An Innovative Approach to Occupational Risk Assessment in OHS: A Case Study on the Verification of the ALrisk Model in Manufacturing Enterprises in Slovakia

Abstract

1. Introduction

Terminology

2. Methodology

- Definition of the subject, aim of the research, and formulation of hypotheses,

- Conducting an initial analysis of existing studies and theories,

- Defining the research methodology,

- Qualitative (interviews, discussions, consultations) and quantitative (questionnaire survey) data collection,

- Processing the results and proposing a solution,

- Verification of the proposed solutions,

- Training of enterprises in the use of the proposed solution,

- Implementation into the specific conditions of enterprises in Slovakia,

- Summary and evaluation of the main benefits.

- Analysis of statistical data—Statistical data from the National Labour Inspectorate and ESENER surveys served as a basis for the research, highlighting the necessity of an effective approach to OHS management and the assessment and management of occupational risks.

- Analysis and comparison of existing methodologies—Existing occupational risk assessment methodologies were analysed and compared to develop the ALrisk model.

- Survey analysis—The results of a conducted survey on occupational risk assessment, carried out within the framework of the scientific project APVV-20-0603, were examined.

- Consultations with experts and academics—Discussions with OHS specialists at both the European and Slovak levels contributed to the development of the model, ensuring its systematic structure and logical sequencing of phases and steps.

- Statistical tools and software support—Tools such as Excel and the web-based platform OiRA were utilised for designing and verifying the model.

- Checklists, point-based methods, and risk catalogues—These were applied during the verification process in real-world conditions, enabling an objective assessment of occupational risks as an integral part of the ALrisk model’s risk evaluation framework.

- Collection and analysis of statistical data—Gathering data from the National Labour Inspectorate and ESENER surveys. These data served as a foundation for the research, emphasising the need for effective occupational risk assessment and management in OHS.

- Baseline analysis of existing methodologies—Reviewing various occupational risk assessment methodologies based on scientific articles, studies, and research. Comparing these methodologies to identify the most effective approaches.

- Expert consultations, safety inspections, and discussions with practice during the model proposal—the proposal of the ALrisk model was consulted with several experts from both academic and corporate sectors to ensure its practical feasibility and professional accuracy. The research involved, for example, Bc. Miloš Eichler, Ing. Katarína Hannelová, Ing. Anna Cidlinová, PhD, Ing. Štefan Káloši, PhDr, David Michalík, PhD, DBA, Ing. Marek Bárdy, PhD, Ing. František Mrásko, and other experts active in the field of OHS. Representatives of the assessed enterprise also played an important role, with 10 expert meetings held at individual plants (e.g., Žilina, Bratislava, Košice, Martin, Trnava, Zvolen). These discussions contributed to the optimisation of the model based on real operational conditions and the needs of the enterprises.

- Integration of selected methods into the proposed model—Utilising findings from OHS-related research. Incorporating information on risk assessment obtained within the framework of the APVV scientific project.

- Systematisation and development of the ALrisk model—Consulting with experts and academics in the field of OHS. Ensuring a logical structure and a clear arrangement of the model’s phases.

- Verification of the model using software tools—testing of the ALrisk model was carried out in real conditions of selected manufacturing companies in Slovakia. Managers, safety technicians and employees working in the given job positions were involved in the assessment. Tools such as Microsoft Excel were used to verify the functionality of the model, where a checklist and risk catalogue were created directly. The OiRA web platform served as an inspirational platform in the verification of the ALrisk model, focusing on micro and small enterprises. These tools proved suitable especially in terms of practical applicability and accessibility. Excel enabled clear processing and comparison of data between individual operations and job positions, while OiRA provided an interactive space and inspirational perspective. The verification results demonstrated a high degree of applicability and benefit of the proposed model in practice, thus confirming its effectiveness in risk reduction and improvement of occupational safety.

- Evaluation of model verification in practice—Using checklists, point-based methods, and risk catalogues for assessing and objectively evaluating occupational risks.

3. Results

- Development of the ALrisk model—A framework for occupational risk assessment.

- Evaluation of key results from the verification of the proposed model for the job position of machine operator in a manufacturing enterprise.

