1. Introduction

At present, addressing environmental concerns about global climate change and resource depletion is a top priority of modern society. The construction sector is a significant consumer of natural resources and produces large amounts of emissions and construction waste [

1]. Buildings influence the environment during each stage of their life cycle, including the production (P), operational energy (OE), and demolition (D) stages, which can be evaluated using life cycle assessment (LCA) methodologies. However, these stages have different influences on the overall environmental impacts: usually, the P and OE stages are much more influential than the D stage, and these two main stages are highly dependent on the local climate, building technologies utilized, and electricity sources for the OE needed to heat, cool, and light buildings [

2].

There are four climatic zones in Israel: a hot Mediterranean climate, an arid climate, a mild Mediterranean climate, and a desert climate [

3]. In all of these climatic zones, buildings should be thermally insulated accordingly [

4]. It is common practice in Israel to design laminate facades that consist of light insulation materials such as polystyrene and a heavy thermal mass such as concrete [

5]. In the past, Israel has primarily used fossil fuels for the electricity source needs in the OE, including coal and gas [

6].

In 2011, the Standards Institution of Israel (SII)—taking into account these climate zones, building technologies, and electricity sources—released Standard SI5282 to rate the OE of buildings. The standard varies OE-influenced design variables, such as insulation, thermal mass, and external and internal shading devices, and evaluates the energy rating of buildings. To achieve the required OE rating, building practitioners can work according to the prescriptive/descriptive approach or the performance approach. The former allows for the use of prescribed sets as design variables, whereas the latter measures OE efficiency using a reference base case building. As a result, buildings can be rated using six ranks of OE performance, from level F (worst) to level A+ (best), ranging through D, C, B, and A [

7].

This OE-oriented standardization was justified at the time, as highly polluting fossil fuels served as the main source for electricity production in Israel. In this context, one group of authors [

8] carried out the LCAs of local Israeli wall technologies found in typical residential buildings, including concrete, regular concrete blocks, lightweight concrete blocks, and autoclaved aerated blocks, and reported that when non-renewable natural gas was used to fulfill the needs of the OE stage, the shares of environmental damage related to the P and OE stages were 15% and 85%, respectively. However, the authors also considered renewable solar energy (photovoltaic panels, PV) for the OE needs and observed opposite values for the P and OE stages, at 70% and 30%, respectively.

Pushkar and Yezioro [

9] analyzed the energy rates of a typical office building located in Tel Aviv (hot Mediterranean climate) according to SI5282-2 alongside an LCA (P and OE stages). The design variables included different wall technologies with different sizes of windows. Two electricity sources that were more and less coal-dependent were applied for the OE needs. The authors showed that the P + OE results for these building technologies contradicted the SI5282-2’s energy ratings; this contradiction was especially prominent when less coal-dependent electricity sources were used in the OE stage. As a result, Pushkar and Yezioro [

9] recommended that when evaluating wall technologies using the SI5282-2 energy rating, the P stage should not be neglected.

According to SI5282-2, the external shading device is the next design variable that must be assessed [

7]. This is due to the high levels of solar radiation in Israel, which are observed in all four climatic zones almost year-round [

10]. It should be noted that shading devices have mostly been studied as a means of reducing the cooling energy and protecting individuals from discomfort due to glare in the OE stage caused by high solar gains in buildings located in hot and dry, hot, mild, tropical, semiarid, humid subtropical, and continental climates [

11,

12,

13,

14,

15]. In Israel, similar to many other areas around the world, the energy and daylighting performance (OE stage) of external shading devices are the main focus of the existing literature. For example, Perez and Capeluto [

16], in their search for building design variables that had a significant influence on the energy needs of a typical school room, reported that the influence of the window shading variable was comparable to that of wall insulation. Grobman et al. [

17] studied the influence of static and dynamic external shading devices on the daylighting performance of a typical office space in a Mediterranean climate and noted that, when compared with static shading, dynamic shading increased the adjusted useful daylight illuminances by up to 51%. Yezioro and Capeluto [

18] proposed the ENERGYui model, which can evaluate energy according to the SI5282-2 standard by changing the design variables; external shading is considered to be among the important architectural geometric parameters.

