Online Monitoring Technology of Metal Powder Bed Fusion Processes: A Review

Abstract

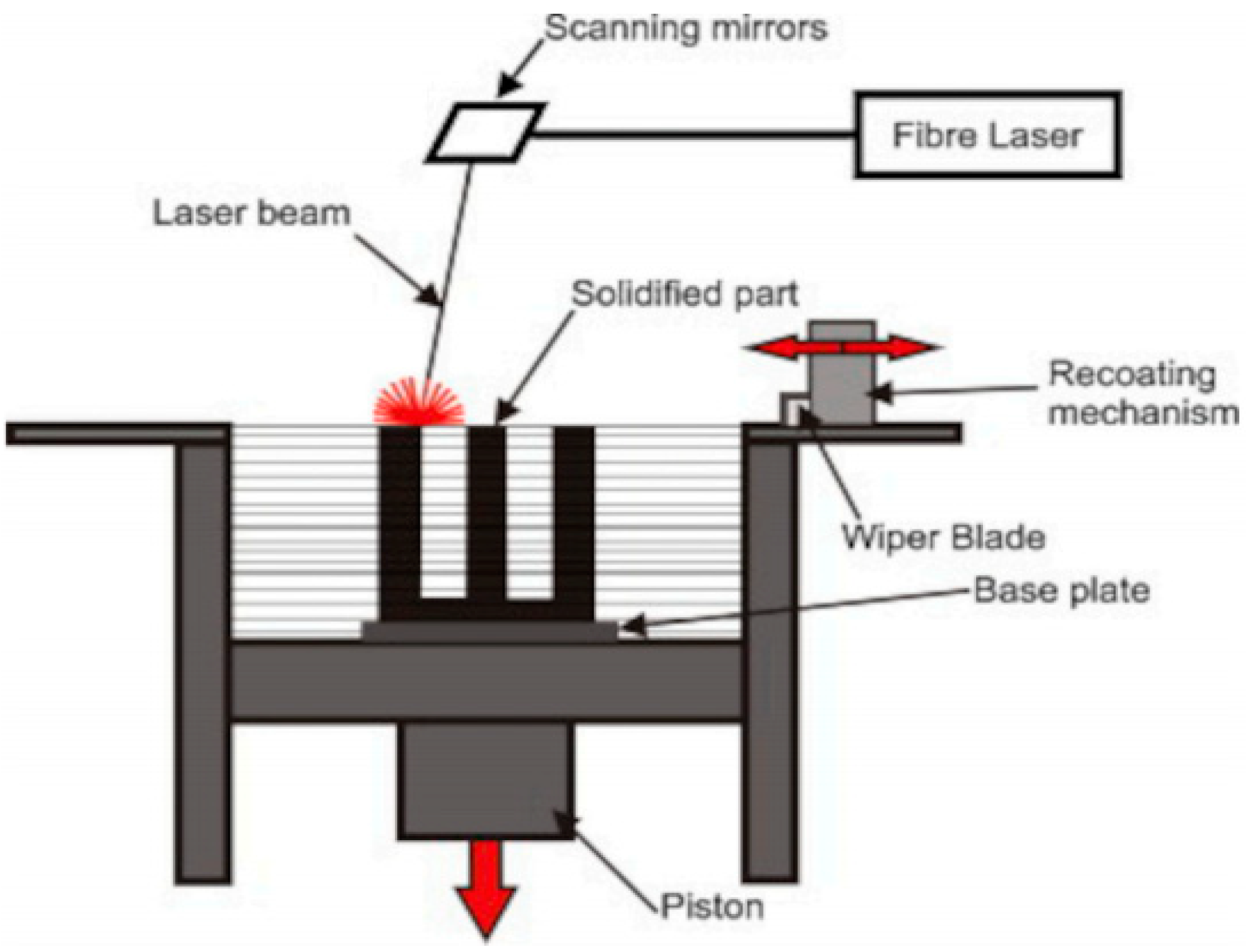

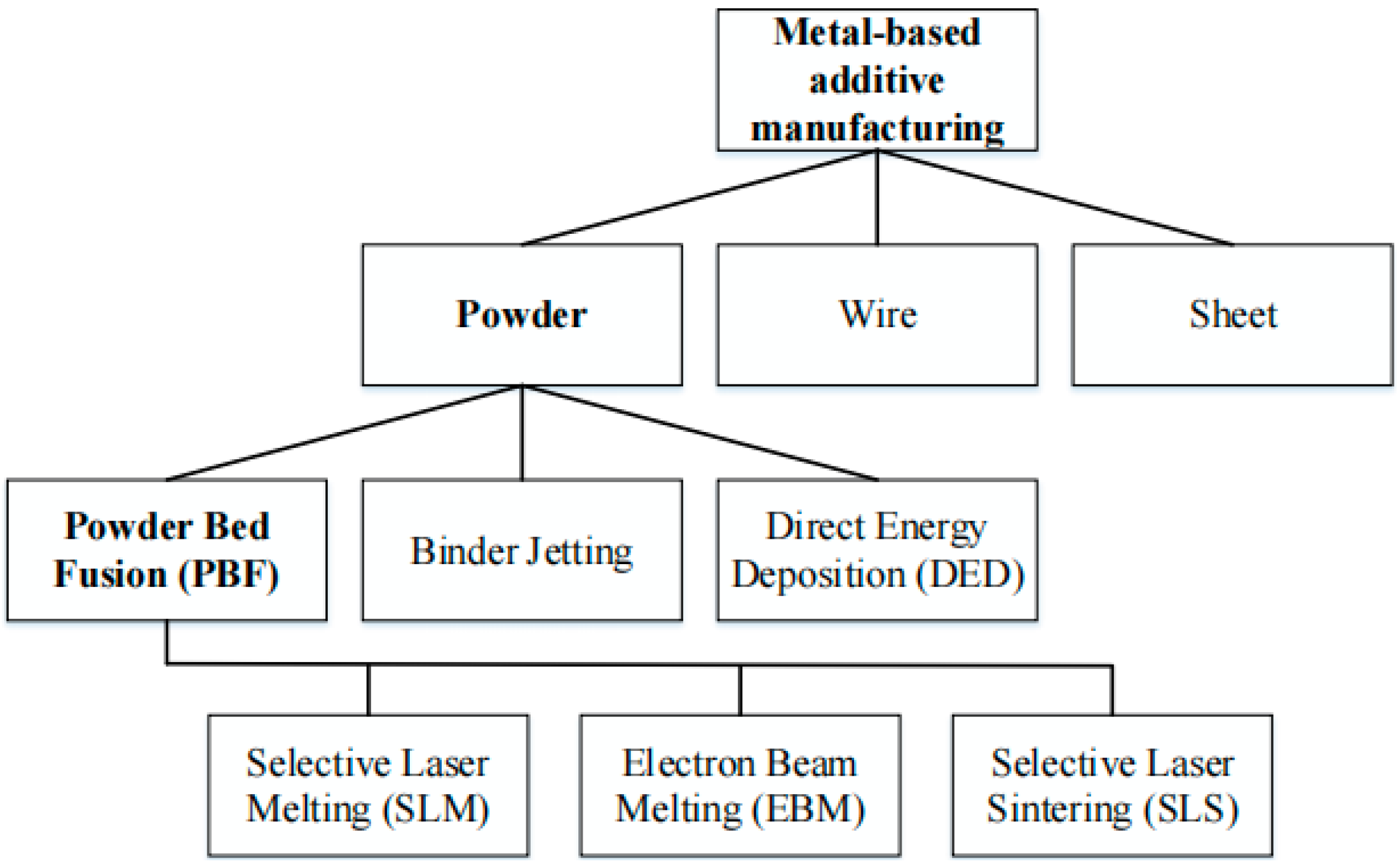

1. Introduction

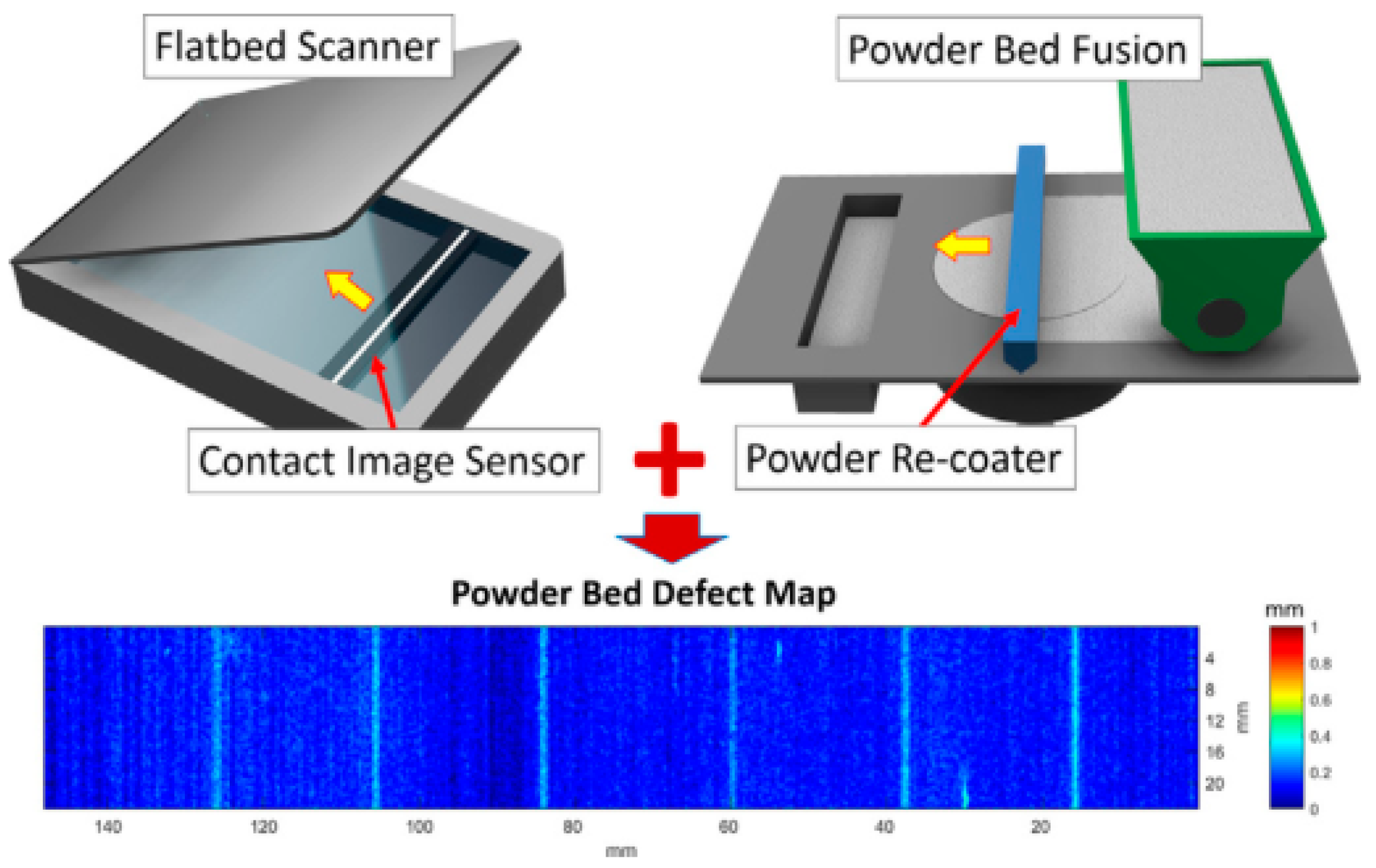