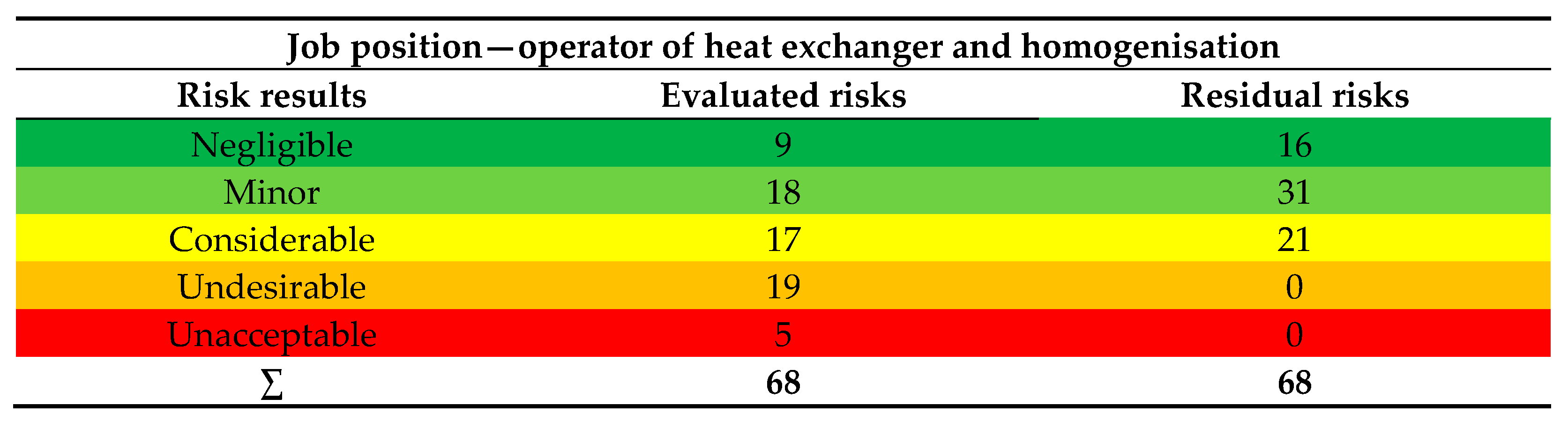

- Evaluation of key results from the verification of the proposed model for the job position operator of heat exchanger and homogenisation in a manufacturing enterprise.

3.1. The ALrisk Model Proposal for Occupational Risk Assessment and Management in OHS

Originality and Significance of the Proposed ALrisk Model

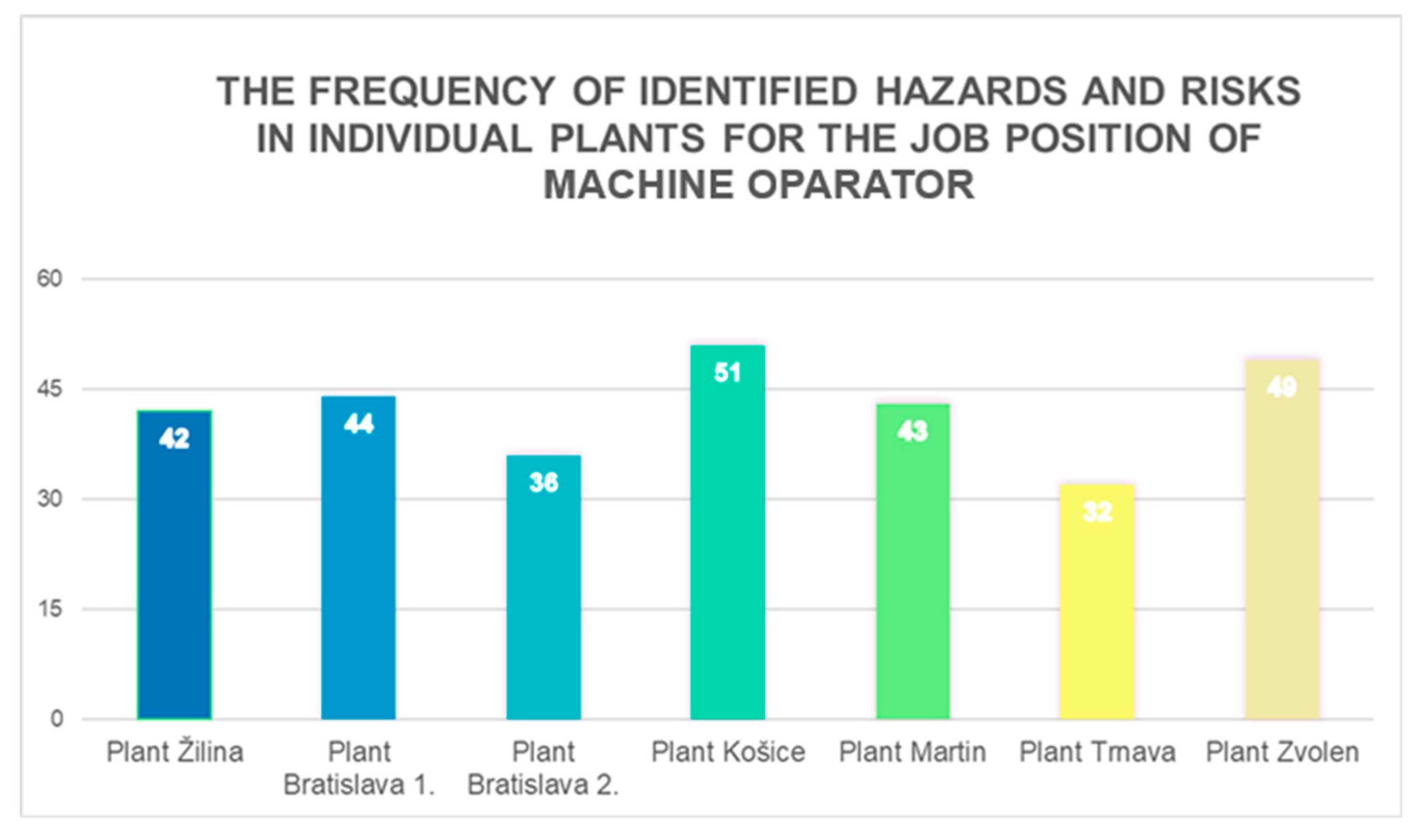

3.2. Evaluation of Key Results from the Verification of the Proposed Model for the Job Position of Machine Operator in a Manufacturing Enterprise