However, the aforementioned studies focused only on OEs and neglected the other LCA-related stages, P and D. Very few of the studies used LCA to evaluate shading devices with a more holistic approach. Huang et al. [

19] analyzed the life cycle energy assessments (LCEAs) of typhoon-resistant external overhang shading structures composed of aluminum and fiberglass in a university campus building in Hong Kong, and the authors reported that around 50 years of OE savings would be needed to offset their production, transportation, construction, and disposal energy. Stazi et al. [

20] estimated the LCAs of aluminum and narrowly spaced horizontal wooden louvers in Italy, which has a typical Mediterranean climate. The narrow spacing increased the artificial light needed for the OE stage and increased the energy needed for the production, use, and end of life of these shading devices. Babaizadeh et al. [

21] studied the LCAs of five external shading devices composed of different combinations of horizontal overhangs and vertical fins in residential buildings located in hot-humid (Miami), mixed-humid (Atlanta), marine (Seattle), cold (Chicago), and very cold (Duluth) climates in the US. Various materials, including aluminum, wood, and polyvinyl chloride (PVC), were analyzed. The authors [

21] concluded from their results that the shares of the OE and P/D stages were approximately equal in terms of the acidification, eutrophication, damage to human health, and ecological toxicity impacts. Mifsud et al. [

22] evaluated the LCEAs of three louvers and two meshed stainless steel and aluminum systems (22 configurations in total) in the Mediterranean region of Malta; they reported that only two mesh configurations displaced the offset of the OE stage in their production and transportation stages.

LCA-based studies have shown that the P stage associated with external shading devices can be significant and almost equal to their OE stage. However, these studies covered different shading configurations, materials, and climate zones. Therefore, the results of these studies are very difficult to compare and adapt to the office buildings in Israel’s Mediterranean climate, where concrete or aluminum external shading devices are commonly used due to the fact that most building materials commercially available in Israel are concrete based [

23]. To address this gap, Pushkar [

23] evaluated both the environmental damage (P stage) and environmental benefit (OE stage) of external shading devices for a standard building unit located in Tel Aviv, Israel. Different combinations of shading components, as suggested by the SI5282-2 standard, were analyzed for the south, west, and east directions. It was found that 65–100% of the building’s OE saving benefit was required to compensate for the environmental damage resulting from the P stage of the shading devices. However, the OE stage was only evaluated using a hypothetical 100% PV electricity fuel source, omitting the actual current fuel composition situation in Israel, which includes a mixture of different shares of fossil and renewable fuel sources. Moreover, the author considered only a typical building module and evaluated shading devices within three completely different energy rating groups.

Thus, an evaluation of the P and OE stages—taking into account the current mixing of fuels for electricity—of alternative shading devices installed in a typical office building located in Israel with similar SI5282 energy ratings has not yet been completed. We hypothesized that the concrete-based external shading devices and aluminum-based light shelf devices that are usually installed in concrete-heavy buildings in Israel might result in increased environmental damage in the P stage [

23], while the transition from high-pollution fossil sources to low-pollution renewable sources—reflecting the current reality in Israel—might result in decreased environmental damage during the OE stage [

9]. It should be noted that concrete and aluminum are the most commonly used materials in the construction sector for those purposes at present, especially for office buildings. The main reasons for their use are, for instance, their relatively easy maintenance and durability. Nevertheless, there are cases where other materials can be implemented, such as glass, fabrics, and wood. However, they are less commonly used for office buildings in Israel.

