Safety Climate and Occupational Injuries in the Iron and Steel Industries in Tanzania

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Design and Population

2.2. Nordic Safety Climate Questionnaire (NOSACQ-50)

2.3. Occupational Injuries

2.4. Pretesting

2.5. Data Analysis

3. Results

3.1. Description of Study Participants: Managers and Workers

3.2. Safety Climate Level Among Managers and Workers

3.3. Prevalence of Occupational Injuries

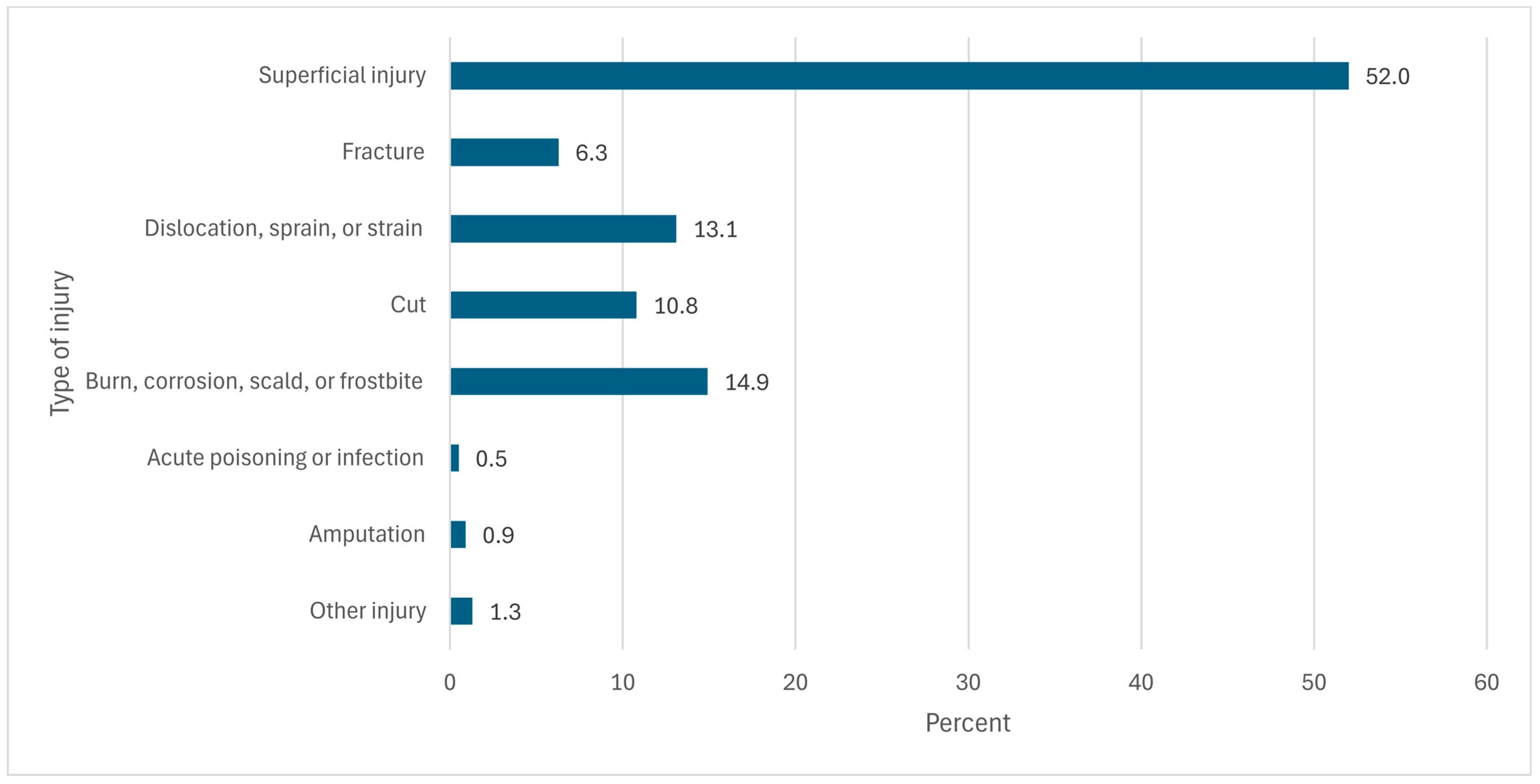

3.4. Safety Climate and Occupational Injuries Among Workers

3.5. Association Between Safety Climate Score and Occupational Injuries in the Past Year Among Workers in the Production Line of the Iron and Steel Industries

4. Discussion

The Strengths and Limitations of the Study

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dutta, S.K.; Chokshi, Y.B. Basic Concepts of Iron and Steel Making, 1st ed.; Springer Nature: Singapore, 2020. [Google Scholar]

- Sarna, S.K. Ispat Guru. Available online: https://www.ispatguru.com/safety-environment-and-health-issues-of-iron-and-steel-industry/1000/ (accessed on 7 July 2025).

