Global Challenges of Current Building-Integrated Solar Water Heating Technologies and Its Prospects: A Comprehensive Review

Abstract

:1. Introduction

- Clear overviews of multiple SWH system configurations, including direct and indirect, passive and active, and compact and split modes within both FPC- and ETC-SWH technologies;

- Concise comparisons of the performance of FPC- and ETC-SWH technologies that encompass several fundamental parameters;

- Technical challenges in FPC-SWH technology are thoroughly evaluated, particularly with regard to the collector’s mechanical dysfunctionality, pipe fouling due to the circulating fluids, pipe overheating, and heat losses;

- Technical challenges in different types of ETC-SWH technology are heavily assessed in terms of the malfunction hazards from the vacuumed space, collector overheating, potential glass tube burst, pipe corrosion, scaling formation in the glass tubes, and leakage problem;

- Economic barriers in both FPC- and ETC-SWH technologies are described based on a few countries from multiple continents with high initial costs and massive subsidies given to fossil fuels as the ultimate obstacles;

- Potential solutions to the stated challenges are proposed based on the support from governmental, industrial, and local players as well as on the application of thermal energy storage (TES) within the SWH systems;

- TES integration is extensively discussed in two separate components of the SWH system, i.e., the solar collector and the insulated water tank;

- The future research directions of SWH technologies are focused on the enhancement methods, TES materials, PVT systems, and the approaches to reducing solar thermal system pricing.

