Mechanisms Analysis for Fatal Accident Types Caused by Multiple Processes in the Workplace: Based on Accident Case in South Korea

Abstract

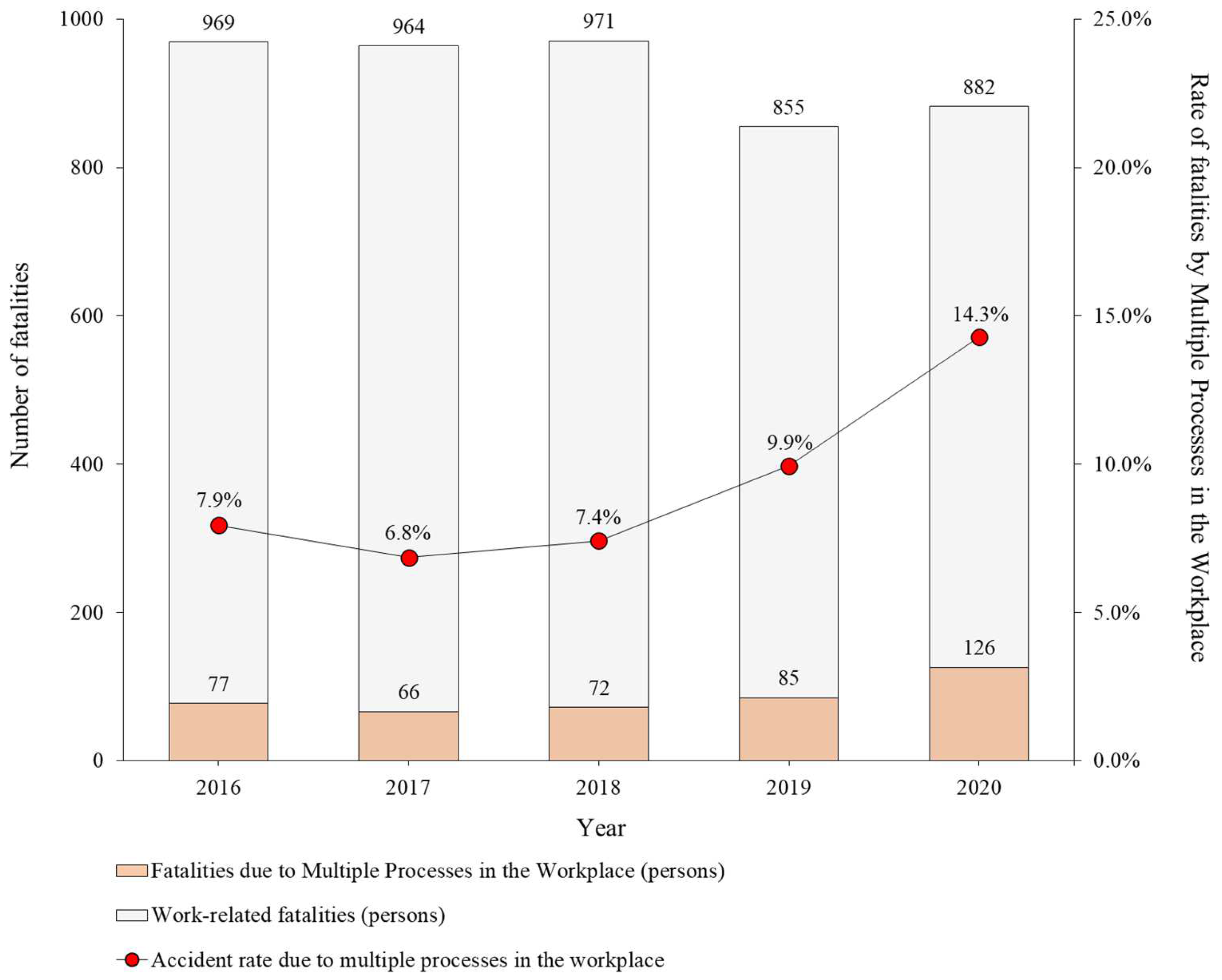

:1. Introduction

2. Definition of Multiple Processes and Drawing of Accident Types

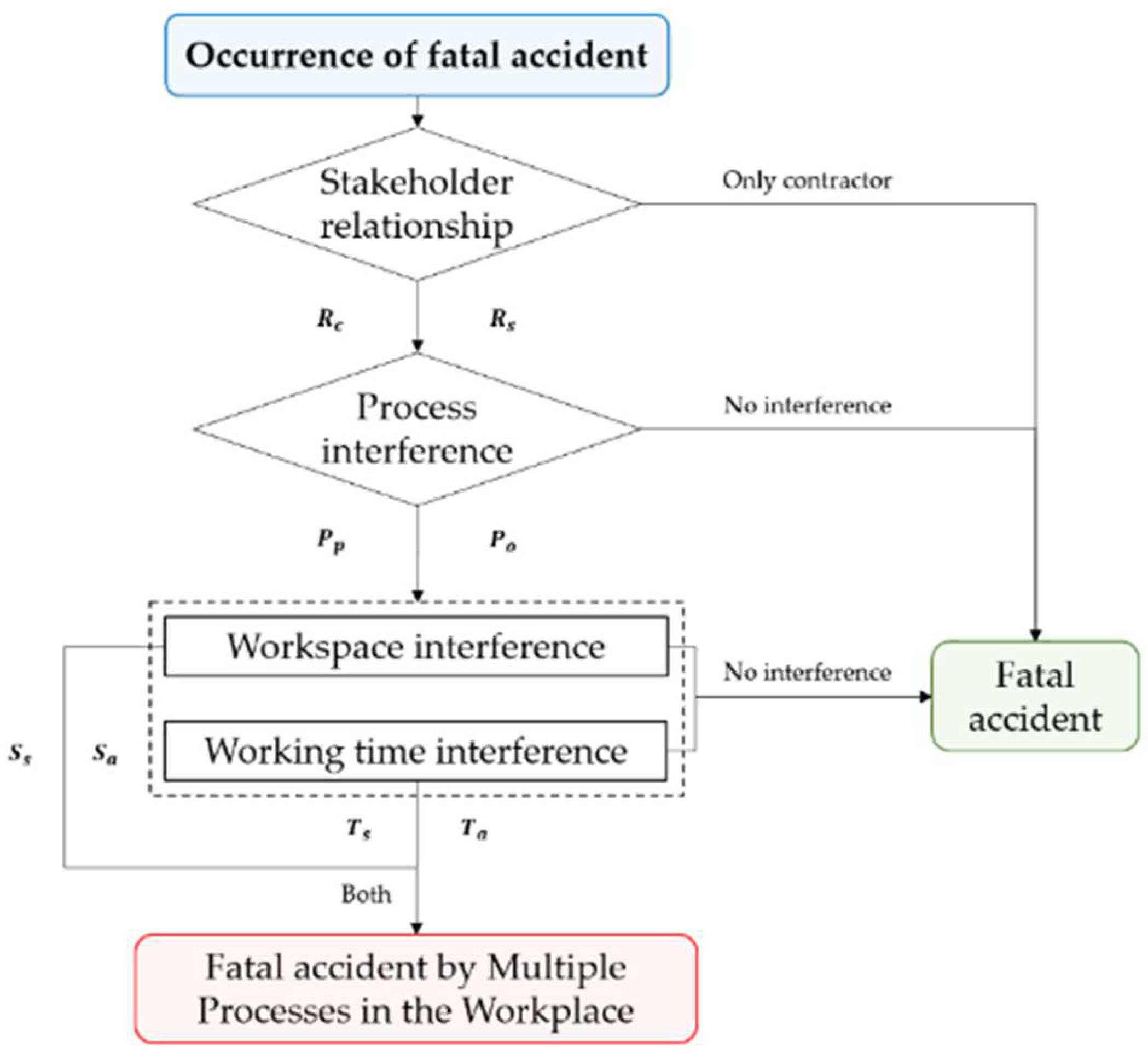

2.1. Definition of Multiple Processes in the Same Workplace

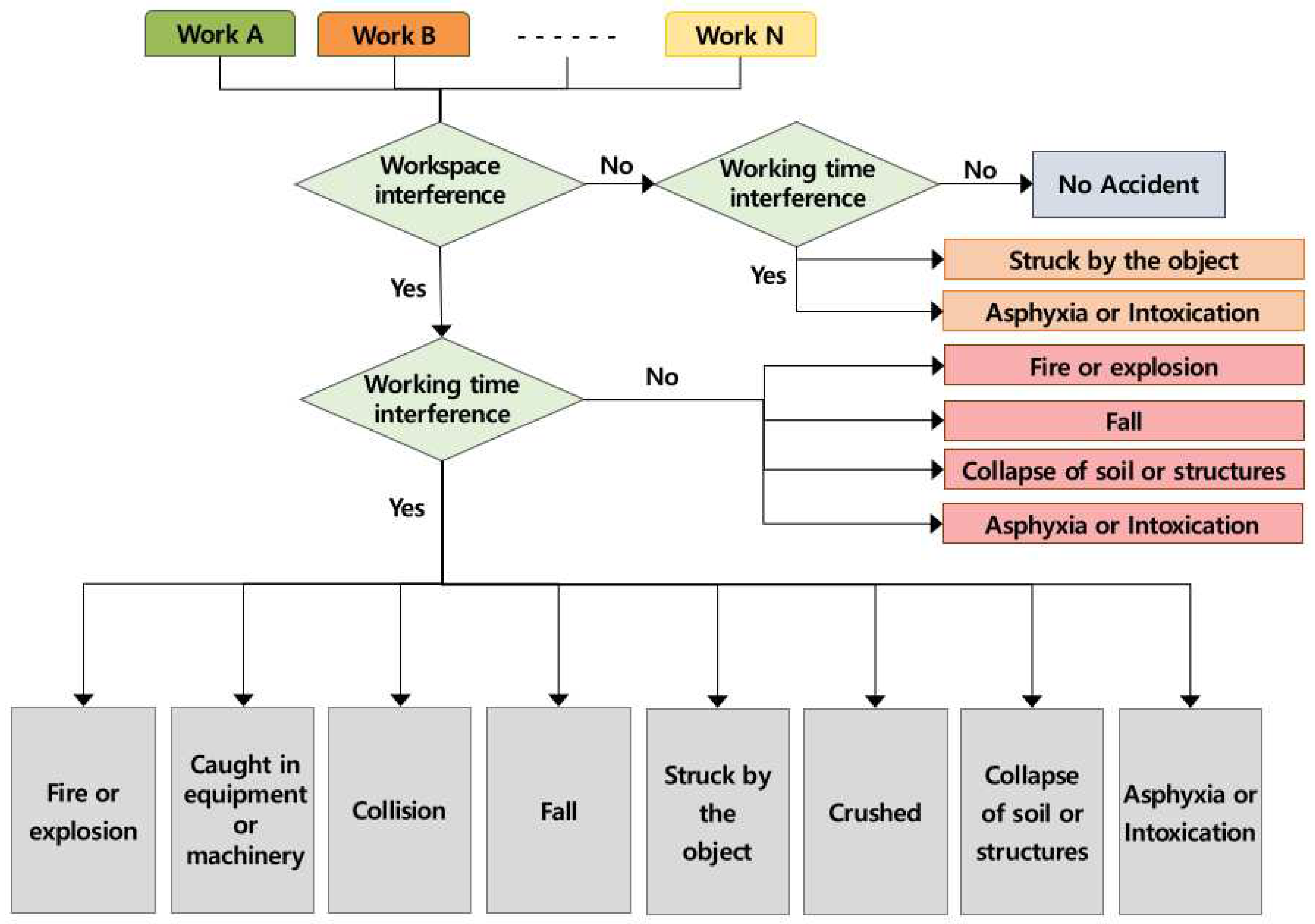

2.2. Types of Accidents Caused by Multiple Processes

3. Analysis of the Process of Accident Occurrence by Multiple Processes

3.1. Cases of Risk in Fire and Explosion

3.2. Cases of Being Caught in Equipment or Machinery

3.3. Cases of Collision with Vehicles for Unloading and Transporting, Construction Machines, etc.

3.4. Cases of Risk in Fall Accidents

3.5. Cases of Being Struck by the Object Falling

3.6. Cases of Risk in Being Crushed by Machinery, Equipment, or Payload

3.7. Cases of Risk in Collapse of Payload such as Soil and Sand, Structure, etc.

3.8. Other Risks (Suffocation, Poisoning by Toxic Gas, etc.)

4. Development of Occurring Mechanism of Each Type of Fatal Accident by Multiple Processes

- (1)

- Checking the overlapping workspace of the multiple processes

- (2)

- Checking the overlapping working time according to the overlapping workspace

- (3)

- Grasping the accident types according to the overlapping workspace and working time

