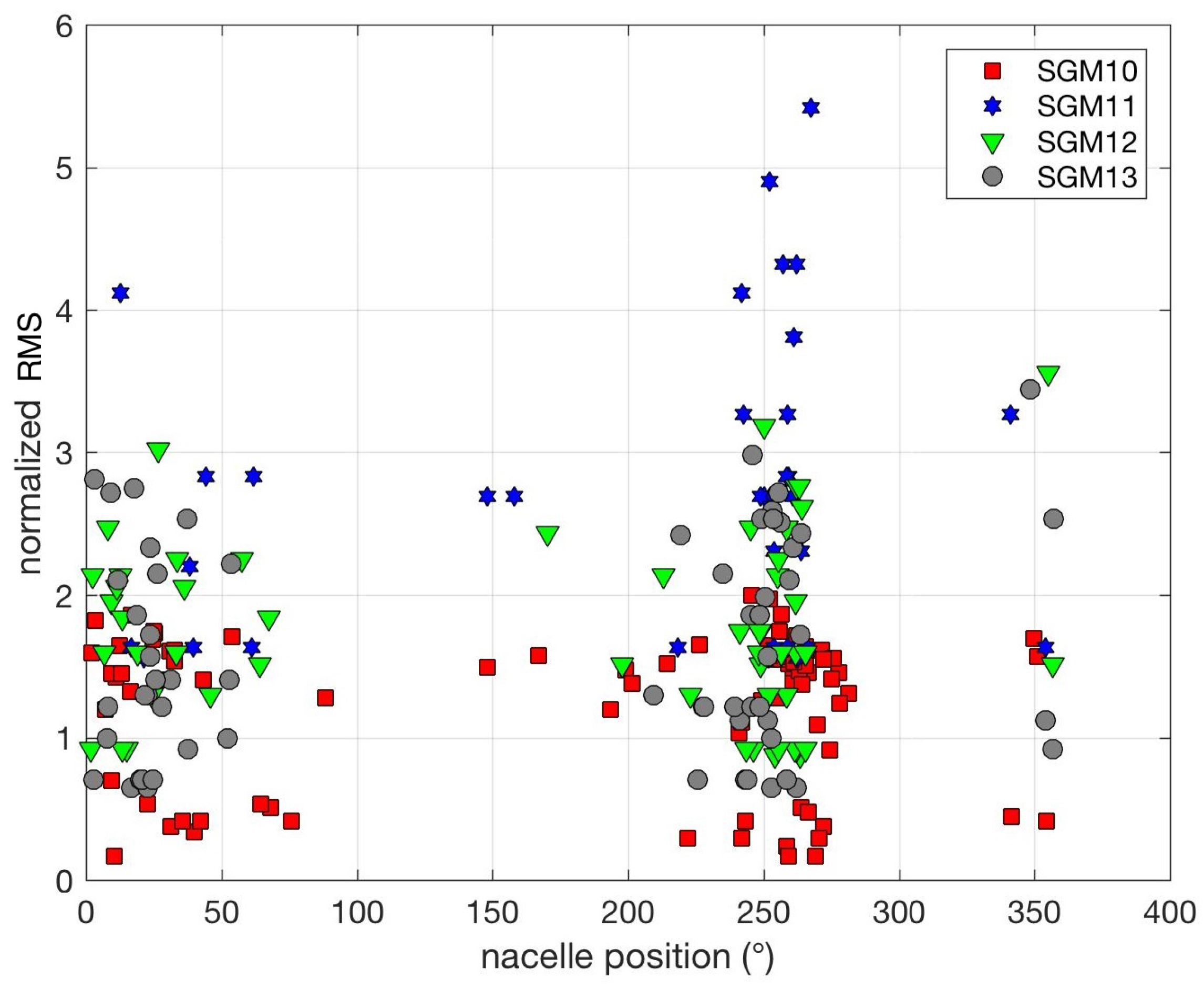

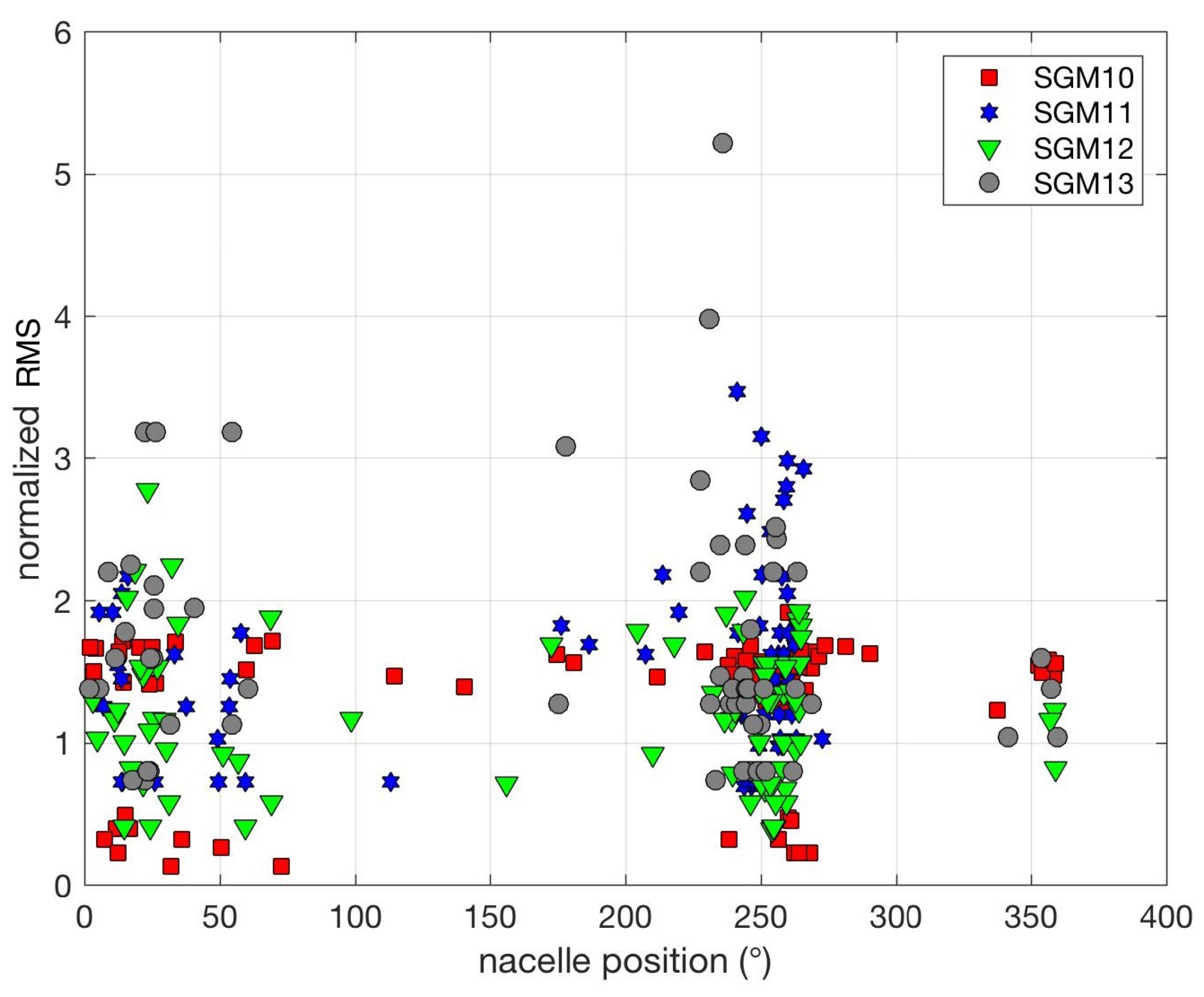

4.1. Tower Vibrations

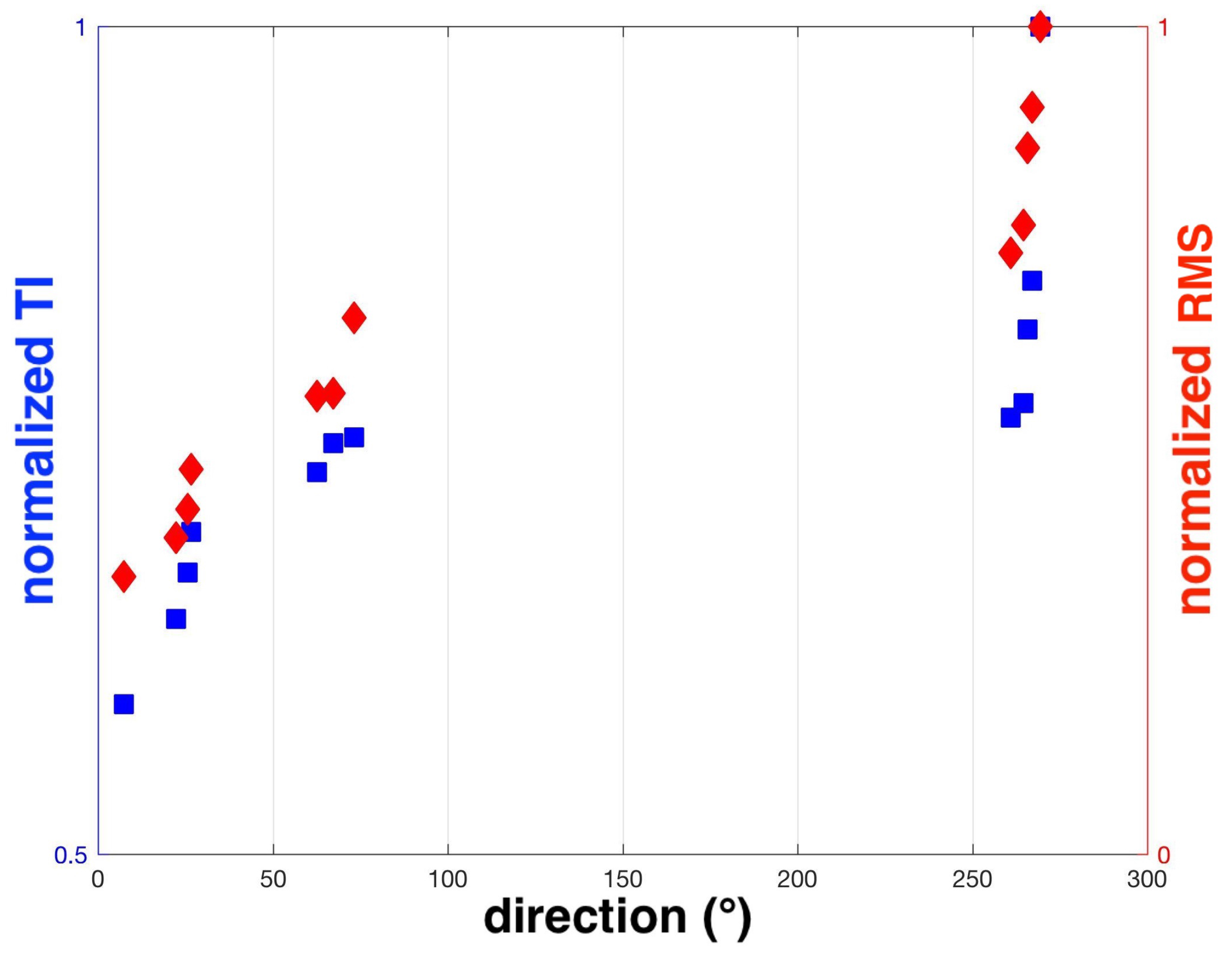

4.2. CFD

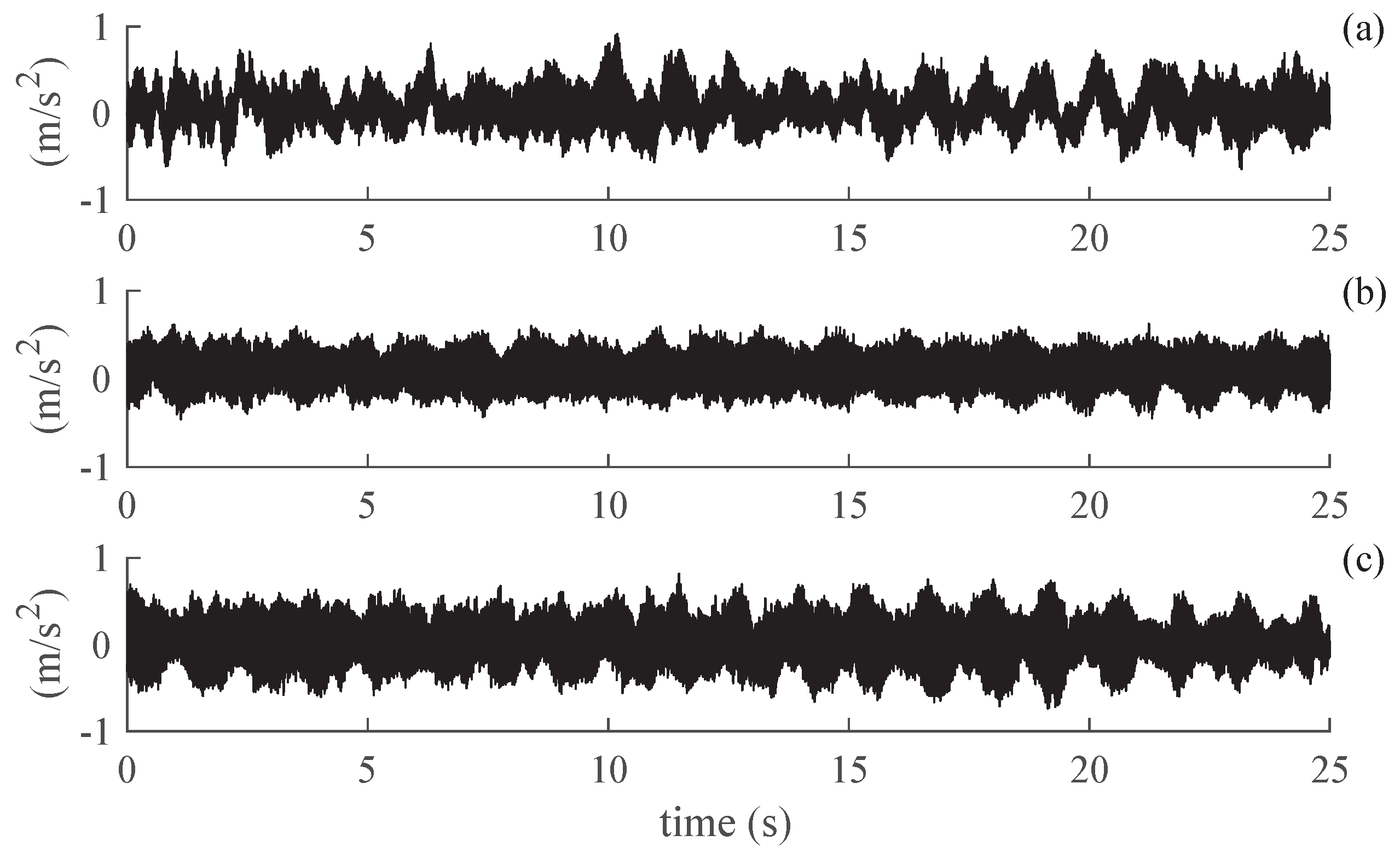

