1. Introduction

Coal mine rockbursts in a coal mine are nonlinear dynamic processes. They start with the deformation of coal and rocks caused by mining. Such deformations steadily accumulate energy, and eventually the energy is released suddenly [

1,

2]. With the increase of mining depth and production, dynamical disasters in coal mines are becoming more serious and frequent, and their intensity is growing, which seriously threatens mining safety [

3,

4].

Mining optimization design [

5,

6], regional hazard prevention [

7,

8], supporting intensity increases or support pattern improvements [

9,

10] can be used to prevent and control rockbursts in coal mines. The regional hazard prevention method is widely used to prevent rockbursts to eliminate high stress concentrations and weaken the elastic energy accumulation through modifying the properties of coal and rocks. Such methods include coal seam blasting [

11], coal seam water injection [

12], drill hole pressure relief [

13] and directional hydraulic water fracturing [

14].

Coal seam water injection can change the bursting liability of coal or rock and reduce or eliminate rockburst disasters in the mining field. It is characterized by a simple operation process, small investment and other favorable features [

15]. At present, it is widely used to prevent and control rockburst disasters in China [

16,

17]. The bursting liability of coal seams is closely related to their water content [

18], and the structure and mechanical properties of coal will be changed by the physical-chemical function of water. As the water content of coal increases, the uniaxial compressive strength, peak stress in the stress-strain curve and

E of coal decrease and the Poisson’s ratio increases [

19,

20]. The bursting liability of coal weakens with the increase of soak time [

21]. The coal seam water injection method is widely applied on site, but it is not necessarily effective in all situations. The properties of coal and rock [

22] and the parameters of water injection, including the hole spacing, water flooding pressure and other factors, can affect its effectiveness. In fact, there is a time effect for coal seam water injection. The structure and mechanical properties of coal show obviously differences after different soak times. As soak time increases, those differences become more apparent. Therefore, the time effect of coal seam water injection is of significant importance in its parameter design and effectiveness evaluation. The above researches focused on the mechanic mechanism of water injection into coal on a macro scale (from centimeter to meter size), but there is little research related to this matter on the micro scale. The scanning electron microscope (SEM) technology [

23] and the porosity testing technology are helpful to analyze the mechanics mechanism on the micro scale of water injection into coal.

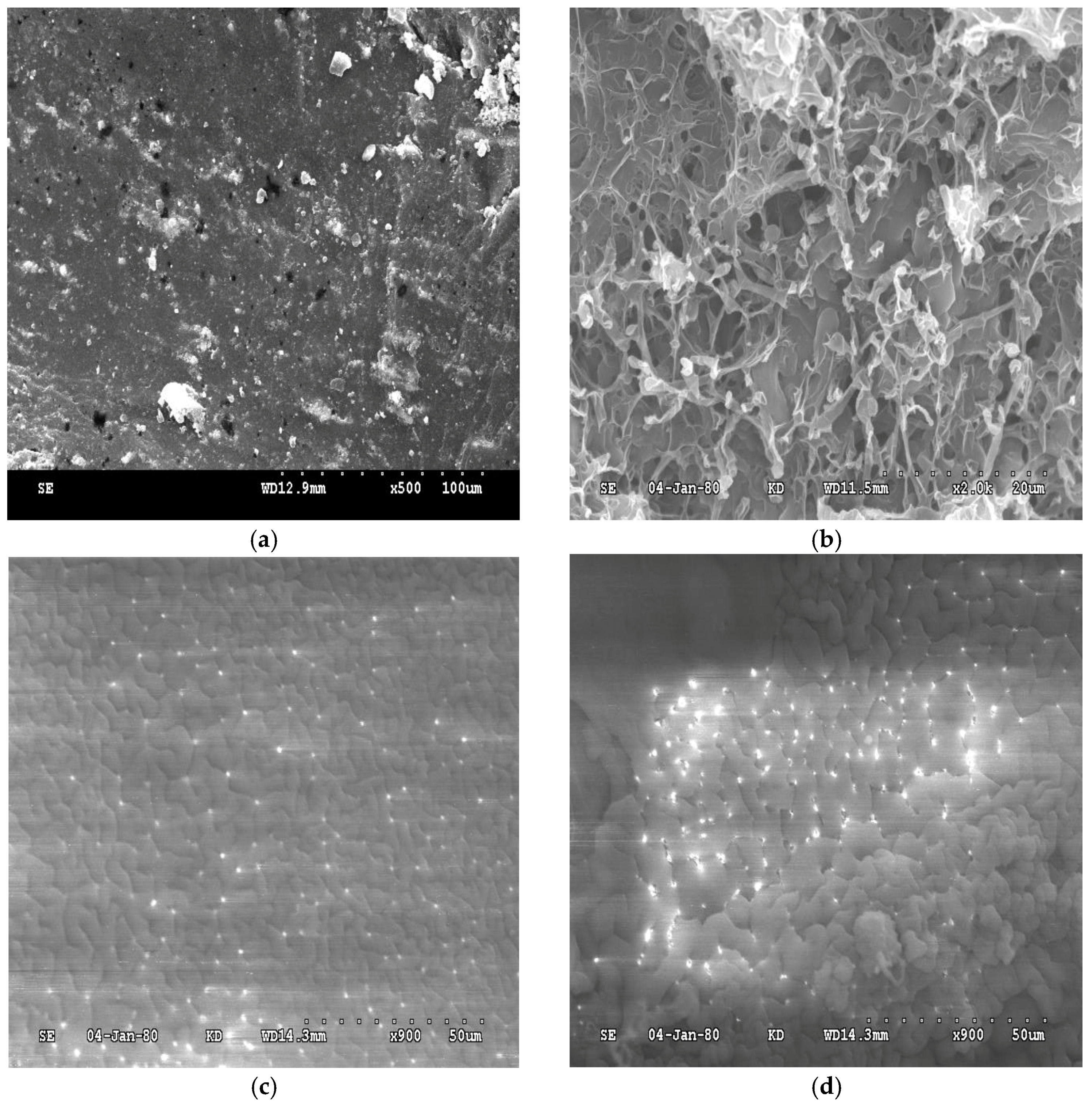

In order to explore the time effect mechanism of water on different sizes of coal (from meter to nanometer size), our study conducted experiments and analyzed the changing law of coal compressive strength, Protodyakonov coefficient, porosity and microstructure of coal samples. By using FLAC-3D, the effect of water injection duration on the effectiveness of rockburst elimination was studied. Based on on-site conditions, an optimized scheme with appropriate parameters was proposed to implement the coal seam water injection method.

2. Experimental Preparation

2.1. Coal Samples Preparation

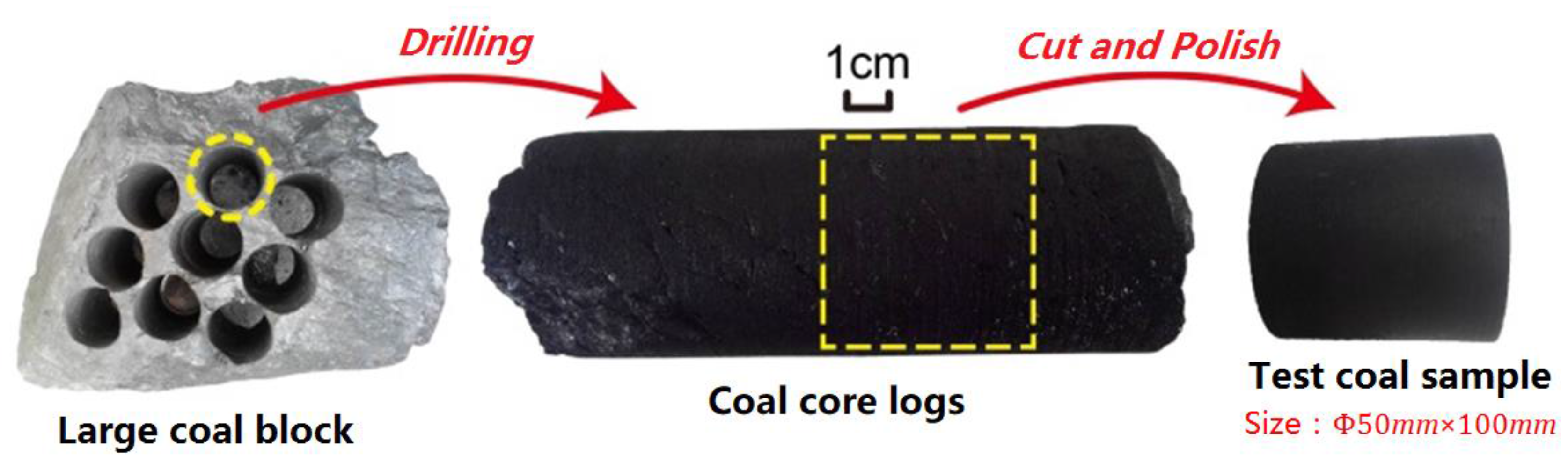

The coal samples were taken from the No. 9 working face of the Changgouyu coal mine in Beijing, which was a bursting mine. To avoid the anisotropy and heterogeneity and ensure experimental reliability and comparability, three large and complete coal blocks from the same position of the working face were chosen. A vertical drilling machine was used to get Φ50 mm coal core logs from these coal blocks, and they were cut into 100 mm long pieces for test. After that, these coal samples (Φ50 mm × 100 mm) were polished and placed into a drying oven for storage. The sample preparation procedure is shown in

Figure 1.

The samples were placed into a water container and the initial height of water was set to 1/4 of the sample height. The height of water was increased 1/4 of the coal sample height after each 2 h, thus the coal samples were totally immersed in water after 6 h. Samples were taken out from water at the fifth day, tenth day and fifteenth day for testing.

2.2. Experimental Devices and Procedures

The mechanical parameters of the coal samples under different soak time were tested. The tested parameters include uniaxial compressive strength, Protodyakonov coefficient, porosity, pore volume, pore surface area and micro structure:

(1) The water content and absorption, the uniaxial compressive strength and Protodyakonov coefficient were tested according to the China GB/T23561 national standard. The size of samples in the uniaxial compressive strength test is Φ50 mm × 100 mm. The grain size of samples in the Protodyakonov coefficient test is less than 20 mm.

(2) The pore parameters of coal were measured by the 9310 mercury pressure microporous structure tester manufactured by Micromeritics (Micromeritics Instrument Corporation, Norcross, GA, USA). The porosity, pore volume and pore surface area of the samples were tested after soaking for 5 days, 10 days and 15 days.

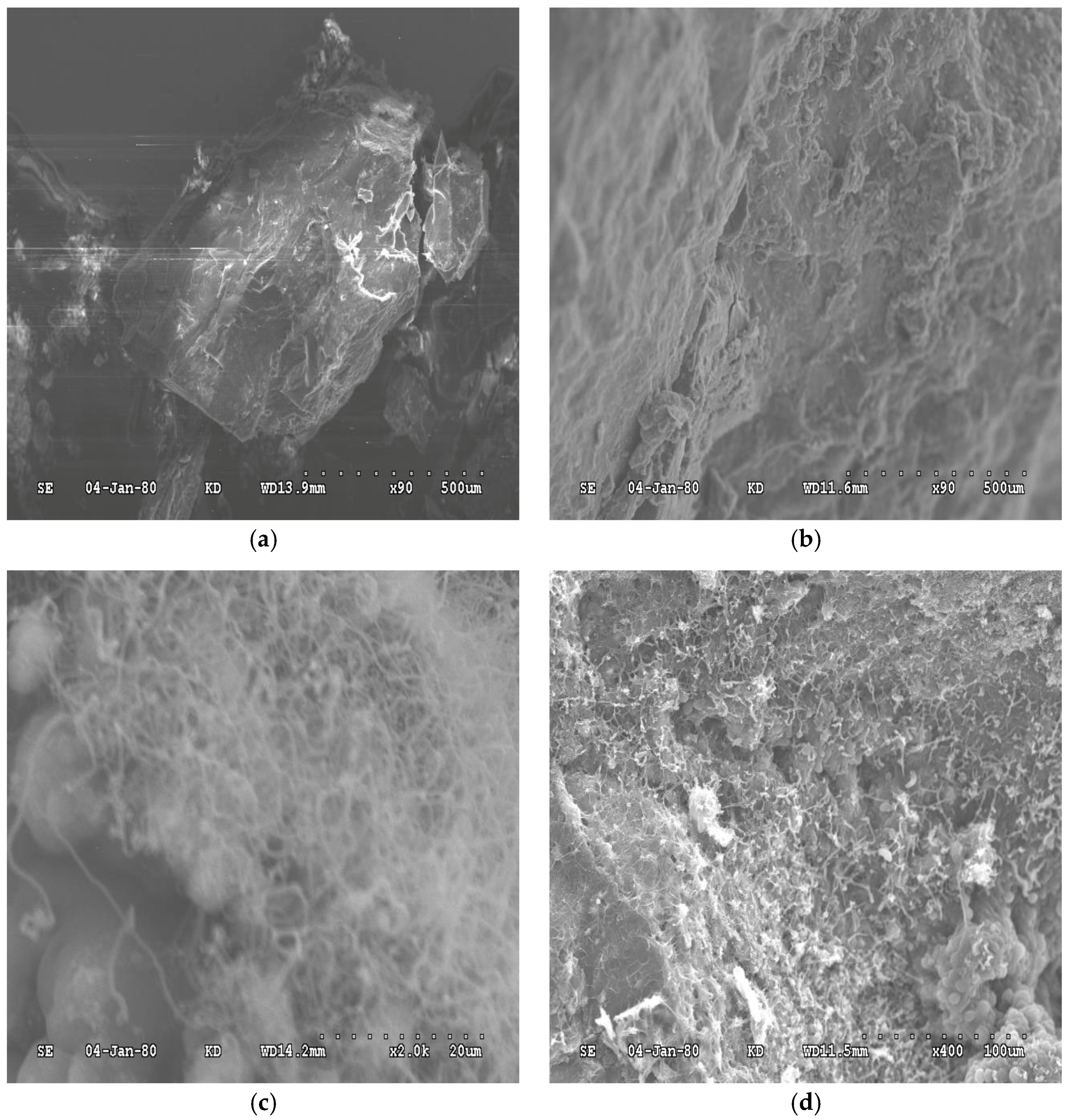

(3) The microstructure and morphology of coal were observed by an S-3000N scanning electron microscope (Hitachi, Ltd., Tokyo, Japan). The sample size was 10 mm × 10 mm × 10 mm. Before testing, the conductivity of samples was treated by the ion sputtering method and the thickness of the gold plating layer was controlled at 5~10 nm.

