Abstract

In light of possible future restrictions on the use of fossil fuel, due to climate change obligations and continuous depletion of global fossil fuel reserves, the search for alternative renewable energy sources is expected to be an issue of great concern for policy stakeholders. This study assessed the feasibility of bioenergy production under relatively low-intensity conservative, eco-agricultural settings (as opposed to those produced under high-intensity, fossil fuel based industrialized agriculture). Estimates of the net energy gain (NEG) and the energy return on energy invested (EROEI) obtained from a life cycle inventory of the energy inputs and outputs involved reveal that the energy efficiency of bioenergy produced in low-intensity eco-agricultural systems could be as much as much as 448.5–488.3 GJ·ha−1 of NEG and an EROEI of 5.4–5.9 for maize ethanol production systems, and as much as 155.0–283.9 GJ·ha−1 of NEG and an EROEI of 14.7–22.4 for maize biogas production systems. This is substantially higher than for industrialized agriculture with a NEG of 2.8–52.5 GJ·ha−1 and an EROEI of 1.2–1.7 for maize ethanol production systems, as well as a NEG of 59.3–188.7 GJ·ha−1 and an EROEI of 2.2–10.2 for maize biogas production systems. Bioenergy produced in low-intensity eco-agricultural systems could therefore be an important source of energy with immense net benefits for local and regional end-users, provided a more efficient use of the co-products is ensured.

1. Introduction

There are conflicting reports on the sustainability of agriculture-based biofuels globally [1,2]. While some claim they are one of the most effective means of addressing global warming and climate change through the reduction of fossil fuel dependencies [3,4], others show that indirect energy investments (e.g., from production of fertilizers and pesticides) makes it energy inefficient and result in a net greenhouse gas emitting process [5,6]. Other studies have identified potential synergies and conflicts between bioenergy and other important sustainability issues such as biodiversity, food security as well as poverty alleviation [7,8,9,10,11]. Irrespective of the conflicting claims, the fact that most sustainability research on agriculture-based biofuels does not adequately consider the role of important agronomic factors prevalent within different agricultural production systems is noteworthy [12,13].

Most sustainability assessments of agricultural based biofuels assume by default that biofuel crops (or energy crops) are produced under high-intensity industrialized agricultural systems [14,15], and only a few studies consider biofuel production under alternative low-intensity eco-agricultural systems [16,17]. High-intensity industrialized agricultural systems assume the use of high tractor power (higher than 50 HP), synthetic fertilizers and pesticides, conventional tillage techniques (i.e., mouldboard), energy intensive irrigation systems (e.g., sprinkler, drip, etc.), and the adoption of hybrid and/or transgenic seeds on large expanses of land (hundreds to thousands of hectares) for maximization of yields and commercial profits [18,19]. Low-intensity eco-agricultural systems on the other hand encourage the use of lower tractor power (less than 50 HP) or human and/or animal labour for cultivation, advocates the application of fertilizers and pesticides from organic waste sources (maize gluten meal, biogas digestate, animal manure, crop residues, etc.), employs reduced and no tillage techniques (e.g., stubble and mulch, strip-till, no-till, disk, chisel, ridge plant, etc.), favours the deployment of less energy intensive irrigation options (e.g., rain-fed, surface, etc.), prefers the adoption of native seeds as planting options on small communally or cooperative owned rural lands (less than 100 hectares of land), usually at a subsistence level, with priority given to conservation practices, ecosystem services and biodiversity concerns [20,21].

Previous sustainability assessments assume that biofuel crops are produced in high-intensity industrialized systems, and are therefore more relevant for developed industrialized countries (where such production systems are more prevalent). Redirecting sustainability assessments to examine the production of biofuel crops under low intensity eco-agricultural systems is especially important for the developed world, where production and use of biofuel can empower local rural economies, providing jobs as well as other socio-economic benefits. It can also be very useful in more advanced industrialized countries where there is a strong trend toward organic, small-scale sustainable food production.

Consequently, this study seeks to assess and compare the sustainability of producing bioenergy from high-intensity industrialized and low-intensity eco-agricultural systems, using energy efficiency indicators such as net energy gain (NEG) and energy return on energy invested (EROEI). Maize ethanol and maize biogas production systems across generic agro-climatic zones (tropics, sub-tropics and temperate) were chosen as case studies because their production is quite widespread across the globe, and inferences from examining them could be drawn for most of the other biofuel production systems worldwide. Agro-climatic zones level was chosen as the scale of study in order to account for the global productivity of maize yields within the context of the study. NEG and EROEI were chosen above greenhouse gas emissions, net greenhouse gas balance and net energy ratio as energy efficiency indicators because previous research has established that there is a strong positive relationship between them and many socio-economic benefits of energy such as energy provision, poverty alleviation, improvement of quality of life, job creation/employment generation, support base for industrialization and economic growth, source of inspiration for art, culture and design, basis for engineering and technological innovations etc. [13,22,23]. The use of other energy efficiency sustainability indicators such as greenhouse gas emissions, net greenhouse gas balance and net energy ratio was avoided in this study to prevent an increase in the complexity of the scope of study.

2. Materials and Methods

2.1. Energy Efficiency Indicators

Net energy gain (NEG) and the energy return on energy invested (EROEI) are two energy efficiency indicators for assessing the sustainability of energy production processes and activities. As a sustainability indicator, they measure the capacity of energy production processes and activities to be of net societal and economic benefits, and support continuous socio-economic functions [22,23].

NEG and EROEI are both estimated by a life cycle inventory analysis of all energy inputs and energy outputs associated with an energy production activity. While NEG is obtained by subtracting total (gross) energy inputs from total energy (gross) outputs, EROEI is obtained by dividing total (gross) energy outputs by total (gross) energy inputs.

Net energy gain (NEG) = Total Energy Output − Total Energy Input

Energy return on energy invested (EROEI) = Total Energy Output/Total Energy Input

While NEG is measured in Joules (J) or Joules per hectare cultivated (J·ha−1) or Joules per tonnes of biomass used (J·t−1), depending on the reference system selected [11,24], EROEI is dimensionless, and presents the fraction of excess energy obtainable from an energy production activity [25,26]. The NEG of an energy production activity could be adjudged productive if above 0, and can be used to assess the contribution to local and/or regional renewable energy targets [27,28]. EROEI of an energy production activity on the other hand could be adjudged efficient if above 1; however it is recommended that it is equal to or above 3 at farm-gate or equal to or above 2 after bio-refinery plant in order to account for numerous transformation processes that are hard to quantify (e.g., land degradation, biodiversity impacts etc.) [22,29].