- Vajda, P.; Aleksić, V.; Hunter, T. Environmental Aspects. In Commentary on the Energy Charter Treaty; Edward Elgar Publishing: Cheltenham, UK, 2018; pp. 269–281. [Google Scholar]

- Shabani, S.; Bachwenkizi, J.; Mamuya, S.H.; Moen, B.E. The prevalence of occupational injuries and associated risk factors among workers in the iron and steel industries: A systematic review and meta-analysis. BMC Public Health 2024, 24, 2602. [Google Scholar] [CrossRef] [PubMed]

- Shabani, S.; Moen, B.E.; Deressa, W.; Mamuya, S.H. Prevalence of Occupational Injuries among Workers in the Iron and Steel Industries in Tanzania. Ann. Glob. Health 2025, 91, 9. [Google Scholar] [CrossRef]

- Kifle, M.; Engdaw, D.; Alemu, K.; Sharma, H.R.; Amsalu, S.; Feleke, A.; Worku, W. Work Related Injuries and Associated Risk Factors among Iron and Steel Industries Workers in Addis Ababa, Ethiopia. Saf. Sci. 2014, 63, 211–216. [Google Scholar] [CrossRef]

- United Republic of Tanzania. National Five-Year Development Plan, 2016/17–2020/21; Ministry of Finance and Planning: Dar es Salaam, Tanzania, 2016. [Google Scholar]

- National Bureau of Statistics and the Ministry of Industry, Trade, and Investment. The 2013 Census of Industrial Production: Summary Report; Ministry of Industry, Trade and Investment: Dar Es Salaam, Tanzania, 2016; Available online: https://www.nbs.go.tz/uploads/statistics/documents/en-1705493816-Census_of_Industrial_Production_2013-Summary_Report.pdf (accessed on 7 July 2025).

- Luo, T. Safety Climate: Current Status of the Research and Future Prospects. J. Saf. Sci. Resil. 2020, 1, 106–119. [Google Scholar] [CrossRef]

- Hertanto, A.; Erwandi, D.; Widanarko, B.; Tejamaya, M. Relationship between Safety Climate and Safety Behavior in Company X in Indonesia. Safety 2023, 9, 89. [Google Scholar] [CrossRef]

- Alfanti, G.; Sawitri, D.R. Safety Climate and Construction Workers’ Compliance on the Use of Personal Protective Equipment in Construction Project Jakarta. Adv. Sci. Lett. 2017, 23, 3399–3401. [Google Scholar] [CrossRef][Green Version]

- Shojaee Barjoee, S.; Rodionov, V.; Rezaei, N. Occupational Injuries Associated with Safety Climate among Ceramic Industry Workers in Iran. Sci. Rep. 2025, 15, 24585. [Google Scholar] [CrossRef]

- Min, J.; Jang, T.-W.; Lee, H.-E.; Kang, M.-Y.; Cho, S.-S. Association between the Safety Climate and Occupational Injury in the Korean Working Population: A Cross-Sectional Study. Epidemiol. Health 2024, 46, e2024082. [Google Scholar] [CrossRef]

- Ajslev, J.Z.N.; Sundstrup, E.; Jakobsen, M.D.; Kines, P.; Dyreborg, J.; Andersen, L.L. Is Perception of Safety Climate a Relevant Predictor for Occupational Accidents? A Prospective Cohort Study among Blue-Collar Workers. Scand. J. Work. Environ. Health 2018, 44, 370–376. [Google Scholar] [CrossRef]

- Su, W.-J. The Effects of Safety Management Systems, Attitude and Commitment on Safety Behaviors and Performance. Int. J. Appl. Inf. Manag. 2021, 1, 187–200. [Google Scholar] [CrossRef]

- Tahapary, K.Y.; Laksono, A.R. The Effect of Safety Leadership on Safety Compliance: The Mediation Role of Safety Behaviors and Safety Motivation. Gold. Ratio Hum. Resour. Manag. 2025, 5, 436–448. [Google Scholar] [CrossRef]