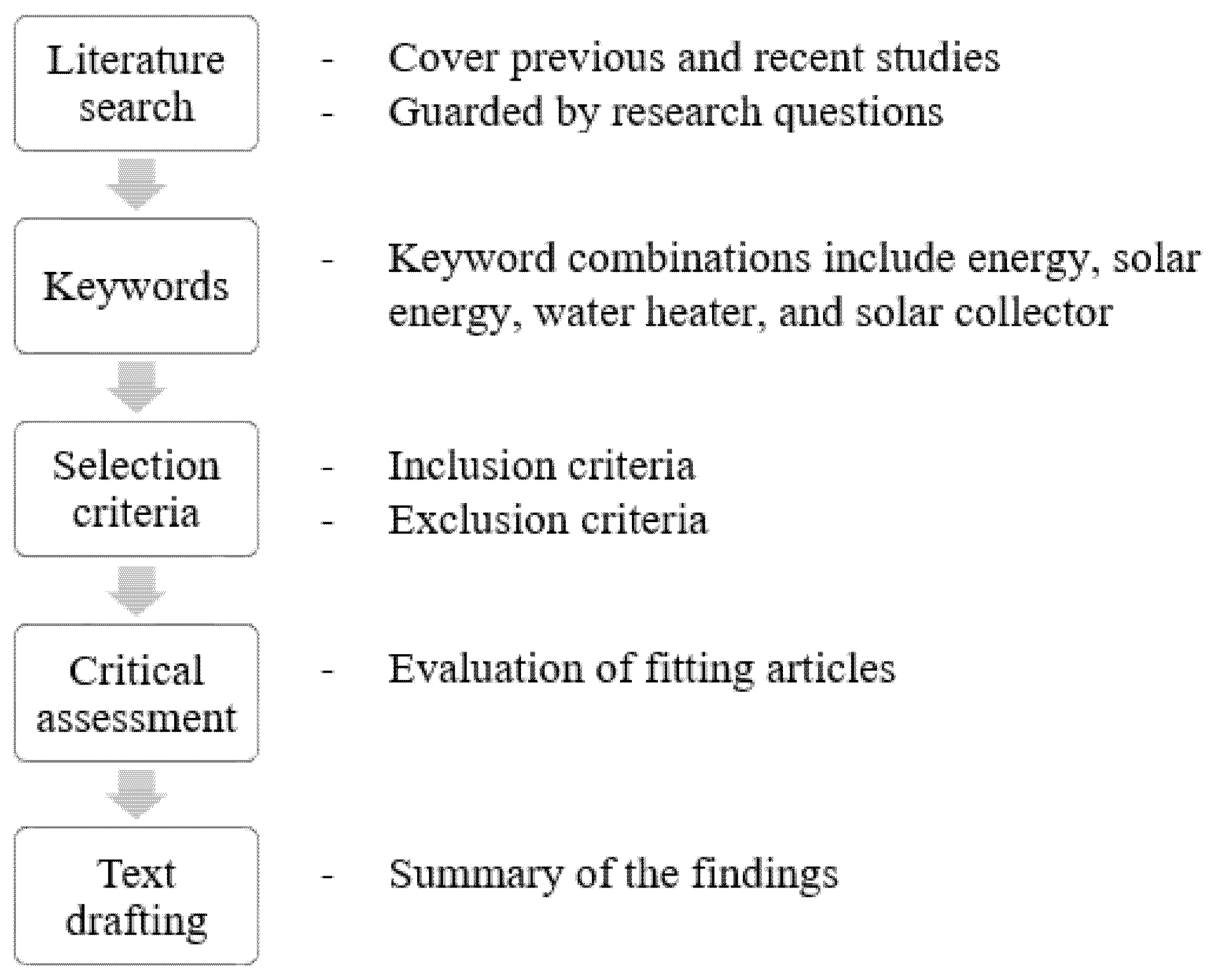

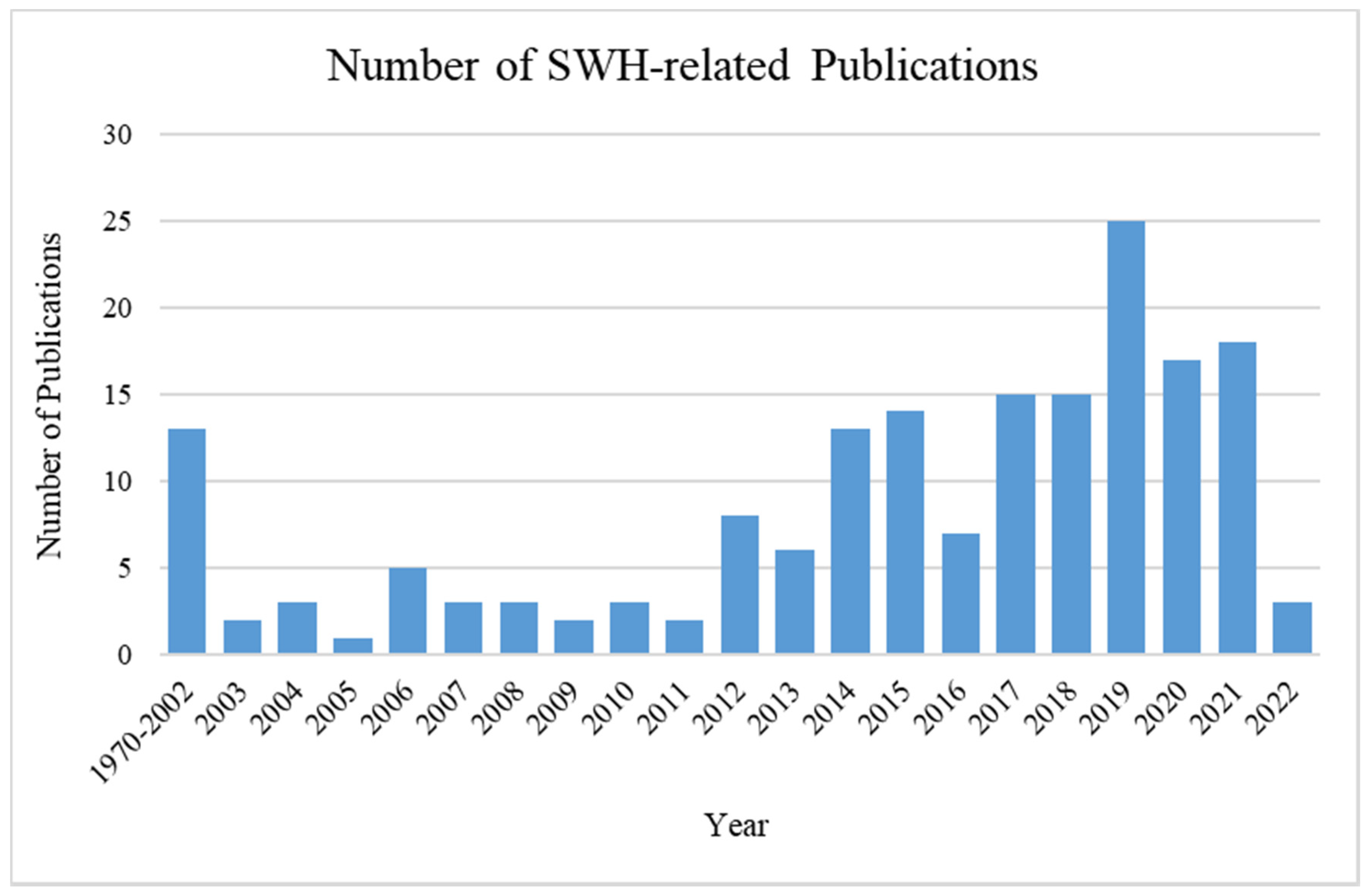

2. Methodology

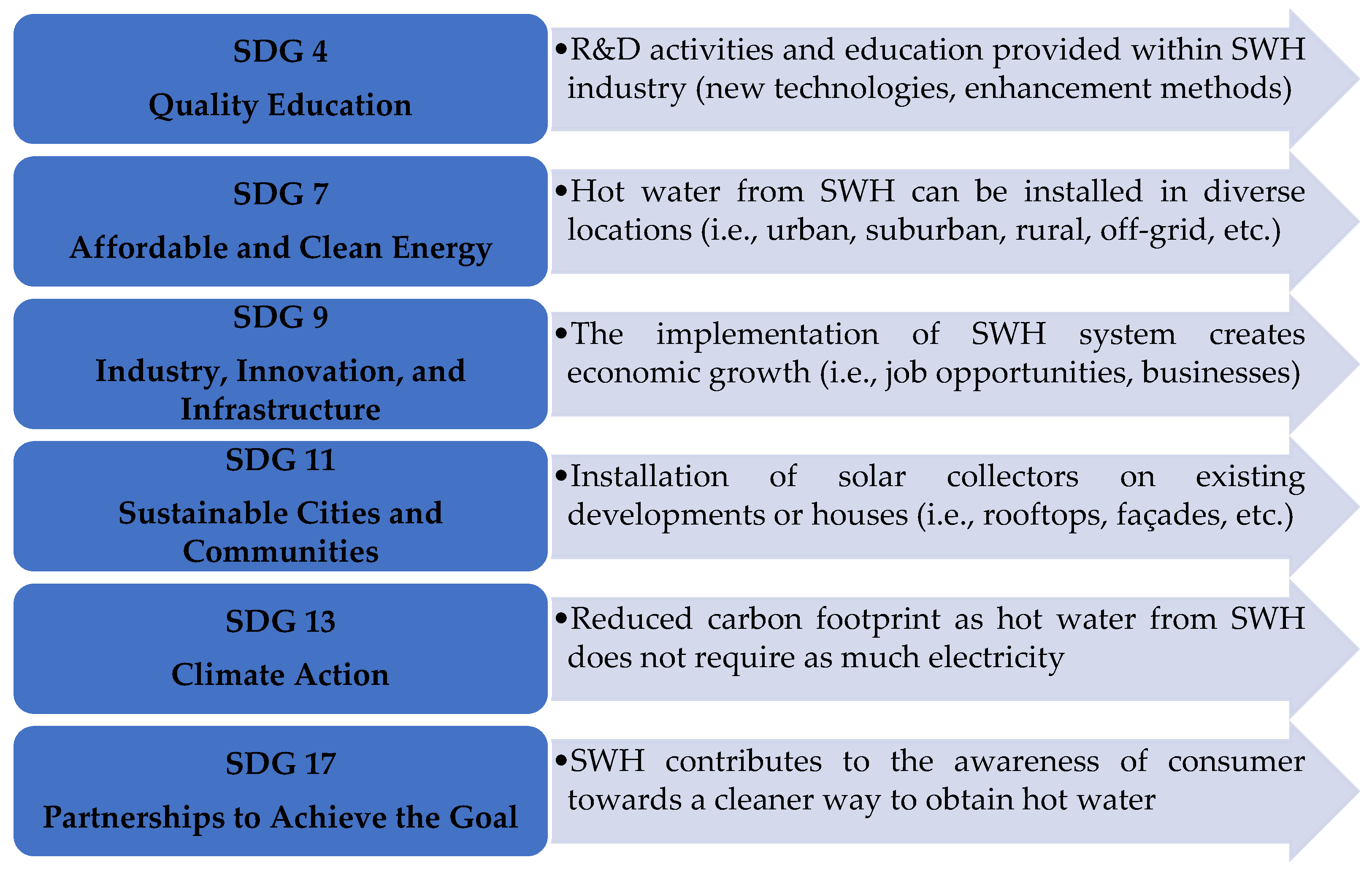

3. Prospects of Solar Water Heating Technology

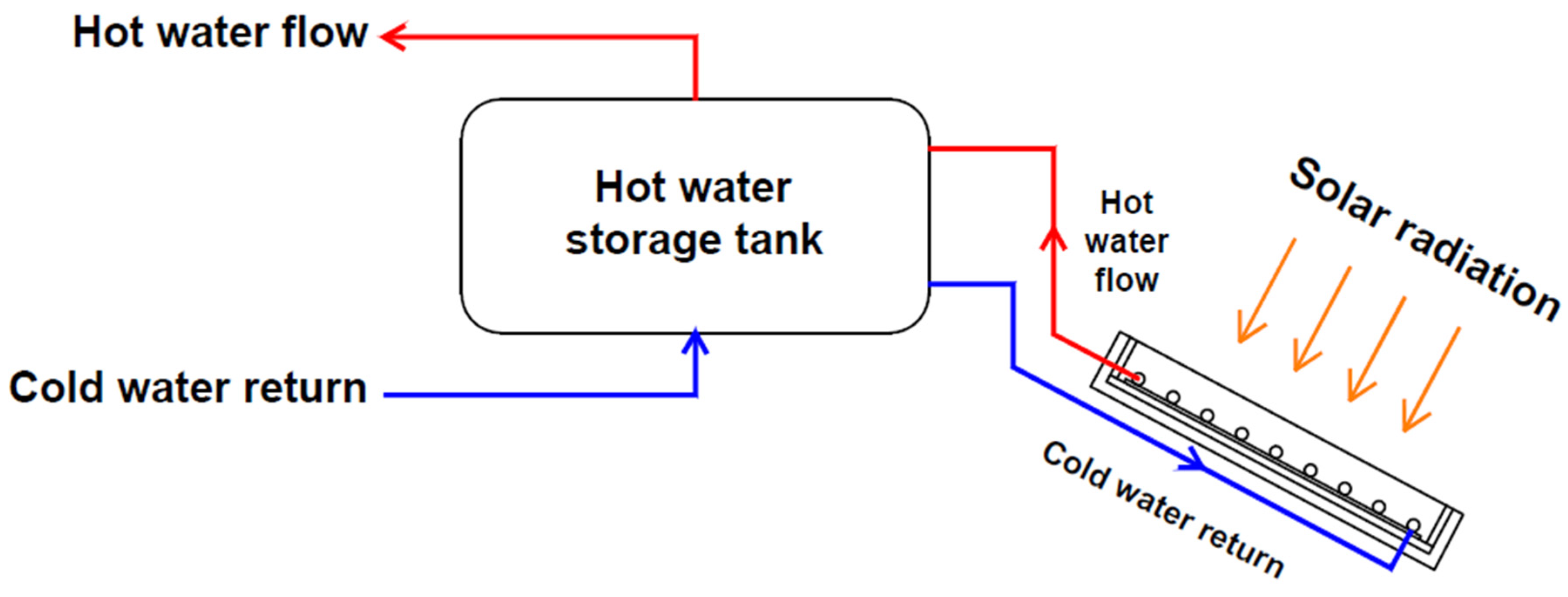

4. Solar Water Heating Technologies

4.1. Global Innovation of Solar Water Heating Technologies

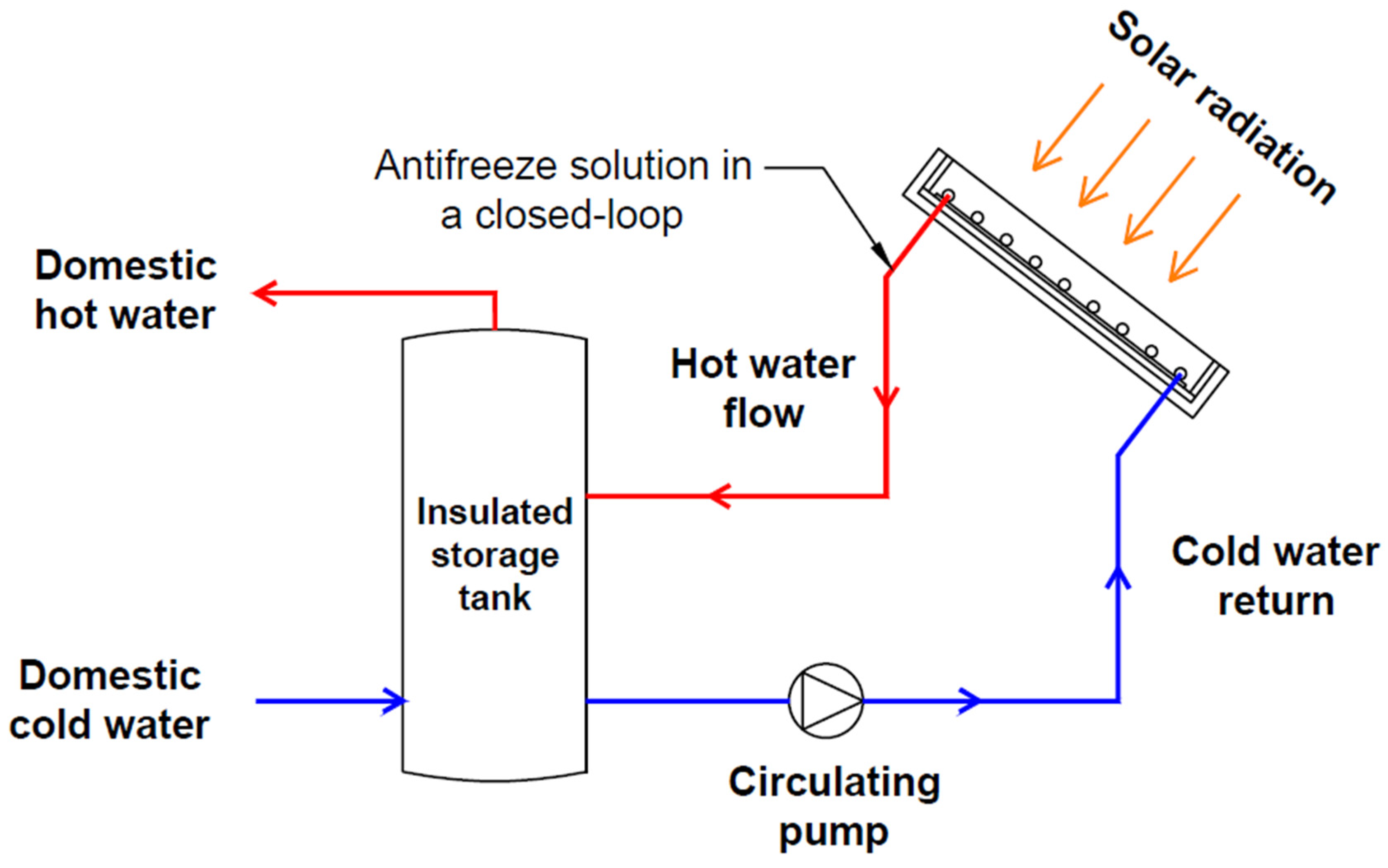

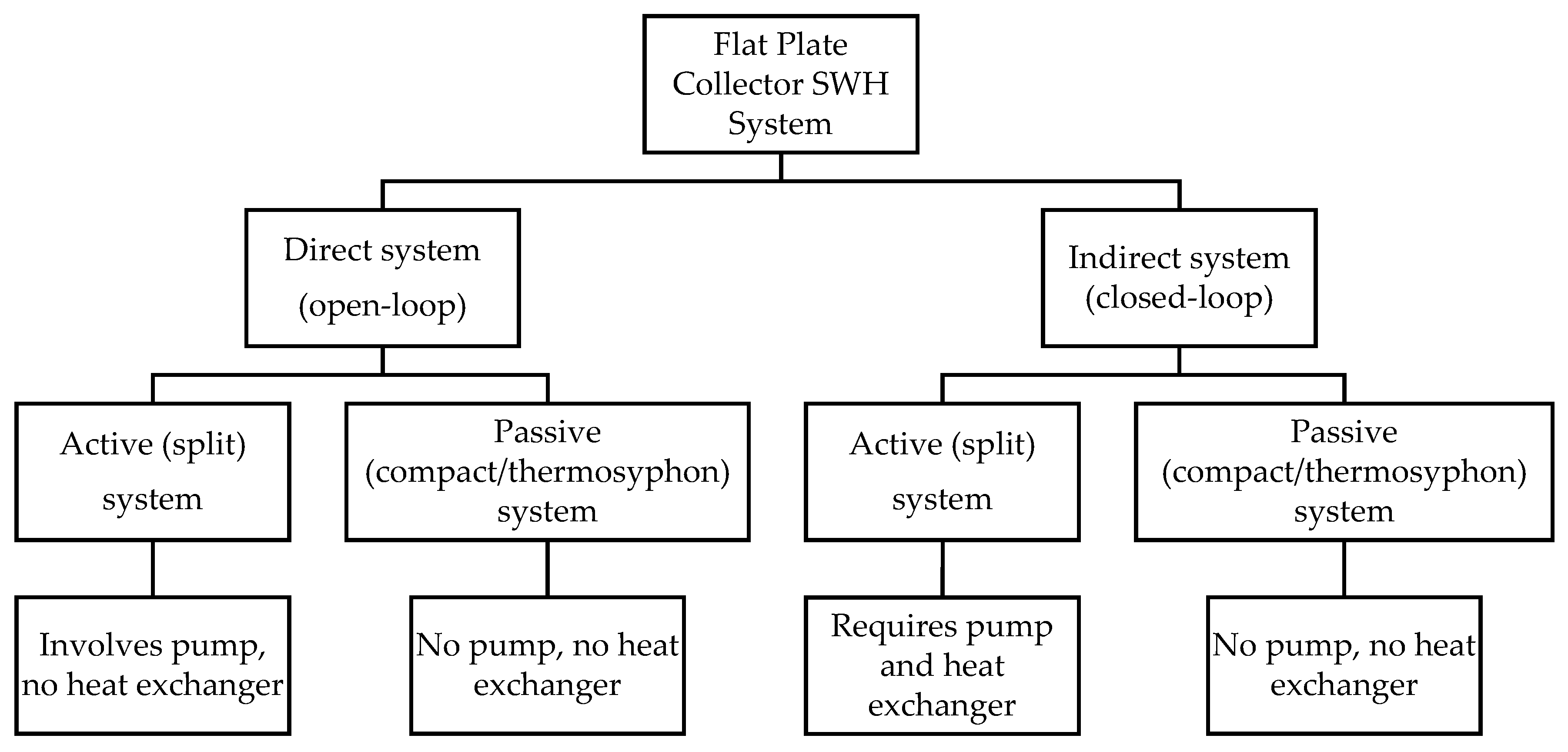

4.2. SWH System with Flat-Plate Collector (FPC)

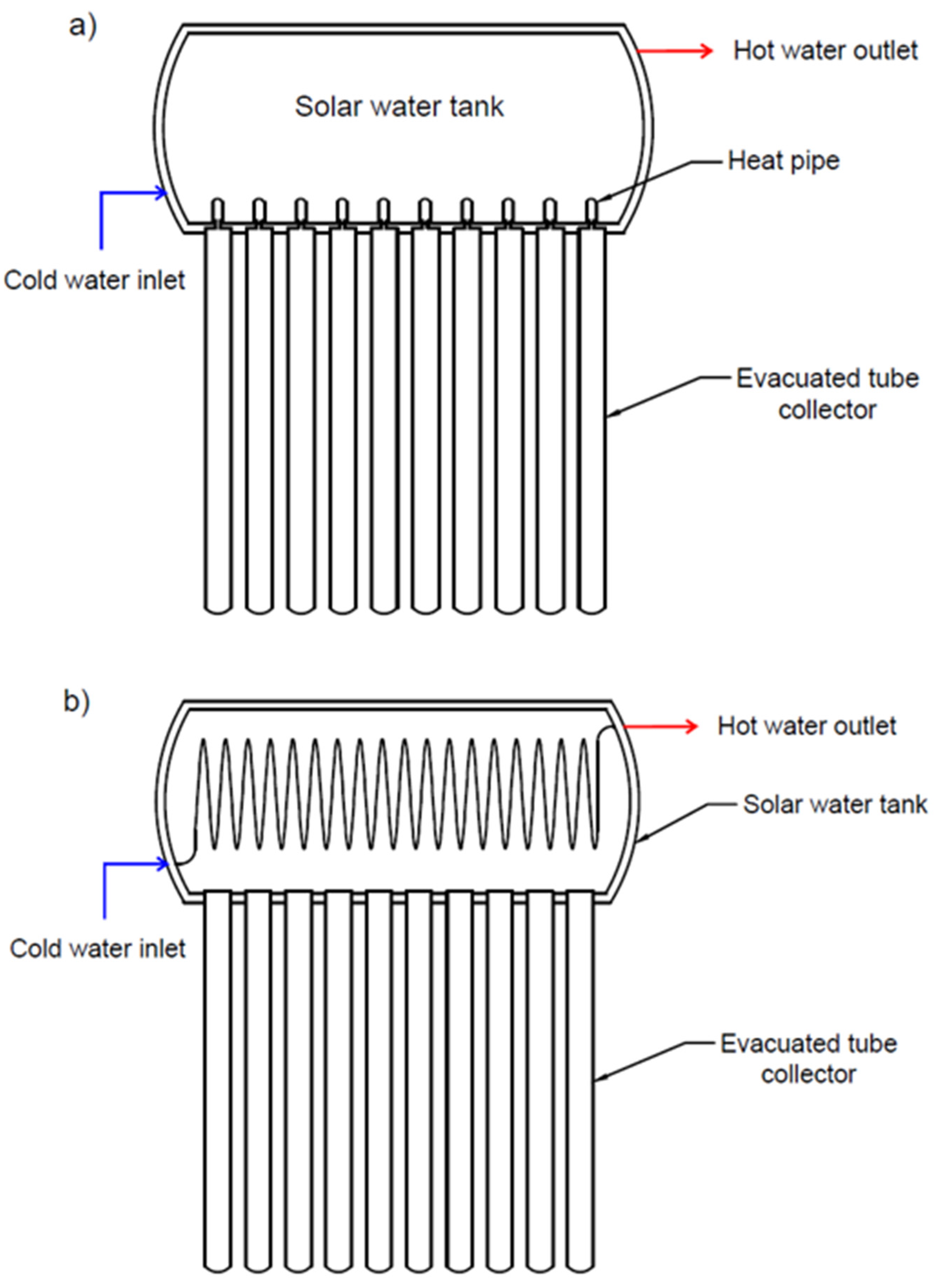

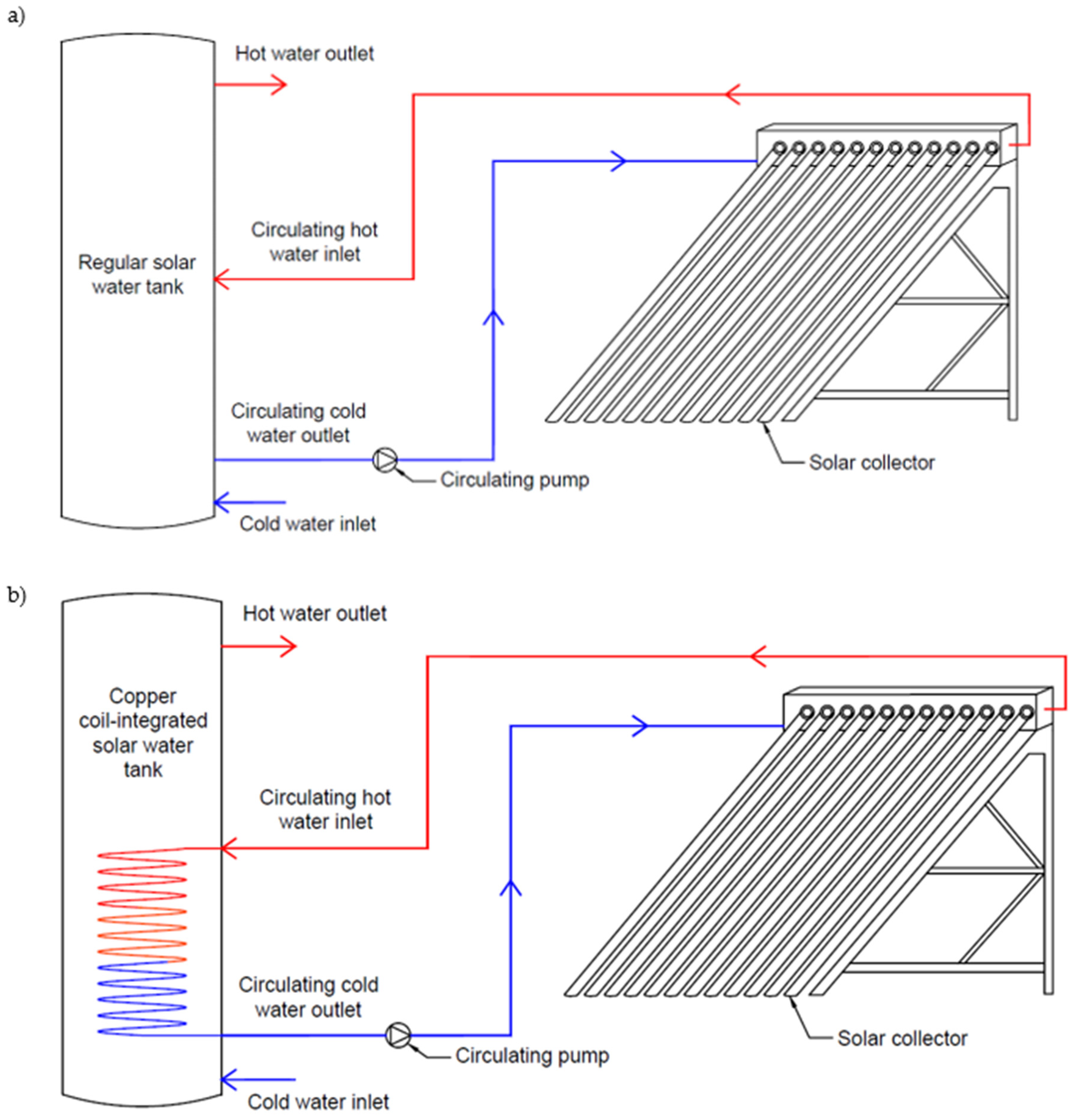

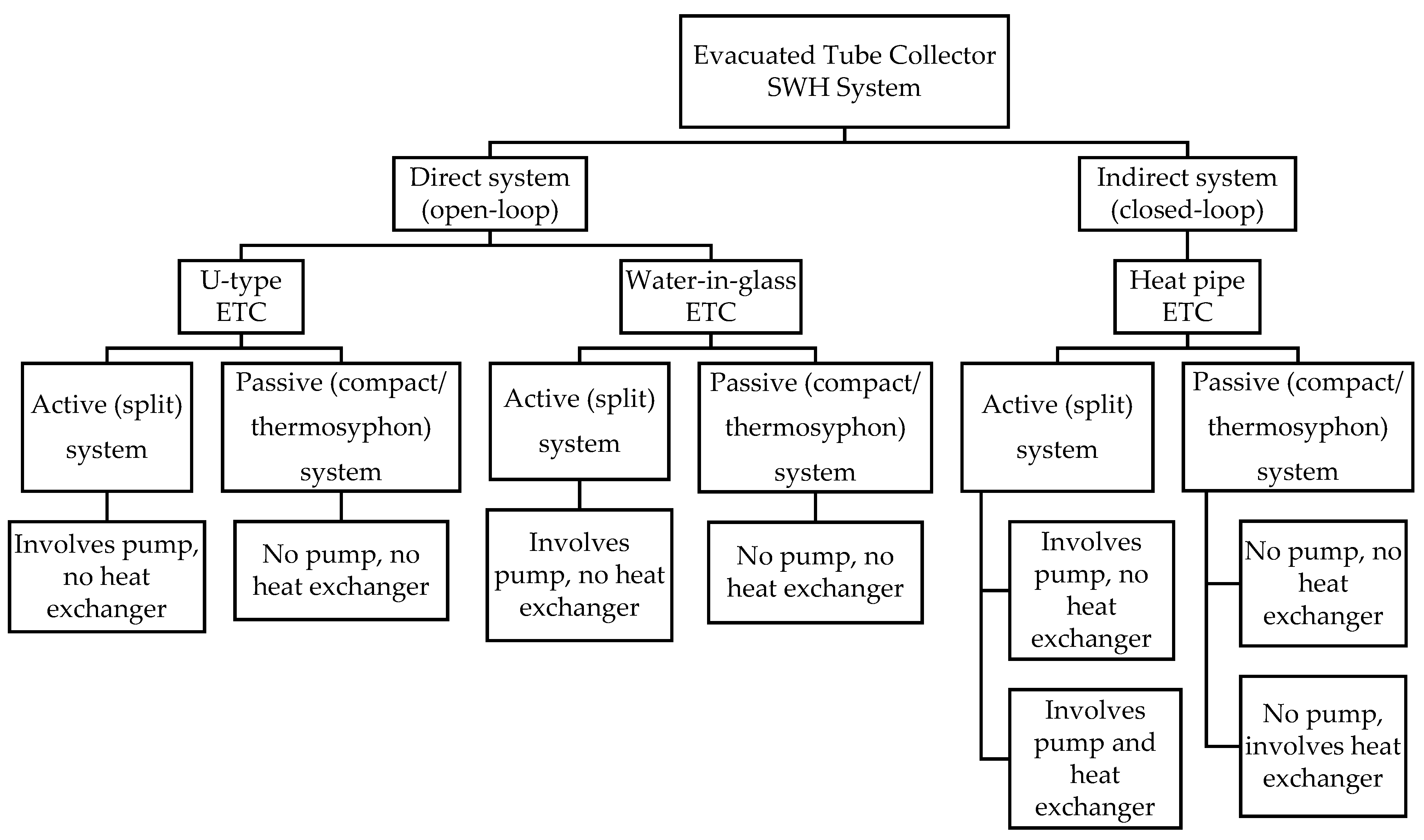

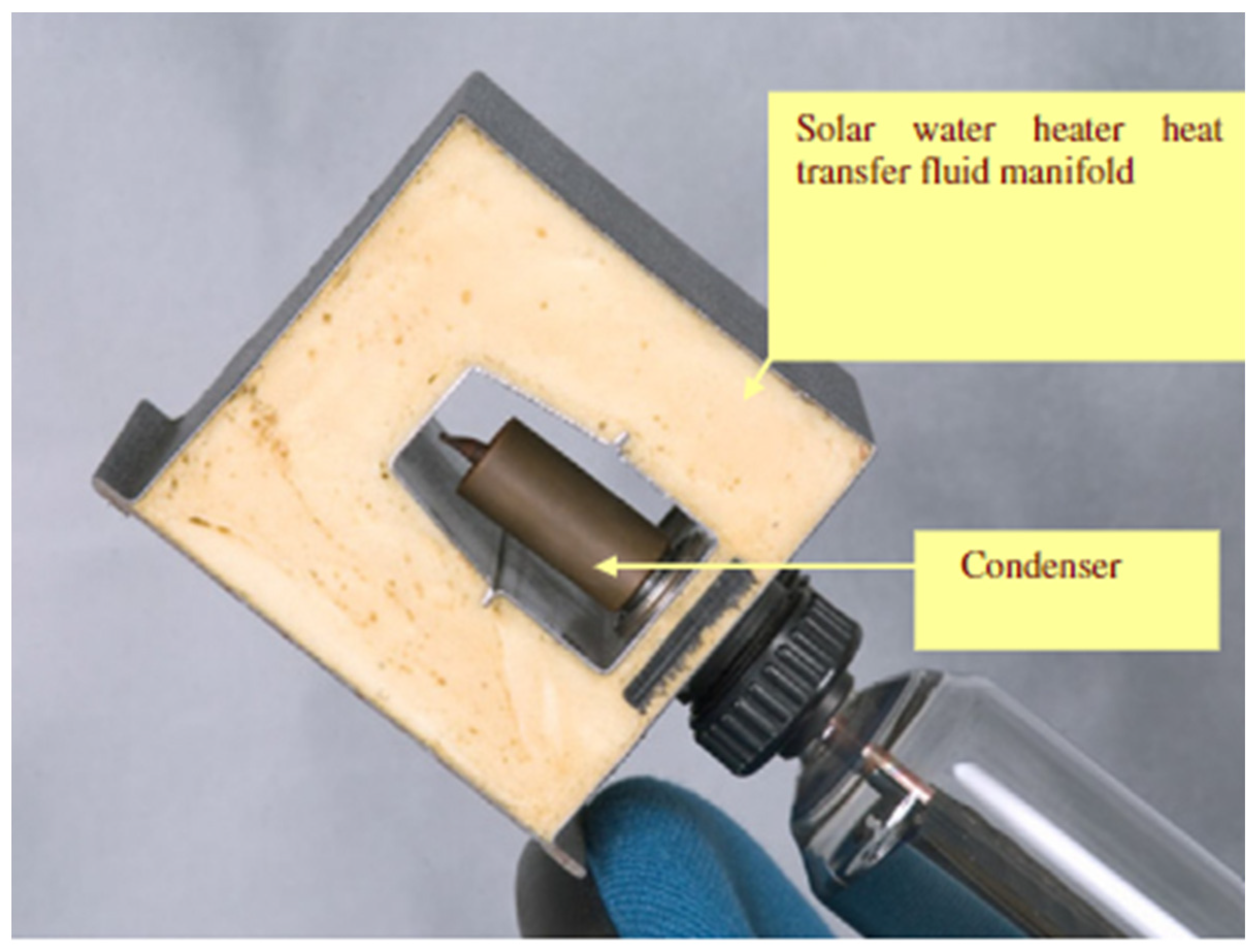

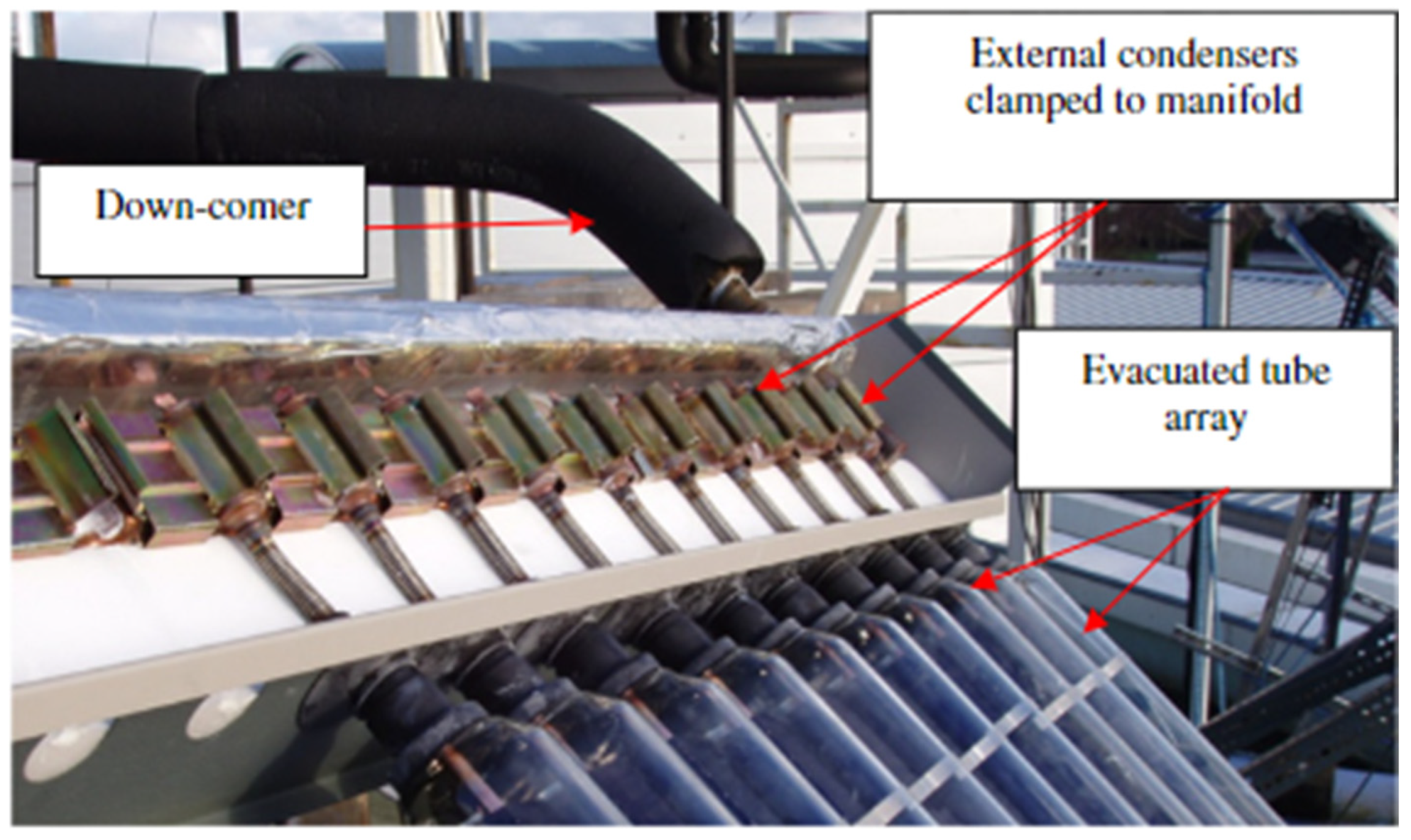

4.3. SWH System with Evacuated Tube Collector (ETC)

4.4. Overall Performance of SWH Technologies

5. Challenges in Solar Water Heating Technologies and Industry

5.1. Technical Challenges

5.1.1. Issues and Challenges in FPC Solar Water Heaters

5.1.2. Issues and Challenges in ETC Solar Water Heaters

5.2. Economic Challenges

6. Potential Solutions to the Challenges and Future Research Directions

6.1. Government, Industrial, and Local Level Support

6.2. Public Awareness

6.3. Low Initial Cost

6.4. Thermal Energy Storage (TES) in the SWH System

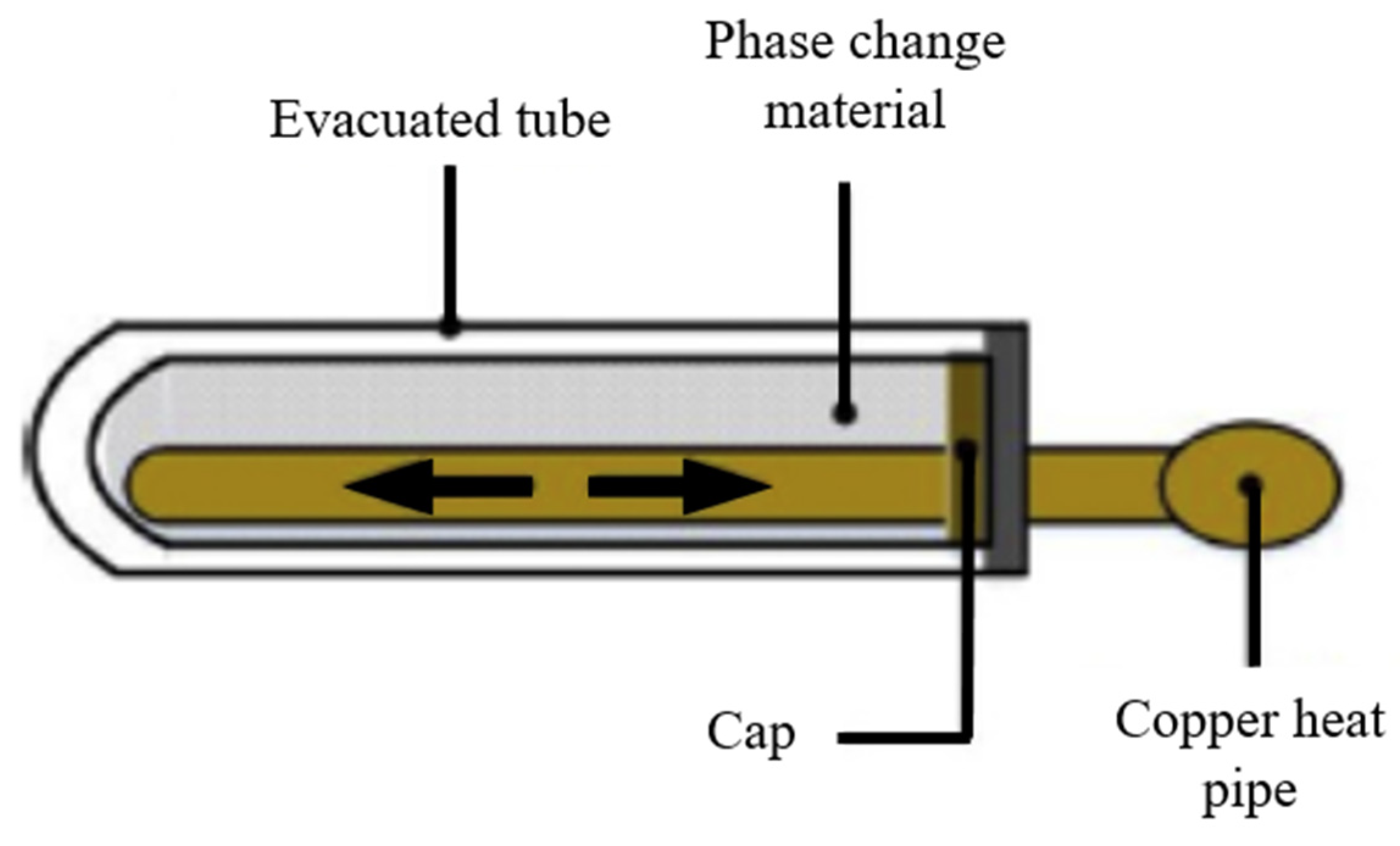

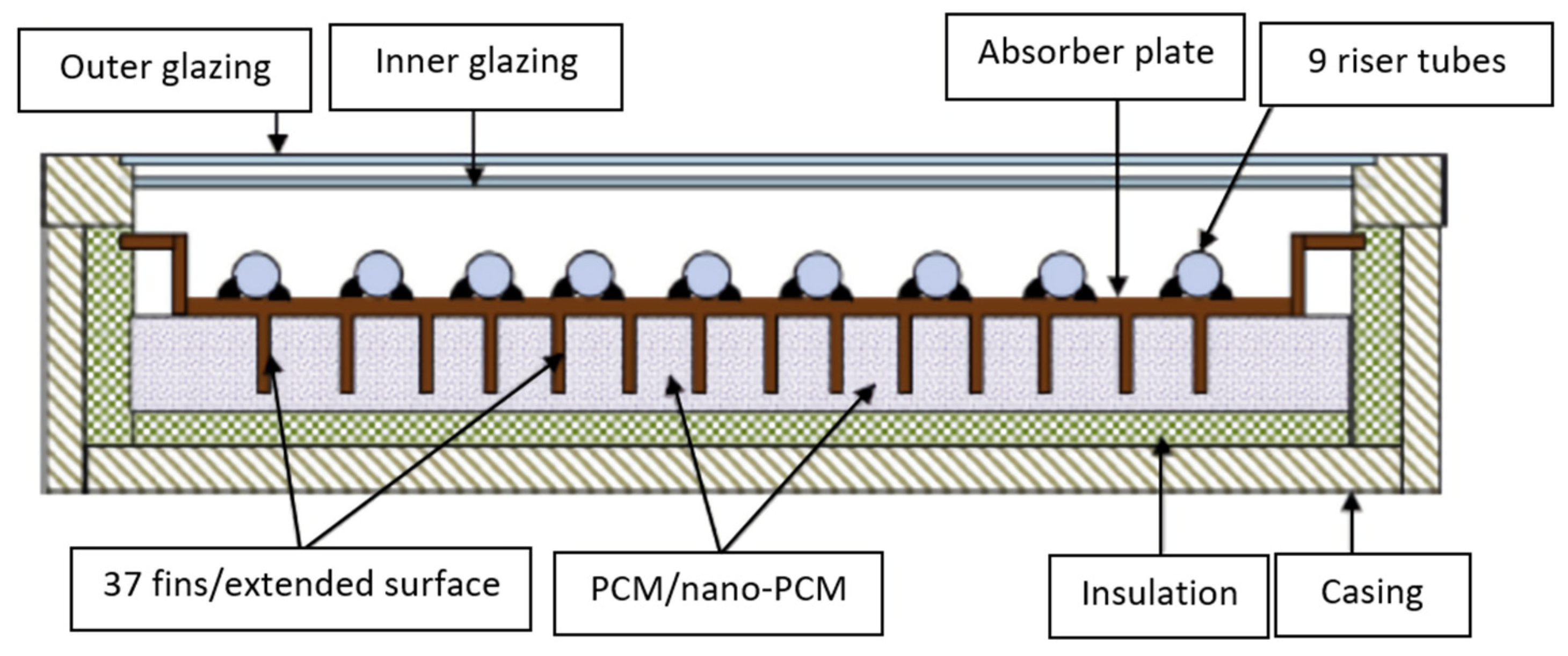

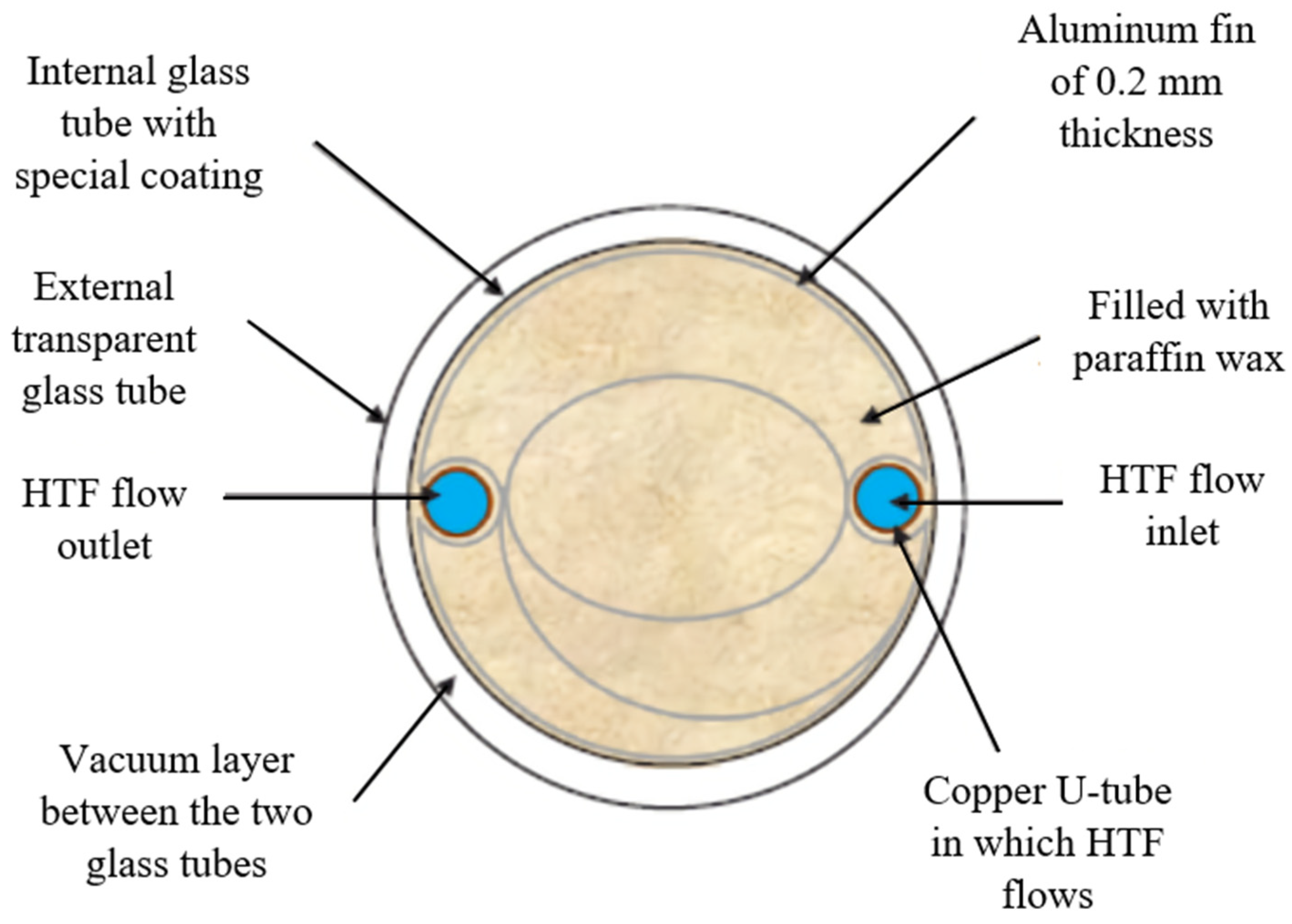

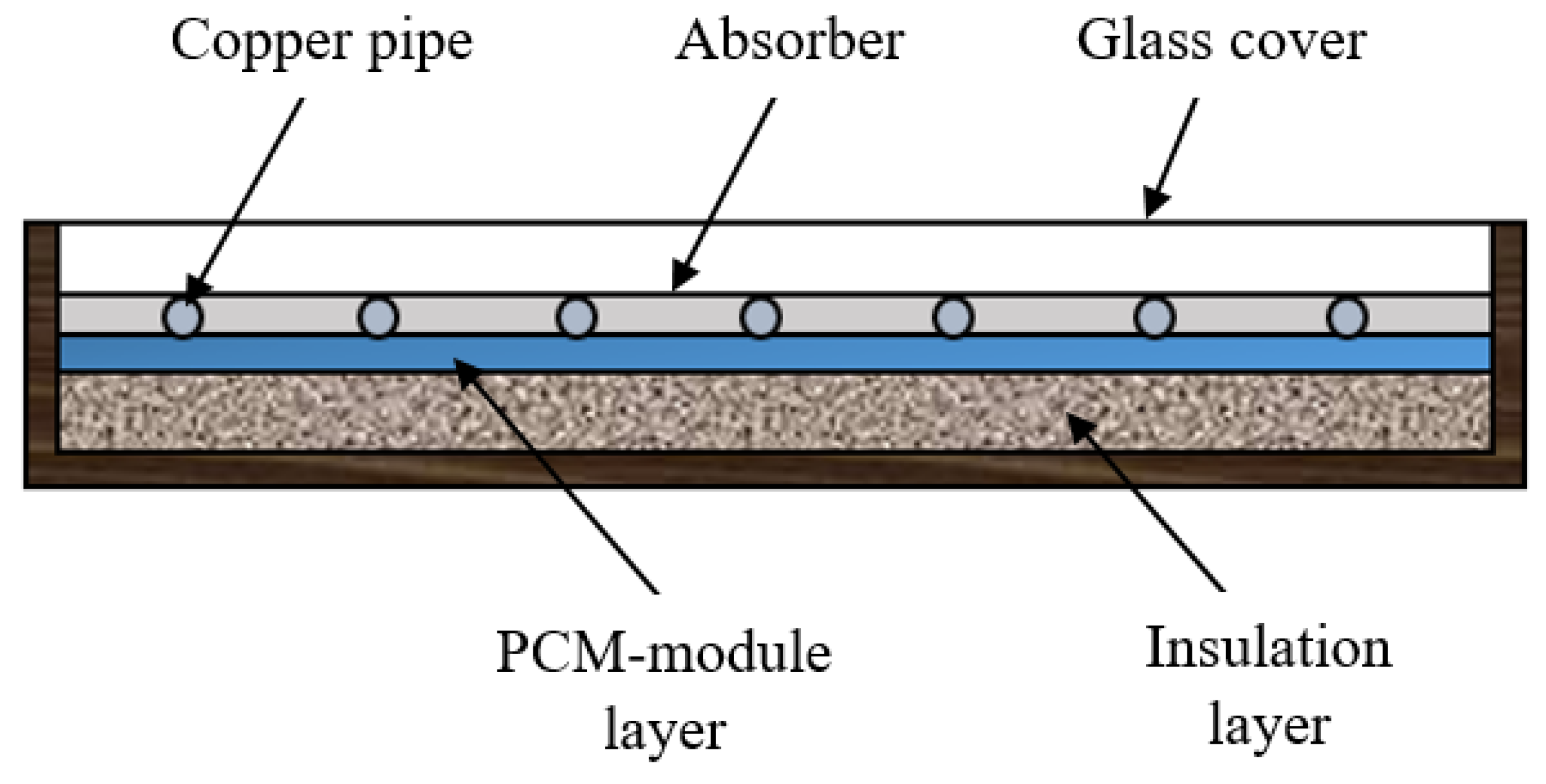

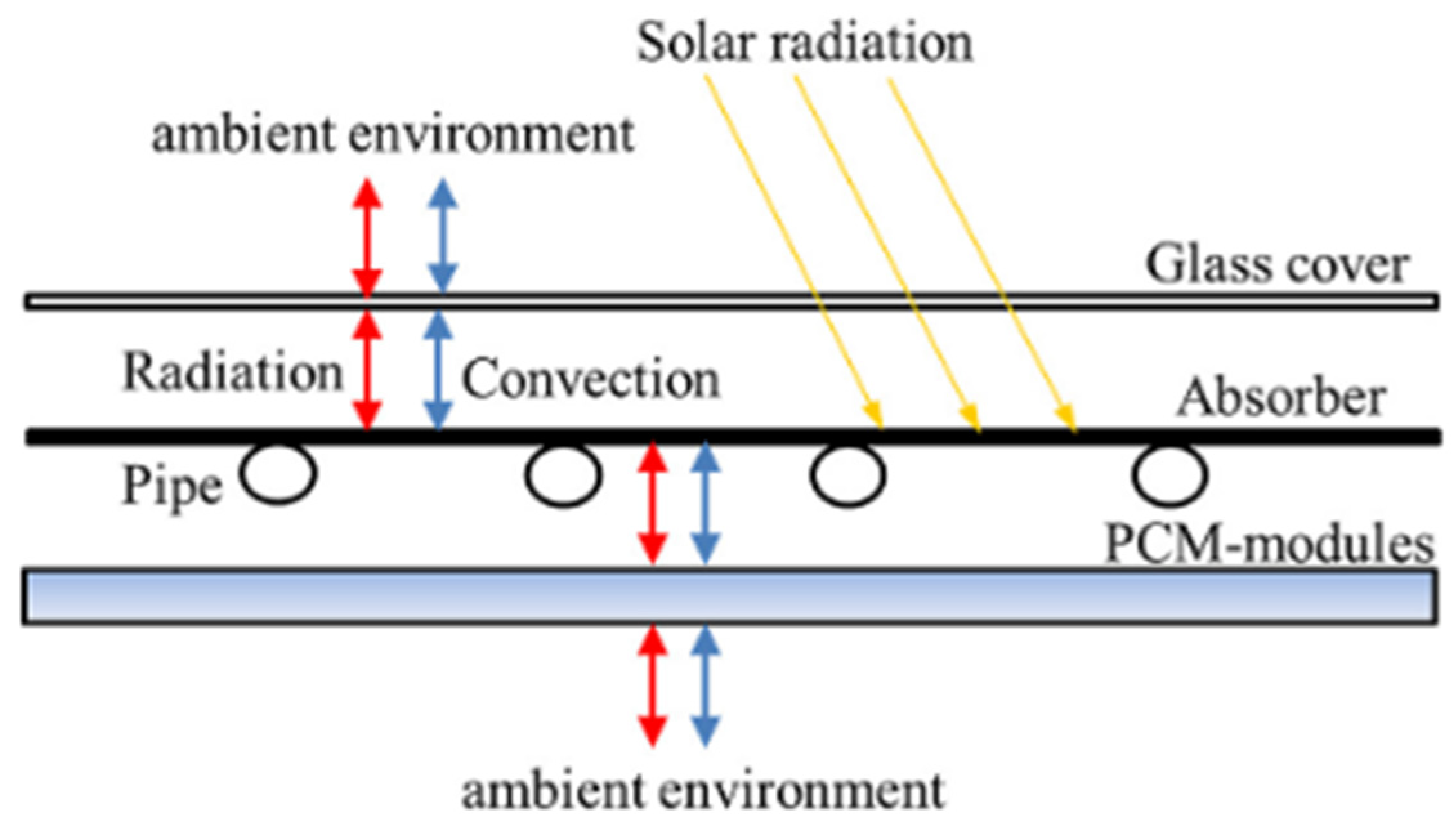

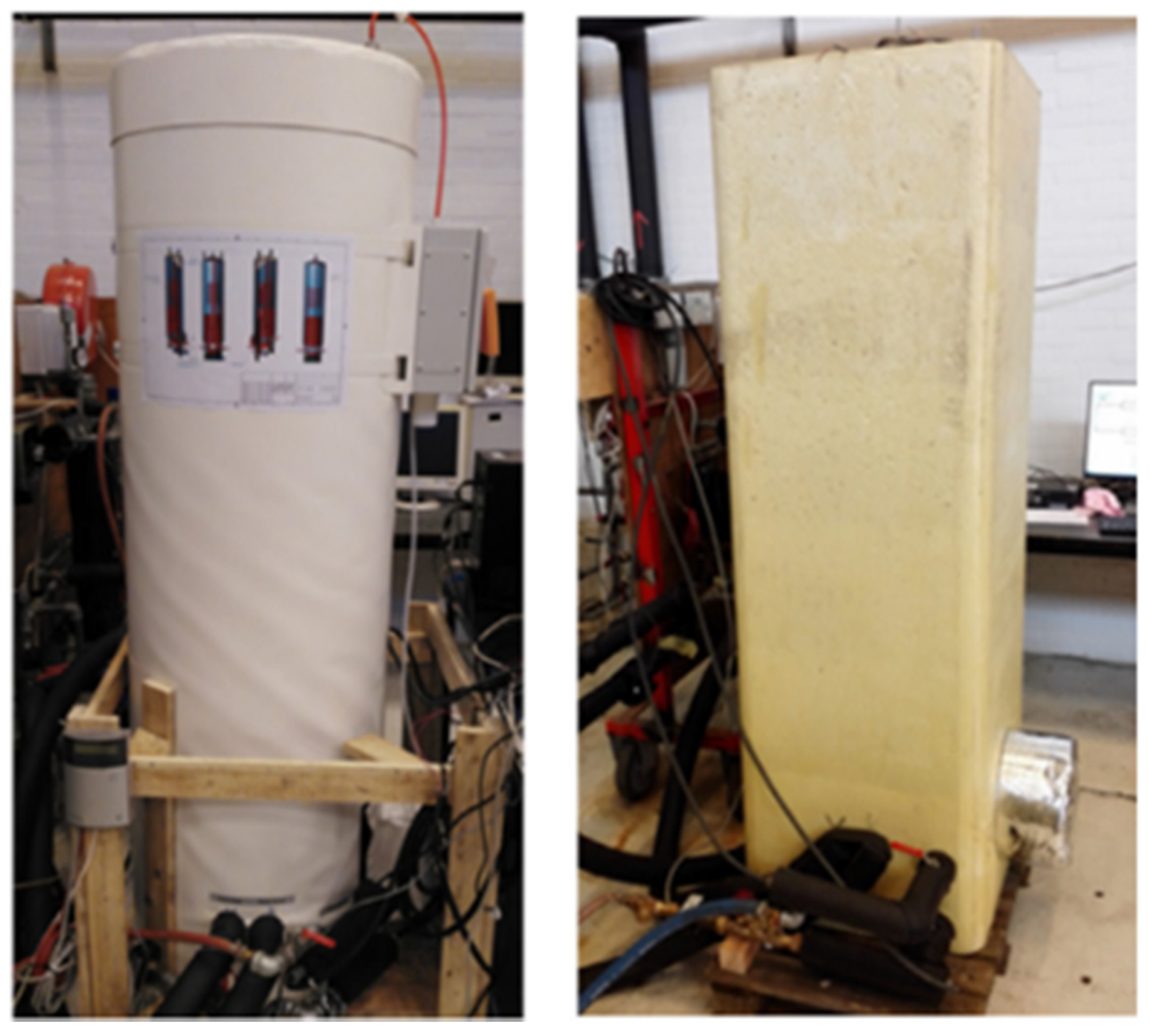

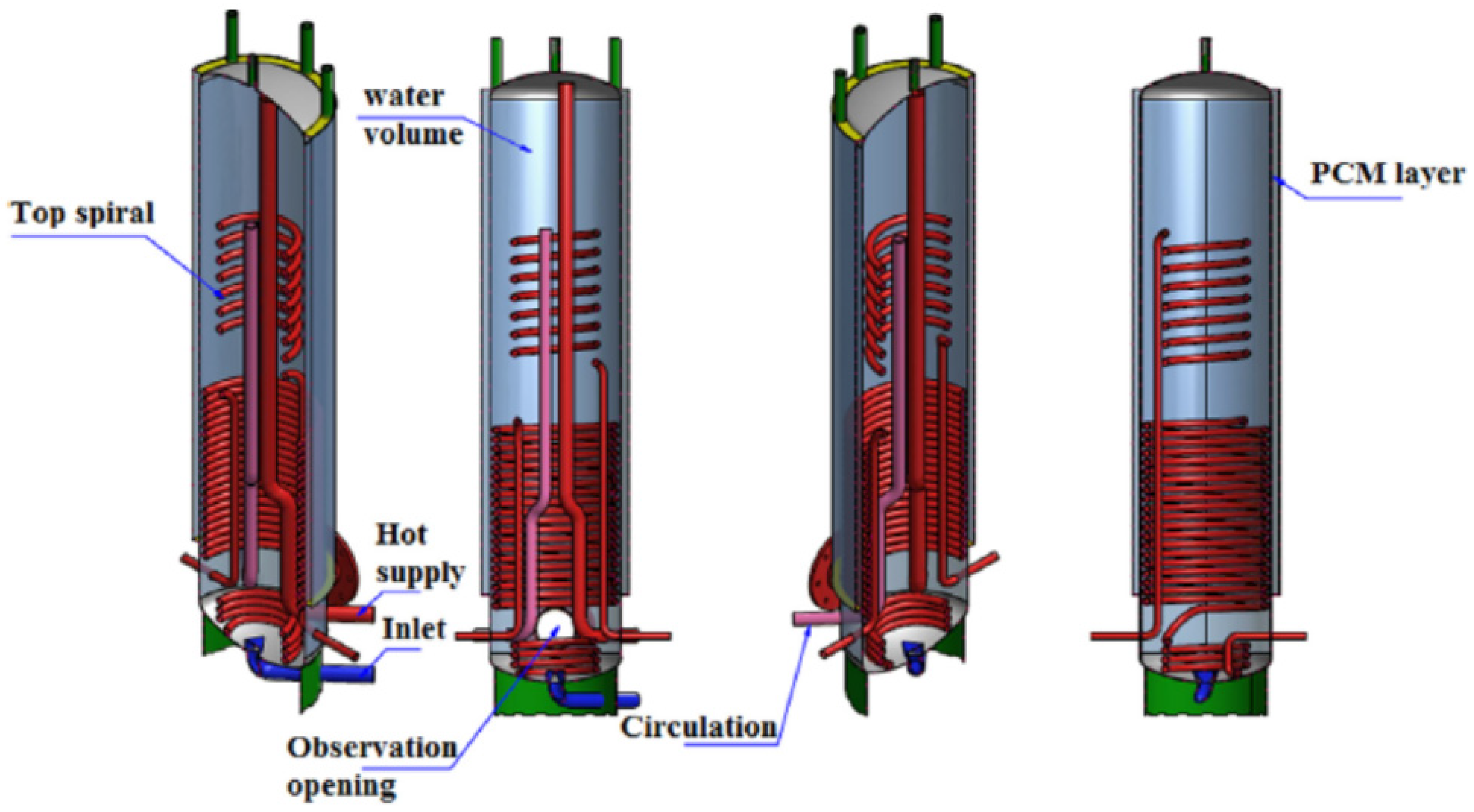

6.4.1. TES Integration on Collectors

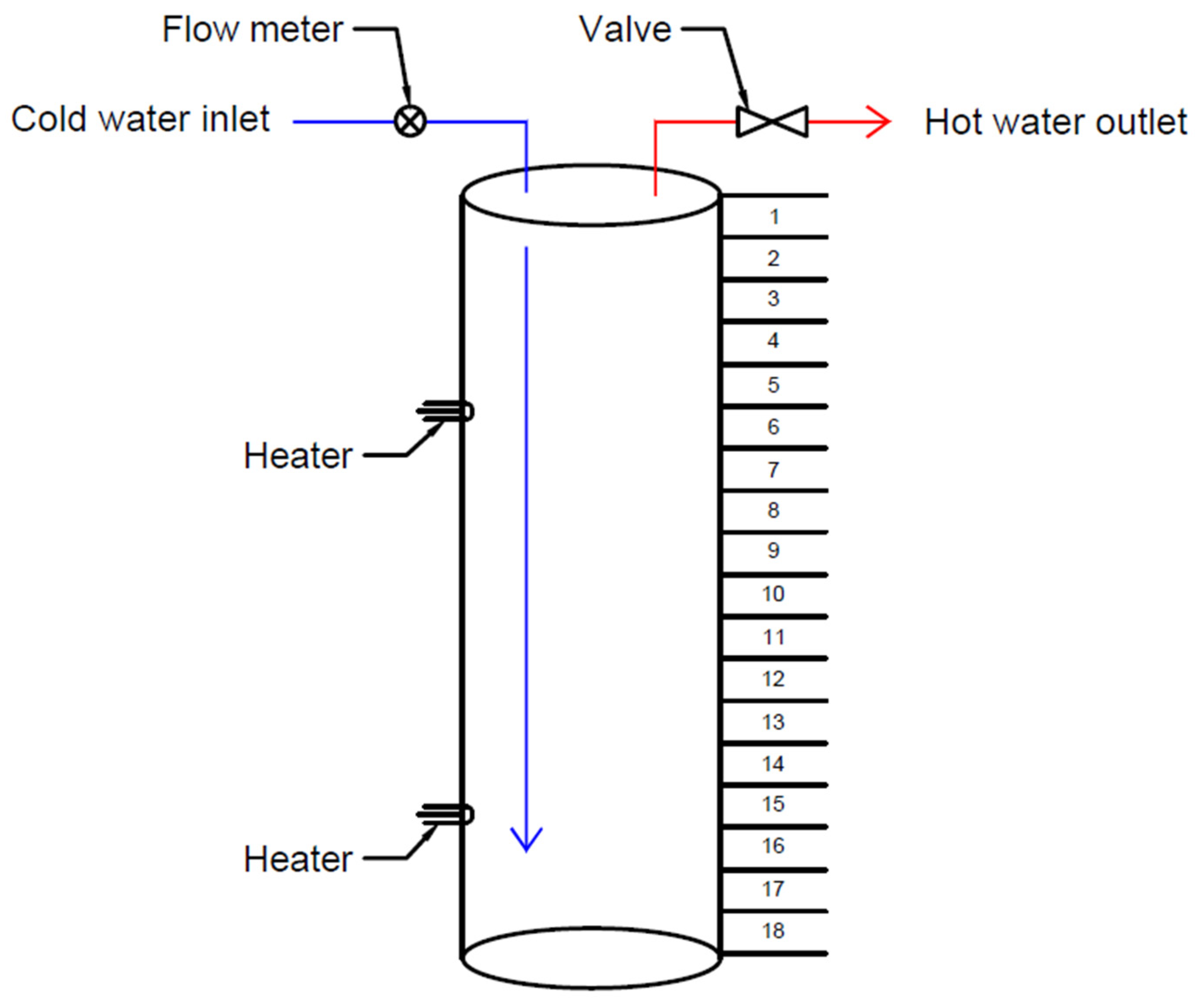

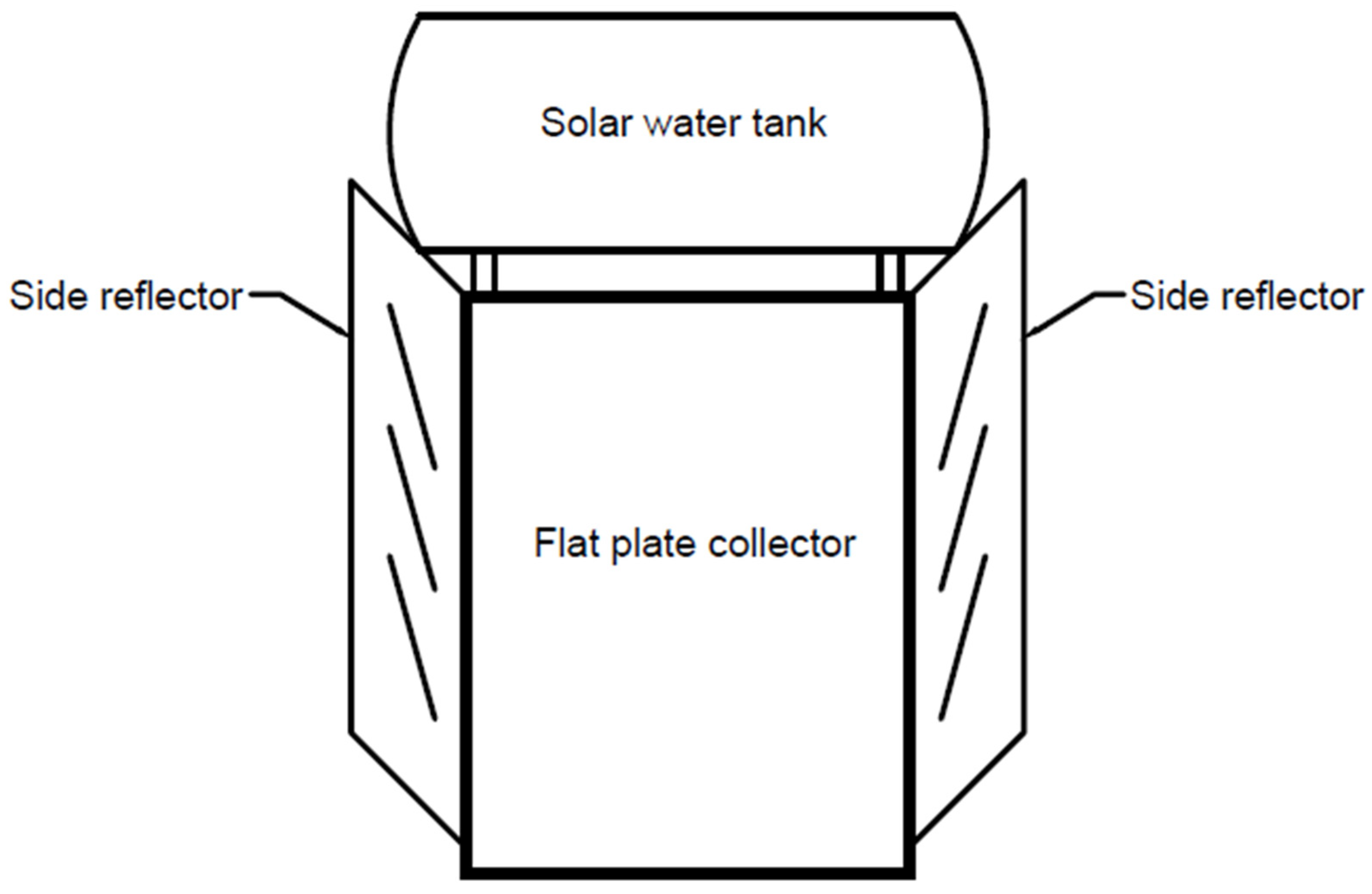

6.4.2. TES Integration on Water Tanks

6.5. Thin-Film Material Coating on FPC

6.6. Feedwater Treatment Process

6.7. Future Research Direction of SWH Technologies

6.7.1. Solar Water Heater Performance Enhancement Methods

6.7.2. Thermal Energy Storage (TES) Materials

6.7.3. Hybrid Solar Photovoltaic-Thermal (PVT) System

6.7.4. Reducing the Price of Solar Thermal Systems

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kumar, A.; Said, Z.; Bellos, E. An up-to-date review on evacuated tube solar collectors. J. Therm. Anal. Calorim. 2020, 145, 2873–2889. [Google Scholar] [CrossRef]

