Kiwi Clear‐Cut: First Evaluation of Recovered Biomass for Energy Production

Abstract

:1. Introduction

2. Materials and Methods

2.1. Dendrometric Analysis

2.2. Tree Cutting and Chipping

2.3. Working Time and Productivity

2.4. Woodchip Quality

2.5. Energy Consumption

2.6. Economic Evaluation

3. Results

3.1. Dendrometric Analysis

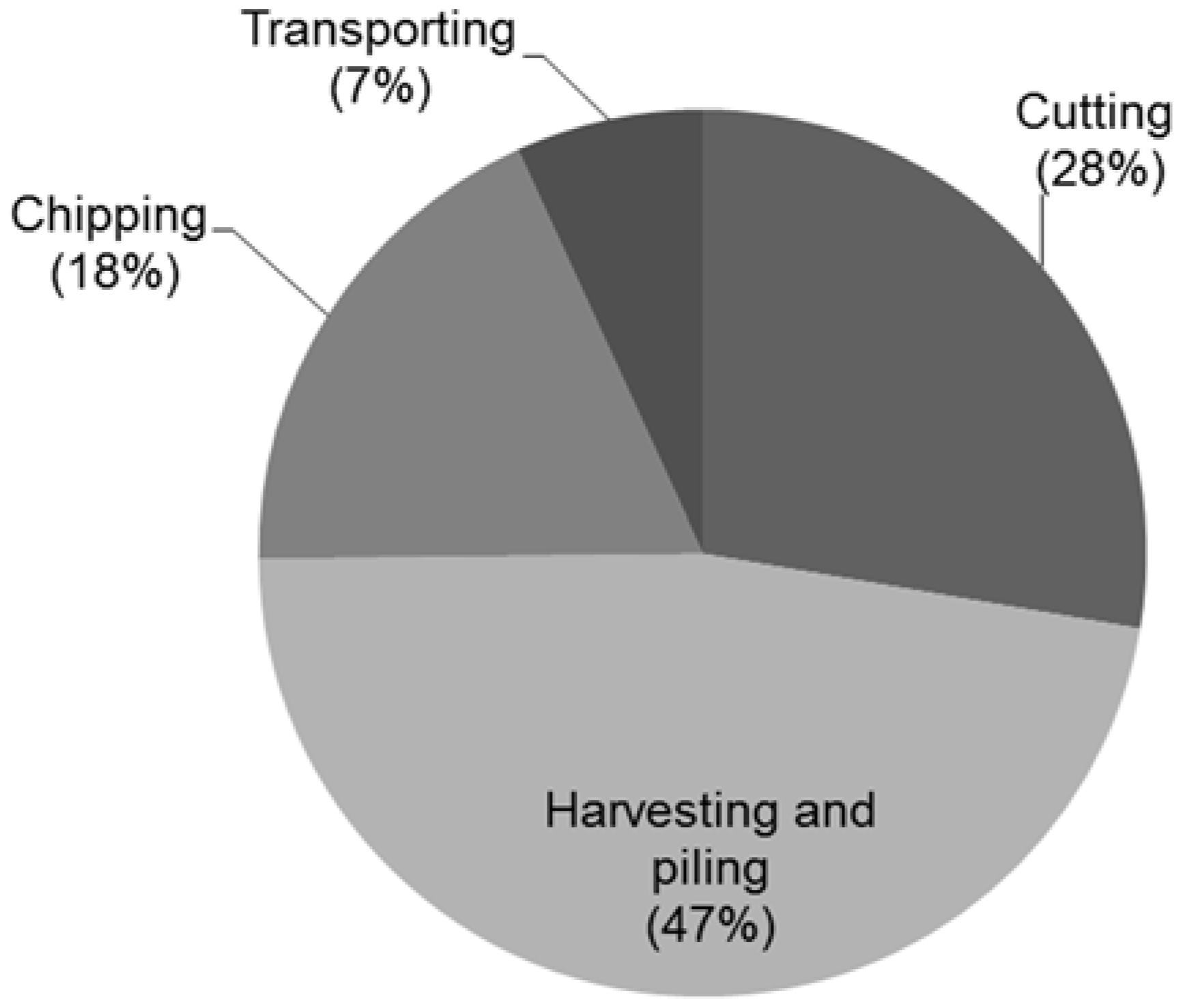

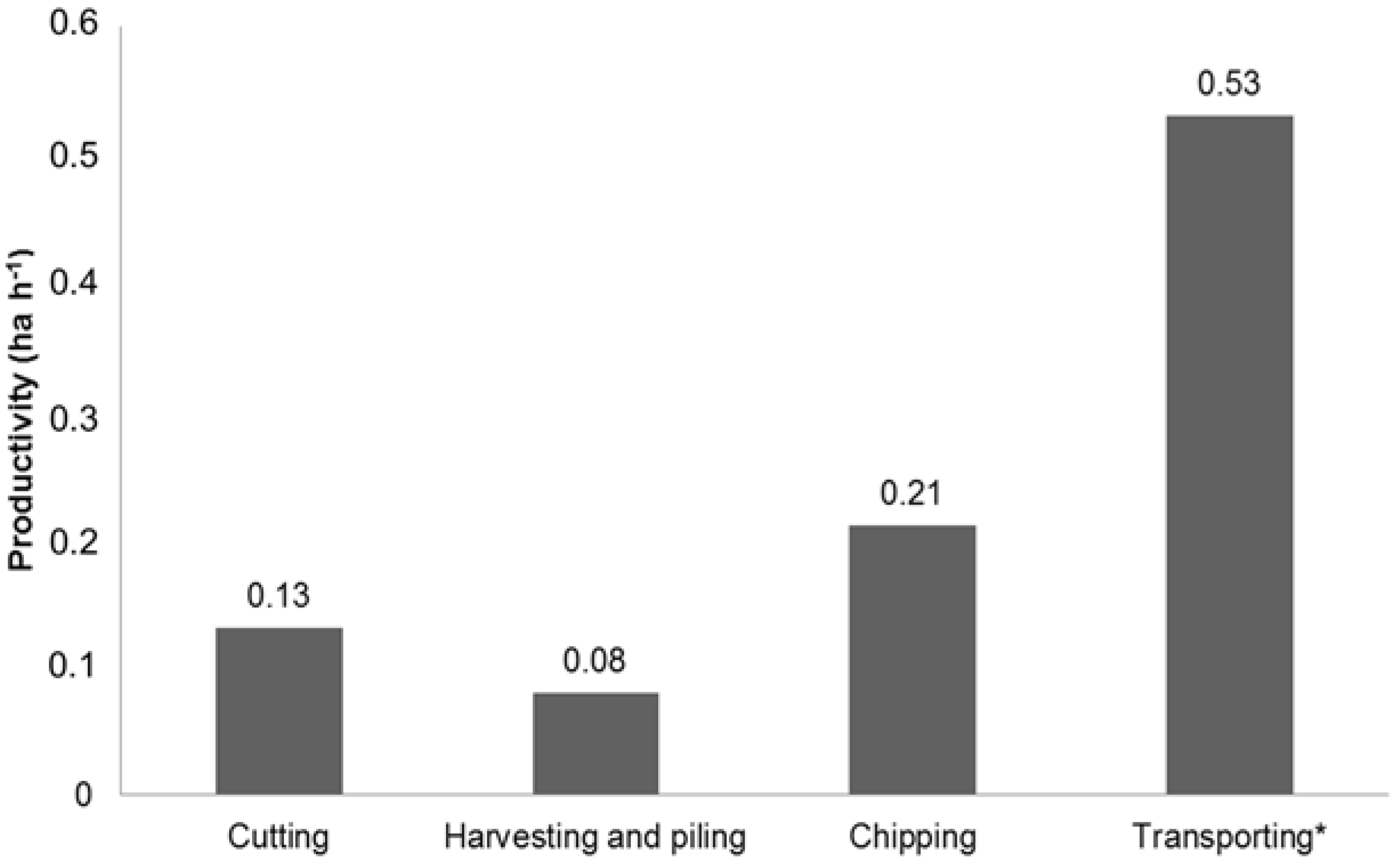