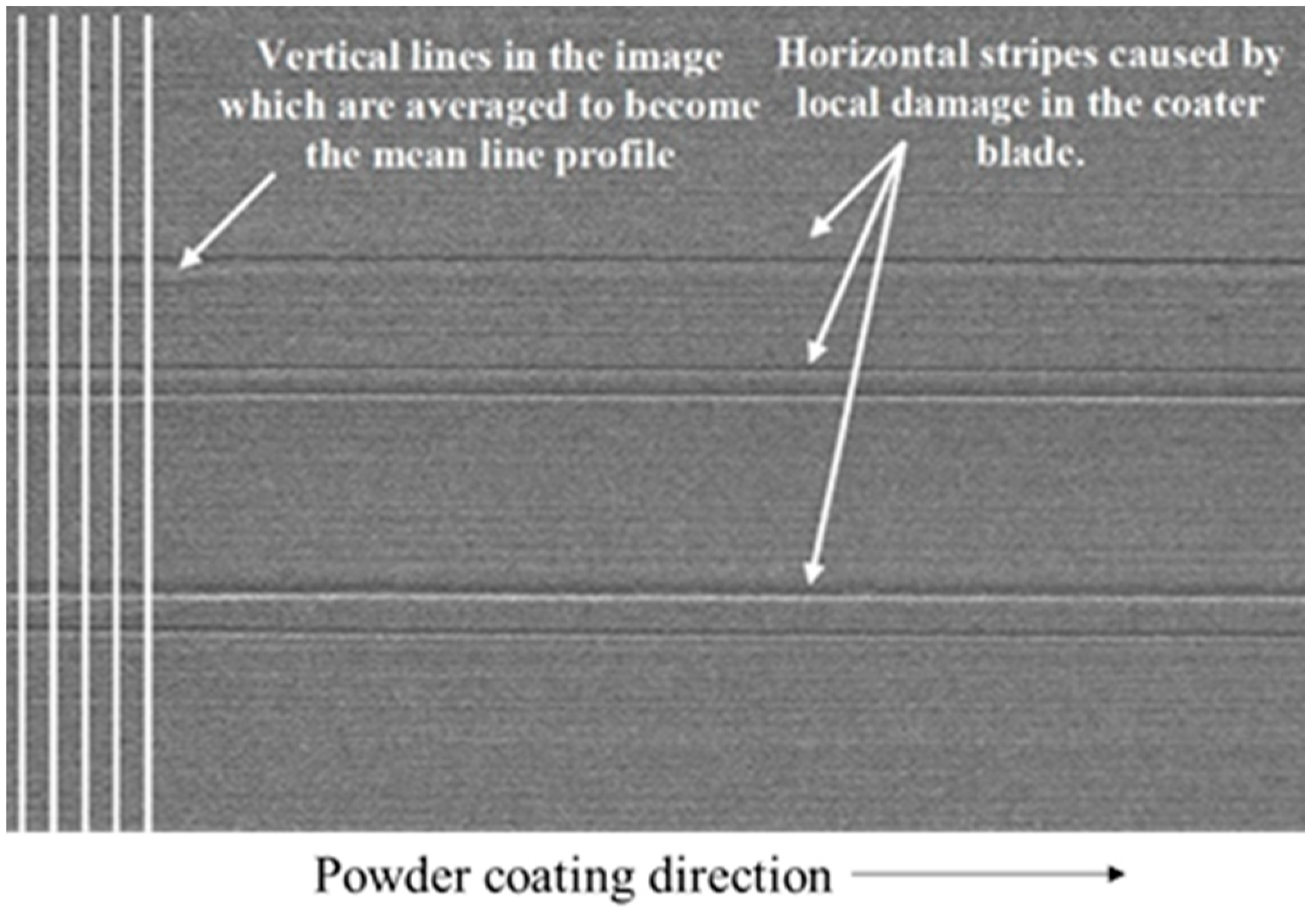

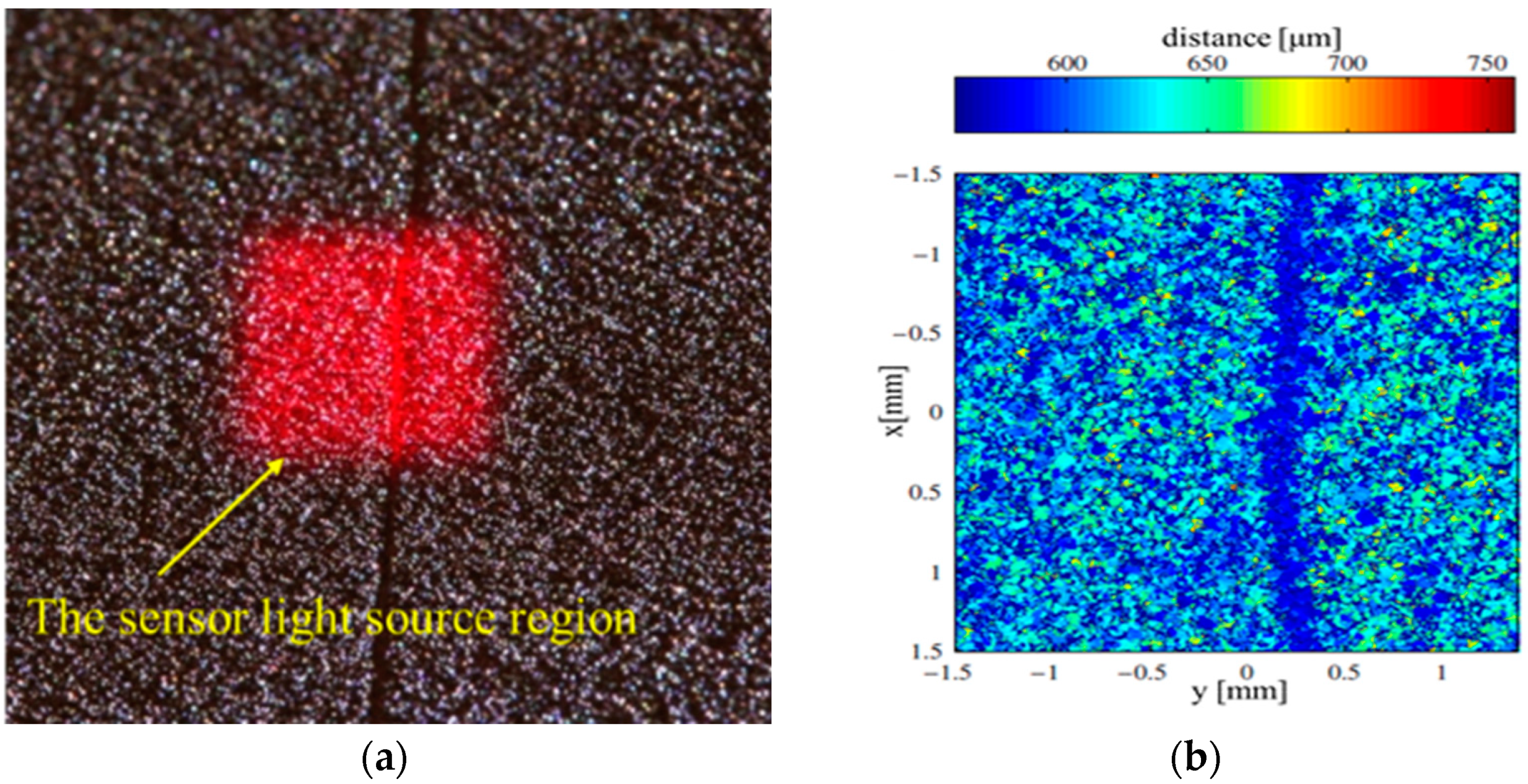

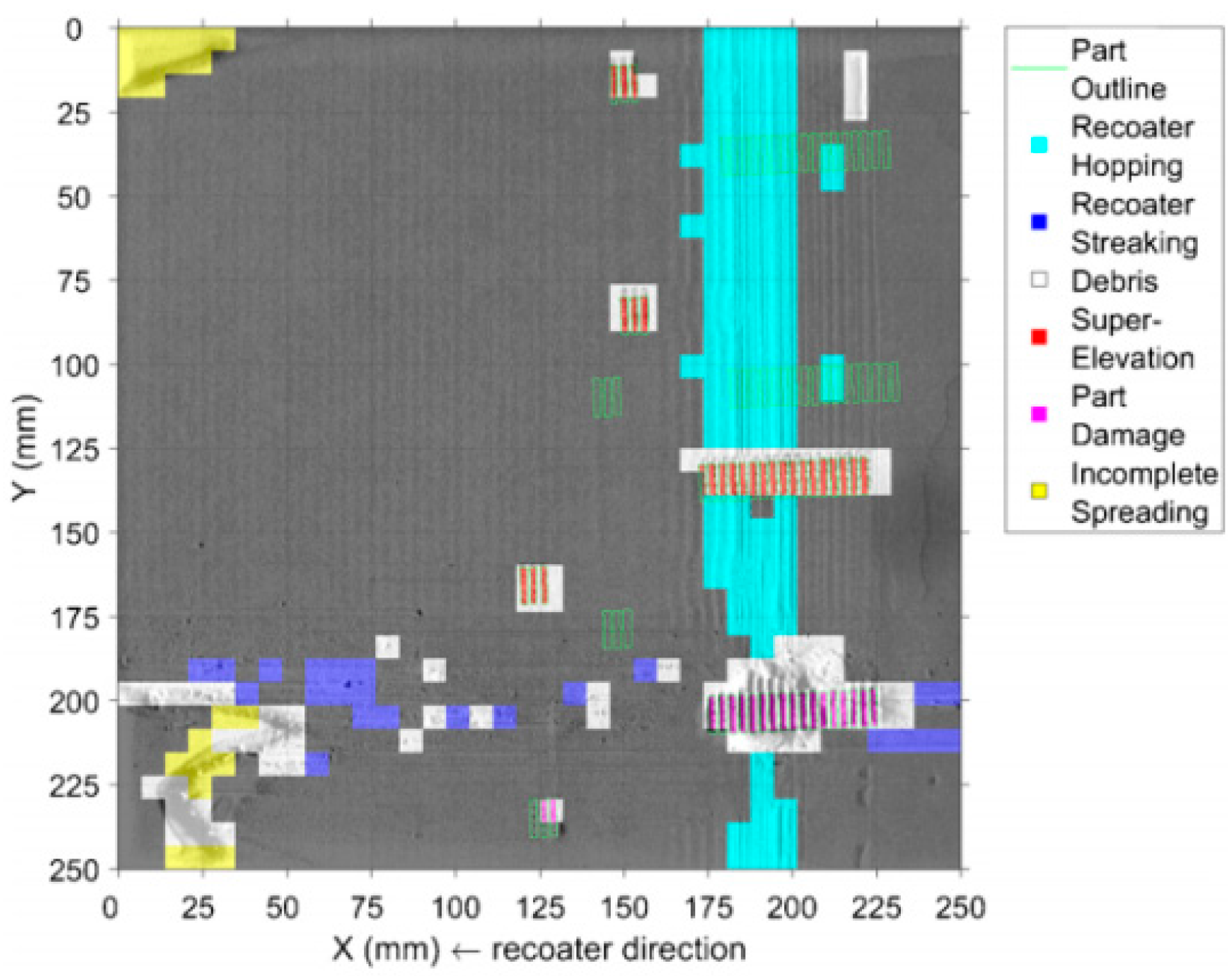

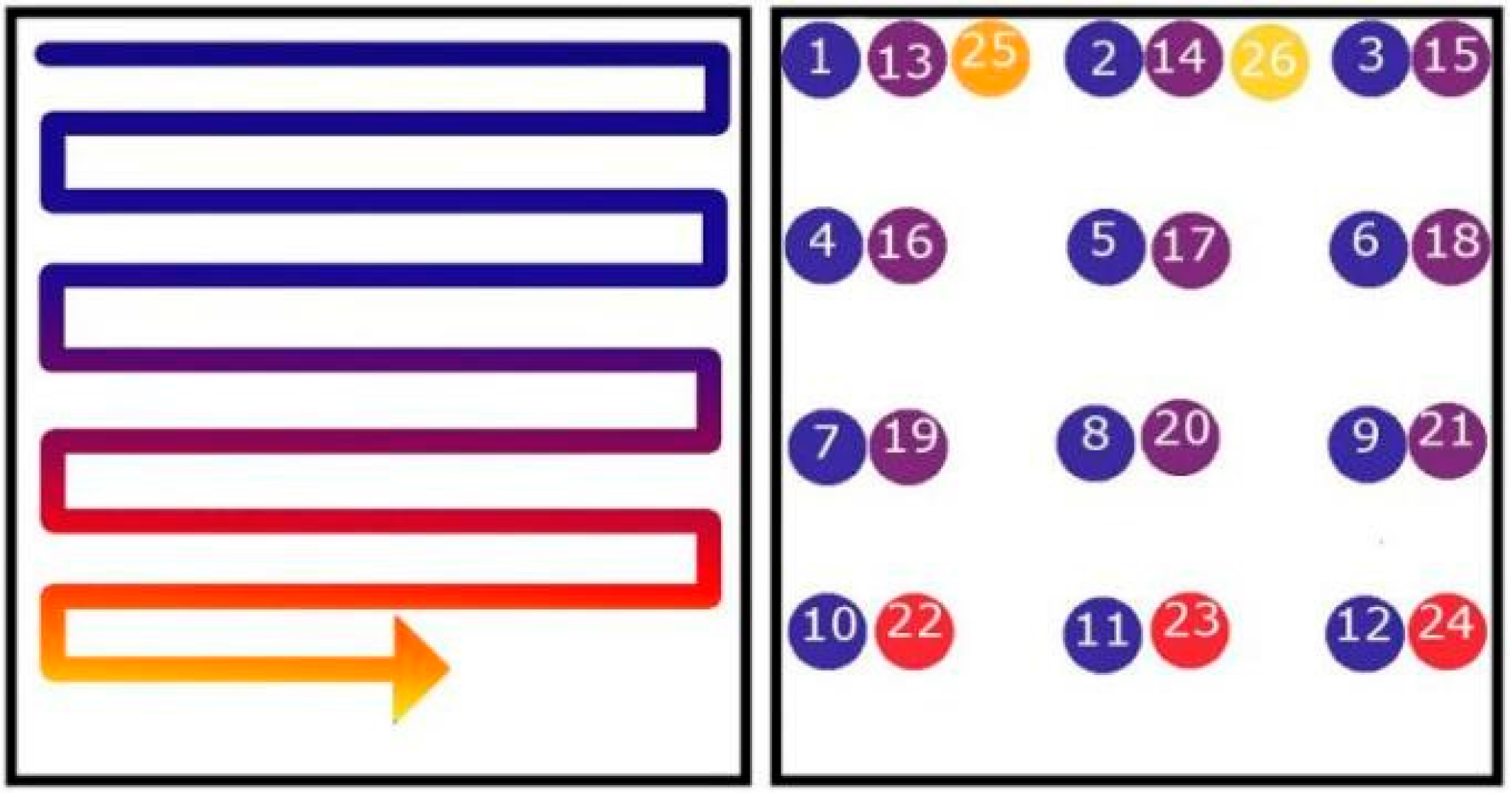

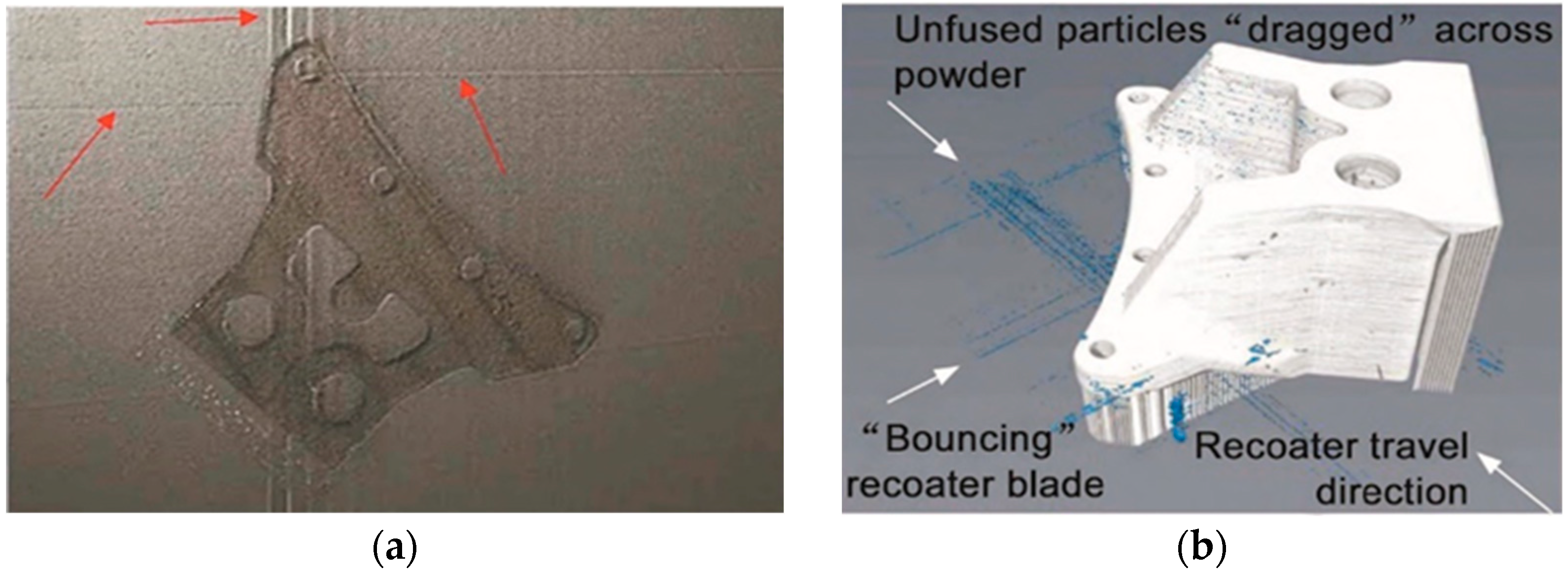

2. Powder Recoating Monitoring

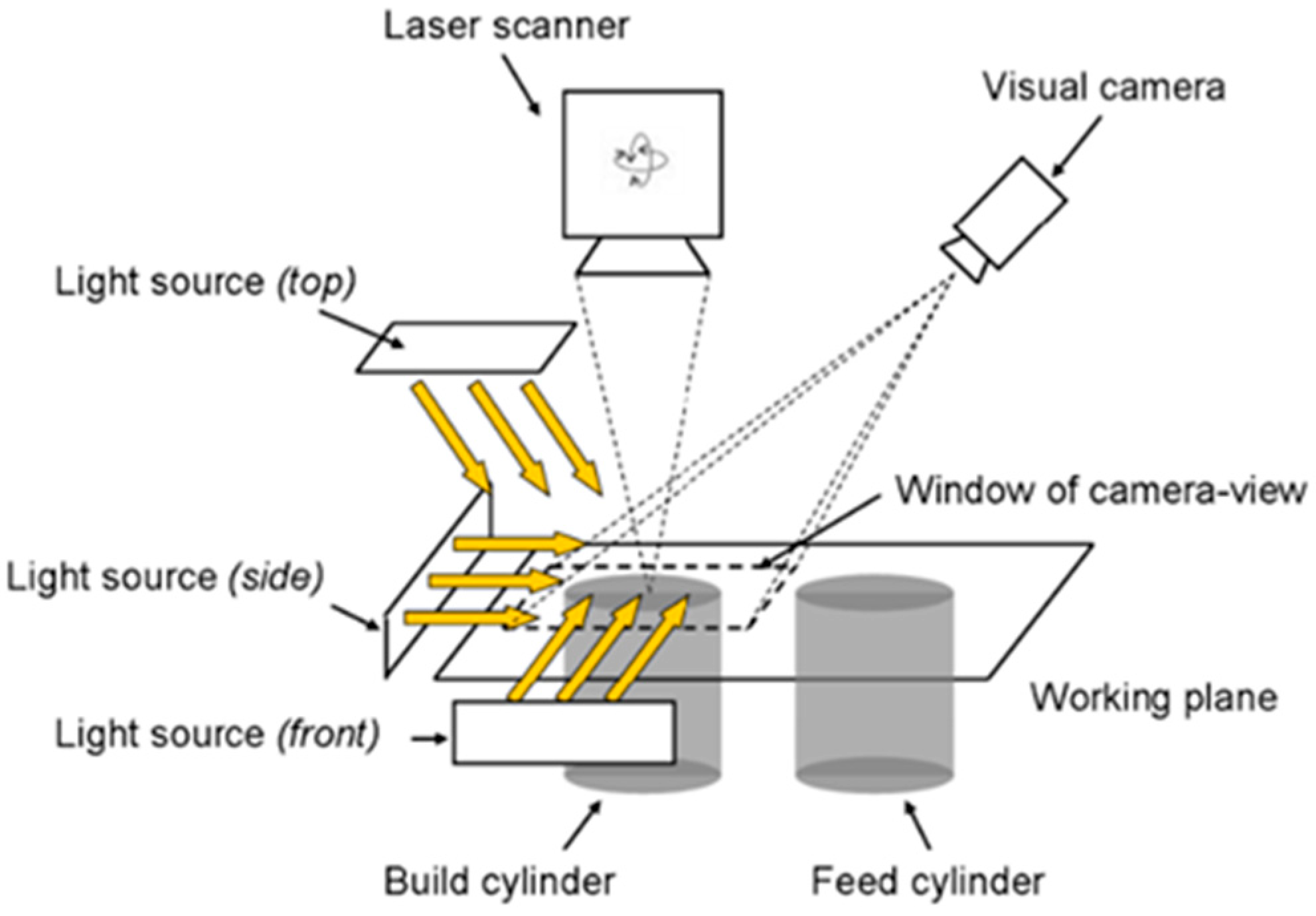