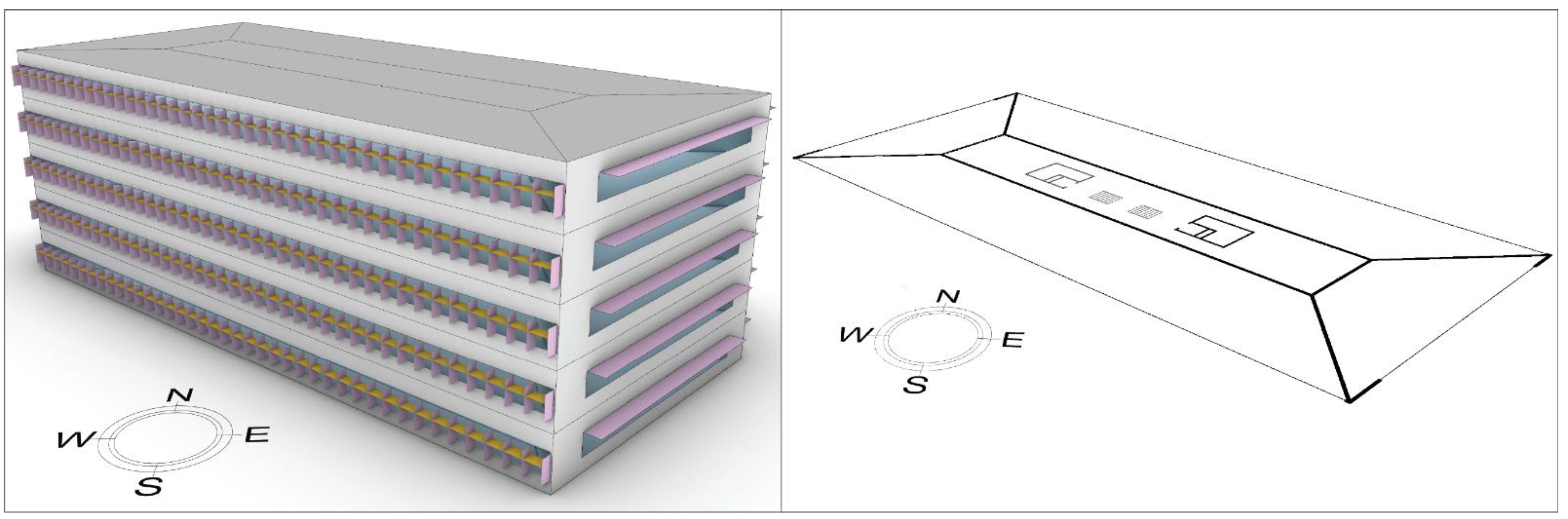

Thus, this study aimed to evaluate the environmental damage resulting from the P stage and the environmental benefit resulting from the OE stage of external shading devices with equivalently high energy ratings (B and A) installed in a typical office building in Tel Aviv under the current and future Israeli energy sources for OE needs. This research continues to develop the idea of the integration of P stage energy design variables into the energy standards, thereby improving building sustainability from an LCA point of view.

The joint consideration of the P and OE stages during a preliminary environmental analysis of the use of external shading devices in typical Israeli office buildings is a novelty of this study, particularly in the face of a rapid transition from fossil fuel energy use to renewable energy use to fill the OE demands. In light of recent authoritative studies such as [

24] which discusses the “unsustainable direction of green building codes”, the originality and topicality of this study are realized through the application of an LCA as a mandatory procedure for the further improvement of Israeli Standards.

