Efficiency Decomposition Analysis of the Marine Ship Industry Chain Based on Three-Stage Super-Efficiency SBM Model—Evidence from Chinese A-Share-Listed Companies

Abstract

1. Introduction

2. Literature Review

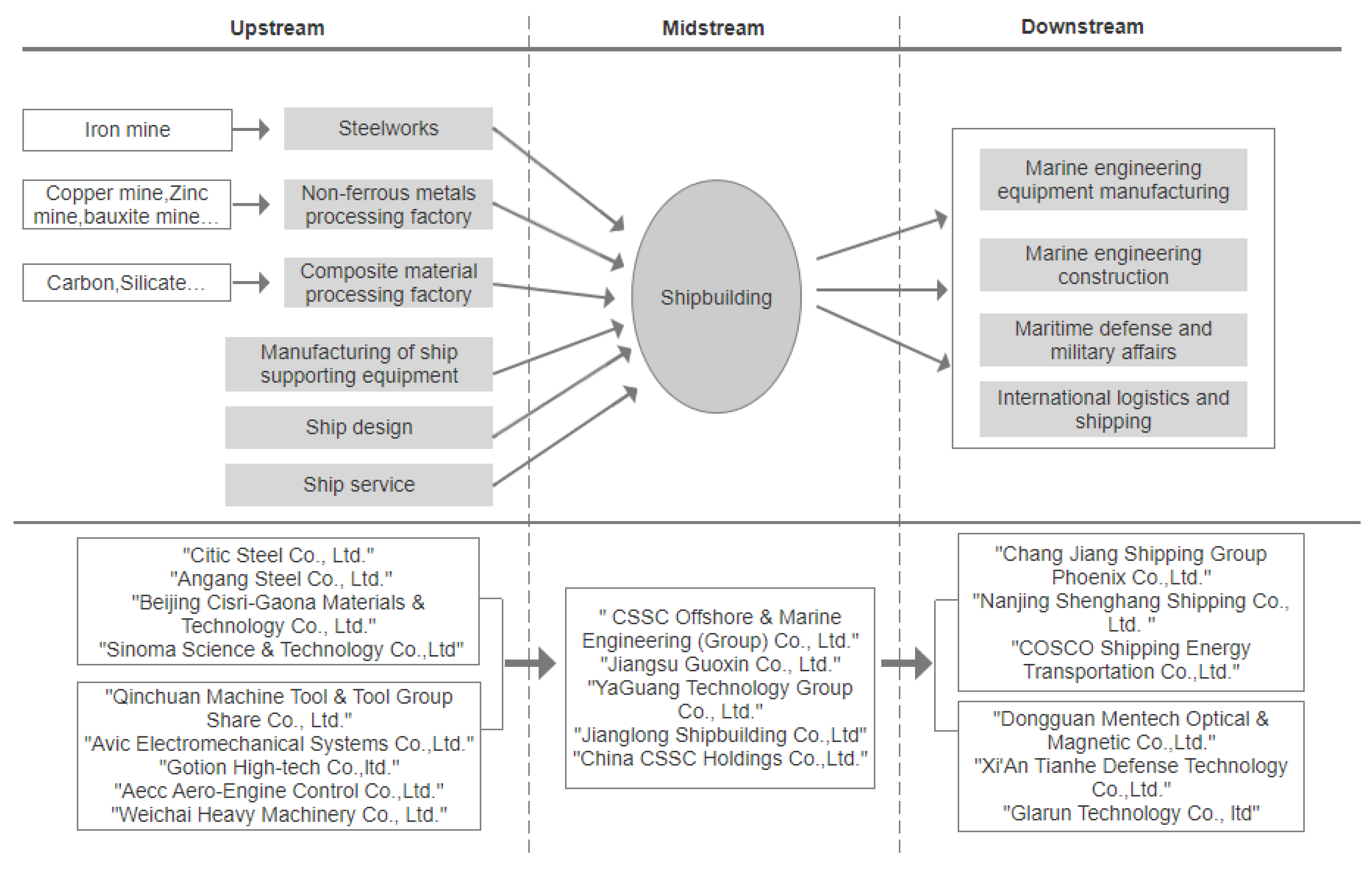

2.1. The Marine Ship Industry Chain

2.2. Calculation Methods of Industrial Chain Efficiency

3. Empirical Methods

3.1. Three-Stage Super-Efficiency SBM Model

3.2. The Kernel Density Estimation Method

4. Empirical Analysis

4.1. Variable Selection and Data Sources

- (1)

- Input and Output Indicators

- (2)

- Environmental Variables

4.2. Empirical Results

- (1)

