Introduction

Reduction of the emission of greenhouse gases is urgently needed for reasons of both climate change and future shortages in the supply of fossil fuels, be it for reasons of physical shortage or because of political and market instabilities. A major part of the Netherlands (and precisely the centre of economic activity) is at or below sea level. The Netherlands, therefore, are among the nations that will be severely threatened by a rise in sea levels. Not surprisingly, the Netherlands are also among the nations that urge further reductions in the emission of greenhouse gases.

The economic shift that will be required in order to arrive at these reductions, is also required by economic necessity. Traditionally strong sectors of the Dutch economy like chemical industry and agriculture are moving to low wage countries with considerable effect on employment. Rotterdam harbour has become less popular with investors. Large engineering firms have less orders for the construction of petrochemical industries in Europe, but more so from the Middle East and Asia. This is partly because the demand for products in the Far East is on the rise, but also because these industries, heavily dependent upon fossil fuels, tend to move toward countries with lower resource and production costs [

1]. Oil has the same price everywhere in the world while natural gas as a major energy supplier to the chemical industry is much more expensive in the EU than in some areas elsewhere. Agricultural land in the Netherlands is relatively expensive, which hampers competition with e.g. Eastern Europe, in spite of higher yields per hectare.

Some world wide developments

During the last few years substantial paradigm changes have occurred which urge us to re-assess our economical position.