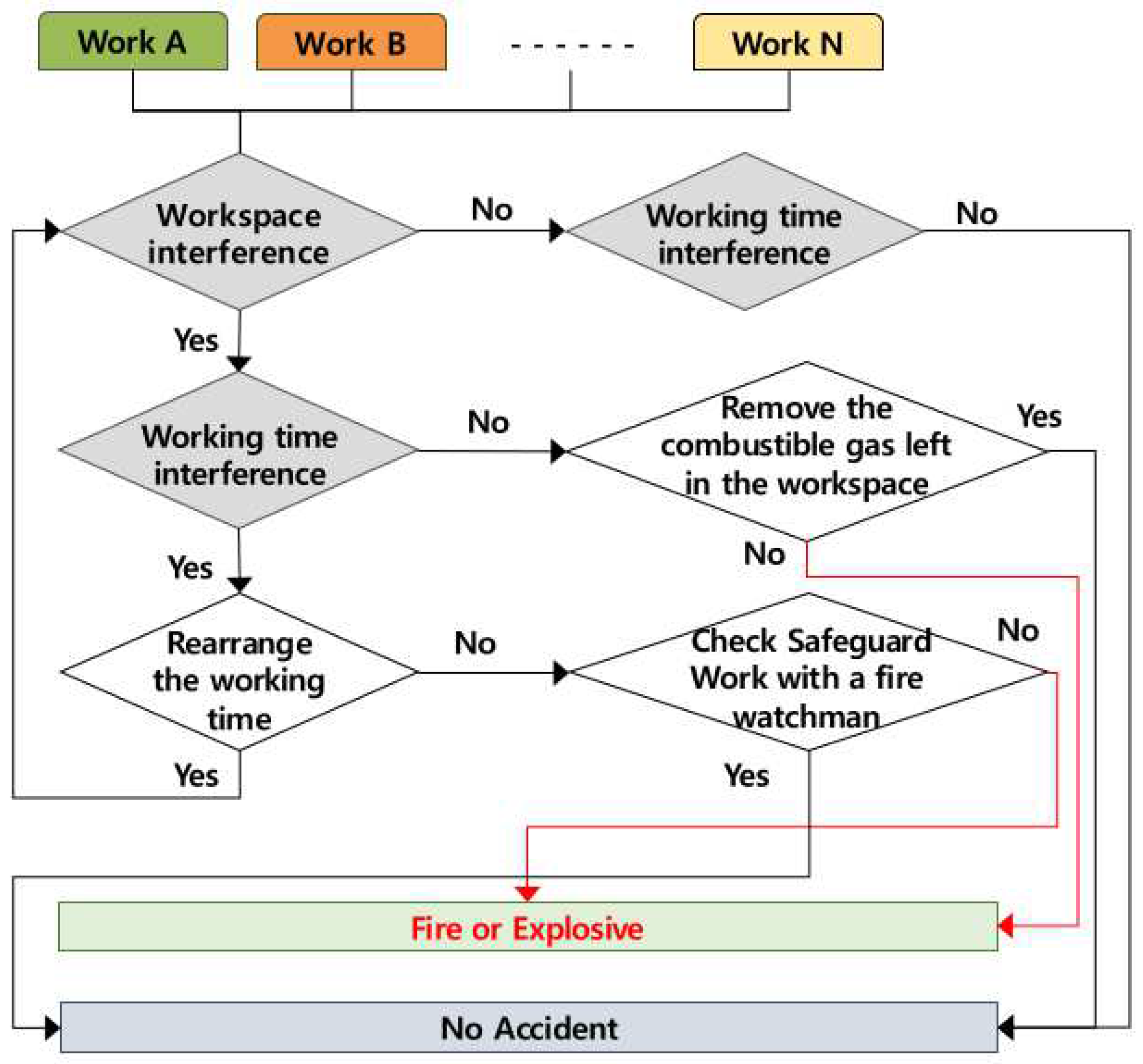

4.1. Occurring Mechanism of Fire and Explosion

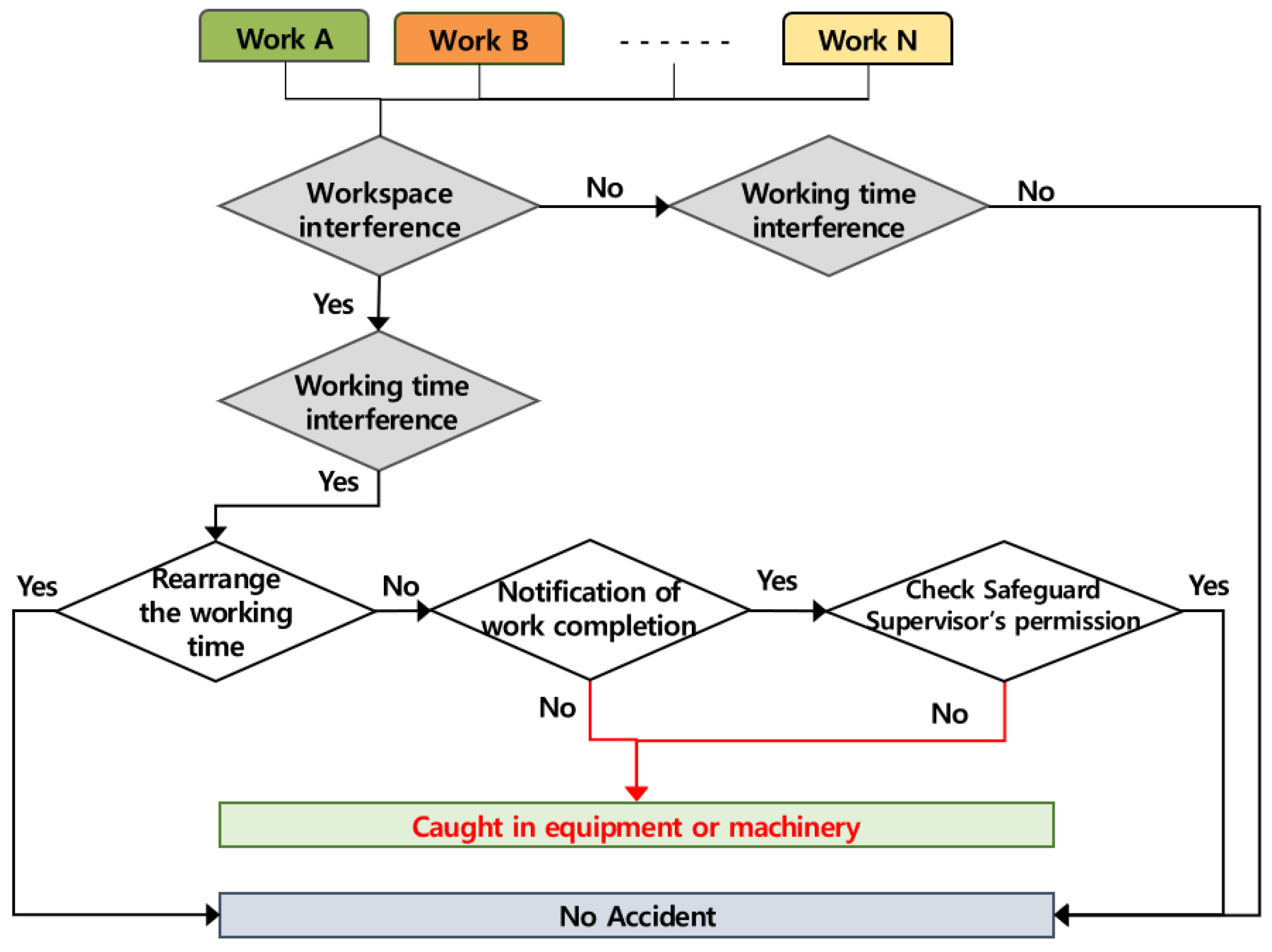

4.2. Occurring Mechanism of Being Caught in Machinery, Equipment, etc.

4.3. Occurring Mechanism of Collision with Construction Machines, etc.

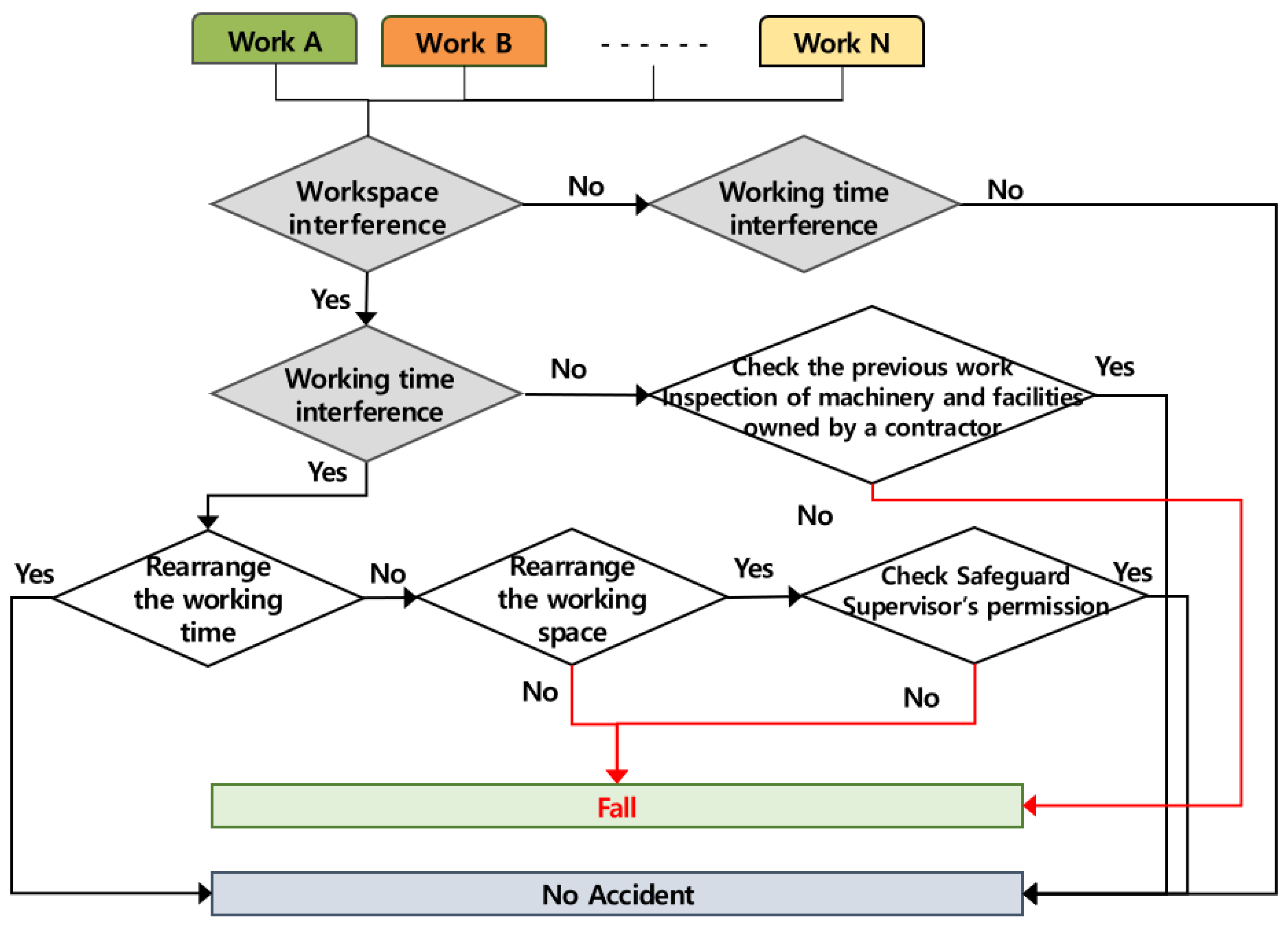

4.4. Occurring Mechanism of Fall Accidents

4.5. Occurring Mechanism of Being Struck by an Object

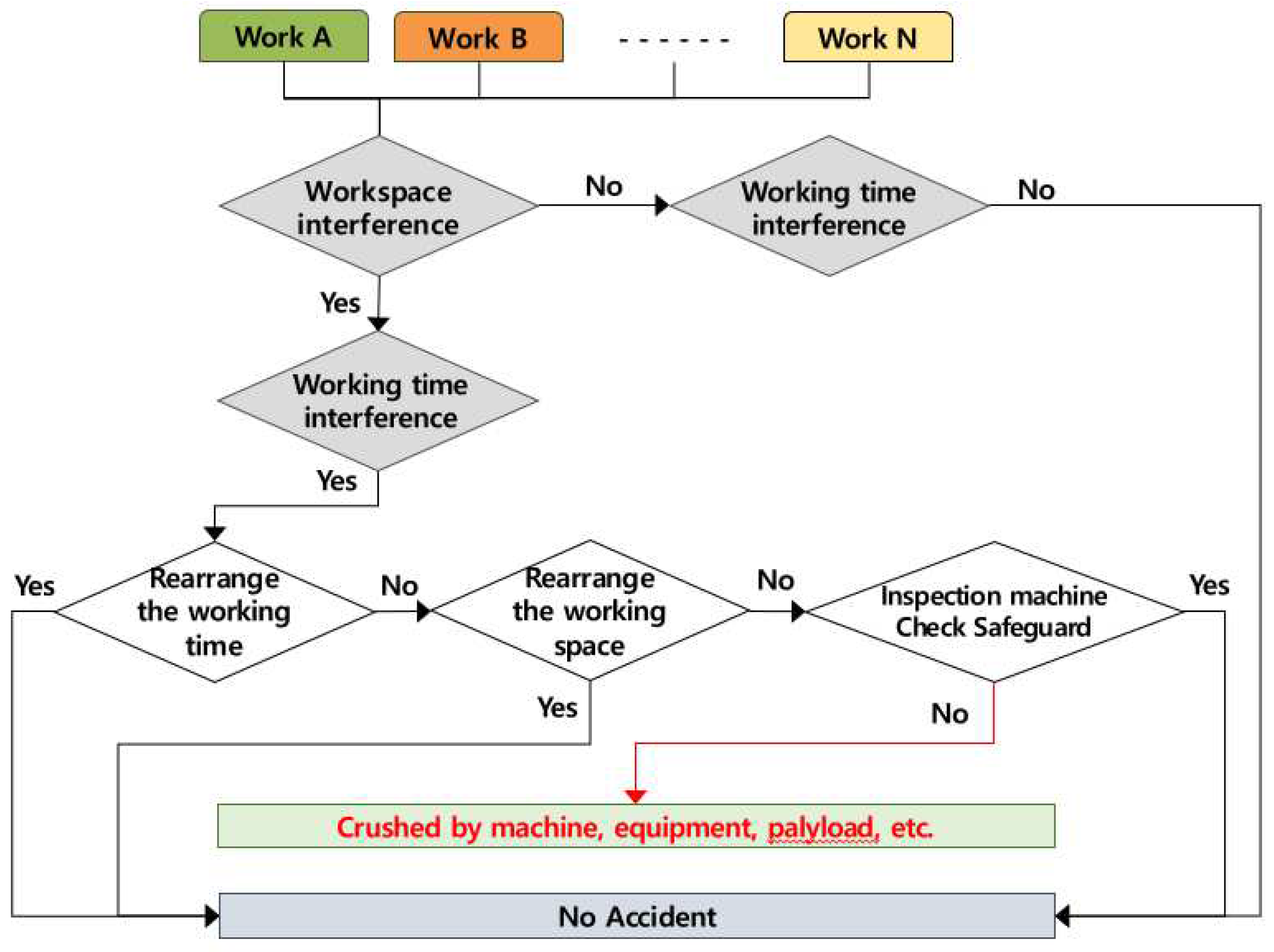

4.6. Occurring Mechanism of Being Crushed by Machinery, Equipment, Payload, etc.

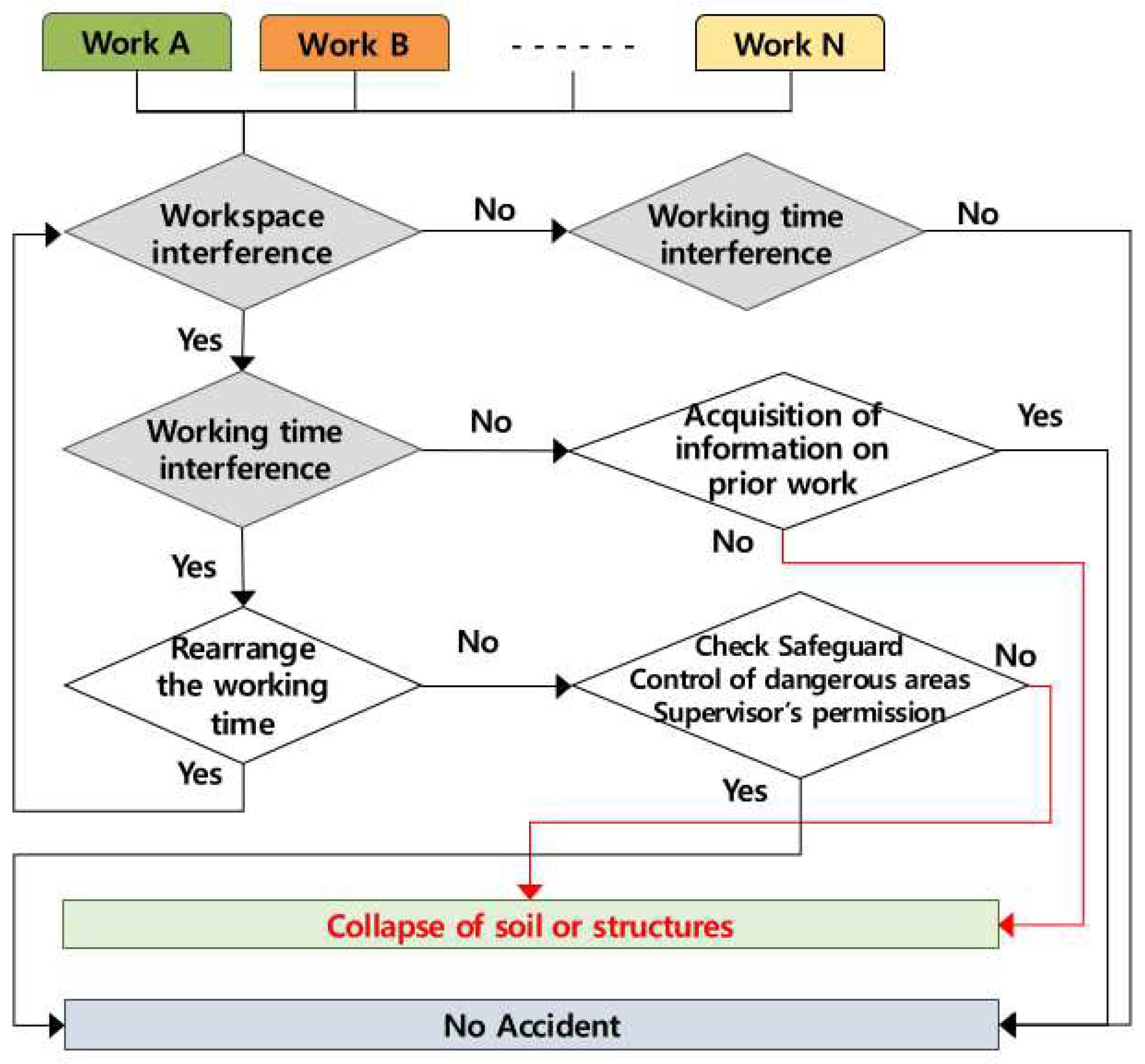

4.7. Occurring Mechanism of Collapse of Soil and Sand and Payload

4.8. Occurring Mechanism of Suffocation and Poisoning by Toxic Gas

5. Conclusions

- (1)

- According to the developed accident occurring mechanism, the accidents of ‘being caught in equipment or machinery’, ‘collision with vehicles for unloading and transporting and construction machines’, and ‘falling and being crushed by machinery or equipment’ occur in the same workspace and working time, while ‘fire and explosion’, ‘fall accidents’, and ‘collapse of soil and sand and payload’ occur in the same workspace regardless of the working time. In addition, it was found that ‘being struck by an object’ occurs in the condition of works being conducted at the same time rather than being conducted in the same space, and ‘suffocation and poisoning’ occur in the condition of works either being in the same workspace or being conducted at the same time.

- (2)