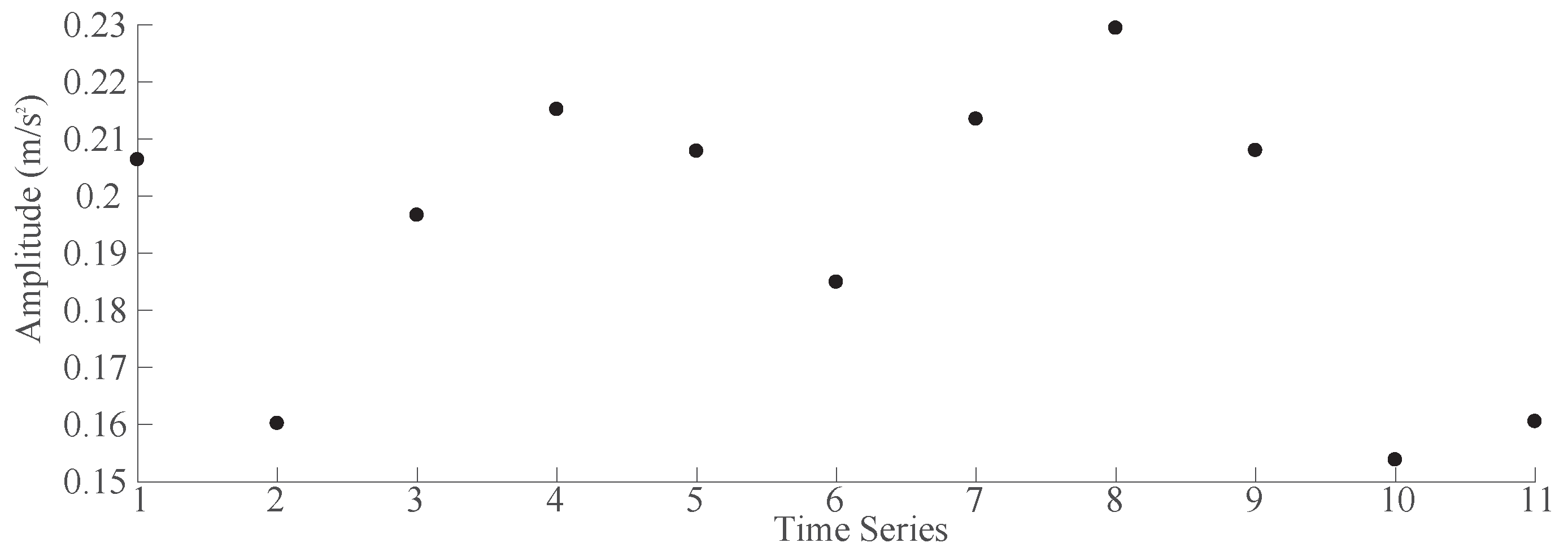

4.3. Main Bearing

- Step 1:

- the (very) low frequency components have been removed by using a high-pass filter;

- Step 2:

- three gear mesh harmonics have been separately filtered by means of a band-pass filter and considering eight sidebands (four each side);

- Step 3:

- the instantaneous phase is computed for each filtered gear mesh component by means of the Hilbert transform;

- Step 4:

- the overall CF is computed by taking the sum of the individual CFs estimated from each filtered gear mesh component.