Growth in energy consumption

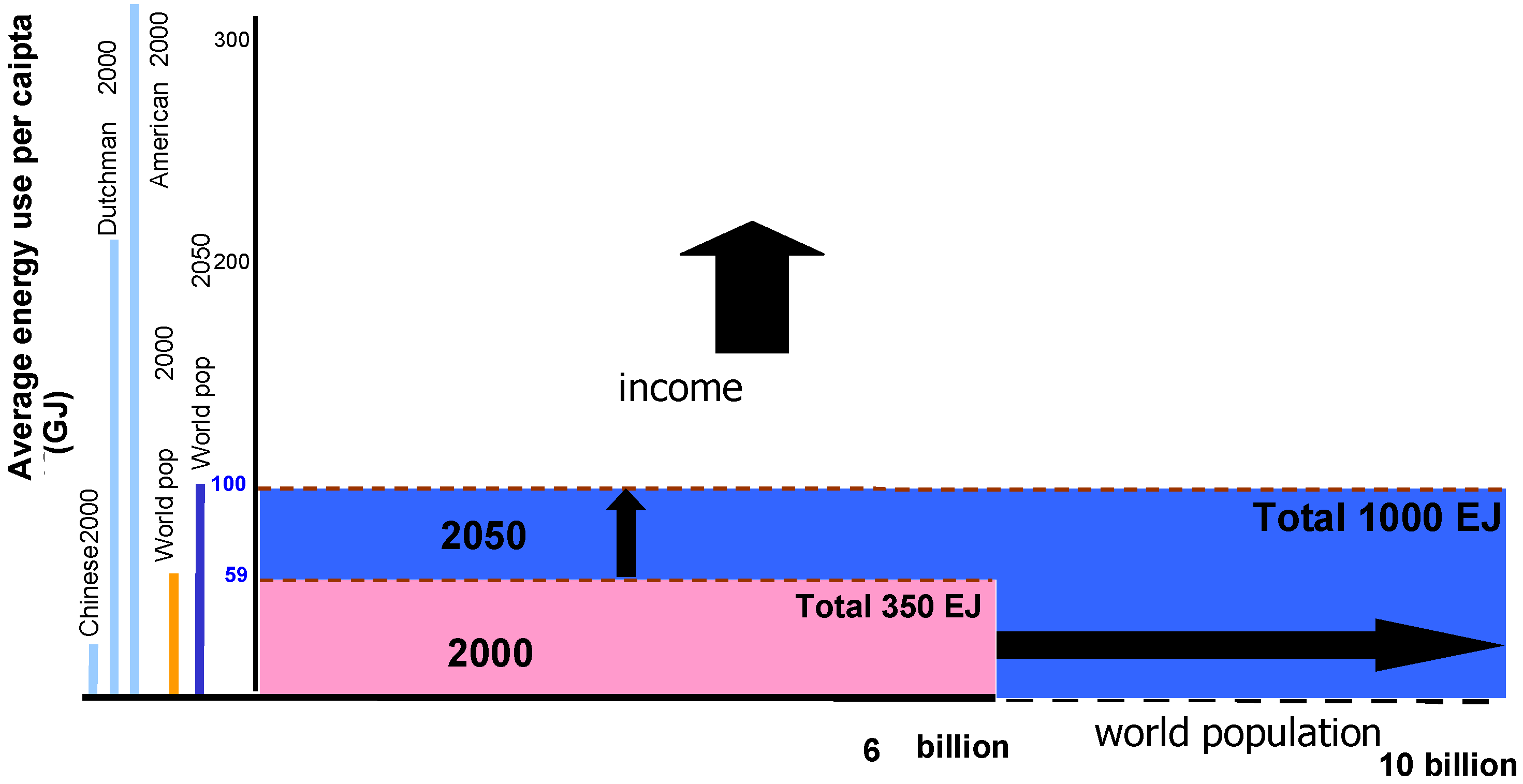

The world consumed 350 EJ in 2000 (

Figure 1), implying a consumption of 59 GJ per capita. According to present extrapolations, this figure is supposed to rise to 100 GJ per year per capita by 2050 (vertical axis). Considering the rise in world population at the same time from 6 billion to 10 billion (horizontal axis), this implies a threefold rise in world energy consumption to the amount of 1000 EJ. The replacement of fossil fuels by CO

2-neutral energy sources is required to meet this demand, and fulfil the Kyoto requirements at the same time, and even more so: any additional requirements in the post-Kyoto and post-Bali era.

Figure 1.

Increase in world energy use. The area in pink indicates world energy consumption in 2000; the area in blue indicates the expected world energy consumption in 2050.

Figure 1.

Increase in world energy use. The area in pink indicates world energy consumption in 2000; the area in blue indicates the expected world energy consumption in 2050.

Supply security

The lack of political stability in many oil and natural gas producing countries poses a threat to supply security of the industrialised countries. Consequently, these countries explore alternatives for oil.

The need to reduce international tensions

Biomass may be produced in a great number of countries. Making this feedstock available will ease up international tensions insofar as these are connected to power over mineral resources; moreover it may enhance regional sustainable development. Preservation of biodiversity is a necessary prerequisite for such a sustainable use of biomass. New applications of biomass may be helpful to develop the economic strength of developing nations, whilst reducing CO2 emissions.

The weakening of typical Dutch strenghts

Next to these 'pull' factors there are also 'push' factors which will promote the development of new competitive strengths of industrial countries. This holds especially for the Netherlands. Traditional strengths of the Dutch economy include the chemical industry, logistics and the agro-food complex, including agriculture, horticulture, and the food and feed industry. All these sectors will be affected by high oil prices and the shift of manufacturing industries to lower wage countries. Especially the large (petro-)chemical industry, the products of which are exported for ca. 90%, may prove to be very vulnerable.

The agro-food complex is a versatile sector of the Dutch economy, and this may prove to be the basis for new venues. Agriculture may grasp the opportunities that are generated by the achievement of food self-sufficiency in Europe [

7,

8,

9,

10,

11]. While the cost of agricultural land is high in the Netherlands, the sector is well organised with very short links between R&D and the industry. Farmers may put to use new technological developments in order to gain new ground. Employment in the agro-food complex now amounts to 660,000, and turnover amounts to € 40 billion, of which 400,000 and € 23 billion on the basis of home grown crops. The Netherlands, with a population of 16 million on an area comparable to Massachusetts, are the third exporting nation of agricultural products in the world [

12]. The strength of this sector, combined with the size of the Rotterdam harbour (largest in Europe and third in the world after Shanghai and Singapore) [

13], and of the chemical industry, may be the basis for the development of new strengths.

Biomass use as an opportunity

Biomass, primary crops as well as residues from agriculture and residues from industry, seems to be an interesting (renewable) substitute for fossil raw materials.