3.2. Working Time and Productivity

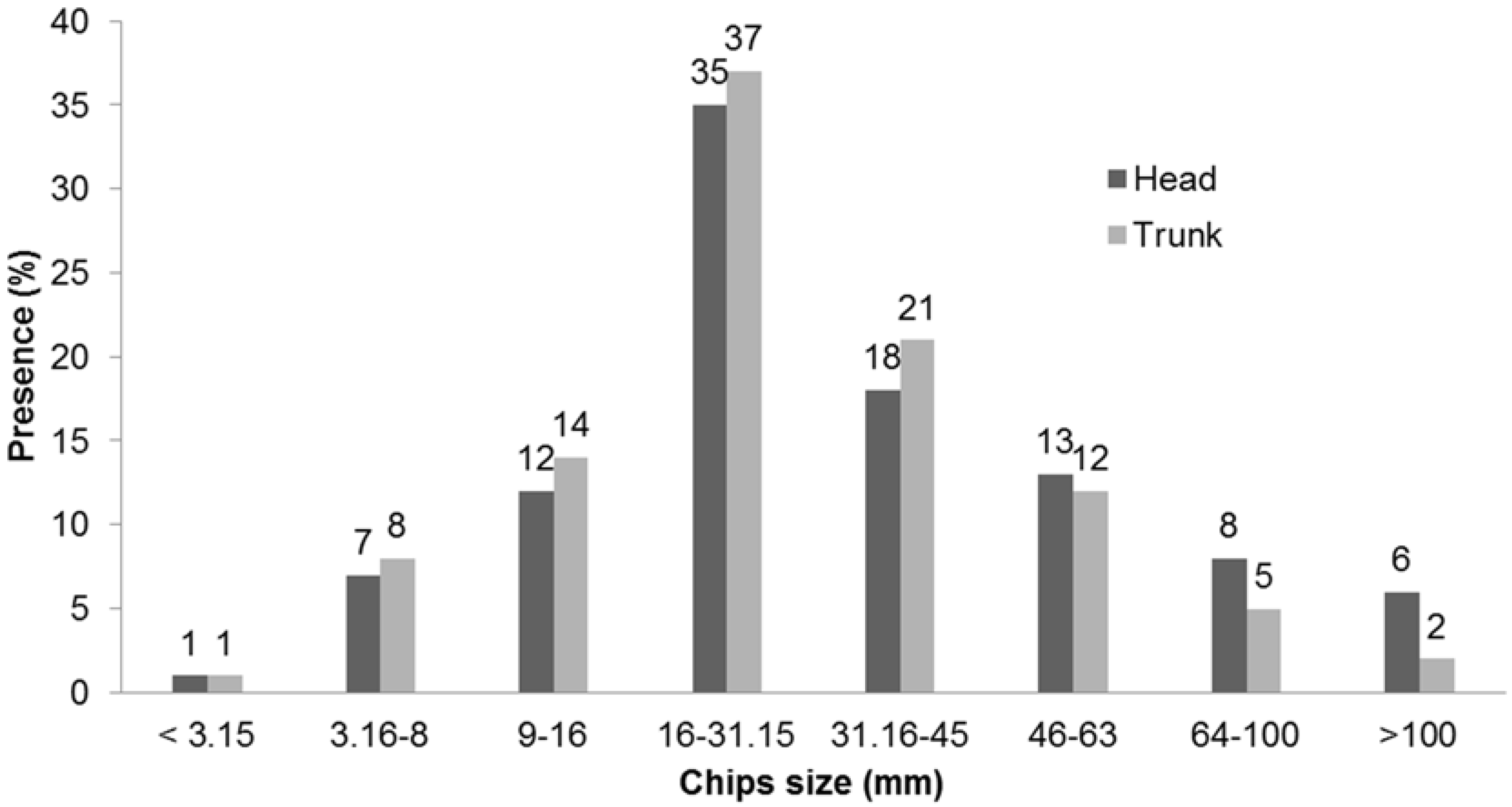

3.3. Woodchip Quality

3.4. Energy Consumption

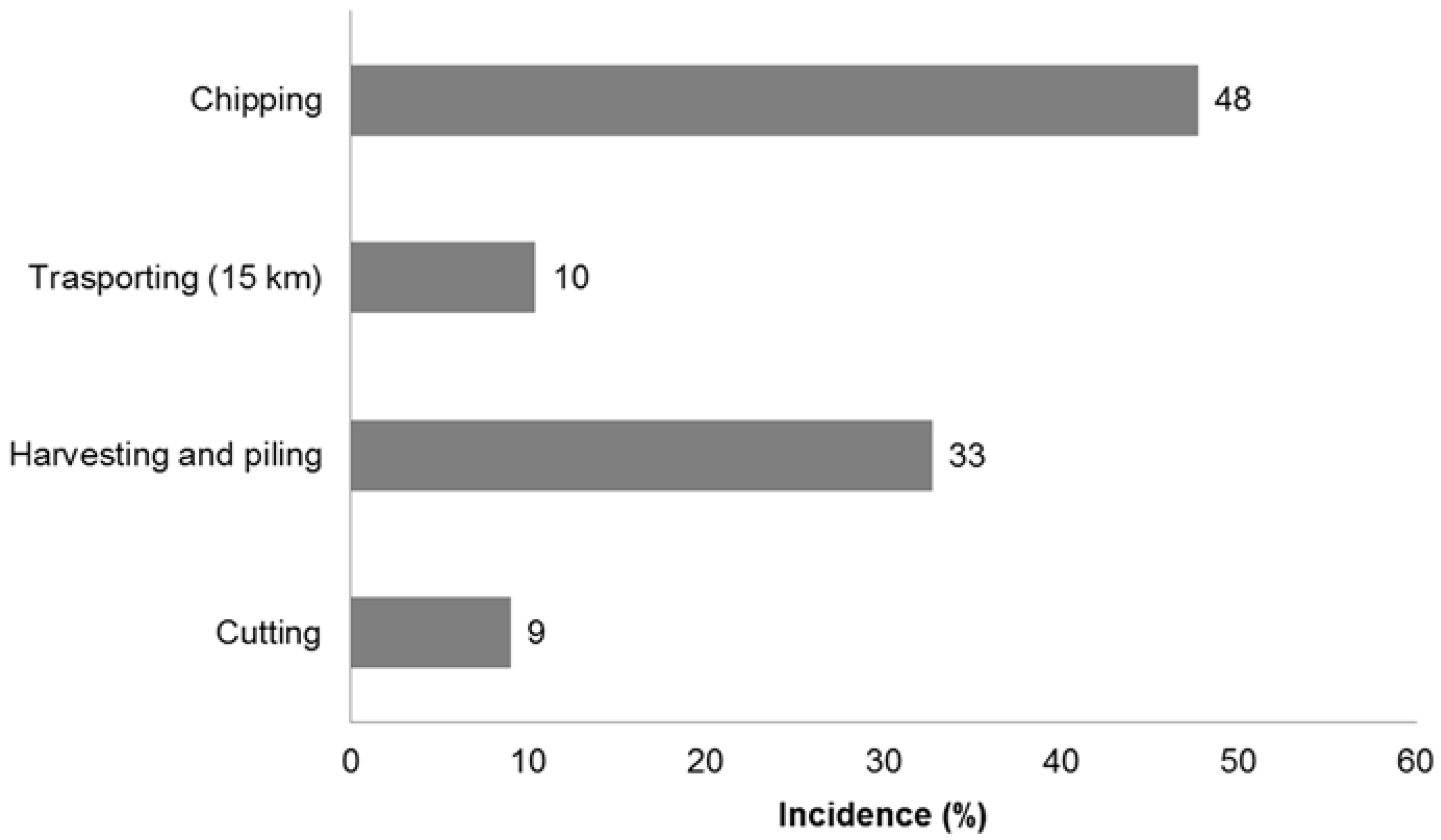

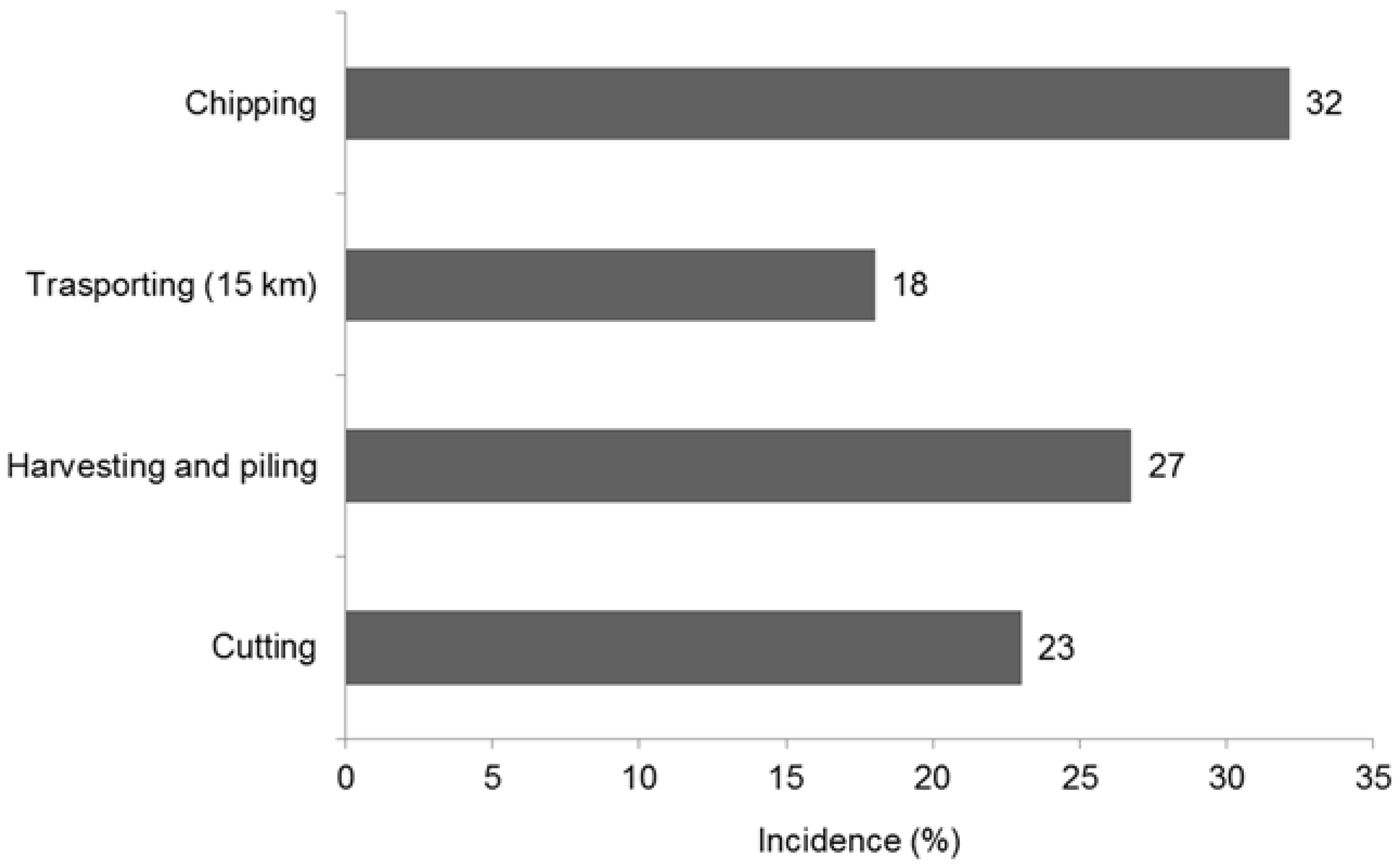