4. Application in Rockburst Prevention

For further studying the time effect of coal seam water injection, this study conducted numerical simulations by using real geological condition data from a mine, and performed on-site tests for validation purposes.

4.1. Numerical Simulation

4.1.1. Model and Parameters

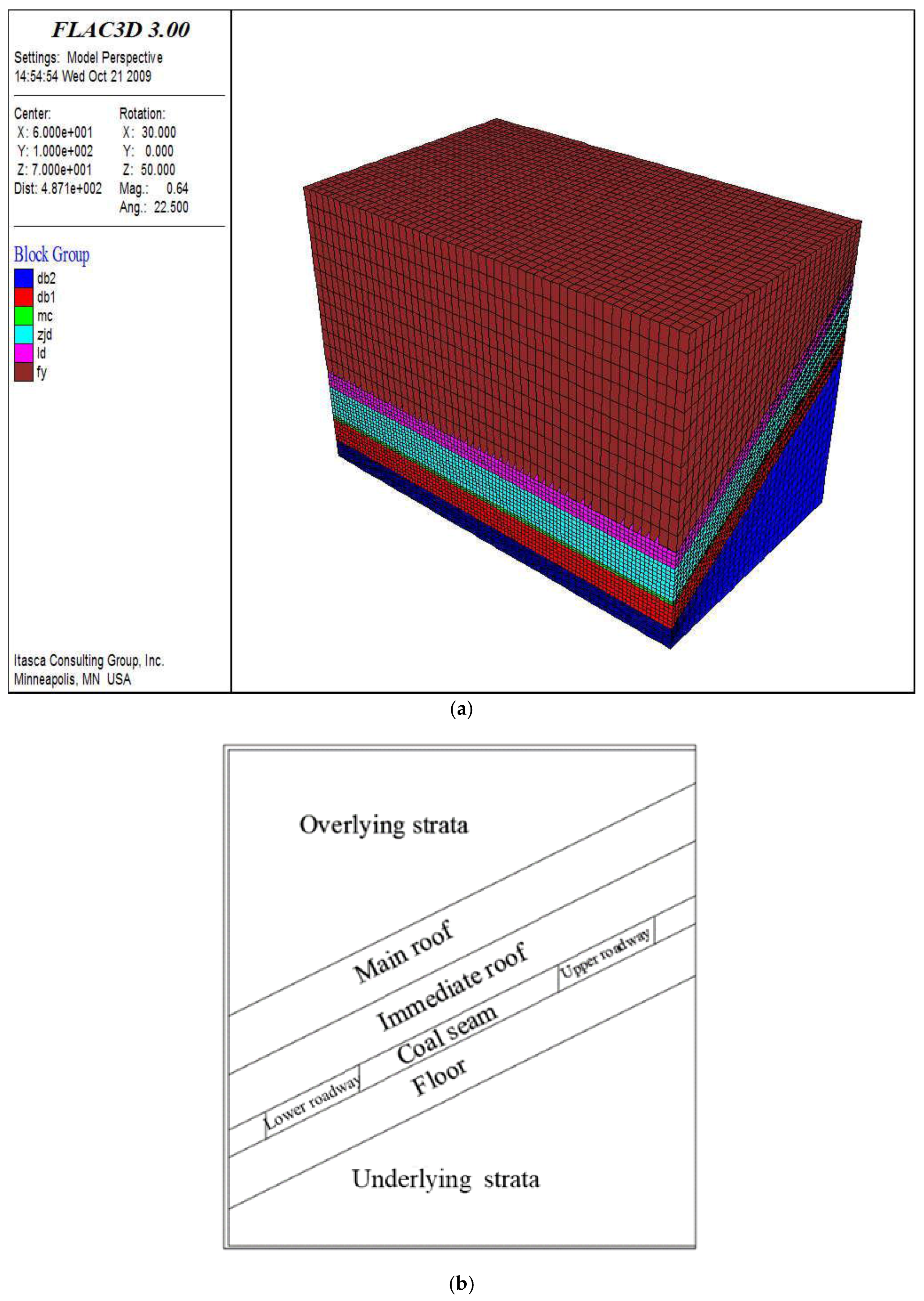

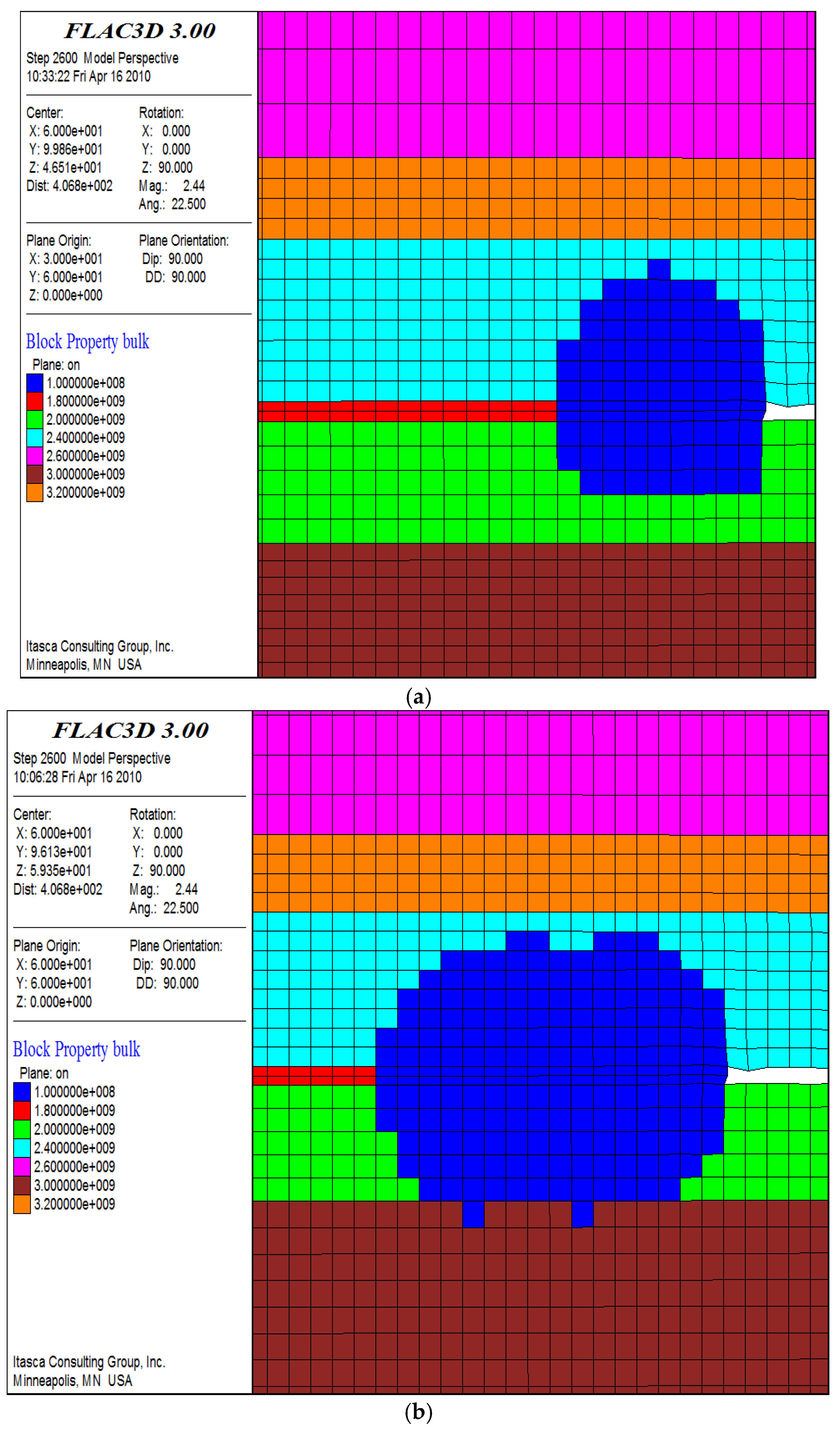

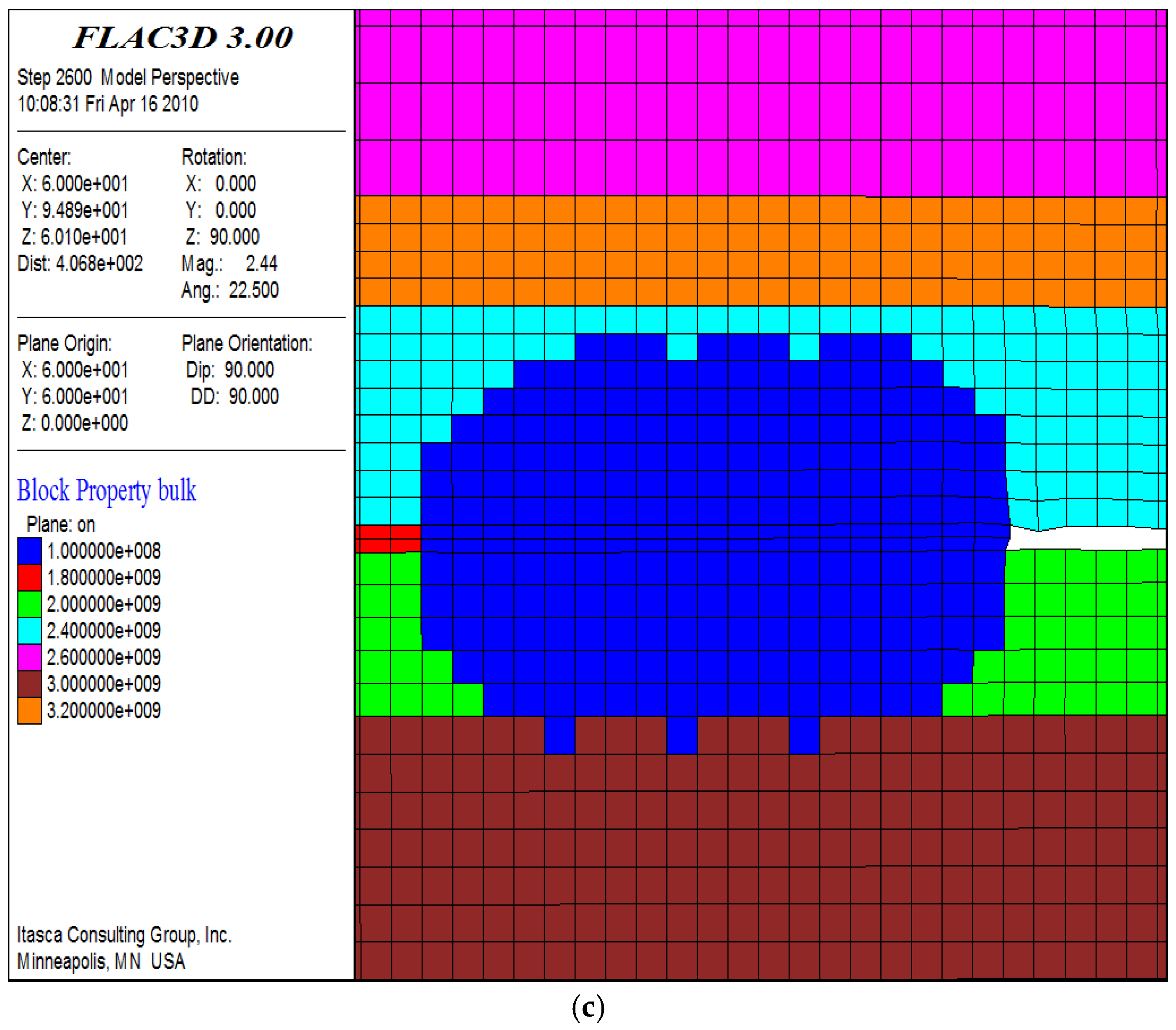

The FLAC-3D software is a professional tool used to simulate the stress and deformation of rock materials under loading conditions [

