Stress Inversion of Coal with a Gas Drilling Borehole and the Law of Crack Propagation

Abstract

:1. Introduction

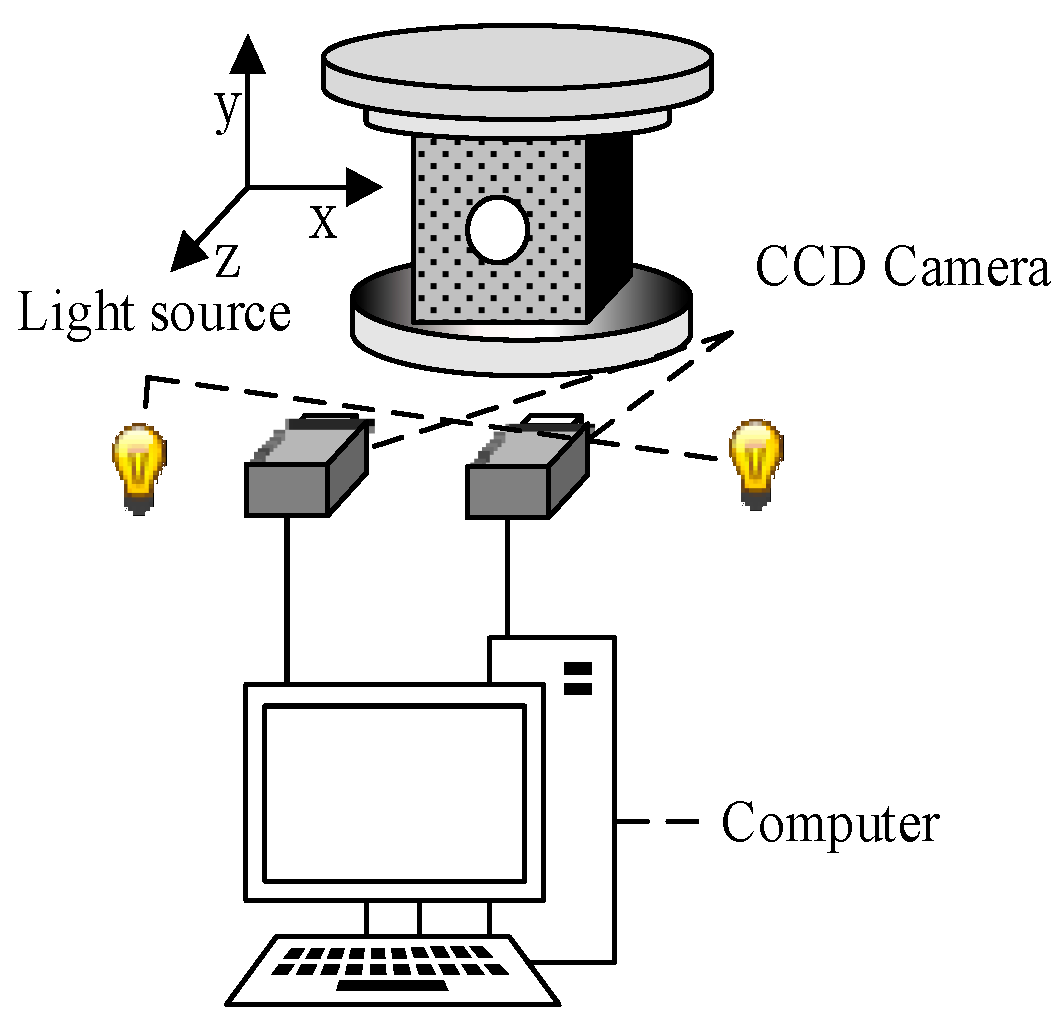

2. Method and Theory

2.1. Digital Image Correlation

2.2. Model of Stress Inversion

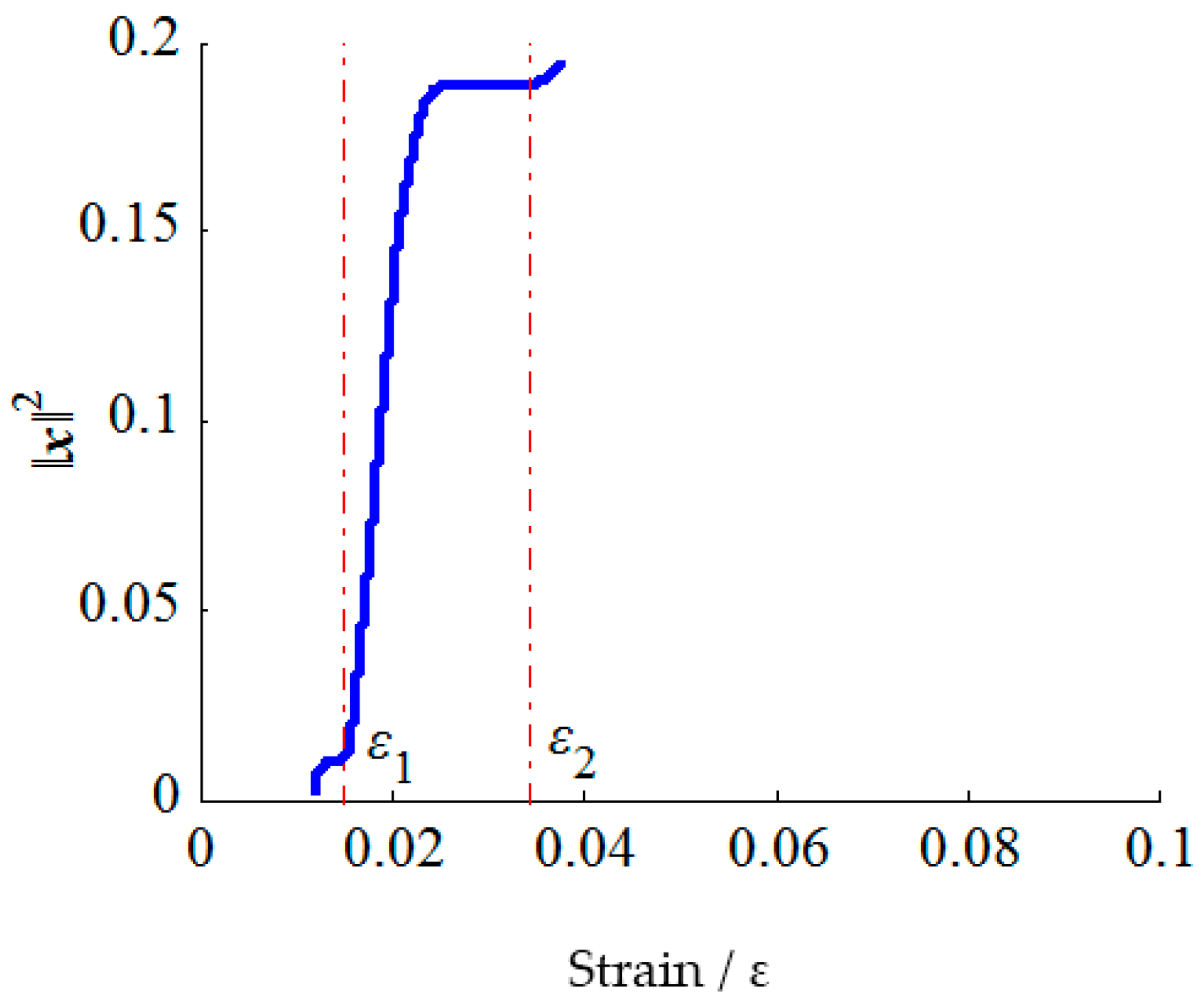

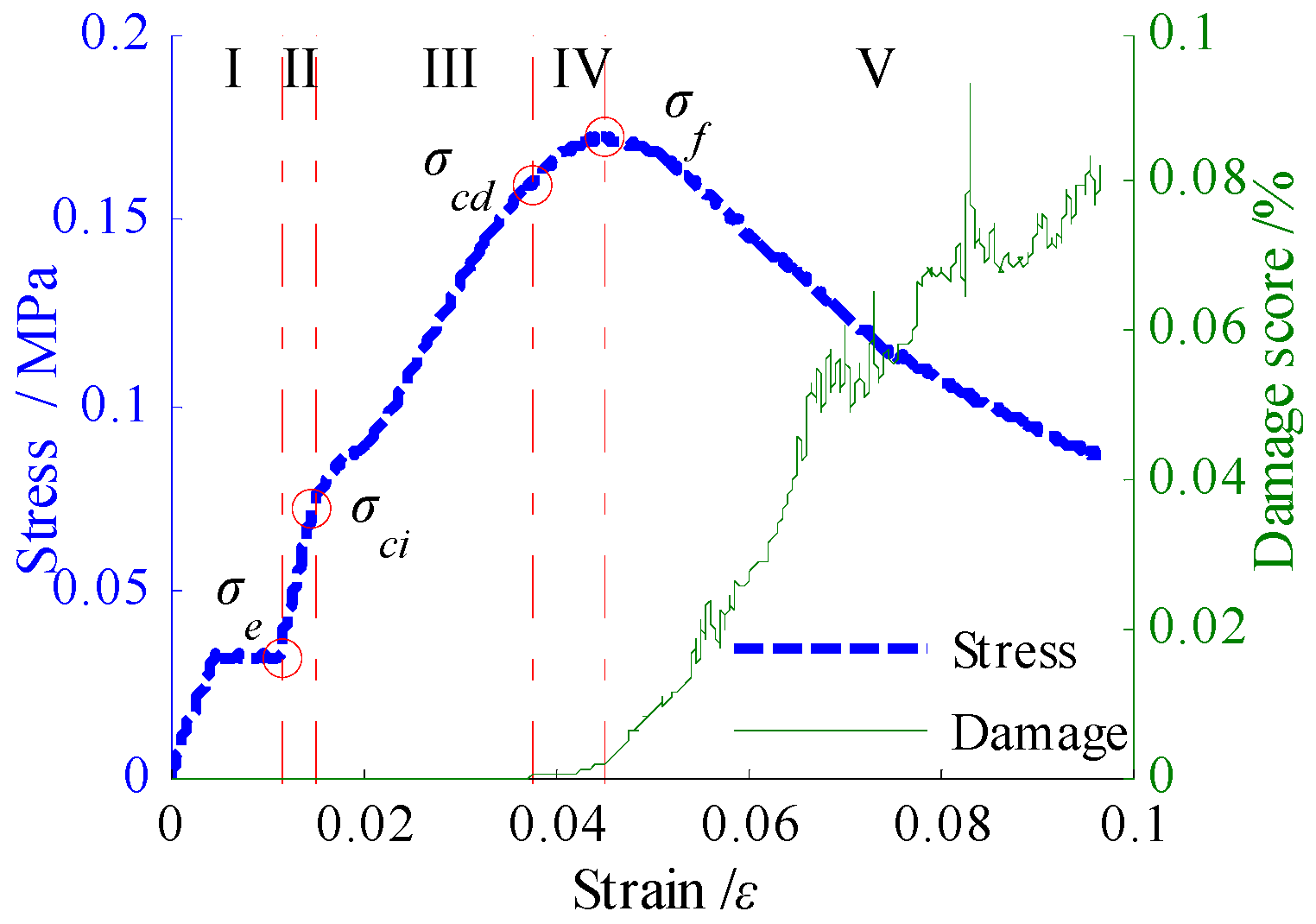

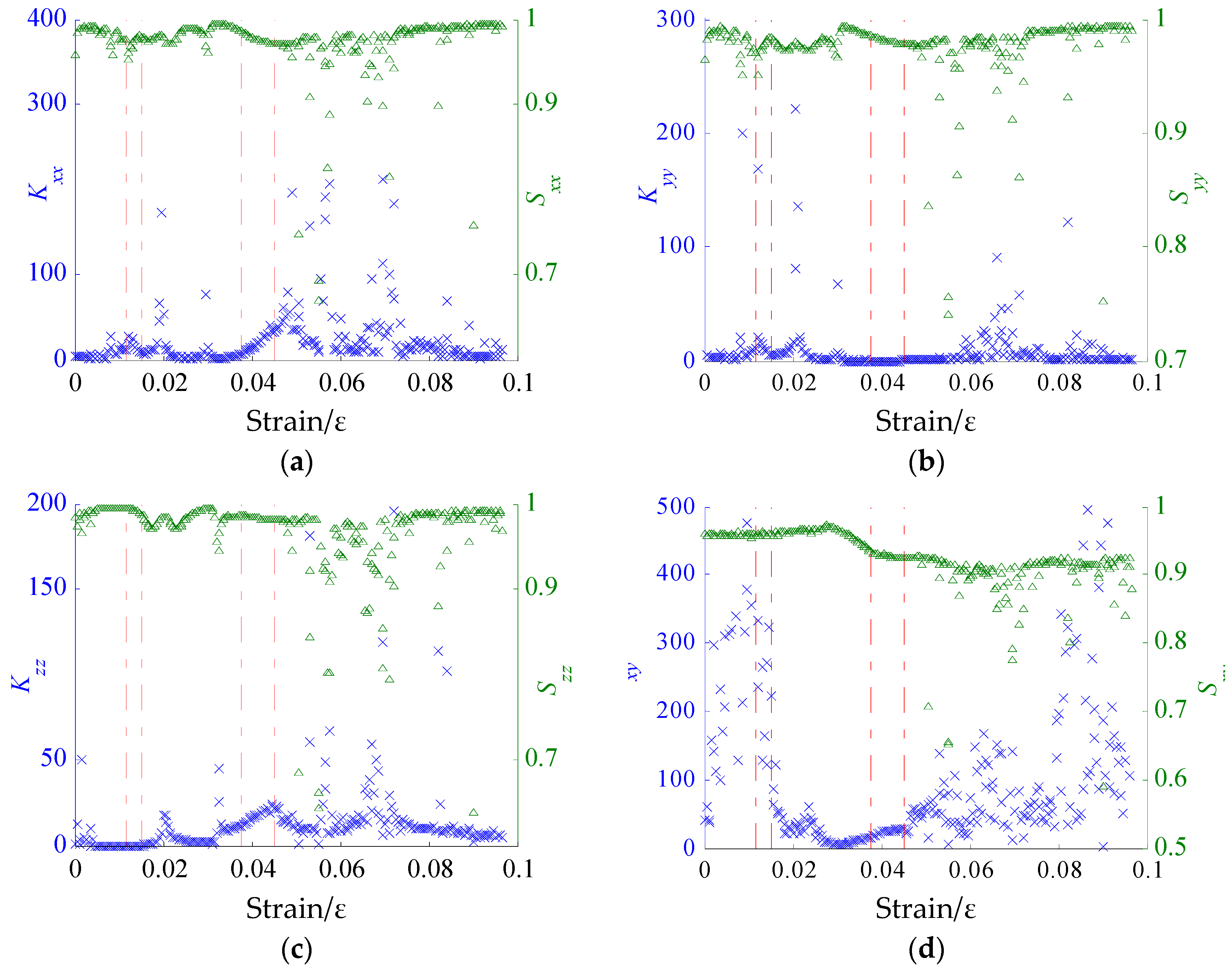

2.3. Method of Defining the Stress-Strain Curve