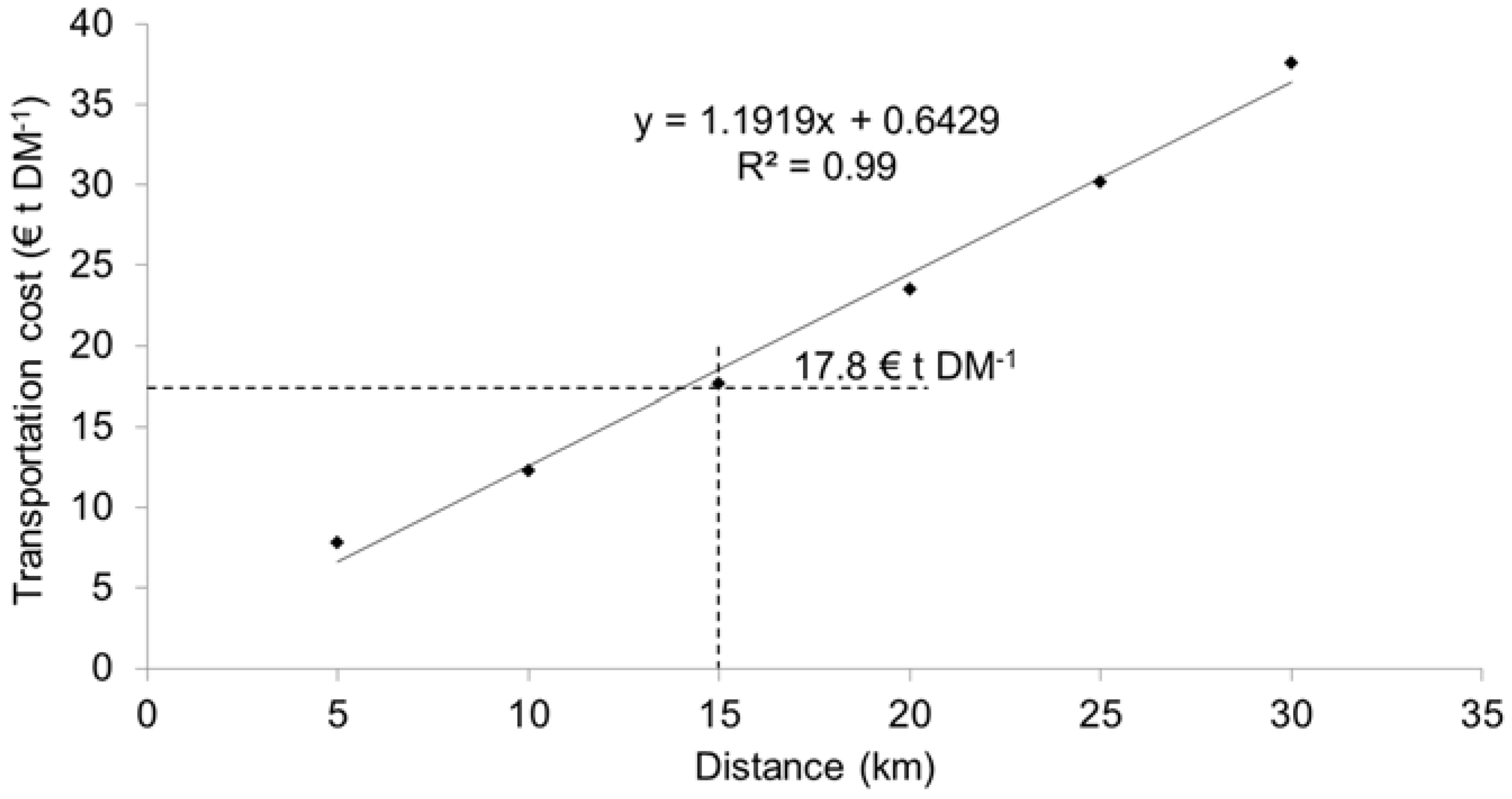

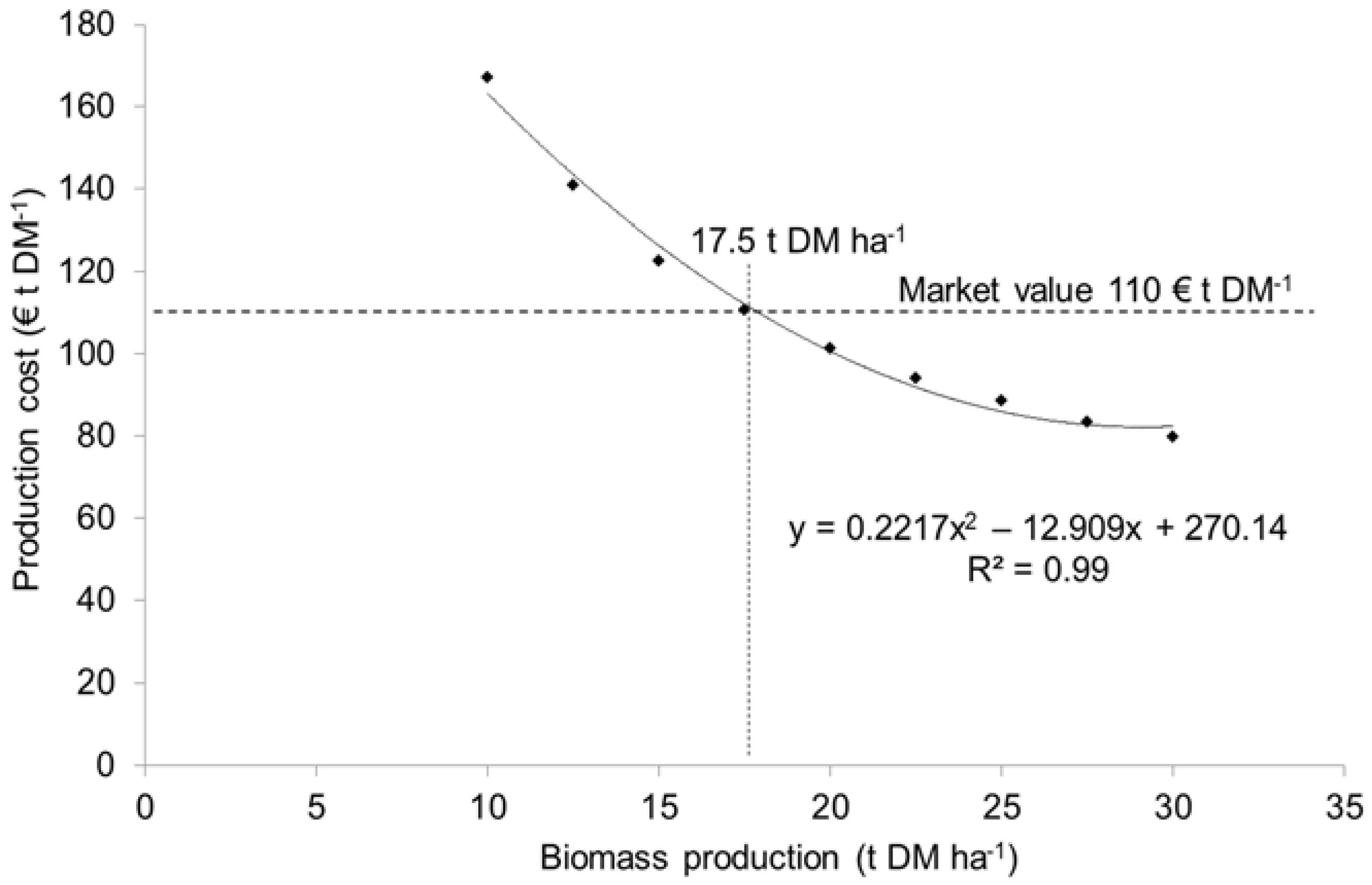

3.5. Economic Evaluation

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- EUROSTAT. European Statistical Office; EUROSTAT: Luxembourg, 2015. [Google Scholar]

- European Commission. National Action Plans. Available online: https://ec.europa.eu/energy/en/topics/renewable-energy/national-action-plans (accessed on 18 March 2016).