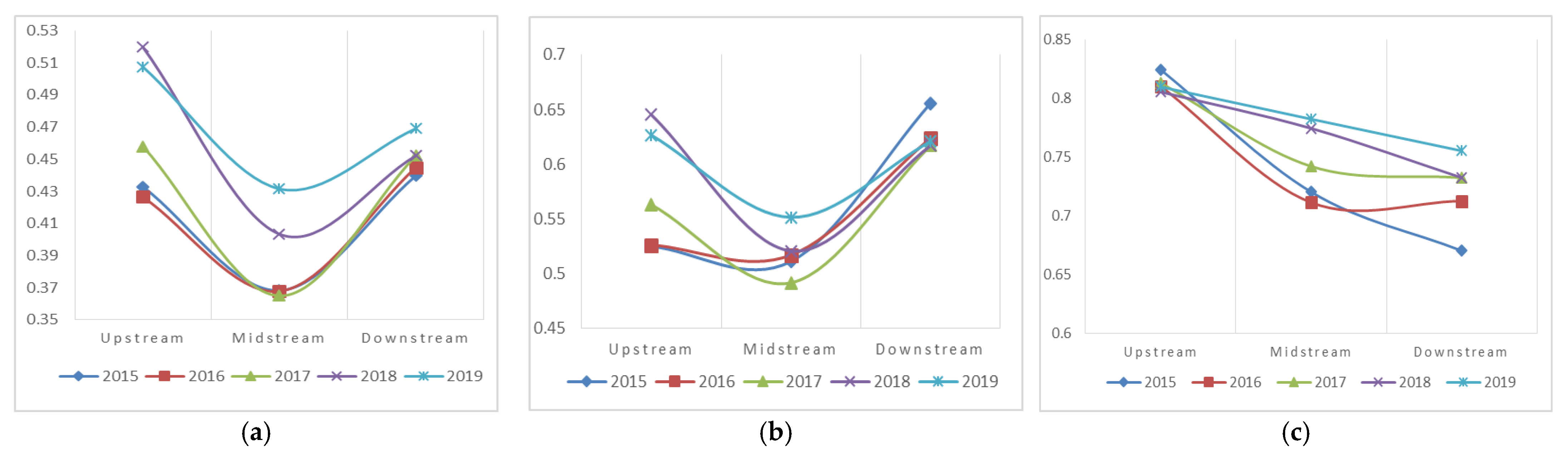

- Stage 1: The Super-Efficiency SBM Model before Adjustment

- (2)

- Stage 2: SFA Model Analysis

- (3)