- Zeb, R.; Salar, L.; Awan, U.; Zaman, K.; Shahbaz, M. Causal links between renewable energy, environmental degradation and economic growth in selected SAARC countries: Progress towards green economy. Renew. Energy 2014, 71, 123–132. [Google Scholar] [CrossRef]

- Weiss, W.; Spörk-Dür, M. Global Market Development and Trends in 2019; Steinhuber Infodes: Gleisdorf, Austria, 2020. [Google Scholar]

- Bhatia, S.C. Solar Thermal Energy. In Advanced Renewable Energy Systems; Bhatia, S.C., Ed.; Woodhead Publishing: New Delhi, India, 2014; pp. 94–143. [Google Scholar]

- Kamarulzaman, A.; Hasanuzzaman, M.; Rahim, N. Global advancement of solar drying technologies and its future prospects: A review. Sol. Energy 2021, 221, 559–582. [Google Scholar] [CrossRef]

- Kumar, L.; Hasanuzzaman, M.; Rahim, N.A.; Islam, M.M. Modeling, simulation and outdoor experimental performance analysis of a solar-assisted process heating system for industrial process heat. Renew. Energy 2021, 164, 656–673. [Google Scholar] [CrossRef]

- Dahlan, N.Y.; Ismail, M.F. Review on solar thermal technologies for low and medium temperature industrial process heat. J. Ind. Technol. 2015, 23, 25–44. [Google Scholar] [CrossRef]

- Kumar, L.; Hasanuzzaman, M.; Rahim, N. Global advancement of solar thermal energy technologies for industrial process heat and its future prospects: A review. Energy Convers. Manag. 2019, 195, 885–908. [Google Scholar] [CrossRef]

- Sanguinetti, A.; Outcault, S.; Alston-Stepnitz, E.; Moezzi, M.; Ingle, A. Residential solar water heating: California adopters and their experiences. Renew. Energy 2021, 170, 1081–1095. [Google Scholar] [CrossRef]

- Karami, M.; Bozorgi, M.; Delfani, S. Effect of design and operating parameters on thermal performance of low-temperature direct absorption solar collectors: A review. J. Therm. Anal. Calorim. 2021, 146, 993–1013. [Google Scholar] [CrossRef]

- Dehghan, M.; Pfeiffer, C.F.; Rakhshani, E.; Bakhshi-Jafarabadi, R. A Review on Techno-Economic Assessment of Solar Water Heating Systems in the Middle East. Energies 2021, 14, 4944. [Google Scholar] [CrossRef]

- Nwaji, G.N.; Okoronkwo, C.A.; Ogueke, N.V.; Anyanwu, E.E. Hybrid solar water heating/nocturnal radiation cooling system I: A review of the progress, prospects and challenges. Energy Build. 2019, 198, 412–430. [Google Scholar] [CrossRef]