- Hon, C.-Y.; Randhawa, J.; Lun, N.; Fairclough, C.; Rothman, L. Comparison of Management and Workers’ Perception, Attitudes and Beliefs toward Health and Safety in the Ontario Manufacturing Sector. J. Saf. Res. 2023, 84, 364–370. [Google Scholar] [CrossRef] [PubMed]

- Fargnoli, M.; Lombardi, M. NOSACQ-50 for Safety Climate Assessment in Agricultural Activities: A Case Study in Central Italy. Int. J. Environ. Res. Public Health 2020, 17, 9177. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M. Safety Climate and the Impact of the COVID-19 Pandemic: An Investigation on Safety Perceptions among Farmers in Italy. Safety 2021, 7, 52. [Google Scholar] [CrossRef]

- Arooj, A.; Majid, M.; Alam, A.; Bilal, M.F. Assessment of Workplace Safety Climate among Power Sector Employees: A Comparative Study of Cross-Culture Employer in Pakistan. PLoS ONE 2022, 17, e0272976. [Google Scholar] [CrossRef] [PubMed]

- Wibowo, A.; Lestari, F.; Modjo, R. Safety Climate Assessment in Fuel Stations in the West Java Region. Safety 2023, 9, 9. [Google Scholar] [CrossRef]

- Sepp, J.; Järvis, M. Relationship between Nursing Home Safety Climate and Caregivers’ Competence. Econ. Bus. 2019, 33, 247–263. [Google Scholar] [CrossRef]

- Moda, H.M.; Dama, F.M.; Nwadike, C.; Alatni, B.S.; Adewoye, S.O.; Sawyerr, H.; Doka, P.J.S.; Danjin, M. Assessment of Workplace Safety Climate among Healthcare Workers During the COVID-19 Pandemic in Low and Middle Income Countries: A Case Study of Nigeria. Healthcare 2021, 9, 661. [Google Scholar] [CrossRef]

- Ramirez, L.S.M. Safety Climate, Safety Hazards and Organizational Practices in the Construction Industry in Colombia. Ph.D. Thesis, University of Massachusetts Lowell, Lowell, MA, USA, 2014. [Google Scholar]

- Abegaz, T.; Deressa, W.; Moen, B.E. The Relationship Between Safety Climate and Safety Performance in the Large-Scale Building Construction Industry in Ethiopia: A Structural Equation Model Using the NOSACQ-50 Tool. Safety 2025, 11, 28. [Google Scholar] [CrossRef]

- Alamoudi, M. The Integration of NOSACQ-50 with Importance-Performance Analysis Technique to Evaluate and Analyze Safety Climate Dimensions in the Construction Sector in Saudi Arabia. Buildings 2022, 12, 1855. [Google Scholar] [CrossRef]

- Durmaz, S.; Atalay, S. The Relationship Between Occupational Accidents and the Safety Climate of Blue-Collar Workers in the Metal Industry. Med Sci. Discov. 2021, 8, 384–388. [Google Scholar] [CrossRef]

- Lin, S.-C.; Mufidah, I.; Persada, S.F. Safety-Culture Exploration in Taiwan’s Metal Industries: Identifying the Workers’ Background Influence on Safety Climate. Sustainability 2017, 9, 1965. [Google Scholar] [CrossRef]

- Jiao, Y.; Chen, Q.; Wu, Y.; Ji, C.; Zhang, N.; Luo, H.; Zhang, K. Designing New Environmental Policy Instruments to Promote the Sustainable Development of Iron and Steel Production in China: A Comparative Analysis of Cleaner Production Assessment Indicator Systems and the Assessment Principles of the Green Factory. Resour. Policy 2024, 96, 105244. [Google Scholar] [CrossRef]

- Braunger, P.; Frank, H.; Korunka, C.; Lueger, M.; Kubicek, B. Validating a Safety Climate Model in Metal Processing Industries: A Replication Study. Int. J. Occup. Saf. Ergon. 2013, 19, 143–155. [Google Scholar] [CrossRef]

- Huang, Y.; Robertson, M.M.; Lee, J.; Rineer, J.; Murphy, L.A.; Garabet, A.; Dainoff, M.J. Supervisory Interpretation of Safety Climate Versus Employee Safety Climate Perception: Association with Safety Behavior and Outcomes for Lone Workers. Transp. Res. Part F Traffic Psychol. Behav. 2014, 26, 348–360. [Google Scholar] [CrossRef]

- The National Research Centre for the Working Environment, Copenhagen, Denmark. Interpreting the Nordic Occupational Safety Climate Questionnaire NOSACQ-50 Results. Available online: https://nfa.dk/vaerktoejer/spoergeskemaer/safety-climate-questionnaire-nosacq-50/how-to-use-the-nordic-occupational-safety-climate-questionnaire-nosacq-50/interpreting-the-nordic-occupational-safety-climate-questionnaire-nosacq-50-results (accessed on 7 July 2025).

