A New Texturing Approach of a Polyimide Shielding Cover for Enhanced Light Propagation in Photovoltaic Devices

Abstract

:1. Introduction

2. Materials and Methods

2.1. PI Synthesis and Film Preparation

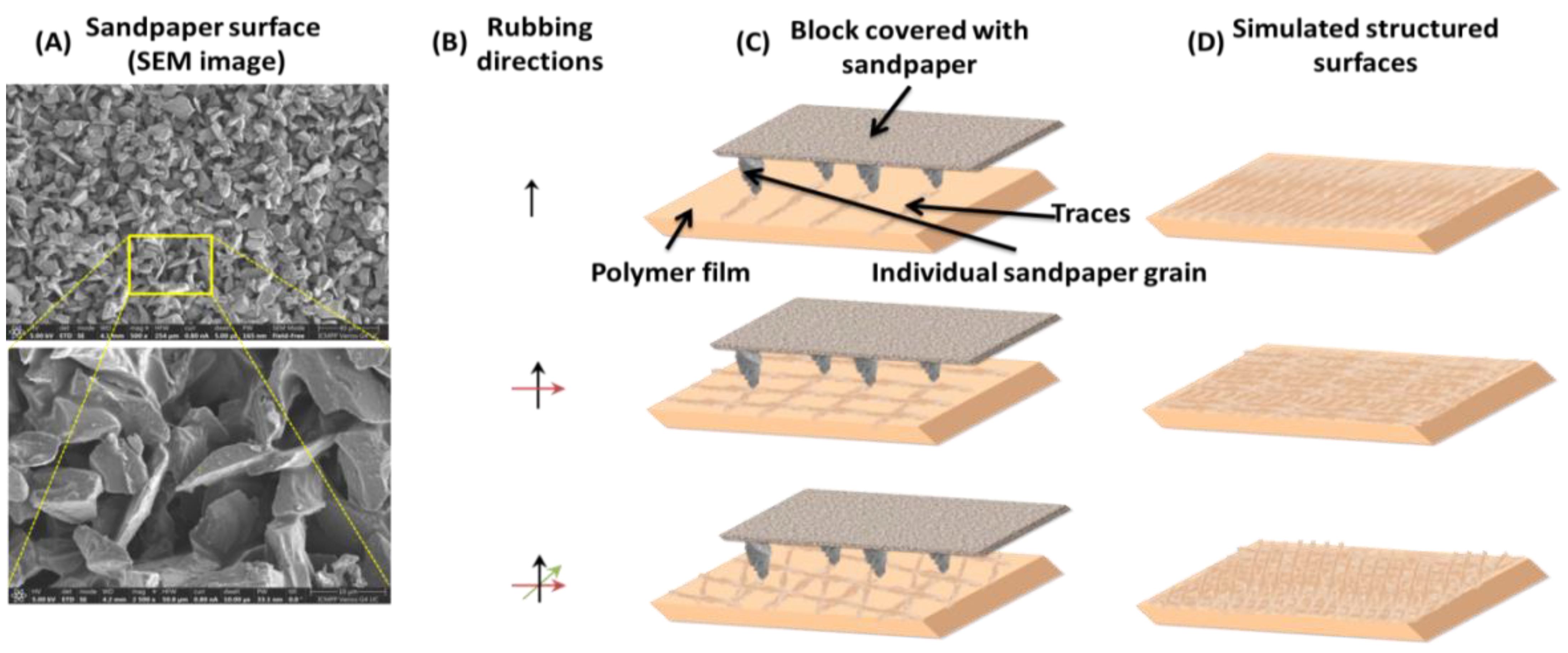

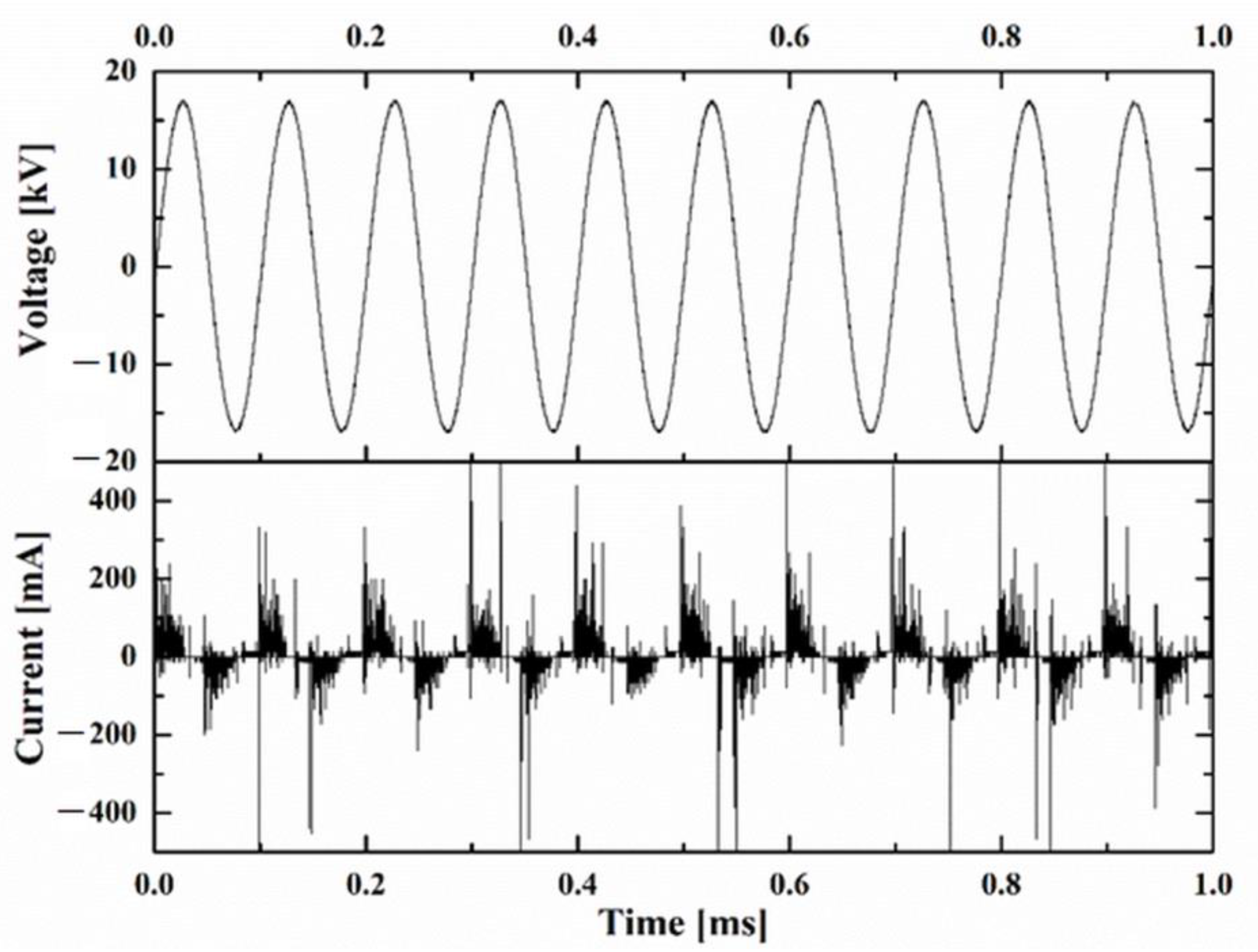

2.2. Surface Modification by Multi-Directional Rubbing and Plasma Treatment

2.3. Characterization

3. Results and Discussion

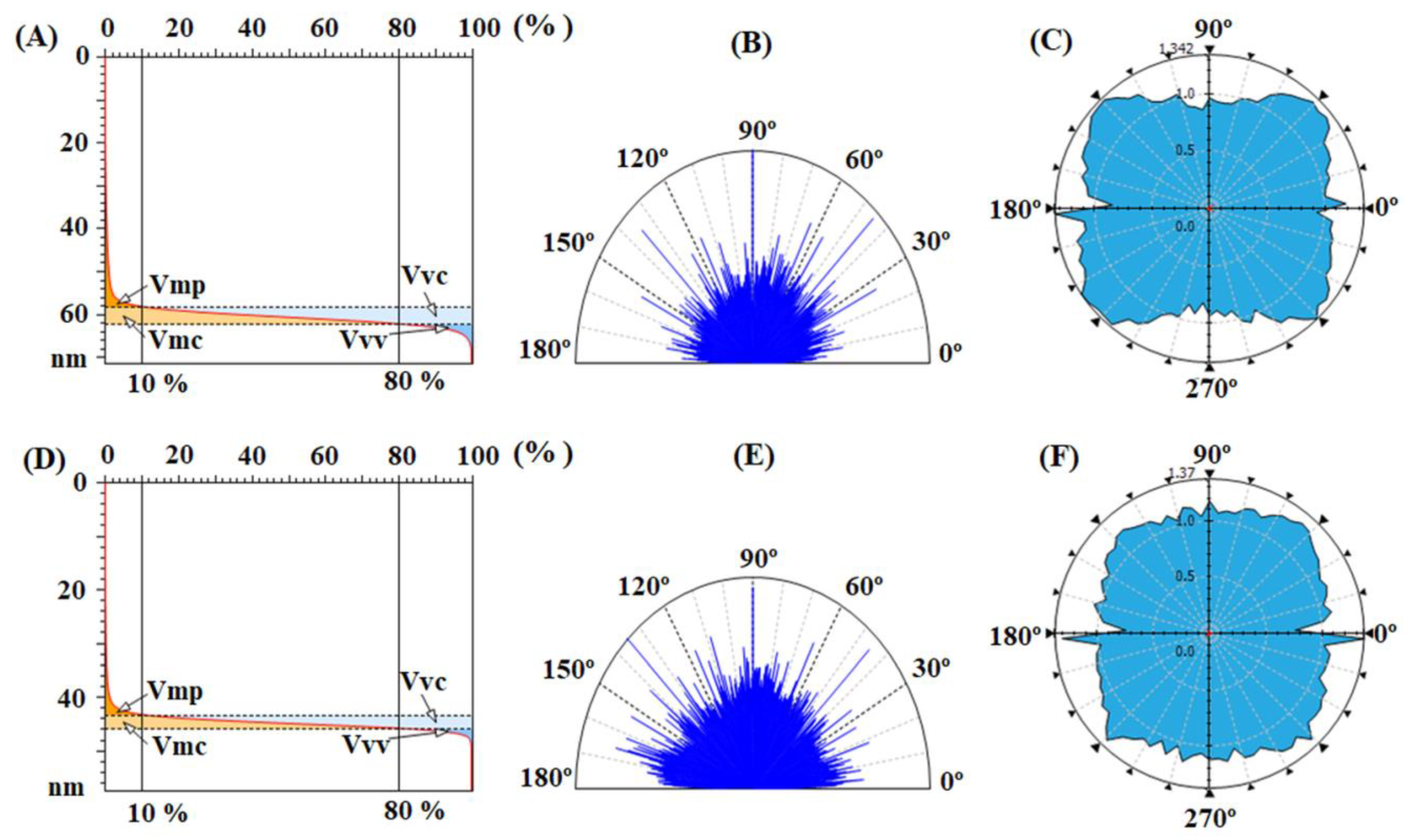

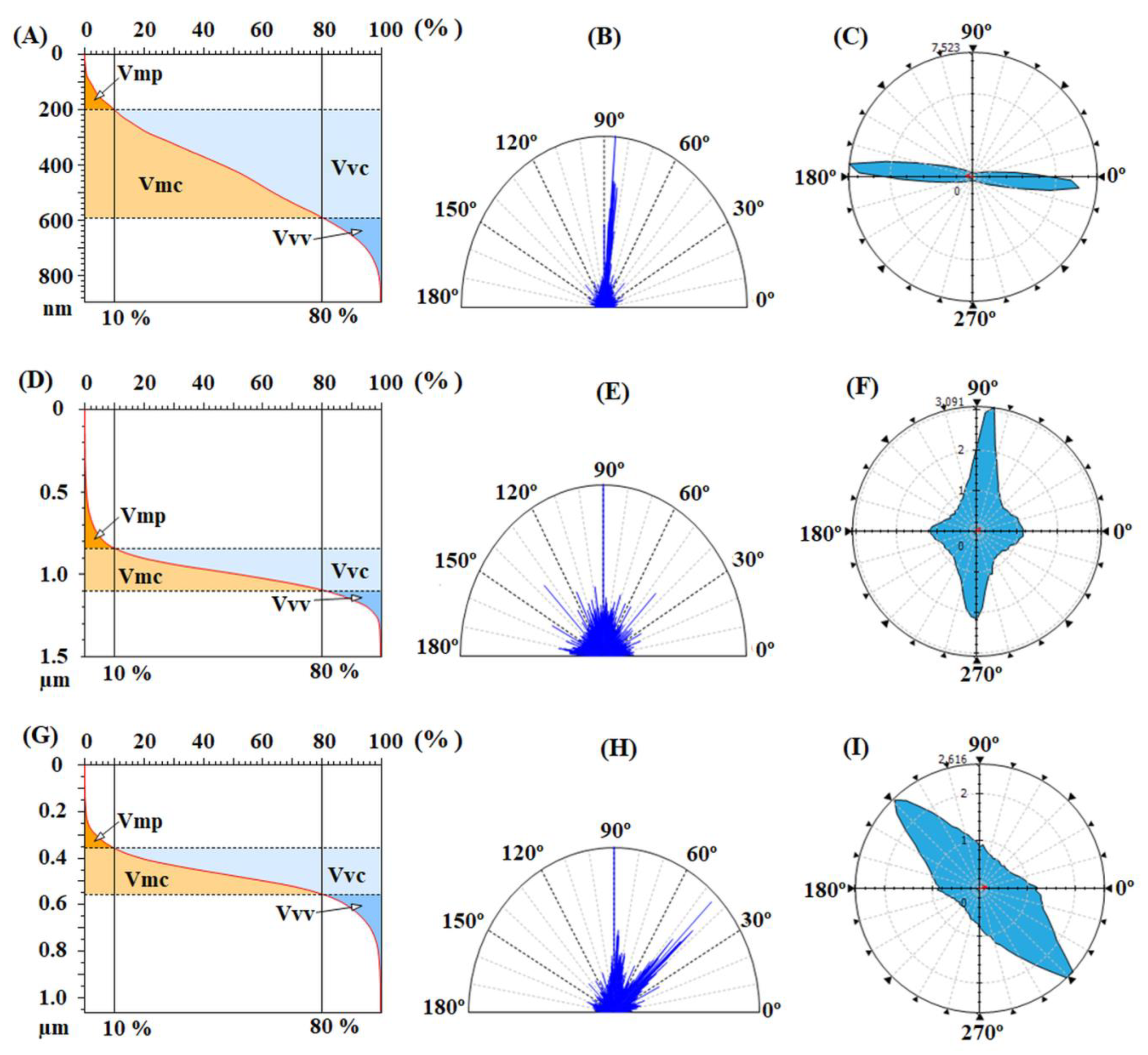

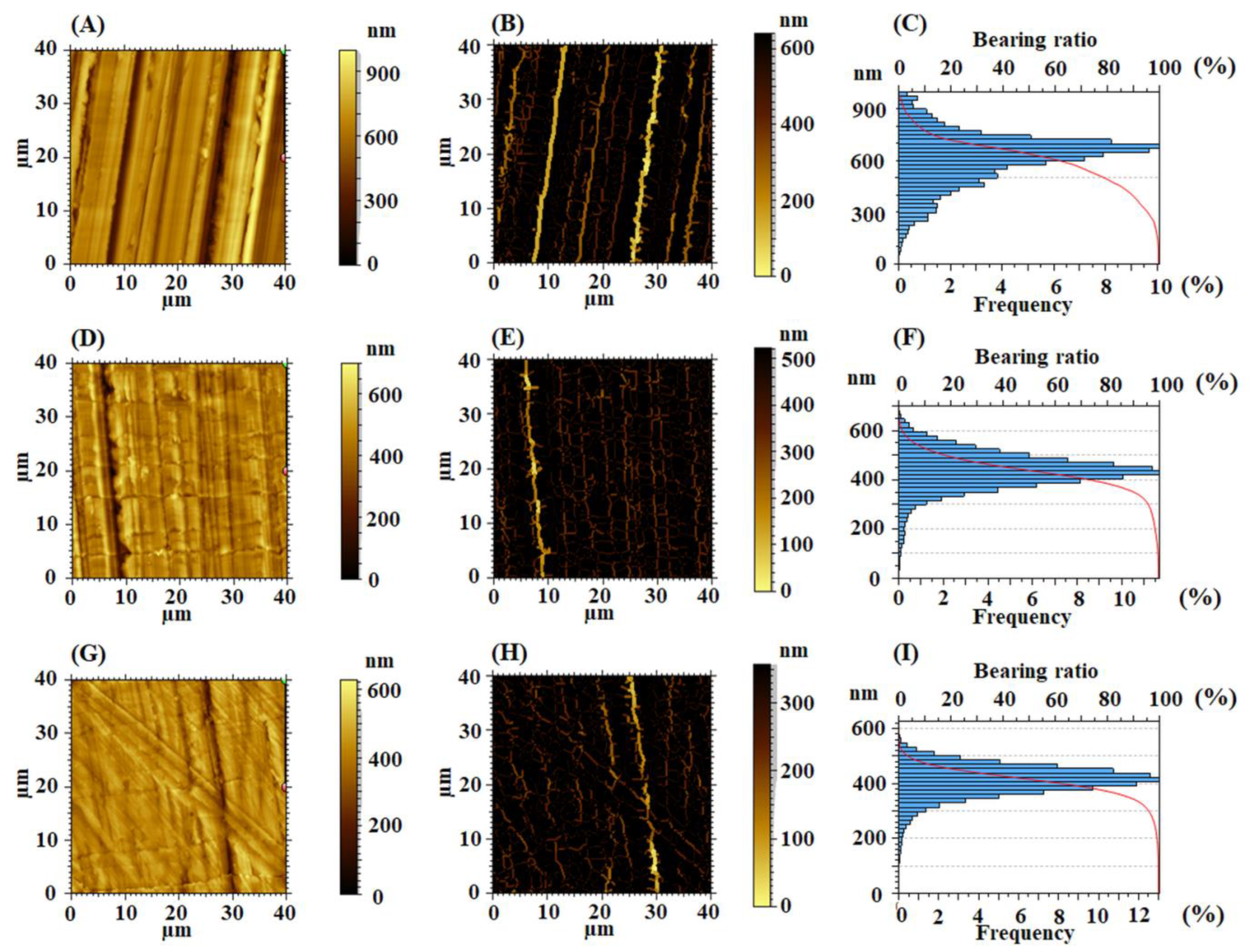

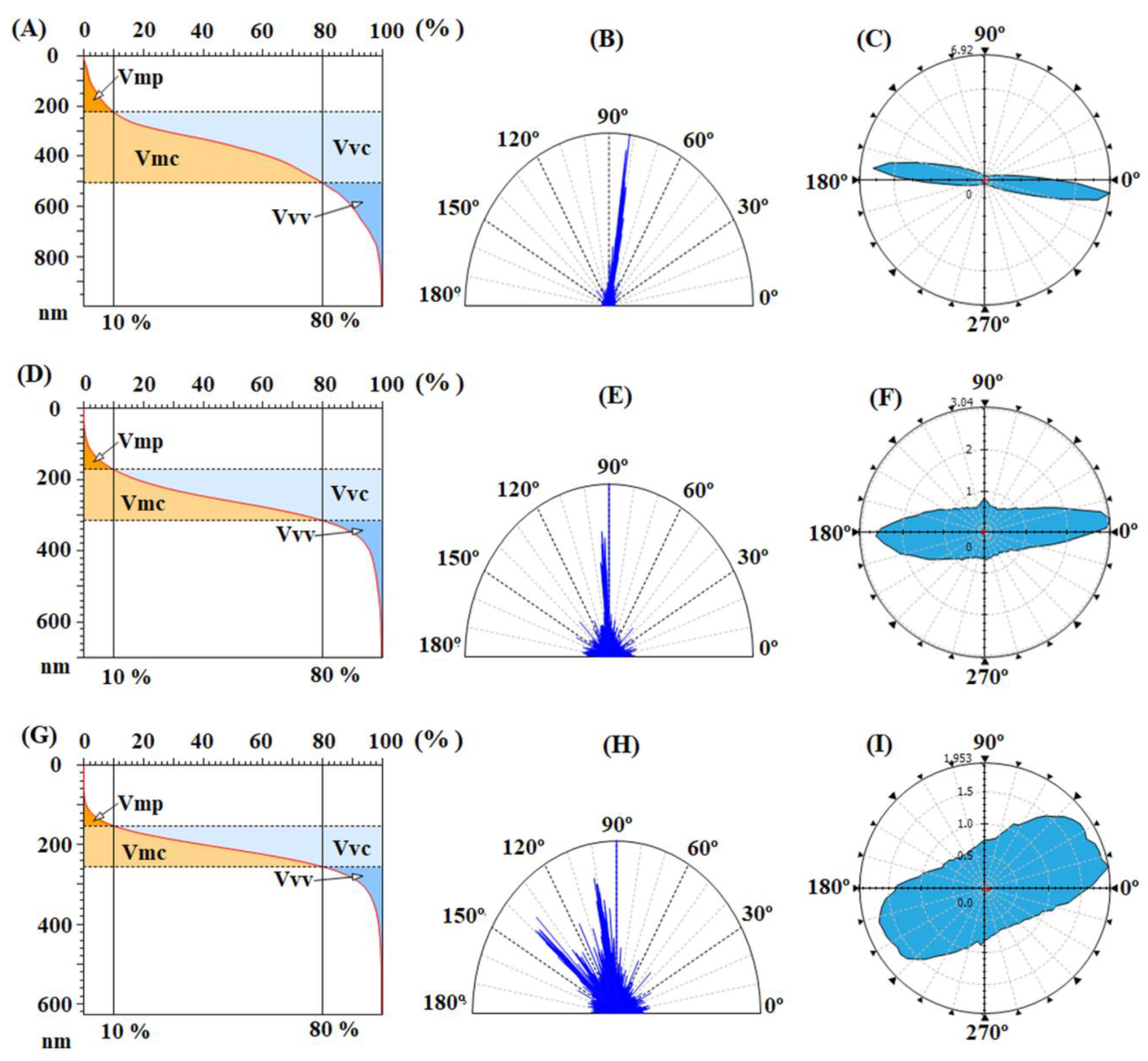

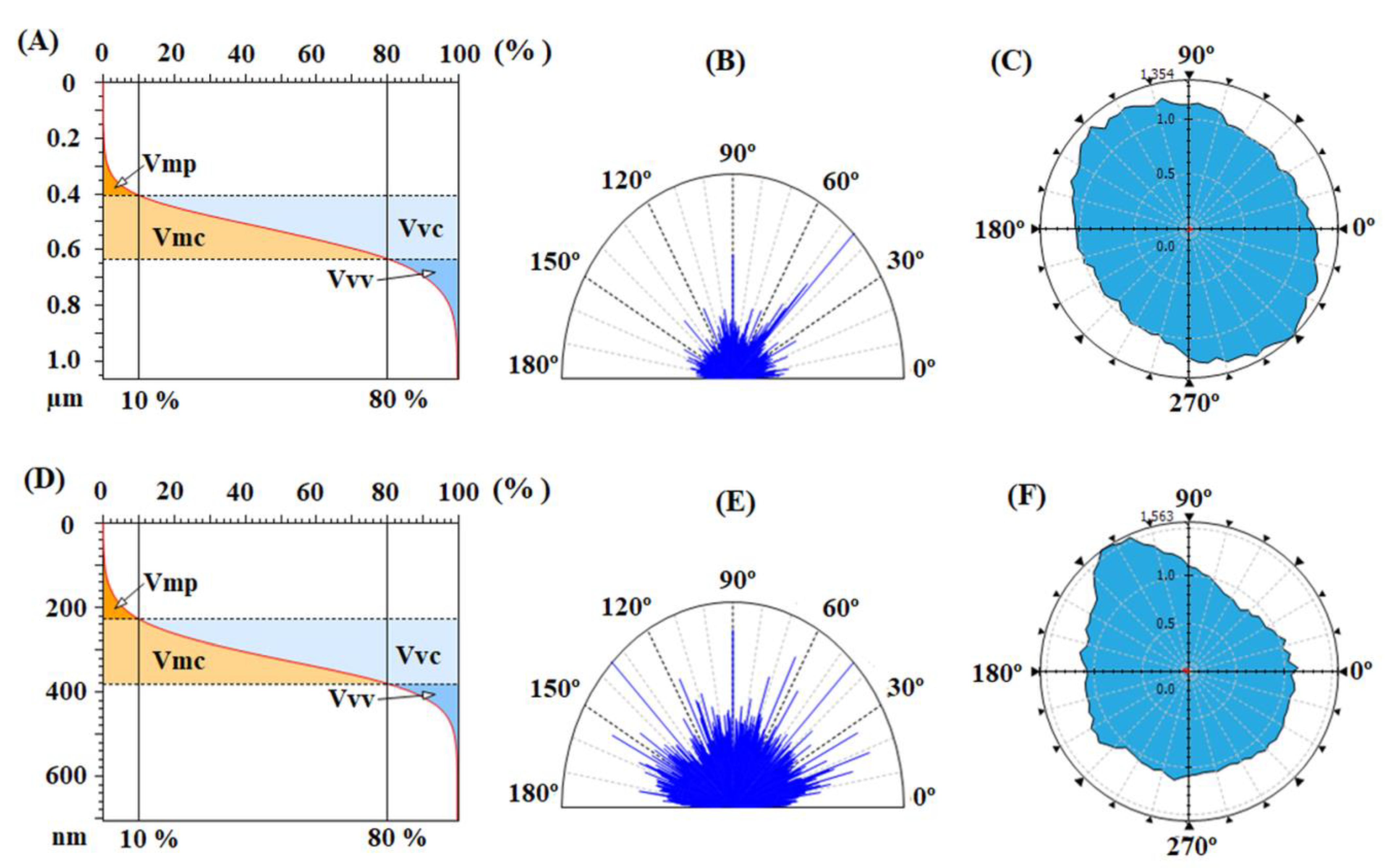

3.1. Morphology

3.2. Wettability and Adhesion