- Netshiozwi, E. Causes of Failure of the South African Solar Water Heating Programme and the Forgone Social Benefits. Rev. Soc. Sci. 2019, 4, 1–15. [Google Scholar]

- Kaur, R. Addressing Climate Change Through Green Technology with Reference to Solar Water Heating System Scheme: A Review of State of Punjab (India). Indian J. Sustain. Dev. 2018, 4, 37–45. [Google Scholar]

- Kalogirou, S.A. Building integration of solar renewable energy systems towards zero or nearly zero energy buildings. Int. J. Low Carbon Technol. 2015, 10, 379–385. [Google Scholar] [CrossRef] [Green Version]

- Veeraboina, P.; Ratnam, G.Y. Analysis of the opportunities and challenges of solar water heating system (SWHS) in India: Estimates from the energy audit surveys & review. Renew. Sustain. Energy Rev. 2012, 16, 668–676. [Google Scholar]

- Brostrom, M.; Howell, G. The Challenges of Designing and Building a Net Zero Energy Home in a Cold High-Latitude Climate. In Proceedings of the 3rd International Solar Cities Congress “Visionary Voices Talk Sustainable Cities”, Adelaide, SA, Australia, 17–21 February 2008. [Google Scholar]

- Ferrari, R. Writing narrative style literature reviews. Med. Writ. 2015, 24, 230–235. [Google Scholar] [CrossRef]

- Amin, S.B.; Mithila, N.N. The Importance of Using Solar Water Heater as an Alternative Eco-Friendly Technology in Global Market: Some Lessons of Experiences for Bangladesh Economy. SSRN Electron. J. 2017, 1–47. [Google Scholar] [CrossRef]

- Suhane, S.; Pandey, P.R. An Energy Saving Opportunity by Replacing Hot Water Geyser with Solar Water Heater. Int. J. Eng. Res. Technol. 2013, 2, 7. [Google Scholar]

- Milton, S.; Kaufman, S. Solar Water Heating as a Climate Protection Strategy: The Role for Carbon Finance; Green Market Internationals Inc.: Arlington, MA, USA, 2005; p. 34. [Google Scholar]

- Öztürk, M.; Çalişir, O.; Genç, G. Energy, exergy and economic (3E) evaluation of the photovoltaic/thermal collector-assisted heat pump domestic water heating system for different climatic regions in Turkey. J. Therm. Anal. Calorim. 2021, 145, 1431–1443. [Google Scholar] [CrossRef]