- Kines, P.; Lappalainen, J.; Mikkelsen, K.L.; Olsen, E.; Pousette, A.; Tharaldsen, J.; Tomasson, K.; Tõrner, M. Nordic Occupational Safety Climate Questionnaire (NOSACQ-50): A new tool for diagnosing occupational safety climate. Int. J. Indust. Erg. 2011, 6, 634–646. [Google Scholar] [CrossRef]

- Taswell, K.; Wingfield-Digby, P. Occupational Injuries Statistics from Household Surveys and Establishment Surveys. Available online: https://www.ilo.org/sites/default/files/wcmsp5/groups/public/@dgreports/@stat/documents/publication/wcms_173153.pdf (accessed on 7 July 2025).

- Nielsen, K.J.; Rasmussen, K.; Glasscock, D.; Spangenberg, S. Changes in Safety Climate and Accidents at Two Identical Manufacturing Plants. Saf. Sci. 2008, 46, 440–449. [Google Scholar] [CrossRef]

- Milczarek, M.; Najmiec, A. The Relationship Between Workers’ Safety Culture and Accidents, Near Accidents and Health Problems. Int. J. Occup. Saf. Ergon. 2004, 10, 25–33. [Google Scholar] [CrossRef]

- Hsieh, C.-M.; Chen, C.-J.; Peng, T.-T.; Chen, S.; Chen, P.-H. The Relationship between Workplace Justice and Self-Reported Occupational Accidents in Construction Employees of Taiwan. Ind. Health 2020, 58, 282–286. [Google Scholar] [CrossRef]

- Kim, S.J.; Chung, E.K. The Effect of Organizational Justice as Perceived by Occupational Drivers on Traffic Accidents: Mediating Effects of Job Satisfaction. J. Saf. Res. 2019, 68, 27–32. [Google Scholar] [CrossRef]

- Bergh, M.; Shahriari, M.; Kines, P. Occupational Safety Climate and Shift Work. Chem. Eng. Trans. 2013, 31, 403–408. [Google Scholar]

- Marin, L.S.; Lipscomb, H.; Cifuentes, M.; Punnett, L. Perceptions of Safety Climate across Construction Personnel: Associations with Injury Rates. Saf. Sci. 2019, 118, 487–496. [Google Scholar] [CrossRef]

- Cheyne, A.; Tomas, J.M.; Cox, S.; Oliver, A. Perceptions of Safety Climate at Different Employment Levels. Work Stress 2003, 17, 21–37. [Google Scholar] [CrossRef]

| Variable | Workers | Managers/Supervisors | p-Value |

|---|---|---|---|

| No (%) | No (%) | ||

| Age group | 0.121 2 | ||

| 18–30 | 179 (56) | 31 (62) | |

| 31–44 | 107 (33) | 18 (36) | |

| ≥45 | 35 (11) | 1 (2) | |

| Education | <0.001 2 | ||

| Never been in school | 19 (6) | - | |

| Primary school | 133 (41) | 3 (6) | |

| Secondary school and above | 169 (53) | 47 (94) | |

| Marital status | 0.134 1 | ||

| Never married | 83 (26) | 18 (36) | |

| Ever married | 238 (74) | 32 (64) | |

| Factory | 0.340 | ||

| A | 96 (31) | 12 (24) | |

| B | 60 (19) | 15 (30) | |

| C | 92 (29) | 13 (26) | |

| D | 70 (22) | 10 (20) | |

| Section | |||

| Furnace | 139 (43) | - | - |

| Rolling mill | 182 (57) | ||

| Working years | 0.003 1 | ||

| 1–4 years | 245 (76) | 28 (56) | |

| >4 years | 76 (24) | 22 (44) | |

| Working hours per day | 0.337 1 | ||

| ≤10 h | 77 (24) | 10 (20) | |

| >10 h | 244 (76) | 40 (80) |

| Dimension | Managers or Supervisors Mean Rank | Workers Mean Rank | Mann– Whitney | p-Value 1 |