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Philibert, C.; Holttinen, H. Wind Energy Technology Roadmap. In Technical Report; OECD/IEA: Paris, France, 2013. [Google Scholar]

- Marti, I. IEA Wind TCP 2016 Annual Report. In Technical Report; IEA: Paris, France, 2017. [Google Scholar]

- Vermeulen, P. An experimental analysis of wind turbine wakes. In Proceedings of the 3rd International Symposium on Wind Energy Systems, Lyngby, Denmark, 26–29 August 1980; pp. 431–450. [Google Scholar]

- Shen, W.Z.; Sørensen, J. Numerical modeling of wind turbine wakes. J. Fluids Eng. 2002, 124, 393–399. [Google Scholar]

- Barthelmie, R.J.; Hansen, K.; Frandsen, S.T.; Rathmann, O.; Schepers, J.; Schlez, W.; Phillips, J.; Rados, K.; Zervos, A.; Politis, E.; et al. Modelling and measuring flow and wind turbine wakes in large wind farms offshore. Wind Energy 2009, 12, 431–444. [Google Scholar] [CrossRef]

- Barthelmie, R.J.; Pryor, S.C.; Frandsen, S.T.; Hansen, K.S.; Schepers, J.; Rados, K.; Schlez, W.; Neubert, A.; Jensen, L.; Neckelmann, S. Quantifying the impact of wind turbine wakes on power output at offshore wind farms. J. Atmos. Ocean. Technol. 2010, 27, 1302–1317. [Google Scholar] [CrossRef]

- Yang, W.; Tavner, P.J.; Crabtree, C.J.; Feng, Y.; Qiu, Y. Wind turbine condition monitoring: Technical and commercial challenges. Wind Energy 2014, 17, 673–693. [Google Scholar] [CrossRef]

- Wilkinson, M.; Darnell, B.; van Delft, T.; Harman, K. Comparison of methods for wind turbine condition monitoring with SCADA data. IET Renew. Power Gener. 2014, 8, 390–397. [Google Scholar] [CrossRef]

- Windpower Monthly. Exploring the Innovations, Challenges and Potential of the Products and Services that Keep Wind Turbines Operating; Windpower Monthly, Haymarket Media Group: London, UK, 2013. [Google Scholar]

- Feng, Y.; Qiu, Y.; Crabtree, C.J.; Long, H.; Tavner, P.J. Monitoring wind turbine gearboxes. Wind Energy 2013, 16, 728–740. [Google Scholar] [CrossRef]

- Wang, Y.; Infield, D. Supervisory control and data acquisition data-based non-linear state estimation technique for wind turbine gearbox condition monitoring. IET Renew. Power Gener. 2013, 7, 350–358. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Z.; Long, H.; Xu, J.; Liu, R. Wind turbine gearbox failure identification with deep neural networks. IEEE Trans. Ind. Inf. 2017, 13, 1360–1368. [Google Scholar] [CrossRef]

- Zhang, Z.; Verma, A.; Kusiak, A. Fault analysis and condition monitoring of the wind turbine gearbox. IEEE Trans. Energy Convers. 2012, 27, 526–535. [Google Scholar] [CrossRef]

- Hu, A.; Yan, X.; Xiang, L. A new wind turbine fault diagnosis method based on ensemble intrinsic time-scale decomposition and WPT-fractal dimension. Renew. Energy 2015, 83, 767–778. [Google Scholar] [CrossRef]

- Zhao, H.; Li, L. Fault diagnosis of wind turbine bearing based on variational mode decomposition and Teager energy operator. IET Renew. Power Gener. 2016, 11, 453–460. [Google Scholar] [CrossRef]

- Peeters, C.; Guillaume, P.; Helsen, J. Vibration-based bearing fault detection for operations and maintenance cost reduction in wind energy. Renew. Energy 2017, 116, 74–87. [Google Scholar] [CrossRef]

- Skrimpas, G.A.; Ursin, T.; Sweeney, C.; Marhadi, K.; Mijatovic, N.; Holboell, J. Residual signal feature extraction for gearbox planetary stage fault detection. Wind Energy 2017. [Google Scholar] [CrossRef]

- Karlina-Barber, S.; Mechler, S.; Nitschke, M. The effect of wakes on the fatigue damage of wind turbine components over their entire lifetime using short-term load measurements. J. Phys. Conf. Ser. 2016, 753, 072022. [Google Scholar] [CrossRef]