3. Powder Bed Inspection

4. Building Process Monitoring

4.1. Melt Pool Monitoring

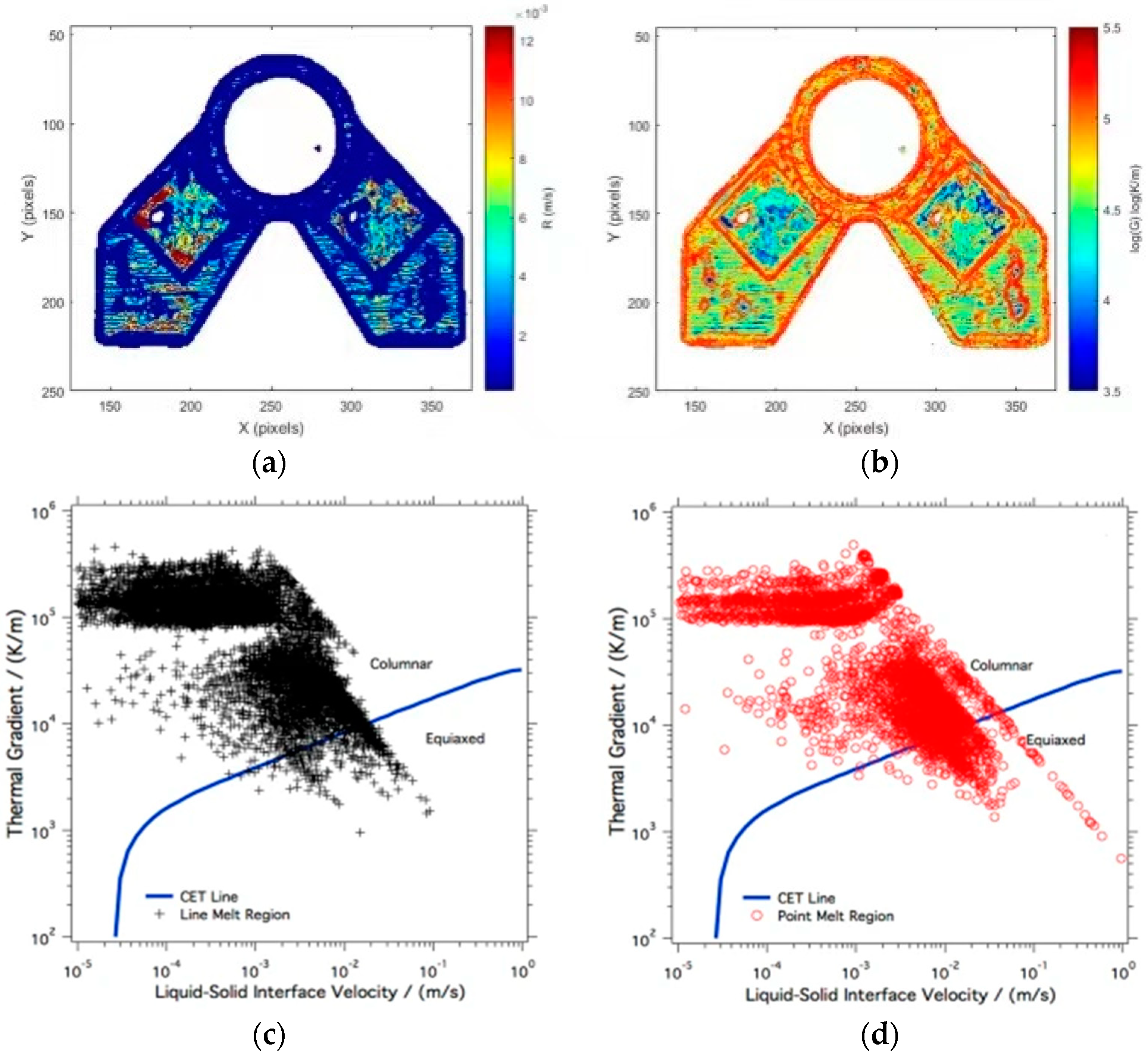

4.2. Temperature Monitoring

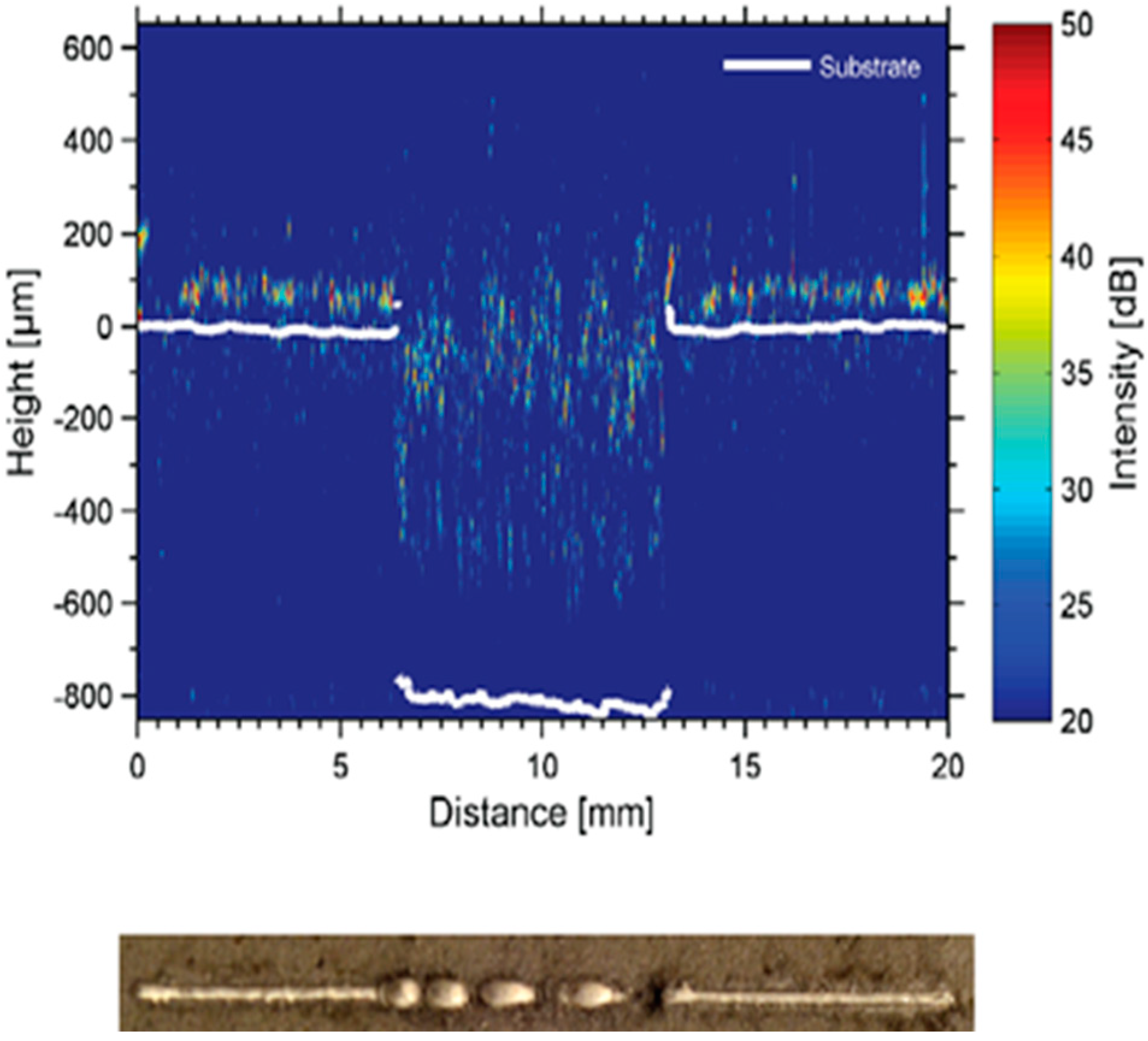

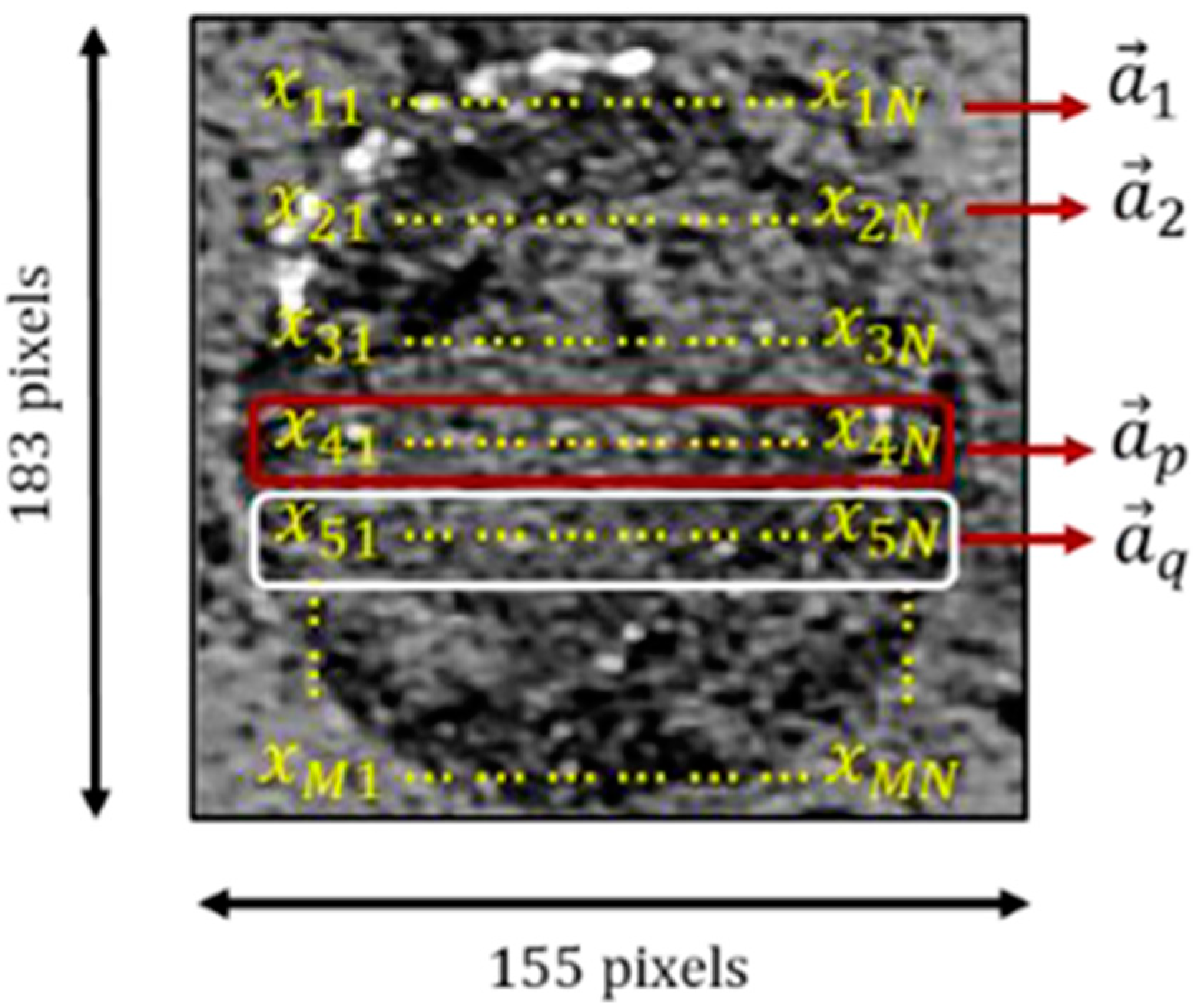