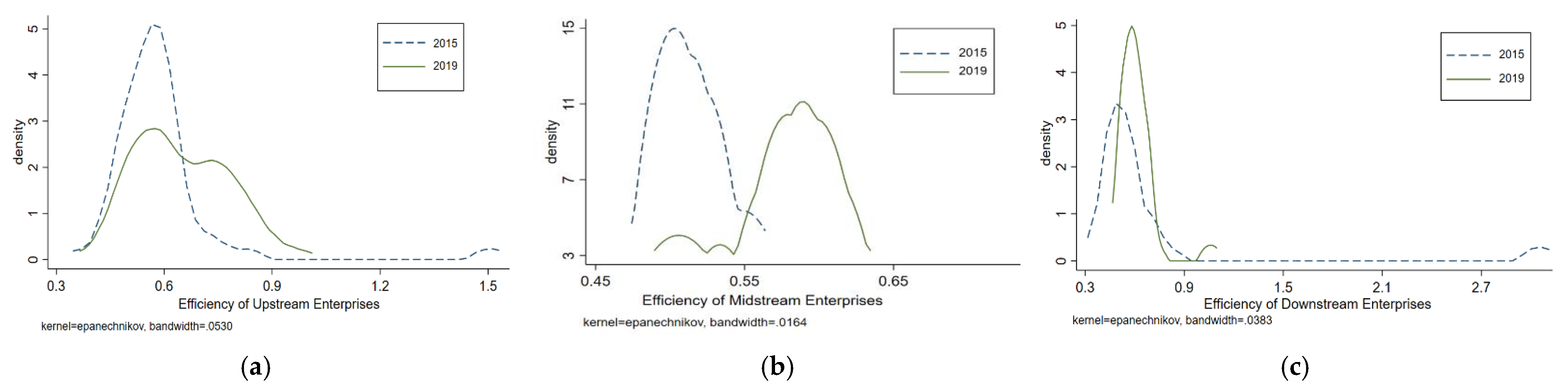

- Stage 3: The Super-Efficiency SBM Model after Adjustment

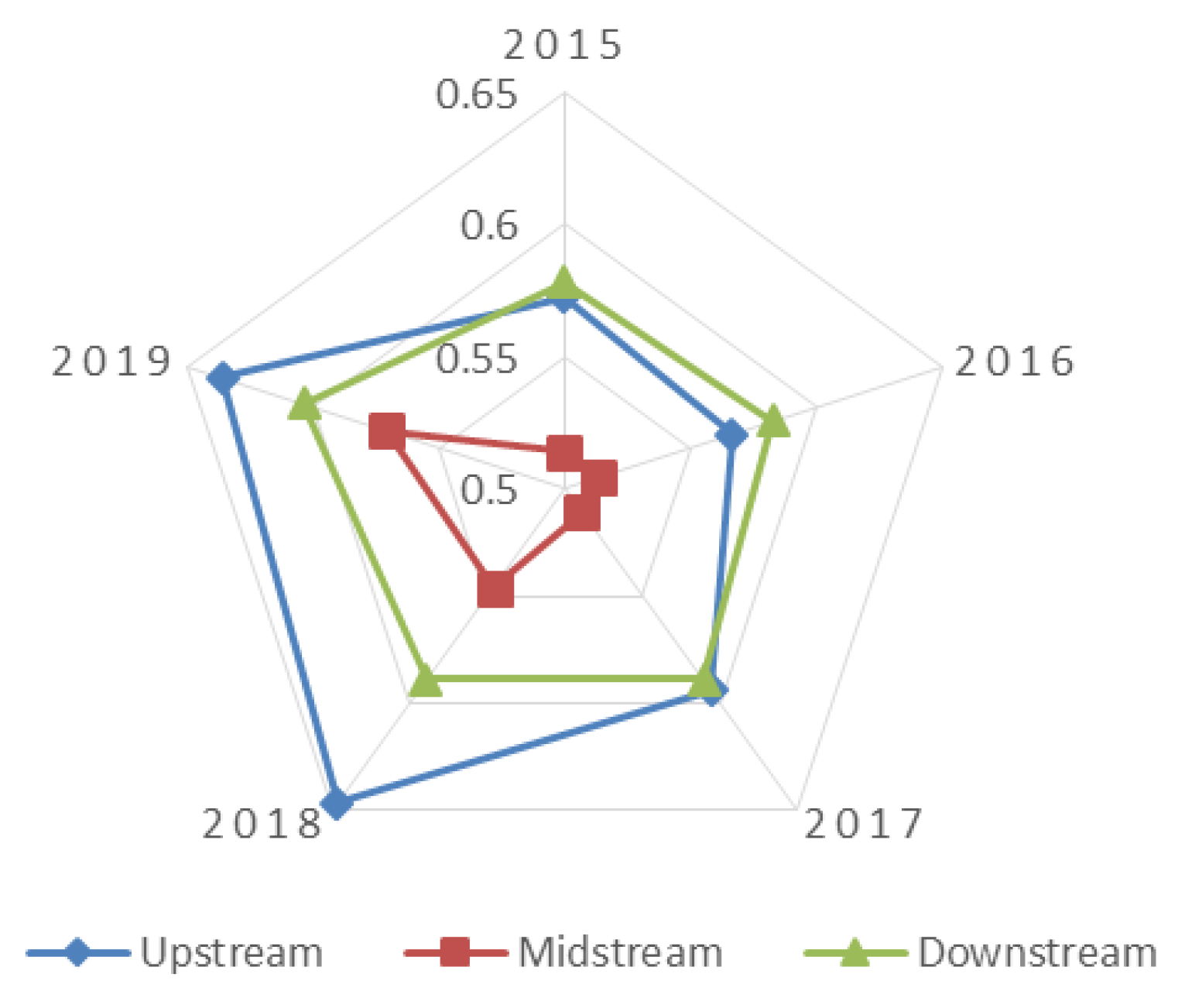

4.3. Coupling Coordination Analysis

5. Conclusions and Policy Implications

5.1. Conclusions

- (1)