- Thapa, S.; Bhoi, R.P.; Kumar, A.; Huhnke, L.R. Effects of Syngas Cooling and Biomass Filter Medium on Tar Removal. Energies 2017, 10, 349. [Google Scholar] [CrossRef]

- Singh, A.; Sevda, S.; Reesh, I.M.A.; Vanbroekhoven, K.; Rathore, D.; Pant, D. Production from Lignocellulosic Biomass: Technology and Sustainability. Energies 2015, 8, 13062–13080. [Google Scholar] [CrossRef]

- Xing, Y.; Hailong, W.; Strong, P.J.; Xu, S.; Liu, S.; Lu, K.; Sheng, K.; Guo, J.; Che, L.; He, L.; et al. Thermal Properties of Biochars Derived from Waste Biomass Generated by Agricultural and Forestry Sectors. Energies 2017, 10, 469. [Google Scholar] [CrossRef]

- Cotana, F.; Cavalaglio, G.; Coccia, V.; Petrozzi, A. Energy Opportunities from Lignocellulosic Biomass for a Biorefinery Case Study. Energies 2016, 9, 748. [Google Scholar] [CrossRef]

- Guo, M.; Song, W.; Buhain, J. Bioenergy and biofuel: History, status and perspective. Renew. Sustain. Energy Rev. 2015, 42, 712–725. [Google Scholar] [CrossRef]

- Zhang, F.; Johnson, D.M.; Wang, J. Life-Cycle Energy and GHG Emissions of Forest Biomass Harvest and Transport for Biofuel Production in Michigan. Energies 2015, 8, 3258–3271. [Google Scholar] [CrossRef]

- Moulogianni, C.; Bournaris, T. Biomass Production from Crops Residues: Ranking of Agro-Energy Regions. Energies 2017, 10, 1061. [Google Scholar] [CrossRef]

- Ren, L.; Cafferty, K.; Roni, M.; Jacobson, J.; Xie, G.; Ovard, L.; Wright, C. Analyzing and Comparing Biomass Feedstock Supply Systems in China: Corn Stover and Sweet Sorghum Case Studies. Energies 2015, 8, 5577–5597. [Google Scholar] [CrossRef]

- Gaitán-Alvarez, J.; Moya, R.; Puente-Urbina, A.; Rodriguez-Zuñiga, A. Physical and Compression Properties of Pellets Manufactured with the Biomass of Five Woody Tropical Species of Costa Rica Torrefied at Different Temperatures and Times. Energies 2017, 10, 1205. [Google Scholar] [CrossRef]

- Hernández, U.F.; Jaeger, D.; Samperio, J.I. Bioenergy Potential and Utilization Costs for the Supply of Forest Woody Biomass for Energetic Use at a Regional Scale in Mexico. Energies 2017, 10, 1192. [Google Scholar] [CrossRef]

- Velazquez-Marti, B.; Fernandez-Gonzales, E.; Lopez-Cortes, I.; Salazar-Hernandezm, D.M. Quantification of the residual biomass obtained from pruning of trees in Mediterranean olive groves. Biomass Bioenergy 2011, 35, 3208–3217. [Google Scholar] [CrossRef]

- Scarlat, N.; Blukdea, V.; Dallemand, J.F. Assessment of the availability of agricultural and forest residues for bioenergy production in Romania. Biomass Bioenergy 2011, 35, 1995–2005. [Google Scholar] [CrossRef]

- Bernetti, I.; Fagarazzi, C.; Fratini, R. A methodology to analyze the potential development of biomass energy sector: An application in Tuscany. For. Policy Econ. 2004, 6, 415–432. [Google Scholar] [CrossRef]

- Beccali, M.; Columba, P.; D’Aleberti, V. Assessment of bioenergy potential in Sicily: A GIS-based support methodology. Biomass Bioenergy 2009, 33, 79–87. [Google Scholar] [CrossRef]

- Gonzalez-Garcia, S.; Dias, A.C.; Clermidy, S.; Benoist, A.; Maurel, V.B.; Gasol, A.M.; Gabarell, X.; Arroja, L. Comparative environmental and energy profiles of potential bioenergy production chains in Southern Europe. J. Clean. Prod. 2014, 76, 42–54. [Google Scholar] [CrossRef]

- Jones, G.; Joeffler, D.; Calkin, D.; Chung, W. Forest treatment residues for thermal energy compared with disposal by onsite burning: Emissions and energy return. Biomass Bioenergy 2010, 34, 737–746. [Google Scholar] [CrossRef]

- ISTAT (Istituto Italiano di Statistica). Principali Coltivazioni Legnose Agrarie. Available online: http://www.istat.it/it/archivio/160233.2015 (accessed on 18 March 2016).

- Istituto Nazionale di Statistica (ISTAT). Available online: http://dati-censimentoagricoltura.istat.it/ (accessed on 18 March 2016).