5. Melt Layer Detection

5.1. Temperature Detection

5.2. Surface Topography Detection

5.2.1. Optical Inspection

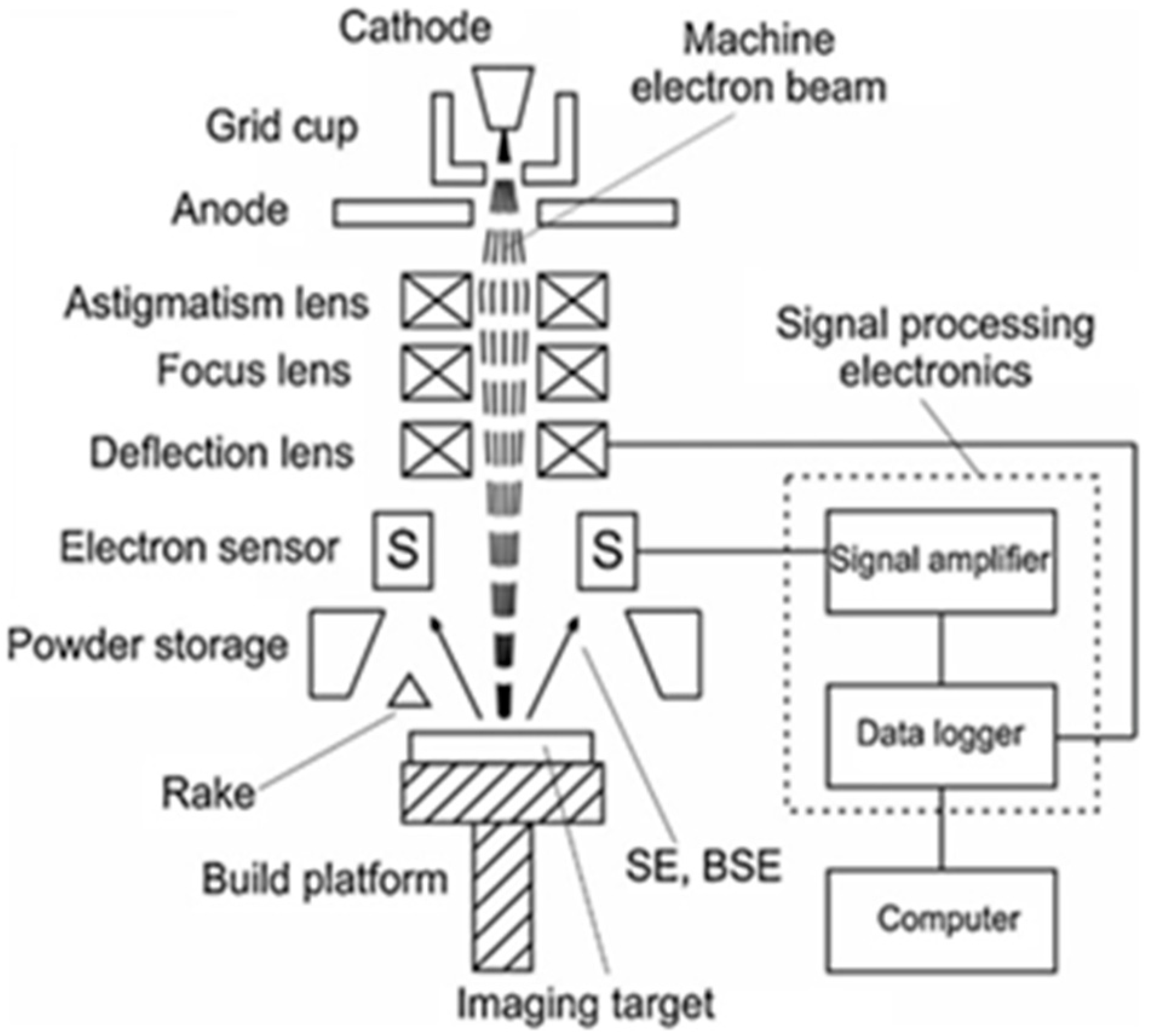

5.2.2. Electro–Optical Inspection

5.2.3. Acoustic Inspection

6. Perspective

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wohlers, T.; Caffrey, T. Additive Manufacturing and 3D Printing State of the Industry: Annual Worldwide Progress Report; Wohlers Associates Inc.: Fort Collins, CO, USA, 2011. [Google Scholar]