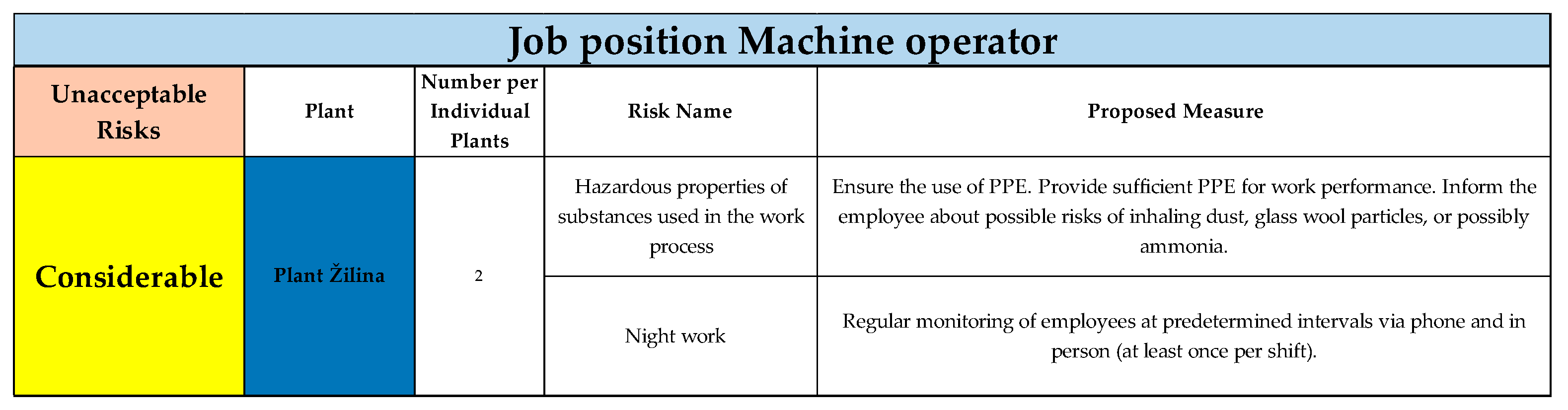

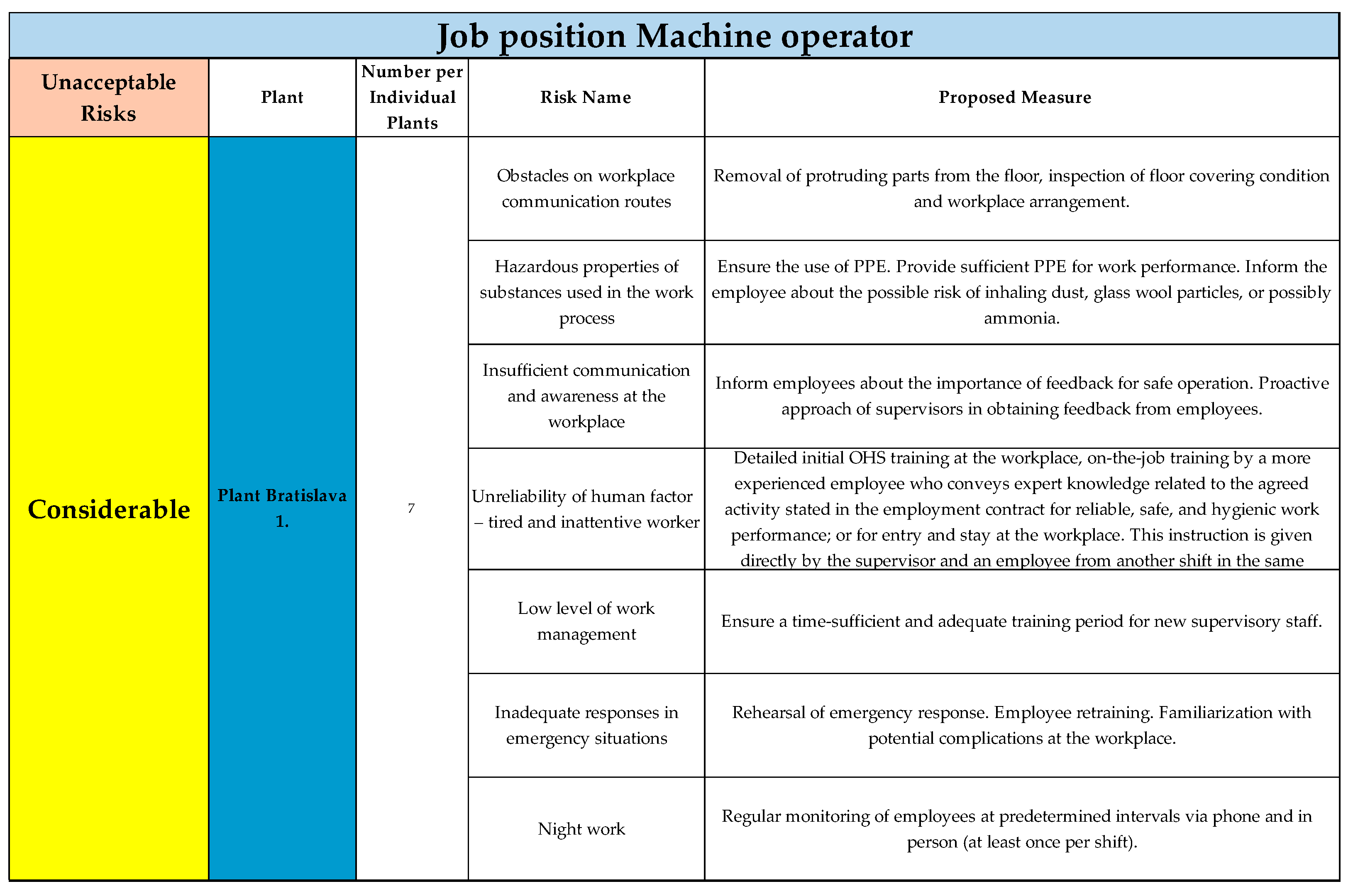

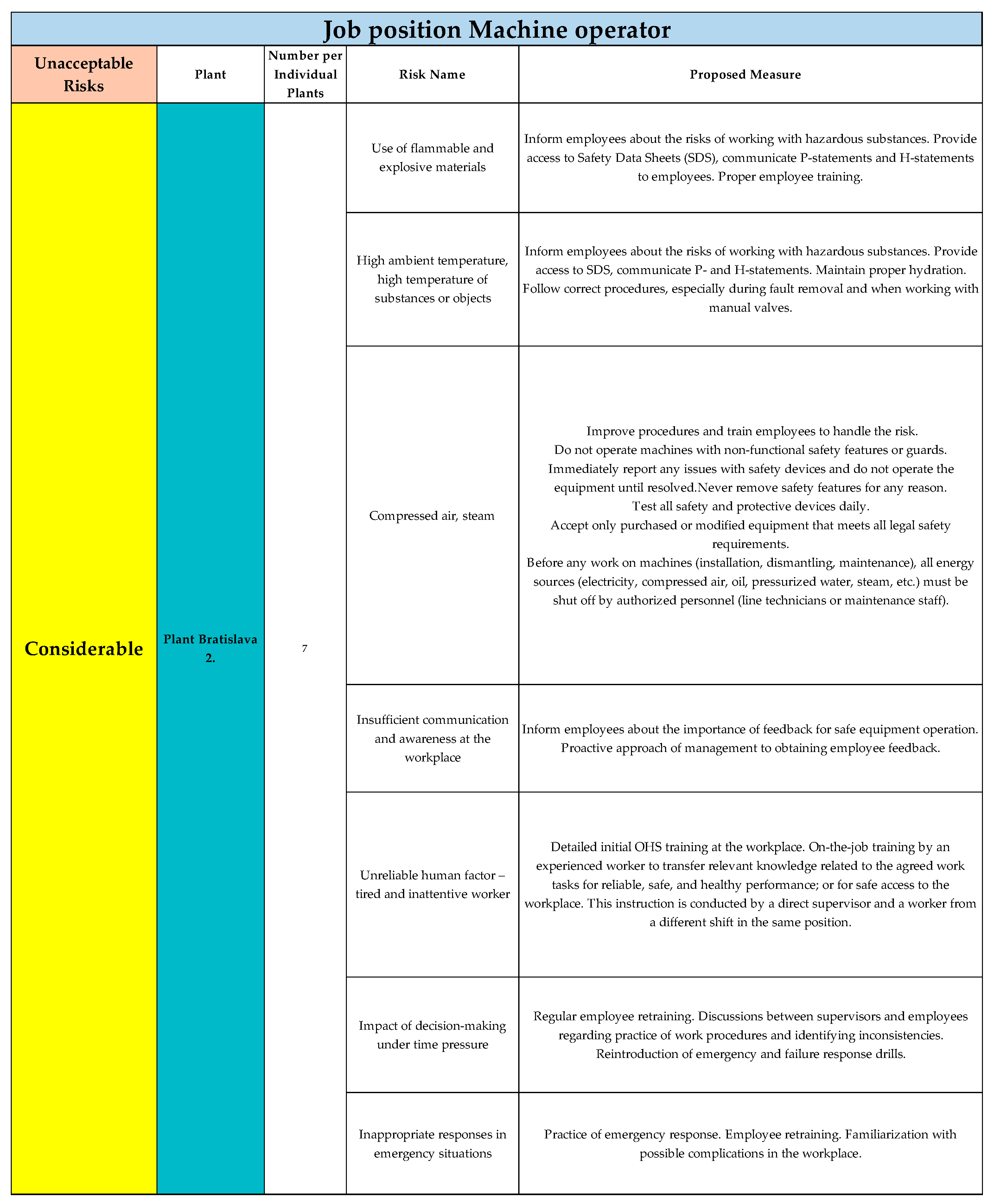

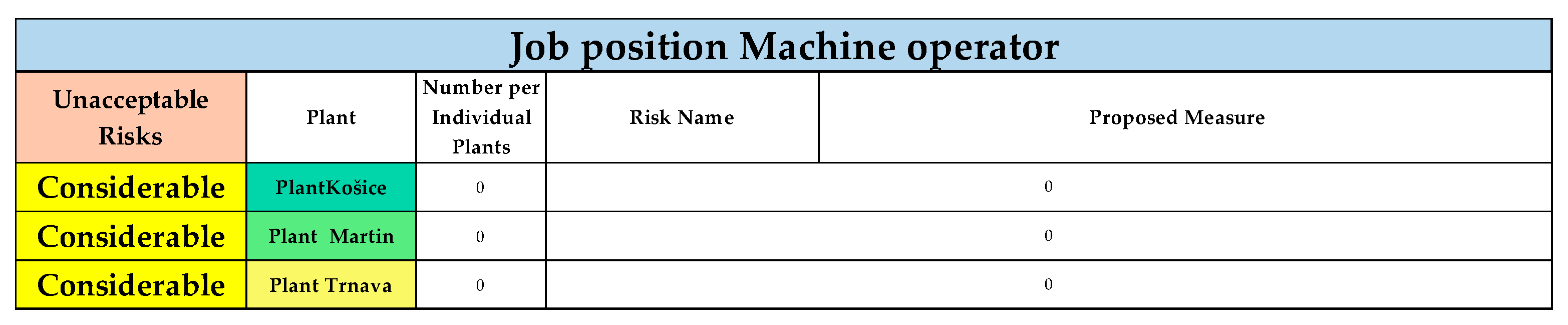

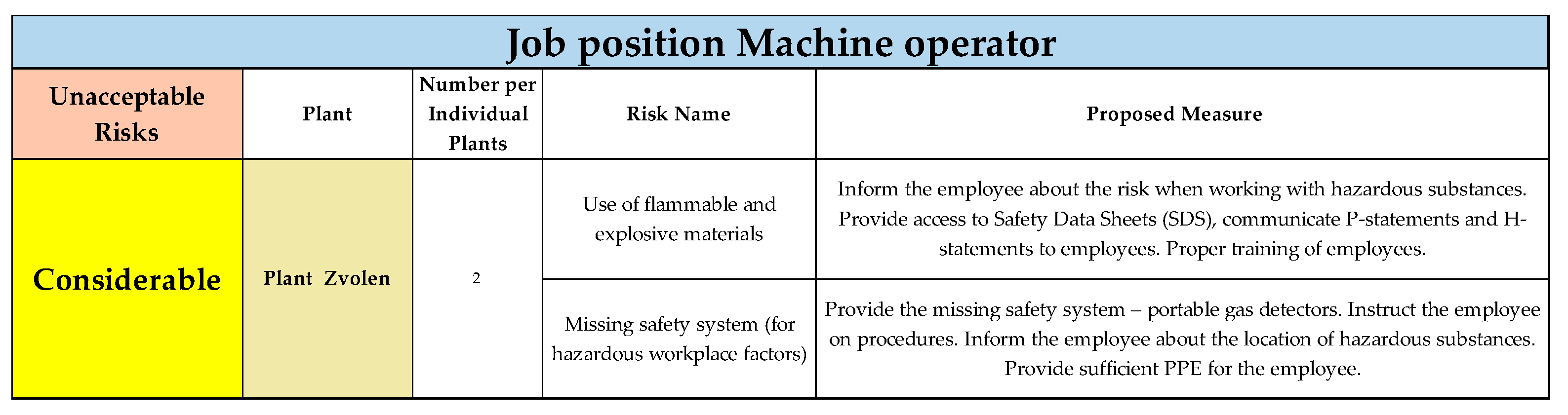

Unacceptable Risks in Individual Categories Classified According to the Risk