- It was found that the role of the contractor is important for the reduction of risk of industrial accidents caused by multiple processes. The common role of the contractor in every accident type is to adjust the working time or separate the workspace, and to check the safety measures before proceeding with the work. If the works are conducted successively in the same space, it is necessary to give the information of the preceding work and notify the completion of the preceding work to the successive work, and to clean the environment of the workplace.

- (3)

- The major safety measures to be taken by the contractor for each of the 8 types of accidents caused by multiple processes were drawn as follows. If there is a risk of ‘fire and explosion’, the contractor must check if inflammable gas was generated in the preceding work conducted in the same place, and if there is inflammable gas, the contractor has to make sure that it has been removed. If the works are conducted at the same time, the working time must be adjusted. If there is a risk of ‘being caught in machinery, equipment, etc.’, the working time must be adjusted. If it is impossible to adjust the working time, the contractor must instruct the facility operator to share the information on the starting and end times of the works to the other workers, take the safety measures, and assign a watchman. If there is a risk of ‘collision with construction machine’ and ‘being crushed by machinery or equipment’, the contractor must adjust the working time and workspace and must check the safety of machinery and equipment. In the case of ‘fall accidents’ and ‘collapse of soil and sand and payload’, the contractor must check the preceding work and then inform the workers of the successive work of the safety information generated in the preceding work. In the case of ‘being struck by a flying or falling object’, the contractor must approve working only after checking the installation of safety devices such as a safety net against falling objects, as damage may be caused by an object falling or flying from an adjacent space rather than from the same space. Lastly, in the case of ‘suffocation and poisoning by toxic gas’, if it is impossible to adjust the working time, the contractor must check the concentration of toxic gas in the workspace after the completion of the preceding work and must take the safety measures in the toxic gas intake passage, in order to prevent the intake of toxic gas due to the adjacent work.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moon, H.; Kim, H.; Kim, C.; Kang, L. Development of a schedule-workspace interference management system simultaneously considering the overlap level of parallel schedules and workspaces. Autom. Constr. 2013, 39, 93–105. [Google Scholar] [CrossRef]

- Gwak, H.-S.; Shin, W.-S.; Park, Y.-J. Space-constrained scheduling optimization method for minimizing the effects of stacking of Trades. Appl. Sci. 2021, 11, 11047. [Google Scholar] [CrossRef]

- Tao, S.; Wu, C.; Hu, S.; Xu, F. Construction project scheduling under workspace interference. Comput. Aided Civ. Infrastruct. Eng. 2020, 35, 923–946. [Google Scholar] [CrossRef]

- Charles, I.; Nasiri, F.; Hammad, A. Construction workspace management: Critical review and roadmap. Int. J. Constr. Manag. 2022, 22, 1960–1973. [Google Scholar]