- Di Blasi, C.; Tanzi, V.; Lanzetta, M. A study on the production of agricultural residues in Italy. Biomass Bioenergy 1997, 12, 321–331. [Google Scholar] [CrossRef]

- Picchi, G.; Silvestri, S.; Cristoforetti, A. Vineyard residues as a fuel for domestic boilers in Trento province (Italy): Comparison to woodchips and means of polluting emission control. Fuel 2013, 113, 43–49. [Google Scholar] [CrossRef]

- Spinelli, R.; Lombardini, C.; Pari, L.; Sadauskiene, L. An alternative to field burning of pruning residues in mountain vineyards. Ecol. Eng. 2014, 70, 212–216. [Google Scholar] [CrossRef]

- Magagnotti, N.; Nati, C.; Spinelli, R.; Vieri, M. Technical protocol for the utilization of pruning residues from vineyards and olive groves. In The Forest-Wood-Energy Chain: Results from the International Project Woodland Energy; ARSIA di Regione Toscana: Florence, Italy, 2009. [Google Scholar]

- Keshtkar, H.; Ashbaugh, L. Size distribution of polycyclic aromatic hydrocarbon particulate emission factors from agricultural burning. Atmos. Res. 2007, 41, 2729–2739. [Google Scholar] [CrossRef]

- Grella, M.; Manzone, M.; Gioelli, F.; Balsari, P. Harvesting of southern Piemonte’s orchards pruning residues: A biomass production and harvest losses first evaluation. J. Agric. Eng. 2013, 44, 97–102. [Google Scholar]

- Torquati, B.; Marino, D.; Venanzi, S.; Porceddu, P.R.; Chiorri, M. Using tree crop pruning for energy purposes: A spatial analysis and an evaluation of the economic and environmental sustainability. Biomass Bioenergy 2016, 95, 124–131. [Google Scholar] [CrossRef]

- Wiskerke, W.T.; Dornburg, V.; Rubanza, C.D.K.; Malimbwi, R.E.; Faaji, A.P.C. Cost/benefit analysis of bioenergy supply options for rural smallholders in the semi-arid eastern part of Shinyanga Region in Tanzania. Renew. Sustain. Energy Rev. 2010, 14, 148–165. [Google Scholar] [CrossRef]

- Kimming, M.; Sundberg, A.; Baky, A.; Bernesson, S.; Noren, O.; Hansson, P.-A. Biomass from agriculture in small-scale combined heat and power plants—A comparative life cycle assessment. Biomass Bioenergy 2011, 35, 1572–1581. [Google Scholar] [CrossRef]

- Ministero delle Politiche Agricole e Forestali. Interventi di Coordinamento ed Implementazione alle azioni di ricerca, lotta e difesa al cancro Batterico Dell’actinidia (PSA)—INTERACT 82. Available online: http://www.kiwifruitpsa.com/psa_en.php (accessed on 18 March 2016).

- Ministero delle Politiche Agricole e Forestali. Decree 20th December—Misure per impedire l’introduzione e la diffusione di Pseudomonas syringaer pv. actinidiae Takikawa, Serizawa, Ichikaea, Tsuyumu & Goto nel territorio della Repubblica italiana. Gazz. Uff. Della Repubbl. Ital. 2013, 62, 39–43. [Google Scholar]

- Magagnotti, N.; Spinelli, R. COST Action FP0902 e Good Practice Guideline for Biomass Production Studies; CNR IVALSA: Florence, Italy, 2012; p. 41. ISBN 978-88-901660-4-4. [Google Scholar]

- Björheden, R.; Apel, K.; Shiba, M.; Thompson, M.A. IUFRO Forest Work Study Nomenclature; Department of Operational Efficiency, Swedish University of Agricultural Science: Garpenberg, Sweden, 1995; p. 16. [Google Scholar]

- UNI EN 15149. Solid Biofuels, Determination of Particle Size Distribution, Part 1; UNI: Milano, Italy, 2011. [Google Scholar]

- UNI EN 14774-2. Solid Biofuels, Determination of Moisture Content—Oven Dry meThod, Part 2: Total Moisture—Simplified Method; UNI: Milano, Italy, 2010. [Google Scholar]

- UNI EN 14918. Solid Biofuels, Determination of Calorific Value; UNI: Milano, Italy, 2010. [Google Scholar]

- UNI EN 14775. Solid Biofuels, Determination of Ash Content; Italian Organization for Standardization, UNI: Milano, Italy, 2010. [Google Scholar]

- Jarach, M. On equivalence values for analysis and balance energy in agriculture (in Italian). Riv. Ing. Agr. 1985, 2, 102–114. [Google Scholar]

- Bailey, A.; Basford, W.; Penlington, N.; Park, J.; Keatinge, J.; Rehman, T.; Tranter, R.; Yates, C. A comparison of energy use in conventional and integrated arable farming in the UK. Agric. Ecosyst. Environ. 2003, 97, 241–253. [Google Scholar] [CrossRef]

- Pellizzi, G. Use of energy and labour in Italian agriculture. J. Agric. Eng. Res. 1992, 52, 111–119. [Google Scholar] [CrossRef]

- Fluck, R.C. Energy sequestered in repairs and maintenance of agricultural machinery. Trans. ASAE 1985, 28. [Google Scholar] [CrossRef]

- Manzone, M.; Spinelli, R. Efficiency of small-scale firewood processing operations in Southern Europe. Fuel Process. Technol. 2014, 122, 58–63. [Google Scholar] [CrossRef]

- ASAE American Society of Agricultural Engineers. ASAE Standards: Agricultural Machinery Management; ASAE: Washington, DC, USA, 1999; EP466.2. [Google Scholar]

- Miyata, E.S. Determining Fixed and Operating Costs of Logging Equipment; General Technical Report NC-55; Forest Service North Central Forest Experiment Station: St. Paul, MN, USA, 1980; 14p. [Google Scholar]