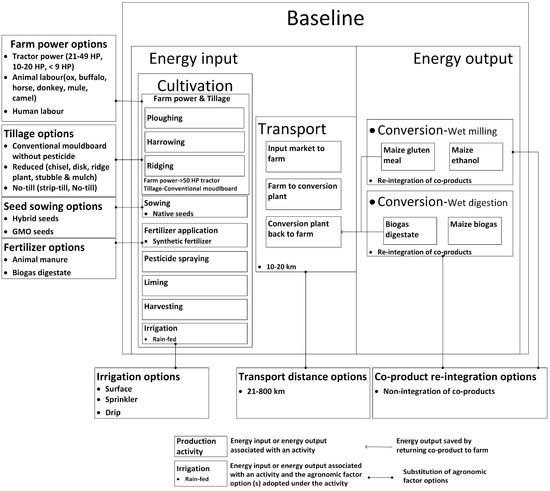

The scope and boundary of the energy life cycle inventory performed by this study is from cradle (including farm, input market and input production plants) to bio-refinery plant and then back to the cradle (i.e., maize biomass for biofuel is assumed to be cultivated and harvested on the farm, transported to the bio-refinery plant for processing and the co-products are returned back to the farm or transferred to other value chains that are not related to agriculture or agro-bioenergy). This is illustrated in Figure 1.

Figure 1.

A graphical illustration of the methodological framework adopted by this study.

2.2. Comparison of the High-Intensity Industrialized and Low-Intensity Eco-Agricultural Systems

While there have been controversies on the properties of industrialized agricultural systems as against eco-agricultural systems, this study classified and compared them in terms of the likelihood of the adoption of alternative agronomic factor options, and in line with energy input intensity. This is described in Table 1.

Table 1.

Classification of the two major agricultural production systems (industrialized agriculture and eco-agricultural systems) based on the likelihood of the adoption of agronomic factors [21,30,31].

In specific cases, alternative agronomic factors adopted under the two production systems may not necessarily follow the pattern described in Table 1. For example, rain-fed and surface irrigation may be adopted under an industrialized system, while drip and sprinkler irrigation may be adopted by eco-agricultural agriculture systems. However based on classification patterns established in literatures and for the purpose of this study, industrialized agriculture system is assumed to be of high input intensity in implementation and mostly practiced in advanced developed economies (mostly Europe and North America). Eco-agricultural systems on the other hand are assumed to be of low input intensity and mostly practiced in developing countries (mostly Asia, Latin America and Africa) even though it is becoming increasingly common in pastoral and organic farming in developed countries, hence sticking to the classifications in Table 1.

2.3. Estimating the Potential Energy Efficiency of High-Intensity Industrialized and Low-Intensity Eco-Agricultural System

The methodology adopted by this study is the life cycle assessment (LCA) substitution approach [32,33]. Within the context of this study, it was implemented in three phases. The first phase involved setting of baseline agronomic factor parameters. The second phase entails the successive substitution of baseline agronomic factor options with alternative agronomic factor options in the same agronomic factor category (e.g., substitution of baseline rain-fed irrigation with surface, drip and sprinkler irrigation), in order to assess the individual effects of the adoption of such agronomic factor options on the energy efficiency of the different biofuel production systems considered. The first and second phases are illustrated in Figure 1. The third phase involved the summing up of the individual effects and differences in the energy efficiency of biofuels (relative to baseline), as a result of the adoption of agronomic factor options under the two agricultural production systems (based on the classifications in Table 1) [19,31]. The sum total of the individual differences in energy efficiency of biofuels (as a result of the adoption of agronomic factor options and based on classifciations in Table 1) culminated into the overall (potential) energy efficiency of the biofuels produced under the two agricultural systems considered.

Note that the baselines were chosen arbitrarily with no regards to the classifications in Table 1. The baselines were not chosen because they were close to what was obtainable in reality globally across the agro-climatic zones. This is because there is no single stereotyped baseline that fits what is obtainable globally across the agro-climatic zones. The purpose for the arbitrary choice of baseline was to objectively account for the individual effects and differences in the energy efficiency of biofuels, as a result of the adoption of the different agronomic factor options under the two agricultural production systems (based on classifications in Table 1).

Within the farm power category, a >50 HP tractor was the baseline. Alternative options considered within this category included different tractor implementations (four wheel drive > 50 HP tractors, two wheel drive 21–49 HP tractors, single axle riding type 10–20 HP tractors and ordinary single axle < 9 HP tractors), different animal labour options (ox, buffalo, horse, donkey, mule, camel), as well as human labour. The baseline for the irrigation category was the natural (or rain-fed) irrigation system. Alternative options considered within this category included artificial irrigation methods such as surface, sprinkler and drip irrigation systems. The tillage category had the conventional mouldboard tillage with pesticide application as its baseline option. Alternative options considered within the tillage category included conventional mouldboard tillage without pesticide application; reduced tillage options such as chisel, disk, ridge plant, and stubble and mulch tillage; and no-tillage options such as strip-till and no-till options. Within the fertilizer agronomic factor category, synthetic (inorganic) fertilizer was adopted as the baseline. The individual effects of alternative options such as animal manure and biogas digestate were considered. For the seed-sowing category, native seeds were selected as baseline, while the individual effects of hybrid and genetically modified (or GMO) seeds were assessed successively. The co-products accounted for within the maize ethanol production system is maize gluten meal (which could be an N-fertilizer and herbicide replacement). The co-products accounted for within the maize biogas production system is the biogas digestate (which could be an N, P and K fertilizer replacement). For co-product reintegration, non-integration of co-products was the baseline. The effects of the integration of co-products back to the agricultural systems were assessed accordingly. For transport distances, 10–20 km was deployed as baseline. The effects of a change to 21–800 km were assessed subsequently. This is further illustrated in Figure 1.

In order to determine the overall (potential) energy efficiencies of producing biofuels under the two agricultural production systems, we summed up the highest positive individual effects or differences and/or the least negative effects or differences obtained across the different agronomic factor categories (i.e., farm power, tillage, fertilizer, seed-sown, irrigation, co-product reintegration), based on the classification patterns in Table 1.