- Staub-French, S.; Khanzode, A. 3D and 4D modeling for design and construction coordination: Issues and lessons learned. J. Inf. Technol. Const. (ITcon) 2007, 12, 381–407. [Google Scholar]

- Choi, B.; Lee, H.-S.; Park, M.; Cho, Y.K.; Kim, H. Framework for work-space planning using four-dimensional BIM in construction projects. J. Constr. Eng. Manag. 2014, 140, 4014041. [Google Scholar] [CrossRef]

- Kang, S.-Y.; Min, S.; Kim, W.-S.; Won, J.-H.; Kang, Y.-J.; Kim, S. Types and Characteristics of Fatal Accidents Caused by Multiple Processes in the Workplace: Based on Actual Cases in South Korea. Int. J. Environ. Res. Public Health 2022, 19, 2047. [Google Scholar] [CrossRef]

- Kim, J.; Kang, K.-S. Improving domestic institutional research through the International Safety Management Practices - Focusing on safety and health management in Japan. J. Korea Saf. Manag. Sci. 2015, 17, 77–86. [Google Scholar]

- Japan Ministry of Health, Labour and Welfare. Database Service such as Ministry of Health, Labor and Welfare Laws. 2021. Available online: https://www.mhlw.go.jp/hourei/ (accessed on 2 September 2021).

- Ministry of Labour and Social Inclusion. Arbeidsmiljøloven. 2015. Available online: https://www.regjeringen.no/no/tema/arbeidsliv/arbeidsmiljo-og-sikkerhet/innsikt/arbeidsmiljoloven/id447107/ (accessed on 2 September 2021).

- United Kingdom Department of Work and Pensions. The Construction (Design and Management) Regulations, CDMR. 2015. Available online: https://www.hse.gov.uk/construction/cdm/2015/index.htm (accessed on 4 September 2021).

- Germany Federal Ministry of Justice. Act on the Implementation of Measures of Occupational Safety and Health to Encourage Improvements in the Safety and Health Protection of Workers at Work (Arbeitsschutzgesetz, ArbSchG). 2021. Available online: https://www.gesetze-im-internet.de/arbschg/ (accessed on 2 September 2021).

- Germany Deutsche Gesetzliche Unfallversicherung. Rules, Regulations and Informations: DGUV Regulation 2. 2021. Available online: https://www.dguv.de/en/prevention/rules_regulations/index.jsp (accessed on 3 September 2021).

- Korea Ministry of Employment and Labor. Occupational Safety and Health Act, Article 68 Safety and Health Coordinators. 2020. Available online: https://www.law.go.kr/LSW/lsInfoP.do?lsiSeq=219125&chrClsCd=010203&urlMode=engLsInfoR&viewCls=engLsInfoR#0000 (accessed on 15 September 2021).

- Ganah, A.A.; John, G.A. BIM and project planning integration for on-site safety induction. J. Eng. Design Technol. 2017, 15, 341–354. [Google Scholar] [CrossRef]

- Martínez-Aires, M.D.; López-Alonso, M.; Martínez-Rojas, M. Building information modeling and safety management: A systematic review. Saf. Sci. 2018, 101, 11–18. [Google Scholar] [CrossRef]

- Pham, K.-T.; Vu, D.-N.; Hong, P.L.H.; Park, C. 4D-BIM-Based Workspace Planning for Temporary Safety Facilities in Construction SMEs. Int. J. Environ. Res. Public Health 2020, 17, 3403. [Google Scholar] [CrossRef] [PubMed]

- Fargnoli, M.; Lombardi, M. Building information modelling (BIM) to enhance occupational safety in construction activities: Research trends emerging from one decade of studies. Build 2020, 10, 98. [Google Scholar] [CrossRef]

- Ganah, A.; John, G.A. Integrating building information modeling and health and safety for onsite construction. Saf. Health Work 2015, 6, 39–45. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- He, Y.; Cui, J.; Liu, F.; Zhu, C. Risk-based quality accident ranking approach using failure mechanism and axiomatic domain mapping. Total Qual. Manag. Bus. Excell. 2018, 31, 847–868. [Google Scholar] [CrossRef]

- Michael, B.; Arthur, S. Application of the Loughborough Construction Accident Causation model: A framework for organizational learning. Constr. Manag. Econ. 2013, 31, 580–595. [Google Scholar]

- Winge, S.; Alberchtsen, E.; Mostue, B.A. Causal factors and connections in construction accidents. Saf. Sci. 2019, 112, 130–141. [Google Scholar] [CrossRef]

- Bellamy, L.J.; Ale, B.J.M.; Geyer, T.A.W.; Goossens, L.H.J.; Hale, A.R.; Oh, J.; Mud, M.; Bloemhof, A.; Papazoglou, I.A.; Whiston, J.Y. Storybuilder—A tool for the analysis of accident reports. Reliab. Eng. Syst. Saf. 2007, 92, 735–744. [Google Scholar] [CrossRef]

- Ale, B.J.M.; Bellamy, L.J.; Baksteen, H.; Damen, M.; Goossens, L.H.J.; Hale, A.R.; Mud, M.; Oh, J.; Papazoglou, I.A.; Whiston, J.Y. Accidents in the construction industry in the Netherlands: An analysis of accident reports using Storybuilder. Reliab. Eng. Syst. Saf. 2008, 93, 1523–1533. [Google Scholar] [CrossRef]

- Xu, Q.; Xu, K. Statistical Analysis and Prediction of Fatal Accidents in the Metallurgical Industry in China. Int. J. Environ. Res. Public Health 2020, 17, 3790. [Google Scholar] [CrossRef]

- Zhang, J.; Bian, H.; Zhao, H.; Wang, X.; Zhang, L.; Bai, Y. Bayesian Network-Based Risk Assessment of Single-Phase Grounding Accidents of Power Transmission Lines. Int. J. Environ. Res. Public Health 2020, 17, 1841. [Google Scholar] [CrossRef]

- Huang, Y.-J.; Tao, J.; Yang, F.-Q.; Chen, C. Construction Safety during Pandemics: Learning from the Xinjia Express Hotel Collapse during COVID-19 in China. Int. J. Environ. Res. Public Health 2021, 18, 11498. [Google Scholar] [CrossRef] [PubMed]

- Fang, M.; Zhang, Y.; Zhu, M.; Chen, S. Cause Mechanism of Metro Collapse Accident Based on Risk Coupling. Int. J. Environ. Res. Public Health 2022, 19, 2102. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Meng, X.; Hassall, M.; Li, X. Accident-causing mechanism in coal mines based on hazards and polarized management. Saf. Sci. 2016, 85, 276–281. [Google Scholar] [CrossRef]

- Carrillo-Castrillo, J.; Trillo-Cabello, A.; Rubio-Romero, J. Construction accidents: Identification of the main associations between causes, mechanisms and stages of the construction process. Int. J. Occup. Saf. Ergon. 2016, 23, 240–250. [Google Scholar] [CrossRef] [PubMed]