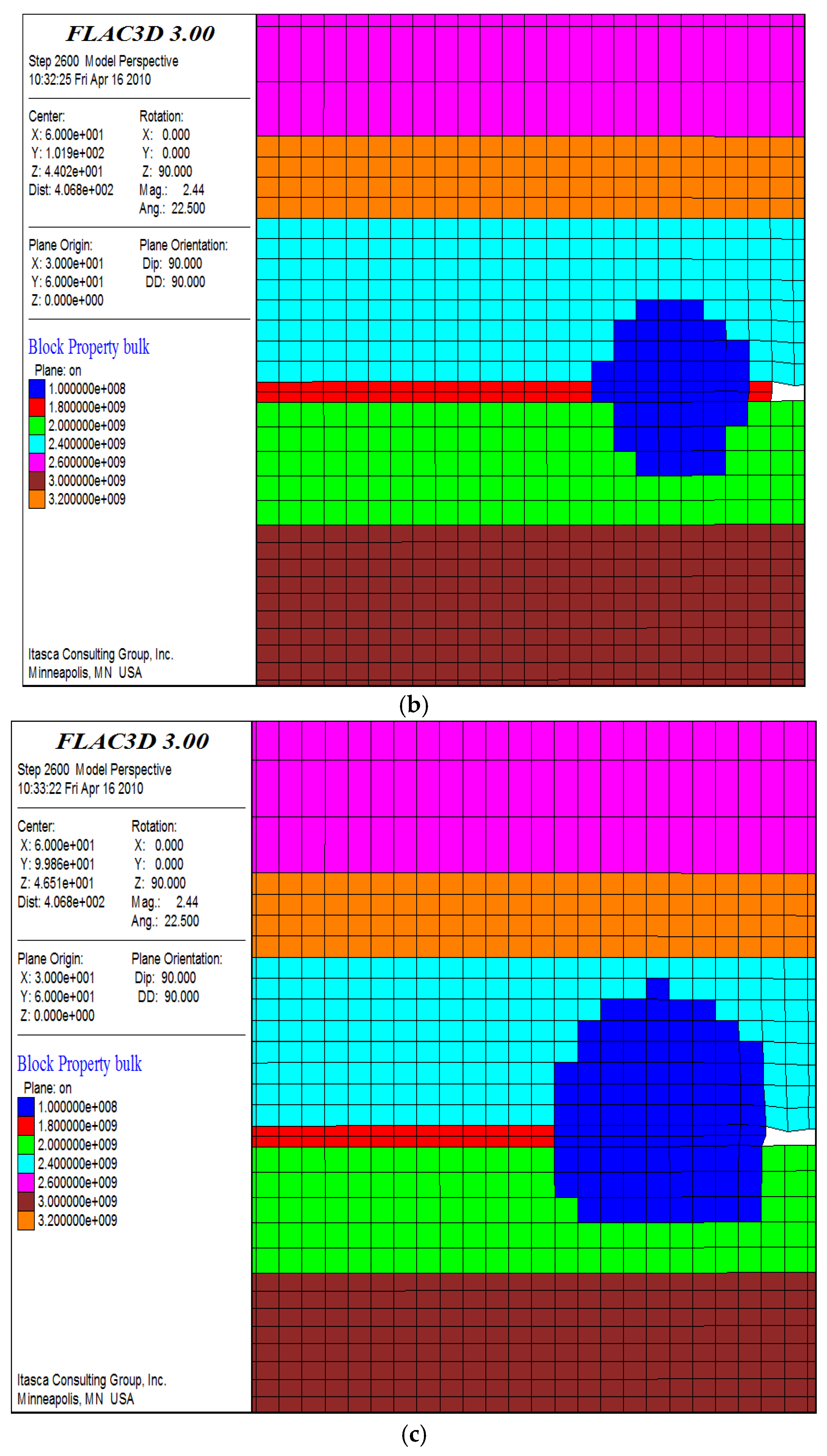

25], and can be used to simulate the water injection process for reducing stress concentration and the danger of rockbursts. The simulated area is based on the conditions of the No. 9 working face in the Changgouyu coal mine where rockbursts have occurred. The model has 156,000 units (

Figure 10) and its dimensions are 120 m × 200 m × 140 m. The model boundary is fixed, with the horizontal displacement and the boundary at the bottom is fixed with the vertical displacement. A uniform loading of 12.0 MPa is applied on the top, which is equivalent to the vertical stress of about 500 m rock mass. The initial displacement and its rate are set to be zero, and the original main stress is installed according to the actual ground stress. The Mohr-Coulomb strain softening failure criterion is adopted in the model. The internal friction angle and cohesion softening parameters used for modelling the immediate and main roof are shown in

Table 6. Coal bedding is simulated by using the interface unit. The normal stiffness and shear stiffness are both 1.0 × 10

4 MPa. The physical mechanics parameters of the coal seam and the immediate roof are set according to test results. The parameters of the floor, roof and other strata are listed in

Table 7. The upper +150 m level is firstly mined, and the gob area is treated as backfilling with soft rocks with parameters listed in

Table 6.

4.1.2. Water Injection Parameters Optimization

Water injection parameters play an important role in the effectiveness of preventing and controlling rockbursts in coal seams. These parameters include borehole length and diameter, borehole interval, borehole number, and water injection time. Firstly, the water injection effect under different conditions of borehole diameter, length, interval and numbers is simulated in this study. After reasonable values for these parameters are determined, the effect of stress reduction and rockburst prevention under varied water injection times (5, 10, 15 and 30 h) are simulated. The simulation results are shown in

Figure 11,

Figure 12,

Figure 13,

Figure 14 and

Figure 15.

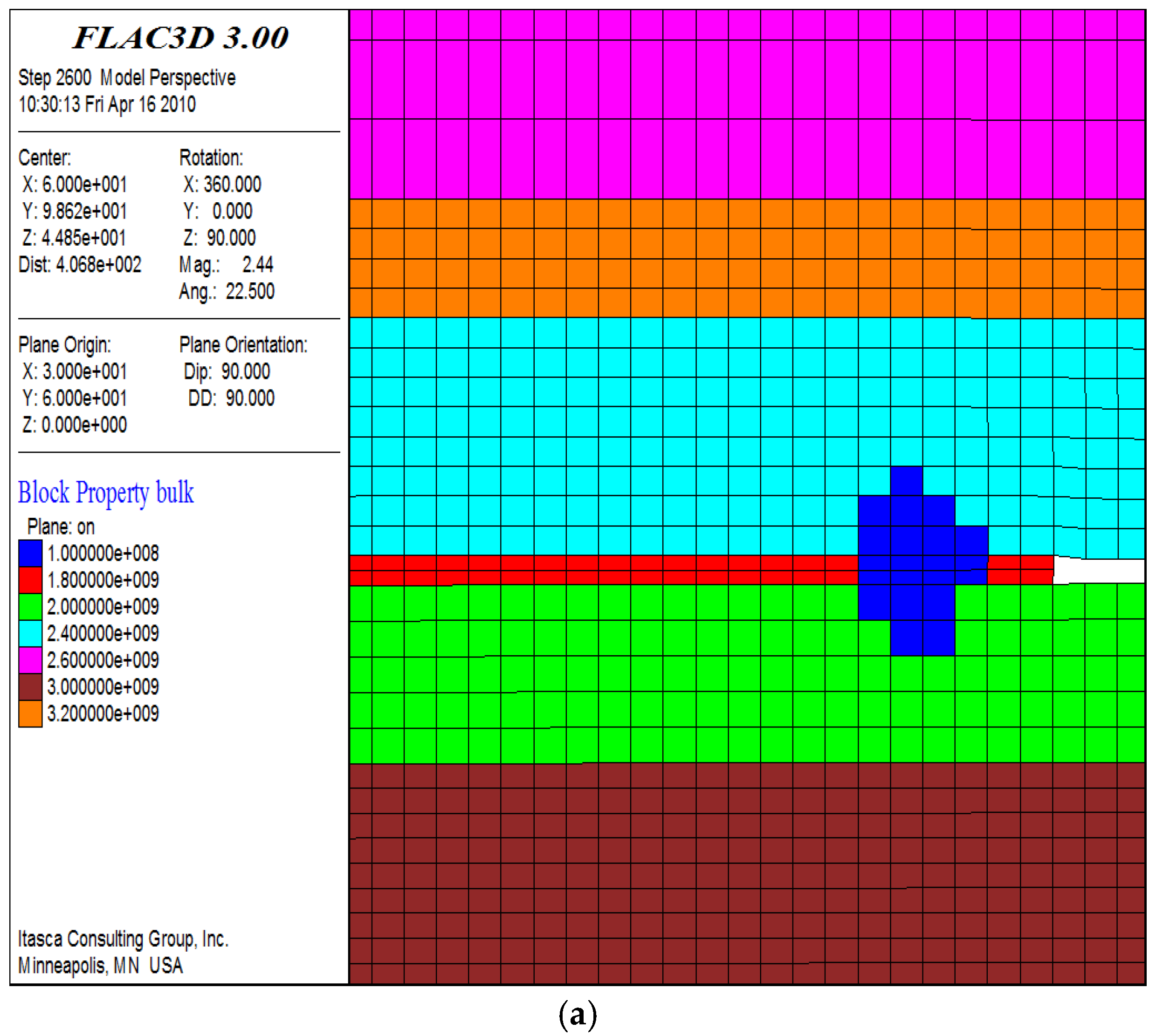

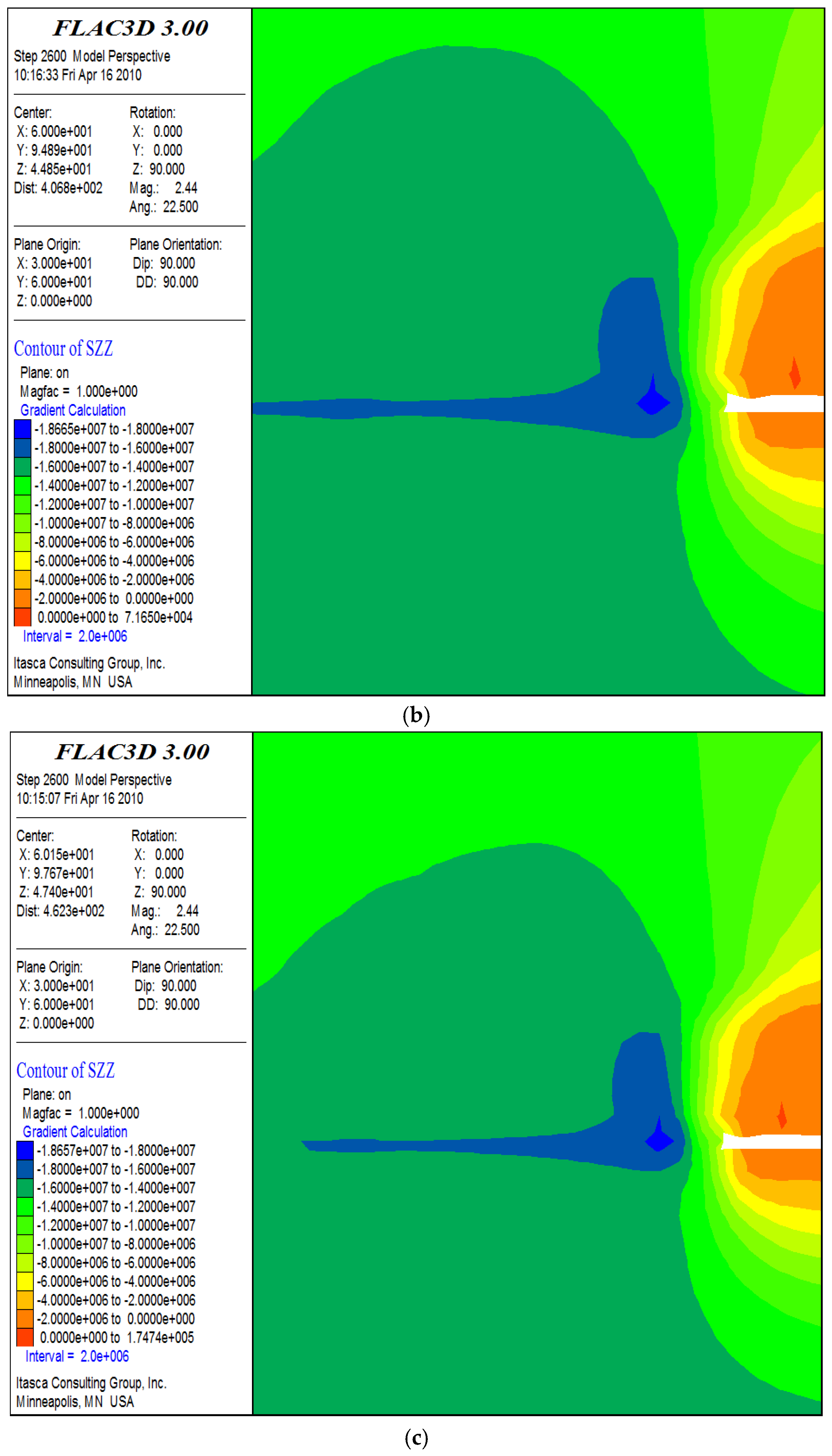

The numerical results for different combinations of borehole lengths and borehole diameters are given in

Figure 11 and

Figure 12. It shows that the water affected area becomes more extensive and the release and transfer of stress concentration are easier with the increase of borehole length and borehole diameter. When using a borehole with length of 60 m and diameter of 60 mm, the stress of coal seam is obviously transferred away from the stress concentration area and the risk of rockburst becomes lower. Based on numerical results and actual mining conditions of the Changgouyu mine, our study can identify that the best borehole length and diameter are 60 m and 60 mm, respectively.