2.4. Data, Conversion Factors and Assumptions

2.4.1. Data

Data for maximum attainable maize grain yields per hectare, across different agro-climatic zones (tropics, sub-tropics, and temperate), and under rain-fed and artificially irrigated conditions were obtained from the Global Agro-ecological Zones (GAEZ) database of the International Institute of Applied System Analysis (IIASA) [34,35]. Three fertilizer application regimes were recorded for rain-fed conditions (low, intermediate and high), while two fertilizer application regimes (intermediate and high) were recorded for artificially irrigated conditions. Data on fertilizer input regimes across the different agro-climatic zones were obtained from best maize management practices published in Crop Nutrition Wiki (CNW) database of the International fertilizer Association (IFA) [36]. Data of best maize management practices from Brazil, Thailand, Philippines and Indonesia (obtained from IFA’s CNW) were assumed to be representative for tropics. Best maize management practices data from India and South Africa (from IFA’s CNW) were assumed to be representative for the sub-tropics. Data on best management practices for maize from France and the United States were assumed to be representative for the temperate zone. Table 2 shows the range of N, P and K fertilizer application rates under different regimes (low, intermediate and high), and the corresponding ranges of maximum attainable maize yields across the three agro-climatic zones considered.

Table 2.

Data on N, P and K fertilizer application rates and maximum attainable maize grain yields across three agro-climatic zones (tropics, sub-tropics and temperate).

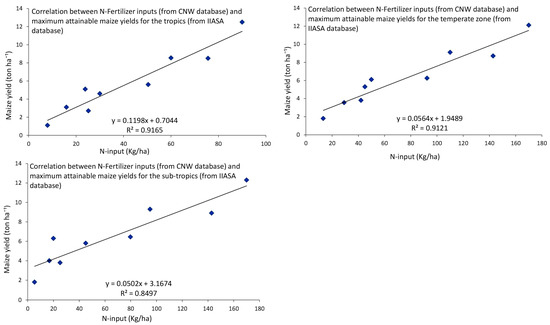

The three different types of application rates (low, intermediate and high) from the CNW database were assumed to correspond to the three different types of maize yield regimes from the GAEZ data. Regression analysis showed that there is a strong correlation between the fertilizer input data [36] and the maximum attainable yield data [34,35] across the three agro-climatic zones considered, with R2 values of 0.92 for the tropics, 0.85 for sub-tropics and 0.91 for temperate zones respectively (Figure 2).

Figure 2.

Correlation between N-Fertilizer inputs (from CNW database) and maximum attainable maize yields for the tropics, sub-tropics and temperate agro-climatic zones (from GAEZ database).

2.4.2. Conversion Factors

For the baseline agronomic factor choices (Figure 1), the conversion factors for the estimation of energy inputs and energy outputs can be found in Table S1 [37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63]. Most conversion factors used within the context of this study were obtained from published data. Some that were however based on acceptable assumptions that are in alignment with conventional life cycle thinking principles are described below.

2.4.3. Other Assumptions

When substituting one agronomic factor for another, the following assumptions were made:

● For human and animal labour

Energy from human and animal labour substitutes energy from tractor’s fuel consumption. Humans needs 60 days for ploughing (using cutlasses and hoes), 1 day for sowing, 1 day for mulching, 10 days for thinning, 30 days for hand weeding, 4 days for fertilizer and lime application, 3 days for pesticide spraying, and 30 days for harvesting [47,48]. The number of days each of ox, buffalo, horse, donkey, mule and camel use for ploughing an hectare of land (ox—6–8 days, buffalo—6–8 days, horse—2 days, donkey—10–12 days, mule—6–8 days, and camel—2–3 days) is assumed to be the same as the number of days they use for completing each of the other seven farm-based operations namely harrowing, ridging, sowing, fertilizer application, liming, pesticide application and harvesting (assuming the required detachable accessories needed to achieve the other tasks are available) [49,50]. Even though this assumption might result in an overestimation of the amount of energy used by human and animal labour because ploughing is the most tedious farm operation, the resulting estimates can be regarded as conservative, safe, and therefore acceptable. Maximum daily energy exertable by humans, ox, buffalo, horse, donkey, mule and camel was assumed to be the amount delivered daily for tedious farm work. This is 2.88–4.8 MJ per day for humans, 10 MJ per day for ox, 9.5 MJ per day for buffalo, 18 MJ per day for horse, 3 MJ per day for donkey, 8.5 MJ per day for mule and 14 MJ per day for camel respectively [48,49,51]. The maximum daily energy exertable was multiplied by the number of days it takes each humans or animal to complete all farm operation for a year, in order to obtain their separate total energy input for farm operation per hectare annually. Maximum daily energy exertable was assumed to be the fraction of energy (from food and water taken) utilizable for farm operations.

Total energy input into farm operation by human labour = Maximum daily energy exertable by humans × Total number of days spent for farm operations annually

Total energy input into farm operation by animal labour = Maximum daily energy exertable by animals × number of days spent by animals for ploughing operations × number of farm operations

This accounting method was preferred to estimating the amount of energy used to produce their food annually, which amounts to gross estimation since on non-farming days human and animals alike perform other functions (e.g., recreation, transport, tourism etc.) other than farming.

- For alternative tractor power options

- All tractor engines considered under this study (four wheel drive > 50 HP, two wheel drive 20–49 HP, single axle riding type 10–19 HP), with the exception of the single axle < 9HP tractor used diesel fuel [39,56,57,58]. Single axle < 9 HP tractor used gasoline.

- While the energy consumed by four wheel drive > 50 HP tractors for all farm operations was obtained from detailed data provided from tractor test runs by Grisso et al. [39], for other smaller tractor implementations (two wheel drive 20–49 HP, single axle riding type 10–19 HP, ordinary single axle < 9HP), energy for ploughing was assumed to be essentially the same and/or not significantly different from those for all the other seven farm operations undertaken (assuming the required detachable implements needed to achieve the other tasks are available). This assumption was made due to lack of data for fuel consumption for all other operations (aside ploughing) by the smaller tractor implementations. As with animal labour, the assumption and resulting estimates were regarded as conservative because ploughing is the most tedious of all the farm operations. Based on the data obtained, two wheel drive 20–49 HP tractor, single axle riding type 10–19 HP tractor, ordinary single axle < 9HP tractor consume 22.5–28.0 L of diesel, 5.0–6.3 L of diesel and 16.7–25.1 L of gasoline per hectare during ploughing operations respectively. Based on the assumption, they are expected to consume approximately 180.0–224.0 L of diesel, 40.0–50.4 L of diesel, and 133.6–200.8 L of gasoline for all farm operations per hectare annually [39,55,57,58].