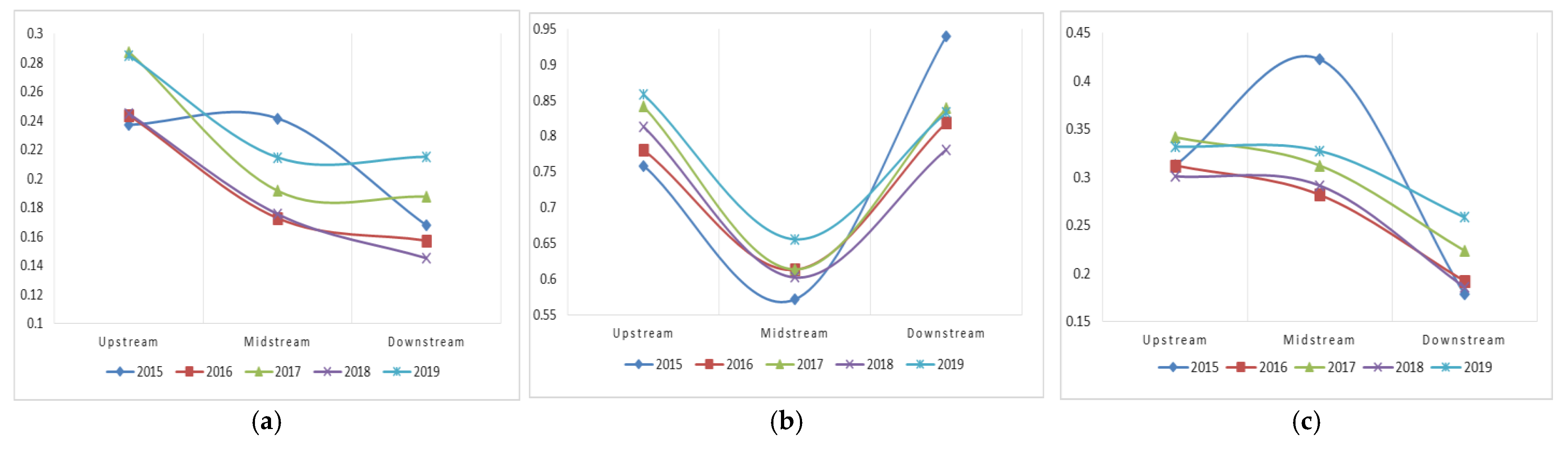

- Before excluding the influence of environmental factors, the efficiencies of the upstream, midstream, and downstream of China’s marine ship industry chain have a “V”-shaped distribution in terms of comprehensive technical efficiency and pure technical efficiency, high at both ends and low in the middle. The efficiency of the midstream is significantly lower than that of the upstream and downstream, appearing as a weak link in terms of the efficiency of the industrial chain. The “V”-shaped distribution of the industrial chain efficiency is not conducive to the development of the industrial chain, since the shipbuilding industry in the midstream is the core link of the industrial chain. If the efficiency of the midstream continues to remain lower than that of the upstream and downstream, it will be difficult to drive the overall efficient operation of the industrial chain and this will limit the development of the industrial chain;

- (2)

- The scale efficiency value of each link of the industrial chain is at a medium–high level, and this is the main driving force promoting the comprehensive technical efficiency of the industrial chain. Specifically, the scale efficiency of each link of the industrial chain is distributed in the order of upstream > midstream > downstream; the scale efficiency is lowest in the downstream of the industrial chain. The existing industrial scale of downstream industries is not economical, which hinders downstream industries from achieving economies of scale;

- (3)

- The results of SFA regression show that environmental variables have significant impacts on the efficiency of the marine ship industry chain. Among them, the existing government support and the degree of regional openness have positive impacts on the efficiency of the industrial chain, so continuing to implement the current policy can effectively promote improvement in industrial efficiency. However, the impacts of the level of economic development and the regional industrial structure on industrial chain efficiency are negative. Therefore, it is necessary to focus on solving the problems related to these two aspects. Optimizing the industrial structure and accelerating industrial transformation and upgrading are important ways to improve the efficiency of the industrial chain;

- (4)

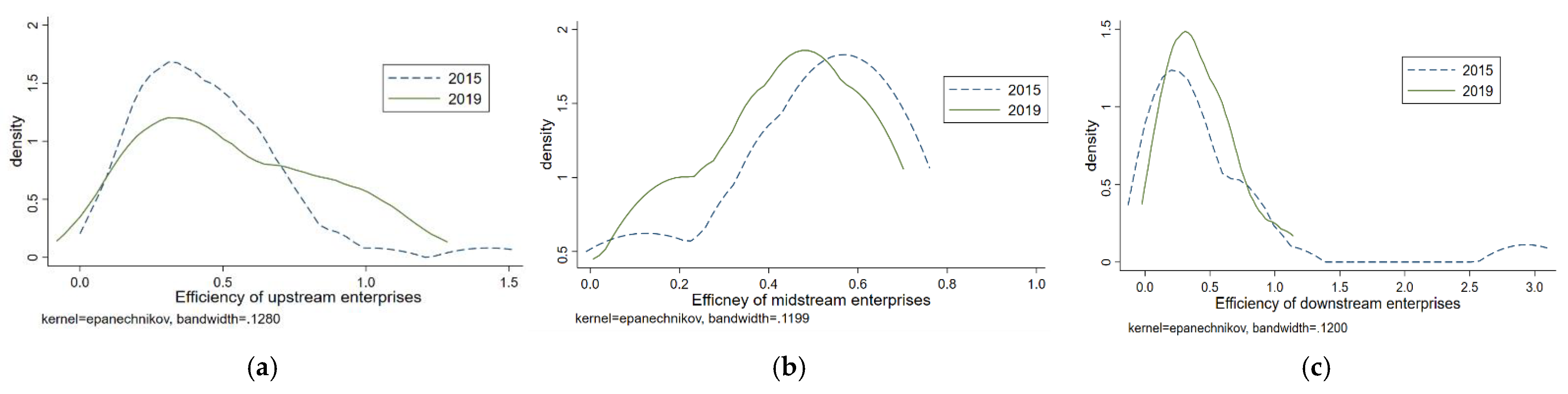

- After eliminating the environmental impact factors and random interference items, the efficiency of each link in the industrial chain significantly changes. The level of pure technical efficiency increases significantly, and the scale efficiency clearly drops. This shows that the pure technical efficiency of each link of the industrial chain is substantially underestimated before environmental factors are excluded. Technological innovation and management system reform are also needed to improve the efficiency of the industrial chain;

- (5)

- In addition, the poor coordination among links in the industrial chain also limits the development of its efficiency. The coupling degree of upstream–midstream and midstream–downstream is high, but their coordination degree is low, and efficient synergy has not yet been achieved among all links in the industrial chain. Moreover, the improvement of the coordination degree of the industrial chain is very slow, and there is no clear trend of improvement. Therefore, strengthening the coordination and cooperation of all links in the industrial chain is also key in improving the efficiency of the industrial chain.