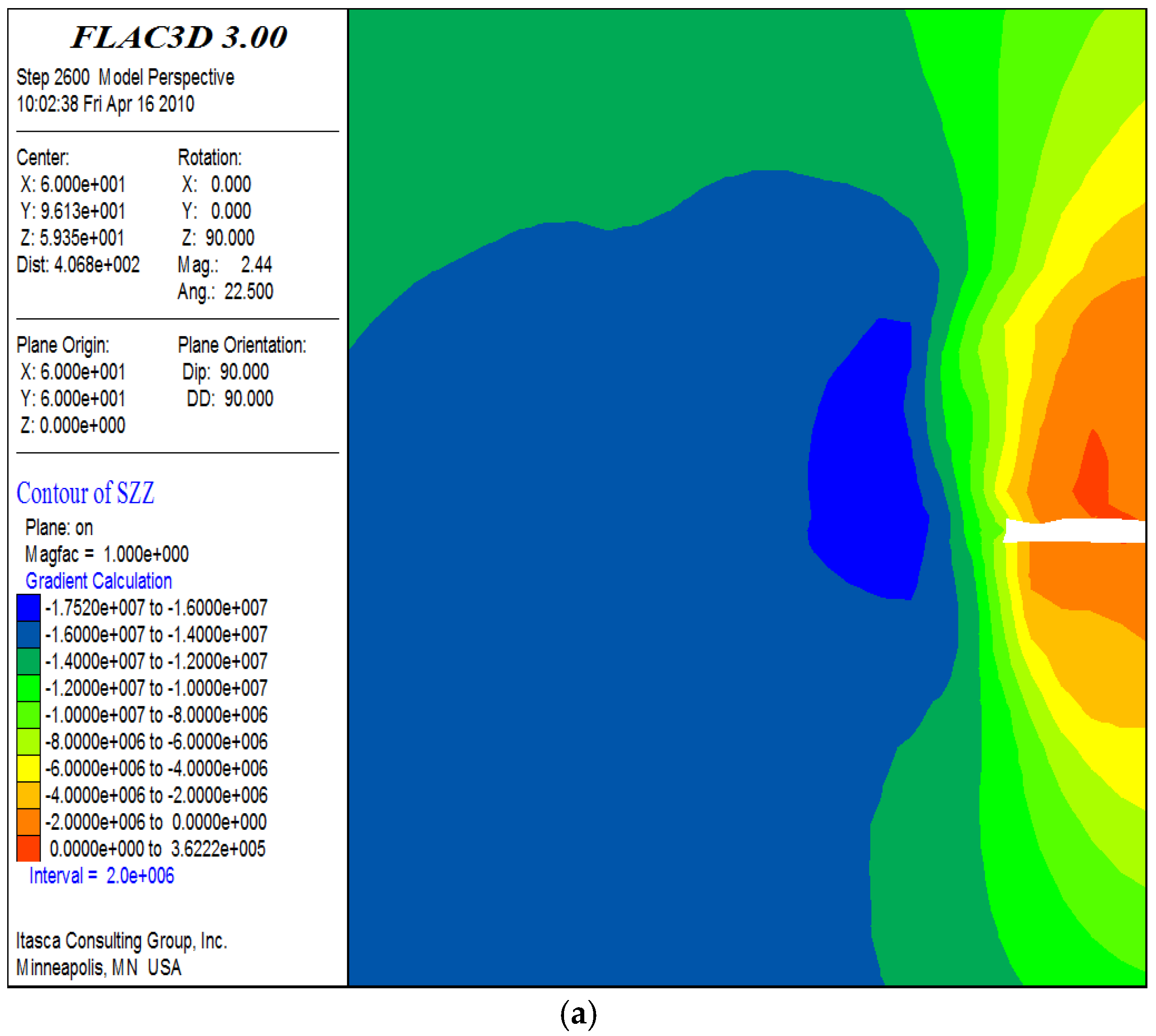

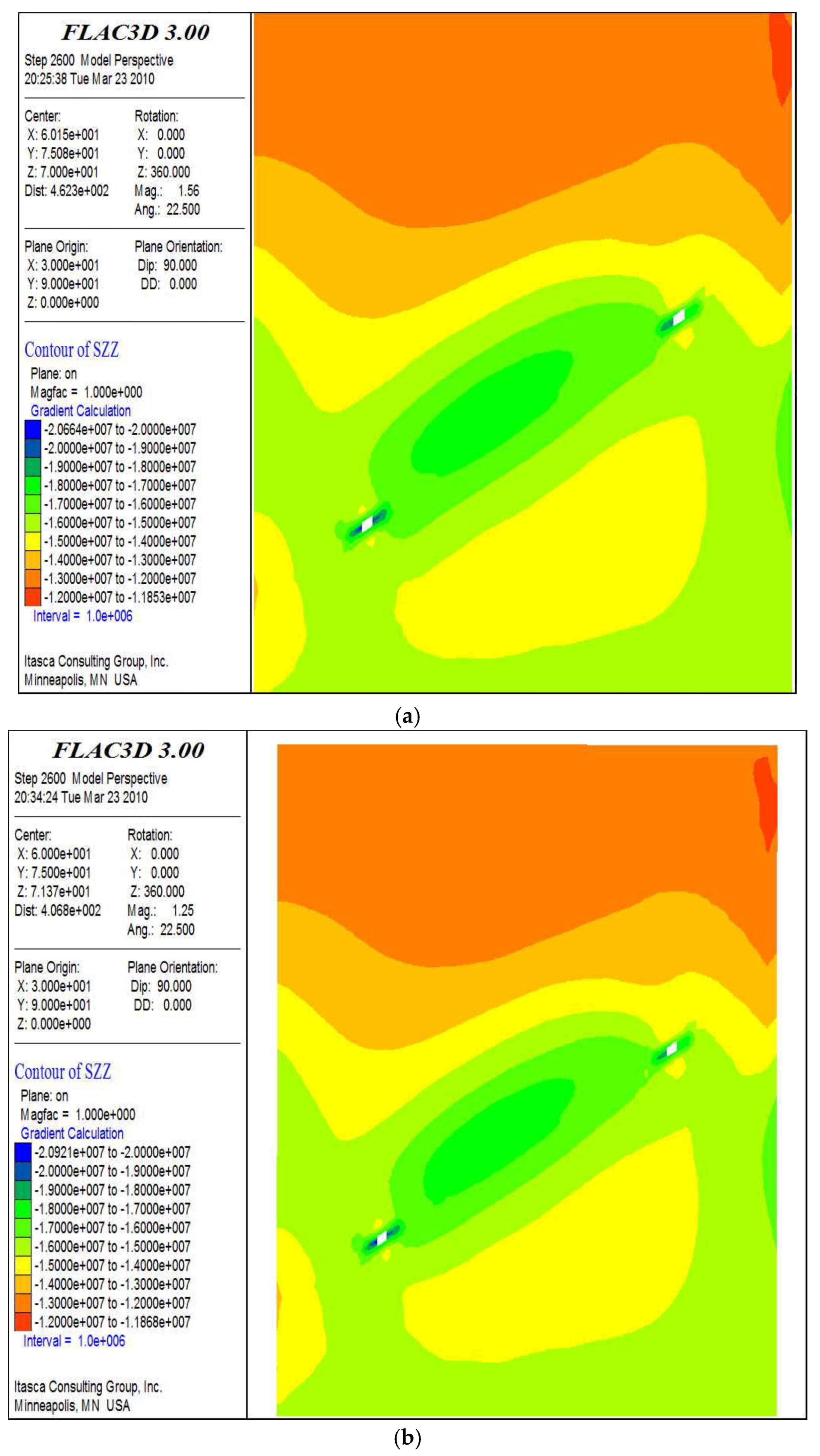

With the 60 m length and 60 mm diameter borehole, the simulation of stress distribution under different borehole intervals are given in

Figure 13. It suggests that water injection with 20 m interval has no obvious influence on stress distribution. However, water injection effectiveness is slightly better when the borehole intervals are 10 m and 15 m. Due to the higher cost associated with small borehole intervals, it is reasonable to choose 15 m as the best borehole interval.

With the above determined borehole parameters, the effect of different borehole number (1, 2 or 3 holes injected simultaneously) are simulated and the results are shown in

Figure 14 and

Figure 15. The effect with three boreholes injecting water simultaneously is far better than that of a single borehole, and the effect of two boreholes is also slightly better than that of a single borehole. It is apparent that more water injection boreholes result in more effective rockburst prevention. However, the construction conditions and the cost should also be considered when determining this parameter.