- Vera-Tudela, L.; Kühn, M. Analysing wind turbine fatigue load prediction: The impact of wind farm flow conditions. Renew. Energy 2017, 107, 352–360. [Google Scholar] [CrossRef]

- Van Dijk, M.T.; van Wingerden, J.W.; Ashuri, T.; Li, Y. Wind farm multi-objective wake redirection for optimizing power production and loads. Energy 2017, 121, 561–569. [Google Scholar] [CrossRef]

- Wei, S.; Han, Q.; Peng, Z.; Chu, F. Dynamic analysis of wind turbine gearboxes with unknown-but-bounded parameters under random wind excitation. IET Renew. Power Gener. 2016, 11, 433–442. [Google Scholar] [CrossRef]

- Bielecki, A.; Barszcz, T.; Wójcik, M. Modelling of a chaotic load of wind turbines drivetrain. Mech. Syst. Signal Process. 2015, 54, 491–505. [Google Scholar] [CrossRef]

- Castellani, F.; Astolfi, D.; Mana, M.; Piccioni, E.; Becchetti, M.; Terzi, L. Investigation of terrain and wake effects on the performance of wind farms in complex terrain using numerical and experimental data. Wind Energy 2017, 20, 1277–1289. [Google Scholar]

- Gasch, R.; Twele, J. Wind Power Plants: Fundamentals, Design, Construction and Operation; Springer Science & Business Media: Berlin, Germany, 2011. [Google Scholar]

- Coats, M.; Randall, R. Single and multi-stage phase demodulation based order-tracking. Mech. Syst. Signal Process. 2014, 44, 86–117. [Google Scholar] [CrossRef]

- Sawalhi, N.; Randall, R.B. Gear parameter identification in a wind turbine gearbox using vibration signals. Mech. Syst. Signal Process. 2014, 42, 368–376. [Google Scholar] [CrossRef]

- Assaad, B.; Eltabach, M.; Antoni, J. Vibration based condition monitoring of a multistage epicyclic gearbox in lifting cranes. Mech. Syst. Signal Process. 2014, 42, 351–367. [Google Scholar] [CrossRef]

- Moreno, P.; Gravdahl, A.; Romero, M. Wind flow over complex terrain: Application of linear and CFD models. In Proceedings of the European Wind Energy Conference and Exhibition, Madrid, Spain, 16–19 June 2003; pp. 16–19. [Google Scholar]

- Dhunny, A.; Lollchund, M.; Rughooputh, S. Wind energy evaluation for a highly complex terrain using Computational Fluid Dynamics (CFD). Renew. Energy 2017, 101, 1–9. [Google Scholar] [CrossRef]

- Berg, J.; Troldborg, N.; Sørensen, N.; Patton, E.; Sullivan, P. Large-Eddy Simulation of turbine wake in complex terrain. J. Phys. Conf. Ser. 2017, 854, 012003. [Google Scholar] [CrossRef]

- Nedjari, H.D.; Guerri, O.; Saighi, M. CFD wind turbines wake assessment in complex topography. Energy Convers. Manag. 2017, 138, 224–236. [Google Scholar] [CrossRef]

- Murali, A.; Rajagopalan, R. Numerical simulation of multiple interacting wind turbines on a complex terrain. J. Wind Eng. Ind. Aerodyn. 2017, 162, 57–72. [Google Scholar] [CrossRef]

- Peralta, C.; Nugusse, H.; Kokilavani, S.; Schmidt, J.; Stoevesandt, B. Validation of the simpleFoam (RANS) solver for the atmospheric boundary layer in complex terrain. In ITM Web of Conferences; EDP Sciences: In Lees, France, 2014; Volume 2, p. 01002. [Google Scholar]

- Abdi, D.S.; Bitsuamlak, G.T. Wind flow simulations on idealized and real complex terrain using various turbulence models. Adv. Eng. Softw. 2014, 75, 30–41. [Google Scholar] [CrossRef]

- Abdi, D.; Bitsuamlak, G.T. Numerical evaluation of the effect of multiple roughness changes. Wind Struct. 2014, 19, 585–601. [Google Scholar] [CrossRef]

- Castellani, F.; Astolfi, D.; Terzi, L.; Hansen, K.S.; Rodrigo, J.S. Analysing wind farm efficiency on complex terrains. J. Phys. Conf. Ser. 2014, 524, 012142. [Google Scholar] [CrossRef]

- Bowen, A.J.; Mortensen, N.G. WAsP Prediction Errors Due to Site Orography; Risø National Laboratories: Roskilde, Denmark, 2004. [Google Scholar]