Biomass, a substitute feedstock

Barely a century ago the Dutch economy, in the areas of energy and materials, was mainly biomass based. By biomass we mean here organic material used for non-food purposes. Substitution, first by coal and then by oil and natural gas, combined with a huge increase in the consumption of energy and materials, have greatly reduced the share of biomass. Nevertheless, a large part of the expensive and dwindling supply of oil may in the future be replaced by biomass. Oil may be substituted by biomass in its three main applications, namely bulk chemicals and materials, transport fuel and energy. Other renewable energy sources for the Netherlands, mainly wind and solar, only produce electricity, which at present is hard to store or to apply as a transportation fuel. Biomass may fill the gap that these energy sources leave. A number of scenario studies, among which one by Shell [

14], show that biomass may cover 15% of world energy demand in 2050. In addition to this, biomass may act as a feedstock for materials production. The sum of this amounts to 50% of present world energy use. The aforementioned share of 15% may be achieved by the Netherlands as well. Recently, an advisory body to the Dutch government argued that under conditions of rigorous energy efficiency policies, biomass may replace as much as 30% of the use of fossil fuels as early as 2030 in the Netherlands [

15]

Gasification

While the majority of biomass for energy production in the Netherlands is used in the form of co-firing in coal fired power stations, the next step would seem to be gasification. Gasification of biomass is among the top priorities of national energy research institute ECN [

16], and its commercial application is expected within a few years. The product of gasification is a mixture consisting mainly of CO and H

2, and this may be used to produce electricity in gas-fired power stations, or be upgraded to biodiesel and chemicals through Fischer-Tropsch synthesis. The projected volumes for applications of gasified biomass (by ECN) are as follows (cf. present energy use in the Netherlands amounts to ca. 3.200 PJ/year).

Technically speaking, biodiesel may well be produced from biomass through the Fischer-Tropsch synthesis; however, this technology has a few drawbacks that will hamper implementation. Firstly, Fischer-Tropsch synthesis requires massive investments as these installations can only be cost-effective on a large scale.

This implies, secondly, the necessity of massive overseas transports to secure supply for these factories. Thirdly, this technology is suboptimal from a thermodynamic point of view: it implies breaking down large organic molecules to simple components, and subsequently putting these components together again to complicated molecules. This drawback is even more severe if the desired products contain nitrogen and oxygen, which were stripped from carbon molecules in the first reaction steps and which are hard to insert into carbon chains subsequently [

17,

18].

Table 1.

Projected use of gasified biomass in the Netherlands.

Table 1.

Projected use of gasified biomass in the Netherlands.

| Application | Projected volume 2010 (PJ/year) | Projected volume 2020 (PJ/year) |

|---|

| Co-firing in gas-fired power stations | 10 | 20 |

| Decentralised applications | 5 | 30 |

| Production of biofuels and chemicals | 5 | 50 |

| Total | 20 | 100 |

For these reasons, synthesis of chemicals from biomass by Fischer-Tropsch will probably be just an intermediate step, until processes are designed, starting from specific substances in biomass, that preserve the valuable carbon-oxygen and carbon-nitrogen bonds. Many bulk chemicals could be readily produced from substances available from biomass, saving energy and the use of organic solvents.

Second generation ethanol production

Whereas present ethanol production is from sugars and starch, and hence competes with food production, 'second generation' ethanol will be produced from cellulose. Cellulase enzymes that can accomplish the transformation of cellulose into sugars that can be easily transformed into ethanol, have been developed by several industries, and their commercial application is imminent. Dutch research institutions and industries are active in this field. As there is an abundance of waste streams containing cellulose in the Netherlands, this may be the basis for new industrial opportunities [

12].

Production of bulk chemicals from biomass

The chemical industry (excluding energy intensive metal industries) accounts for roughly 20% of Dutch energy use [

12]. A great deal of this energy is used for cracking crude oil into smaller units, and subsequent steps in which these are reconstructed to useful chemicals. In several future scenarios, both in Europe [

19] and in the United States [

3], it is assumed that by 2030 about 30% of petrochemical bulk chemicals may be substituted by feedstock from biomass.

We estimate that for about one quarter of bulk chemicals, biomass will be an attractive substitute for oil. These chemicals account for ca. 10% of Dutch energy use [

20,

21]. Biomass offers major energy savings in the production of these chemicals, primarily because substances from cracking of crude oil usually undergo a substitution reaction with chlorine or ammonia; in doing so, a large share of the energy needed to produce these latter substances is lost. Starting from the right biomass components, these substitution reactions are either wholly, or to a large part, superfluous.

