A Case Study of Ergonomic Risk Assessment in Slovakia with Respect to EU Standard

Abstract

1. Introduction

1.1. Musculoskeletal Disorders and Their Possible Reduction

1.2. Important Issues of Standards for Physical Load Assessment Applied in Slovakia

2. Materials and Methods

2.1. Captiv Measurement System

2.2. Measurement Procedure

2.2.1. Measurement Plan

- ▪

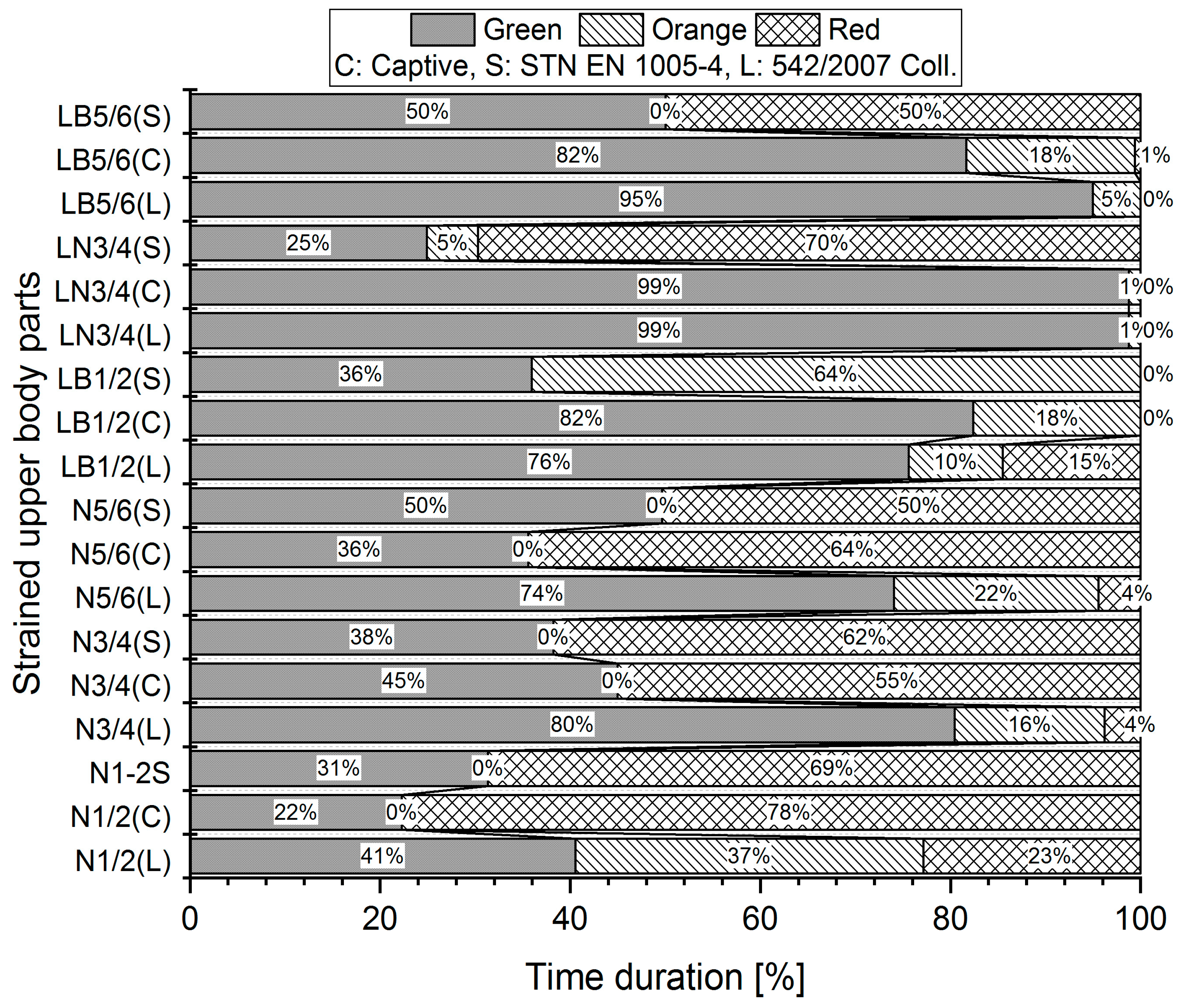

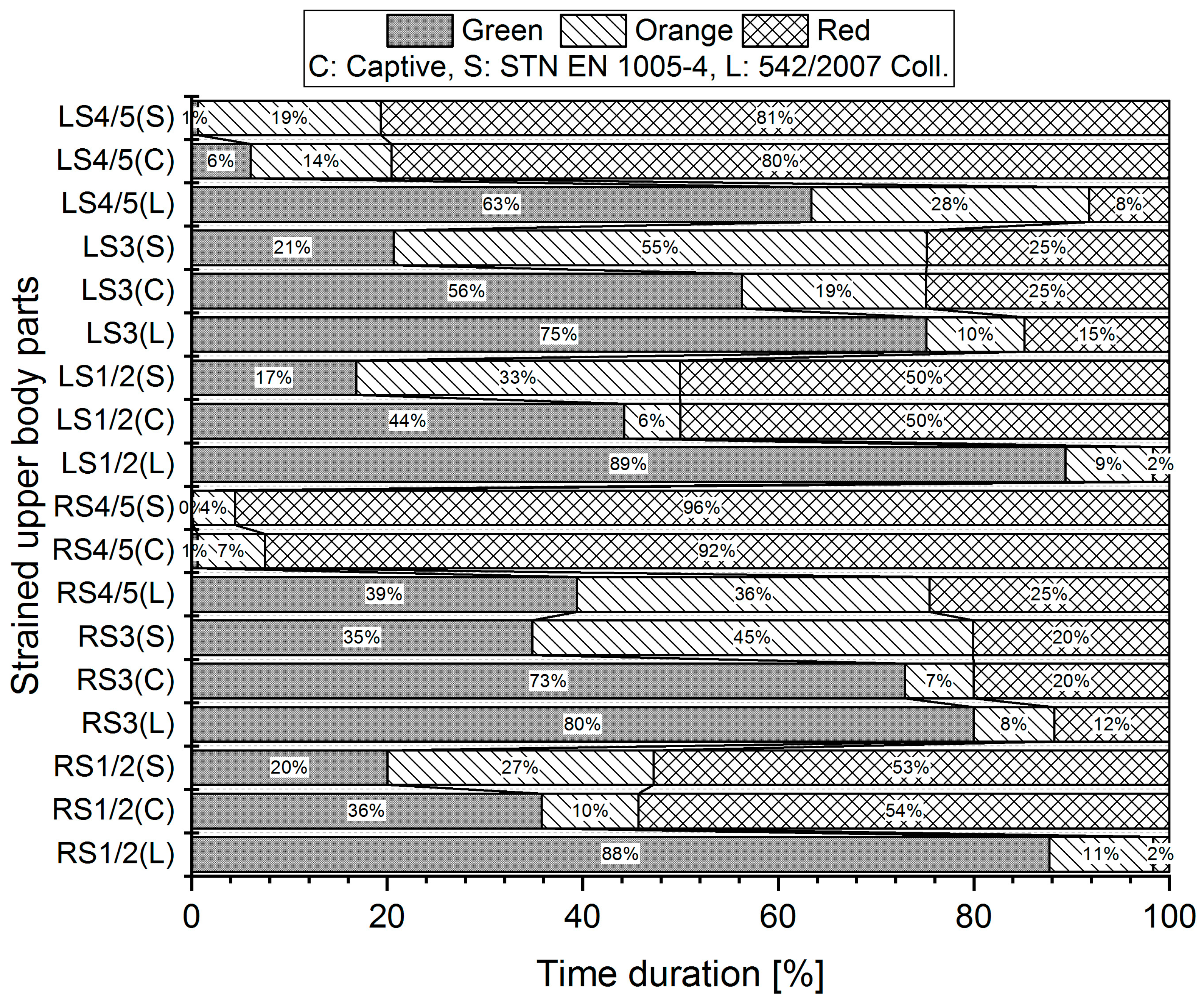

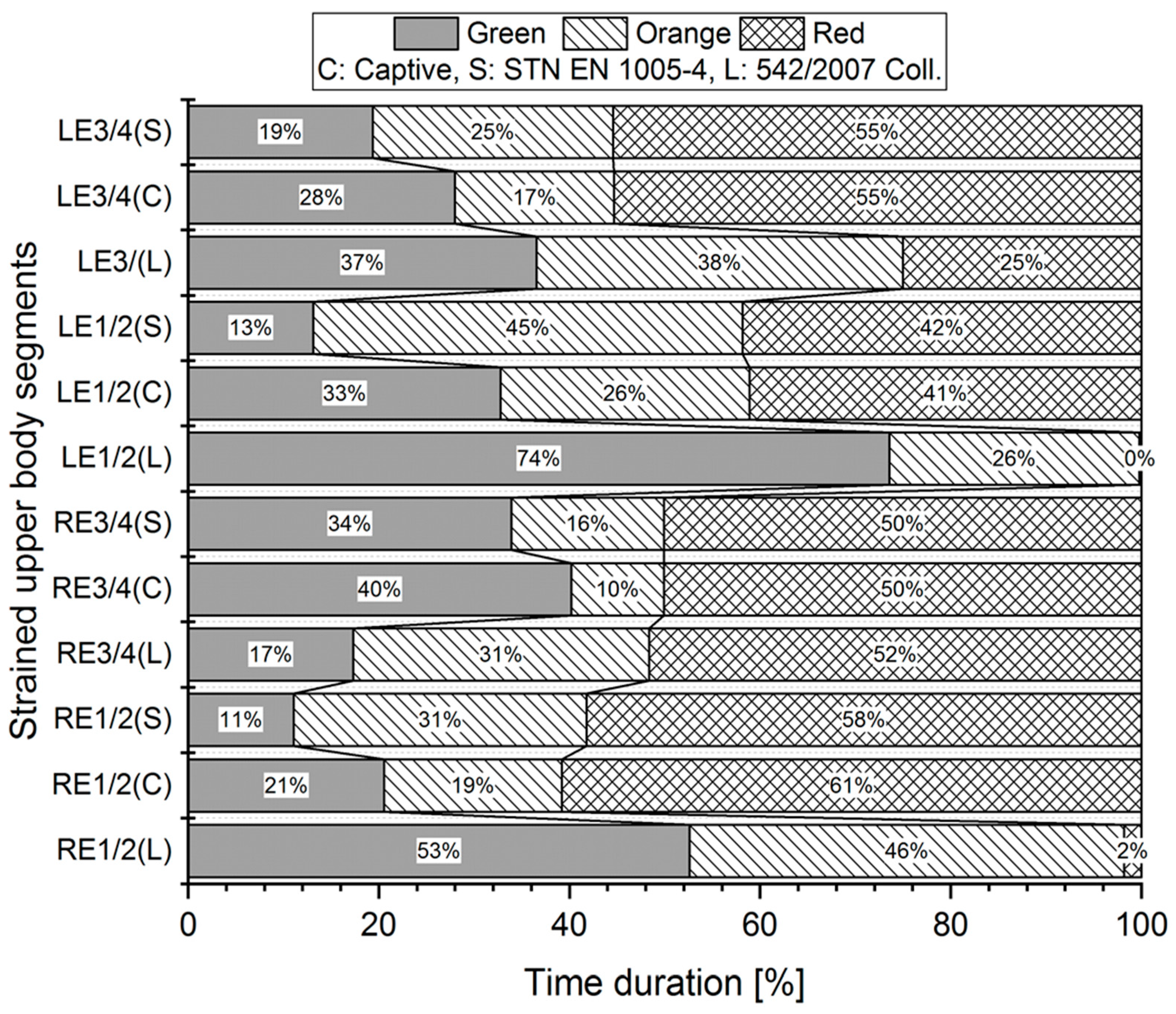

- To measure the time individual body segments spend in a specific working posture for 5 workers using three assessment methods;