Score for the Job Position of Machine Operator

3.3. Evaluation of Key Results from the Verification of the Proposed Model for the Job Position Operator of Heat Exchanger and Homogenisation in a Manufacturing Enterprise

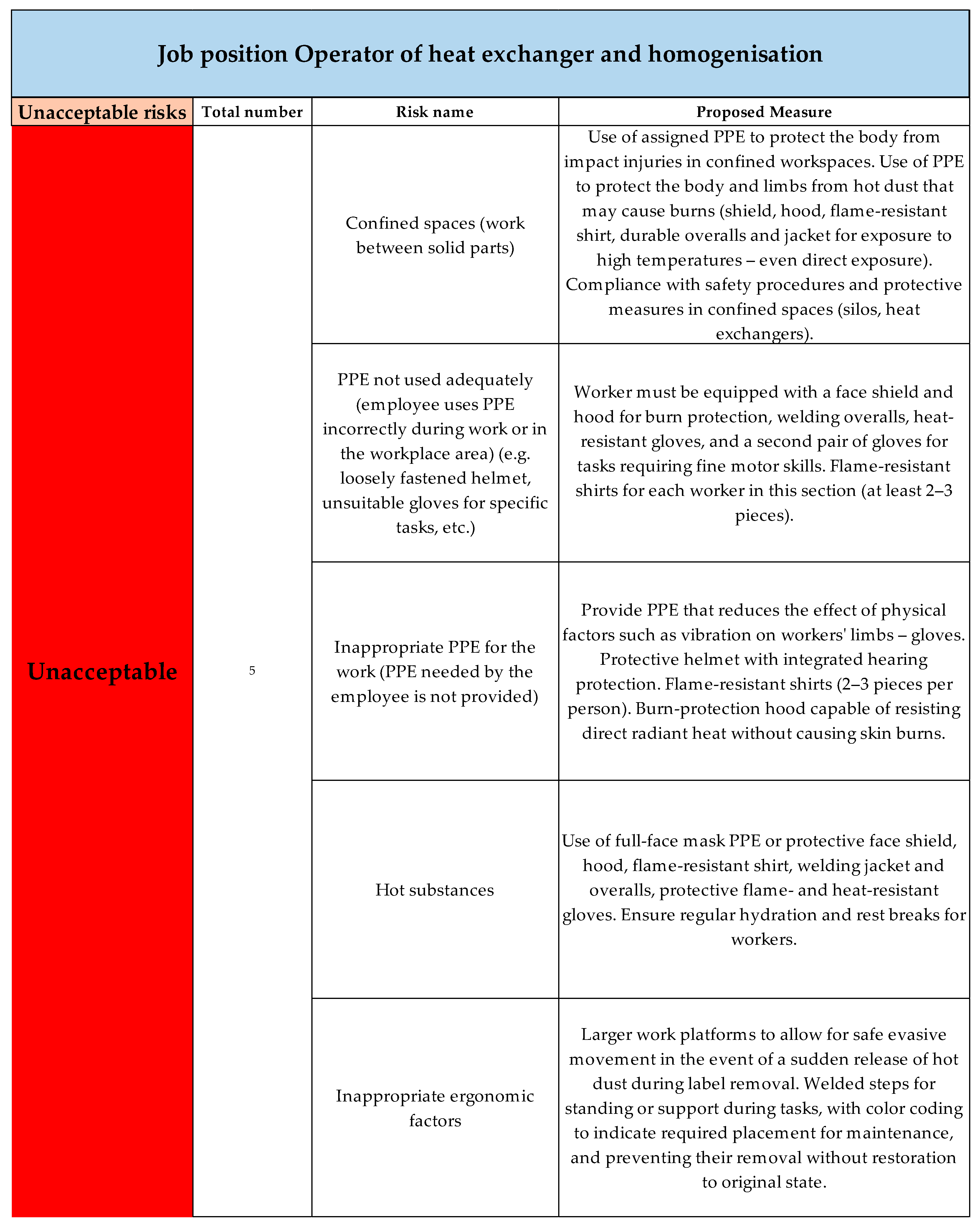

Unacceptable Risks in Individual Categories Classified According to the Risk Score for the Job Position Operator of Heat Exchanger and Homogenisation

4. Discussion

- Flexibility—The ALrisk model can be applied across various industries, company sizes, and specific working conditions, making it highly adaptable.