- For alternative tillage options

The amount of fuel and energy for conventional mouldboard tillage with pesticide application was substituted with the various amounts of fuel and energy consumed as a result of adoption of different tillage techniques. These were as follows: mouldboard with pesticide application—29.9–156.3 L·ha−1, mouldboard without pesticide application—25.2–146 L·ha−1, chisel—23.4–130.6 L·ha−1, disk—20.6–105.8 L·ha−1, ridge plant—20.6–100.3 L·ha−1, stubble and mulch—32.7–97.3 L·ha−1, strip-till—22.1–77.1 L·ha−1, and no-till—23.4–85.2 L·ha−1 [39,59]. Unlike conventional tillage, no-till and some of the reduced tillage options have more frequent pesticide application sessions. This was also factored into the estimations.

● For alternative irrigation options

- It was assumed that there were zero energy requirements for natural, rain-fed irrigation. The zero energy consumption for rain-fed irrigation was however substituted with various amounts of energy (mostly electricity) used for powering artificial irrigation options: surface—0.2–6.5 GJ·ha−1, sprinkler—3.9–10.4 GJ·ha−1, drip—3.1–9.5 GJ·ha−1 [60,61]. Note that water is assumed to be pumped directly from surface and ground water. Energy for storage in tanks is not included.

- While the substitution of other agronomic factors was assumed not to result in significant change in maize yield, artificial irrigation was assumed to cause an increase as shown in Table 2.

● For alternative seed sowing options

While energy for production of native seeds (mostly in form of electricity) was assumed to be 0–14.9 MJ·kg−1 (depending on the production process, which may vary from sun-drying to the use of maize driers), the energy for hybrid seeds was assumed to be as high as 104.3 MJ·kg−1 (seven times that for native seeds) [37]. Since, it is not explicitly found in literature, energy for production of GMO seeds was conservatively assumed to be between that for production of native seeds and that for production of hybrid seeds (14.9–104.3 MJ·kg−1), even though it may be less in reality [62]. Energy for production of insecticides and fungicides was not accounted for within the inventory for adoption of GMO seeds. This is because some varieties of GMOs maize seeds do not require insecticides and fungicides [62,63].

● For alternative fertilizer options

Energy for production of synthetic N, P and K fertilizers, as well as lime (CaO) is substituted as follows:

- Energy for production of N, P and K fertilizers was zero if obtained from animal manure and biogas digestate. This is because they are freely delivered to the field from farm or bio-refinery plant. Only energy for transport and manure spreading was considered as fertilization costs.

- For biogas digestate, energy for lime (CaO) production and application was also zero because it is freely delivered to the field with the biogas digestate.

● For transport distances

To typify the small scale nature of low-intensity eco-agricultural systems, maximum transport or travel distance was assumed to be between 10 and 20 km. In other words, the maximum travel distance from farm to input market and back, farm to conversion plant and back, when cultivating maize and converting it to biofuels for use within local and/or regional agricultural sectors does not exceed 10–20 km. This was the baseline for this study. For high intensity industrialized agricultural systems, 10–20 km baseline was substituted with 21–800 km as the maximum transport or travel distance from farm to input market and conversion plant, as well as from conversion plant and input market back to the farm.

● For co-product reintegration

The effects of co-product reintegration (i.e., energy saved from the reintegration of co-products back into the agricultural systems as fertilizers and pesticides) were not considered in the baseline scenario. The effects of co-product reintegration were accounted for by adding the fossil energy saved by the reintegration of co-products to the total energy output obtained from the biofuels (i.e., maize ethanol and maize biogas) per hectare of maize cultivated across the different agro-climatic zones considered. The conversion factors for estimating the energy saved from co-product reintegration can be found in Table 3.

Table 3.

Conversion factors for estimating the energy saved from co-product reintegration into agricultural system.

3. Results

The individual effects or differences in NEG and EROEI (relative to the baseline) as a result of the adoption of individual alternative agronomic factors vary in magnitude from one agro-climatic zone another. Despite the variations, each agronomic factor option considered followed essentially the same pattern from negative to no effects to positive effects. This is illustrated in Table S2.

Based on classifications in Table 1, the most energy efficient farm power sub-option (i.e., with the highest positive individual effects or differences in terms of NEG and EROEI) under the high-intensity industrialized agricultural production system is the baseline > 50 HP tractor option. Human power however is the most energy efficient farm power sub-option under the low-intensity eco-agricultural production system. Also noteworthy however is the fact that the baseline > 50 HP tractor option is the most energy efficient tractor option under the high-intensity industrialized production system. Single axle riding type 10–20 HP tractor option is the most energy efficient tractor option under the low-intensity eco-agricultural production system.

With regards to tillage, the most energy efficient sub-option (with the highest positive individual differences in terms of NEG and EROEI) under the high-intensity industrialized production system classification is the mouldboard tillage without pesticide option. The most energy efficient tillage sub-option under the low-intensity eco-agricultural production system is the strip-till (no-till) option.

The most energy efficient option in the fertilizer category (i.e., with the highest positive individual difference in terms of NEG and EROEI) under the high-intensity industrialized production system is the baseline synthetic fertilizer option. The fertilizer sub-option with the highest energy efficiency (in terms of NEG and EROEI) under the low-intensity eco-agricultural production system is the biogas digestate option (due to its N, P and K fertilizer, as well as lime content).

No seed sub-option has a positive individual difference (in terms of NEG and EROEI) under the high-intensity industrialized production system. GMO seeds are however more energy efficient with the least negative difference in terms of NEG, as well as a negative to neutral effects in terms of EROEI. The seed sowing option with the highest energy efficiency (in terms of NEG and EROEI) under the low-intensity eco-agricultural production system is the baseline native seeds.

The most energy efficient irrigation option (with highest positive individual differences in terms of NEG) under the high-intensity industrialized production system is the drip irrigation system. Even though drip irrigation sub-option had less negative effects compared to the sprinkler option, there were no positive individual differences for any of the irrigation sub-options classified under the high-intensity industrialized production system in terms of EROEI. The irrigation sub-option with highest positive individual differences (in terms of NEG and EROEI) under the low-intensity eco-agricultural production system is the surface irrigation option.