- ▪

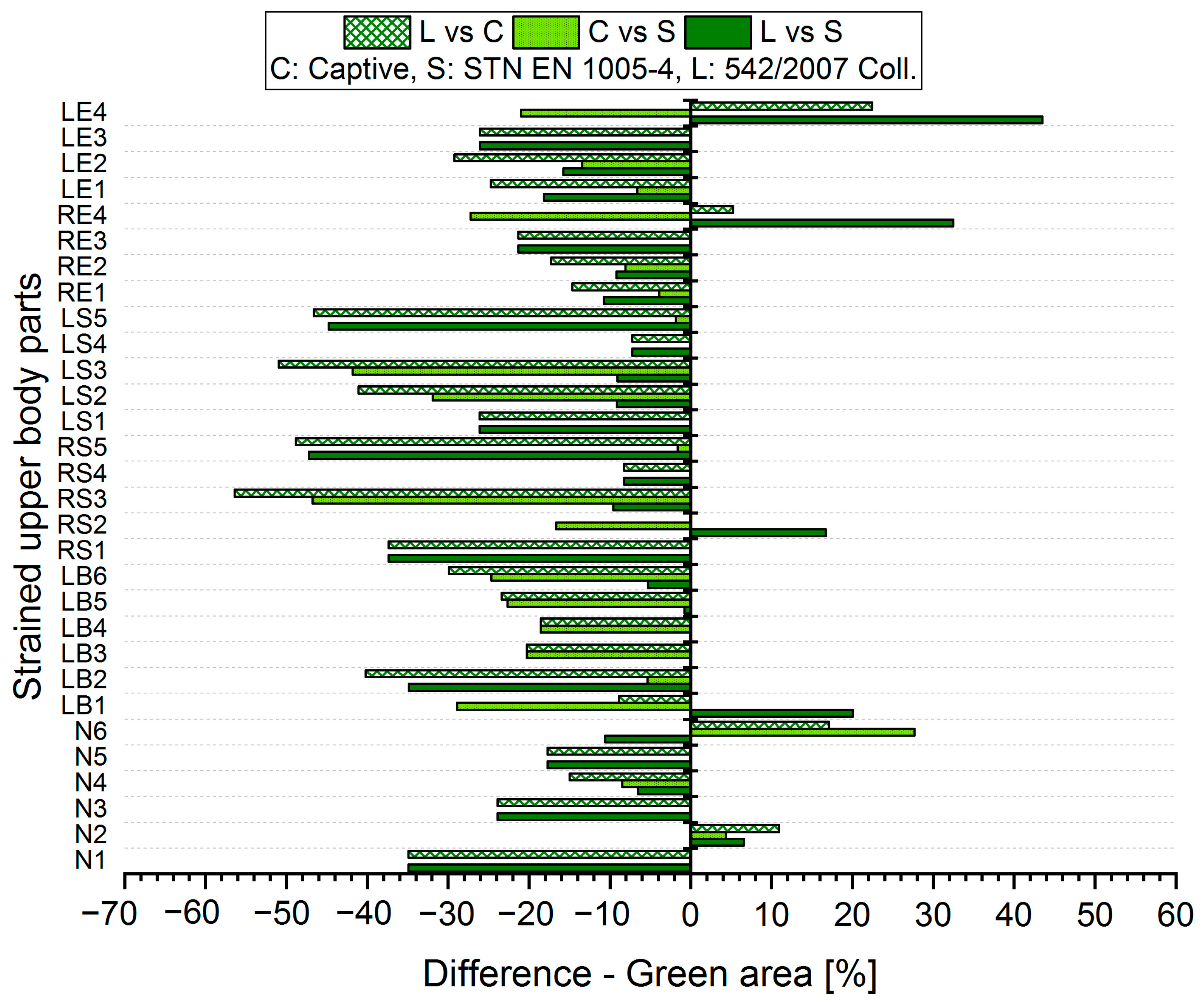

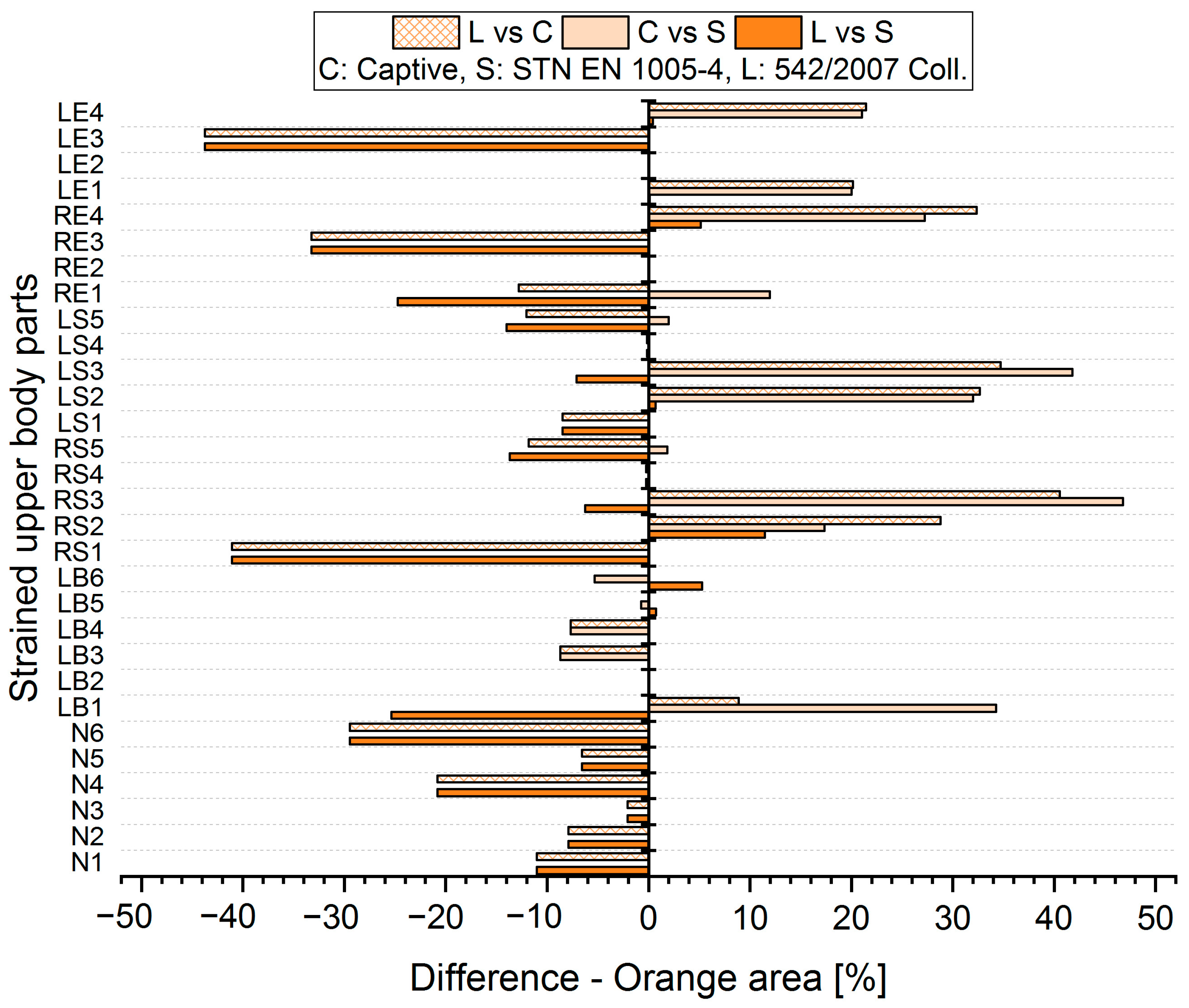

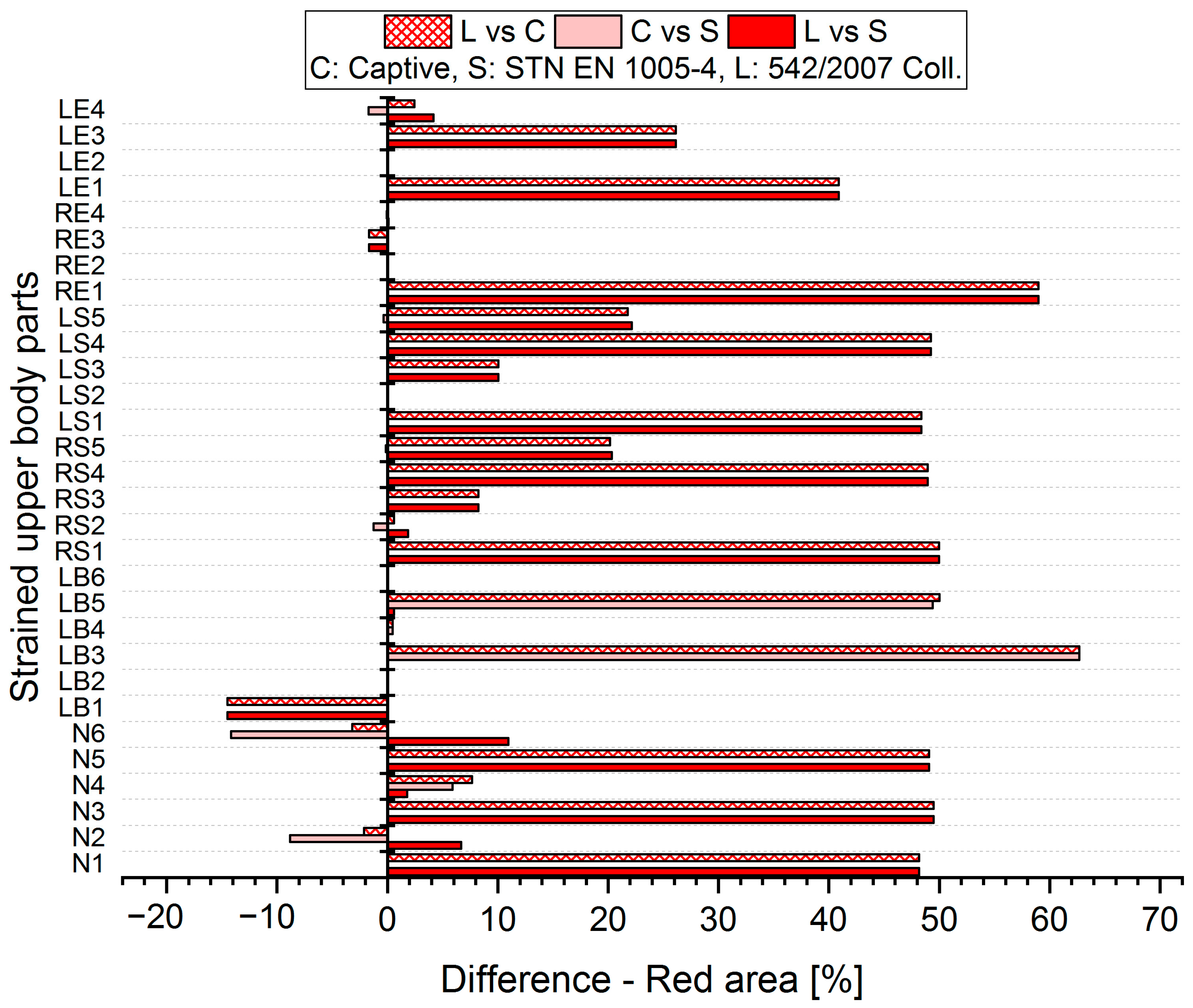

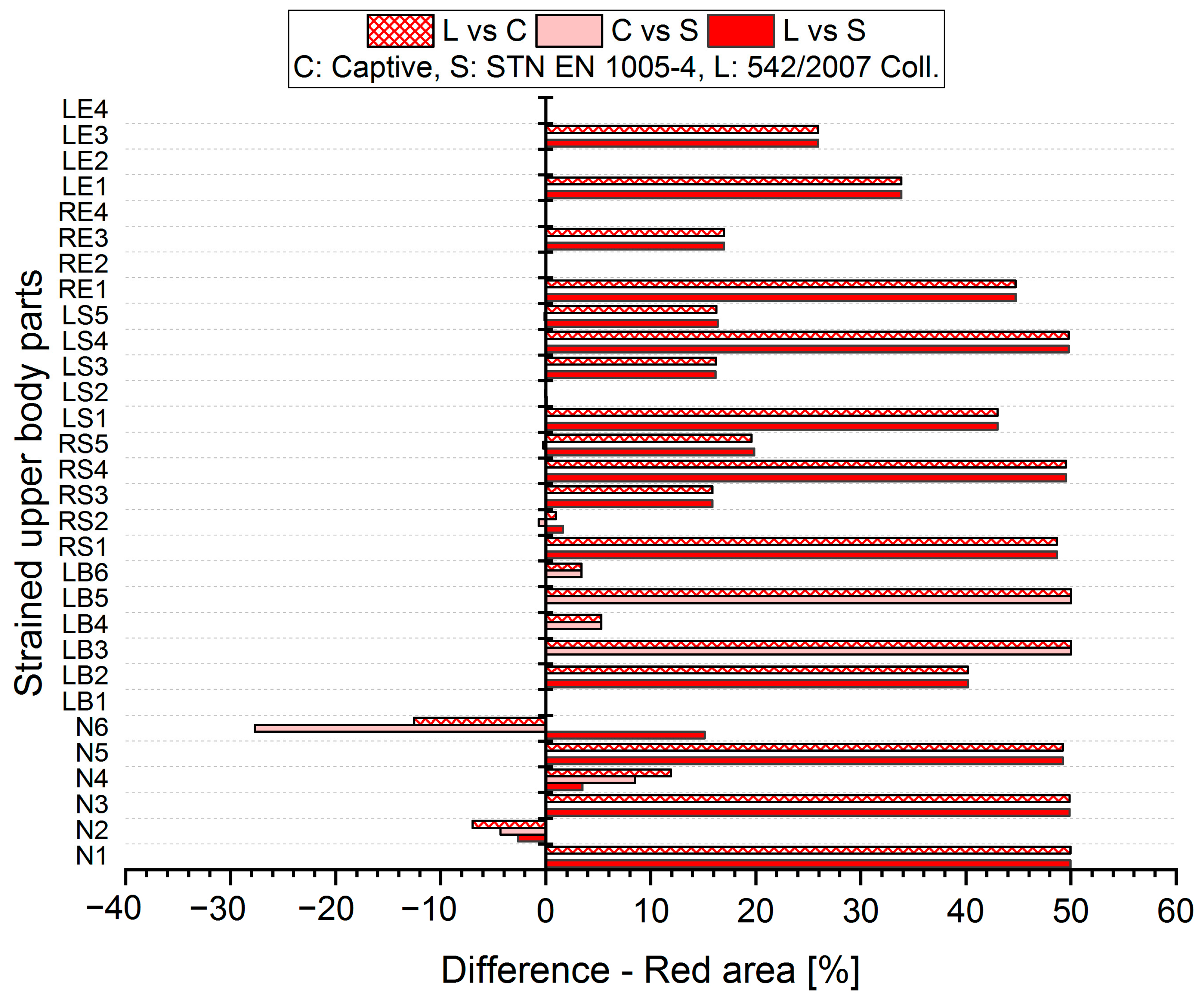

- To determine the time individual body segments spend in acceptable (Green), conditionally acceptable (Orange), and unacceptable (Red) working postures;