4. Conclusions

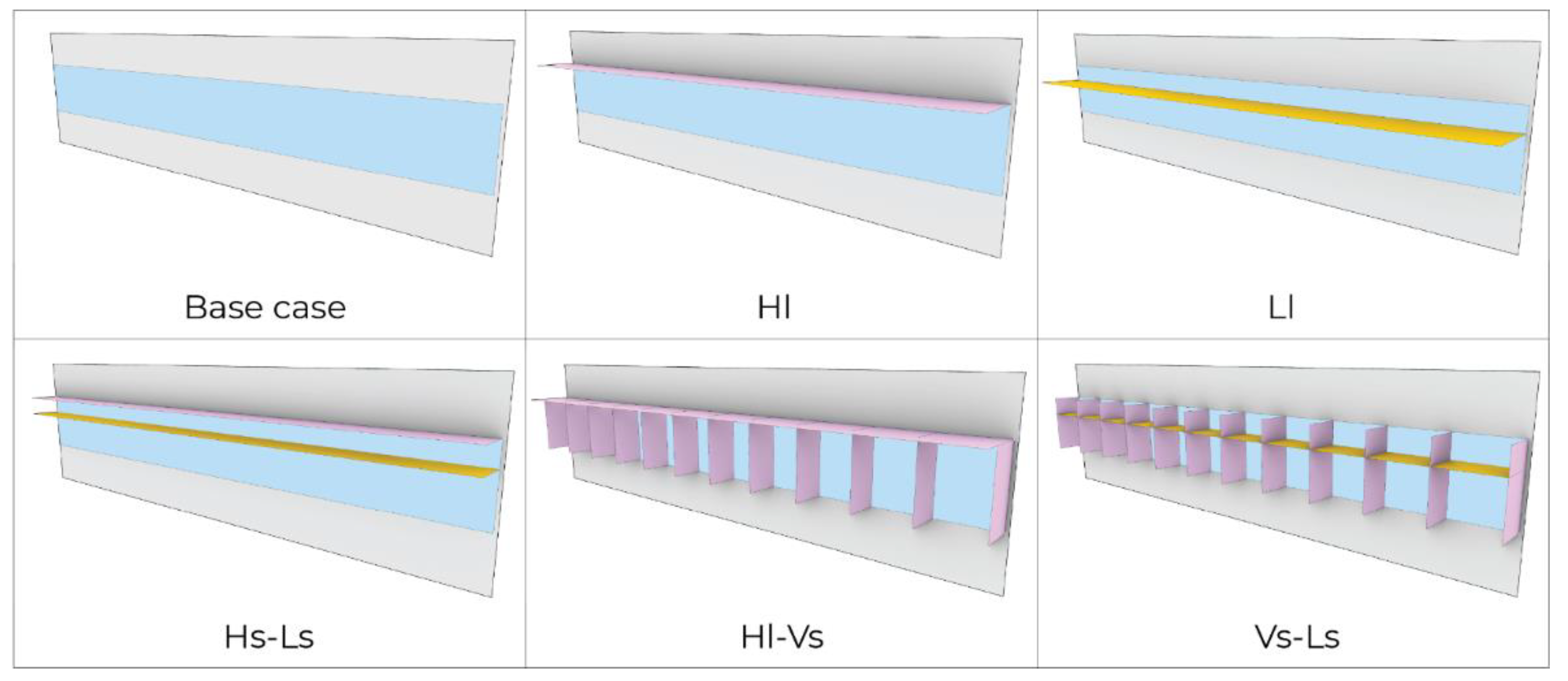

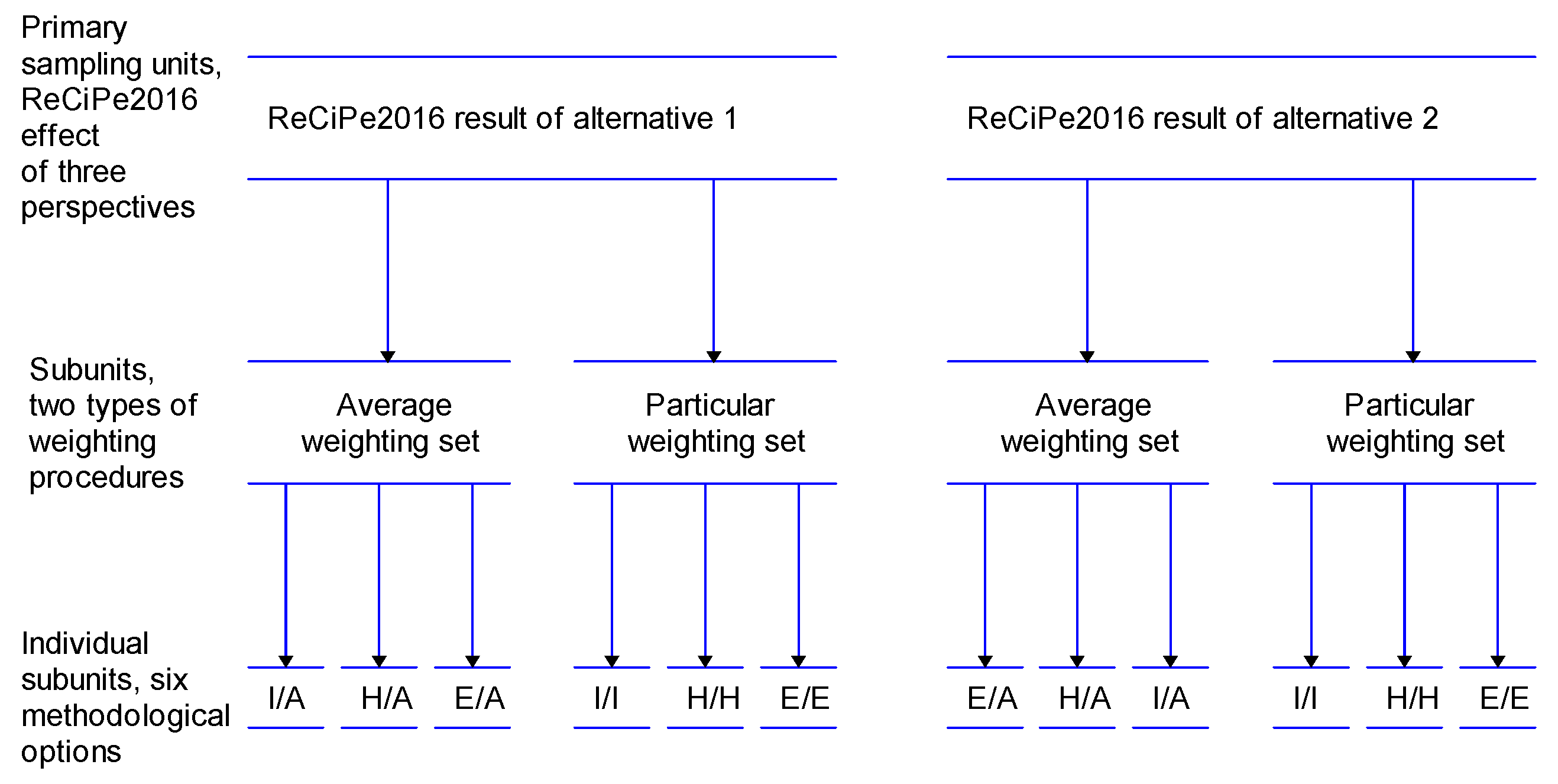

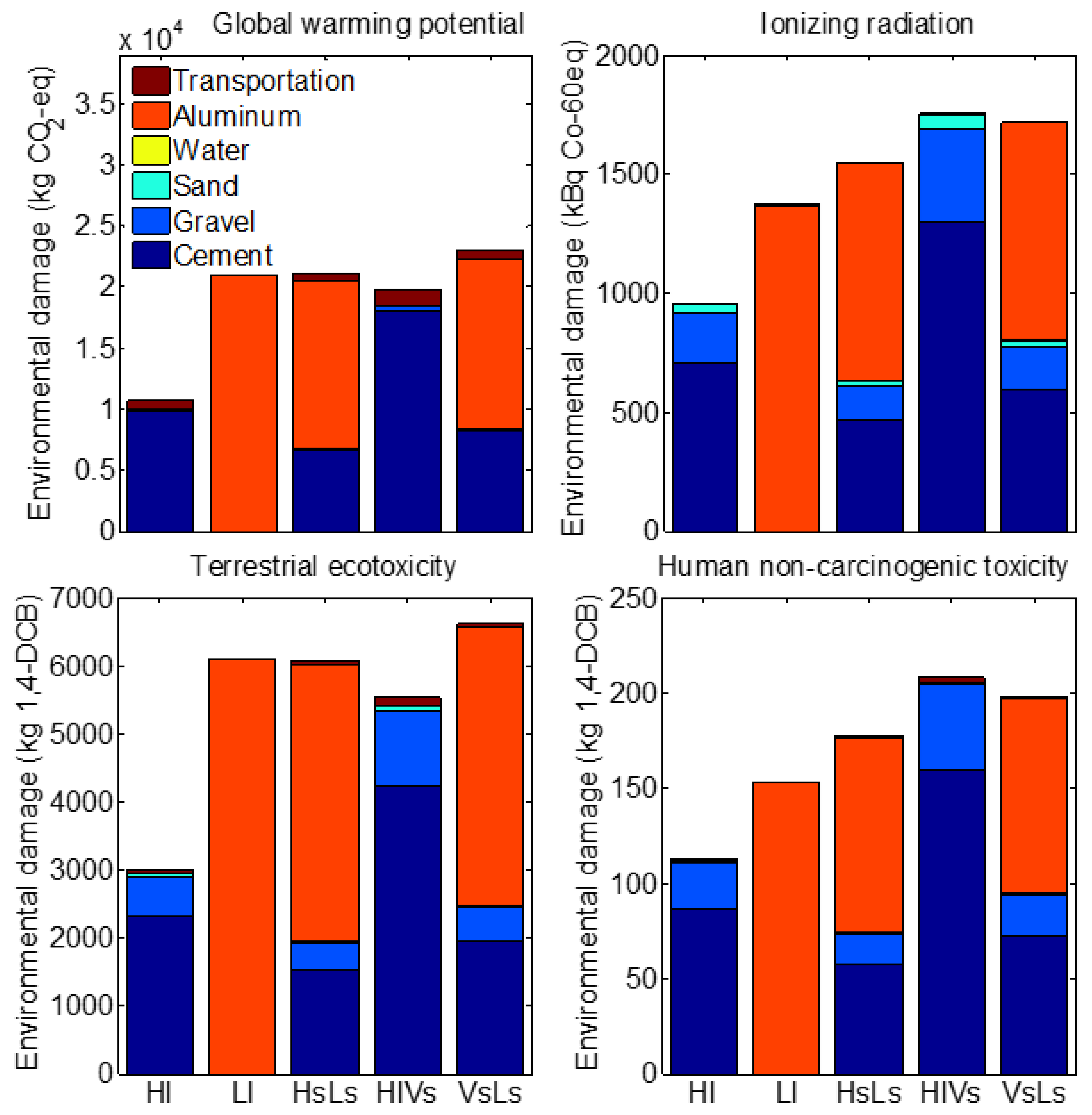

This study aimed to evaluate the environmental damage related to the P stage and the environmental benefit of the OE stage for five alternative shading devices recommended by the Israeli Standard SI5282. The five selected shading devices (with A and B energy ratings), composed of different combinations of concrete-based horizontal overhangs and vertical fins and aluminum-based light shelves, were Hl, Ll, Hs-Ls, Hl-Vs, and Vs-Ls. For the OE needs, we considered the electricity sources relevant in 2020, as well as those planned for 2025. The results were evaluated based on a (i) ReCiPe2016 midpoint impact assessment and (ii) ReCiPe2016 endpoint single-score damage assessment. The following results were revealed:

- (i)