5.2. Policy Implications

- (1)

- We need to strengthen the technological collaborative innovation among the upstream, midstream, and downstream of the industrial chain, extend the technological advantages of the upstream to the midstream and downstream, and promote the technological progress of all links of the industrial chain with the help of a technology spillover effect. As weak links in terms of industrial chain efficiency, the midstream and downstream of the industrial chain should increase the learning and transformation of advanced management experience and technical knowledge, optimize the weakness in their production and operation processes, improve the level of efficiency, and supplement the weaknesses in industrial chain development. In addition, the cooperation between enterprises among all links of the industrial chain and regional research institutions and universities need to be strengthened, breakthroughs in key and difficult technologies and the transformation of technological innovation achievements need to be promoted, and the technical strength of the industrial chain, with the help of the strengths of all parties, must be enhanced;

- (2)

- It is important to improve the spatial planning and optimize the layout of the marine ship industry chain. In order to achieve economies of scale, we should improve the supporting facilities, concentrate on the production factors required for industrial development, and promote the agglomeration and development of the marine ship industry in the region. Moreover, the cooperation and exchanges among all links of the industrial chain in the region need to be strengthened, and the formation of alliances between enterprises must be promoted. It is important to accelerate the flow of products and information between links and to improve the coordination and cooperation of production and operation in each link of the industrial chain;

- (3)

- The government should strengthen policy encouragement and support for technological innovation of enterprises in all links of China’s marine ship industry chain, break foreign technical barriers, promote the introduction of advanced technology, and help the industry achieve transformation and upgrading. At the same time, it should accelerate the conversion of the manufacturing industry in the region from old to new kinetic energy, optimize links with high amounts of consumption and pollution in the traditional industrial structure, and improve industrial efficiency. The government should promote the integration of emerging technologies, such as big data, the Internet of things, and artificial intelligence, with the marine ship industry chain and build a smart marine ship industry chain.

5.3. Research Deficiencies and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gülmez, S.; Şakar, G.D.; Baştuğ, S. An overview of maritime logistics: Trends and research agenda. Marit. Policy Manag. 2021, 1–20. [Google Scholar] [CrossRef]

- Shi, W.; Xiao, Y.; Chen, Z.; McLaughlin, H.; Li, K.X. Evolution of green shipping research: Themes and methods. Marit. Policy Manag. 2018, 45, 863–876. [Google Scholar] [CrossRef]

- Zheng, D.; Zhang, Z.; Yu, J. Discussion on the Theory of Industrial Chain Integration. Sci. Technol. Prog. Policy 2011, 28, 64–68. [Google Scholar] [CrossRef]

- Guo, X.; Li, L. Choice of Strategic Adjustment on China’s Shipbuilding Industry in Post-crisis Era. J. Jiangsu Univ. Sci. Technol. (Soc. Sci. Ed.) 2010, 10, 29–33. [Google Scholar] [CrossRef]

- Xu, J. Strategic Thinking on Development of Chinese Shipbuilding Industry. China Ind. Econ. 2002, 12, 48–56. [Google Scholar] [CrossRef]

- Li, G.; Zhang, G.; Liu, J. Regional Differences and Convergence Analysis of Technical Efficiency of Shipbuilding Industry in China. Shipbuild. China 2017, 58, 165–177. [Google Scholar]

- Shen, T.; Li, S.; Shi, X. Research on the Spatial Pattern and Influence Factors of Total Factor Productivity of Shipbuilding Industry in China. Mar. Econ. 2018, 8, 45–55. [Google Scholar] [CrossRef]

- Guo, T.; Wang, S.; Li, P. Evaluation of Innovation Ability of Chinese Shipbuilding Listed Companies from the Perspective of Civil-Military Integration. Oper. Res. Manag. Sci. 2021, 30, 114–120. [Google Scholar] [CrossRef]

- Liu, H.; Shi, Y.; Zeng, C. Spatial Layout and Development Strategy of the Ship-Related Industry in China. Econ. Geogr. 2017, 37, 99–107. [Google Scholar] [CrossRef]

- Zhou, Z.; Guan, H. Analysis of Total Factor Productivity and Influencing Factors in China’s Shipbuilding Industry: Based on Industrial Environment Perspective. Ocean Dev. Manag. 2019, 36, 114–120. [Google Scholar]