- Zwęgliński, T. Conventional Event Tree Analysis on Emergency Release of Liquefied Natural Gas. Int. J. Environ. Res. Public Health 2022, 19, 2961. [Google Scholar] [CrossRef] [PubMed]

| Article 64 Measures for Preventing Industrial Accidents in Contracting | |

|---|---|

| Paragraph 1 | A contractor shall take the following measures when employees of a relevant contractor work at his or her place of business: |

| No. 1 | Organizing and operating a council on safety and health consisting of a contractor and subcontractors |

| No. 2 | A routine inspection of the workplace |

| No. 3 | Supporting safety and health education that a relevant subcontractor provides to his or her employees pursuant to Article 29 (1) through (3), including providing the place and materials for such education |

| No. 4 | Verifying the conduct of safety and health education that a relevant subcontractor provides to his or her employees pursuant to Article 29 (3) |

| No. 5 | Operating a warning system, conducting evacuation drills, etc., in preparation for any of the following cases: (a) Where explosives are set for blasting at a work site (b) Where fire, explosion, collapse of soil, structures, etc., an earthquake, or any other accident occurs at a work site |

| No. 6 | Providing places necessary to install facilities, etc., prescribed by Ordinance of the Ministry of Employment and Labor, such as sanitary facilities, or cooperating in the use of sanitary facilities installed by a contractor |

| No. 7 | Confirming the work period and contents of the subcontractor, etc., safety measures, health measures, etc., in the work of a contractor and a subcontractor or subcontractors in the same workplace |

| No. 8 | Adjusting the work period and contents of the subcontractors, etc., if there is a risk that a risk prescribed by Presidential Decree, such as fire or explosion, may occur due to the multiple processes in the workplace of related recipients, etc., according to the result of the confirmation of No. 7. |

| Step | Classification | Decision Criteria | Notation |

|---|---|---|---|

| A | Stakeholder relationship | Accidents between a contractor and a subcontractor Accidents between subcontractors | |

| B | Process interference | Accidents caused by other processes Accidents caused by two or more operations within a process | |

| C | Workspace interference | Accidents occurring in the same workspaces Accidents occurring in adjacent workspaces | |

| Working time interference | Accidents occurring during the same working time Accidents caused by the previous process affecting continuous working time |

| Accident Type | Risk of Fatal Accidents due to Multiple Processes in the Workplace by Industry | Interference Characteristics | |

|---|---|---|---|

| Space | Time | ||

| Caught in equipment or machinery | When working with operating (powered on) equipment or machinery, there is a risk of interference with other operations performed in the same workplace at the same time. | Same workplace | Work at the same time |

| Collision | Risk arises when other operations are simultaneously interfered with within the working radius or movement range of the equipment, machinery, or means of transport used during the process. | Same workplace | Work at the same time |

| Struck by the object | When equipment, machinery, parts, or materials that have been displaced during work fly into or fall into another workspace where they are performed at the same time. | Upper and lower workplace or adjacent workplace | Work at the same time |

| Fire or explosion | Risk of interference when welding and cutting by operating equipment or machines at the same time in a workplace that uses inflammable substances or combustible gas. | Same workplace | Work at the same time |

| Crushed | Risk of interference if equipment, machinery, parts, materials, or vehicles fall over during work or at the same time invade the work area being carried out in the workplace. | Same workplace | Work at the same time |

| Fall | When equipment, machinery, parts, materials, or structures used for other work interfere with the working space of the worker and cause a fall. | Same workplace | Work at the same time or successive temporal relationships |

| Collapse | When a region or all of a part, material, or structure collapses and spills out and at the same time invades the workplace being carried out in the same place. | Same workplace | Work at the same time |

| Etc. | When performing other work in a space where oxygen deprivation or toxic gases that may cause suffocation or poisoning have accumulated or injected for work. | Same workplace | Work at the same time or successive temporal relationships |

| Year | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|

| Caught in equipment or machinery | 20 | 17 | 19 | 22 | 29 |

| Collision | 24 | 15 | 20 | 23 | 23 |

| Struck by the object | 11 | 15 | 10 | 18 | 17 |

| Fire or explosion | 9 | 3 | 2 | 3 | 36 |

| Crushed | 4 | 8 | 7 | 12 | 9 |

| Fall | 4 | 3 | 7 | 1 | 4 |

| Collapse | 2 | 3 | 2 | 2 | 7 |

| Others | 3 | 2 | 5 | 4 | 1 |

| Total | 77 | 66 | 72 | 85 | 126 |

| Industrial Accident Occurrence Process | Same Space Work (○, x) | Same Time Work (○, x) | Safety and Health Measures of Contractor against Accidents Caused by Multiple Processes |

|---|---|---|---|

| Air leaked during blind patch bolt locking operation of By-Pass Filter Tank airtight test. Bolt locking work and compressed air injection work were carried out at the same time. →By-Pass Filter Tank explosion caused subcontractor worker’s death | ○ | ○ | Supervise to ensure that both hazardous operations do not occur at the same time (bolt locking, compressed air injection) |

| The snuff occurred during welding work by a daily employed weld worker belonging to a contractor. Fires in insulation due to the snuff→Many workers working on other jobs died. | ○ | ○ | If the welding work is performed in the same place or on the same floor, the welding work is finished and another operation is performed. If work needs to be done on another floor, check safeguard and the placement of fire watchman |

| Welding and painting work were carried out simultaneously. Welding sparks scattered in combustible gas generated from painting and exploded→Subcontractor worker’s death. | ○ | ○ | Adjust welding working time or separate it from other work. When welding and other work are performed at the same time, a supervisor is arranged to check the explosion hazard factors in advance and implement ventilation. |

| Combustible gas accumulated in the workplace due to another work performed before welding work→ Worker death due to explosion caused by welding work. | ○ | x | When welding and other work are performed at the same time, a supervisor is arranged to check the explosion hazard factors in advance and implement ventilation. |

| Industrial Accident Occurrence Process | Same Space Work (○, x) | Same Time Work (○, x) | Safety and Health Measures of Contractor against Accidents Caused by Multiple Processes |

|---|---|---|---|

| The subcontractor’s worker used the machine and equipment owned by the contractor to work → The subcontractor’s worker died by being caught in machinery and equipment while working. | ○ | ○ | The contractor must check the protective measures for machinery and equipment before the subcontractor performs the work. Working in pairs of two. |

| The contractor’s machinery and equipment suddenly operated while the subcontractor’s worker performed maintenance/inspection/repair/repair/cleaning of the machine and equipment → The subcontractor’s worker died from being caught in machinery and equipment. | ○ | ○ | Procedures should be established to ensure that machinery and equipment are not operated until work is completed. Notify when subcontractor’s work is complete. |

| Although the machine and equipment inspection work was not completed, the contractor’s driver decided the work had been completed and operated → The subcontractor’s worker died from being caught in machinery and equipment. | ○ | ○ | The communication of information on completion about inspection of machinery and equipment and the operating system should be confirmed, and machine inspection and operating time should be separated. |

| When worker had replaced the sensor in the upper part of the injection molding machine, another worker operated the overhead crane for transport → The contractor worker died from being caught in machinery and equipment. | ○ | ○ | If the worker does other work within the working range of the overhead crane, the crane work must be stopped. |

| The contractor’s industrial robot malfunctioned → Subcontractor’s worker died by hitting the industry robot. | ○ | ○ | Industrial robot must be inspected. |