- Obaideen, K.; Nooman AlMallahi, M.; Alami, A.H.; Ramadan, M.; Abdelkareem, M.A.; Shehata, N.; Olabi, A.G. On the contribution of solar energy to sustainable developments goals: Case study on Mohammed bin Rashid Al Maktoum Solar Park. Int. J. Thermofluid. 2021, 12, 100123. [Google Scholar] [CrossRef]

- Multi Family Solar Water Heating. 2014. Available online: http://sfenvironment.org/sites/default/files/fliers/files/sfe_re_factsheet_multifamilysolarwaterheating.pdf (accessed on 24 September 2020).

- Gadgil, A. Domestic Solar Water Heater for Developing Countries. 2007, pp. 1–25. Available online: https://www.solaripedia.com/files/587.pdf (accessed on 24 September 2020).

- Brown, L.R. Harnessing the Sun’s Energy for Water and Space Heating. 2011. Available online: http://www.earth-policy.org/data_highlights/2011/highlights23 (accessed on 24 September 2020).

- Ramlow, B. Reduce Your Energy Bills with a Solar Hot Water Heater. 2007. Available online: https://www.motherearthnews.com/renewable-energy/solar-hot-water-heater-zmaz07fmzpit (accessed on 24 September 2020).

- Arefin, M.K.; Hasan, M.R.; Azad, A. Characteristics and Cost Analysis of an Automatic Solar Hot Water System in Bangladesh. In Proceedings of the 2nd International Conference on Environmental Science and Technology IPCBEE, Singapore, 26–28 February 2011; p. 5. [Google Scholar]

- Abokersh, M.H.; Osman, M.; El-Baz, O.; El-Morsi, M.; Sharaf, O. Review of the phase change material (PCM) usage for solar domestic water heating systems (SDWHS). Int. J. Energy Res. 2018, 42, 329–357. [Google Scholar] [CrossRef]

- Mofijur, M.; Mahlia, T.M.I.; Ong, H.C.; Silakhori, M.; Hasan, M.H.; Putra, N.; Rahman, S.M.A. Phase Change Materials (PCM) for Solar Energy Usages and Storage: An Overview. Energies 2019, 12, 3167. [Google Scholar] [CrossRef] [Green Version]

- Douvi, E.; Pagkalos, C.; Dogkas, G.; Koukou, M.K.; Stathopoulos, V.N.; Caouris, Y.; Vrachopoulos, M.G. Phase change materials in solar domestic hot water systems: A review. Int. J. Thermofluid. 2021, 10, 100075. [Google Scholar] [CrossRef]

- Gulati, S. Solar Water Heating System & Its Working Principle. In Our Blog Education. 2020. Available online: https://blog.oureducation.in/solar-water-heating-system/ (accessed on 2 February 2021).

- SWH. Solar Water Heaters. 2021. Available online: https://www.energy.gov/energysaver/water-heating/solar-water-heaters (accessed on 2 February 2021).