- Systematic Approach—It provides clearly defined steps and a structured framework for risk assessment and management, eliminating ambiguity and disorganisation.

- Practicality—Designed to address the real needs of enterprises, it is easily applicable in practice due to its detailed structure, including its supporting components, main sections, phases, and steps.

- Innovation—The model is research-based and integrates modern technologies, methodologies, and online tools for risk assessment, such as the OiRA web platform.

- Dynamism—ALrisk is not a static document but a living process that can be continuously updated, improved, and adapted to emerging risks.

- Predictive Capability—Beyond assessing current risks, the model’s supporting and main components allow companies to anticipate future hazards, threats, and risks and implement preventive measures accordingly.

- Proactive Approach—The model does not merely address problems but focuses on preventing them and strategic safety planning.

- Efficiency—ALrisk reduces redundancy in risk assessment and management, saving both time and costs for enterprises.

- Adaptability—The model functions effectively under various working conditions and is designed to respond to legal and technical changes.

5. Conclusions

- The ALrisk model made it possible to unify risk assessment procedures in seven operations and six plants in Slovakia,

- Standardisation of the job title terminology was achieved, which had previously been recorded in various forms (e.g., machine operator–technician, machine operator–mechanic, machine operator–walker), and were merged under the unified designation “machine operator”,

- Employees’ trust in the OHS system increased, as they perceived that a consistent and thorough approach to the protection of their health and safety was being applied.

- The job position was reclassified from category 2 to category 3 based on the identified exceeded limits (e.g., noise, vibrations),

- The model ensured a clear step-by-step process, which enabled managers to proceed systematically without omitting any steps,

- Specific risks were identified and adequate measures were proposed for their elimination,

- A safety manual was proposed for the job position, serving as a clear document outlining the most serious risks in the workplace, necessary personal protective equipment, and other information about the job position,

- An information safety brochure was created for the company, intended for visitors to provide them with basic information about OHS rules within the company.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AHP | Analytic Hierarchy Process |

| DTE | Designated Technical Equipment |

| ETA | Event Tree Analysis |

| ESENER | European Survey of Enterprises on New and Emerging Risks |

| EU-OSHA | European Agency for Safety and Health at Work |

| FMEA | Failure Mode and Effects Analysis |

| FTA | Fault Tree Analysis |

| HAZOP | Hazard and Operability Study |

| ISO | International Organization for Standardization |

| MSDs | Musculoskeletal Disorders |

| OHS | Occupational Health and Safety |

| OiRA | Online Interactive Risk Assessment |

| PPE | Personal Protective Equipment |

| SDS | Safety Data Sheet |

| SMEs | Small and Medium-Sized Enterprises |

References

- Nenonen, N.; Tappura, S.; Rantala, M.; Lindholm, M. Workplace Hazards Difficult to Identify and Manage; Springer International Publishing: Berlin/Heidelberg, Germany, 2021. [Google Scholar] [CrossRef]

- Levashov, S.P.; Karnachev, I.P.; Cheltybashev, A.A. The Strategy of Occupational Risk Management through the Analysis of Key Indicators of Monitoring Safety. Proc. Tula State Univ. Sci. Earth 2018, 2, 146–153. [Google Scholar]

- Bouzerara, R.; Chaib, R.; Verzea, I. For Better Governance of Harmfulness in Companies: A Case Study. Procedia Struct. Integr. 2023, 48, 4–11. [Google Scholar] [CrossRef]

- Kielesińska, A. Evaluation of Safe and Hygienic Work Conditions in the COVID-19 Era: A Case Study in a Production Company. Mater. Res. Proc. 2023, 34, 414–421. [Google Scholar] [CrossRef]

- Bejinariu, C.; Darabont, D.C.; Burduhos-Nergis, D.-P. INCDPM Method for Assessing the Risks of Occupational Injury and Illness at Work; Bentham Science Publishers: Sharjah, United Arab Emirates, 2024; pp. 127–147. [Google Scholar] [CrossRef]

- Boyd, L.K.; Mills, L.; Jacintho, A.; Martínez, G.d.l.C. Risk Assessments to Improve Workplace Compliance and Safety. In Proceedings of the International Petroleum Technology Conference; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar] [CrossRef]

- Trishch, R.; Nechuiviter, O.; Hrinchenko, H.; Bubela, T.; Riabchykov, M.; Pandová, I. Assessment of Safety Risks Using Qualimetric Methods. MM Sci. J. 2023, 2023, 6668–6674. [Google Scholar] [CrossRef]

- Adem, A. A Guide Proposal for the Evaluation of Risk Analysis Techniques Used in Occupational Health and Safety. Politek. Derg. 2022, 25, 1319–1328. [Google Scholar] [CrossRef]

- Rantala, M.; Lindholm, M.; Tappura, S.; Kivistö Rahnasto, J. Criteria for Successful Occupational Health and Safety Risk Assessment: A Systematic Review. In Safety Management and Human Factors; AHFE International: Orlando, FL, USA, 2022. [Google Scholar] [CrossRef]