- Fang, C.; Guan, X. Comprehensive Measurement and Spatial Distinction of Input-output Efficiency of Urban Aqqlomerations in China. Acta Geogr. Sin. 2011, 66, 1011–1022. [Google Scholar]

- Yang, L.; Wang, X. The Efficiency of Non-ferrous Metals Industry Chain in China and Influencing Factors—Two-stage Analysis Based on Network DEA Model. Reform. Strategy 2018, 34, 102–109. [Google Scholar] [CrossRef]

- Tan, S.; Yan, K. Evaluation Research of China Regional Shipbuilding Competitiveness in Global Value Chain. J. Ind. Technol. Econ. 2011, 30, 24–30. [Google Scholar] [CrossRef]

- Su, Y.; Wang, F.-Y.; An, X.-L. Coupling Mechanism and Coupling Degree Measurement Model of Shipbuilding Industry Cluster. Pol. Marit. Res. 2016, 23, 78–85. [Google Scholar] [CrossRef]

- Caniëls, M.C.J.; Cleophas, E.; Semeijn, J. Implementing green supply chain practices: An empirical investigation in the shipbuilding industry. Marit. Policy Manag. 2016, 43, 1005–1020. [Google Scholar] [CrossRef]

- Ferreira, F.D.A.L.; Scavarda, L.F.; Ceryno, P.S.; Leiras, A. Supply chain risk analysis: A shipbuilding industry case. Int. J. Logist. Res. Appl. 2018, 21, 542–556. [Google Scholar] [CrossRef]

- Ramirez-Peña, M.; Fraga, F.J.A.; Sotano, A.J.S.; Batista, M. Shipbuilding 4.0 Index Approaching Supply Chain. Materials 2019, 12, 4129. [Google Scholar] [CrossRef]

- Praharsi, Y.; Abu Jami’In, M.; Suhardjito, G.; Reong, S.; Wee, H.M. Supply chain performance for a traditional shipbuilding industry in Indonesia. Benchmarking Int. J. 2021, 29, 622–663. [Google Scholar] [CrossRef]

- Qu, Y. The Productivity Growth and Convergence Analysis on Shipbuilding Industry in China. J. Hebei Univ. Econ. Bus. 2014, 35, 116–120. [Google Scholar] [CrossRef]

- Xue, L.; Shi, G.; Dai, D.; Xu, Y. Two-Stage Efficiency Structure Analysis Model of Shipbuilding Based on Driving Factors: The Case of Chinese Shipyard. Open J. Soc. Sci. 2020, 08, 182–200. [Google Scholar] [CrossRef][Green Version]

- Huang, H. Research on the new mode of independent innovation and collaborative innovation based on industry convergence. Sci. Manag. Res. 2016, 34, 42–45. [Google Scholar] [CrossRef]

- Barwick, P.J.; Kalouptsidi, M.; Zahur, N.B. Industrial Policy Implementation: Empirical Evidence from China’s Shipbuilding Industry; Cato Institute: Washington, DC, USA, 2021. [Google Scholar]

- Yan, J.; Hou, M. Study on technology efficiency and spatial-temporal characteristics of mineral resources industry chains in China. China Min. Mag. 2018, 27, 65–69. [Google Scholar]

- Tu, N.; Xie, R.; Wang, X. Study on the transformation efficiency of China’s non-ferrous metal industrial chain. China Min. Mag. 2020, 29, 32–39. [Google Scholar] [CrossRef]

- Liu, B.; Wang, M.; Li, L.; Wang, R.; Meng, J. Research on Comprehensive Efficiency, Pure Technical Efficiency and Scale Efficiency of Two Stages of Chinese Construction Industry Chain and Their Influencing Factors. Oper. Res. Manag. Sci. 2019, 28, 174–183. [Google Scholar] [CrossRef]

- Jiang, Z.; Liu, Z. Can wind power policies effectively improve the productive efficiency of Chinese wind power industry? Int. J. Green Energy 2021, 18, 1339–1351. [Google Scholar] [CrossRef]

- Chu, S.; Wang, T.; Xia, S.; Yang, X.; Chen, J. Differences and Influencing Factors of Enterprise Innovation Efficiency Based on Innovation Value Chain: A Case Study on Enterprises of National High-tech Zones in Jiangsu Province. Resour. Environ. Yangtze Basin 2021, 30, 269–279. [Google Scholar] [CrossRef]

- Li, H.; He, H.; Shan, J.; Cai, J. Research on technology innovation efficiency of China’s IC industry eliminating the influence of non-operating factors: Analysis based on generalized GRA-DEA and Tobit. J. Ind. Eng. Eng. Manag. 2020, 34, 60–70. [Google Scholar] [CrossRef]

- Luo, X.; Lai, D. Measuring and Comparing the Efficiency of the Whole Industry Chain of Rare Earths from the Perspective of Industry Chain Extension: Based on Three-Stage DEA Model. Sci. Decis. Mak. 2021, 06, 104–121. [Google Scholar] [CrossRef]