- Zee, A. Solar Water Heating Systems. 2017. Available online: https://medium.com/@alphazee17/solar-water-heating-systems-4a72f46b113a (accessed on 23 November 2017).

- Okafor, B. Thermo Siphon Solar Water Heater. Int. J. Eng. Technol. 2013, 3, 1–5. [Google Scholar]

- Islam, M.R.; Sumathy, K.; Khan, S.U. Solar water heating systems and their market trends. Renew. Sustain. Energy Rev. 2013, 17, 1–25. [Google Scholar] [CrossRef]

- Choi, S.U.S.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nanoparticles; Argonne National Laboratory: Lemont, IL, USA, 1995. [Google Scholar]

- Kapstein, E.B.; Butti, K.; Perlin, J.B. A Golden Thread: 2500 Years of Solar Architecture and Technology; John Wiley & Sons: Hoboken, NJ, USA, 1980. [Google Scholar]

- Perlin, J. The evolution of the design of solar water heaters in North America. In Proceedings of the Third International PLEA Conference, Mexico City, Mexico, 6–11 August 1984; pp. 864–867. [Google Scholar]

- Perlin, J.; Butti, K. Solar Hot Water Heating. In A Golden Thread: 2500 Years of Solar Architecture and Technology; Van Nostrand Reinhold Company: New York, NY, USA, 1980; pp. 114–155. [Google Scholar]

- Runqing, H.; Peijun, S.; Zhongying, W. An overview of the development of solar water heater industry in China. Energy Policy 2012, 51, 46–51. [Google Scholar] [CrossRef]

- Chen, Z.; Gu, M.; Peng, D.; Peng, C.; Wu, Z. A Numerical Study on Heat Transfer of High Efficient Solar Flat-Plate Collectors with Energy Storage. Int. J. Green Energy 2010, 7, 326–336. [Google Scholar] [CrossRef]

- Tsai, H.-L. Design and Evaluation of a Photovoltaic/Thermal-Assisted Heat Pump Water Heating System. Energies 2014, 7, 3319–3338. [Google Scholar] [CrossRef] [Green Version]

- Moghadam, A.J.; Farzane-Gord, M.; Sajadi, M.; Hoseyn-Zadeh, M. Effects of CuO/water nanofluid on the efficiency of a flat-plate solar collector. Exp. Therm. Fluid Sci. 2014, 58, 9–14. [Google Scholar] [CrossRef]

- Naghavi, M.S.; Ong, K.S.; Badruddin, I.A.; Mehrali, M.; Silakhori, M.; Metselaar, H.S.C. Theoretical model of an evacuated tube heat pipe solar collector integrated with phase change material. Energy 2015, 91, 911–924. [Google Scholar] [CrossRef]

- Hasan, M.F.; Mahadi, M.S.; Miyazaki, T.; Koyama, S.; Thu, K. Exergy Analysis of Serpentine Thermosyphon Solar Water Heater. Appl. Sci. 2018, 8, 391. [Google Scholar] [CrossRef] [Green Version]

- Kumar, P.M.; Mylsamy, K. A comprehensive study on thermal storage characteristics of nano-CeO2 embedded phase change material and its influence on the performance of evacuated tube solar water heater. Renew. Energy 2020, 162, 662–676. [Google Scholar] [CrossRef]

- Essa, M.A.; Rofaiel, I.Y.; Ahmed, M.A. Experimental and Theoretical Analysis for the Performance of Evacuated Tube Collector Integrated with Helical Finned Heat Pipes using PCM Energy Storage. Energy 2020, 206, 118166. [Google Scholar] [CrossRef]

- Zwalnan, S.J.; Caleb, N.M.; Mangai, M.M.; Sanda, N.Y. Comparative Analysis of Thermal Performance of a Solar Water Heating System Based on the Serpentine and Risers-Head Configurations. J. Renew. Energy Environ. 2021, 8, 21–30. [Google Scholar]

- Mondragón, R.; Sánchez, D.; Cabello, R.; Llopis, R.; Juliá, J.E. Flat plate solar collector performance using alumina nanofluids: Experimental characterization and efficiency tests. PLoS ONE 2019, 14, e0212260. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saffarian, M.R.; Moravej, M.; Doranehgard, M.H. Heat transfer enhancement in a flat plate solar collector with different flow path shapes using nanofluid. Renew. Energy 2020, 146, 2316–2329. [Google Scholar] [CrossRef]

- Wole-osho, I.; Okonkwo, E.C.; Abbasoglu, S.; Kavaz, D. Nanofluids in Solar Thermal Collectors: Review and Limitations. Int. J. Thermophys. 2020, 41, 157. [Google Scholar] [CrossRef]

- Mahamude, A.S.; Kamarulzaman, M.K.; Harun, W.S.; Kadirgama, K.; Ramasamy, D.; Farhana, K.; Bakar, R.A.; Yusaf, T.; Subramanion, S.; Yousif, B. A Comprehensive Review on Efficiency Enhancement of Solar Collectors Using Hybrid Nanofluids. Energies 2022, 15, 1391. [Google Scholar] [CrossRef]

- Jinyi-Solar, Indirect Flat Panel Solar Water Heaters. 2021. Available online: https://www.jinyi-solar.com/indirect-flat-plate-solar-water-heater.html (accessed on 11 June 2021).

- Saagoto, M.S.; Sobhan Chowdhury, A. A Review of Solar Flat Plate Thermal Collector; Tehnical Report; Islamic University of Technology: Gazipur, Bangladesh, 2020. [Google Scholar]

- Alternative Energy Tutorials (AET). Solar Flat Plate Collectors for Solar Hot Water. 2021. Available online: https://www.alternative-energy-tutorials.com/solar-hot-water/flat-plate-collector.html (accessed on 11 June 2021).

- Sunpower-solar. Compact Pressurized heat pipe Solar Water Heater (SPP). 2021. Available online: https://www.sunpower-solar.com/Compact-Pressurized-heat-pipe-Solar-Water-Heater-SPP-pd6822775.html (accessed on 11 June 2021).

- Imposol, Split Villa Water Heater System. 2021. Available online: https://www.czimposol.cn/new_detail/nid/2184.html (accessed on 11 June 2021).

- Sunflower Solar. Comparison between Evacuated Tube Collector & Flat Plate Collector. 2021. Available online: http://www.sunflower-solar.com/index.php?act=content&scheduler_id=390 (accessed on 11 June 2021).

- Khan, M.M.A.; Ibrahim, N.I.; Mahbubul, I.M.; Muhammad Ali, H.; Saidur, R.; Al-Sulaiman, F.A. Evaluation of solar collector designs with integrated latent heat thermal energy storage: A review. Sol. Energy 2018, 166, 334–350. [Google Scholar] [CrossRef]

- Badiei, Z.; Eslami, M.; Jafarpur, K. Performance improvements in solar flat plate collectors by integrating with phase change materials and fins: A CFD modeling. Energy 2020, 192, 116719. [Google Scholar] [CrossRef]

- Evangelisti, L.; Vollaro, R.D.L.; Asdrubali, F. Latest advances on solar thermal collectors: A comprehensive review. Renew. Sustain. Energy Rev. 2019, 114, 109318. [Google Scholar] [CrossRef]

- Balakrishnan, D.B.K.; Ramesh Bapu, B.R. Experimental Study of Thermal Energy Storage in Solar System Using PCM. Adv. Mater. Res. 2012, 433–440, 1027–1032. [Google Scholar]

- Abhilash, A.; Dheeraj, K.; Balachandran, M.; Aby Kurian, M. An Experimental Investigation on PCM Incorporated Solar Water Heater. Int. J. Innov. Res.Sci. Eng. Technol. 2016, 5, 8. [Google Scholar]

- Rathore, P.K.S. An experimental study on solar water heater integrated with phase change material. In Advances in Fluid and Thermal Engineering; Springer: Singapore, 2019. [Google Scholar]

- Raul, A.; Jain, M.; Gaikwad, S.; Saha, S.K. Modelling and experimental study of latent heat thermal energy storage with encapsulated PCMs for solar thermal applications. Appl. Therm. Eng. 2018, 143, 415–428. [Google Scholar] [CrossRef]

- Wu, W.; Dai, S.; Liu, Z.; Dou, Y.; Hua, J.; Li, M.; Wang, X.; Wang, W. Experimental study on the performance of a novel solar water heating system with and without PCM. Sol. Energy 2018, 171, 604–612. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Khalil, A.; Shalaby, S.M.; Zayed, M.E. Improvement of thermal performance of the finned plate solar air heater by using latent heat thermal storage. Appl. Therm. Eng. 2017, 123, 546–553. [Google Scholar] [CrossRef]

- Sabiha, M.A.; Saidur, R.; Mekhilef, S.; Mahian, O. Progress and latest developments of evacuated tube solar collectors. Renew. Sustain. Energy Rev. 2015, 51, 1038–1054. [Google Scholar] [CrossRef]

- Kalogirou, S. Solar Energy Engineering; Academic Press: Cambridge, MA, USA, 2014; pp. 131–262. [Google Scholar]

- Wang, D.; Liu, H.; Liu, Y.; Xu, T.; Wang, Y.; Du, H.; Wang, X.; Liu, J. Frost and High-temperature resistance performance of a novel dual-phase change material flat plate solar collector. Sol. Energy Mater. Sol. Cells 2019, 201, 110086. [Google Scholar] [CrossRef]

- Hussein, A.K.; Li, D.; Kolsi, L.; Kata, S.; Sahoo, B. A Review of Nano Fluid Role to Improve the Performance of the Heat Pipe Solar Collectors. Energy Procedia 2017, 109, 417–424. [Google Scholar] [CrossRef]

- Sun Power-Solar. What Should Be Done to Remove Scale from Vacuum Tube Solar Water Heater? 2019. Available online: https://www.sunpower-solar.com/What-should-be-done-to-remove-scale-from-vacuum-tube-solar-water-heater-id3909785.html (accessed on 9 June 2022).

- Rassamakin, B.; Khairnasov, S.; Zaripov, V.; Rassamakin, A.; Alforova, O. Aluminum heat pipes applied in solar collectors. Sol. Energy 2013, 94, 145–154. [Google Scholar] [CrossRef]

- Zhou, F.; Ji, J.; Cai, J.; Yu, B. Experimental and numerical study of the freezing process of flat-plate solar collector. Appl. Therm. Eng. 2017, 118, 773–784. [Google Scholar] [CrossRef]

- Shafieian, A.; Khiadani, M.; Nosrati, A. Strategies to improve the thermal performance of heat pipe solar collectors in solar systems: A review. Energy Convers. Manag. 2019, 183, 307–331. [Google Scholar] [CrossRef]

- Khoukhi, M.; Maruyama, S.; Komiya, A.; Behnia, M. Flat-Plate Solar Collector Performance with Coated and Uncoated Glass Cover. Heat Transf. Eng. 2006, 27, 46–53. [Google Scholar] [CrossRef]

- Hussain, S.; Harrison, S.J. Evaluation of thermal characteristics of a flat plate solar collector with a back mounted air channel. Appl. Therm. Eng. 2017, 123, 940–952. [Google Scholar] [CrossRef]

- Gladen, A.C.; Davidson, J.H.; Mantell, S.C. Selection of thermotropic materials for overheat protection of polymer absorbers. Sol. Energy 2014, 104, 42–51. [Google Scholar] [CrossRef]

- Bhowmik, H.; Amin, R. Efficiency improvement of flat plate solar collector using reflector. Energy Rep. 2017, 3, 119–123. [Google Scholar] [CrossRef]

- Chougule, S.; Sahu, S.K.; Pise, A. Thermal Performance of Two Phase Thermosyphon Flat-Plate Solar Collectors Using Nanofluid. J. Sol. Energy Eng. 2014, 136, 014503. [Google Scholar] [CrossRef]

- Aruna, V.; Channakaiah, D.; Murali, G. A study on a flat plate type of solar water heater with an thermosyphon using different working fluid. Int. J. Eng. Trends Technol. 2015, 22, 493–497. [Google Scholar]

- AET. Evacuated Tube Collector. 2019. Available online: https://www.alternative-energy-tutorials.com/solar-hot-water/evacuated-tube-collector.html (accessed on 17 August 2020).

- Advantages of Evacuated Tube Solar Hot Water Systems. Available online: https://www.solarhotwatercanberra.com.au/advantages-of-evacuated-tube-systems/ (accessed on 14 August 2020).

- Hammad, M. Experimental study of the performance of a solar collector cooled by heat pipes. Renew. Energy 1995, 6, 11–15. [Google Scholar] [CrossRef]

- Kumbhar, S. Failure Investigation of Evacuated Tube Solar Collector of Water Heater. J. Fail. Anal. Prev. 2019, 19, 1202–1206. [Google Scholar] [CrossRef]

- Bourdoukan, P.; Wurtz, E.; Joubert, P.; Spérandio, M. Potential of solar heat pipe vacuum collectors in the desiccant cooling process: Modelling and experimental results. Sol. Energy 2008, 82, 1209–1219. [Google Scholar] [CrossRef]

- Hussein, H.M.S.; El-Ghetany, H.H.; Nada, S.A. Performance of wickless heat pipe flat plate solar collectors having different pipes cross sections geometries and filling ratios. Energy Convers. Manag. 2006, 47, 1539–1549. [Google Scholar] [CrossRef]

- Nkwetta, D.N.; Smyth, M. Performance analysis and comparison of concentrated evacuated tube heat pipe solar collectors. Appl. Energy 2012, 98, 22–32. [Google Scholar] [CrossRef]

- Putra, N.; Kristian, M.; David, R.; Haliansyah, K.; Ariantara, B. Thermal performance of evacuated tube heat pipe solar collector. AIP Conf. Proc. 2016, 1737, 50004. [Google Scholar]

- Redpath, D.A.G. Thermosyphon heat-pipe evacuated tube solar water heaters for northern maritime climates. Sol. Energy 2012, 86, 705–715. [Google Scholar] [CrossRef]

- Kang, S.-W.; Wei, W.-C.; Tsai, S.-H.; Yang, S.-Y. Experimental investigation of silver nano-fluid on heat pipe thermal performance. Appl. Therm. Eng. 2006, 26, 2377–2382. [Google Scholar] [CrossRef]

- Reddy, S.; Painuly, J.P. Diffusion of renewable energy technologies—Barriers and stakeholders’ perspectives. Renew. Energy 2004, 29, 1431–1447. [Google Scholar] [CrossRef]

- Thiruchelvam, M.; Kumar, S.; Visvanathan, C. Policy options to promote energy efficient and environmentally sound technologies in small- and medium-scale industries. Energy Policy 2003, 31, 977–987. [Google Scholar] [CrossRef]

- Rheem or Edwards Solar Hot Water. 2015. Available online: https://forums.whirlpool.net.au/archive/1155612#r18372105 (accessed on 23 September 2020).

- Naicker, J.S. Solar Water Heating: Reducing the Barriers. Master’s Thesis, University of Kwazulu-Natal, Durban, South Africa, 2010; pp. 10–58. [Google Scholar]

- Djordkevic, S.; Baverstock, G.; Walker, E.; Urmee, T. Identification of the barriers for the slow uptake of solar water heaters in Australia. In Proceedings of the 52nd Annual Conference of the Australian Solar Energy Society, Melbourne, VIC, Australia, 8–9 May 2014. [Google Scholar]

- Annual Report 2014–2015; Australia Council: Sydney, NSW, Australia, 2015.

- Solar Thermal in the Mediterranean Region: Solar Thermal Action Plan. In Solar Thermal Action Plan: Transformation and Strengthening Initiative; OME: Brescia, Italy; International Copper Association: Nanterre, France, 2012; p. 19.

- IRENA. Renewable Energy Benefits: Leveraging Local Capacity for Solar Water Heaters. In Renewable Energy Benefits; Ferroukhi, R., García-Baños, C., Eds.; International Renewable Energy Agency (IRENA): Abu Dhabi, United Arab Emirates, 2021; pp. 10–40. [Google Scholar]

- Caird, S.; Roy, R.; Herring, H. Improving the energy performance of UK households: Results from surveys of consumer adoption and use of low- and zero-carbon technologies. Energy Effic. 2008, 1, 149. [Google Scholar] [CrossRef]

- Caird, S.; Roy, R. Adoption and Use of Household Microgeneration Heat Technologies. Sci. Res. 2010, 1, 61–70. [Google Scholar]

- Sidiras, D.K.; Koukios, E.G. Solar systems diffusion in local markets. Energy Policy 2004, 32, 2007–2018. [Google Scholar] [CrossRef]

- Elmustapha, H.; Hoppe, T.; Bressers, H. Understanding Stakeholders’ Views and the Influence of the Socio-Cultural Dimension on the Adoption of Solar Energy Technology in Lebanon. Sustainability 2018, 10, 364. [Google Scholar] [CrossRef] [Green Version]

- Urban, F.; Geall, S.; Wang, Y. Solar PV and solar water heaters in China: Different pathways to low carbon energy. Renew. Sustain. Energy Rev. 2016, 64, 531–542. [Google Scholar] [CrossRef] [Green Version]

- Stern, P.C.; Dietz, T.; Abel, T.; Guagnano, G.A.; Kalof, L. A Value-Belief-Norm Theory of Support for Social Movements: The Case of Environmentalism. Hum. Ecol. Rev. 1999, 6, 81–97. [Google Scholar]

- Steg, L.; Perlaviciute, G.; van der Werff, E. Understanding the human dimensions of a sustainable energy transition. Front. Psychol. 2015, 6, 805. [Google Scholar] [CrossRef] [Green Version]

- Ghazali, E.M.; Nguyen, B.; Mutum, D.S.; Yap, S.-F. Pro-Environmental Behaviours and Value-Belief-Norm Theory: Assessing Unobserved Heterogeneity of Two Ethnic Groups. Sustainability 2019, 11, 3237. [Google Scholar] [CrossRef] [Green Version]

- Urban, F.; Geall, S. Pathways Towards Renewable Energy in China: Prospects, Politics and Practices; STEPS Centre: Brighton, UK; University of London: London, UK; Economic and Social Research Council: Swindon, UK, 2014; p. 37. [Google Scholar]

- Dissemination of Solar Water Heating in Brazil and Mexico; Federal Ministry for the Environment, Nature Conservation, Building and Nuclear Safety (BMUB): Berlin, Germany, 2017.