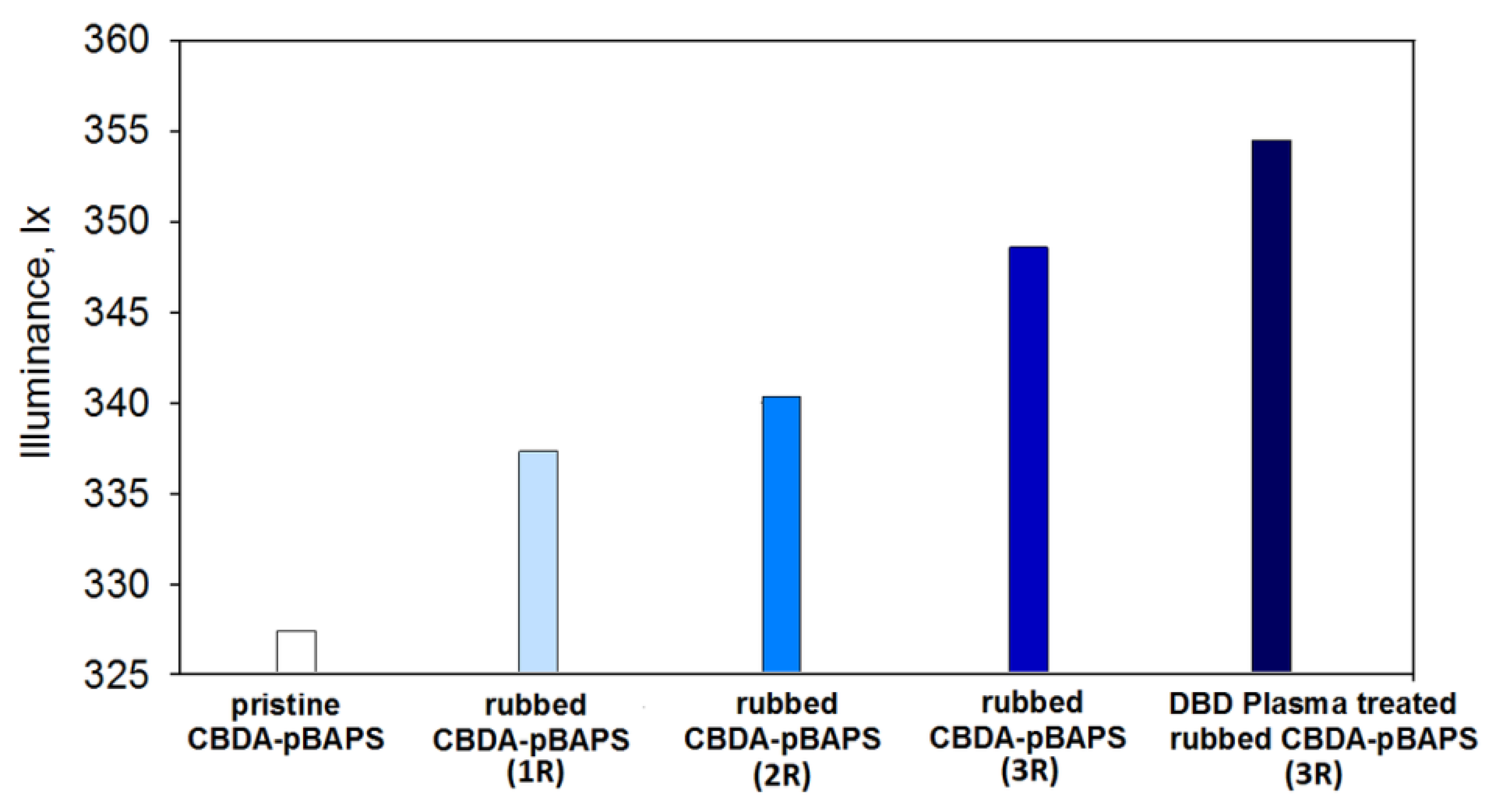

3.3. Illuminance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dambhare, M.V.; Butey, B.; Moharil, S.V. Solar photovoltaic technology: A review of different types of solar cells and its future trends. J. Phys. Conf. Ser. 2021, 1913, 012053. [Google Scholar] [CrossRef]

- Lee, T.D.; Ebong, A.U. A review of thin film solar cell technologies and challenges. Renew. Sustain. Energy Rev. 2017, 70, 1286–1297. [Google Scholar] [CrossRef]

- Avrutin, V.; Izyumskaya, N.; Morkoç, H. Semiconductor solar cells: Recent progress in terrestrial applications. Superlattices Microstruct. 2011, 49, 337–364. [Google Scholar] [CrossRef]