- Manzone, M. Energy consumption and CO2 analysis of different types of chippers used in wood biomass plantations. Appl. Energy 2015, 156, 686–692. [Google Scholar] [CrossRef]

- Manzone, M.; Balsari, P. The energy consumption and economic costs of different vehicles used in transporting woodchips. Fuel 2015, 139, 511–515. [Google Scholar] [CrossRef]

- Hartsough, B. Economics of harvesting to maintain high structural diversity and resulting damage to residual trees. West. J. Appl. For. 2003, 18, 133–142. [Google Scholar]

- Einot, I.; Gabriel, K.R. A study of the Powers of Several Methods of Multiple Comparisons. J. Am. Stat. Assoc. 1975, 70, 351. [Google Scholar]

- Rosso, L.; Facciotto, G.; Bergante, S.; Vietto, L.; Nervo, G. Selection and testing of Populus alba and Salix spp. as bioenergy feedstock: Preliminary results. Appl. Energy 2013, 102, 87–92. [Google Scholar] [CrossRef]

- Manzone, M.; Spinelli, R. Wood chipping performance of a modified forager. Biomass Bioenergy 2013, 55, 101–106. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Picchi, G.; Lombardini, C.; Nati, C. Upsized harvesting technology for coping with the new trends in short-rotation coppice. Appl. Eng. Agric. 2011, 27, 551–557. [Google Scholar] [CrossRef]

- Manzone, M.; Airoldi, G.; Balsari, P. Energetic and economic evaluation of a poplar cultivation for the biomass production in Italy. Biomass Bioenergy 2009, 33, 1258–1264. [Google Scholar] [CrossRef]

- Manzone, M.; Bergante, S.; Facciotto, G. Energetic and economic evaluation of a poplar plantation for woodchips production in Italy. Biomass Bioenergy 2014, 60, 164–170. [Google Scholar] [CrossRef]

- Manzone, M.; Bergante, S.; Facciotto, G. Energetic and economic sustainability of woodchip production by black locust (Robinia pseudoacacia L.) plantations in Italy. Fuel 2015, 140, 555–560. [Google Scholar] [CrossRef]

- Manzone, M. Energy and moisture losses during poplar and black locust logwood storage. Fuel Proc. Technol. 2015, 138, 194–201. [Google Scholar] [CrossRef]

- Casal, M.D.; Gil, M.V.; Pevida, C.; Rubiera, F.; Pis, J.J. Influence of storage time on the quality and combustion behaviour of pine woodchips. Energy 2010, 35, 3066–3071. [Google Scholar] [CrossRef]

- EN 14961. Solid Biofuels. Fuel Specifications and Classes (Part. 3), New; European Committee for Standardization (CEN): Paris, France, 2011. [Google Scholar]

- Manzone, M.; Balsari, P.; Spinelli, R. Small-scale storage techniques for fuel chips from short rotation forestry. Fuel 2013, 109, 687–692. [Google Scholar] [CrossRef]

- Spinelli, R.; Nati, C.; Sozzi, L.; Magagnotti, N.; Picchi, G. Physical characterization of commercial woodchips on the Italian energy market. Fuel 2011, 90, 2198–2202. [Google Scholar] [CrossRef]

- EN 14961. Solid Biofuels. Fuel Specifications and Classes (Part. 1); European Committee for Standardization (CEN): Paris, France, 2011. [Google Scholar]

- Fiala, M.; Becenetti, J. Economic, energetic and environmental impact in short rotation coppice harvesting operations. Biomass Bioenergy 2012, 42, 107–113. [Google Scholar] [CrossRef]

- Manzone, M.; Balsari, P. Productivity and woodchip quality of different chippers used in Short Rotation Coppice. Biomass Bioenergy 2015, 83, 278–283. [Google Scholar] [CrossRef]

| Machine | Purchase Cost (€) | |

|---|---|---|

| Type | Model | |

| Chainsaw | Stihl MS 231 | 900 |

| Trailer | Silvercar SRC502 | 13,000 |

| Loader | Baratti 500 | 8500 |

| Tractor | Carraro TRX 7800 S | 28,000 |

| Chipper | Pezzolato PTH 900/660 | 160,000 |

| Tractor | New Holland T7.235 | 145,000 |

| Net Working Time (%) | Complementary Working Time (%) | Unproductive Time (%) | |

|---|---|---|---|

| Cutting | 79 | 11 | 10 |

| Harvesting and Piling | 84 | 10 | 6 |

| Chipping | 80 | 17 | 3 |

| Transporting | 78 | 20 | 2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manzone, M.; Gioelli, F.; Balsari, P. Kiwi Clear‐Cut: First Evaluation of Recovered Biomass for Energy Production. Energies 2017, 10, 1837. https://doi.org/10.3390/en10111837

Manzone M, Gioelli F, Balsari P. Kiwi Clear‐Cut: First Evaluation of Recovered Biomass for Energy Production. Energies. 2017; 10(11):1837. https://doi.org/10.3390/en10111837

Chicago/Turabian StyleManzone, Marco, Fabrizio Gioelli, and Paolo Balsari. 2017. "Kiwi Clear‐Cut: First Evaluation of Recovered Biomass for Energy Production" Energies 10, no. 11: 1837. https://doi.org/10.3390/en10111837

APA StyleManzone, M., Gioelli, F., & Balsari, P. (2017). Kiwi Clear‐Cut: First Evaluation of Recovered Biomass for Energy Production. Energies, 10(11), 1837. https://doi.org/10.3390/en10111837