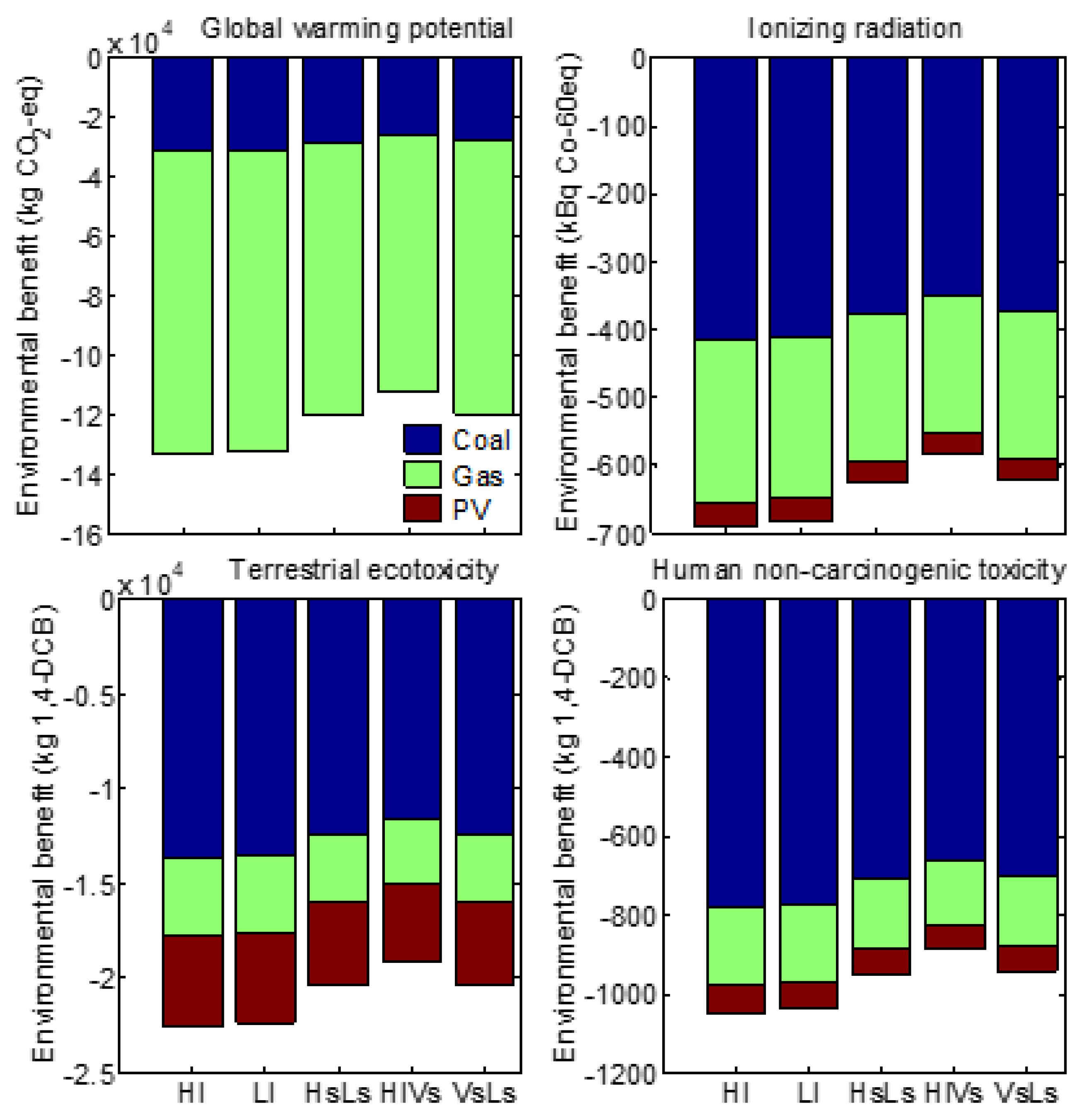

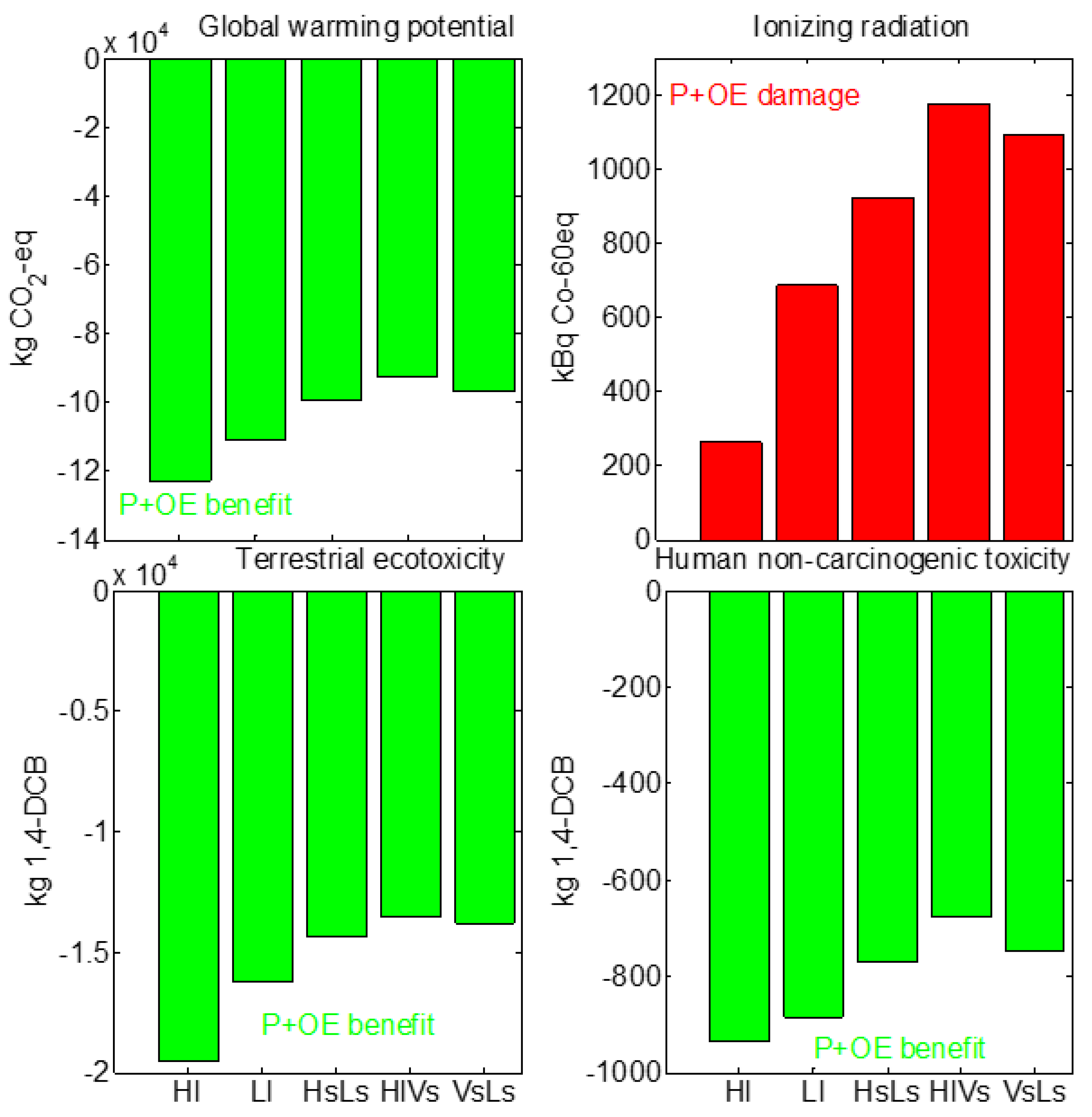

In the ReCiPe2016 midpoint impact assessment, the P stage evaluation indicated that, in terms of global warming potential and terrestrial ecotoxicity, the ranking (in ascending order of environmental damage) of the five shading devices differed from their ranking when considering the ionizing radiation and human non-carcinogenic toxicity. The OE stage evaluation demonstrated that the ranking of the shading devices (in descending order of environmental benefit) had the same tenancy when considering the four aforementioned impacts. The results of the P and OE stage evaluations of the five shading devices showed environmental benefits in terms of global warming potential, terrestrial ecotoxicity, and human non-carcinogenic toxicity impacts and environmental damage in terms of ionizing radiation.

- (ii)

In the ReCiPe2016 endpoint single-score damage assessment, the P stage evaluation showed that only two shading devices had the same environmental damage (Hl and Hs-Ls), while the other shading devices (Ll, Hl-Vs, and Vs-Ls) significantly differed from each other, as well as from Hl and Hs-Ls. The OE stage evaluation demonstrated that the five shading devices had the same environmental benefit; these results were confirmed for both electricity fuel source scenarios (i.e., OE2020 and OE2025). The P and OE stage evaluations of the five shading devices indicated that, under OE2020, only Hl, Hs-Ls, and Vs-Ls had similar environmental benefits, while under OE2025, only Hl and Vs-Ls had similar environmental benefits. The rest of the shading devices differed significantly from one another as well as from the group with similar benefits.

Thus, we concluded that the alternative shading devices recommended by Israeli Standard SI5282, as well as alternatives with similar energy rates, should be considered with caution, and their relevant P stage environmental assessments should be taken into account for correct P and OE stage evaluations. In particular, we recommend that the SI5282 energy rating be supplemented with P stage data for external shading devices made of concrete- and aluminum-based components. This way, the SI5282 energy rating standard may allow for more sustainable choices for this design variable. This issue becomes more critical when low-pollution electricity sources, such as natural gas and PV, are used to fulfill OE needs. For these assessments, we recommend using the ReCiPe2016 method with a two-stage nested mixed ANOVA analysis, as their conjugation allows for the simultaneous consideration of the six methodological options of ReCiPe2016, thus taking into account different perspectives on environmental issues.