- ▪

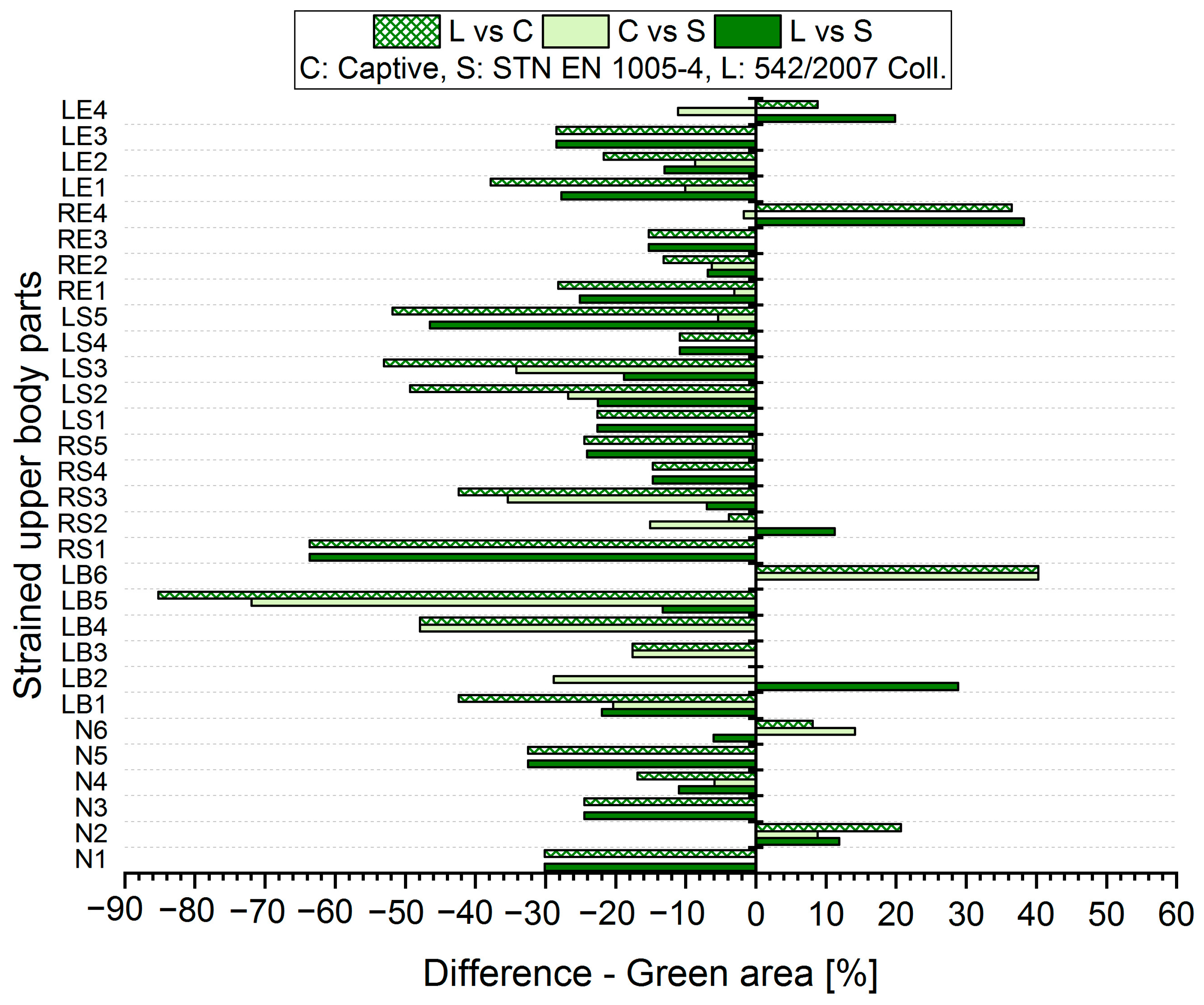

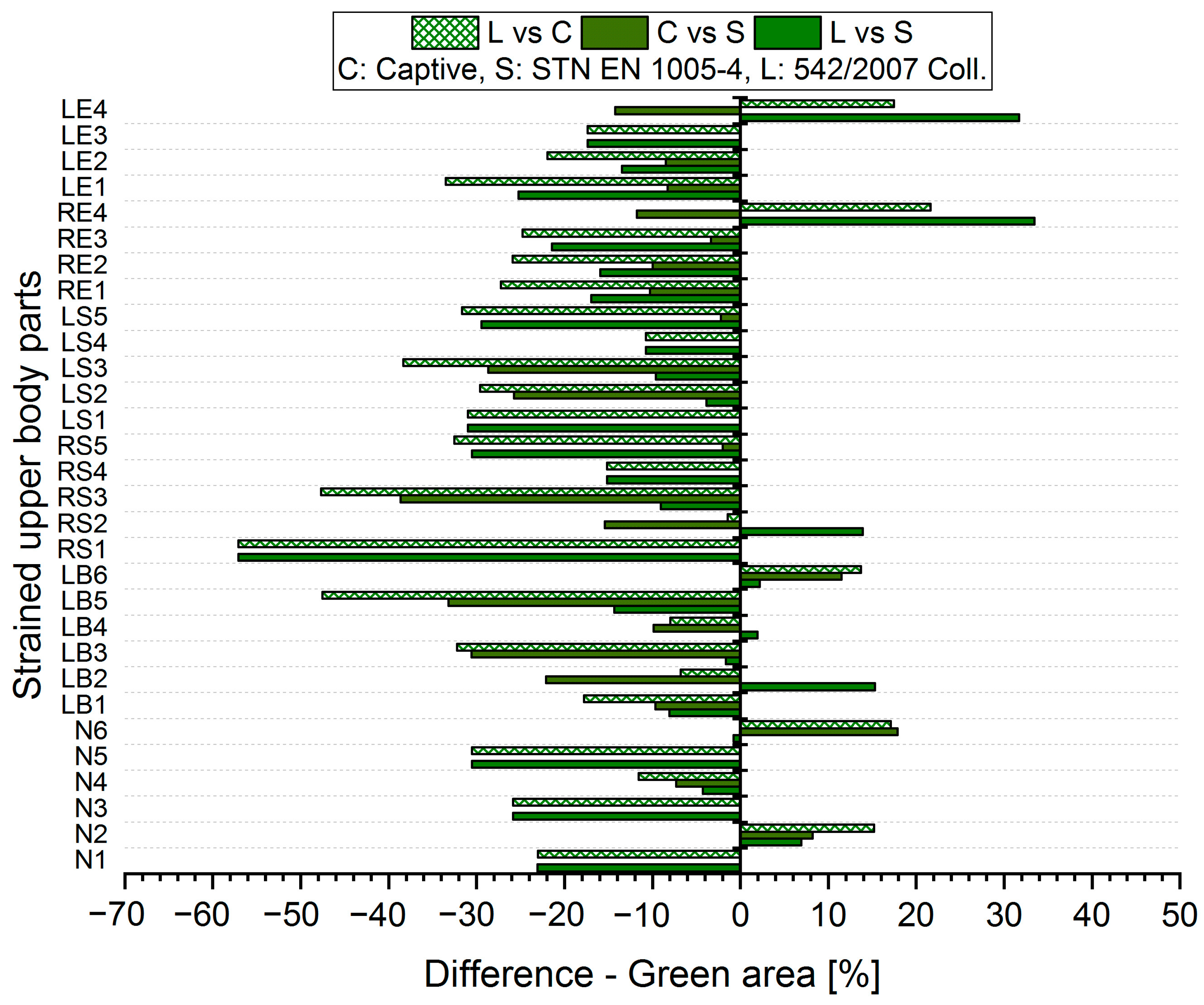

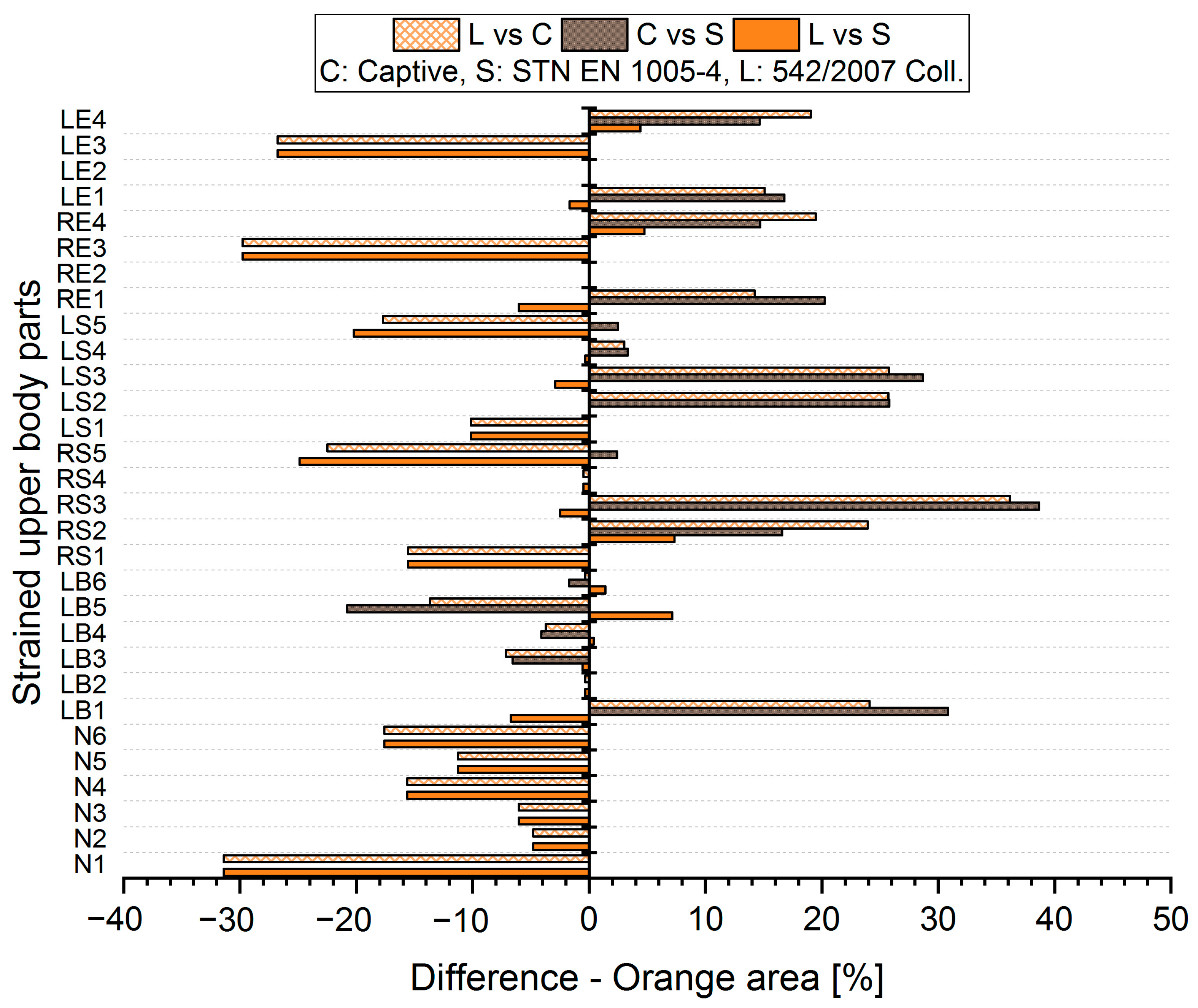

- To determine the difference between three methods: the SK Legislation (L), the STN EN (S), and the Captiv system (C).

- Calibration of Captiv sensors.Calibration is a very important step. All wireless sensors must be synchronized with the receiver unit. It is crucial to avoid magnetic disturbances.

- Positioning of the sensors on the worker.The position may differ based on the activity to be performed and the observed location of the expected strain.

- Processing the measured values of time for each body segment and evaluating the risk.An algorithm evaluates the proportion of time for each evaluated body segment remaining in an acceptable, conditionally acceptable, or unacceptable position. Such an evaluation is provided separately for each of the three different standards.

- Evaluation of the measured values and their comparison.The results of the ergonomic risk analysis for each of the 3 different standards were compared, and the differences between them were calculated by statistical tests.

- Description of the findings from the processed measured and compared values.This step was to identify if there were differences in the proportion of time spent by a body segment in acceptable, conditionally acceptable, and unacceptable risk.

2.2.2. Description of Experimental Workplace

2.2.3. Description of Sensors and Their Placement

2.3. Statistical Testing for the Evaluation of Measured and Processed Data

3. Ergonomic Risk Assessment Applying Three Alternative Standards

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kok, J.; Vroonhof, P.; Snijders, J.; Roullis, G.; Clarke (Panteia), M.; Peereboom, K.; Dorst, P.; Isusi, I. Work-Related Musculoskeletal Disorders: Prevalence, Costs and Demographics in the EU; European Agency for Safety and Health at Work: Bilbao, Spain, 2019; ISSN 1831-9343. [CrossRef]

- National Health Information Centre (NCZI). Occupational Disease or Threat of Occupational Disease. Available online: https://www.nczisk.sk/statisticke_vystupy/tematicke_statisticke_vystupy/choroby_povolania_alebo_ohrozenia_chorobou_povolania/Pages/default.aspx (accessed on 18 May 2022).