3. Experimental Details

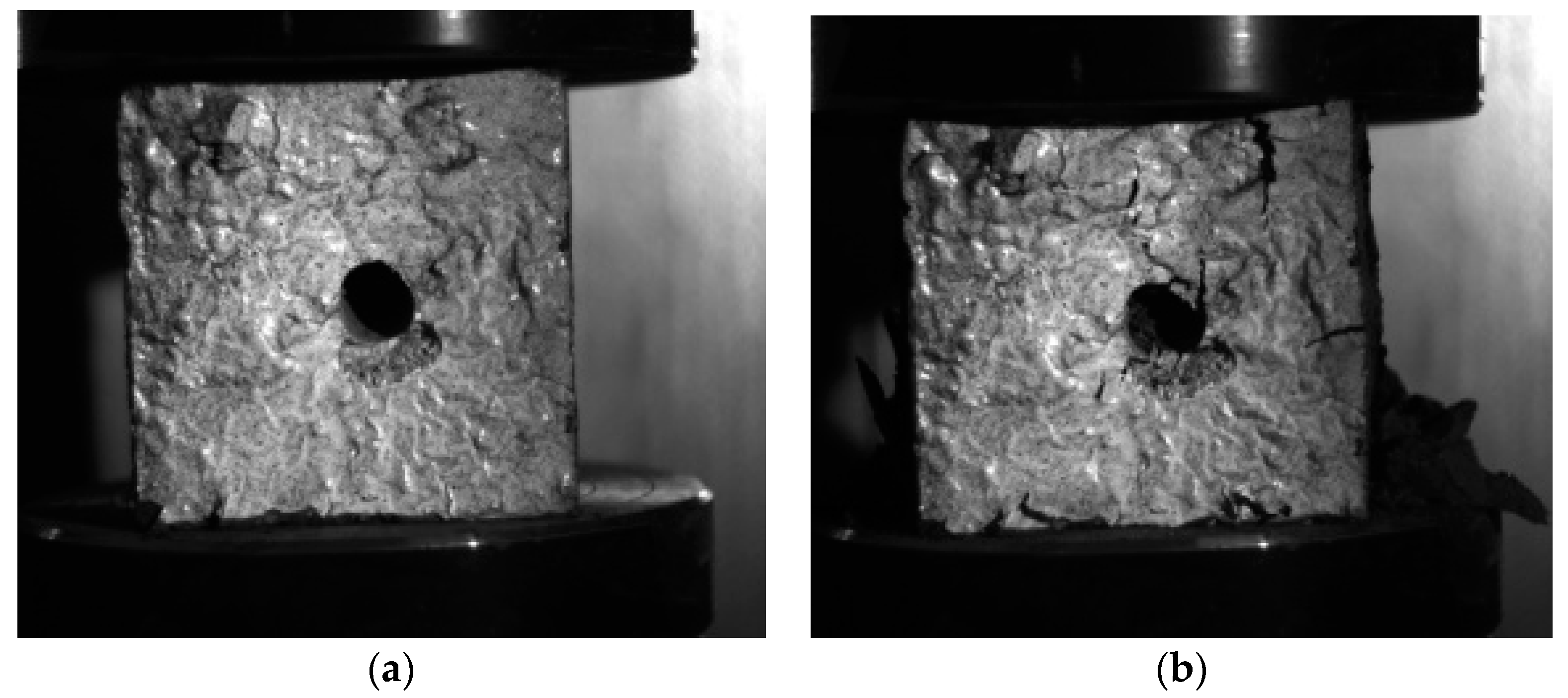

3.1. Specimen Preparation

3.2. Experiments Result

4. Results and Discussion

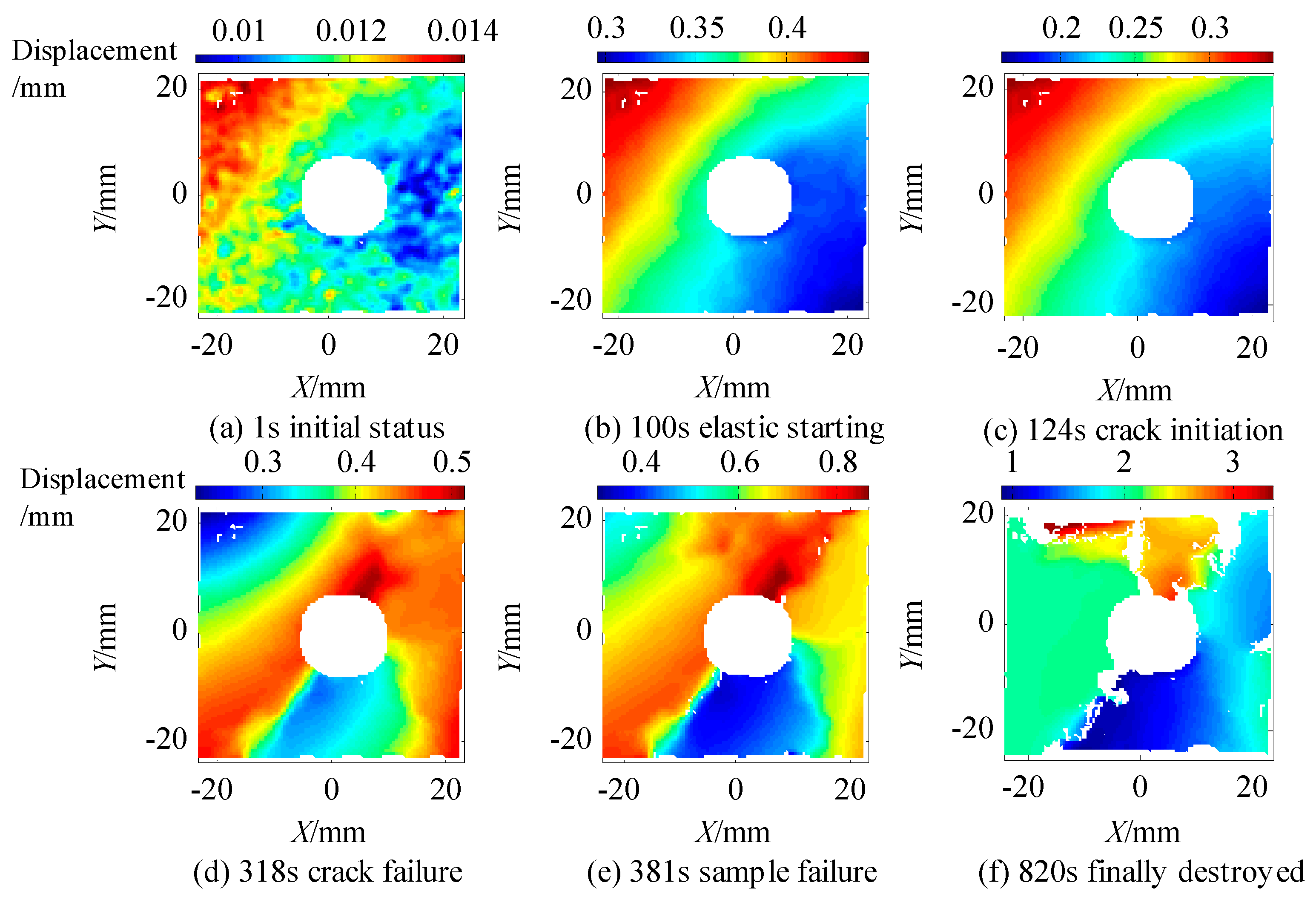

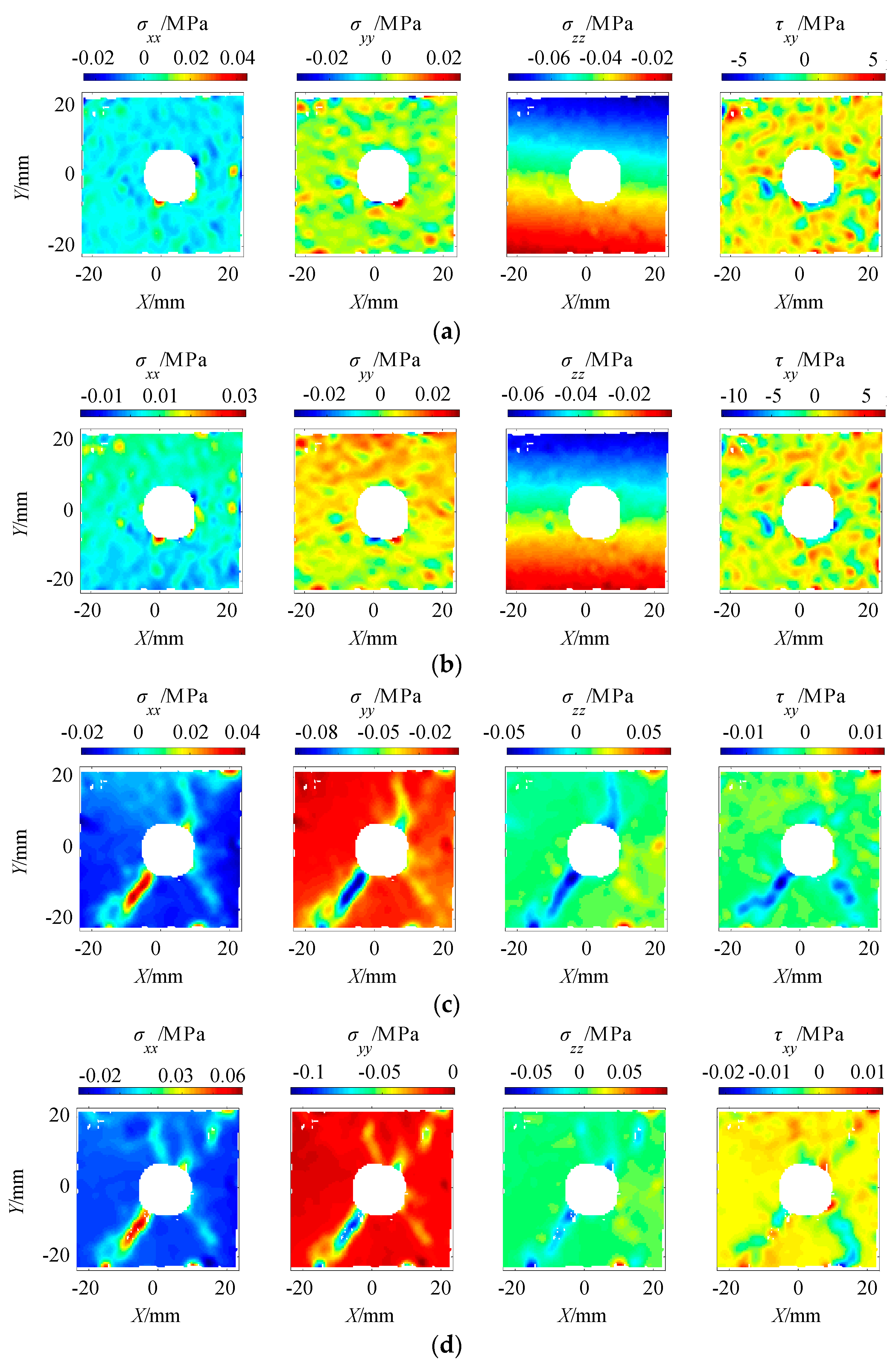

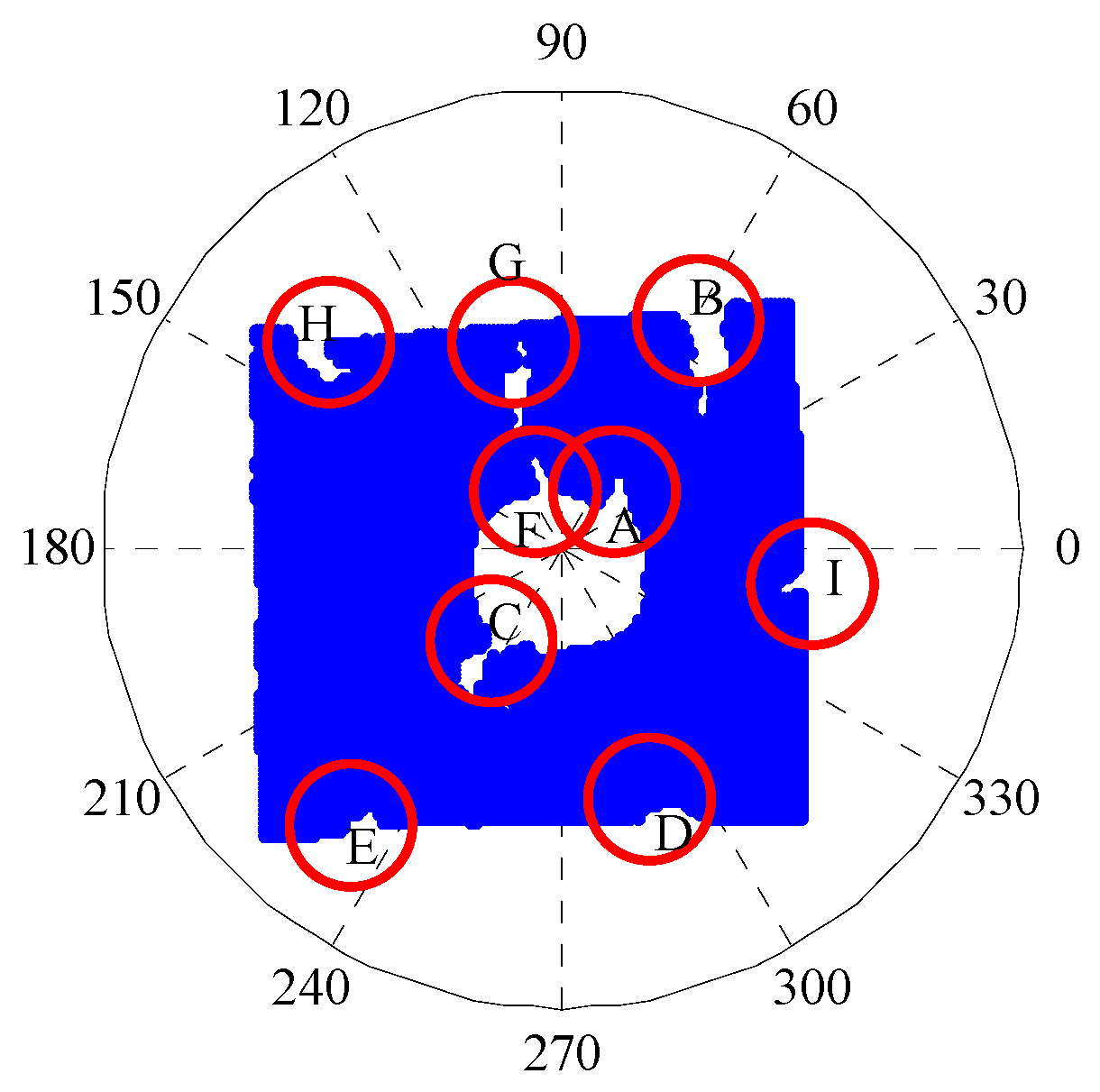

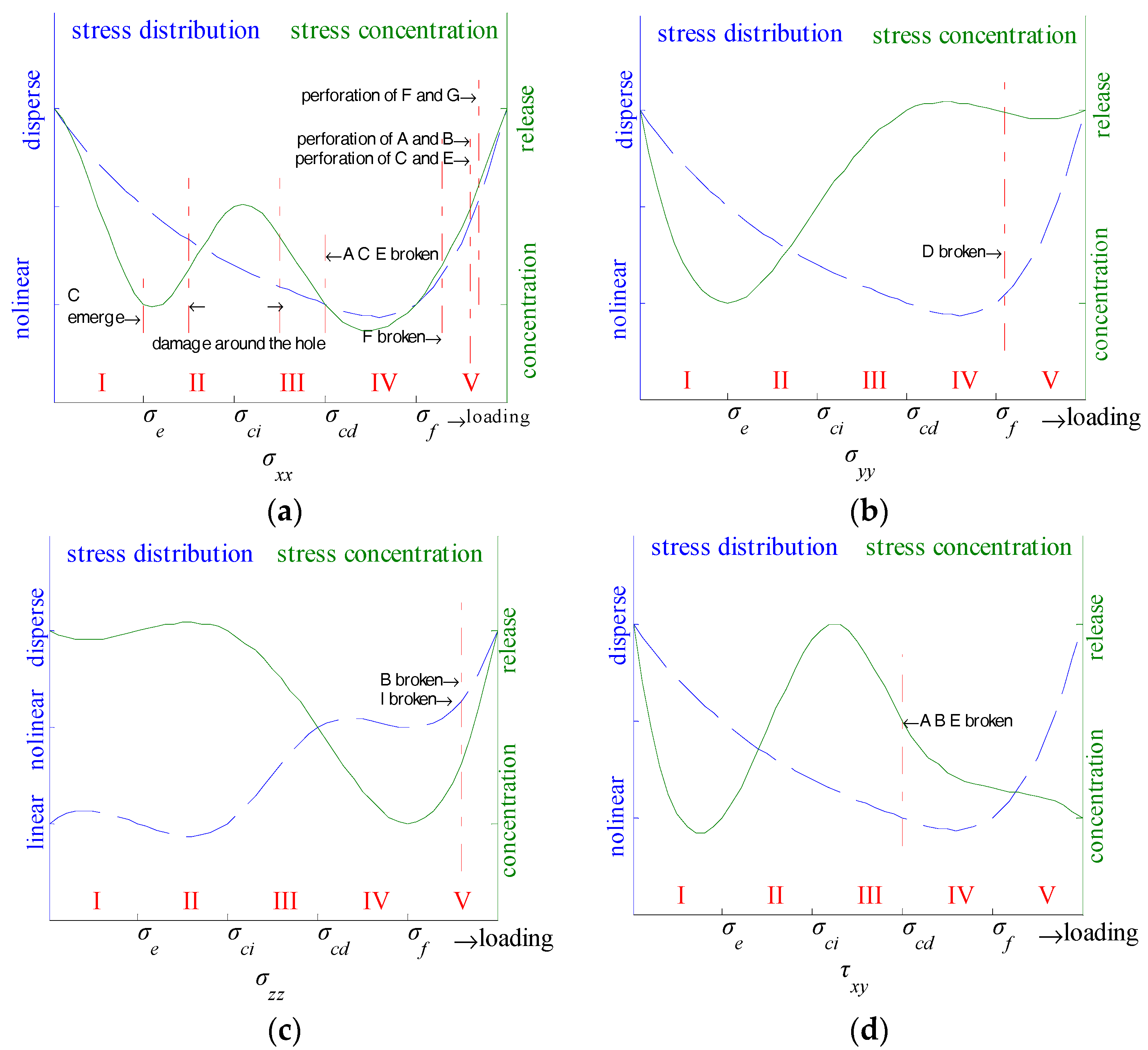

4.1. Stress Calculation around the Hole

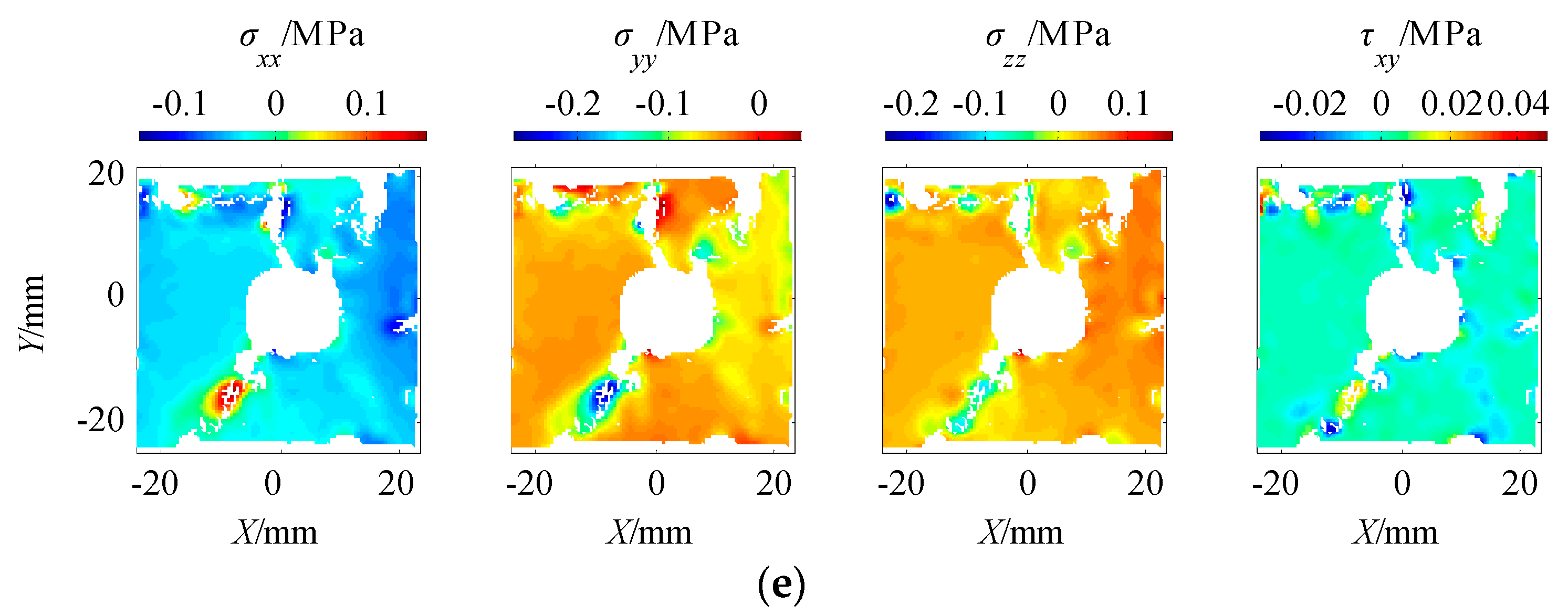