- Bibire, L.; Lazar, F.I.; Chitimus, A.D.; Ghenadi, A.S. Risk Management in Industrial Companies, Case Study: Collective Work Accident at a Brewery. Sci. Study Res. Chem. Chem. Eng. Biotechnol. Food Ind. 2020, 21, 111–124. [Google Scholar]

- Kuzheleva, M.; Pushenko, S.; Staseva, E. Methodology for Improving the Efficiency of Occupational Safety Management of an Enterprise Based on the Theory of Risk Management. BIO Web Conf. 2024, 113, 06032. [Google Scholar] [CrossRef]

- Driscoll, T. Guide to Managing OHS Risks in the Health Care Industry. Aust. New Zealand J. Public Health 2007, 31, 91. [Google Scholar] [CrossRef]

- Hayashi, Y.; Kamei, K. Risk Management. Sci. Soc. Saf. Living Times Risks Disasters 2019, 2, 121–128. [Google Scholar] [CrossRef]

- Chencheva, O.; Sukach, S.; Rieznik, D.; Petrenko, I.; Lashko, Y.; Hladiuk, O. Modern Concept of Occupational Safety and Health Management with a Risk-Based Approach. Koмyнaльне Гocnoдapcmвo Micm 2024, 4, 221–227. [Google Scholar] [CrossRef]

- Nitescu, H.-M.; Gheorghe, M.; Amza, C.G. Occupational Health and Safety Risk Assessment Using the MAXM Method. Bul. Ştiinţific Al Univ. Politeh. Din Timişoara. Ser. Ing. Şi Manag. 2023, 9, 45–51. [Google Scholar] [CrossRef]

- OSH WIKI. Occupational Safety and Health Risk Assessment Methodologies. OSHwiki 2022. Available online: https://oshwiki.osha.europa.eu/en/themes/occupational-safety-and-health-risk-assessment-methodologies (accessed on 21 January 2025).

- Holla, K.; Mitasova, V.; Pavlenko, T. Risk Assessment Model Verification in Hazardous Industrial Processes. Procedia Eng. 2017, 192, 324–329. [Google Scholar] [CrossRef]

- EU-OSHA. Európska Príručka—Základy Posudzovania Rizík; European Agency for Safety and Health at Work: Bilbao, Spain, 2007; Available online: https://osha.europa.eu/sk/publications/risk-assessment-essentials (accessed on 21 January 2025).

- Kimmel, G.; Vu, V. Framework for Human Health Risk Assessment. Hum. Ecol. Risk Assess. 2001, 7, 153–156. [Google Scholar] [CrossRef]

- The National Labour Inspectorate of Slovakia. Available online: https://www.ip.gov.sk/ (accessed on 21 January 2025).

- Slovak Republic. Act No. 124/2006 Coll. on Occupational Health and Safety and on Amendments and Supplements to Certain Acts; Collection of Laws of the Slovak Republic; Ministry of Justice of the Slovak Republic: Bratislava, Slovakia, 2006. [Google Scholar]

- Occupational Health and Safety Concerns Us All. 2025. Available online: https://ec.europa.eu/social/BlobServlet?langId=sk&docId=16893& (accessed on 21 January 2025).

- Ramos, D.G.G.; Afonso, P.; Costa, A. Integration of ISO 31000 into the Organization’s Health and Safety Management Processes. In Proceedings of the SHO2015: International Symposium on Occupational Safety and Hygiene, Guimaraes, Portugal, 12–13 February 2015; pp. 285–287. [Google Scholar]

- Podgórski, D. The Use of Tacit Knowledge in Occupational Safety and Health Management Systems. Int. J. Occup. Saf. Ergon. 2010, 16, 283–310. [Google Scholar] [CrossRef]

- Komzolov, A.A.; Kirichenko, T.V.; Barkhatov, V.; Manezheva, M. Quantitative Assessment of Occupational Risk Based on Determining the Costs of Ensuring Life and Health of Employees. Mosc. Univ. Econ. Bull. 2024, 6, 134–161. [Google Scholar] [CrossRef]

- Kvitkina, M.; Pushenko, S.L.; Staseva, E.V. The Method of Assessing Occupational Risk Based on the Materials of a Special Assessment of Working Conditions. E3S Web Conf. 2023, 381, 01090. [Google Scholar] [CrossRef]

- Gerasimenko, N.M. Some Aspects of Hazards Analysis and Assessment of the Degree of Occupational Risk Based on a Risk-Based Approach. Bezop. Tr. V Promyshlennosti 2023, 9, 89–95. [Google Scholar] [CrossRef]

- Golinko, V.; Cheberyachko, S.I.; Deryugin, O.V.; Arkhirei, M. Improvement of the Procedure of Occupational Risk Assessment in Industrial Production. Labour Prot. Probl. Ukr. 2022, 38, 3–14. [Google Scholar] [CrossRef]

- Petchenko, I.V. Evaluation of the Occupational Safety Management System: Occupational Safety Audit as a Key Tool to Enhance Safety in the Enterprise. Labour Prot. Probl. Ukr. 2023, 39, 59–63. [Google Scholar] [CrossRef]

- Khamidullina, E.A.; Nayanov, P.A. Impact of the Oil and Gas Production Process on the Environment and Human Health. IOP Conf. Ser. Earth Environ. Sci. 2022, 979, 012168. [Google Scholar] [CrossRef]

- Nunes, I.L. Human Factors in Risk Analysis of Technological Systems. In Advances in Human Factors and Ergonomics in Healthcare; Stanton, N.A., Ed.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 100–110. [Google Scholar] [CrossRef]

- OIRA EU-OSHA. How to Carry Out a Risk Assessment. Online Interactive Risk Assessment (OIRA), European Agency for Safety and Health at Work 2025. Available online: https://oira.osha.europa.eu/en/how-carry-out-risk-assessment (accessed on 21 January 2025).