- Mueller, B. Additive manufacturing technologies–Rapid prototyping to direct digital manufacturing. Assem. Autom. 2012, 32. [Google Scholar] [CrossRef]

- Patterson, A.E.; Messimer, S.L.; Farrington, P.A. Overhanging features and the SLM/DMLS residual stresses problem: Review and future research need. Technologies 2017, 5, 15. [Google Scholar] [CrossRef]

- Zhangong, Y.; Feng, L.; Yongnian, Y. Overview of Direct Metal Rapid Prototyping and Manufacturing Technologies. Chin. J. Mech. Eng. 2005, 41, 1–7. [Google Scholar]

- Grasso, M.; Colosimo, B.M. Process defects and in situ monitoring methods in metal powder bed fusion: A review. Meas. Sci. Technol. 2017, 28, 044005. [Google Scholar] [CrossRef]

- Foster, B.; Reutzel, E.; Nassar, A.; Hall, B.; Brown, S.; Dickman, C. Optical, layerwise monitoring of powder bed fusion. In 2014 Solid Freeform Fabrication Symposium; University of Texas at Austin: Austin, TX, USA, 2015; pp. 10–12. [Google Scholar]

- Grasso, M.; Laguzza, V.; Semeraro, Q.; Colosimo, B.M. In-process monitoring of selective laser melting: Spatial detection of defects via image data analysis. J. Manuf. Sci. Eng. 2017, 139, 051001. [Google Scholar] [CrossRef]

- Zäh, M.F.; Lutzmann, S. Modelling and simulation of electron beam melting. Prod. Eng. 2010, 4, 15–23. [Google Scholar] [CrossRef]

- Kahnert, M.; Lutzmann, S.; Zaeh, M. Layer formations in electron beam sintering. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017; pp. 88–99. [Google Scholar]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Gaytan, S.; Ramirez, D.; Machado, B.; Shindo, P.; Martinez, J.; Medina, F.; Wooten, J.; Ciscel, D. Microstructural architecture, microstructures, and mechanical properties for a nickel-base superalloy fabricated by electron beam melting. Metall. Mater. Trans. A 2011, 42, 3491–3508. [Google Scholar] [CrossRef]

- Cunningham, R.; Narra, S.P.; Ozturk, T.; Beuth, J.; Rollett, A. Evaluating the effect of processing parameters on porosity in electron beam melted Ti-6Al-4V via synchrotron X-ray microtomography. Jom 2016, 68, 765–771. [Google Scholar] [CrossRef]

- De Pond, P.J.; Guss, G.; Ly, S.; Calta, N.P.; Deane, D.; Khairallah, S.; Matthews, M.J. In situ measurements of layer roughness during laser powder bed fusion additive manufacturing using low coherence scanning interferometry. Mater. Des. 2018, 154, 347–359. [Google Scholar] [CrossRef]

- Everton, S.K.; Dickens, P.; Tuck, C.; Dutton, B. Identification of Sub-Surface Defects in Parts Produced by Additive Manufacturing, Using Laser Generated Ultrasound. Mater. Sci. Technol. 2016, 1, 141–148. [Google Scholar]

- Casati, R.; Lemke, J.; Vedani, M. Microstructure and fracture behavior of 316L austenitic stainless steel produced by selective laser melting. J. Mater. Sci. Technol. 2016, 32, 738–744. [Google Scholar] [CrossRef]

- Puebla, K.; Murr, L.E.; Gaytan, S.M.; Martinez, E.; Medina, F.; Wicker, R.B. Effect of melt scan rate on microstructure and macrostructure for electron beam melting of Ti-6Al-4V. Mater. Sci. Appl. 2012, 3, 259–264. [Google Scholar] [CrossRef]

- McCann, R.; Obeidi, M.A.; Hughes, C.; McCarthy, É.; Egan, D.S.; Vijayaraghavan, R.K.; Brabazon, D. In-situ sensing, process monitoring and machine control in Laser Powder Bed Fusion: A review. Addit. Manuf. 2021, 45, 102058. [Google Scholar] [CrossRef]

- Mani, M.; Lane, B.M.; Donmez, M.A.; Feng, S.C.; Moylan, S.P. A review on measurement science needs for real-time control of additive manufacturing metal powder bed fusion processes. Int. J. Prod. Res. 2017, 55, 1400–1418. [Google Scholar] [CrossRef]

- Berumen, S.; Bechmann, F.; Craeghs, T. Quality control system for the coating process in laser-and powder bed-based additive manufacturing technologies. In Proceedings of the Direct Digital Manufacturing Conference, Berlin, Germany, 18–19 March 2020. [Google Scholar]

- Reinarz, B.; Witt, G. Process monitoring in the laser beam melting process-Reduction of process breakdowns and defective parts. Proc. Mater. Sci. Technol. 2012, 2012, 9–15. [Google Scholar]

- Kleszczynski, S.; zur Jacobsmühlen, J.; Reinarz, B.; Sehrt, J.T.; Witt, G.; Merhof, D. Improving process stability of laser beam melting systems. In Proceedings of the Fraunhofer Direct Digital Manufacturing Conference, Berlin, Germany, 18–19 March 2020. [Google Scholar]

- Liu, Y.; Blunt, L.; Zhang, Z.; Rahman, H.A.; Gao, F.; Jiang, X. In-situ areal inspection of powder bed for electron beam fusion system based on fringe projection profilometry. Addit. Manuf. 2020, 31, 100940. [Google Scholar] [CrossRef]

- Seita, M. A high-resolution and large field-of-view scanner for in-line characterization of powder bed defects during additive manufacturing. Mater. Des. 2019, 164, 107562. [Google Scholar]

- Craeghs, T.; Clijsters, S.; Yasa, E.; Kruth, J.-P. Online quality control of selective laser melting. In Proceedings of the 20th Solid Freeform Fabrication (SFF) Symposium, Austin, TX, USA, 8–10 August 2016; pp. 212–226. [Google Scholar]

- zur Jacobsmühlen, J.; Kleszczynski, S.; Schneider, D.; Witt, G. High resolution imaging for inspection of laser beam melting systems. In Proceedings of the 2013 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Minneapolis, MN, USA, 6–9 May 2013; pp. 707–712. [Google Scholar]

- zur Jacobsmühlen, J.; Kleszczynski, S.; Witt, G.; Merhof, D. Elevated region area measurement for quantitative analysis of laser beam melting process stability. In Proceedings of the 26th International Solid Freeform Fabrication Symposium, Austin, TX, USA, 10–12 August 2015; pp. 549–559. [Google Scholar]

- Abdelrahman, M.; Reutzel, E.W.; Nassar, A.R.; Starr, T.L. Flaw detection in powder bed fusion using optical imaging. Addit. Manuf. 2017, 15, 1–11. [Google Scholar] [CrossRef]

- Neef, A.; Seyda, V.; Herzog, D.; Emmelmann, C.; Schönleber, M.; Kogel-Hollacher, M. Low coherence interferometry in selective laser melting. Phys. Procedia 2014, 56, 82–89. [Google Scholar] [CrossRef]

- Fleming, T.G.; Nestor, S.G.; Allen, T.R.; Boukhaled, M.A.; Smith, N.J.; Fraser, J.M. Tracking and Controlling the Morphology Evolution of 3D Powder-Bed Fusion in situ using Inline Coherent Imaging. Addit. Manuf. 2020, 32, 100978. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Vatanparast, S.; Veniali, F. Part defects identification in selective laser melting via digital image processing of powder bed anomalies. Prod. Eng. 2022, 16, 691–704. [Google Scholar] [CrossRef]

- Li, Z.; Liu, X.; Wen, S.; He, P.; Zhong, K.; Wei, Q.; Shi, Y.; Liu, S. In situ 3D monitoring of geometric signatures in the powder-bed-fusion additive manufacturing process via vision sensing methods. Sensors 2018, 18, 1180. [Google Scholar] [CrossRef] [PubMed]

- Grasso, M. In Situ Monitoring of Powder Bed Fusion Homogeneity in Electron Beam Melting. Materials 2021, 14, 7015. [Google Scholar] [CrossRef]

- Jahan, S.A.; Al Hasan, M.; El-Mounayri, H. A framework for graph-base neural network using numerical simulation of metal powder bed fusion for correlating process parameters and defect generation. Manuf. Lett. 2022, 33, 765–775. [Google Scholar] [CrossRef]

- Xiao, L.; Lu, M.; Huang, H. Detection of powder bed defects in selective laser sintering using convolutional neural network. Int. J. Adv. Manuf. Technol. 2020, 107, 2485–2496. [Google Scholar] [CrossRef]

- Scime, L.; Beuth, J. A multi-scale convolutional neural network for autonomous anomaly detection and classification in a laser powder bed fusion additive manufacturing process. Addit. Manuf. 2018, 24, 273–286. [Google Scholar] [CrossRef]

- Scime, L.; Beuth, J. Anomaly detection and classification in a laser powder bed additive manufacturing process using a trained computer vision algorithm. Addit. Manuf. 2018, 19, 114–126. [Google Scholar] [CrossRef]

- Berumen, S.; Bechmann, F.; Lindner, S.; Kruth, J.-P.; Craeghs, T. Quality control of laser-and powder bed-based Additive Manufacturing (AM) technologies. Phys. Procedia 2010, 5, 617–622. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Mercelis, P.; Van Vaerenbergh, J.; Craeghs, T. Feedback control of selective laser melting. In Proceedings of the 3rd International Conference on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 24–29 September 2007; CRC Press: Boca Raton, FL, USA, 2007; pp. 521–527. [Google Scholar]