With respect to co-product reintegration, the only sub-option under the high-intensity industrialized production system was the baseline i.e., non-integration of co-products option. Similarly, the only under the low-intensity eco-agricultural production system was the reintegration of co-products option.

Of all the agronomic factors considered, co-product reintegration into agricultural systems is the single most energy efficient agronomic factor sub-option. It has the highest positive individual effects on the energy efficiency of biofuel production systems. Table 4 lists the range of positive effects that agronomic factors have on NEG and EROEI relative to the baselines.

Table 4.

Individual positive effects of different agronomic factor categories.

Maximum transport distance has the highest negative individual effects reducing NEG and EROEI by 39.6%–60.4% and 29.1%–38.5% respectively. Seed sowing and some irrigation options (drip and sprinkler) also have considerable negative individual effects. Seed sowing options (hybrid and GMOs) reduce NEG and EROEI by 5.1%–12.5% and 7.7%–53.0% respectively; drip and sprinkler irrigation options lower NEG and EROEI by 7.3%–9.2% and 7.7%–23.9%, respectively.

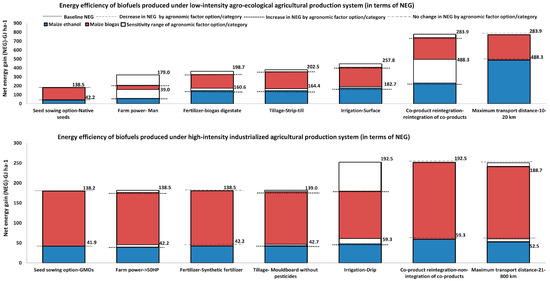

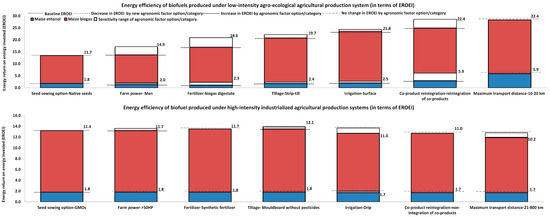

After summing up the highest individual positive and the least negative effects or differences elicited by sub-options across the different agronomic factor categories, the overall potential energy efficiency of producing biofuels under high-intensity industrialized agricultural production system amounted to as much as 2.8–52.5 GJ·ha−1 of NEG and an EROEI of 1.2–1.7 for maize ethanol production systems, and as much as 59.3–188.7 GJ·ha−1 of NEG and an EROEI of 2.2–10.2 for maize biogas production systems. The overall potential energy efficiency of producing biofuels under low-intensity eco-agricultural production system culminated to as much as 448.5–488.3 GJ·ha−1 of NEG and an EROEI of 5.4–5.9 for maize ethanol production systems, and as much as 155.0–283.9 GJ·ha−1 of NEG and an EROEI of 14.7–22.4 for maize biogas production systems. This is further illustrated in Figure 3 and Figure 4. Figure 3 and Figure 4 compare the net energy gain and the energy return on energy invested of the two agricultural production systems (i.e., high-intensity industrialized agricultural production systems and low-intensity eco-agricultural production systems) respectively.

Figure 3.

Comparison of the energy efficiency of biofuels produced under alternative agricultural production systems, i.e., high-intensity industrialized agricultural systems and low-intensity eco-agricultural production systems (in terms of NEG).

Figure 4.

Comparison of the energy efficiency of biofuels produced under alternative agricultural production systems, i.e., high-intensity industrialized agricultural systems and low-intensity eco-agricultural production systems (in terms of EROEI).

4. Discussion

Based on the classification of agricultural production systems in Table 1 and the comparison of bioenergy produced, bioenergy production under low-intensity eco-agricultural systems shows huge comparative advantage (in terms of NEG and EROEI) (as seen in Figure 3). Alternative farm power, fertilizer, tillage, irrigation and co-product reintegration options (classified under low-intensity eco-agricultural systems in Table 1) can be employed for optimization of energy efficiency. Based on the classifications in Table 1, bioenergy produced from high-intensity industrialized agricultural production systems seem to have reached a saturation point (as seen in Figure 2), because it has little pressure points (few alternative agronomic factor options) for further improvement. Only tillage (mouldboard with pesticide application) and irrigation (drip and sprinkler irrigation improves NEG but not EROEI) offer room for optimization of energy efficiency for bioenergy produced under high-intensity industrialized systems. With an EROEI of 1.2–1.7, and in line with previous studies [22,28], it appears that in terms of EROEI, cultivating maize as a feedstock for ethanol production under high-intensity industrialized agriculture is not energy efficient (i.e., less than 2 after bio-refinery plant).

Since biofuels produced from high-intensity industrialized agricultural systems are more common in developed countries (mostly Europe and North America), reaping more societal and economic benefits from bioenergy production systems in the developed countries going forward may not be very feasible, because improvements by one agronomic factor might be counterbalanced by some others (as seen in Figure 2). Conversely, since low-intensity eco-agricultural systems are more prevalent in developing countries (mostly Latin America, Africa and Asia), there exists a wide range of energy efficiency improvements possible for bioenergy production systems in developing countries. Bioenergy produced on small-scale, family or communally owned, rural neighbourhood farms in developing countries (using low-intensity eco-agricultural principles) can be expected to reap some energy benefits from reduced farming intensity. While not assuming that bioenergy produced under low-intensity eco-agricultural systems can contribute immensely to fossil fuel replacement and greenhouse gas emission reduction targets globally due to limitations from scale, it can still be expected to contribute to sustainable agriculture goals such as the provision of renewable energy for agricultural production at local and regional scales, as well as the actualization of food and energy independence and sovereignty goals for rural farmers [30,31]. Aside sustainable agriculture goals, it also has the potential to contribute to other sustainable development goals such as engendering a more holistic, integrated and resilient rural development paradigm, eradicating rural energy poverty, as well as reducing rural poverty and rural-urban drifts, through the provision of modest energy infrastructures and new rural energy jobs/employments [12,21].