- Din, A.T.; Azlan, K. Development of Low-Cost Solar Water Heater Using Recycled Solid Waste for Domestic Hot Water Supply. MATEC Web Conf. 2018, 150, 04010. [Google Scholar]

- Din, A.T.; Hafiz, N.M.; Rus, A.Z.M. Exploration to Find Heat Absorbent Materials from Recycled Solid Wastes for the Design and Development of Low Operational Cost and Affordable Water Heating System for Domestic Application. In Proceedings of the 4th International Scientific Conference on Applied Sciences and Engineering, Langkawi, Malaysia, 3–4 October 2015. [Google Scholar]

- Islam, M.M.; Hasanuzzaman, M.; Rahim, N.A.; Pandey, A.K.; Rawa, M.; Kumar, L. Real time experimental performance investigation of a NePCM based photovoltaic thermal system: An energetic and exergetic approach. Renew. Energy 2021, 172, 71–87. [Google Scholar] [CrossRef]

- Saha, S.; Ruslan, A.R.M.; Monjur Morshed, A.K.M.; Hasanuzzaman, M. Global prospects and challenges of latent heat thermal energy storage: A review. Clean Technol. Environ. Policy 2020, 23, 531–559. [Google Scholar] [CrossRef]

- Murali, G.; Mayilsamy, K.; Arjunan, T.V. An Experimental Study of PCM-Incorporated Thermosyphon Solar Water Heating System. Int. J. Green Energy 2014, 12, 978–986. [Google Scholar] [CrossRef]

- El-Bassuoni, A.-M.A.; Tayeb, A.M.; Helwa, N.H.; Fathy, A.M. Modification of urea–sodium acetate trihydrate mixture for solar energy storage. Renew. Energy 2003, 28, 1629–1643. [Google Scholar] [CrossRef]

- Lee, W.-S.; Chen, B.-R.; Chen, S.-L. Latent Heat Storage in a Two-Phase Thermosyphon Solar Water Heater. J. Sol. Energy Eng. 2006, 128, 69. [Google Scholar] [CrossRef]

- Xue, H.S. Experimental investigation of a domestic solar water heater with solar collector coupled phase-change energy storage. Renew. Energy 2016, 86, 257–261. [Google Scholar] [CrossRef]

- Li, B.; Zhai, X. Experimental investigation and theoretical analysis on a mid-temperature solar collector/storage system with composite PCM. Appl. Therm. Eng. 2017, 124, 34–43. [Google Scholar] [CrossRef]

- Tarhan, S.; Sari, A.; Yardim, M.H. Temperature distributions in trapezoidal built in storage solar water heaters with/without phase change materials. Energy Convers. Manag. 2006, 47, 2143–2154. [Google Scholar] [CrossRef]

- Papadimitratos, A.; Sobhansarbandi, S.; Pozdin, V.; Zakhidov, A.; Hassanipour, F. Evacuated tube solar collectors integrated with phase change materials. Sol. Energy 2016, 129, 10–19. [Google Scholar] [CrossRef] [Green Version]

- Feliński, P.; Sekret, R. Effect of PCM application inside an evacuated tube collector on the thermal performance of a domestic hot water system. Energy Build. 2017, 152, 558–567. [Google Scholar] [CrossRef]

- Islam, M.M.; Pandey, A.K.; Hasanuzzaman, M.; Rahim, N.A. Recent progresses and achievements in photovoltaic-phase change material technology: A review with special treatment on photovoltaic thermal-phase change material systems. Energy Convers. Manag. 2016, 126, 177–204. [Google Scholar] [CrossRef]

- Mahfuz, M.H.; Anisur, M.R.; Kibria, M.A.; Saidur, R.; Metselaar, I.H.S.C. Performance investigation of thermal energy storage system with Phase Change Material (PCM) for solar water heating application. Int. Commun. Heat Mass Transf. 2014, 57, 132–139. [Google Scholar] [CrossRef]

- Wang, Z.; Qiu, F.; Yang, W.; Zhao, X. Applications of solar water heating system with phase change material. Renew. Sustain. Energy Rev. 2015, 52, 645–652. [Google Scholar] [CrossRef]

- Essa, M.A.; Mostafa, N.H.; Ibrahim, M.M. An experimental investigation of the phase change process effects on the system performance for the evacuated tube solar collectors integrated with PCMs. Energy Convers. Manag. 2018, 177, 1–10. [Google Scholar] [CrossRef]

- Abokersh, M.H.; El-Morsi, M.; Sharaf, O.; Abdelrahman, W. On-demand operation of a compact solar water heater based on U-pipe evacuated tube solar collector combined with phase change material. Sol. Energy 2017, 155, 1130–1147. [Google Scholar] [CrossRef]

- Al-Kayiem, H.H.; Lin, S.C. Performance evaluation of a solar water heater integrated with a PCM nanocomposite TES at various inclinations. Sol. Energy 2014, 109, 82–92. [Google Scholar] [CrossRef]

- Lin, S.; Al-Kayiem, H.; Aris, M. Experimental Investigation on the Performance Enhancement of Integrated PCM-Flat Plate Solar Collector. J. Appl. Sci. 2012, 12, 2390–2396. [Google Scholar] [CrossRef] [Green Version]

- Carmona, M.; Palacio, M. Thermal modelling of a flat plate solar collector with latent heat storage validated with experimental data in outdoor conditions. Sol. Energy 2019, 177, 620–633. [Google Scholar] [CrossRef]

- Zhou, F.; Ji, J.; Yuan, W.; Zhao, X.; Huang, S. Study on the PCM flat-plate solar collector system with antifreeze characteristics. Int. J. Heat Mass Transf. 2019, 129, 357–366. [Google Scholar] [CrossRef]

- Suffer, K.; Jalil, J.; Hasan, H. Numerical Investigation of PCM Thermal Storage in Water Solar Collector. J. Adv. Res. Fluid Mech. Therm. Sci. 2020, 66, 164–178. [Google Scholar]

- Naghavi, M.S.; Silaakhori, M.; Mehrali, M.; Metselaar, H.S.C.; Badruddin, I.A. Analytical thermal modeling of a heat pipe solar water heater system integrated with phase change material. Comput. Appl. Environ. Sci. Renew. Energy 2014, 197–208. [Google Scholar]

- Khalifa, A.J.N.; Suffer, K.H.; Mahmoud, M.S. A storage domestic solar hot water system with a back layer of phase change material. Exp. Therm. Fluid Sci. 2013, 44, 174–181. [Google Scholar] [CrossRef]

- Shukla, A.; Buddhi, D.; Sawhney, R.L. Solar water heaters with phase change material thermal energy storage medium: A review. Renew. Sustain. Energy Rev. 2009, 13, 2119–2125. [Google Scholar] [CrossRef]

- Beih, O.; Chakra, S.A. Phase Change Materials in a Domestic Solar Hot Water Storage Tank of the Lebanese Market. In Proceedings of the 2018 4th International Conference on Renewable Energies for Developing Countries (REDEC), Beirut, Lebanon, 1–2 November 2018. [Google Scholar]

- Deng, J.; Furbo, S.; Kong, W.; Fan, J. Thermal performance assessment and improvement of a solar domestic hot water tank with PCM in the mantle. Energy Build. 2018, 172, 10–21. [Google Scholar] [CrossRef]

- Gürtürk, M.; Koca, A.; Öztop, H.; Varol, Y.; Şekerci, M. Energy and exergy analysis of a heat storage tank with novel eutectic phase change material layer of a solar heater system. Int. J. Green Energy 2017, 14, 1073–1080. [Google Scholar] [CrossRef]

- Manoj Kumar, P.; Mylsamy, K. Experimental investigation of solar water heater integrated with a nanocomposite phase change material. J. Therm. Anal. Calorim. 2019, 136, 121–132. [Google Scholar] [CrossRef]

- Najafian, A.; Haghighat, F.; Moreau, A. Integration of PCM in domestic hot water tanks: Optimization for shifting peak demand. Energy Build. 2015, 106, 59–64. [Google Scholar] [CrossRef] [Green Version]

- Eisenmann, W.; Jack, S.; Lampe, C.; Giovannetti, F.; Brendel, R. High-Efficiency Flat-Plate Solar Collectors Based on Selective Glazing. In Proceedings of the 3rd European Solar Thermal Energy Conference (ESTEC), Freiburg, Germany, 19–20 June 2007. [Google Scholar]

- Foeste, S.; Ehrmann, N.; Degenhardt, P.; Rockendorf, G.; Scheuren, J. High efficiency flat plate solar collector based on a selective double-glazing. In Proceedings of the 29th ISES Biennial Solar World Congress, Johannesburg, South Africa, 11–14 October 2009. [Google Scholar]

- Ehrmann, N.; Reineke-Koch, R. Selectively coated high efficiency glazing for solar-thermal flat-plate collectors. Thin Solid Film. 2012, 520, 4214–4218. [Google Scholar] [CrossRef]

- Ajeena, A.M.; Víg, P.; Farkas, I. Anti-Reflection and Self-Cleaning Nanocoating to Improve the Performance of Flat Plate Solar Collector. Eur. J. Energy Res. 2022, 2, 13–18. [Google Scholar] [CrossRef]

- Siegel, R.; Howell, J.R. Thermal Radiation Heat Transfer; Hemisphere Publishing Corporation: Washington, DC, USA, 1992. [Google Scholar]

- Taylor, R.P.; Viskanta, R. Spectral and directional radiation characteristics of thin-film coated isothermal semitransparent plates. Wärme Stoffübertragung 1975, 8, 219–227. [Google Scholar] [CrossRef]

- Solastar. 3 Ways to Protect Your Health and Solar Water Heater from Hard Water. 2020. Available online: https://www.solostar.in/blog/3-ways-to-protect-your-health-and-solar-water-heater-from-hard-water/ (accessed on 9 June 2022).

- Energy Saver. Solar Water Heating System Maintenance and Repair. 2022. Available online: https://www.energy.gov/energysaver/solar-water-heating-system-maintenance-and-repair#:~:text=You%20can%20avoid%20scaling%20by,necessary%20depending%20on%20water%20conditions (accessed on 9 June 2022).

- Cho, Y.I.; Fridman, A.F.; Lee, S.H.; Kim, W.T. Physical Water Treatment for Fouling Prevention in Heat Exchangers. In Advances in Heat Transfer; Elsevier: Amsterdam, The Netherlands, 2004; pp. 1–72. [Google Scholar]

- Cho, Y.I.; Kim, H.-S. Nonchemical Methods to Control Scale and Deposit Formation. In Mineral Scales and Deposits; Amjad, Z., Demadis, K.D., Eds.; Chapter 9; Elsevier: Amsterdam, The Netherlands, 2015; pp. 193–221. [Google Scholar]

- Bott, T.R. Crystallisation and Scale Formation. In Fouling of Heat Exchangers; Bott, T.R., Ed.; Chapter 8; Elsevier: Amsterdam, The Netherlands, 1995; pp. 97–135. [Google Scholar]

- Kronenberg, K. Experimental evidence for effects of magnetic fields on moving water. IEEE Trans. Magn. 1985, 21, 2059–2061. [Google Scholar] [CrossRef]

- Baker, J.S.; Judd, S.J.; Parsons, S.A. Antiscale magnetic pretreatment of reverse osmosis feedwater. Desalination 1997, 110, 151–165. [Google Scholar] [CrossRef]

- Donaldson, J. Magnetic Treatment of Fluids—Preventing Scale; Finishing Line Press: Georgetown, KY, USA, 1988. [Google Scholar]

- Vengadesan, E.; Senthil, R. A review on recent development of thermal performance enhancement methods of flat plate solar water heater. Sol. Energy 2020, 206, 935–961. [Google Scholar] [CrossRef]

- Hajabdollahi, Z.; Hajabdollahi, H. Thermo-economic modeling and multi-objective optimization of solar water heater using flat plate collectors. Sol. Energy 2017, 155, 191–202. [Google Scholar] [CrossRef]

- El-Assal, B.; Irshad, K.; Ali, A. Effect of Side Reflectors on the Performance of Flat Plate Solar Collector: A Case Study for Asir Region, Saudi Arabia. Arab. J. Sci. Eng. 2020, 45, 1035–1050. [Google Scholar] [CrossRef]

- Visa, I.; Moldovan, M.; Duta, A. Novel triangle flat plate solar thermal collector for facades integration. Renew. Energy 2019, 143, 252–262. [Google Scholar] [CrossRef]

- Kim, S.; Jeong, H.; Park, J.Y.; Baek, S.Y.; Lee, A.; Choi, S.-H. Innovative flat-plate solar collector (FPC) with coloured water flowing through a transparent tube. RSC Adv. 2019, 9, 24192–24202. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, G.; Tang, Y.; Duan, L.; Tang, H.; Zhong, G.; Wan, Z.; Zhang, S.; Fu, T. Thermal performance enhancement of micro-grooved aluminum flat plate heat pipes applied in solar collectors. Renew. Energy 2020, 146, 2234–2242. [Google Scholar] [CrossRef]

- Muthuraman, U.; Shankar, R.; Nassa, V.K.; Karthick, A.; Malla, C.; Kumar, A.; Kumar, P.M.; Rahim, R.; Bharani, M. Energy and Economic Analysis of Curved, Straight, and Spiral Flow Flat-Plate Solar Water Collector. Int. J. Photoenergy 2021, 2021, 5547274. [Google Scholar] [CrossRef]

- Alva, G.; Liu, L.; Huang, X.; Fang, G. Thermal energy storage materials and systems for solar energy applications. Renew. Sustain. Energy Rev. 2017, 68, 693–706. [Google Scholar] [CrossRef]

- Sawant, S.R.; Mohod, S.A. Review on solar water heaters using PCM (Phase change materials) in TES (Thermal energy storage) systems. Int. J. Adv. Res. Sci. Eng. 2015, 4, 11. [Google Scholar]

- Baptista, J.A.; Eusébio, M.E.S.; Pereira, M.M. New renewable raw materials for thermal energy storage. J. Therm. Anal. Calorim. 2020, 145, 27–37. [Google Scholar] [CrossRef]

- IEA-SHC. Solar Heat Worldwide 2019: Growth Reported in 10 of the Top 20 Markets. In Solar Update; International Energy Agency (IEA): Paris, France, 2019; pp. 1–25. [Google Scholar]

- Nahar, A.; Hasanuzzaman, M.; Rahim, N.A. A Three-Dimensional Comprehensive Numerical Investigation of Different Operating Parameters on the Performance of a Photovoltaic Thermal System with Pancake Collector. J. Sol. Energy Eng. 2017, 139, 031009. [Google Scholar] [CrossRef]

- Nasrin, R.; Hasanuzzaman, M.; Rahim, N.A. Effect of high irradiation and cooling on power, energy and performance of a PVT system. Renew. Energy 2018, 116, 552–569. [Google Scholar] [CrossRef]

- Nasrin, R.; Hasanuzzaman, M.; Rahim, N.A. Effect of nanofluids on heat transfer and cooling system of the photovoltaic/thermal performance. Int. J. Numer. Methods Heat Fluid Flow 2019, 29, 1920–1946. [Google Scholar] [CrossRef]

- Nasrin, R.; Rahim, N.A.; Fayaz, H.; Hasanuzzaman, M. Water/MWCNT nanofluid based cooling system of PVT: Experimental and numerical research. Renew. Energy 2018, 121, 286–300. [Google Scholar] [CrossRef]

- Moezzi, M.; Ingle, A.; Outcault, S.; Sanguinetti, A.; Lutzenhiser, L.; Wilhite, H.; Lutz, J.D.; Meier, A.; Kutzleb, J. Solar Water Heating Assessment Project: Understanding and Improving Effectiveness for California Households. In Final Project Report; University of California: Davis, CA, USA; Ghoulem Research: San Rafael, CA, USA, 2019. [Google Scholar]