- Zhao, W.; Qiu, Y.; Lu, W.; Yuan, P. Input–Output Efficiency of Chinese Power Generation Enterprises and Its Improvement Direction-Based on Three-Stage DEA Model. Sustainability 2022, 14, 7421. [Google Scholar] [CrossRef]

- Huang, X.; Lu, X.; Sun, Y.; Yao, J.; Zhu, W. A Comprehensive Performance Evaluation of Chinese Energy Supply Chain under Double-Carbon Goals Based on AHP and Three-Stage DEA. Sustainability 2022, 14, 10149. [Google Scholar] [CrossRef]

- Li, G.; Ma, X.; Song, Y. Green Building Efficiency and Influencing Factors of Transportation Infrastructure in China: Based on Three-Stage Super-Efficiency SBM–DEA and Tobit Models. Buildings 2022, 12, 623. [Google Scholar] [CrossRef]

- Yan, Z.; Zhou, W.; Wang, Y.; Chen, X. Comprehensive Analysis of Grain Production Based on Three-Stage Super-SBM DEA and Machine Learning in Hexi Corridor, China. Sustainability 2022, 14, 8881. [Google Scholar] [CrossRef]

- Simar, L.; Wilson, P.W. Sensitivity Analysis of Efficiency Scores: How to Bootstrap in Nonparametric Frontier Models. Manag. Sci. 1998, 44, 49–61. [Google Scholar] [CrossRef]

- Daraio, C.; Simar, L. Advanced Robust and Nonparametric Methods in Efficiency Analysis: Methodology and Applications; Springer: Berlin/Heidelberg, Germany, 2007; pp. 3–7. [Google Scholar]

- Nepomuceno, T.C.; Santiago, K.T.; Daraio, C.; Costa, A.P. Exogenous crimes and the assessment of public safety efficiency and effectiveness. Ann. Oper. Res. 2022, 316, 1349–1382. [Google Scholar] [CrossRef]

- Bădin, L.; Daraio, C.; Simar, L. Explaining inefficiency in nonparametric production models: The state of the art. Ann. Oper. Res. 2014, 214, 5–30. [Google Scholar] [CrossRef]

- Tone, K. A slacks-based measure of efficiency in data envelopment analysis. Eur. J. Oper. Res. 2001, 130, 498–509. [Google Scholar] [CrossRef]

- Shen, C.; Zhang, D. Research on the Government’s Optimization of the Allocation of Scientific and Technological Resources; Peking University Press: Beijing, China, 2013; pp. 96–97. [Google Scholar]

- Fried, H.O.; Lovell, C.K.; Schmidt, S.S.; Yaisawarng, S. Accounting for Environmental Effects and Statistical Noise in Data Envelopment Analysis. J. Product. Anal. 2002, 17, 157–174. [Google Scholar] [CrossRef]

- Andersen, P.; Petersen, N.C. A procedure for ranking efficient units in data envelopment analysis. Manag. Sci. 1993, 39, 1261–1264. [Google Scholar] [CrossRef]

- Tone, K. A slacks-based measure of super-efficiency in data envelopment analysis. Eur. J. Oper. Res. 2002, 143, 32–41. [Google Scholar] [CrossRef]

- Wang, Q.; Dong, Y.; Dong, Y. Evaluation on Efficiency of Fiscal Expenditure for Science and Technology on the Background of the Strategy of Innovation-driven Development: Based on Three-stage Super-efficiency SBM-DEA Model. Sci. Technol. Manag. Res. 2020, 40, 23–33. [Google Scholar] [CrossRef]

- Luo, D. A Note on Estimating Managerial Inefficiency of Three-Stage DEA Model. Stat. Res. 2012, 29, 104–107. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, L.; Ma, T. Research on Three-stage DEA Model. Syst. Eng. 2014, 32, 144–149. [Google Scholar]

- Wang, X.; Chu, T. Non-Parametric Statistics, 2nd ed.; Tsinghua University Press: Beijing, China, 2014; pp. 213–218. [Google Scholar]

- Wang, F.H. Quantitative Methods and Socio-Economic Applications in GIS; CRC Press: Boca Raton, FL, USA, 2015; pp. 176–180. [Google Scholar] [CrossRef]