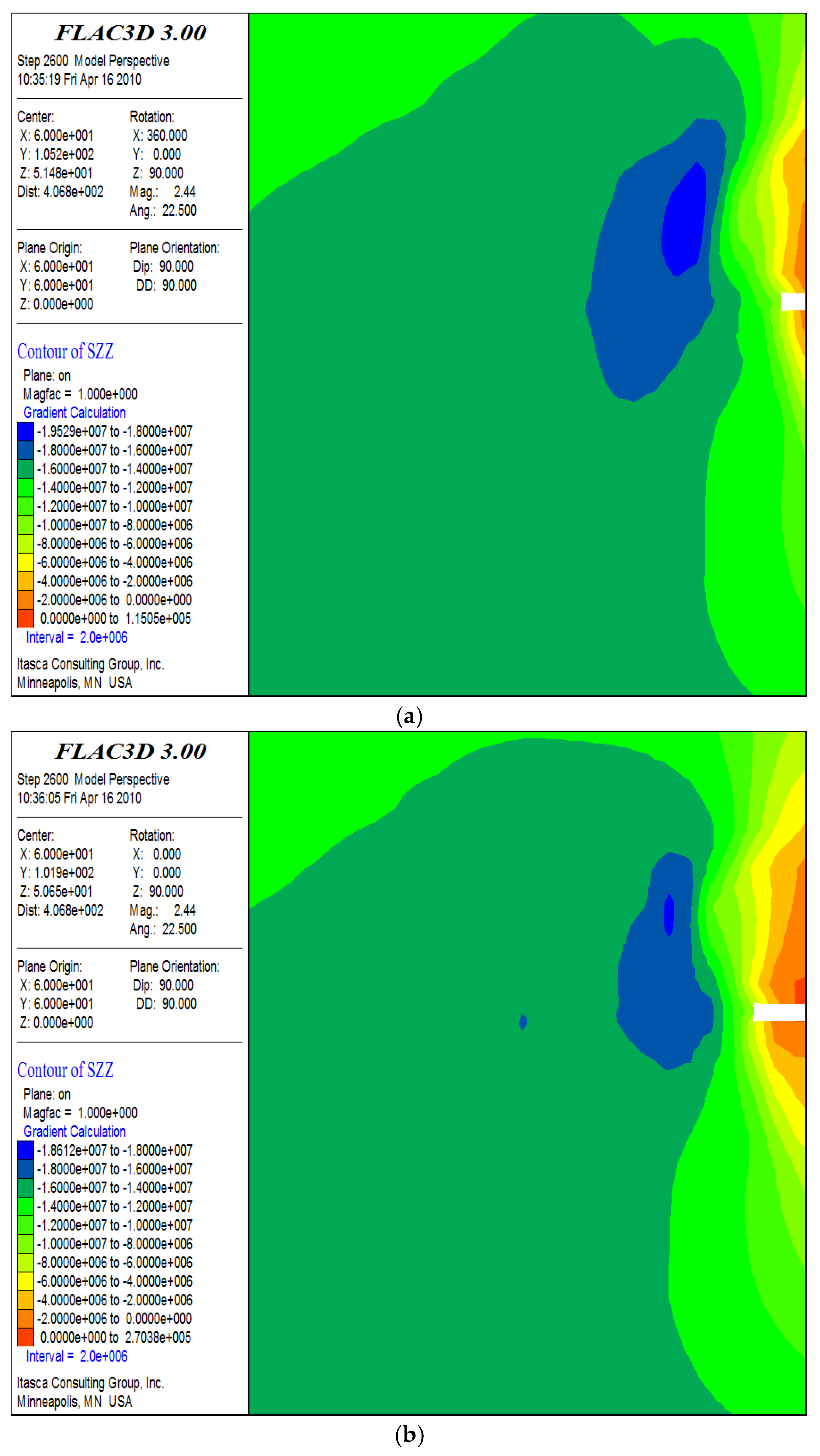

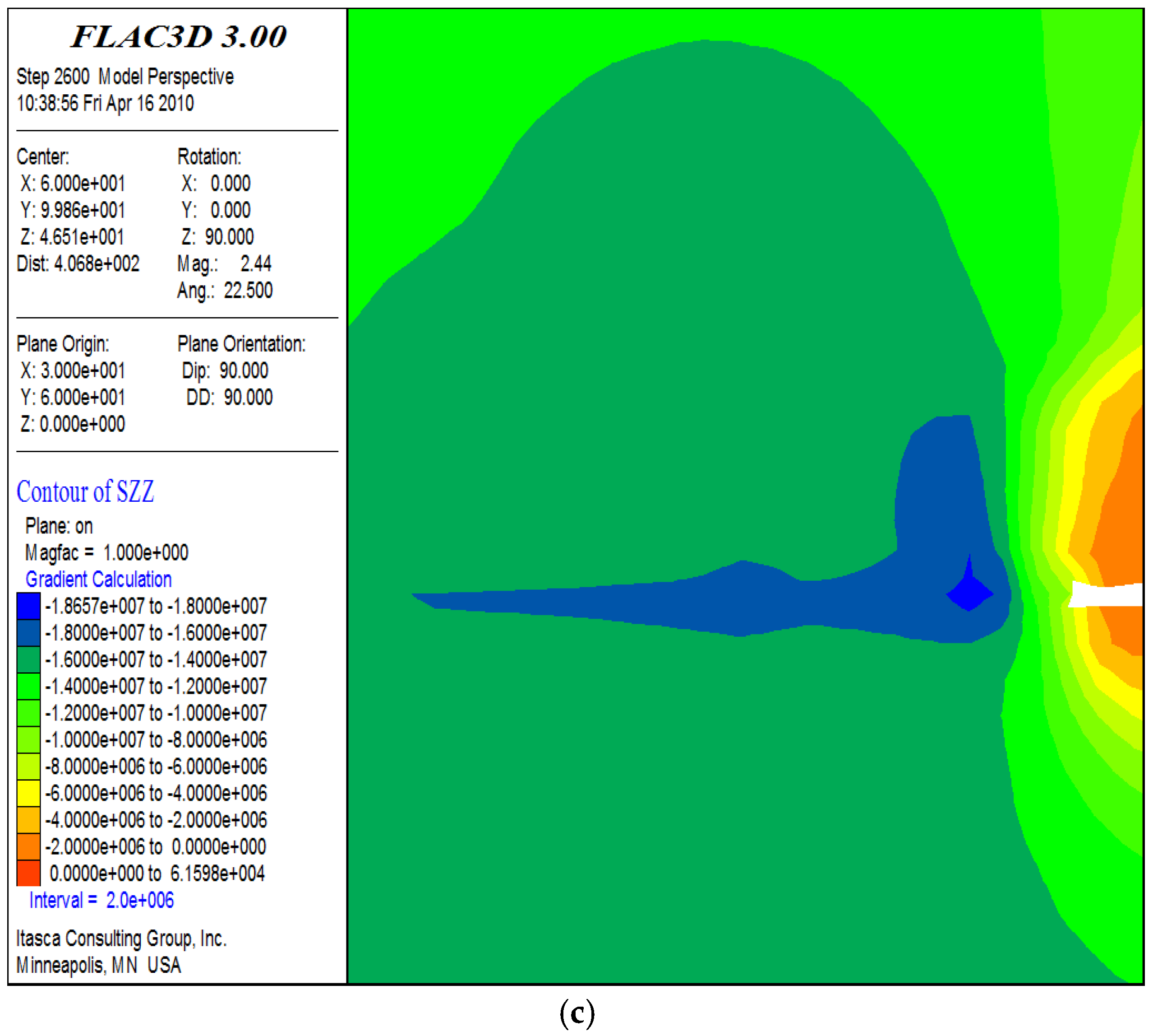

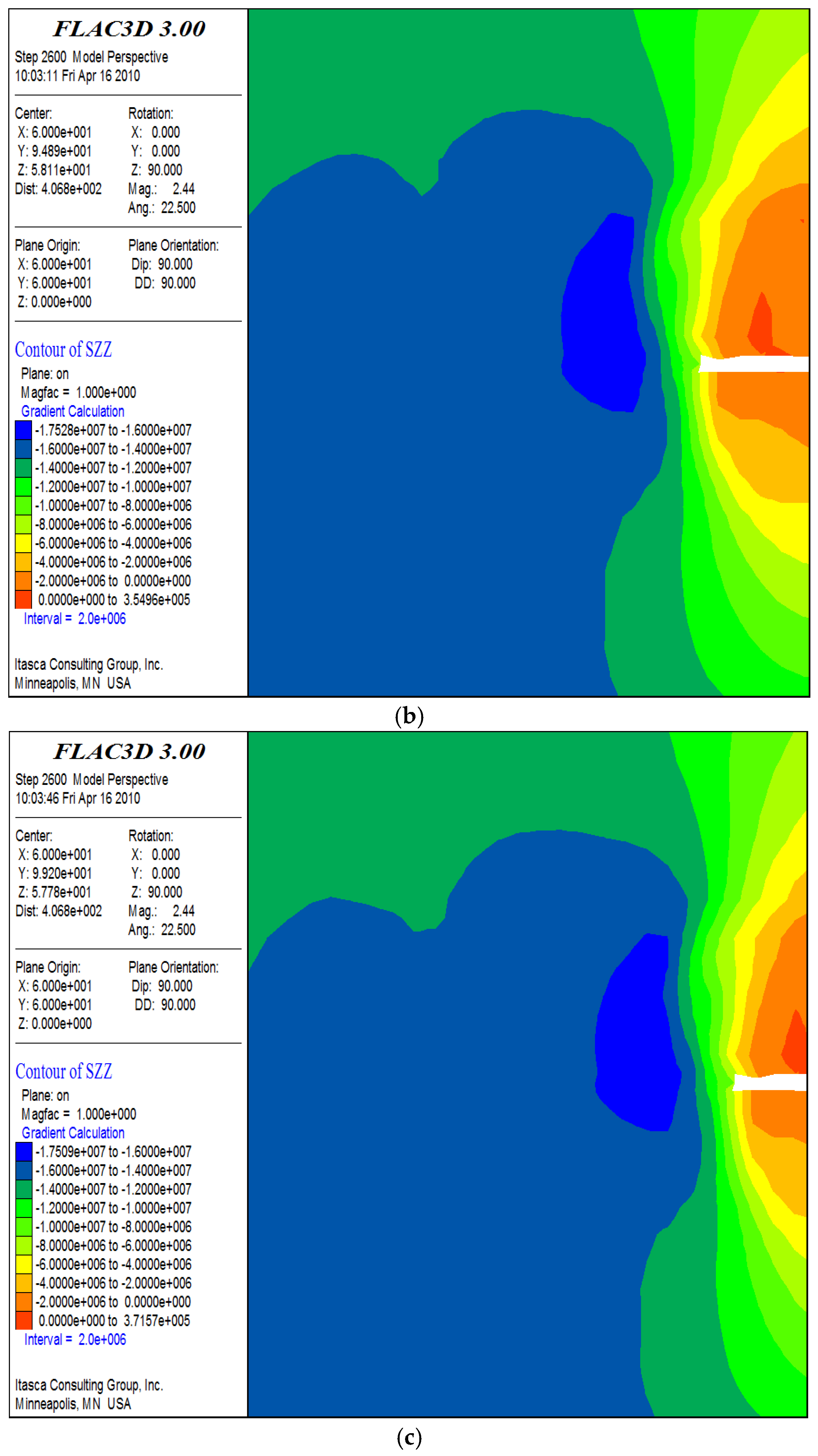

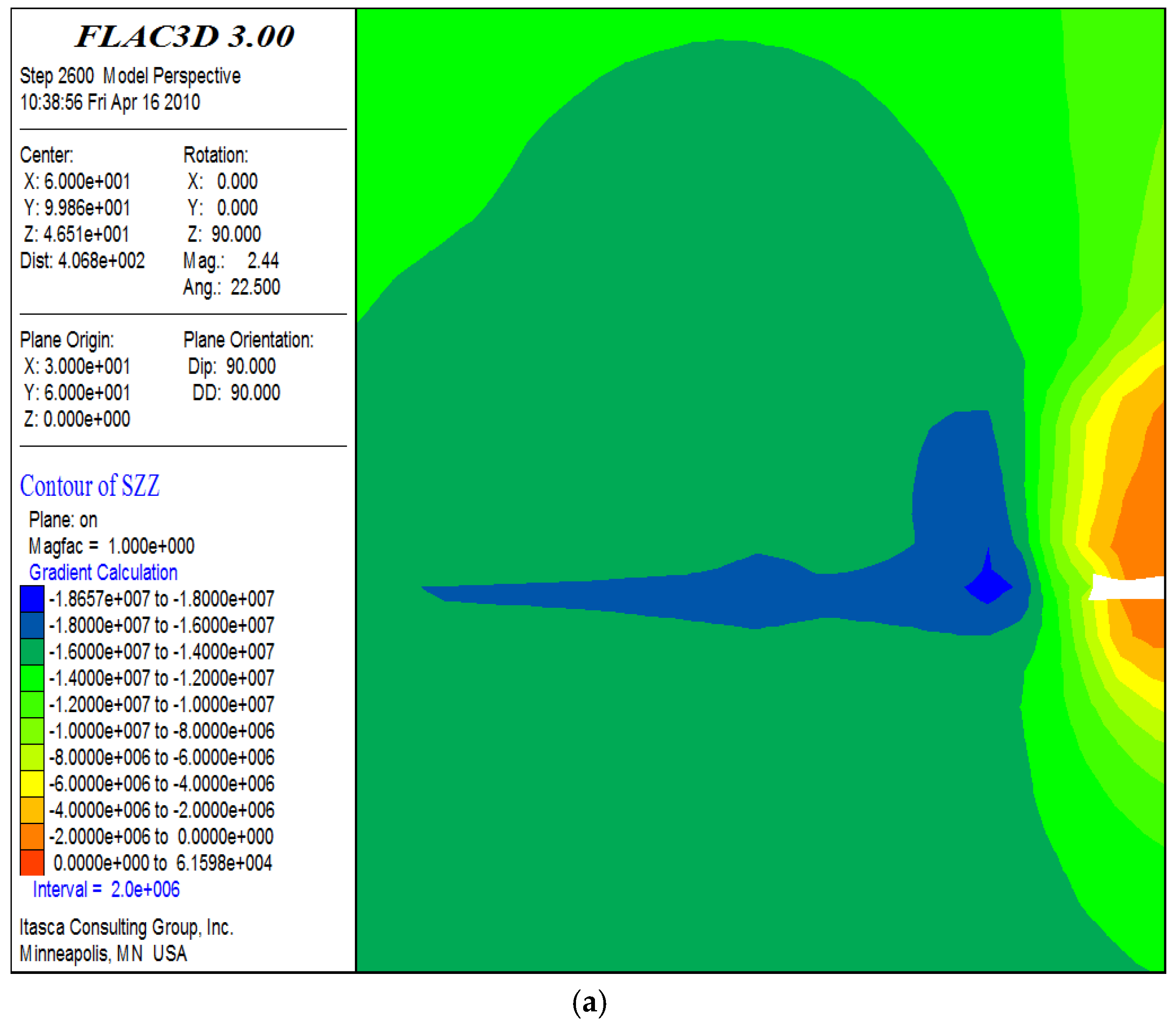

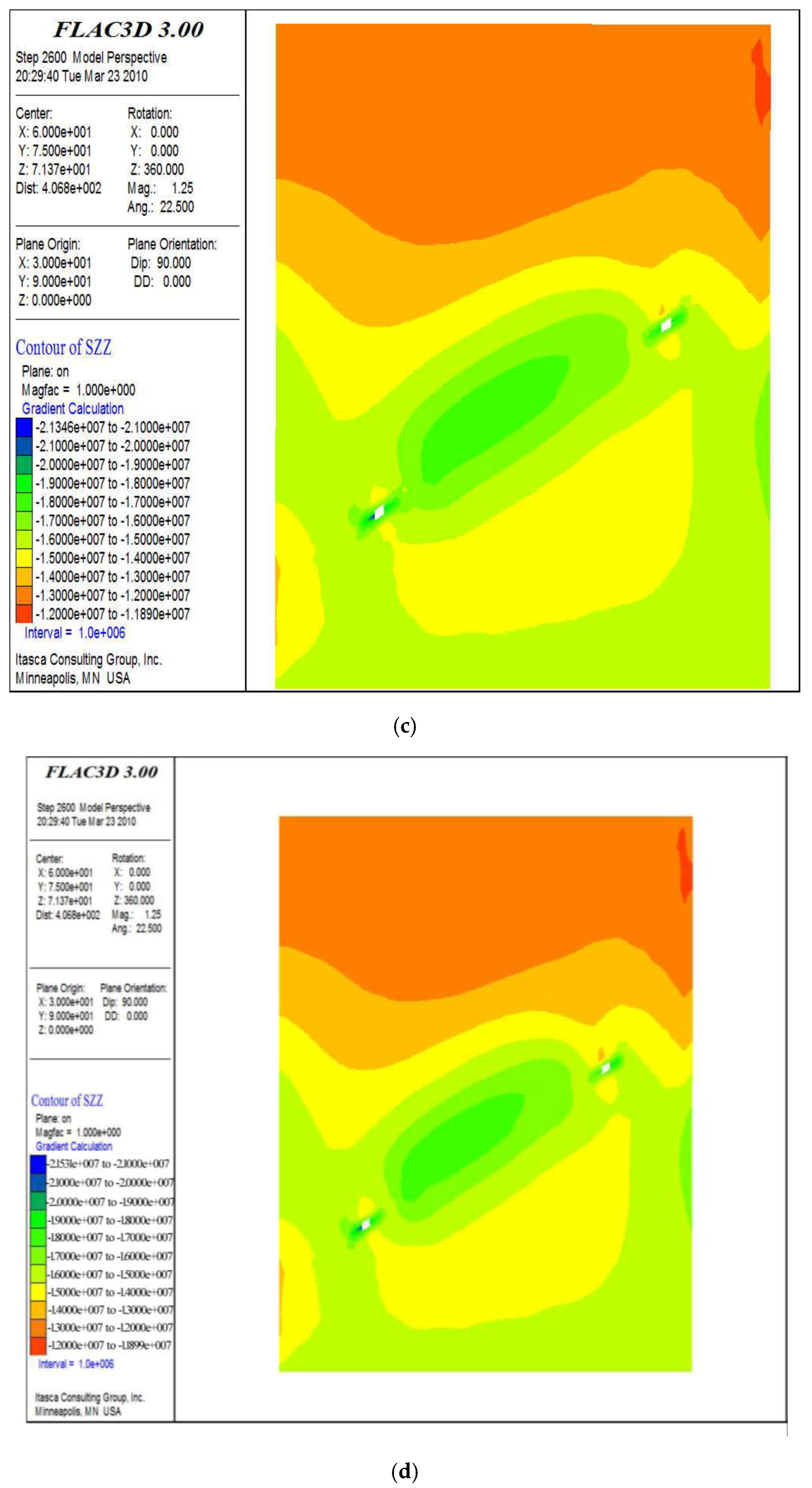

4.1.3. Simulation of the Time Effect of Water Injection on Reducing Vertical Stress

Three water injection boreholes, along the coal seam tendency, are drilled in the coal body of the roadway of No. 9 working face. The depth and diameter of each borehole is 60 m and 60 mm. The space between two adjacent holes is 10 m, with the first one 15 m from the cutting of working face. Water is injected to the three injection boreholes at the same time, and the changes of vertical stress in coal seam are shown in

Figure 16. As a result of water injection, coal body is softened and the stress concentration changes significantly. With the duration of water injection increase, the stress concentration is gradually released or transferred.