This can be illustrated by examination of energy use in the production of diamines, important building bricks for polymers like lubricants, rubber and nylon. The production cost of ethanediamine from crude oil in energy terms is ca. 80 GJ/ton. This breaks down into ca. 20 GJ for feedstock, 30 GJ for the production of chlorine, used in the first reaction step to produce dichloroethane from ethene, and another 30 GJ for the production of ammonia, used to replace chlorine with amine groups. The same compound, ethanediamine, may be produced from biomass, starting from serine or its decarboxylated product ethanolamine, which can be extracted from plants. For the isolation of ethanolamine we need relatively little energy. For the transformation of ethanolamine into ethanediamine we need only half as much ammonia, and no chlorine at all. Hence, the synthesis of ethanediamine from biomass may be achieved using only 25 GJ/ton, 3-4 times less than when starting from crude oil [

12].

Technological breakthroughs

We are only on the brink of technological breakthroughs that will amount to the valorisation of many components of biomass. In recent years we have seen the breakthrough of bio-based plastics. Polylactic acid from biomass (Natureworks® from Cargill) is replacing PE (polyethylene) for isolation purposes in electric casing, and part of the feedstock for PET bottles is now substituted by corn based 1,3-propyleneglycol [

5,

22,

23] resulting in bottles from PTT, which is marketed by DuPont as Sorona®.

Technologies that are instrumental to this valorisation of biomass include biorefinery, separation technology, and white and green biotechnologies. With biorefinery, valuable components from biomass can be extracted from the crude feedstock. Genetic modification (green biotechnology) may be helpful to increase the concentration of any required substances in the plant-feedstock. Fermentation and enzymatic reactions (white biotechnology) [

1,

2,

5] as well as chemical conversions are the preferred vehicle to transform these substances into useful chemicals. And in order to isolate these chemicals in pure form, new separation technologies, specifically from aqueous solutions, are required. Technology is rapidly developing in all these fields.

A common factor for these technologies is that they are applicable at a much smaller scale than present chemical industries. Investments costs are expected to be much lower, mainly because complicated equipment for heat transfer is not required for most of these reactions, which typically proceed at low temperatures in contrast to many petrochemical processes [

24].

Availability of biomass

World Wide growth of biomass nowadays consists of about 150 billion tonnes, or 2,250 EJ [

25] which is five fold global energy consumption. We can harvest a significant part of this.

Supply

Many studies have shown that enough biomass is, or will come available in order to cover demand in an energy economy based on a 15% share of biomass [

26]. A share of 6-10% of yearly global biomass production would be sufficient. This is an important amount, certainly when taking into account that world food supply will have to increase considerably. Much of global biomass production will take place in areas where it cannot be harvested, e.g. because of possible loss of biodiversity. On the other hand we need to take into account the production of agricultural residues as side products of food production. At present, production of agricultural residues is estimated at 3% of total biomass production: 5 billion tonnes in the world [

14], not counting leaves, that often contain valuable substances. In view of the necessary doubling of world food production, the volume of agricultural residues will also double, leading to about 10 billion tonnes of world biomass production in the form of agricultural residues, by itself sufficient to cover 15% of world energy needs in 2050.

New technologies will have to be developed in order to put to use these usually diffuse sources and avoid high transport costs. In the Netherlands, many side products from agriculture and food production are collected and re-used, often with low efficiencies in the feed industry. This is acceptable because of low production costs. Many of these side products end up in manure, and if the Netherlands could valorise this waste stream, this would be sufficient by itself to cover a large part of the required percentage of biomass in the energy economy. The volume of manure from cattle, pigs and poultry is about 66 Mm

3 [

27] with a total dry weight of about 10%, which could represent about 100 PJ lower heating value.

Nevertheless, cultivation of specific crops that increase the degree of substitution of fossil fuels per hectare of land may be useful. An example of this may be wood production. The area of European forests, excluding Russia, amounts to 175 million ha. Yearly stem wood production equals 750 million m3, of which just over 50% is harvested. The remainder, say 300 million m3 at 7.8 GJ/m3, equals 2.3 EJ [

28]. Contrary to public perception, the exploitation of these reserves does not as a rule amount to deforestation. As a matter of fact, deforestation does take place in the tropics (and locally on a large scale) because of the high quality and value of this wood.

Competition with food supply

It is challenging to develop the projected potential of biomass in socially, ecologically and economically acceptable ways. It is imperative that such a development would not damage biodiversity and would not compete with food supply. But if correctly applied, utilisation of agricultural residues and (re)forestation could be the basis for new economic strengths especially in developing nations, in which agriculture is an important part of the economy. This could reinforce the economic structure of the countryside. Extra income to the farmer from non-food utilisation of biomass will increase income security and may reduce food prices. Poorer agricultural land could be re-used for crops dedicated to non-food applications.