- Mortensen, N.G.; Landberg, L.; Troen, I.; Lundtang Petersen, E.; Rathmann, O.; Nielsen, M. Wind Atlas Analysis and Application program (WAsP): Vol. 3: Utility Programs; Technical Report; Risø National Laboratory: Roskilde, Denmark, 1999. [Google Scholar]

- Feldman, M. Hilbert transform in vibration analysis. Mech. Syst. Signal Process. 2011, 25, 735–802. [Google Scholar] [CrossRef]

- Braun, S. The synchronous (time domain) average revisited. Mech. Syst. Signal Process. 2011, 25, 1087–1102. [Google Scholar] [CrossRef]

- Tibaldi, C.; Henriksen, L.C.; Hansen, M.H.; Bak, C. Wind turbine fatigue damage evaluation based on a linear model and a spectral method. Wind Energy 2016, 19, 1289–1306. [Google Scholar] [CrossRef]

- Kim, S.H.; Shin, H.K.; Joo, Y.C.; Kim, K.H. A study of the wake effects on the wind characteristics and fatigue loads for the turbines in a wind farm. Renew. Energy 2015, 74, 536–543. [Google Scholar] [CrossRef]

| Number of Sensors | Direction | |

|---|---|---|

| main bearing | 1 | radial |

| gearbox | 3 | radial |

| generator bearing | 1 | radial |

| tower | 1 | axial and traversal |

| Feature | Set Up |

|---|---|

| Number of cells in the x direction | 104 |

| Number of cells in the y direction | 90 |

| Number of cells in the z direction | 61 |

| Resolution in the x direction | 3.1 m. min. to 66.9 m. max. |

| Resolution in the y direction | 3.1 m. min. to 52 m. max. |

| Resolution in the z direction | 3.1 m. min. to 159.8 m. max. |

| Extension of the domain in the x direction | 2500 m. |

| Extension of the domain in the y direction | 1700 m. |

| Extension of the domain in the z direction | 2380 m. |

| Boundary layer height | 400 m. |

| Speed above boundary layer | 16 m/s |

| Top boundary conditions | Fixed pressure |

| Solver | General Collocated Velocity (GCV) |

| Turbulence model | RNG (Re-Normalisation Group) k- |

| Time-Series (TS) | Active Power (kW) | Generator Rotation Speed (rpm) | Yaw Position (deg) |

|---|---|---|---|

| TS1 | 2303 | 1463 | 252 |

| TS2 | 2309 | 1456 | 244 |

| TS3 | 2286 | 1444 | 246 |

| TS4 | 2279 | 1441 | 354 |

| TS5 | 2294 | 1446 | 265 |

| TS6 | 2312 | 1453 | 255 |

| TS7 | 2308 | 1451 | 25 |

| TS8 | 2224 | 1431 | 9 |

| TS9 | 2310 | 1458 | 250 |

| TS10 | 2333 | 1458 | 7 |

| TS11 | 2294 | 1473 | 29 |

| Time-Series (TS) | Active Power (kW) | Generator Rotation Speed (rpm) | Yaw Position (deg) | Time (hh:mm) |