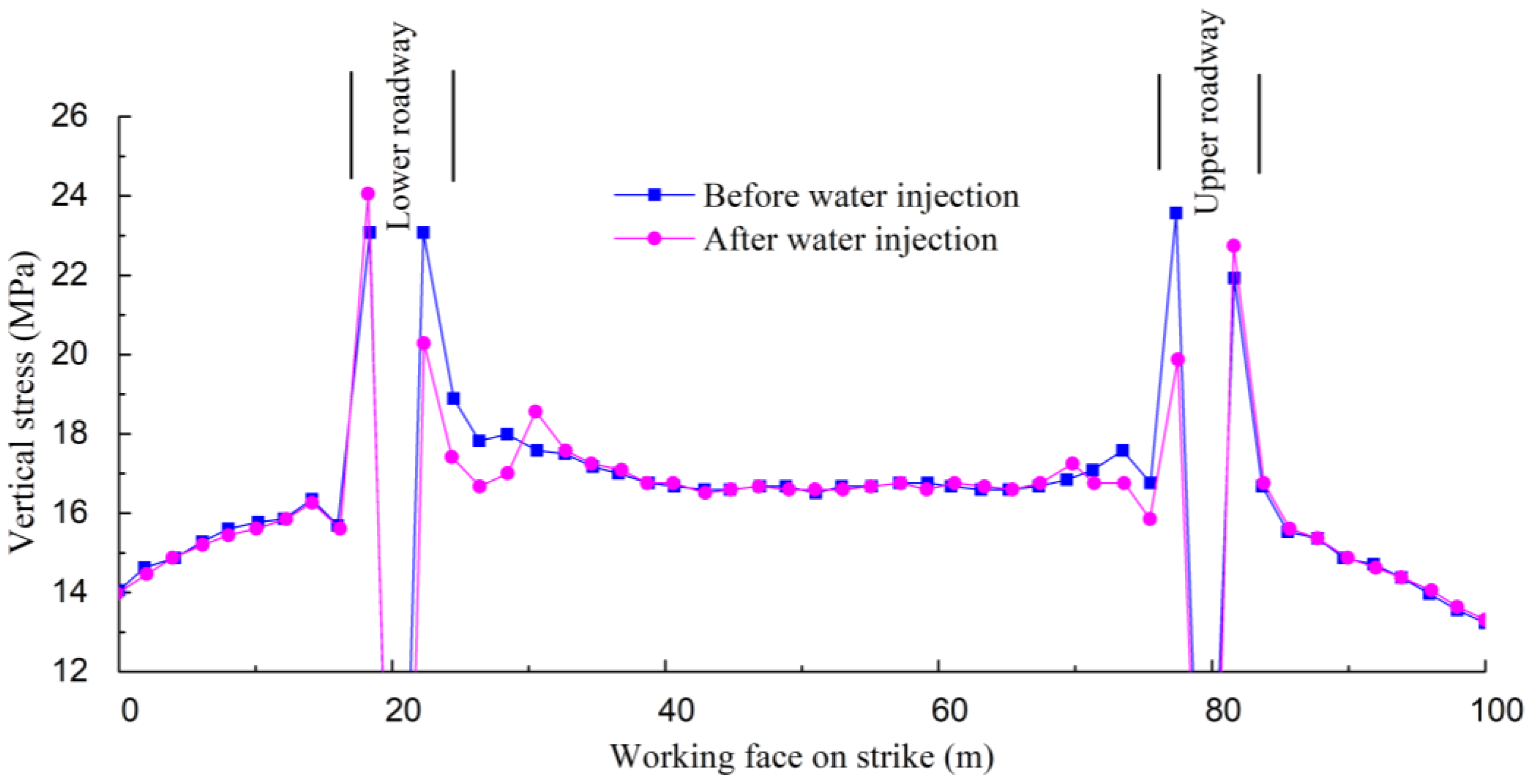

The vertical stress of working face on strike before and after water injection are shown in

Figure 17. Before water injection, the stress concentration is located on the front area of the plastic zone of the upper and lower roadway and expands about 3–10 m to the sides. The maximum stress is close to the mining face and the stress of the lower roadway is greater than that of the upper one. When the time of water injection reaches 30 h, the maximum stress and stress in the plastic zone obviously decreases and the stress concentration surrounding the water injection hole is generally disappeared. This illustrates that water injection can effectively soften the coal body and release or partially transfer the stresses. This can effectively reduce stress concentration at the working face and the danger of rockbursts.

4.2. The On-Site Test

The measures of preventing and controlling rockbursts by using water injection were used on another similar working face in the Changgouyu coal mine. Water injection of long borehole length was applied in both upper and lower roadway along the coal seam tendency. Water was injected to the three boreholes at the same time, and circular water injection was used per 10 days. The details of other water injection parameters were shown in

Table 8.

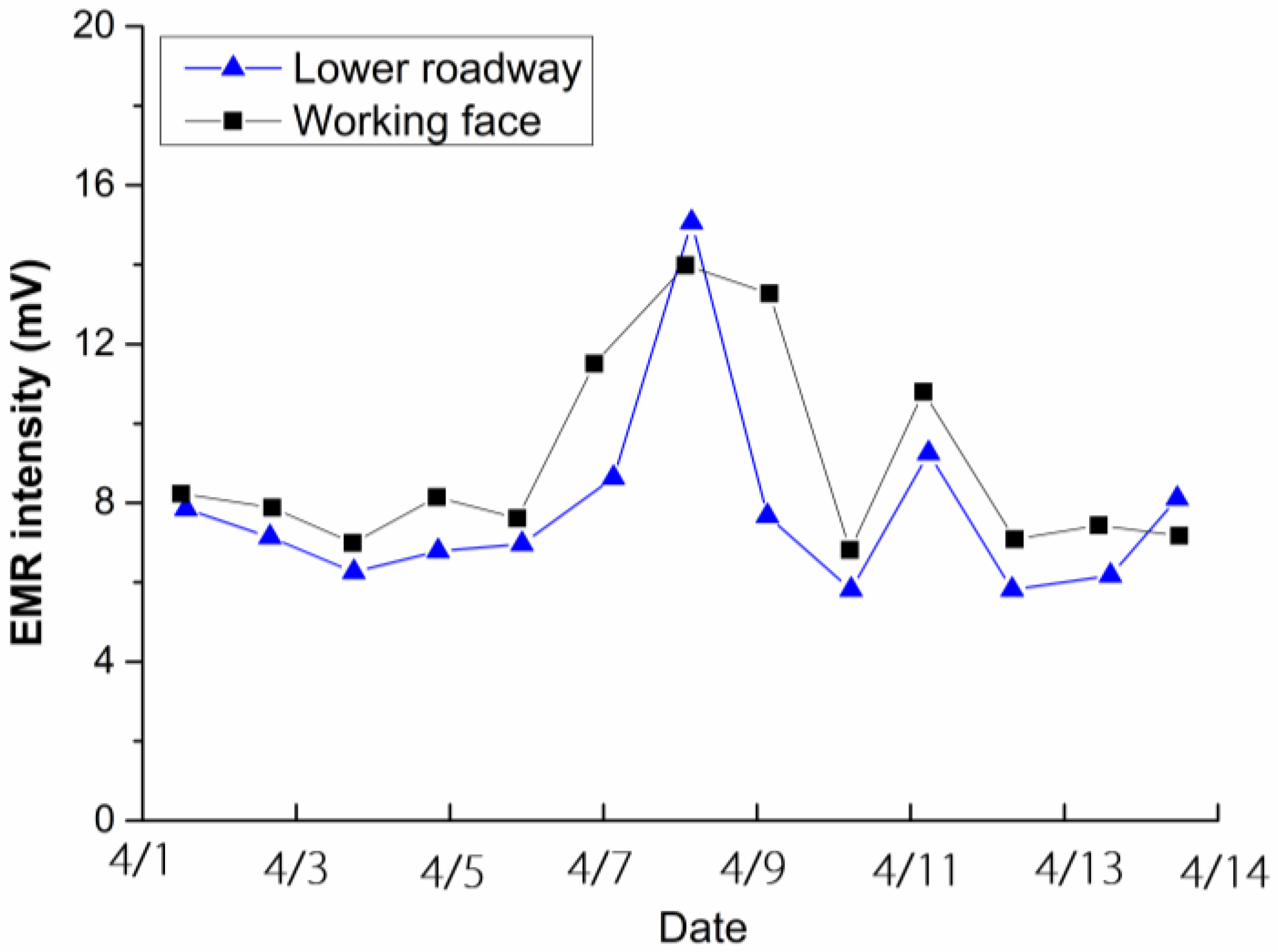

The water injection effectiveness was tested by the electromagnetic radiation (abbreviated EMR) technology. EMR is related to the stress of the coal and rock mass, and it reflects the stress concentration on the front of the working face. The higher the stress is, the more intense the deformation and fractures of a coal body and the stronger the EMR signals. EMR signals reflect the degrees of concentrated stress of a coal body and danger of a rockburst. The electromagnetic radiation technology can be used to test the effectiveness of stress concentration relieving caused by water injection.

A KBD5 type portable EMR monitor (Fu’an Technology Co., Ltd, Xuzhou, China) was used in the study. The distance between two adjacent EMR testing points in the coal wall or roadway is 10 m and the testing time at each testing point is 2 min [

26,

27]. EMR intensity (abbreviated E), measured as mV, is selected as the EMR testing index for the stress distribution. EMR methods for predicting rock burst are dynamic and a critical value is used in this method. In general, based on the EMR forecasting criterion, the E value which is 1.5 times the normal E value is selected as the initial critical E value in the monitoring area. After a period of testing and according to the E value before the incidence of a rock burst, the initial critical E value is modified by fuzzy mathematics. After further validation, a critical E value can be confirmed. The critical E value of this working face in the Changgouyu coalmine was determined as 12 mV. During the test process, if the E value of the monitoring area exceeds 15 mV and it appears as a special time trend (the trend is explained in reference [

28] in details) over several shifts or days, then a rockburst will likely occur in this monitoring area.

Figure 18 shows that the EMR signals were relatively stable from 1 April 2011 to 5 April 2011, and the strength was less than 10 mV. The E value gradually increased on April 6th and it reached 15 mV on 7 April that was above the critical value. This indicated that the stress at the working face and the lower roadway had increased, and the stress concentration and the danger of strong rock pressure were also increased. Therefore, measures should be taken to reduce such risks.

From 8 April and the following three days, beyond the circular water injection of long borehole length, the emergent water injection of short borehole length started at the working face and lower roadway. The depth of the borehole was only 10 m, but the number of boreholes was added by 8, 1 and 5 in the three days, and the injection durations is was min, 30 min, and 30 min per day.

After water injection for three days, the EMR intensity at the working face and lower roadway decreased, its value was lower than 10 mV and it became stable again. This illustrated that the water injection is effective. It can effectively soften the coal body and release or transfer the stress. The danger of strong rock stress disappeared.

There was a strong rockburst on 23 May in another coal seam, which caused apparent damage to one of the roadways and the working face. After that, water injection also was used as a preventative action. Although three weak rockbursts happened after that, the damage caused was small. This shows the obvious effect of coal seam water injection on the preventing and controlling of rock stress on-site.