- Wang, C.; Tang, N. Spatio-temporal characteristics and evolution of rural production living-ecological space function coupling coordination in Chongqing Municipality. Geogr. Res. 2018, 37, 1100–1114. [Google Scholar] [CrossRef]

| Main Business Income | Total Profits | Main Business Costs | Management Fees | The Number of Employees | |

|---|---|---|---|---|---|

| Main business income | 1.0000 | ||||

| Total profits | 0.7211 *** | 1.0000 | |||

| Main business costs | 0.9987 *** | 0.6928 *** | 1.0000 | ||

| Management fees | 0.8253 *** | 0.5767 *** | 0.8209 *** | 1.0000 | |

| The number of employees | 0.8267 *** | 0.4577 *** | 0.8290 *** | 0.7985 *** | 1.0000 |

| Variable Type | Variable Name | Specific Description of Variable | Unit | Data Sources |

|---|---|---|---|---|

| Input indicators | Labor input | Number of employees | People | CSMAR database |

| Capital input | Main business costs | Yuan | CSMAR database | |

| Management fees | Yuan | CSMAR database | ||

| Output indicators | Enterprise income | Main business income | Yuan | CSMAR database |

| Total profits | Yuan | CSMAR database | ||

| Environmental variables | The level of economic development | Provincial GDP | Yuan | National Bureau of Statistics |

| Government support | Provincial fiscal expenditure on science and technology | Yuan | National Bureau of Statistics | |

| The degree of regional openness | Total provincial exports/provincial GDP × 100% | % | National Bureau of Statistics | |

| Regional industrial structure | Output value of provincial secondary industry / provincial GDP × 100% | % | National Bureau of Statistics |

| Slack Variable of Main Business Costs | Slack Variable of Management Fees | Slack Variable of Number of Employees | |

|---|---|---|---|

| Constant term | 60,373.6830 *** | −20430.5440 *** | −3737.3830 *** |

| The level of economic development | 6.9402 *** | 0.8883 *** | 0.0387 |

| Government support | −0.0363 | −0.0058 *** | −0.0008 * |

| The degree of regional openness | −6759.7631 *** | −103.9413 *** | 58.6994 |

| Regional industrial structure | 559.2412 *** | 184.5237 | 136.8167 *** |

| 6.0803 × 1011 *** | 7.8633 × 109 *** | 2.0663 × 108 *** | |

| 0.3687 *** | 0.6439 *** | 0.7586 *** | |

| LR | 24.1032 *** | 99.0837 *** | 164.7311 *** |

| LR | 24.1032 *** | 99.0837 *** | 164.7311 *** |

| Value of C | Grade of C | Value of D | Grade of D |

|---|---|---|---|

| (0.0–0.3) | Separation stage | (0.0–0.2) | Extreme incoordination |

| [0.3–0.5) | Antagonistic stage | [0.2–0.4) | Moderate incoordination |

| [0.5–0.8) | Grinding-in stage | [0.4–0.6) | Basic coordination |

| [0.8–1.0) | Highly coupled stage | [0.6–0.8) | Moderate coordination |

| —— | —— | [0.8–1.0) | Superior coordination |

| Year | Upstream—Midstream | Midstream—Downstream | ||||

|---|---|---|---|---|---|---|

| Value of C | Value of D | Grade | Value of C | Value of D | Grade | |

| 2015 | 1 | 0.651 | Highly coupled and moderately coordinated | 1 | 0.648 | Highly coupled and moderately coordinated |

| 2016 | 0.994 | 0.631 | Highly coupled and moderately coordinated | 0.999 | 0.61 | Highly coupled and moderately coordinated |

| 2017 | 0.991 | 0.654 | Highly coupled and moderately coordinated | 0.998 | 0.628 | Highly coupled and moderately coordinated |

| 2018 | 0.993 | 0.634 | Highly coupled and moderately coordinated | 1 | 0.603 | Highly coupled and moderately coordinated |

| 2019 | 0.995 | 0.666 | Highly coupled and moderately coordinated | 0.999 | 0.646 | Highly coupled and moderately coordinated |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, H.; Wang, Y.; Dong, L.; Zhao, A. Efficiency Decomposition Analysis of the Marine Ship Industry Chain Based on Three-Stage Super-Efficiency SBM Model—Evidence from Chinese A-Share-Listed Companies. Sustainability 2022, 14, 12155. https://doi.org/10.3390/su141912155

Guan H, Wang Y, Dong L, Zhao A. Efficiency Decomposition Analysis of the Marine Ship Industry Chain Based on Three-Stage Super-Efficiency SBM Model—Evidence from Chinese A-Share-Listed Companies. Sustainability. 2022; 14(19):12155. https://doi.org/10.3390/su141912155

Chicago/Turabian StyleGuan, Hongjun, Yu Wang, Liye Dong, and Aiwu Zhao. 2022. "Efficiency Decomposition Analysis of the Marine Ship Industry Chain Based on Three-Stage Super-Efficiency SBM Model—Evidence from Chinese A-Share-Listed Companies" Sustainability 14, no. 19: 12155. https://doi.org/10.3390/su141912155

APA StyleGuan, H., Wang, Y., Dong, L., & Zhao, A. (2022). Efficiency Decomposition Analysis of the Marine Ship Industry Chain Based on Three-Stage Super-Efficiency SBM Model—Evidence from Chinese A-Share-Listed Companies. Sustainability, 14(19), 12155. https://doi.org/10.3390/su141912155