- Yusoff, A.R.M.M.; Syahrul, M.N.; Henkel, K. Film adhesion in amorphous silicon solar cells. Bull. Mater. Sci. 2007, 30, 329–331. [Google Scholar] [CrossRef]

- Patel, D.; Deshmukh, S.P. Polymer in Sustainable Energy. J. Miner. Mater. Charact. Eng. 2012, 11, 661–666. [Google Scholar] [CrossRef]

- Dayneko, S.; Tameev, A.; Tedoradze, M.; Martynov, I.; Artemyev, M.; Nabiev, I.; Chistyakov, A. Hybrid heterostructures based on aromatic polyimide and semiconductor CdSe quantum dots for photovoltaic applications. Appl. Phys. Lett. 2013, 103, 063302. [Google Scholar] [CrossRef]

- Hulubei, C.; Albu, R.M.; Lisa, G.; Nicolescu, A.; Hamciuc, E.; Hamciuc, C.; Barzic, A.I. Antagonistic effects in structural design of sulfur-based polyimides as shielding layers for solar cells. Sol. Energy Mater. Sol. Cells 2019, 193, 219–230. [Google Scholar] [CrossRef]

- Barzic, A.I.; Albu, R.M.; Hulubei, C. Polyimides Containing Chalcogen Atoms in Solution Phase: Viscoelasticity and Interferometry Analyses. Rev. Roum. Chim. 2021, 66, 361–366. [Google Scholar] [CrossRef]

- Barzic, A.I.; Albu, R.M.; Stoica, I.; Varganici, C.D.; Hulubei, C. Polyimides containing cycloaliphatic units and chalcogen atoms as alternative shielding coatings for solar cells. Polym. Bull. 2022, 2022, 1–20. [Google Scholar] [CrossRef]

- Barzic, A.I.; Albu, R.M.; Stoica, I.; Hulubei, C. New shielding covers based on transparent polyimide/ferrous sulfide composites that reduce optical losses in solar cells. Compos. Sci. Technol. 2022, 218, 109140. [Google Scholar] [CrossRef]

- Zeman, M.; Isabella, O.; Jäger, K.; Santbergen, R.; Solntsev, S.; Topic, M.; Krc, J. Advanced Light Management Approaches for Thin-Film Silicon Solar Cells. Energy Procedia 2012, 15, 189–199. [Google Scholar] [CrossRef]

- Meier, M.; Paetzold, U.W.; Ghosh, M.; van Erven, R. Periodic nano-textures enhance efficiency in multi-junction silicon thin-film solar cells. Phys. Status Solidi 2015, 212, 30–35. [Google Scholar] [CrossRef]