5. Discussion

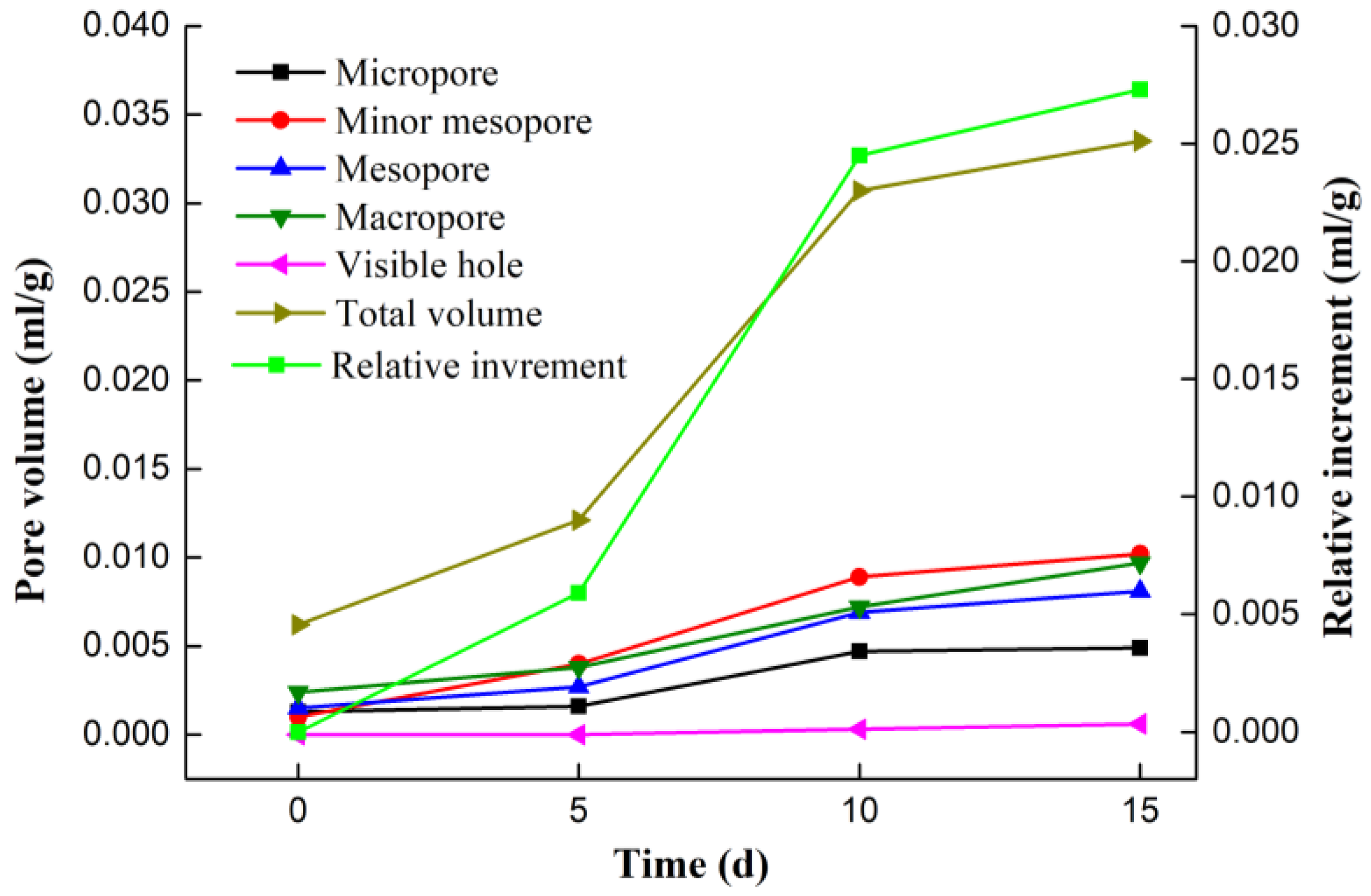

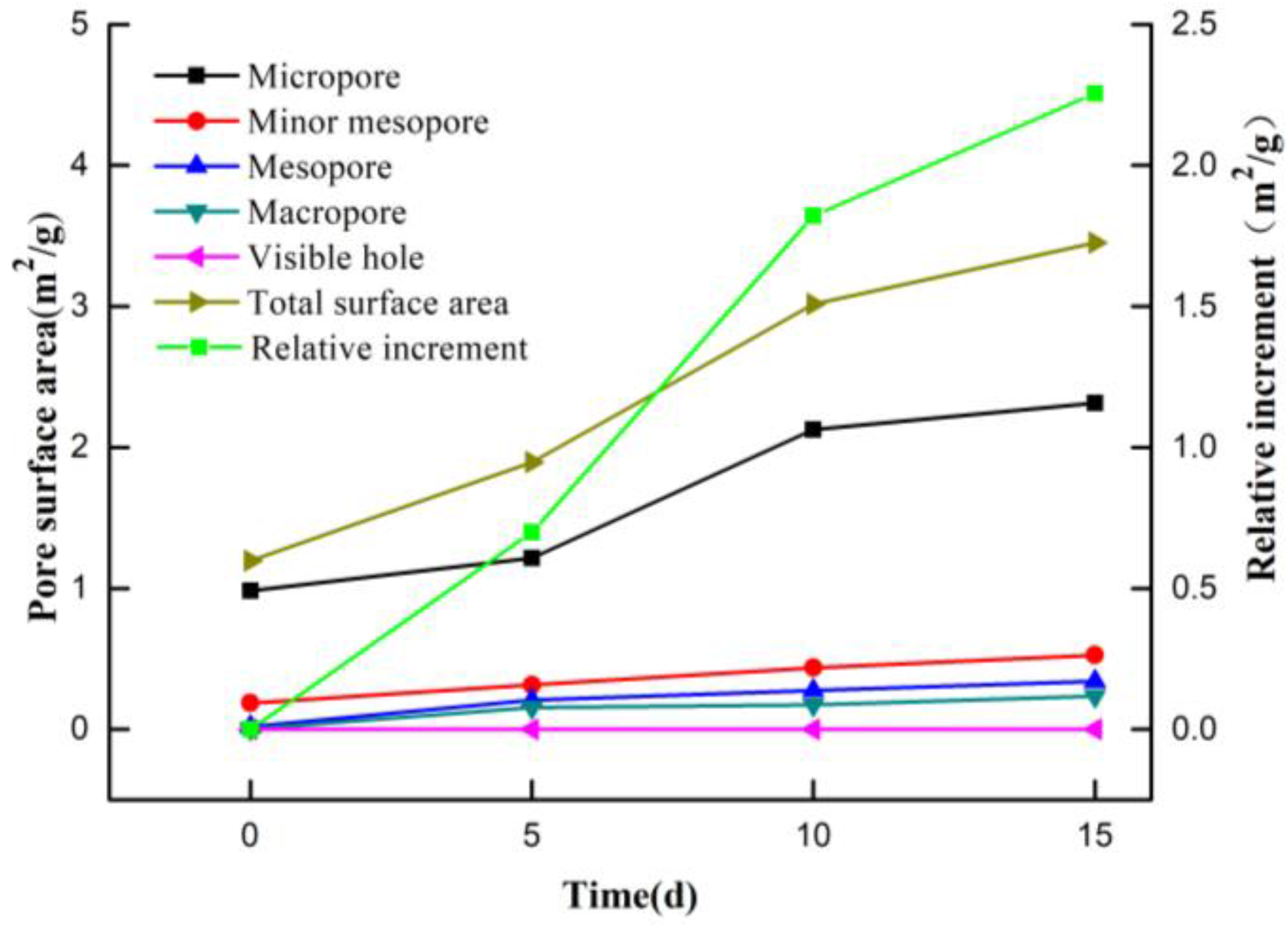

Coal is a porous medium with a large number of cracks and pores inside. Water flows inside coal in the form of permeation, capillary movement and diffusion. After soaking, water slowly flows along cracks and capillaries. As soaking time increases, the water pressure at crack surfaces and mineral swelling cause changes to the mechanical properties of coal, including an increase of plasticity, and a decline of hardness and compressive strength.