It should be noted that in our estimates, time did not have any energy value. Using human and animal labour certainly requires more time for similar tractor-driven operations. This certainly becomes a limiting factor in large-scale operations and is therefore an unrealistic option for high-intensity industrialized agriculture systems. Since human and animal labour is associated with drudgery, boredom, accidents and other health risks, lower tractor implementation (single axle riding type 10–20 HP tractor) may be a more attractive farm power option within the context of the production of bioenergy under low intensity eco-agricultural systems. Even though it is less energy efficient than human and animal labour (in terms of NEG and EROEI), it will help reduce drudgery, boredom, accidents and other health risks associated with the use of human and animal labour. The replacement of human and animal labour with machines must however also be done strategically to avoid loss of farm jobs and employments, as well as further impoverishment of rural dwellers who previously earned a living as farm hands. Even though low-intensity eco-agricultural systems are still more prevalent in the developing world, their importance in the developed world is also increasing because of the growing trend towards organic and small scale pastoral farming, largely driven by growing concerns about nutrient pollution from high-intensity industrialized agricultural systems. As a result, the production of bioenergy in low-intensity eco-agricultural systems is also likely to gain more traction in developed countries.

It is however important to note that this study avoided generalizations across broad agro-climatic zones (tropics, sub-tropics and temperate) due to the coarseness of the scale of the study. Better local and regional estimates can be expected if data was collected and assessment was done locally or regionally. This study also chose to capture its potential energy efficiency (NEG and EROEI) estimates in ranges because of the variety of sources of the conversion factors used, and the different assumptions underlying the LCA substitution approach employed. This is expected to provide boundaries of estimates across which policymakers can benchmark their decision-making.

While this study considered only the energy flows associated with biofuel production under the two agricultural systems (using energy efficiency based sustainability indicators namely NEG and EROEI), future studies should also look at greenhouse gas and water flows (using greenhouse gas emissions/greenhouse gas balance, and water footprint/water use efficiency as sustainability indicators) in order to provide a more balanced view of the findings of this research [11,13].

5. Conclusions

In an era of climate change mitigation and adaptation, and in cases of severe energy insecurity, where the use of fossil fuels becomes restricted, using biofuels produced under low-intensity, small-scale (10–20 km transport distance) and conservative eco-agricultural systems can contribute to emerging renewable energy demands. It can also contribute to other sustainable development goals such as carbon emission reduction, elimination of rural energy poverty, poverty alleviation through provision of new rural energy jobs, as well as the furtherance of more integrated rural development. Institutional frameworks (e.g., formation of local and regional farm energy cooperatives and/or associations etc.) which favours small holders will however be needed to facilitate the actualization of these goals. More efficient and effective utilization strategies for harnessing the potentials of co-products of biofuel production is however the key to maximizing the energy efficiency of bioenergy production systems. Since biofuel production under low-intensity eco-agricultural system represent a more energy efficient approach, its use can be incorporated into emerging agricultural policy frameworks geared towards ensuring more resilient and sustainable agricultural systems. It may be especially relevant for small family and community farms, because it can potentially make them entirely energy independent and self-sufficient, through powering all their farm based operations (both on the field and nearby agro-allied processing plants) with relatively more energy efficient, locally and/or regionally produced biofuels. This can be made possible if small scale (family and community) farmers within rural localities form viable networks and cooperatives to harness such potentials. This however opens up interesting research questions on optimal clustering scale and structure for such farm energy cooperatives or networks. For example, in order to ensure maximum benefits for all members, what should be maximum number of family or community farms or farm owners or agro-allied industry within a farm energy network or cooperative, OR what should be the maximum transportation distance or locational radii within each cluster etc.

Supplementary Materials

The following are available online at www.mdpi.com/1996-1073/10/1/29/s1, Table S1: Conversion factors for estimating energy inputs and energy outputs of baseline options, Table S2: The individual differences in values of NEG and EROEI (for maize ethanol and maize biogas production systems), as a result of the adoption of different agronomic factor options across different agro-climatic zones.

Acknowledgments

This study and the cost to publish in open access was supported by the EU through the Marie Curie Initial Training Networks (ITN) action CASTLE, grant agreement No. 316020. Alexey Voinov was supported by the EU-FP7-308601 COMPLEX project.

Author Contributions

Oludunsin Arodudu designed the study, performed the analysis and drafted the manuscript; Katharina Helming, Hubert Wiggering and Alexey Voinov contributed to interpreting the results, as well as reviewing and editing the manuscript.

Conflicts of Interest

The authors declare no conflict of interest. Although the research leading to these results has been supported by the EU through the Marie Curie Initial Training Networks (ITN) action CASTLE, grant agreement No. 316020, the contents of this publication reflect only the author’s/authors’ views. The European Union is not liable for any use that may be made of the information contained therein. The European Union had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Fischer, G.; Schrattenholzer, L. Global bioenergy potentials through 2050. Biomass Bioenergy 2001, 20, 151–159. [Google Scholar] [CrossRef]

- Koizumi, T. Biofuel and food security in China and Japan. Renew. Sustain. Energy Rev. 2013, 21, 102–109. [Google Scholar] [CrossRef]

- Dincer, I. Environmental impacts of energy. Energy Policy 1999, 27, 845–854. [Google Scholar] [CrossRef]

- Fischer, G.; Prieler, S.; van Velthuizen, H.; Berndes, G.; Faaij, A.; Londo, M.; de Wit, M. Biofuel production potentials in Europe: Sustainable use of cultivated land and pastures, Part II: Land use scenarios. Biomass Bioenergy 2010, 34, 173–187. [Google Scholar] [CrossRef]

- Pimentel, D. Ethanol fuels: Energy balance, economics, and environmental impacts are negative. Nat. Resour. Res. 2003, 12, 127–134. [Google Scholar] [CrossRef]

- Hill, J.; Nelson, E.; Tilman, D.; Polasky, S.; Tiffany, D. Environmental, economic, and energetic costs and benefits of biodiesel and ethanol biofuels. Proc. Natl. Acad. Sci. USA 2006, 103, 1206–11210. [Google Scholar] [CrossRef] [PubMed]

- Graham-Rowe, D. Agriculture: Beyond food versus fuel. Nature 2011, 474, S6–S8. [Google Scholar] [CrossRef] [PubMed]

- Loarie, S.R.; Lobell, D.B.; Asner, G.P.; Mu, Q.; Field, C.B. Direct impacts on local climate of sugar-cane expansion in Brazil. Nat. Clim. Chang. 2011, 1, 105–109. [Google Scholar] [CrossRef]

- Lynd, L.R.; Woods, J. Perspectives: A New Hope for Africa. Nature 2011, 474, S20–S21. [Google Scholar] [CrossRef] [PubMed]

- Grayson, M. Biofuels. Nature 2011, 474, S1–S25. [Google Scholar] [CrossRef] [PubMed]