- Grooten, J.W.A.; Elin, J. Observational Methods for Assessing Ergonomic Risks for Work-Related Musculoskeletal Disorders. J. Rev. Cienc. Salud 2018, 18, 8–38. [Google Scholar] [CrossRef]

- Dutta, A.; Breloff, S.P.; Dai, F.; Sinsel, E.W.; Warren, C.M.; Carey, R.E.; Wu, J.Z. Effects of working posture and roof slope on activation of lower limb muscles during shingle installation. J. Ergon. 2020, 63, 1182–1193. [Google Scholar] [CrossRef] [PubMed]

- Barakovic Husic, J.; Melero, F.J.; Barakovic, S.; Lameski, P.; Zdravevski, E.; Maresova, P.; Krejcar, O.; Chorbev, I.; Garcia, N.M.; Trajkovik, V. Aging at Work: A Review of Recent Trends and Future Directions. J. Environ. Res. Public Health 2020, 17, 7659. [Google Scholar] [CrossRef] [PubMed]

- Fejer, R.; Ruhe, A. What is the prevalence of musculoskeletal problems in the elderly population in developed countries? A systematic critical literature review. J. Chiropr. Man. Ther. 2012, 20, 31. [Google Scholar] [CrossRef]

- European Standard EN 16710-2; Ergonomics Methods Part 2: A Methodology for Work Analysis to Support Design. CEN-CENELEC Management-Zentrum: Brüssel, Belgium, 2016.

- European Standard EN ISO 11228-1; Ergonomics. Manual Handling. Part 1: Lifting, Lowering and Carrying. ISO Copyright Office: Vernier, Geneva, 2021.

- Standard STN EN 1005-4+A1; Safety of Machinery. Human physical Performance. Part 4: Evaluation of Working Postures and Movements in Relation to Machinery. CEN-CENELEC Management-Zentrum: Brüssel, Belgium, 2009.

- Gualtieri, L.; Rauch, E.; Vidoni, R. Development and validation of guidelines for safety in human-robot collaborative assembly systems. Comput. Ind. Eng. 2022, 163, 107801. [Google Scholar] [CrossRef]

- Makovicka Osvaldova, L.; Sventekova, E.; Maly, S.; Dlugos, I. A Review of Relevant Regulations, Requirements and Assessment Methods Concerning Physical Load in Workplaces in the Slovak Republic. J. Saf. 2021, 1, 23. [Google Scholar] [CrossRef]

- David, G.C. Ergonomic methods for assessing exposure to risk factors for work-related musculoskeletal disorders. J. Occup. Med. 2005, 55, 190–199. [Google Scholar] [CrossRef] [PubMed]

- Antwi-Afari, M.F.; Li, H.; Chan, A.H.S.; Seo, J.; Anwer, S.; Mi, H.Y.; Wu, Z.; Wong, A.Y.L. A science mapping-based review of work-related musculoskeletal disorders among construction workers. J. Saf. Res. 2023, 85, 114–128. [Google Scholar] [CrossRef] [PubMed]

- Hita-Gutiérrez, M.; Gómez-Galán, M.; Díaz-Pérez, M.; Callejón-Ferre, Á.J. An Overview of REBA Method Applications in the World. Int. J. Environ. Res. Public Health 2020, 17, 2635. [Google Scholar] [CrossRef]

- Kakaraparthi, V.N.; Vishwanathan, K.; Gadhavi, B.; Reddy, R.S.; Tedla, J.S.; Alshahrani, M.S.; Dixit, S.; Gular, K.; Zaman, G.S.; Gannamaneni, V.K.; et al. Clinical Application of Rapid Upper Limb Assessment and Nordic Musculoskeletal Questionnaire in Work-Related Musculoskeletal Disorders: A Bibliometric Study. Int. J. Environ. Res. Public Health 2023, 20, 1932. [Google Scholar] [CrossRef]

- Kee, D. Systematic Comparison of OWAS, RULA, and REBA Based on a Literature Review. Int. J. Environ. Res. Public Health 2022, 19, 595. [Google Scholar] [CrossRef]

- Hignett, S.; McAtamney, L. Rapid Entire Body Assessment (REBA). J. Appl. Ergon. 2000, 31, 201–205. [Google Scholar] [CrossRef] [PubMed]

- McAtamney, L.E.; Corlett, N. RULA: A survey method for the investigation of work-related upper limb disorders. Appl. Ergon. 1993, 24, 91–99. [Google Scholar] [CrossRef] [PubMed]

- Karhu, O.; Kansi, P.; Kuorinka, I. Correcting working postures in industry: A practical method for analysis. J. Appl. Ergon. 1977, 8, 199–201. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Galán, M.; Pérez-Alonso, J.; Callejón-Ferre, Á.J.; López-Martínez, J. Musculoskeletal disorders: OWAS review. J. Ind. Health 2017, 55, 314–337. [Google Scholar] [CrossRef]

- Kee, D.; Karwowski, W. LUBA: An assessment technique for postural loading on the upper body based on joint motion discomfort and maximum holding time. J. Appl. Ergon. 2001, 32, 357–366. [Google Scholar] [CrossRef] [PubMed]

- Roman-Liu, D. Repetitive task indicator as a tool for assessment of upper limb musculoskeletal load induced by repetitive task. J. Ergon. 2007, 50, 1740–1760. [Google Scholar] [CrossRef]

- Donisi, L.; Cesarelli, G.; Coccia, A.; Panigazzi, M.; Capodaglio, E.M.; D’Addio, G. Work-Related Risk Assessment According to the Revised NIOSH Lifting Equation: A Preliminary Study Using a Wearable Inertial Sensor and Machine Learning. Sensors 2021, 21, 2593. [Google Scholar] [CrossRef]

- Waters, T.R.; Putz-Anderson, V.; Garg, A.; Fine, L.J. Revised NIOSH equation for the design and evaluation of manual lifting tasks. J. Ergon. 1993, 36, 749–776. [Google Scholar] [CrossRef] [PubMed]

- Roman-Liu, D.; Groborz, A.; Tokarskai, T. Comparison of risk assessment procedures used in OCRA and ULRA methods. Ergonomics 2013, 56, 1584–1598. [Google Scholar] [CrossRef]

- Occhipinti, E. OCRA: A concise index for the assessment of exposure to repetitive movements of the upper limbs. J. Ergon. 1998, 41, 1290–1311. [Google Scholar] [CrossRef] [PubMed]

- Garg, A.; Moore, J.S.; Kapellusch, J.M. The strain index to analyze jobs for risk of distal upper extremity disorders: Model validation. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 2–4 January 2008. [Google Scholar] [CrossRef]

- Nunes, M.L.; Folgado, D.; Fujão, C.; Silva, L.; Rodrigues, J.; Matias, P.; Barandas, M.; Carreiro, A.V.; Madeira, S.; Gamboa, H. Posture Risk Assessment in an Automotive Assembly Line Using Inertial Sensors. IEEE Access 2022, 10, 83221–83235. [Google Scholar] [CrossRef]

- Rybnikar, F.; Kacerova, I.; Horejsí, P.; Simon, M. Ergonomics Evaluation Using Motion Capture Technology-Literature Review. J. Appl. Sci. 2023, 13, 162. [Google Scholar] [CrossRef]