- Kowalczewski, P.; Bozzola, A.; Liscidini, M.; Andreani, L.C. Tailoring randomly rough textures for light trapping in thin-film solar cells. In Photonics for Solar Energy Systems V; Wehrspohn, R.B., Gombert, A., Eds.; SPIE: Bellingham, WA, USA, 2014; p. 91400N. [Google Scholar]

- Martins, E.R.; Li, J.; Liu, Y.; Zhou, J.; Krauss, T.F. Engineering gratings for light trapping in photovoltaics: The supercell concept. Phys. Rev. B 2012, 86, 041404. [Google Scholar] [CrossRef]

- Bozzola, A.; Liscidini, M.; Andreani, L.C. Broadband light trapping with disordered photonic structures in thin-film silicon solar cells. Prog. Photovolt. Res. Appl. 2014, 22, 1237–1245. [Google Scholar] [CrossRef]

- Muller, J.; Herman, A.; Mayer, A.; Deparis, O. A fair comparison between ultrathin crystalline-silicon solar cells with either periodic or correlated disorder inverted pyramid textures. Opt. Express 2015, 23, A657. [Google Scholar] [CrossRef] [PubMed]

- Oskooi, A.; Favuzzi, P.A.; Tanaka, Y.; Shigeta, H.; Kawakami, Y.; Noda, S. Partially disordered photonic-crystal thin films for enhanced and robust photovoltaics. Appl. Phys. Lett. 2012, 100, 181110. [Google Scholar] [CrossRef]

- Peretti, R.; Gomard, G.; Lalouat, L.; Seassal, C.; Drouard, E. Absorption control in pseudodisordered photonic-crystal thin films. Phys. Rev. A 2013, 88, 053835. [Google Scholar] [CrossRef]

- Lin, C.; Huang, N.; Povinelli, M.L. Effect of aperiodicity on the broadband reflection of silicon nanorod structures for photovoltaics. Opt. Express 2012, 20, A125. [Google Scholar] [CrossRef] [PubMed]

- Vynck, K.; Burresi, M.; Riboli, F.; Wiersma, D.S. Photon management in two-dimensional disordered media. Nat. Mater. 2012, 11, 1017–1022. [Google Scholar] [CrossRef] [PubMed]

- Haug, F.-J.; Söderström, T.; Python, M.; Terrazzoni-Daudrix, V.; Niquille, X.; Ballif, C. Development of micromorph tandem solar cells on flexible low-cost plastic substrates. Sol. Energy Mater. Sol. Cells 2009, 93, 884–887. [Google Scholar] [CrossRef] [Green Version]

- Escarré, J.; Battaglia, C.; Söderström, K.; Pahud, C.; Biron, R.; Cubero, O.; Haug, F.-J.; Ballif, C. UV imprinting for thin film solar cell application. J. Opt. 2012, 14, 024009. [Google Scholar] [CrossRef]

- Deckman, H.W.; Dunsmuir, J.H. Natural lithography. Appl. Phys. Lett. 1982, 41, 377–379. [Google Scholar] [CrossRef]

- Chen, L.; Fang, B.; Ke, Q.; Wangyang, P.; Hu, K.; Zhang, W. Quasi-hemispherical pit array textured surface for increasing the efficiency of thin-film solar cells. AIP Adv. 2022, 12, 015111. [Google Scholar] [CrossRef]

- Park, H.; Shin, M.H.; Iftiquar, S.M.; Hussain, S.Q.; Ju, M.; Kim, Y.; Cho, E.-C.; Yi, J. The light-trapping effect in various textured cover glass for enhancing the current density in silicon heterojunction solar cells. Opt. Commun. 2020, 467, 125657. [Google Scholar] [CrossRef]

- Park, H.; Jeong, Y.; Myunghun, L.; Lee, S.Y.; Lee, J.; Park, C. Effects of Glass Texturing Structure on the Module Efficiency of Heterojunction Silicon Solar Cells. Curr. Photovolt. Res. 2018, 6, 102–108. [Google Scholar]

- Liu, H.; Du, Y.; Yin, X.; Bai, M.; Liu, W. Micro/Nanostructures for Light Trapping in Monocrystalline Silicon Solar Cells. J. Nanomater. 2022, 2022, 1–40. [Google Scholar] [CrossRef]

- Kim, S.R. Surface Modification of Poly(tetrafluoroethylene) Film by Chemical Etching, Plasma, and Ion Beam Treatments. J. Appl. Polym. Sci. 2000, 77, 1913–1920. [Google Scholar] [CrossRef]

- Popovici, D.; Barzic, A.I.; Stoica, I.; Butnaru, M.; Ioanid, G.E.; Vlad, S.; Hulubei, C.; Bruma, M. Plasma modification of surface wettability and morphology for optimization of the interactions involved in blood constituents spreading on some novel copolyimide films. Plasma Chem. Plasma Process. 2012, 32, 781–799. [Google Scholar] [CrossRef]

- Stoica, I.; Epure, E.L.; Constantin, C.P.; Damaceanu, M.D.; Ursu, E.L.; Mihaila, I.; Sava, I. Evaluation of local mechanical and chemical properties via afm as a tool for understanding the formation mechanism of pulsed uv laser-nanoinduced patterns on azo-naphthalene-based polyimide films. Nanomaterials 2021, 11, 812. [Google Scholar] [CrossRef]

- Stoica, I.; Barzic, A.I.; Hulubei, C. Fabrication of nanochannels on polyimide films using dynamic plowing lithography. Appl. Surf. Sci. 2017, 426, 307–314. [Google Scholar] [CrossRef]

- Yamahara, M.; Nakamura, M.; Koide, N.; Sasaki, T. Influence of rubbing conditions of polyimide alignment layer on optical anisotropy of immobilized liquid crystal film. Liq. Cryst. 2007, 34, 381–387. [Google Scholar] [CrossRef]

- Epure, E.-L.; Stoica, I.; Albu, R.M.; Hulubei, C.; Barzic, A.I. New Strategy for Inducing Surface Anisotropy in Polyimide Films for Nematics Orientation in Display Applications. Nanomaterials 2021, 11, 3107. [Google Scholar] [CrossRef] [PubMed]

- Stoica, I.; Barzic, A.I.; Hulubei, C. The impact of rubbing fabric type on surface roughness and tribological properties of some semi-alicyclic polyimides evaluated from atomic force measurements. Appl. Surf. Sci. 2013, 268, 442–449. [Google Scholar] [CrossRef]

- Luo, B.; Li, L.; Liu, H.; Xu, M.; Xing, F. Analysis of Sanding Parameters, Sanding Force, Normal Force, Power Consumption, and Surface Roughness in Sanding Wood-Based Panels. BioResources 2014, 9, 7494–7503. [Google Scholar] [CrossRef]