4.2. Stress Evolution around the Hole

4.3. Crack Propagation Process around the Hole

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Haifeng, W.; Yuanping, C.; Lei, W. Regional gas drainage techniques in Chinese coal mines. Int. J. Min. Sci. Technol. 2012, 22, 873–878. [Google Scholar] [CrossRef]

- Lajtai, E.Z.; Lajtai, V.N. Collapse of Cavities. Int. J. Rock Mech. Min. Sci. 1975, 12, 81–86. [Google Scholar] [CrossRef]

- Carter, B.J.; Lajtai, E.Z.; Petukhov, A. Primary and remote fracture around underground cavities. Int. J. Numer. Anal. Methods Geomech. 1991, 15, 21–40. [Google Scholar] [CrossRef]

- Wang, S.Y.; Sun, L.; Yang, C.; Yang, S.Q.; Tang, C.A. Numerical study on static and dynamic fracture evolution around rock cavities. J. Rock Mech. Geotech. Eng. 2013, 5, 262–276. [Google Scholar] [CrossRef]

- Tao, M.; Li, X.; Wu, C. 3D numerical model for dynamic loading-induced multiple fracture zones around underground cavity faces. Comput. Geotech. 2013, 54, 33–45. [Google Scholar] [CrossRef]

- Zhang, C.; Lin, B.; Zhou, Y.; Zhai, C.; Zhu, C. Study on “fracturing-sealing” integration technology based on high-energy gas fracturing in single seam with high gas and low air permeability. Int. J. Min. Sci. Technol. 2013, 23, 841–846. [Google Scholar] [CrossRef]

- Bai, Y.L.; Wang, H.Y.; Xia, M.F.; Ke, F.J. Statistical Mesomechanics of Solid, Linking Coupled Multiple Space and Time Scales. Appl. Mech. Rev. 2005, 58, 372. [Google Scholar] [CrossRef]

- Jin, P.; Wang, E.; Liu, X.; Huang, N.; Wang, S. Damage evolution law of coal-rock under uniaxial compression based on the electromagnetic radiation characteristics. Int. J. Min. Sci. Technol. 2013, 23, 213–219. [Google Scholar] [CrossRef]

- Peters, W.H.; Ranson, W.F. Digital Imaging Techniques in Experimental Stress Analysis. Opt. Eng. 1982, 21, 427–431. [Google Scholar] [CrossRef]

- Ma, S.-P.; Liu, S.-J.; Zhao, Y.-H. Gray correlation of digital images from loaded rock specimen surface to evaluate its damage evolution. Yanshilixue Yu Gongcheng Xuebao/Chin. J. Rock Mech. Eng. 2006, 25, 590–595. [Google Scholar]