- Savage, N. Fuels options: The ideal biofuel. Nature 2011, 474, S9–S11. [Google Scholar] [CrossRef] [PubMed]

- Altieri, M.A.; Funes-Monzote, F.R.; Petersen, P. Agroecologically efficient agricultural systems for smallholder farmers: Contributions to food sovereignty. Agron. Sustain. Dev. 2012, 32, 1–13. [Google Scholar] [CrossRef]

- Arodudu, O.T.; Helming, K.; Wiggering, H.; Voinov, A. Towards a more holistic sustainability assessment framework for agro-bioenergy systems—A review. Environ. Impact Assess. Rev. 2017, 62, 61–75. [Google Scholar] [CrossRef]

- Wiens, J.; Fargione, J.; Hill, J. Biofuels and biodiversity. Ecol. Appl. 2011, 21, 1085–1095. [Google Scholar] [CrossRef] [PubMed]

- Searchinger, T.; Heimlich, R.; Houghton, R.A.; Dong, F.; Elobeid, A.; Fabiosa, J.; Tokgoz, S.; Hayes, D.; Yu, T.H. Use of U.S. Croplands for Biofuels Increases Greenhouse Gases Through Emissions from Land-Use Change. Science 2008, 319, 1238–1240. [Google Scholar] [CrossRef] [PubMed]

- Venkat, K. Comparison of Twelve Organic and Conventional Farming Systems: A Life Cycle Greenhouse Gas Emissions Perspective. J. Sustain. Agric. 2012, 36, 620–649. [Google Scholar] [CrossRef]

- Meier, M.S.; Stoessel, F.; Jungbluth, N.; Juraske, R.; Schader, C.; Stolze, M. Environmental impacts of organic and conventional agricultural products—Are the differences captured by life cycle assessment? J. Environ. Manag. 2015, 149, 193–208. [Google Scholar] [CrossRef] [PubMed]

- Smith, M. Against ecological sovereignty: Agamben, politics and globalization. Environ. Polit. 2009, 18, 99–116. [Google Scholar] [CrossRef]

- Wezel, A.; Bellon, S.; Doré, T.; Francis, C.; Vallod, D.; David, C. Agroecology as a science, a movement and a practice. A review. Agron. Sustain. Dev. 2009, 29, 503–515. [Google Scholar] [CrossRef]

- Blesh, J.; Wolf, S.A. Transitions to agroecological farming systems in the Mississippi River Basin: Toward an integrated socioecological analysis. Agric. Hum. Values 2014, 31, 621–635. [Google Scholar] [CrossRef]

- Altieri, M.A.; Nicholls, C.I.; Henao, A.; Lana, M.A. Agroecology and the design of climate change-resilient farming systems. Agron. Sustain. Dev. 2015, 35, 869–890. [Google Scholar] [CrossRef]

- Hall, C.A.S.; Balogh, S.; Murphy, D.J.R. What is the minimum EROI that a sustainable society must have? Energies 2009, 2, 25–47. [Google Scholar] [CrossRef]

- Lambert, J.G.; Hall, C.A.S.; Balogh, S.; Gupta, A.; Arnold, M. Energy, EROI and quality of life. Energy Policy 2014, 64, 153–167. [Google Scholar] [CrossRef]

- Meyer, A.K.P.; Raju, C.S.; Kucheryavskiy, S.; Holm-Nielsen, J.B. The energetic feasibility of utilising nature conservation grasses from meadows in Danish biogas production. Resour. Conserv. Recycl. 2015, 104, 265–275. [Google Scholar] [CrossRef]

- Poisson, A.; Hall, C.A.S. Time Series EROI for Canadian Oil and Gas. Energies 2013, 6, 5940–5959. [Google Scholar] [CrossRef]

- Gagnon, N.; Hall, C.A.S.; Brinker, L. A preliminary investigation of the energy return on energy invested for global oil and gas extraction. Energies 2009, 2, 490–503. [Google Scholar] [CrossRef]

- Arodudu, O.T.; Ibrahim, E.S.; Voinov, A.; van Duren, I. Exploring bioenergy potentials of built-up areas based on NEG-EROEI indicators. Ecol. Indic. 2014, 47, 67–79. [Google Scholar] [CrossRef]

- Murphy, D.J.; Hall, C.A.S. Year in review—EROI or energy return on (energy) invested. Ann. N. Y. Acad. Sci. 2010, 1185, 102–118. [Google Scholar] [CrossRef] [PubMed]

- Voinov, A.; Arodudu, O.T.; van Duren, I.; Morales, J.; Qin, L. Estimating the potential of roadside vegetation for bioenergy production. J. Clean. Prod. 2015, 102, 213–225. [Google Scholar] [CrossRef]

- Altieri, M. Small Farms as a Planetary Ecological Asset: Five Key Reasons Why We Should Support the Revitalisation of Small Farms in the Global South. Available online: http://www.agroeco.org/doc/smallfarmes-ecolasset.pdf (accessed on 8 January 2015).

- Altieri, M.A.; Nicholls, C.I. Scaling up agroecological approaches for food sovereignty in Latin America. Development 2008, 51, 472–480. [Google Scholar] [CrossRef]

- Brander, M.; Wylie, C. The use of substitution in attributional life cycle assessment. Greenh. Gas Meas. Manag. 2011, 1, 161–166. [Google Scholar] [CrossRef]

- Weidema, B.P. Has ISO 14040/44 failed its role as a standard for LCA? J. Ind. Ecol. 2014, 18, 324–326. [Google Scholar] [CrossRef]

- IIASA. Table 38- Maximum Attainable Crop Yield Ranges (t/ha Dry Weight) for High and Intermediate level Inputs in Tropical, Subtropical and Temperate Environments under Irrigated Conditions. Available online: webarchive.iiasa.ac.at/Research/LUC/GAEZ/tab/t38.htm (accessed on 19 October 2014).

- IIASA. Table 39- Average of Year 1960–1996 Simulated Maximum Attainable Crop Yield Ranges (t/ha Dry Weight) for High, Intermediate and Low Level Inputs in Tropical, Subtropical and Temperate Environments under Rain-Fed Conditions. Available online: webarchive.iiasa.ac.at/Research/LUC/GAEZ/tab/t39.htm (accessed on 19 October 2014).

- IFA. Maize/Corn: Fertilizer Best Management Practices. Crop Nutrition Wikidot: International Fertilizer Application. Available online: www.cropnutrition.wikidot.com/maize-corn (accessed on 19 October 2014).