- Clijsters, S.; Craeghs, T.; Buls, S.; Kempen, K.; Kruth, J.-P. In situ quality control of the selective laser melting process using a high-speed, real-time melt pool monitoring system. Int. J. Adv. Manuf. Technol. 2014, 75, 1089–1101. [Google Scholar] [CrossRef]

- Craeghs, T.; Bechmann, F.; Berumen, S.; Kruth, J.-P. Feedback control of Layerwise Laser Melting using optical sensors. Phys. Procedia 2010, 5, 505–514. [Google Scholar] [CrossRef]

- Kanko, J.A.; Sibley, A.P.; Fraser, J.M. In situ morphology-based defect detection of selective laser melting through inline coherent imaging. J. Mater. Process. Technol. 2016, 231, 488–500. [Google Scholar] [CrossRef]

- Krauss, H.; Eschey, C.; Zaeh, M. Thermography for monitoring the selective laser melting process. In 2012 Solid Freeform Fabrication Symposium; University of Texas at Austin: Austin, TX, USA, 2012; pp. 999–1014. [Google Scholar]

- Le, T.N.; Lee, M.H.; Lin, Z.H.; Tran, H.C.; Lo, Y.L. Vision-based in-situ monitoring system for melt-pool detection in laser powder bed fusion process. J. Manuf. Process. 2021, 68, 1735–1745. [Google Scholar] [CrossRef]

- Price, S.; Cooper, K.; Chou, K. Evaluations of temperature measurements by near-infrared thermography in powder-based electron-beam additive manufacturing. In 2012 Solid Freeform Fabrication Symposium; University of Texas at Austin: Austin, TX, USA, 2012; pp. 761–773. [Google Scholar]

- Pavlov, M.; Doubenskaia, M.; Smurov, I. Pyrometric analysis of thermal processes in SLM technology. Phys. Procedia 2010, 5, 523–531. [Google Scholar] [CrossRef]

- Cheng, B.; Price, S.; Lydon, J.; Cooper, K.; Chou, K. On process temperature in powder-bed electron beam additive manufacturing: Model development and validation. J. Manuf. Sci. Eng. 2014, 136, 061018. [Google Scholar] [CrossRef]

- Price, S.; Cheng, B.; Lydon, J.; Cooper, K.; Chou, K. On process temperature in powder-bed electron beam additive manufacturing: Process parameter effects. J. Manuf. Sci. Eng. 2014, 136, 061019. [Google Scholar] [CrossRef]

- Price, S.; Lydon, J.; Cooper, K.; Chou, K. Experimental temperature analysis of powder-based electron beam additive manufacturing. In Proceedings of the 24th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2013; pp. 162–173. [Google Scholar]

- Gong, X.; Cheng, B.; Price, S.; Chou, K. Powder-bed electron-beam-melting additive manufacturing: Powder characterization, process simulation and metrology. In Proceedings of the Early Career Technical Conference, Birmingham, AL, USA, 2–3 November 2013; pp. 55–66. [Google Scholar]

- Krauss, H.; Zeugner, T.; Zaeh, M.F. Thermographic process monitoring in powder bed based additive manufacturing. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2015; pp. 177–183. [Google Scholar]

- Krauss, H.; Zeugner, T.; Zaeh, M.F. Layerwise monitoring of the selective laser melting process by thermography. Phys. Procedia 2014, 56, 64–71. [Google Scholar] [CrossRef]

- Raplee, J.; Plotkowski, A.; Kirka, M.M.; Dinwiddie, R.; Okello, A.; Dehoff, R.R.; Babu, S.S. Thermographic microstructure monitoring in electron beam additive manufacturing. Sci. Rep. 2017, 7, 43554. [Google Scholar] [CrossRef]

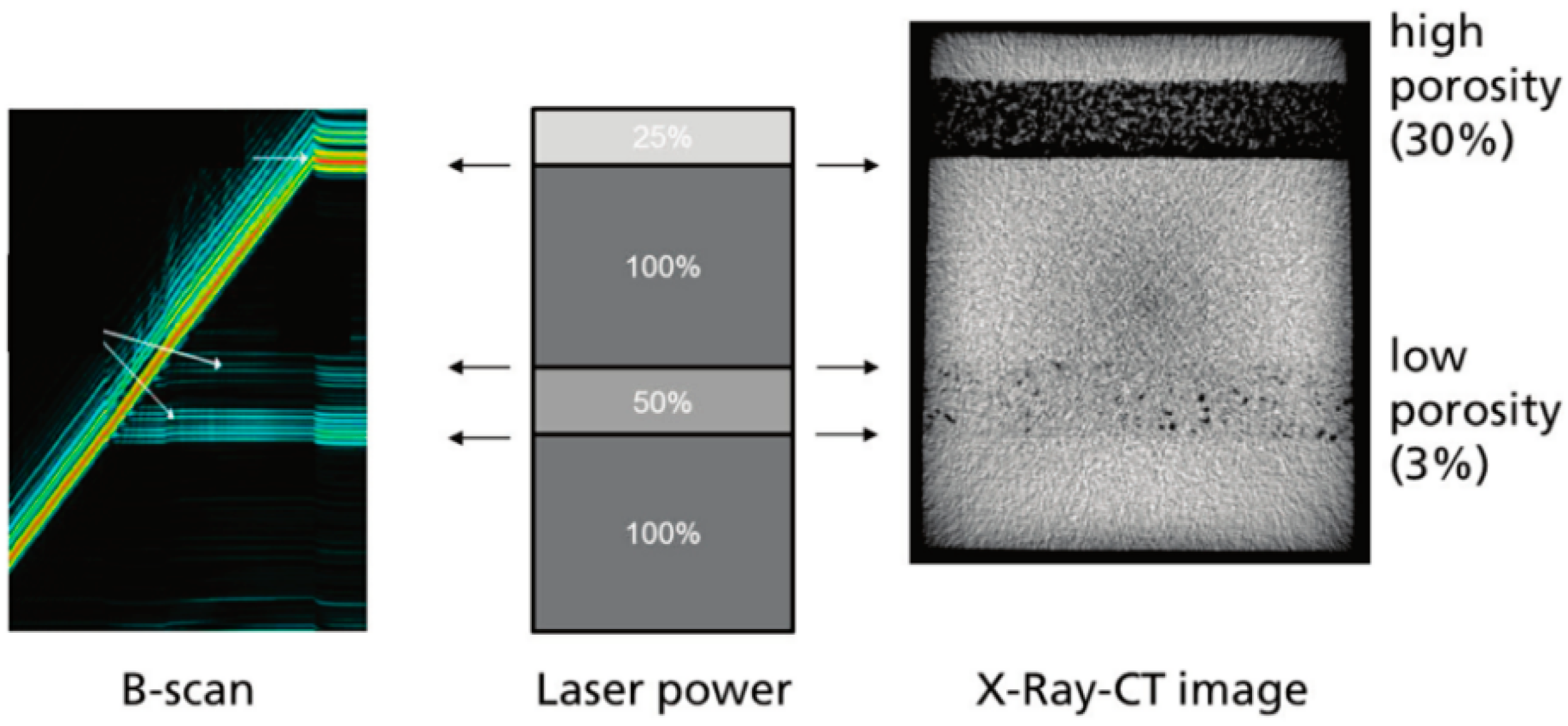

- Williams, R.J.; Piglione, A.; Rønneberg, T.; Jones, C.; Pham, M.-S.; Davies, C.M.; Hooper, P.A. In situ thermography for laser powder bed fusion: Effects of layer temperature on porosity, microstructure and mechanical properties. Addit. Manuf. 2019, 30, 100880. [Google Scholar] [CrossRef]

- Dinwiddie, R.B.; Dehoff, R.R.; Lloyd, P.D.; Lowe, L.E.; Ulrich, J.B. Thermographic in-situ process monitoring of the electron-beam melting technology used in additive manufacturing. In Thermosense: Thermal Infrared Applications XXXV; SPIE: Baltimore, MD, USA, 2013; p. 87050K. [Google Scholar]

- Price, S.; Lydon, J.; Cooper, K.; Chou, K. Temperature measurements in powder-bed electron beam additive manufacturing. In Proceedings of the ASME 2014 International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014. [Google Scholar]

- Rodriguez, E.; Medina, F.; Espalin, D.; Terrazas, C.; Muse, D.; Henry, C.; MacDonald, E.; Wicker, R.B. Integration of a thermal imaging feedback control system in electron beam melting. In WM Keck Center for 3D Innovation; University of Texas at El Paso: Austin, TX, USA, 2012; pp. 945–961. [Google Scholar]

- Rodriguez, E.; Mireles, J.; Terrazas, C.A.; Espalin, D.; Perez, M.A.; Wicker, R.B. Approximation of absolute surface temperature measurements of powder bed fusion additive manufacturing technology using in situ infrared thermography. Addit. Manuf. 2015, 5, 31–39. [Google Scholar] [CrossRef]

- Schwerdtfeger, J.; Singer, R.F.; Körner, C. In situ flaw detection by IR-imaging during electron beam melting. Rapid Prototyp. J. 2012, 18, 259–263. [Google Scholar] [CrossRef]

- Ridwan, S.; Mireles, J.; Gaytan, S.; Espalin, D.; Wicker, R. Automatic layerwise acquisition of thermal and geometric data of the electron beam melting process using infrared thermography. In 2014 International Solid Freeform Fabrication Symposium; University of Texas at Austin: Austin, TX, USA, 2014; pp. 343–352. [Google Scholar]

- Mireles, J.; Ridwan, S.; Morton, P.A.; Hinojos, A.; Wicker, R.B. Analysis and correction of defects within parts fabricated using powder bed fusion technology. Surf. Topogr. Metrol. Prop. 2015, 3, 034002. [Google Scholar] [CrossRef]

- Erler, M.; Streek, A.; Schulze, C.; Exner, H. Novel machine and measurement concept for micro machining by selective laser sintering. In 2014 International Solid Freeform Fabrication Symposium; University of Texas at Austin: Austin, TX, USA, 2014; pp. 4–6. [Google Scholar]