- Yang, S.-Q.; Huang, Y.-H.; Jing, H.-W.; Liu, X.-R. Discrete element modeling on fracture coalescence behavior of red sandstone containing two unparallel fissures under uniaxial compression. Eng. Geol. 2014, 178, 28–48. [Google Scholar] [CrossRef]

- Zhao, C.; Matsuda, H.; Morita, C.; Shen, M.R. Study on failure characteristic of rock-like materials with an open-hole under uniaxial compression. Strain 2011, 47, 405–413. [Google Scholar] [CrossRef]

- Mallela, K.; Ilinich, A.; Luckey, S.; Zeng, D.; Gan, Y. Characterization of 6XXX Series Aluminum Extrusions Using Digital Image Correlation (DIC) Technique. In Proceedings of the SAE World Congress Experience (WCX 2017), Detroit, MI, USA, 4–6 April 2017; SAE International: Detroit, MI, USA; ADIENT: Plymouth, MI, USA; HITACHI: Tokyo, Japan; Mentor Automotive: Wilsonville, OR, USA; OMRON: Osaka, Japan; Southwest Research Institute (SwRI): San Antonio, TX, USA, 2017. [Google Scholar]

- Tuononen, A.J. Digital Image Correlation to analyse stick–slip behaviour of tyre tread block. Tribol. Int. 2014, 69, 70–76. [Google Scholar] [CrossRef]

- Ma, S.P.; Yan, D.; Wang, X.; Cao, Y.Y. Damage Observation and Analysis of a Rock Brazilian Disc Using High-Speed DIC Method. Appl. Mech. Mater. 2011, 70, 87–92. [Google Scholar] [CrossRef]

- Nunes, L.C.S.; Reis, J.M.L. Experimental investigation of mixed-mode-I/II fracture in polymer mortars using digital image correlation method. Lat. Am. J. Solids Struct. 2014, 11, 330–343. [Google Scholar] [CrossRef]

- Schreier, H.; Orteu, J.-J.; Sutton, M.A. Image Correlation for Shape, Motion and Deformation Measurements: Basic Concepts, Theory and Applications; Springer: New York, NY, USA, 2009; pp. 1–321. [Google Scholar]

- Taubin, G. Improved Algorithm for Algebraic Curve and Surface Fitting. In Proceedings of the 1993 IEEE 4th International Conference on Computer Vision, Berlin, Germany, 11–14 May 1993; IEEE: Berlin, Germany, 1993; pp. 658–665. [Google Scholar]

- Martin, C.D.; Chandler, N.A. Progressive fracture of Lac du Bonnet granite. Int. J. Rock Mech. Min. Sci. 1994, 31, 643–659. [Google Scholar] [CrossRef]

- Wang, X.-B.; Du, Y.-Z.; Pan, Y.-S.; Zhang, C.-Y. Lateral deformation measurements for sand specimens under uniaxial compression based on digital image correlation with coarse-fine search method. Gongcheng Lixue/Eng. Mech. 2013, 30, 184–190. [Google Scholar]

- Ma, S.-P.; Wang, L.-G.; Zhao, Y.-H. Experimental study on deformation field evolution during failure procedure of a rock borehole structure. Yantu Lixue/Rock Soil Mech. 2006, 27, 1082–1086. [Google Scholar]

- Yin, Q.; Jing, H.-W.; Zhu, T.-T. Experimental Study on Mechanical Properties and Cracking Behavior of Pre-cracked Sandstone Specimens under Uniaxial Compression. Indian Geotech. J. 2016, 47, 265–279. [Google Scholar] [CrossRef]

- Yang, S.-Q.; Jing, H.-W.; Xu, T. Mechanical behavior and failure analysis of brittle sandstone specimens containing combined flaws under uniaxial compression. J. Cent. South Univ. 2014, 21, 2059–2073. [Google Scholar] [CrossRef]

| Index | E/MPa | Size(mm × mm × mm) | φ/(mm) | Total Time/s |

|---|---|---|---|---|

| 16 | 11.0948 | 69.9 × 69.7 × 69.9 | 10.4 | 820 |

| 18 | 2.0643 | 69.8 × 69.9 × 69.6 | 10.6 | 420 |

| 22 | 8.7863 | 69.5 × 69.5 × 69.7 | 10.2 | 490 |

| Index | σe (MPa) | σci (MPa) | σcd (MPa) | σf (MPa) | σci/σf (%) | σcd/σf (%) |

|---|---|---|---|---|---|---|

| 16 | 0.0324 | 0.0718 | 0.1504 | 0.1722 | 41.71 | 87.34 |

| 18 | 0.0012 | 0.0304 | 0.0812 | 0.1004 | 30.28 | 80.89 |

| 22 | 0.0373 | 0.0671 | 0.1363 | 0.1641 | 40.87 | 83.08 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Zhang, L.; Li, S.; Liu, J.; Pan, H.; Song, S. Stress Inversion of Coal with a Gas Drilling Borehole and the Law of Crack Propagation. Energies 2017, 10, 1743. https://doi.org/10.3390/en10111743

Zhang T, Zhang L, Li S, Liu J, Pan H, Song S. Stress Inversion of Coal with a Gas Drilling Borehole and the Law of Crack Propagation. Energies. 2017; 10(11):1743. https://doi.org/10.3390/en10111743

Chicago/Turabian StyleZhang, Tianjun, Lei Zhang, Shugang Li, Jialei Liu, Hongyu Pan, and Shuang Song. 2017. "Stress Inversion of Coal with a Gas Drilling Borehole and the Law of Crack Propagation" Energies 10, no. 11: 1743. https://doi.org/10.3390/en10111743

APA StyleZhang, T., Zhang, L., Li, S., Liu, J., Pan, H., & Song, S. (2017). Stress Inversion of Coal with a Gas Drilling Borehole and the Law of Crack Propagation. Energies, 10(11), 1743. https://doi.org/10.3390/en10111743