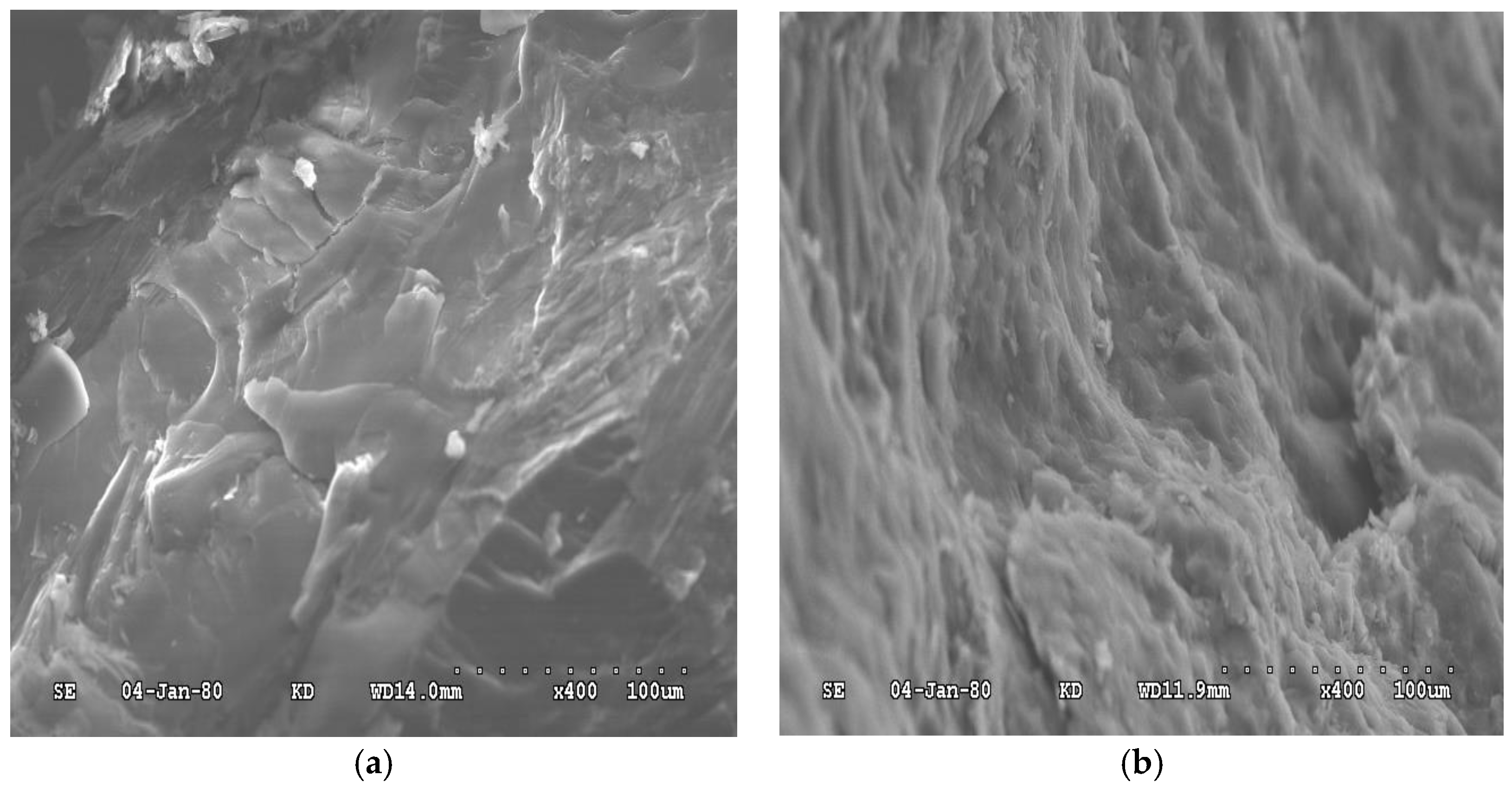

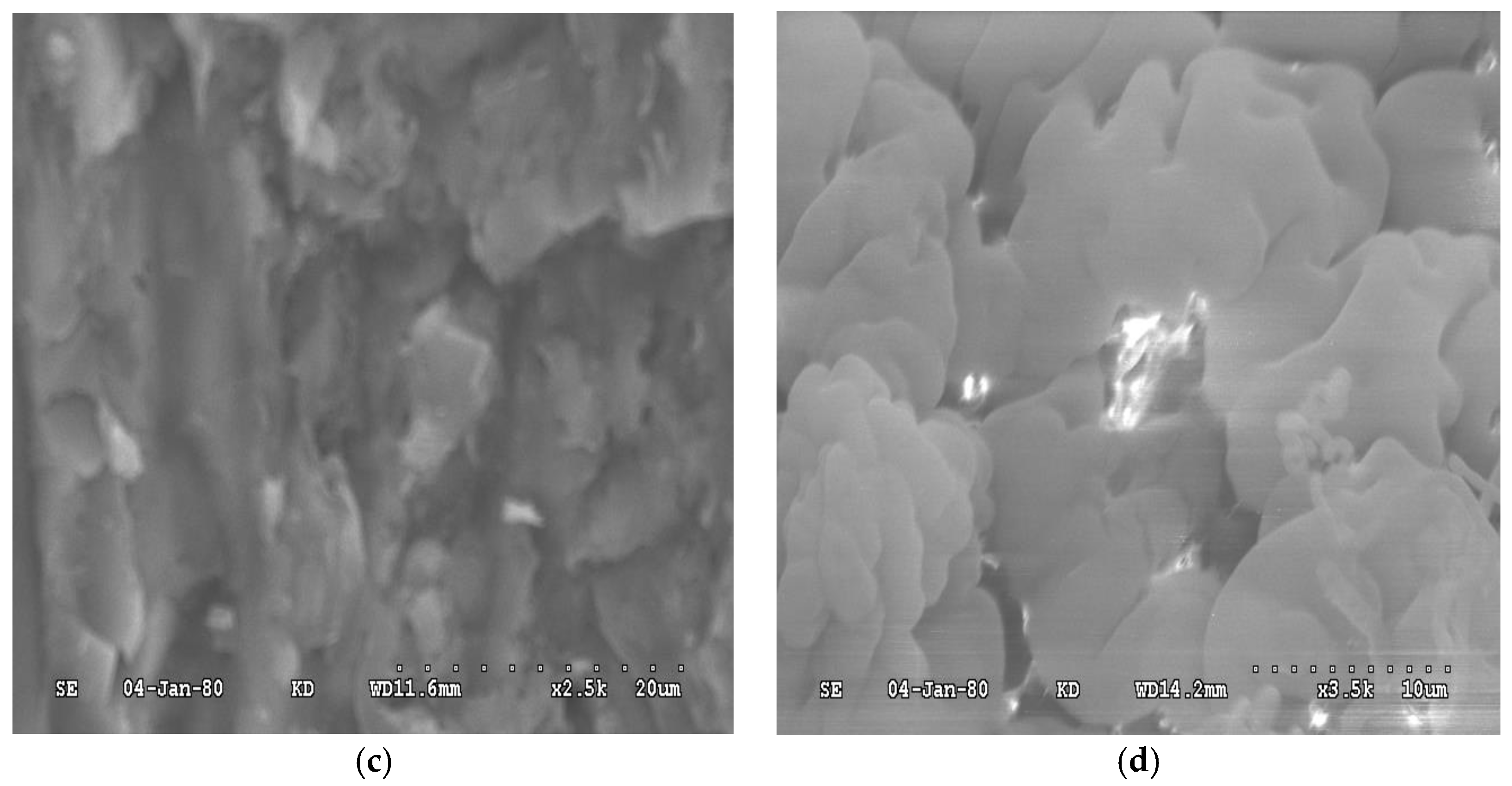

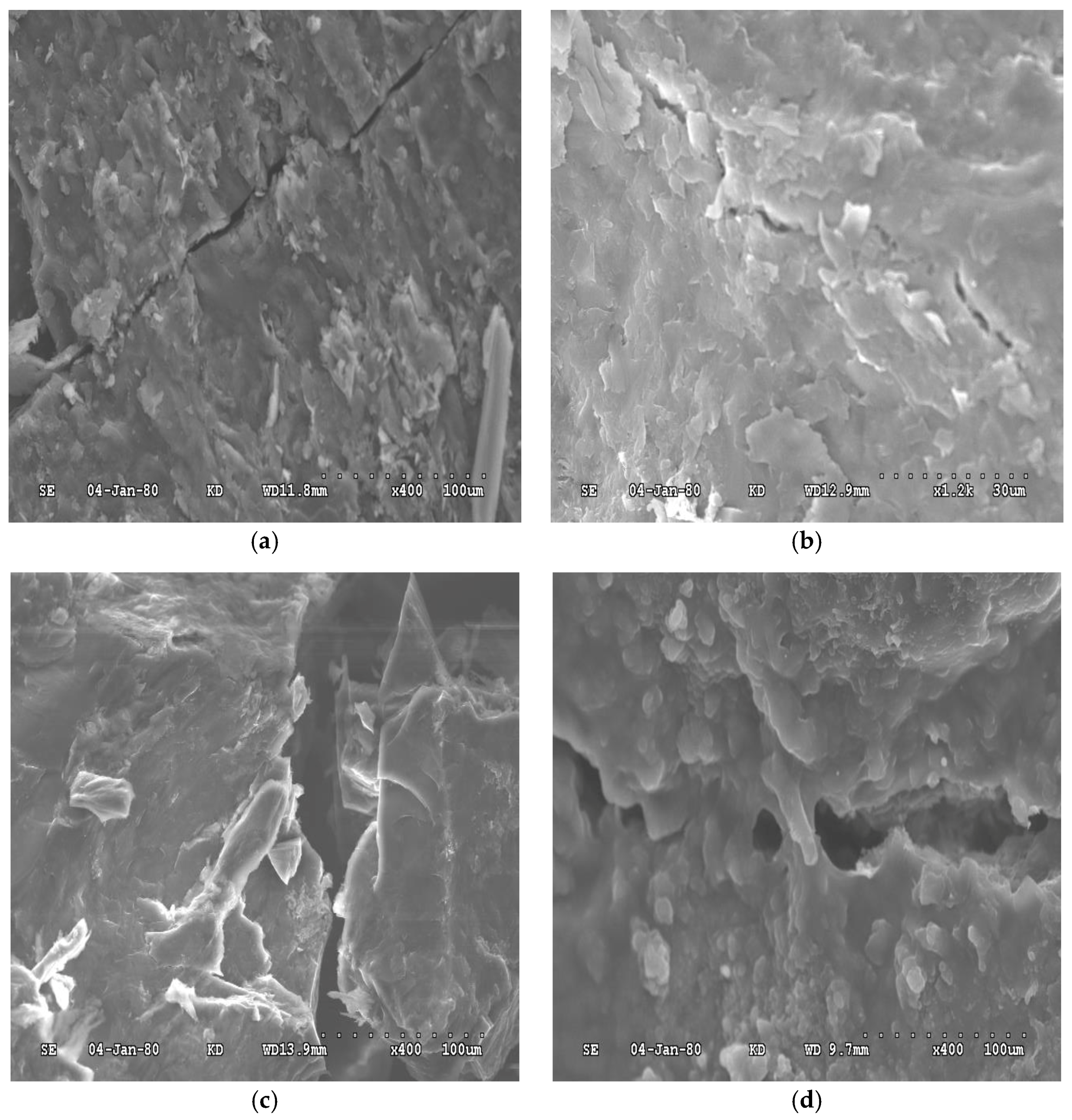

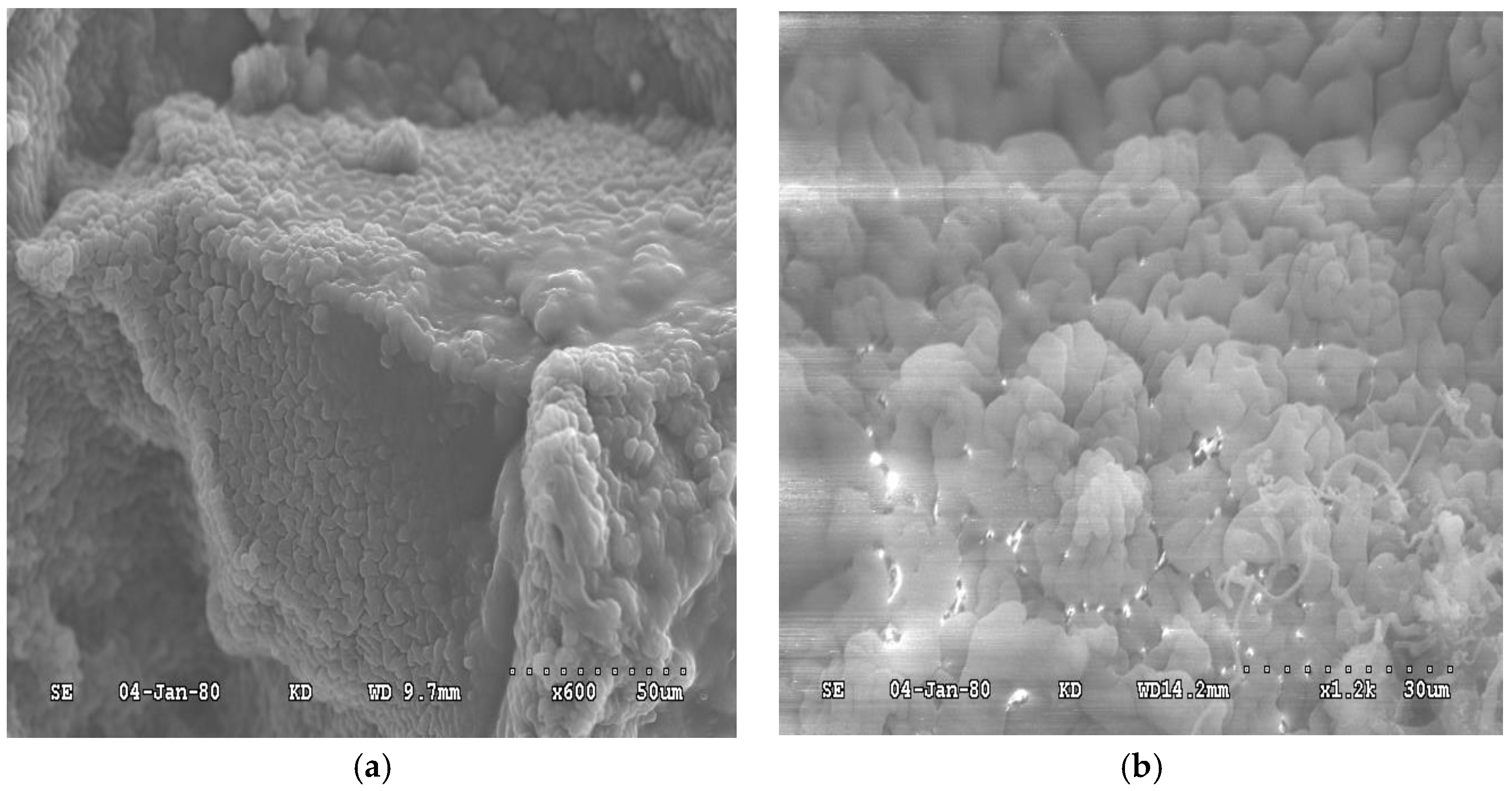

On one hand, water has an expansion effect on the primary cracks of coal. As depicted in

Figure 8, the effect changes the pore structure, the number of the cracks and their width. The microstructure surface area increases due to the development of mesostructure. On the other hand, after soaking, water inside samples causes coal body swelling, which not only expands the original crack but also produces new cracks (as shown in

Figure 7). As soaking time increases, at the end of the cracks protruding structures develop with a large number of flake structures, and the number and length of cracks increases obviously. Soaking causes a microstructure change, which is determined by soaking time. The surface area and total volume of the internal microstructure of coal samples can be greatly increased by soaking, so it is possible to use water injection to change the the mechanical properties of coal.

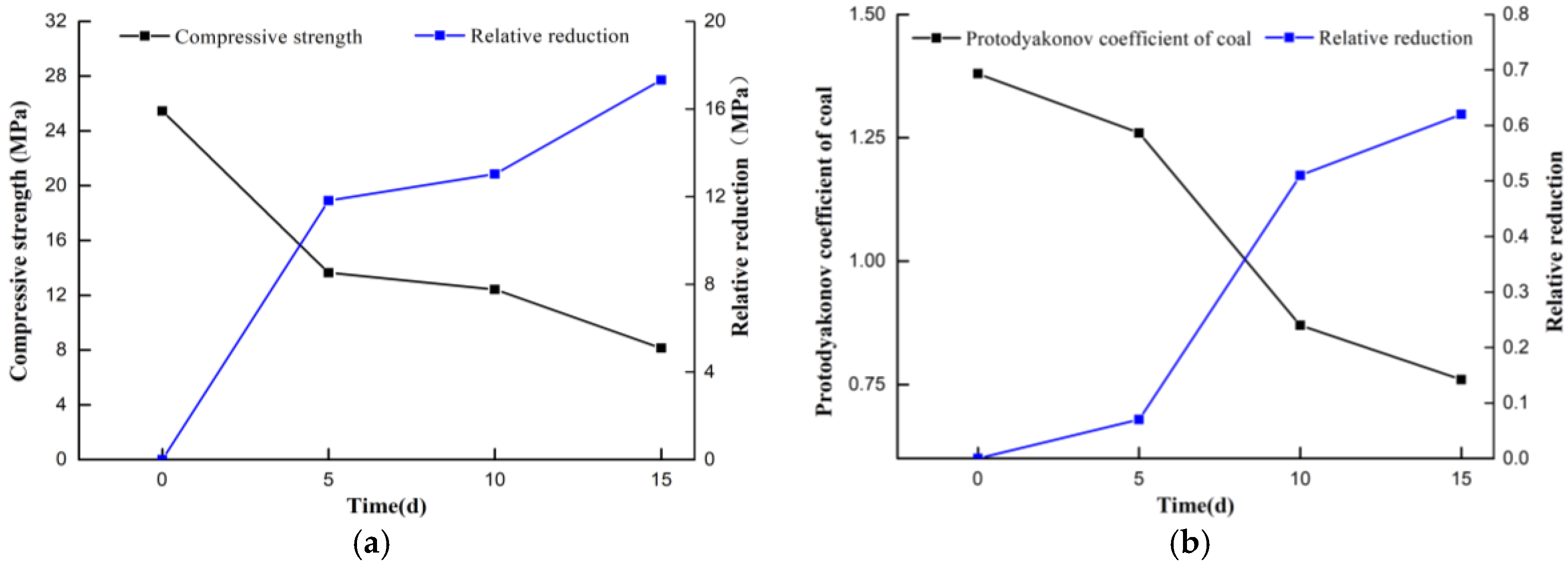

After soaking, the mechanical properties of coal have changed. Uniaxial compressive strength, Protodyakonov coefficient and porosity are obviously changed after different soaking times. This demonstrates a time effect. Through studying experimental data, the slope between the relative variation of mechanical parameters of different coal size and soaking time is obtained, as shown in

Table 9. The time effect is different for different coal sizes. The obvious effective soaking time in centimeter and millimeter sized coal is the first five days after soaking, but for micron size coal, this is from five to 10 days after soaking.

The variation of physical-mechanical parameters of coal in different soaking time is obvious. When the soaking time is 5 days, the decrease of uniaxial compressive strength is the maximum. Although, uniaxial compressive strength continually decreases as soaking time increases, the decrease rate becomes slower at the later stage. There is a change point of pore volume and Protodyakonov coefficient when soaking for five days and 10 days. During this time the decrease rate of the Protodyakonov coefficient and increase of porosity and pore surface area reach the maximum. Based on the analysis, it can be found that the mechanical properties of coal show a time effect during soaking. There is a changing point where mechanical properties of coal are changed dramatically. Therefore, studying the optimal time of coal soaking in the laboratory has an important guiding significance for the on-site application of coal seam water injection.

Bursting liability theory holds that under the same geological and mining conditions, rockbursts in coal seams yield large differences, and their occurrence is determined by the inherent mechanical properties of coal. These inherent properties are regarded as the bursting liability of coal. The so-called bursting liability indices, duration of dynamic fracture (

DT), elastic strain energy index (

WET), bursting energy index (

KE), and uniaxial compressive strength (

RC) were proposed to evaluate the bursting liability of coal [

29]. Wu et al. [

15] concluded that when the moisture content increases by 3%, the uniaxial compressive strength of coal samples reduces by 32%, and there is an exponential relationship between the reduction of coal strength and the immersion time. Pan et al. [

21] pointed out that extending the soaking time can reduce the overall degree of burst tendency of coal samples with strong tendency. Uniaxial compressive strength falls rapidly after seven days of soaking, and the degree of the other three indexes begins to increase after 20 days soaking. Mao et al. [

18] determined the relationship between the burst liability and water content and porosity in coal seam by experimental studies, and found that the burst liability depends inversely on the water content, and is most sensitive to the original water content. Studies by Liu [

16] and Sun [

17] applied water injection measures to rockburst prevention in different coal mines. The above studies focused on the mechanic mechanism of water injection on coal on a macro scale (from centimeter to meter size), and the micro scale mechanics mechanism had not been studied.

We analyzed the time effect mechanism of water on different sizes of coal (from meter to nano-meter size). Uniaxial compressive strength, Protodyakonov coefficient and the porosity are measured after the samples have completely soaked in water for a period of time. During soaking, a small amount of hydrophilic mineral absorbs water and swells that cause a decrease of coal strength. Water is a solvent that can dissolve soluble minerals, and the degree of dissolution is related to soaking time. Because of this, the strength of coal increases, which leads to the burst liability of coal samples changing with soaking time. In the numerical simulation and on-site application, pressurized water is used which is favorable for infiltrating the coal seams, reducing the effective time of water injection and improving efficiency.

Our research had provided a method to study the time effect of water injection on the mechanical properties of coal of different sizes and its application in rockburst prevention. The proposed water injection measure and parameters are only applicable to the Changgouyu coal mine, where the natural water content of its coal is 0.26%, and the average water content exceeds 1.29% after absorption, so the permeability of this coal seam is relatively poor. Further studies are needed for different coal seams with different coal properties

6. Conclusions

(1) The mechanical properties of coal samples under soaking for different durations are tested in the laboratory. The time effect differs with the coal size. When the soaking time was five days, the rate of decrease of uniaxial compressive strength was the maximum. In addition, there was a changing point in the Protodyakonov coefficient, porosity and pore volume and surface area. After soaking for 10 days, the surface area increase of micropore, small pore, mesopore, big pore and visible pores and total surface area of pores reached the maximum.

(2) As soaking time increases, changes to the pores, cracks, bubbles and flake structures inside the coal body take place and develop gradually. When the soaking time is between 10 days and 15 days, the development of the microstructure inside the coal body is sufficient and it shows that the internal skeleton and the mechanical properties of coal are changed.

(3) The numerical simulation results show that the coal body is softened and the stress concentration changes significantly as a result of water injection. As the duration of water injection increases, the stress concentration is gradually released or transferred. When the injection time reaches 30 h, the stress concentration in the water injection area disappears, and the stress in the whole plastic zone also decreases significantly. On-site test results in the Changgouyu coal mine demonstrated that water injection can effectively soften coal bodies and release or transfer stresses, and showed the apparent time effect of water injection on rock prevention and control.