|---|---|---|---|---|

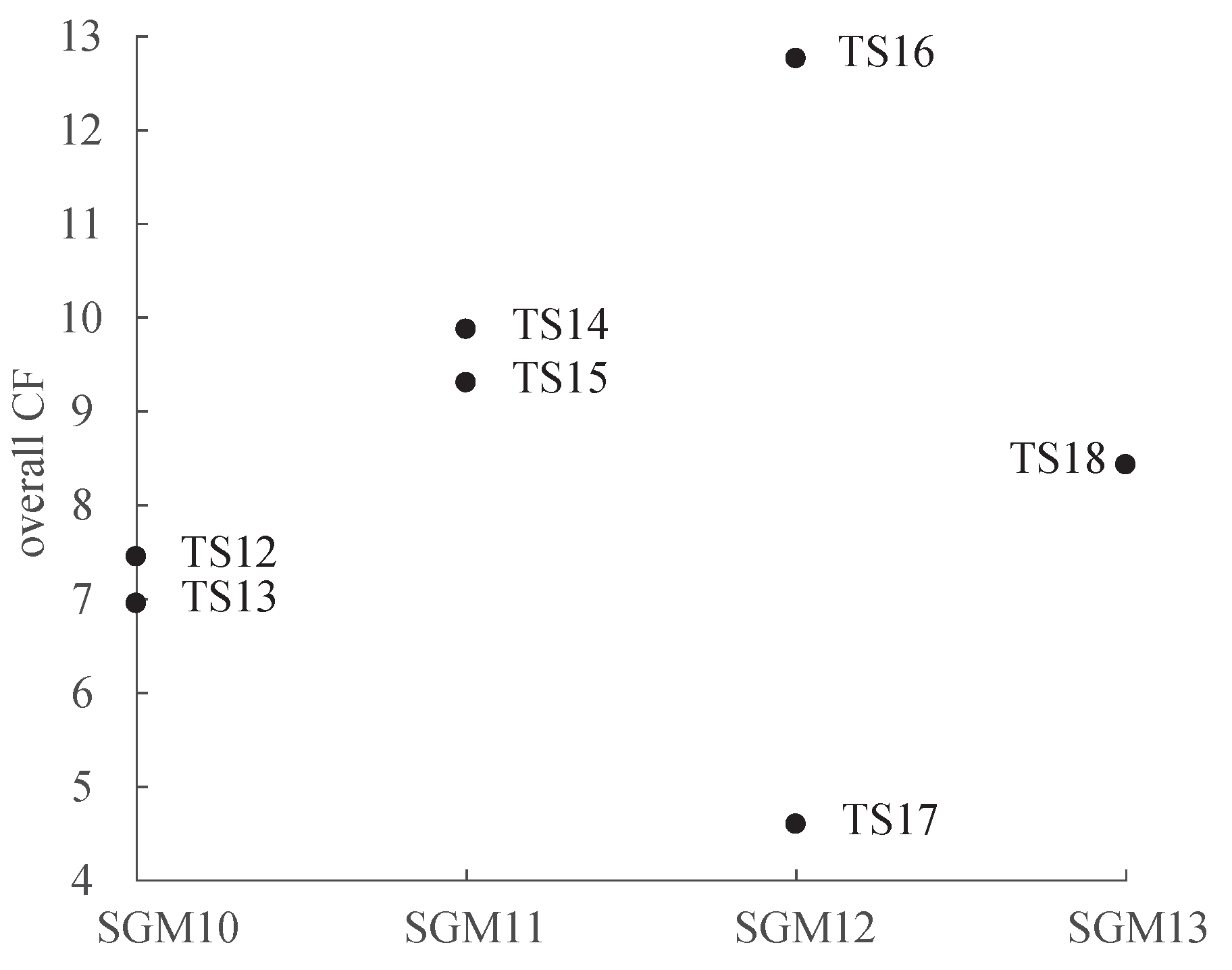

| TS12 (SGM10) | 2313 | 1467 | 254 | 20:14 |

| TS13 (SGM10) | 2303 | 1448 | 254 | 20:14 |

| TS14 (SGM11) | 2321 | 1461 | 250 | 20:06 |

| TS15 (SGM11) | 2310 | 1460 | 250 | 20:06 |

| TS16 (SGM12) | 2326 | 1475 | 250 | 20:19 |

| TS17 (SGM12) | 2295 | 1476 | 250 | 20:19 |

| TS18 (SGM13) | 2307 | 1452 | 243 | 20:06 |

| Gear Pair | Meshing Frequency (Hz) |

|---|---|

| G1/G2 | 530.13 |

| G3/G4 | 110.96 |

| Planetary | 22.98 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castellani, F.; Buzzoni, M.; Astolfi, D.; D’Elia, G.; Dalpiaz, G.; Terzi, L. Wind Turbine Loads Induced by Terrain and Wakes: An Experimental Study through Vibration Analysis and Computational Fluid Dynamics. Energies 2017, 10, 1839. https://doi.org/10.3390/en10111839

Castellani F, Buzzoni M, Astolfi D, D’Elia G, Dalpiaz G, Terzi L. Wind Turbine Loads Induced by Terrain and Wakes: An Experimental Study through Vibration Analysis and Computational Fluid Dynamics. Energies. 2017; 10(11):1839. https://doi.org/10.3390/en10111839

Chicago/Turabian StyleCastellani, Francesco, Marco Buzzoni, Davide Astolfi, Gianluca D’Elia, Giorgio Dalpiaz, and Ludovico Terzi. 2017. "Wind Turbine Loads Induced by Terrain and Wakes: An Experimental Study through Vibration Analysis and Computational Fluid Dynamics" Energies 10, no. 11: 1839. https://doi.org/10.3390/en10111839

APA StyleCastellani, F., Buzzoni, M., Astolfi, D., D’Elia, G., Dalpiaz, G., & Terzi, L. (2017). Wind Turbine Loads Induced by Terrain and Wakes: An Experimental Study through Vibration Analysis and Computational Fluid Dynamics. Energies, 10(11), 1839. https://doi.org/10.3390/en10111839