It should be possible to develop the potential of biomass in synergy with food production. In the Netherlands, which has a general shortage of agricultural land, crop revenues are optimised and side streams are directed to non-food applications. In areas without agricultural land shortages, there is room in principle to cultivate specific non-food crops, for instance in Europe, where fallow land is used for the production of biodiesel.

It goes without saying that, even if there is no need for competition between food and non-food crops, abuse could develop in specific circumstances, motivated by greed or power. It would be unwise, however, to decide on beforehand that because of these possibilities, agriculture for non-food purposes should not be allowed [

29]. It must be borne in mind, inter alia, that agricultural land is also used for the production of timber, flowers and fragrance. A decision to counteract non-food agricultural production might well rob developing countries from valuable assets. But international inspection and certification will be needed in order to protect local population from abuse, be it because of the threat of famine, loss of biodiversity, unnecessary use of pesticides, depletion of minerals, or uncontrolled erosion.

Opportunities for the Netherlands

The Netherlands processes a very high amount of biomass per hectare. This offers an advantageous progress position as compared to surrounding countries.

Exploiting dense biomass streams

One of the main assets of the Netherlands for the development of a strong position in this field, is the density of the biomass throughput. In plain terms: there is a lot of biomass available on a small area. Whereas average yearly throughput of biomass per hectare for the world is 1.5 tons, this amounts to 2.5 tons for the US, 5 tons for France and Germany, and 13 tons for the Netherlands (40 million tons on a area of 3,300,000 ha). This is the result of high imports of agricultural products for the feed industry, the relatively high acreage of meadows, and the intensity of agriculture [

27].

Production of food in industrialised countries is energy intensive. If we value all nationally produced and imported biomass to its energy value, and add the energy consumption in agriculture, horticulture, transports of biomass, food and feed, the agro-industry, and home cooking, we arrive at a figure 15-20 times higher than the net energy content of our food. For the Netherlands, this amounts to one third of national energy use [

27].

The agricultural soil needs organic matter to a certain extend but for the Netherlands in principle, a great deal of the excess energy content of our food can be profitably utilised while in larger countries this biomass is required to keep the soil quality to optimal standards. Cellulose, for example, is imported in large quantities in feedstock for fodder and feed, passes almost unmodified through the intestinal tracks of cattle and pigs, and ends up in manure, where it is the component principally responsible for the difficulty of treatment of this waste stream. It could be profitably used for energy production or building materials if it were separated on the outset. Food and fodder is much less protein rich than optimal; if proteins were separated from other plant components, this would increase the efficiency of the (animal) food chain, while releasing useful compounds for the production of chemicals. Proteins from plants, again, are relatively poor in essential amino acids; if proteins were split, and cattle and pigs were fed with the right proportion of amino acids, the remaining amino acids could be used for the production of nitrogen containing chemicals.

The fulfilment of these demands is mainly dependent on the further development of biorefinery and separation technologies. The Netherlands have a strong position in these technologies, based on the upgrading of feedstock like potatoes, beet, soy and wheat. These technological assets, together with the density of biomass streams, may be further developed to new economic strengths [

27].

Biogas and biofuel production from waste streams

In recent years, many biogas installations have been constructed. In these, waste products from agriculture are fermented together with manure in order to produce methane. At present, this technology still needs to be subsidised. Strict rules for use of agricultural products in these installations sometimes act as a barrier to their deployment. A project for production of second generation bio-ethanol from a waste stream of the wheat processing industry has not yet been able to raise sufficient investment funds.

Imports

Imports of biomass play an important role in the Netherlands, both at present and in the future. There is a good infrastructure for biomass imports in Rotterdam harbour, based on traditional imports of feedstock for the food and feed industry, and recent imports of wood pellets for co-firing. This infrastructure will have to be scaled up in order to meet market demands for energy and chemicals production from biomass. An impediment could be formed by the low energy content of biomass. Even after densification, biomass contains an economic value of 30-40 €/ton, whereas crude oil contains 450 €/ton at 90 $/barrel. In competition for scarce quays, this may prove to be an obstacle. Nevertheless, the strength of Rotterdam harbour, coupled with a possibly dwindling oil trade in the long term, must be valued as an asset to the development of a bio-based economy in the Netherlands.