- European Union. Council Directive 89/391/EEC of 12 June 1989 on the Introduction of Measures to Encourage Improvements in the Safety and Health of Workers at Work. Off. J. Eur. Communities 1989, L183, 1–8. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex%3A31989L0391 (accessed on 21 January 2025).

- ISO 31000:2018; Risk Management—Guidelines. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 45001:2018; Occupational Health and Safety Management Systems—Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2018.

- Karanikas, N.; Weber, D.; Bruschi, K.; Brown, S. Identification of Systems Thinking Aspects in ISO 45001:2018 on Occupational Health & Safety Management. Saf. Sci. 2022, 148, 105671. [Google Scholar] [CrossRef]

- Rantala, M.; Lindholm, M.; Tappura, S. Supporting Occupational Health and Safety Risk Assessment Skills: A Case Study of Five Companies. Int. J. Environ. Res. Public Health 2022, 19, 1720. [Google Scholar] [CrossRef]

- Felknor, S.A.; Streit, J.M.K.; McDaniel, M.; Schulte, P.A.; Chosewood, L.C.; Delclos, G.L. How Will the Future of Work Shape OSH Research and Practice? A Workshop Summary. Int. J. Environ. Res. Public Health 2021, 18, 5696. [Google Scholar] [CrossRef]

- Klimová, E.V.; Ryzhikov, E.N. Reducing Workplace Injuries by Improving Safety Management System. Proc. Tula State Univ. Sci. Earth 2017, 1, 41–51. [Google Scholar]

- Rudakov, M.; Gridina, E.; Kretschmann, J. Risk-Based Thinking as a Basis for Efficient Occupational Safety Management in the Mining Industry. Sustainability 2021, 13, 470. [Google Scholar] [CrossRef]

- Pinto, A.; Ribeiro, R.A.; Nunes, I.L. Ensuring the Quality of Occupational Safety Risk Assessment. Risk Anal. 2012, 33, 409–419. [Google Scholar] [CrossRef]

- Matkovčíková, N. Health and Safety Management in Companies of All Sizes. Strategies for Psychosocial Risk Management in Manufacturing. Hradec Econ. Days 2017, 7, 597–603. [Google Scholar]

- Kuricová, A. Posudzovanie a Riadenie Pracovných Rizík. Ph.D. Thesis, University of Žilina, Faculty of Security Engineering, Žilina, Slovakia, 2024; p. 203. Available online: https://opac.crzp.sk/?fn=detailBiblioForm&sid=0CD22148AAB768F4945D74857C89 (accessed on 15 September 2024).

- Kuricová, A.; Hollá, K.; Kočkár, S.; Boudébs, M. Model ALrisk BOZP pre posudzovanie a riadenie pracovných rizík a jeho verifikácia v podnikoch. Verif. Model. ALrisk V Praxi 2024. Available online: https://app.crepc.sk/?fn=detailBiblioForm&sid=BC2DF5561E82DF976EE36B82E23B (accessed on 21 January 2025).

- CEMMAC, a.s. Safety Data Sheet: Cement According to EN 197—General Purpose Cements [online]. Horné Srnie: CEMMAC, a.s., 1/2025. Available online: http://www.cemmac.sk/dev/wp-content/uploads/Karta_bezpecnostnych_udajov.pdf (accessed on 21 January 2025).

| Hazards, Threats, and Sources of Risk in the Workplace |

|---|

| Job position: Machine operator |

| Machine and vehicle movement |

| Flammability, explosiveness |

| Improper workplace layout |

| Sharp edges, corners, points, rough surfaces, protruding parts Working at heights Obstacles in workplace pathways Electrical switches of machines Impact of portable electrical devices Dangerous properties of substances used in the work process Use of flammable and explosive materials High temperature of the environment, high temperature of materials or objects Compressed air, steam Presence of allergens Insufficient communication and awareness in the workplace Unreliable human factor—tired and distracted workers Impact of decision-making under time pressure Night work Workplace rotation Manual handling of loads Pressure equipment Gas equipment |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuricová, A.; Hudáková, M.; Kočkár, S.; Hollá, K. An Innovative Approach to Occupational Risk Assessment in OHS: A Case Study on the Verification of the ALrisk Model in Manufacturing Enterprises in Slovakia. Int. J. Environ. Res. Public Health 2025, 22, 757. https://doi.org/10.3390/ijerph22050757

Kuricová A, Hudáková M, Kočkár S, Hollá K. An Innovative Approach to Occupational Risk Assessment in OHS: A Case Study on the Verification of the ALrisk Model in Manufacturing Enterprises in Slovakia. International Journal of Environmental Research and Public Health. 2025; 22(5):757. https://doi.org/10.3390/ijerph22050757

Chicago/Turabian StyleKuricová, Alena, Mária Hudáková, Samuel Kočkár, and Katarína Hollá. 2025. "An Innovative Approach to Occupational Risk Assessment in OHS: A Case Study on the Verification of the ALrisk Model in Manufacturing Enterprises in Slovakia" International Journal of Environmental Research and Public Health 22, no. 5: 757. https://doi.org/10.3390/ijerph22050757

APA StyleKuricová, A., Hudáková, M., Kočkár, S., & Hollá, K. (2025). An Innovative Approach to Occupational Risk Assessment in OHS: A Case Study on the Verification of the ALrisk Model in Manufacturing Enterprises in Slovakia. International Journal of Environmental Research and Public Health, 22(5), 757. https://doi.org/10.3390/ijerph22050757