- Imani, F.; Gaikwad, A.; Montazeri, M.; Rao, P.; Yang, H.; Reutzel, E. Layerwise in-process quality monitoring in laser powder bed fusion. In Proceedings of the ASME 2018 13th International Manufacturing Science and Engineering Conference, College Station, TX, USA, 18–22 June 2018. [Google Scholar]

- Watt, I.M. The Principles and Practice of Electron Microscopy; Cambridge University Press: Cambridge, MA, USA; New York, NY, USA; Port Chester, NY, USA; Melbourne, Australia; Sydney, Australia, 1997. [Google Scholar]

- Arnold, C.; Pobel, C.; Osmanlic, F.; Körner, C. Layerwise monitoring of electron beam melting via backscatter electron detection. Rapid Prototyp. J. 2018, 24, 1401–1406. [Google Scholar] [CrossRef]

- Wong, H.; Neary, D.; Jones, E.; Fox, P.; Sutcliffe, C. Pilot capability evaluation of a feedback electronic imaging system prototype for in-process monitoring in electron beam additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 100, 707–720. [Google Scholar] [CrossRef]

- Wong, H.; Neary, D.; Jones, E.; Fox, P.; Sutcliffe, C. Benchmarking spatial resolution in electronic imaging for potential in-situ Electron Beam Melting monitoring. Addit. Manuf. 2019, 29, 100829. [Google Scholar] [CrossRef]

- Rieder, H.; Dillhöfer, A.; Spies, M.; Bamberg, J.; Hess, T. Online monitoring of additive manufacturing processes using ultrasound. In Proceedings of the 11th European Conference on Non-Destructive Testing, Prague, Czech Republic, 6–10 October 2014; pp. 6–10. [Google Scholar]

- Ye, D.; Hong, G.S.; Zhang, Y.; Zhu, K.; Fuh, J.Y.H. Defect detection in selective laser melting technology by acoustic signals with deep belief networks. Int. J. Adv. Manuf. Technol. 2018, 96, 2791–2801. [Google Scholar] [CrossRef]

- Smith, R.J.; Hirsch, M.; Patel, R.; Li, W.; Clare, A.T.; Sharples, S.D. Spatially resolved acoustic spectroscopy for selective laser melting. J. Mater. Process. Technol. 2016, 236, 93–102. [Google Scholar] [CrossRef]

- Shevchik, S.A.; Kenel, C.; Leinenbach, C.; Wasmer, K. Acoustic emission for in situ quality monitoring in additive manufacturing using spectral convolutional neural networks. Addit. Manuf. 2018, 21, 598–604. [Google Scholar] [CrossRef]

| Monitoring Process | Monitoring Method | Monitored Defects | Advantages | Disadvantages |

|---|---|---|---|---|

| Powder recoating monitoring | Digital camera | Coater problems, low or excessive powder feed | Low cost | Precision errors, requiring a trade–off between field of view and spatial resolution |

| Piezoelectric accelerometer | Smoothness of coating, unevenness of previous deposited layer | - | - | |

| High–resolution CCD camera | Poor supports, coater damage, insufficient powder | Easy to operate | CCD cameras have a single use | |

| Edge projection profilometry | Powder overfeed, powder shortage, part thermal expansion | Low cost, no vacuum environment, fast acquisition time, | No automatic feedback, no intelligent measurement | |

| Powder scanner | Grooves, ultra–high edges, powder unevenness | High spatial resolution, automation | To ensure the synchronization of the recoater module movement and the CIS sample rate | |

| The coating process is the key first step, but there is little information about the formation of defects. | ||||

| Monitoring Process | Monitoring Method | Monitored Defects | Advantages | Disadvantages |

|---|---|---|---|---|

| Powder bed inspection | Visible light imaging | Damage to the coater | - | The exact location of the defect could not be obtained. |

| Methods for thresholding grayscale images | Topological defects, powder bed defects | Parameter optimization (material identification) | The monitoring method based on optical imaging has higher requirements regarding the relative position of the sensor and the light source. | |

| Image–based two–dimensional acceleration | Influence of the angle of the overhang structure and the parameters of the support structure on the expanded melt layer | Sorting the stability of different components | ||

| Low–coherence interferometry | Powder bed flatness | - | ||

| Inline coherence imaging | Surface roughness, recoater blade damage, powder packing density | Correction of surface roughness based on ICI measurements, closed loop control, full feedback control | ||

| 3D indexing | 3D locations of powder bed anomalies | Accurate location of defects | - | |

| Digital image processing | Single–layer defects and defects between layers | Accurate, fast, and low cost | Image distortion | |

| EPMP | Inhomogeneities in powder beds, irregular surface of fusion area | Reliable, high precision, high efficiency | Failure to implement real–time closed–loop control or automatic defect identification and classification | |

| Camera layered acquisition combined with image processing | Powder deficiency, powder overload, powder bed contamination | Highly usable for industrial EBM | Cannot be used to monitor oxidation of surface powders | |

| Numerical simulation combined with GBNN | Thermal anomalies | Feedback control | - | |

| TS–CNN model | Warpage, short feed, part shifting | High precision, high efficiency, anti–geometric distortion | No real–time control | |

| MSCNN model | Debris, coater jumps, recoat streaks, | High anomaly classification accuracy | Lack of real time | |

| ML and DSLR camera | Recoater hopping, recoater streaking, debris, superelevation, part failure, incomplete | Less amount of calculation | Less accurate monitoring of repaint streaks | |

| The powder bed is the basis of the melting process and effectively reflects the quality of current layer. Limited to monitoring the surface state of the current layer. | ||||

| Monitoring Process | Monitoring Method | Monitored Defects | Advantages | Disadvantages | |

|---|---|---|---|---|---|

| Building process monitoring | Melt pool monitoring | Coaxial sensor | Warpage, spheroidization, | High local spatial resolution, high timeliness | With an on–axis setup, the laser can be affected by lens characteristics in the Lagrangian reference frame. |

| Photodiode and CMOS camera | Spheroidization, convex hulls at corners, powder coating failures | Keeping the molten pool size constant by controlling the laser power, improving the forming accuracy of suspended surface structures | |||

| Low–coherence interferometry | Globular defects | High speed, real time | |||

| Location–based visual pore detection | Pore defects | Real time, high sampling rate | No feedback controls | ||

| Thermal imaging and off–axis sensor | Pore defects, irregularities close to overhang structures | Widely used | Parameter deviation, no real–time control | ||

| Numerical simulation combined with CMOS camera | Melting pool size | Low cost, feedback control | - | ||

| Temperature monitoring | Near–infrared thermal imaging | Pore defects | Visibility | Insufficient temporal and spatial resolution, inaccurate temperature | |

| Two–wavelength pyrometer | Filling interval, filling strategy, thickness of powder layer | Sensitive to parameter changes | - | ||

| Based on longitudinal temperature distribution | Internal void defects | Sensitive to heat dissipation conditions, defect size information can be obtained. | Evaporation, no real–time control, insufficient accuracy and sensitivity of defect detection | ||

| Wide–field in situ infrared imaging | Pore defects | Error calibration, prediction of the microstructure of formed parts | - | ||

| Effectively reflecting the internal formation process. Contributing to real–time defect repair and organization control. | |||||

| Monitoring Process | Monitoring Method | Monitored Defects | Advantages | Disadvantages | |

|---|---|---|---|---|---|

| Melt layer inspection | Temperature detection | Infrared or near infrared | Pore defects, Unmelted material within the cambium, non–uniformity of temperature distribution | - | Lack of real–time control |

| Surface topography detection | Visible light imaging | Inhomogeneous powder bed, internally not fused | Contour extraction, defect recognition | Analysis and processing of grayscale images, offline processing | |

| Low–coherence interferometry | Melt layer surface rough, suspended structure rough | Less analysis data | Long time, complex system, point–by–point scan | ||

| 3D mapping technology | Uniformity, thickness, layer defects | ||||

| Electro–optical inspection | Pore defects, surface defects | Suitable for EBM, online monitoring, feedback control | Optical image research, roughness cannot be monitored | ||

| Ultrasonic testing | Porosity | Correlated online and offline data | This method cannot be used for complex geometry. | ||

| Acoustic emission spectroscopy | Spheroidization, slight spheroidization, slight overheating, overheating | - | - | ||

| Spatially resolved acoustic spectroscopy | Porosity | - | PBF process signals are complex and must be integrated with ML. | ||

| Acoustic emission spectroscopy and convolutional neural network | Porosity | Fast, efficient, positioning defects | - | ||

| Most intuitively reflecting the quality of melt layer. | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Z.-J.; Wang, Q.; Zhao, C.-G.; Zheng, J.; Tian, J.-M.; Ge, X.-H.; Liu, Y.-G. Online Monitoring Technology of Metal Powder Bed Fusion Processes: A Review. Materials 2022, 15, 7598. https://doi.org/10.3390/ma15217598

Hou Z-J, Wang Q, Zhao C-G, Zheng J, Tian J-M, Ge X-H, Liu Y-G. Online Monitoring Technology of Metal Powder Bed Fusion Processes: A Review. Materials. 2022; 15(21):7598. https://doi.org/10.3390/ma15217598

Chicago/Turabian StyleHou, Zhuo-Jun, Qing Wang, Chen-Guang Zhao, Jun Zheng, Ju-Mei Tian, Xiao-Hong Ge, and Yuan-Gang Liu. 2022. "Online Monitoring Technology of Metal Powder Bed Fusion Processes: A Review" Materials 15, no. 21: 7598. https://doi.org/10.3390/ma15217598

APA StyleHou, Z.-J., Wang, Q., Zhao, C.-G., Zheng, J., Tian, J.-M., Ge, X.-H., & Liu, Y.-G. (2022). Online Monitoring Technology of Metal Powder Bed Fusion Processes: A Review. Materials, 15(21), 7598. https://doi.org/10.3390/ma15217598