The agricultural sector

Dutch agriculture may make a significant contribution, not by changing Dutch landscape into plantations of energy crops, but primarily by application of know-how. Utilising the existent area of meadows and fields, there is room for the development of new varieties of crops that can serve as a valuable feedstock for the industry, often in dual purpose, i.e. serving food and chemicals supply at the same time. In order to achieve this, new technologies will have to be developed. These cultures will produce sugars as side streams, which can be used to produce bio-ethanol or other products from fermentation, which will allow this strong European industry to remain footed in Europe instead of having to move to countries with cheap resources. The knowledge thus developed may later be put to use abroad.

The optimal mix of plant valorisation (using components for the sectors in which they carry maximum revenues) will produce more income per hectare to the farmer than the best crops in the Netherlands, like potatoes and sugar beets. Genetic modification and new separation technologies are a prerequisite to this development, in order to achieve sufficient concentrations of valuable components in plants, and to isolate these from the plant material. We assume that by 2020 any impediments to the utilisation of GMO technology for useful purposes will have been overcome. Such multi-purpose crops can best be grown in the largely rural northern part of the Netherlands, situated near the important Eems harbour, which can act as an import harbour but also as an export harbour to, e.g. Rotterdam.

With this strategy, the Netherlands will use in an optimal way its assets for the bio-based economy, namely its strong position in logistics, the existence of a large hinterland for Rotterdam harbour, the combination of a strong agro-food complex and a large chemical industry, and the know-how in all these sectors. On the basis of such a strategy the Netherlands may develop into a hub for trade in bio-based products world-wide.

Quantification

Both in terms of fossil energy substituted by biomass, and in terms of value created by use of biomass, the results depend upon the share of biomass that can be used in the higher value markets, notably for the production of chemicals. It is obvious that 1 GJ of heat, which is traded at ca. € 4/GJ, is worth less than 1 GJ of electricity sold at € 22/GJ, or 1 GJ of chemicals, which are traded typically at € 75/GJ [

18]. But also, and this is less obvious, the amount of fossil fuels substituted by biomass is higher as more biomass is transformed into chemicals. This is true because in utilising biomass as a feedstock for chemicals, we substitute the feedstock, and in addition to that dispense with the energy-intensive processes that are used to produce chemicals at present.

As an example we elaborate the effects on the energy economy for three scenarios in which 25% of the Dutch agricultural acreage has been devoted to the production of biomass (

Table 2). This would include 250,000 ha of meadows, and 200,000 ha of fields. At a yield of 22 ton/ha this area will produce 10 Mton of biomass. We quantify the effects for three scenarios: no biomass used to produce chemicals, 10% or 20%. Since the structure of functionalised chemicals is present in plant fractions (10% or 20%), there is no need to use an amount of often three times the energy as compared with the energy content of the product that results from the petrochemical process. This explains the different fossil substitution between the three different scenarios.

Table 2.

Substitution of fossil fuels, and value created by biomass in three scenarios based on 25% of Dutch agricultural acreage devoted to production of biomass.

Table 2.

Substitution of fossil fuels, and value created by biomass in three scenarios based on 25% of Dutch agricultural acreage devoted to production of biomass.

| Item | Scenario 1: no biomass to chemicals | Scenario 2: 10% biomass to chemicals | Scenario 3: 20% biomass to chemicals |

|---|

| Substitution of fossil fuels (PJ) | | | |

| Feedstock for chemicals | 0 | 50 | 100 |

| Transport fuels + electricity | 150 | 135 | 120 |

| Total substitution | 150 | 185 | 220 |

| As a percentage of national energy consumption | 5 | 6 | 7 |

| Value created by use of biomass (M€) | | | |

| Feedstock for chemicals | 0 | 500 | 1,000 |

| Electricity | 225 | 200 | 180 |

| Transport fuels | 375 | 340 | 300 |

| Total | 600 | 1,040 | 1,480 |

| Gross value per hectare (€/ha) | 1,330 | 2,330 | 3,330 |

The substitution figures mentioned in

Table 2 by primary biomass will have to be added to the figures mentioned in

Table 1 by substantially residual biomass products, in order to arrive at the amount of substitution of fossil fuels by biomass in the outlined scenarios. The same case could be argued for global scenarios. In doing so, we could multiply the figures mentioned in

Table 2 by a factor of 100 since the energy consumption of the Netherlands is about 1% of the global consumption. If we assume the market for chemicals to grow at the same rate as energy consumption, we can triple again these figures for year 2050, and we arrive at a substitution of fossil fuels by biomass to the amount of 60-70 EJ/year, equal to 6-7% of global energy consumption in 2050. (For the moment we exclude extra growth in chemicals that are exclusively or mainly bio-based). In order to achieve this level of substitution, we would need a surface of 150 million ha, equivalent to 4% of the global surface suited for agriculture.