- Barzic, A.I.; Albu, R.M.; Hulubei, C.; Thabet, H.K.; Abu Ali, O.A.; El-Bahy, Z.M.; Stoica, I. Polyimide layers with high refractivity and surface wettability adapted for lowering optical losses in solar cells. Polymers 2022. [Google Scholar]

- Barzic, A.I.; Stoica, I.; Fifere, N.; Vlad, C.D.; Hulubei, C. Morphological effects on transparency and absorption edges of some semi-alicyclic polyimides. J. Polym. Res. 2013, 20, 130. [Google Scholar] [CrossRef]

- Stoica, I.; Barzic, A.I.; Hulubei, C.; Timpu, D. Statistical analysis on morphology development of some semialicyclic polyimides using atomic force microscopy. Microsc. Res. Tech. 2013, 76, 503–513. [Google Scholar] [CrossRef] [PubMed]

- Kacalak, W.; Lipiński, D.; Szafraniec, F.; Zawada-Tomkiewicz, A.; Tandecka, K.; Królczyk, G. Metrological basis for assessing the state of the active surface of abrasive tools based on parameters characterizing their machining potential. Measurement 2020, 165, 108068. [Google Scholar] [CrossRef]

- Lemesle, J.; Robache, F.; Le Goic, G.; Mansouri, A.; Brown, C.A.; Bigerelle, M. Surface Reflectance: An Optical Method for Multiscale Curvature Characterization of Wear on Ceramic–Metal Composites. Materials 2020, 13, 1024. [Google Scholar] [CrossRef]

- ISO 25178-2:2012; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. ISO: Geneve, Switzerland, 2012. Available online: https://www.iso.org/standard/42785.html (accessed on 23 July 2021).

- Lou, S.; Pagani, L.; Zeng, W.; Jiang, X.; Scott, P.J. Watershed segmentation of topographical features on freeform surfaces and its application to additively manufactured surfaces. Precis. Eng. 2020, 63, 177–186. [Google Scholar] [CrossRef]

- Barré, F.; Lopez, J. Watershed lines and catchment basins: A new 3D-motif method. Int. J. Mach. Tools Manuf. 2000, 40, 1171–1184. [Google Scholar] [CrossRef]

- Blateyron, F. The Areal Field Parameters. In Characterisation of Areal Surface Texture; Springer: Berlin/Heidelberg, Germany, 2013; pp. 15–43. [Google Scholar]

- Blateyron, F. The Areal Feature Parameters. In Characterisation of Areal Surface Texture; Springer: Berlin/Heidelberg, Germany, 2013; pp. 45–65. [Google Scholar]

- Pickering, T.; Shanks, K.; Sundaram, S. Modelling technique and analysis of porous anti-reflective coatings for reducing wide angle reflectance of thin-film solar cells. J. Opt. 2021, 23, 025901. [Google Scholar] [CrossRef]

- Lee, C.; Kramer, T.A. Prediction of three-dimensional fractal dimensions using the two-dimensional properties of fractal aggregates. Adv. Colloid Interface Sci. 2004, 112, 49–57. [Google Scholar] [CrossRef]

- Boschloo, G.; Edvinsson, T.; Hagfeldt, A. Dye-Sensitized Nanostructured ZnO Electrodes for Solar Cell Applications. In Nanostructured Materials for Solar Energy Conversion; Elsevier: Amsterdam, The Netherlands, 2006; pp. 227–254. [Google Scholar]

- Mehta, R.; Min, M.; Kaul, A.B. Sol-gel synthesized indium tin oxide as a transparent conducting oxide with solution-processed black phosphorus for its integration into solar-cells. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2020, 38, 063203. [Google Scholar] [CrossRef]

- Oss, C.J.V.; Good, R.J.; Chaudhury, M.K. Additive and nonadditive surface tension components and the interpretation of contact angles. Langmuir 2002, 4, 884–891. [Google Scholar] [CrossRef]

- Krč, J.; Zeman, M.; Kluth, O.; Smole, F.; Topič, M. Effect of surface roughness of ZnO:Al films on light scattering in hydrogenated amorphous silicon solar cells. Thin Solid Films 2003, 426, 296–304. [Google Scholar] [CrossRef]

- Scholtz, L.; Ladanyi, L.; Mullerova, J. Influence of Surface Roughness on Optical Characteristics of Multilayer Solar Cells. Adv. Electr. Electron. Eng. 2015, 12, 631–638. [Google Scholar] [CrossRef]

- Brongersma, M.L.; Cui, Y.; Fan, S. Light management for photovoltaics using high-index nanostructures. Nat. Mater. 2014, 13, 451–460. [Google Scholar] [CrossRef] [PubMed]

- Kim, E.; Cho, Y.; Sohn, A.; Hwang, H.; Lee, Y.U.; Kim, K.; Park, H.-H.; Kim, J.; Wu, J.W.; Kim, D.-W. Mie Resonance-Modulated Spatial Distributions of Photogenerated Carriers in Poly(3-hexylthiophene-2,5-diyl)/Silicon Nanopillars. Sci. Rep. 2016, 6, 29472. [Google Scholar] [CrossRef] [PubMed]

- Garnett, E.C.; Ehrler, B.; Polman, A.; Alarcon-Llado, E. Photonics for Photovoltaics: Advances and Opportunities. ACS Photonics 2021, 8, 61–70. [Google Scholar] [CrossRef] [PubMed]

- Tonkaev, P.; Kivshar, Y. High-Q Dielectric Mie-Resonant Nanostructures (Brief Review). JETP Lett. 2020, 112, 615–622. [Google Scholar] [CrossRef]

| Sample Name | Description |

|---|---|

| EPI-pBAPS | Pristine EPI-pBAPS sample with no surface modification |

| Rubbed EPI-pBAPS (1R) | Rubbed EPI-pBAPS sample along one direction |

| Rubbed EPI-pBAPS (2R) | Rubbed EPI-pBAPS sample along two perpendicular directions |

| Rubbed EPI-pBAPS (3R) | Rubbed EPI-pBAPS sample along perpendicular directions followed by additional rubbing at 45° |

| DBD Plasma treated Rubbed EPI-pBAPS (3R) | Rubbed EPI-pBAPS sample along perpendicular directions followed by additional rubbing at 45° and then exposed to dielectric barrier discharge plasma |

| CBDA-BAPS | Pristine CBDA-BAPS sample with no surface modification |

| Rubbed CBDA-pBAPS (1R) | Rubbed CBDA-BAPS sample along one direction |

| Rubbed CBDA-pBAPS (2R) | Rubbed CBDA-BAPS sample along two perpendicular directions |

| Rubbed CBDA-pBAPS (3R) | Rubbed CBDA-BAPS sample along perpendicular directions followed by additional rubbing at 45° |