- Parker, D.; Colon, C.; Merrigan, T.; Maguire, J. Potential of a Very High Efficiency Solar-Assisted Heat Pump Water Heater. In 2018 ACEEE Summer Study on Energy Efficiency in Buildings; Florida Solar Energy Center: Washington, DC, USA, 2018. [Google Scholar]

- Nahar, A.; Hasanuzzaman, M.; Rahim, N.A. Numerical and experimental investigation on the performance of a photovoltaic thermal collector with parallel plate flow channel under different operating conditions in Malaysia. Sol. Energy 2017, 144, 517–528. [Google Scholar] [CrossRef]

- Nahar, A.; Hasanuzzaman, M.; Rahim, N.A.; Parvin, S. Numerical investigation on the effect of different parameters in enhancing heat transfer performance of photovoltaic thermal systems. Renew. Energy 2019, 132, 284–295. [Google Scholar] [CrossRef]

- Fayaz, H.; Nasrin, R.; Rahim, N.A.; Hasanuzzaman, M. Energy and exergy analysis of the PVT system: Effect of nanofluid flow rate. Sol. Energy 2018, 169, 217–230. [Google Scholar] [CrossRef]

- Fayaz, H.; Rahim, N.A.; Hasanuzzaman, M.; Rivai, A.; Nasrin, R. Numerical and outdoor real time experimental investigation of performance of PCM based PVT system. Sol. Energy 2019, 179, 135–150. [Google Scholar] [CrossRef]

- Fayaz, H.; Rahim, N.A.; Hasanuzzaman, M.; Nasrin, R.; Rivai, A. Numerical and experimental investigation of the effect of operating conditions on performance of PVT and PVT-PCM. Renew. Energy 2019, 143, 827–841. [Google Scholar] [CrossRef]

- Kumar, L.; Hasanuzzaman, M.; Rahim, N.A. Real-Time Experimental Performance Assessment of a Photovoltaic Thermal System Cascaded with Flat Plate and Heat Pipe Evacuated Tube Collector. J. Sol. Energy Eng. 2021, 144, 011004. [Google Scholar] [CrossRef]

- Kostić, L.T.; Aleksić, J.S. Review of research, development and application of photovoltaic/thermal water systems. Open Phys. 2020, 18, 1025–1047. [Google Scholar] [CrossRef]

- Hudon, K. Low Cost Solar Water Heating R&D; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2013; p. 14. [Google Scholar]

- Wallner, G.M.; Povacz, M.; Hausner, R.; Lang, R.W. Lifetime modeling of polypropylene absorber materials for overheating protected hot water collectors. Sol. Energy 2016, 125, 324–331. [Google Scholar] [CrossRef]

- Meegoda, J.N.; Jawidzik, J.; Rodriguez, P. Design, Fabrication and Testing of an Inexpensive Solar Water Heater. Peer Rev. J. Sol. Photoenergy Syst. 2019, 1, 1–9. [Google Scholar]

| Title | Year | Description | Shortfall | Source |

|---|---|---|---|---|

| Residential Solar Water Heating: California Adopters and their Experiences | 2021 | Survey on the adoption of SWH systems in 227 single-family households in California. Challenges at each stage of adoption are lined up. | Challenges are portrayed based on the adopters’ point of view and specific to particular households. | [9] |

| Effect of Design and Operating Parameters on Thermal Performance of Low-temperature Direct Absorption Solar Collectors: A Review | 2021 | Highlights the current challenges for direct absorption solar collectors (DASC) and its future directions in domestic sectors. | Issues integrated towards DASC only and are not specific to SWH technologies. | [10] |

| A Review on Techno-Economic Assessment of Solar Water Heating Systems in the Middle East | 2021 | Recent studies on techno-economic assessment for SWH integration in the Middle East region are reviewed. | The current position, progress, barriers, and challenges of the broader SWH market are explored in the Middle East. | [11] |

| Hybrid solar water heating/nocturnal radiation cooling system I: A review of the progress, prospects, and challenges | 2019 | Combined heating and cooling functionality using a single collector/radiator is presented. The prospects, advancements, and a few barriers are discussed. | Discussions are only centralized on hybrid solar water heating and cooling systems. | [12] |

| Causes of Failure of the South African Solar Water Heating Programme and the Forgone Social Benefits | 2019 | Assessment of the failure of an SWH program in South Africa. Institutional, social, and technical challenges are addressed. | Challenges are only catered to the targeted population and sample in South African regions. | [13] |

| Addressing Climate Change Through Green Technology with Reference to Solar Water Heating System Scheme: A Review of State of Punjab (India) | 2018 | Investigation towards the subsidized SWH project under Punjab Energy Development Agency (PEDA). SWH installation process and functionality challenges are highlighted. | Issues focused on Ludhiana, Jalandhar, and Kapurthala districts in Punjab, India. | [14] |

| Building Integration of Solar Renewable Energy Systems towards Zero or Nearly Zero Energy Buildings | 2015 | Suggestions for better integration of solar thermal systems on building roofs and façades. | Issues are addressed aesthetically. | [15] |

| Analysis of the Opportunities and Challenges of Solar Water Heating System (SWHS) in India: Estimates from the Energy Audit Surveys & Review | 2012 | Survey of SWH system market and opportunities in India. The main emphasis on prospects and challenges of SWHs in India. | Challenges are only accentuated in terms of India’s financial and market sides. | [16] |

| The Challenges of Designing and Building a Net Zero Energy Home in a Cold High-Latitude Climate | 2008 | Solutions for technical and policy challenges for the implementation of net-zero technologies in Canadian residencies. | Challenges are non-specific to domestic SWH technologies (a few sectors are covered). | [17] |

| Year | Technology | Location | Configuration | References |

|---|---|---|---|---|

| 1760s–early 1800s | Bare tank heater | USA | Two small boxes (filled with water) are fabricated inside a rectangular box. The inner side of the rectangular box is insulated, and a glass cover top is installed to trap heat. | [38] |

| 1891 | 1st commercial solar water heater | USA | A new design is patented with an integration of a hot box for better heat accumulation. | [38] |

| Early 1900s | Split system solar water heater | USA | The same collector-storage configuration is used, with water being heated in a new way: a non-freezing liquid is used in the collector and flows through a coil in the storage tank to pass heat to the water. The now-cooled liquid returns to the collector, and the cycle repeats. | [39] |

| 1960s–1970s | Cylindrical solar water heater | Japan | A simple design comprises a cylindrical-shaped metal water tank embedded in a box with a glass cover. | [38,40] |

| 1970s–late 1980s | Integral collector-tank solar water heater | Australia | The water storage tank is fabricated on the collector’s upper edge. This configuration avoids unnecessary piping and a heavy water storage tank in the attics. Due to its easy installation on Australian pitched roof houses, the integral collector-tank design is preferable. | [38,39] |

| Late 1980s | Solar water heater with FPCs | Canada | The production line of composite copper-aluminum absorbers for FPCs is launched. A self-designed selective oxidation line is being developed. | [41] |

| 1990s | Solar water heater with ETCs | China | Significant breakthroughs were achieved when China developed the all-glass vacuum tubes production line. Over the years, the invention of heat pipes within glass tubes emerged. | [41] |

| Recent years | Solar water heater with FPCs and ETCs | - | Many types with multiple configurations. Various enhancement methods have been introduced (e.g., nanofluids, TES, fins, heat pump, PVT, geometric pipe design, etc.) | - |

| Year | Location | Innovation | Configuration | Results | References |

|---|---|---|---|---|---|

| 2010 | China | An FPC solar water heater with a PCM-TES | Paraffin (PCM) saturated in aluminum foams is integrated onto the solar collector. The PCM layer is embedded underneath the collector’s selective absorber plate. | A remarkable enhancement of the heat-transfer ability is achieved. The aluminum foams help with a better temperature distribution in the PCM layer. | [42] |

| 2013 | Taiwan | A prototype of a PVT-assisted heat pump water heating system (PVT-HPWH) | An array of PVT evaporators is connected with a 1 kW HPSW and installed on a rooftop. A water tank of 200 L capacity is utilized. | Steady outputs are obtained even under fluctuated weather conditions. | [43] |

| 2014 | Iran | Copper (II) oxide (CuO)-water nanofluid in FPC | CuO particle size is 40 nm. CuO-water nanofluid acts as the working fluid in an FPC with flow rates ranging from 1 to 3 kg/min. | The collector efficiency with the nanofluid increases by 21.8% compared to just water as the working fluid. | [44] |

| 2015 | Malaysia | A heat-pipe ETC solar water heater equipped with a finned PCM-TES tank | An array of heat-pipe ETC is connected to a manifold filled with PCM. A vertical finned heat exchanger is fabricated inside the TES tank. | The solar water heater with a TES unit has higher efficiency than a conventional system. | [45] |

| 2018 | Bangladesh | Serpentine-type thermosyphon FPC solar water heater | The serpentine pipes are placed on top of the FPC’s absorber plate. The solar water heater works on the thermosyphon principle. | The proposed passive SWH system yields an exergy efficiency of about 3.7%. | [46] |

| 2020 | India | Cerium dioxide (CeO2) nanoparticles incorporated into a PCM-TES of all-glass ETC solar water heater | The TES unit is in nano-embedded PCM (NEPCM) and standard PCM forms, assembled in a horizontal cylindrical tank in the middle of a 125 L solar water tank. | The energy and exergy efficiencies of the PCM-TES SWH system are 10.89% and 3.96% higher than those without PCM; 1.0 mass% of CeO2 is adequate for maximum efficiencies. | [47] |

| 2020 | Egypt | An ETC solar water heater with novel helical finned heat pipes using PCM-TES | A multi-step helix of 0.5 mm thick coper disks is welded onto the heat pipes of 5 evacuated tubes | PCM with helical fins achieved better temperature homogeneity than that of regular fins. | [48] |

| 2021 | Nigeria | Active SWH systems with serpentine and risers-head flat-plate configurations | A 1.5 m2 is divided into two sections to accommodate the two pipe configurations. The first section is the risers-head pattern, while the second section is the serpentine pattern. | The serpentine model has a 2.62% more usable thermal energy than the risers-head. It also has better efficiency on a cloudy day. | [49] |

| Evacuated Tube Collector SWH System | Flat-Plate Collector SWH System | |

|---|---|---|

| Thermal output | Fast | Moderate |

| Performance | Good performance at hotter temperature | Poor performance at hotter temperature |

| Heat dissipation | Insignificant during the day | High |

| Efficiency in frigid temperatures | Moderate | Low due to water freezing |

| Range of temperature (°C) | 60–120 | 60–80 |

| Insulation | Polyurethane insulation on hot water tank | Glass or rockwool insulation on collector and hot water tank |

| Tube scaling risk | Little to none—with periodic maintenance | Substantial on the metal tubes |

| Peak absorption period | All-day long whenever the sun is out | Optimum at noon |

| Yearly hot water output | 350 days | ≈ 300 days |

| Life span | >15 years | >15 years |

| Maintenance | Simple—one faulty tube would not affect the whole system’s operation | Complex and high cost—glass sheet is expensive, and there is the possibility of replacing the whole panel due to any faulty |

| PCM | Chemical Composition | Melting Point (°C) | Heat of Fusion (kJ/kg) | Specific Heat (kJ/kg∙°C) | Reference |

|---|---|---|---|---|---|

| Paraffin wax | CnH2n+2 | 56 | 142.7 | 2.4 (s) 1.6 (l) | [115] |

| Urea | CO(NH2)2 | 132 | 250.66 | 1.34 (s) 2.99 (l) | [116] |

| Sodium acetate trihydrate (SAT) | NaC2H3O2∙3H2O | 58 | 264.18 | 1.7 (s) 2.9 (l) | [116] |

| Lead acetate trihydrate | C2H3O2Pb∙3H2O | 75 | 174 | 0.76 (s) 2.14 (l) | [116] |

| Tricosane | C23H48 | 45–47 | 210 | 2.89 (s) 2.89 (l) | [117] |

| Sodium acetate | NaCH3COO∙3H2O | 57–58 | 226 | 1.7 (s) 2.79 (l) | [117] |

| Water | H2O | 0 | 333 | 2.09 (s) 4.18 (l) | [117] |

| Barium hydroxide | Ba(OH)2·8H2O | 78–82 | 193 | 1.17 | [118] |

| Erythritol and graphite composite | - | 119 | 312.2 | - | [119] |

| Myristic acid | C14H28O2 | 51–52 | 196.2 | 1.60 (s) | [120] |

| Erythritol | C4H10O4 | 119 | 332–340 | 1.38 (s) 2.76 (l) | [121] |

| Pentaerythritol | C5H12O4 | 186–187 | 287–298 | - | [121] |

| Azelaic acid | C9H16O4 | 98–108 | 174 | - | [121] |

| Sebacic acid | C10H18O4 | 130–134 | 228 | - | [121] |

| Dimethyl terephthalate | C10H10O4 | 142 | 170 | - | [121] |

| P-toluic acid | C8H8O2 | 180 | 167 | - | [121] |

| Octadecanamide | C18H37NO | 106 | 211 | - | [121] |

| Organic chemical-based HS29 | - | 29 | 190 | 1.51 (s) 2.62 (l) | [65] |

| PCM | Melting Point (°C) | Collector Type | PCM Placement | Results | Reference |

|---|---|---|---|---|---|

| Paraffin wax | 40 | Heat-pipe FPC | PCM layer was placed at the bottom of the solar absorber plate and heat pipe. | The PCM layer improved the overall system performance. | [133] |

| Paraffin wax | 46.7 | FPC | A PCM container is placed at the back of the collector’s copper pipes. | Depending on the weather conditions, around 45% to 54% efficiency enhancement was achieved. | [134] |

| Urea–sodium acetate trihydrate (USAT) | 30 | FPC | PCM mixture was poured into the collector’s container. | The melting point of the storage material was increased by 12.5 °C. | [116] |

| Barium hydroxide | 78–82 | All glass ETC | A PCM storage unit was built-in inside each collector tube. | Efficiency was enhanced by 8% as compared to conventional SWH unit. | [118] |

| Erythritol and graphite composite | 119 | ETC | PCM was filled in aluminum pipes inside the tubes | Average storage efficiency of nearly 41% was achieved. | [119] |

| Triacontane and Erythritol | 71, 118 | Heat-pipe ETC | The heat pipes inside evacuated tubes are fully immersed in the dual-PCM. | There was 26% efficiency improvement for normal operation and 66% for stagnation mode. | [121] |

| PCM | Melting Point (°C) | PCM Placement | Results | Reference |

|---|---|---|---|---|

| Paraffin wax C-32 | 66–69 | A smaller tank of PCM was fabricated at the center of the solar water tank. | Energy discharge for a system with PCM is longer than the conventional one (hot water available for a more extended period). | [64] |

| HS29 Calcium chloride-based | 29 | PCM was placed in a stainless-steel cylinder outer tank. | The capacity for heat storage and thermal performance of the system was enhanced. | [65] |

| Sodium acetate trihydrate (SAT) | 58 | PCM was placed in aluminum cylinders and tubes within a solar water tank. | Primary energy consumption was reduced, and water was kept warmer than 55 °C for 10 h. | [136] |

| SAT composite | 58 | PCM was sealed in the mantle (22 mm thickness) in between the solar tank’s inner tank and insulation material. | The PCM layer within the water tank was proven to act well as a heat storage medium, with over 70% of the stored heat energy contributed to the hot water supply. | [137] |

| Aluminum ammonium sulfate and sodium hydrogen phosphate mixture | 42–60 | A heat storage tank with PCM was embedded underneath the water tank. | The PCM-integrated heat storage tank has higher efficiency with maximum exergy efficiency of 22%. | [138] |

| Commercial-grade paraffin wax | 63.74 | A PCM container was fabricated inside the solar tank. | Solar collector’s energy efficiency was increased by over 10%, exergy efficiency was improved by 5%, and there was a higher hot water temperature in the morning. | [139] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fadzlin, W.A.; Hasanuzzaman, M.; Rahim, N.A.; Amin, N.; Said, Z. Global Challenges of Current Building-Integrated Solar Water Heating Technologies and Its Prospects: A Comprehensive Review. Energies 2022, 15, 5125. https://doi.org/10.3390/en15145125

Fadzlin WA, Hasanuzzaman M, Rahim NA, Amin N, Said Z. Global Challenges of Current Building-Integrated Solar Water Heating Technologies and Its Prospects: A Comprehensive Review. Energies. 2022; 15(14):5125. https://doi.org/10.3390/en15145125

Chicago/Turabian StyleFadzlin, Wan Afin, Md. Hasanuzzaman, Nasrudin Abd Rahim, Norridah Amin, and Zafar Said. 2022. "Global Challenges of Current Building-Integrated Solar Water Heating Technologies and Its Prospects: A Comprehensive Review" Energies 15, no. 14: 5125. https://doi.org/10.3390/en15145125

APA StyleFadzlin, W. A., Hasanuzzaman, M., Rahim, N. A., Amin, N., & Said, Z. (2022). Global Challenges of Current Building-Integrated Solar Water Heating Technologies and Its Prospects: A Comprehensive Review. Energies, 15(14), 5125. https://doi.org/10.3390/en15145125