With the development of a global trading system in CO2 emission rights, there are additional economic reasons to embark upon such a path. For the Netherlands, projected CO2 emissions for 2012 are 240 million tons. At 20 €/ton, a 10% reduction in CO2 emissions would represent a value of 480 M€/year, and this figure could be multiplied if higher prices for emission rights would have to be paid.

Such a 10% reduction of CO

2 emissions can be achieved by better utilisation of biomass:

use of one quarter of arable land in the Netherlands for production of biomass

productive use of just one quarter of biomass throughput in the Netherlands (total 40 Mton/year) instead of allowing it to degrade to waste

additional imports to the amount of 10 Mton/year for transport fuel and the chemical industry.

On top of that, imports of Brazilian ethanol, about one million m

3 in 2007 [

30], will further reduce greenhouse emissions. If 10% of transport fuel use in the Netherlands would have to be replaced by bio-ethanol, this would require 3 Mton/year and would reduce national CO

2 emissions by 1.5%.

Policy measures

The new conditions require policy measures for the transition from fossil to renewable resources.

Adequate policy measures will have to be characterised by a set of simple principles:

Seize the opportunity

Dutch policy making is quick in setting goals but slow in implementing adequate instruments. In the past, this has led to events like the loss of momentum in the implementation of wind energy in the nineties, and likewise in the implementation of biogas in recent years. As a result of this, wind technology has been developed mainly in Denmark and development of know-how in handling side streams of the agro-food complex has taken place in Germany rather than in the Netherlands.

Stimulate and regulate

In the development of new business like in the bio-based economy, government regulation may be of prime importance. The utilisation of side streams from the agro-food complex, for example, has been hampered because some of these side streams were officially classified as waste, and had to be handled accordingly. New regulations may be needed in order to create new opportunities. The (international) trade in biomass would be greatly enhanced if an international classification and control system would be designed and implemented. Financial stimuli are often needed to develop new markets. The object of such measures may be to restore market distortions, or to supply a temporary steppingstone in the development of new technologies. Intelligently designed financial stimuli, that can last for a number of years and hence contribute to market stability, are of prime importance. Germany has been very successful in sustaining a financial stimulus to 'green electricity' for a number of years; compared to the Dutch policy, the United States have worked out an intelligent scheme for the introduction of ethanol, in which not the ethanol as such but blended gasoline was subsidised so that the regular distribution companies will benefit as well from the National subsidies. In the Netherlands, no subsidy is provided but a mandatory blending in gasoline and diesel that increases 0.75% every year due to the European Union directive 2003/96/EC has been issued. New entrants to the biofuel market are discouraged because high blends of ethanol such as E85 are much more expensive than regular petrol while these new entrants have only little access to the traditional distribution channels. Sweden has supported the development of renewable technologies with tax cuts and an R&D programme, with pilot plants for ethanol production and a flex fuel scheme, with reduced levies on special cars and a government demand for them.

Stop counterproductive policies

Counterproductive measures should be phased out. Often, these are in the interest of the owners of 'old' and energy intensive technologies. In many countries, including the Netherlands, artificially low fuel and electricity tariffs are charged for energy intensive processes like metallurgy and production of ammonia, chlorine and caustic soda. This will be an obstacle on the road to a bio-based economy.

Stimulate R&D

Technologies that need special attention for the development of a bio-based economy include:

separation technologies, both large scale and small scale: biorefinery technologies.

processing of waste streams

fermentation and enzymatic technologies

catalysis

plant breeding including GMO technology in order to enrich crops in desired substances.

Develop climate neutral industrial policies

As shown, there is no conflict per se between climate neutral policies and sound industrial development. A proactive attitude is the best way to prepare for a future in which the emission of greenhouse gases will be strictly limited. Technological scenarios need to be developed for a cost-effective reduction of such emissions, with a number of alternatives for oil, and a better spread of feedstock producing countries around the world. Such policies would include the development of a global system of certification and control of biomass, in order to counteract loss of biodiversity and other adverse effects, and to create a level playing field.