|---|---|---|---|---|

| Management safety priority and ability | 165.73 | 189.16 | 7011.500 | 0.150 |

| Management safety empowerment | 251.46 | 175.80 | 11,298.000 | <0.001 |

| Management safety justice | 265.55 | 173.61 | 12,002.500 | <0.001 |

| Worker safety commitment | 41.12 | 208.57 | 781.000 | <0.001 |

| Workers’ safety priority and risk non-acceptance | 219.88 | 180.72 | 9719.000 | 0.016 |

| Peer safety communication, learning, and trust in safety ability | 112.84 | 197.40 | 4367.000 | <0.001 |

| Workers’ trust in the efficacy of safety systems | 232.79 | 178.71 | 10,364.500 | 0.001 |

| Variables | Occupational Injury | Univariate COR (95% CI) | Multivariate AOR (95% CI) | |

|---|---|---|---|---|

| Yes | No | |||

| Management safety priority and ability | ||||

| Good | 26 (27.3) | 59 (72.7) | 1 | 1 |

| Low | 183 (80.4) | 53 (19.6) | 7.835 (4.51–13.63) * | 6.73 (3.65–12.41) * |

| Management safety empowerment | ||||

| Good | 78 (42.5) | 60 (57.5) | 1 | 1 |

| Low | 131 (70.7) | 52 (29.3) | 1.94 (1.22–3.09) * | 0.98 (0.55–1.75) |

| Management safety justice | ||||

| Good | 51 (29.6) | 56 (70.4) | 1 | 1 |

| Low | 158 (92.3) | 56 (7.7) | 3.09 (1.90–5.04) * | 1.80 (1.02–3.19) * |

| Worker safety commitment | ||||

| Good | 84 (57.1) | 45 (42.9) | 1 | - |

| Low | 125 (68.1) | 67 (31.9) | 0.999 (0.626–1.596) | - |

| Workers’ safety priority and risk non-acceptance | ||||

| Good | 16 (57.1) | 12 (42.9) | 1 | - |

| Low | 193 (65.9) | 100 (34.1) | 1.447 (0.659–3.178) | - |

| Peer safety communication, learning, and trust in safety ability | ||||

| Good | 171 (29.6) | 83 (70.4) | 1 | 1 |

| Low | 38 (92.3) | 29 (7.7) | 0.64 (0.37–1.10) | 0.666 (0.35–1.25) |

| Workers’ trust in the efficacy of safety systems | ||||

| Good | 154 (65) | 83 (35) | 1 | - |

| Low | 55 (65.5) | 29 (34.5) | 1.022 (0.606–1.724) | - |

| Working years (Experience) | ||||

| 1–4 years | 169 (69) | 76 (31) | 2.001 (1.183–3.384) | |

| >4 years | 40 (52.3) | 36 (47.4) | 1 | |

| Working hours per day | ||||

| ≤10 h | 38 (49.4) | 39 (50.6) | 1 | |

| >10 h | 171 (70.1) | 73 (29.9) | 2.404 (1.423–4.060) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shabani, S.; Moen, B.E.; Abegaz, T.; Mamuya, S.H. Safety Climate and Occupational Injuries in the Iron and Steel Industries in Tanzania. Int. J. Environ. Res. Public Health 2025, 22, 1372. https://doi.org/10.3390/ijerph22091372

Shabani S, Moen BE, Abegaz T, Mamuya SH. Safety Climate and Occupational Injuries in the Iron and Steel Industries in Tanzania. International Journal of Environmental Research and Public Health. 2025; 22(9):1372. https://doi.org/10.3390/ijerph22091372

Chicago/Turabian StyleShabani, Saumu, Bente Elisabeth Moen, Teferi Abegaz, and Simon Henry Mamuya. 2025. "Safety Climate and Occupational Injuries in the Iron and Steel Industries in Tanzania" International Journal of Environmental Research and Public Health 22, no. 9: 1372. https://doi.org/10.3390/ijerph22091372

APA StyleShabani, S., Moen, B. E., Abegaz, T., & Mamuya, S. H. (2025). Safety Climate and Occupational Injuries in the Iron and Steel Industries in Tanzania. International Journal of Environmental Research and Public Health, 22(9), 1372. https://doi.org/10.3390/ijerph22091372