| DBD Plasma treated Rubbed CBDA-pBAPS (3R) | Rubbed CBDA-BAPS sample along perpendicular directions followed by additional rubbing at 45° and then exposed to dielectric barrier discharge plasma |

| Sample | Height and Hybrid Parameters | Fractal Analysis | |||

|---|---|---|---|---|---|

| Sq (nm) | Sent | Sdr (%) | Df | Lsfc | |

| Pristine EPI-pBAPS | 3.2 | 7.99 | 0.23 | 2.42 | 0.38 |

| Rubbed EPI-pBAPS (1R) | 170.6 | 13.99 | 8.77 | 2.48 | 19.29 |

| Rubbed EPI-pBAPS (2R) | 134.7 | 13.60 | 7.26 | 2.49 | 13.11 |

| Rubbed EPI-pBAPS (3R) | 106.5 | 13.35 | 3.82 | 2.51 | 7.61 |

| DBD Plasma treated Rubbed EPI-pBAPS (3R) | 116.3 | 13.51 | 8.14 | 2.72 | 14.11 |

| Pristine CBDA-BAPS | 1.8 | 7.28 | 0.02 | 2.34 | 0.23 |

| Rubbed CBDA-pBAPS (1R) | 152.1 | 13.74 | 4.28 | 2.42 | 11.47 |

| Rubbed CBDA-pBAPS (2R) | 77.2 | 12.96 | 2.64 | 2.69 | 6.44 |

| Rubbed CBDA-pBAPS (3R) | 56.5 | 12.51 | 1.59 | 2.83 | 3.33 |

| DBD Plasma treated Rubbed CBDA-pBAPS (3R) | 74.9 | 12.91 | 6.16 | 2.85 | 15.59 |

| Sample | Furrow Analysis | Feature Parameters | |||

|---|---|---|---|---|---|

| Fdmax (nm) | Fdmean (nm) | Fρmean (cm/cm2) | Sda (µm2) | Sha (µm2) | |

| Pristine EPI-pBAPS | 7.2 | 3.2 | 25,878 | 2.2 | 0.4 |

| Rubbed EPI-pBAPS (1R) | 610.9 | 234.7 | 5651 | 6.4 | 7.1 |

| Rubbed EPI-pBAPS (2R) | 603.9 | 231.0 | 5736 | 14.5 | 9.6 |

| Rubbed EPI-pBAPS (3R) | 497.2 | 159.5 | 5287 | 12.9 | 12.4 |

| DBD Plasma treated Rubbed EPI-pBAPS (3R) | 534.1 | 171.7 | 5820 | 5.5 | 3.1 |

| Pristine CBDA-pBAPS | 4.4 | 2.1 | 21,520 | 1.3 | 0.2 |

| Rubbed CBDA-pBAPS (1R) | 609.7 | 180.0 | 5311 | 10.7 | 20.6 |

| Rubbed CBDA-pBAPS (2R) | 472.5 | 136.9 | 6124 | 6.1 | 5.8 |

| Rubbed CBDA-pBAPS (3R) | 352.4 | 87.2 | 5802 | 8.1 | 8.2 |

| DBD Plasma treated Rubbed CBDA-pBAPS (3R) | 368.9 | 130.9 | 6407 | 2.3 | 1.9 |

| Sample | Functional Volume Parameters | Spatial Parameter | |||

|---|---|---|---|---|---|

| Vmp (µm3/µm2) | Vmc (µm3/µm2) | Vvc (µm3/µm2) | Vvv (µm3/µm2) | Stdi | |

| Pristine EPI-pBAPS | 0.000325 | 0.00168 | 0.00237 | 0.000236 | 0.644 |

| Rubbed EPI-pBAPS (1R) | 0.0057 | 0.1724 | 0.2186 | 0.0154 | 0.165 |

| Rubbed EPI-pBAPS (2R) | 0.0112 | 0.106 | 0.148 | 0.0138 | 0.419 |

| Rubbed EPI-pBAPS (3R) | 0.00544 | 0.0839 | 0.113 | 0.0164 | 0.424 |

| DBD Plasma treated Rubbed EPI-pBAPS (3R) | 0.00521 | 0.101 | 0.127 | 0.0159 | 0.526 |

| Pristine CBDA-pBAPS | 0.000182 | 0.00103 | 0.00155 | 0.000125 | 0.753 |

| Rubbed CBDA-pBAPS (1R) | 0.00772 | 0.134 | 0.148 | 0.0234 | 0.175 |

| Rubbed CBDA-pBAPS (2R) | 0.00364 | 0.0590 | 0.0850 | 0.0113 | 0.225 |

| Rubbed CBDA-pBAPS (3R) | 0.00228 | 0.0452 | 0.0577 | 0.00874 | 0.315 |

| DBD Plasma treated Rubbed CBDA-pBAPS (3R) | 0.00441 | 0.0636 | 0.0899 | 0.00840 | 0.636 |

| Sample | Contact Angle (°) | (mN/m) | (mN/m) | Wad (ITO) (mN/m) | Wad (ZnO) (mN/m) | |

|---|---|---|---|---|---|---|

| W | EG | |||||

| CBDA-pBAPS | 66 | 48 | 12.06 | 24.00 | 81.02 | 43.43 |

| CBDA-pBAPS plasma | 31 | 10 | 6.32 | 61.18 | 99.48 | 44.90 |

| EPI-pBAPS | 73 | 55 | 12.75 | 18.09 | 75.82 | 42.18 |

| EPI-pBAPS plasma | 60 | 33 | 18.16 | 23.62 | 88.43 | 49.66 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stoica, I.; Albu, R.M.; Hulubei, C.; Astanei, D.G.; Burlica, R.; Mersal, G.A.M.; Seaf Elnasr, T.A.; Barzic, A.I.; Elnaggar, A.Y. A New Texturing Approach of a Polyimide Shielding Cover for Enhanced Light Propagation in Photovoltaic Devices. Nanomaterials 2022, 12, 3249. https://doi.org/10.3390/nano12183249

Stoica I, Albu RM, Hulubei C, Astanei DG, Burlica R, Mersal GAM, Seaf Elnasr TA, Barzic AI, Elnaggar AY. A New Texturing Approach of a Polyimide Shielding Cover for Enhanced Light Propagation in Photovoltaic Devices. Nanomaterials. 2022; 12(18):3249. https://doi.org/10.3390/nano12183249

Chicago/Turabian StyleStoica, Iuliana, Raluca Marinica Albu, Camelia Hulubei, Dragos George Astanei, Radu Burlica, Gaber A. M. Mersal, Tarek A. Seaf Elnasr, Andreea Irina Barzic, and Ashraf Y. Elnaggar. 2022. "A New Texturing Approach of a Polyimide Shielding Cover for Enhanced Light Propagation in Photovoltaic Devices" Nanomaterials 12, no. 18: 3249. https://doi.org/10.3390/nano12183249