- Patzek, T. Thermodynamics of the corn-ethanol biofuel cycle. Crit. Rev. Plant Sci. 2004, 23, 519–567. [Google Scholar] [CrossRef]

- ORNL. Conversion Factors for Bioenergy. Oak Ridge National Laboratory, U.S. Department of Energy. Available online: https://content.ces.ncsu.edu/conversion-factors-for-bioenergy (accessed on 22 December 2016).

- Grisso, R.; Perumpral, J.V.; Vaughan, D.; Roberson, G.T.; Pitman, R. Predicting Tractor Diesel Fuel Consumption; Virginia Cooperative Extension, Virginia Tech; Virginia State University: Petersburg, VA, USA, 2010; p. 10. [Google Scholar]

- Arodudu, O.T.; Voinov, A.; van Duren, I. Assessing bioenergy potentials in rural areas. Biomass Bioenergy 2013, 58, 350–364. [Google Scholar] [CrossRef]

- Graboski, M.S. Fossil Energy Use in the Manufacture of Corn Ethanol. A Report for the National Corn Growers Association; Colorado School of Mines: Golden, CO, USA, 2002; p. 113. [Google Scholar]

- Galitsky, C.; Worrel, E.; Ruth, M. Energy Efficiency Improvement and Cost Saving Opportunities for the Corn Wet Milling Industry. An Energy Star® Guide for Energy and Plant Managers; Ernest Orlando Lawrence Berkeley National Laboratory, University of California: Berkeley, CA, USA, 2003; p. 84. [Google Scholar]

- Uellendahl, H.; Wang, G.; Møller, H.B.; Jørgensen, U.; Skiadas, I.V.; Gavala, H.N.; Ahring, B.K. Energy balance and cost-benefit analysis of biogas production from perennial energy crops pretreated by wet oxidation. Water Sci. Technol. 2008, 58, 1841–1847. [Google Scholar] [CrossRef] [PubMed]

- White, P.J.; Johnson, L.A. Corn Chemistry and Technology; American Association of Cereal Chemists: St. Paul, MN, USA, 2003; p. 892. [Google Scholar]

- Bonnardeaux, J. Potential Uses for Distillers Grains. Department of Agriculture and Food, Government of Western Australia: South Perth, Australia. Available online: https://www.agric.wa.gov.au/ (accessed on 19 October 2014).

- Naylor, R.L.; Liska, A.J.; Burke, M.B.; Falcon, W.P.; Gaskell, J.C.; Rozelle, S.D.; Cassman, K.G. The Ripple Effect: Biofuels, Food Security, and the Environment. Environment 2007, 49, 30–43. [Google Scholar] [CrossRef]

- Heney, J. Talking about Money: Explaining the Finances of Machinery Ownership; Rural Infrastructure and Agro-Industries Division, Food and Agriculture Organization of the United Nations: Rome, Italy, 2009. [Google Scholar]

- Belfield, S.; Brown, C. Field Crop Manual: Maize—A Guide to Upland Production in Cambodia; New South Wales Department of Primary Industries: Orange, Australia, 2008; p. 43. [Google Scholar]

- Food and Agriculture Organization of the United Nations (FAO). Environment and Natural Resources Working Paper No. 4; FAO: Rome, Italy, 2000. [Google Scholar]

- Joshi, D.D. Livestock Rearing; Myers, M.L., Stellman, J.M., Eds.; International Labour Organization: Geneva, Switzerland, 2011. [Google Scholar]

- Naudé-Moseley, B.; Jones, P.A. Donkeys Don’t Need Roads. Available online: https://www.researchgate.net/publication/236347326_with_B_Naude-Moseley_Donkeys_don%27t_need_roads_Farmer%27s_Weekly_92046Grow_22_November_4 (accessed on 12 October 2013).

- Christians, N.E. Preemergence Weed Control Using Corn Gluten Meal. U.S. Patent 5,030,268, 9 July 1991. [Google Scholar]

- Bomford, M.; Silvernail, A.; Peterson, A.; Detenber, S. Corn Gluten Meal as Organic Herbicide: A Worthwhile Investment for Organic Growers? Agricultural Sciences Section, Kentucky Academy of Science Meeting: Morehead, KY, USA, 2006. [Google Scholar]

- Gebrezgabher, S.A.; Meuwissen, M.P.M.; Oude Lansink, A.G.J.M.; Prins, B.A.M. Economic analysis of anaerobic digestion: A case of green power biogas plant in The Netherlands. In Proceedings of the 18th International Farm Management Congress, Bloomington, IL, USA, 19–24 July 2009; pp. 231–244.

- KWS. Biogas in Practice; KWS UK Limited: Hertfordshire, UK, 2012; p. 38. [Google Scholar]

- United Nations Asia Pacific Centre for Agricultural Engineering and Machinery (UNAPCAEM), Beijing, P.R. China. Country Report: Sri Lanka; Available online: http://unapcaem.org/activities%20files/a07/country%20paper-sri%20lanka(hanoi%2004).pdf (accessed on 6 October 2013).

- National Centre for Agricultural Mechanization (NCAM). Report of the National Centre for Agricultural Mechanization on Vari Mini Multi-Purpose Tractor; NCAM: Ilorin, Nigeria, 2011; p. 10. [Google Scholar]

- Kulkarni, M. Greaves launches mini tractor. Business Standard, 15 April 2013. [Google Scholar]

- Cropwatch. Tillage Systems Descriptions. Cropwatch, University of Nebraska-Lincoln: United States, 2013; Available online: http://cropwatch.unl.edu/tillage (accessed on 12 October 2013).

- Jacobs, S. Comparison of Life Cycle Energy Consumption of Alternative Irrigation Systems. Ph.D. Thesis, University of Southern Queensland, Toowoomba, Australia, 2006. [Google Scholar]

- Jackson, T. An Appraisal of the On-Farm Water and Energy Nexus in Irrigated Agriculture. Ph.D. Thesis, Charles Sturt University, Bathurst, Australia, 2009. [Google Scholar]

- Goldenberg, S. GM Corn Being Developed for Fuel Instead of Food; The Guardian: London, UK, 2011. [Google Scholar]

- Goho, A.M. Corn Primed for Making Biofuel. MIT Technology Review: Big Sandy, TX, USA, 2008; Available online: http://www.technologyreview.com/news/409913/corn-primed-for-making-biofuel/ (accessed on 12 October 2013).

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).