| Industrial Accident Occurrence process | Same Space Work (○, x) | Same Time Work (○, x) | Safety and Health Measures of Contractor against Accidents Caused by Multiple Processes |

|---|---|---|---|

| Excavator was used to transport soil → A subcontractor worker performed a wire clean up after a sleeve work was hit by an excavator and died. | ○ | ○ | Working time must be adjusted. If it is impossible to adjust the working time, a signal man must be allocated and workers must be prohibited from entering within the working area of the excavator. |

| The subcontractor’s construction machinery was going backwards → A worker got caught and died during cleanup. | ○ | ○ | Working time and workplace must be adjusted. Must check signal man arrangement plan. |

| Workers carried out waste loading by operating excavators and dump trucks → A subcontractor worker while cleaning up residue was hit and died. | ○ | ○ | Since it is difficult to separate the working time and space, the signal system and the signal man arrangement plan should be checked before work. |

| Excavator overturned while moving on a slope → A worker died while working on a water pipe splicing. | ○ | ○ | Working time should be adjusted to stop other work during excavator moving work. |

| Industrial accident Occurrence Process | Same Space Work (○, x) | Same Time Work (○, x) | Safety and Health Measures of Contractor against Accidents Caused by Multiple Processes |

|---|---|---|---|

| Fracture of contractor’s machinery and equipment, failure of safety devices → Subcontractor worker fell to their death. | ○ | x | Since the contractor’s machinery and equipment used by the subcontractor are used in the same space, the contractor must inspect the machinery and equipment and confirm the safety certification before work. |

| The workbench installed by the contractor or other subcontractor broke off or fell off → The subcontractor worker who was working on the workbench fell and died. | ○ | x | Since the workbench installed by another subcontractor is used in the same space, it is necessary for the contractor to inspect the workbench safety before work. |

| Impacted by the material that fell out during the work of dismantling the Soil–Cement Wall → The signal man fell and died. | ○ | ○ | Examine the scope of impact of the work and check the plan, such as placement of signal numbers. |

| After dismantling the form, the form fell due to the falling off of the sling belt while moving → Another subcontractor worker on the scaffold fell due to the impact. | ○ | ○ | Temporarily separate the worker’s movement path from the work area during the lifting operation. |

| Industrial accident Occurrence Process | Same Space Work (○, x) | Same Time Work (○, x) | Safety and Health Measures of Contractor against Accidents Caused by Multiple Process |

|---|---|---|---|

| Part of the subcontractor worker’s equipment fell off → Another subcontractor worker who was working in the lower part of the workspace was struck by the object and died. | ○ | ○ | Safety measures against equipment falling off should be checked. |

| Breakage of lifting mechanism, malfunction of machinery and equipment, fall of lifting object → Another subcontractor worker who was working in the lower part of the workspace was struck by the object and died. | ○ | ○ | Arrangements should be made to temporarily prohibit workers from working in the lifting path. |

| The object of the subcontractor worker who was working on the upper part fell → Another subcontractor worker who was working in the lower part of the workspace was struck by the object and died. (The two workplaces are not on the same floor, but are placed vertically.) | x | ○ | After checking the measures to prevent falling objects in the upper work area, work must be done. |

| Industrial accident Occurrence Process | Same Space Work (○, x) | Same Time Work (○, x) | Safety and Health Measures of Contractor against Accidents Caused by Multiple Process |

|---|---|---|---|

| Moving material handling equipment collided with a loaded heavy object → The worker was crushed by a heavy load during inspection. | ○ | ○ | The time for inspection work must be adjusted while the heavy object is moving. |

| The heavy object piled up during the sculpture loading operation fell down → The worker who was working on the sculpture painting work was crushed. | ○ | ○ | Check work done within the impact range of heavy load and check safety measures. |

| The table foam being moved by the forklift collapsed → Workers working on the height adjustment of the form were crushed. | ○ | ○ | It is necessary to check the types of work performed in the moving work route in advance and check safety measures. |

| The crane fell down → The worker was crushed. | ○ | ○ | Machines and instruments must be inspected. |

| Industrial accident Occurrence Process | Same Space Work (○, x) | Same Time Work (○, x) | Safety and Health Measures of Contractor against Accidents Caused by Multiple Process |

|---|---|---|---|

| During maintenance work, an error occurred in communication between the contractor and the subcontractor; and it was insufficient to identify the load inside the tank → The worker was crushed and died due to the collapse of a heavy object during the maintenance work. | ○ | x | The contractor must communicate and confirm accurate information about the maintenance work to the subcontractor. |

| During the demolition work, the slab could not endure the load of the excavator and collapsed → A worker during the watering operation was buried and died. | ○ | ○ | During demolition work, it is necessary to check the measures to separate workers within the range of influence. |

| Industrial Accident Occurrence Process | Same Space Work (○, x) | Same Time Work (○, x) | Safety and Health Measures of Contractor against Accidents Caused by Multiple Process |

|---|---|---|---|

| Gas remained in the pipe → A worker who entered the pipe for welding work died from oxygen starvation. | ○ | × | Before welding, the work must be permitted after measuring the gas generated in the preceding work. |

| Nitrogen flew in from machine operation while working inside the cooling tower → Worker died due to a lack of oxygen. | x | ○ | It is necessary to permit work after preventing the inflow of gases such as nitrogen into the path leading to the enclosure. |

| Operation of vacuum chamber incomplete → Death from asphyxia. | ○ | ○ | After confirming that the number of workers put into the work matches the number of workers who came out after completing the work, the operation measures should be confirmed to operate the equipment. |

| Sulfuric acid leaked when entering the repair work area → Death due to burns. | ○ | ○ | Safety and health information should be provided to relevant contractors beforehand and risk prevention measures should be installed. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Won, J.-H.; Jeong, H.-J.; Kim, W.; Kim, S.; Kang, S.-Y.; Hwang, J.M. Mechanisms Analysis for Fatal Accident Types Caused by Multiple Processes in the Workplace: Based on Accident Case in South Korea. Int. J. Environ. Res. Public Health 2022, 19, 11430. https://doi.org/10.3390/ijerph191811430

Won J-H, Jeong H-J, Kim W, Kim S, Kang S-Y, Hwang JM. Mechanisms Analysis for Fatal Accident Types Caused by Multiple Processes in the Workplace: Based on Accident Case in South Korea. International Journal of Environmental Research and Public Health. 2022; 19(18):11430. https://doi.org/10.3390/ijerph191811430

Chicago/Turabian StyleWon, Jeong-Hun, Hyeon-Ji Jeong, WonSeok Kim, Seungjun Kim, Sung-Yong Kang, and Jong Moon Hwang. 2022. "Mechanisms Analysis for Fatal Accident Types Caused by Multiple Processes in the Workplace: Based on Accident Case in South Korea" International Journal of Environmental Research and Public Health 19, no. 18: 11430. https://doi.org/10.3390/ijerph191811430

APA StyleWon, J.-H., Jeong, H.-J., Kim, W., Kim, S., Kang, S.-Y., & Hwang, J. M. (2022). Mechanisms Analysis for Fatal Accident Types Caused by Multiple Processes in the Workplace: Based on Accident Case in South Korea. International Journal of Environmental Research and Public Health, 19(18), 11430. https://doi.org/10.3390/ijerph191811430