- Bednar, M.; Simon, M.; Rybnikar, F.; Kacerova, I.; Kleinova, J.; Vranek, P. Managing Risks and Risk Assessment in Ergonomics-A Case Study. In Research and Innovation Forum; Springer Nature Switzerland AG: Cham, Switzerland, 2023; pp. 683–697. [Google Scholar] [CrossRef]

- Cerqueira, S.M.; Da Silva, A.F.; Santos, C.P. Smart Vest for Real-Time Postural Biofeedback and Ergonomic Risk Assessment. IEEE Access 2017, 8, 107583–107592. [Google Scholar] [CrossRef]

- Monod, H.; Kapitaniak, B. Ergonomie. In Collections des Abrégés de Médecine, 2nd ed.; Elsevier Masson: Issy-les-Moulineaux, Paris, 2003. [Google Scholar]

- Fernandez, V.; Mendonça, É.; Palma, M.L.; Nogueira, M.; Godina, R.; Gabriel, A.T. Ergonomics and Machine Learning: Wearable Sensors in the Prevention of Work-Related Musculoskeletal Disorders. In Occupational and Environmental Safety and Health IV. Studies in Systems, Decision and Control; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Government Regulation No. 542/2007 of 16 August 2007 on the Details of Health Protection against Physical Strain at Work, Psychological Workload and Sensory Strain at Work. Available online: https://www.epi.sk/zz/2007-542 (accessed on 18 May 2022).

- Onofrejova, D.; Balazikova, M.; Porubcanova, D. Legislative support for prevention and evaluation of ergonomic risks. J. Actual Issues Work Saf. 2022, 35, 111–117. [Google Scholar]

- Onofrejova, D.; Balazikova, M.; Kotianova, Z.; Glatz, J.; Vaskovicova, K. Ergonomic Assessment of Physical Load In Slovak Industry Using Wearable Technologies. J. Appl. Sci. 2022, 12, 3607. [Google Scholar] [CrossRef]

- Andrejiova, M.; Kimakova, Z. Basics of Mathematical Statistics, 1st ed.; Technical University of Kosice: Kosice, Slovakia, 2022; p. 318. [Google Scholar]

| Segment | Risk Level | Type of Work | SK Legislation (Coll. SR 542/2007) | STN EN (STN EN 1005-4) | Captiv |

|---|---|---|---|---|---|

| Head and Neck | Unacceptable | Static | Forward flexion without support 25° | Forward flexion 40° | / |

| Extension without support | Lateral flexion > 10° | ||||

| Lateral flexion/Rotation > 15° | Rotation > 45° | ||||

| Dynamic | Forward flexion > 25°, f ≥ 2/min | Forward flexion 40°, f ≥ 2/min. | Forward flexion ≥ 30° | ||

| Lateral flexion/Rotation 15°, f ≥ 2/min | Lateral flexion > 10°, f ≥ 2/min. | Extension ≥ 20° | |||

| Rotation > 45°, f ≥ 2/min. | Lateral flexion ≥ 20° | ||||

| Rotation ≥ 30° | |||||

| Conditionally acceptable | Static | Forward flexion 25–40° with back support | / | / | |

| Dynamic | Forward flexion 25–40°, f = 2/min | Forward flexion 40°, f < 2/min. | Forward flexion ≥ 15° | ||

| Extension < 15°, f < 2/min | Lateral flexion > 10°, f < 2/min. | Extension ≥ 10° | |||

| Lateral flexion < 15°, f < 2/min | Rotation > 45°, f < 2/min. | Lateral flexion ≥ 10° | |||

| Rotation < 15°, f < 2/min | Rotation ≥ 15° | ||||

| Back | Unacceptable | Static | Forward flexion > 60° | Forward flexion > 60° | / |

| Extension without support/significant lateral flexion/rotation > 20° | Lateral flexion/Rotation > 10° | ||||

| Dynamic | Forward flexion ≥ 60°, f ≥ 2/min | Forward flexion > 20°, f ≥ 2/min. | Forward flexion ≥ 45° | ||

| Significant lateral flexion/rotation > 20°, f ≥ 2/min. | Extension, f ≥ 2/min. | Extension ≥ 20° | |||

| Lateral flexion/Rotation > 10°, f ≥ 2/min. | Lateral flexion ≥ 20° | ||||

| Rotation ≥ 30° | |||||

| Conditionally acceptable | Static | Forward flexion without support 40–60° | Forward flexion with support 20–60° | / | |

| Extension with support | Extension with support | ||||

| Lateral flexion/Rotation > 10° a < 20° | |||||

| Dynamic | Forward flexion 60°, f = 2/min. | Forward flexion > 60°, f < 2/min. | Forward flexion ≥ 30° | ||

| Extension, f < 2/min. | Extension, f < 2/min. | Extension ≥ 10° | |||

| Lateral flexion right/left > 20°, f < 2/min. | Lateral flexion/Rotation > 10°, f < 2/min. | Lateral flexion ≥ 10° | |||

| Rotation ≥ 15° | |||||

| Upper limb | Unacceptable | Static | Shoulder flexion > 60° | Flexion > 60° | / |

| Awkward positions | Extension | ||||

| Abduction > 60° | |||||

| Adduction | |||||

| Dynamic | Shoulder flexion > 60°, f ≥ 2/min. | Flexion > 60°, f ≥ 2/min | Vertical rotation right/left ≥ 90° | ||

| Shoulder extension, f ≥ 2/min. | Extension, f ≥ 2/min. | Horizontal rotation right/left −90°/30° | |||

| Abduction > 60°, f ≥ 2/min. | Rotation internal/external −60°/45° | ||||

| Adduction, f ≥ 2/min. | |||||

| Conditionally acceptable | Static | Shoulder flexion 40–60° without support | Flexion 20–60° with shoulder support | / | |

| Abduction 20–60° with shoulder support | |||||

| Dynamic | Shoulder flexion 40–60°, f = 2/min. | Flexion > 60°, Extension, f < 2/min. | Vertical rotation right/left ≥ 60° | ||

| Shoulder extension, f < 2/min. | Abduction > 60°, Adduction, f < 2/min | Horizontal rotation right/left −70°/10° | |||

| Flexion 20–60°, f ≥ 2/min. | Rotation internal/external −40°/20° | ||||

| Abduction 20–60°, f ≥ 2/min. | |||||

| Lower limb | Unacceptable | Static | Extreme positions of knee/ankle | UNDEFINED | / |

| Dynamic | Movements close to range of motion limits, f ≥ 2/min. | Rotation internal/external 30°/−20° | |||

| Flexion/extension 100°/−20° | |||||

| Abduction/adduction 30°/−20° | |||||

| Conditionally acceptable | Static | / | / | ||

| Dynamic | Movements close to range of motion limits, f < 2/min. | Rotation internal/external 10°/−10° | |||

| Flexion/extension 70°/−10° | |||||

| Abduction/adduction 20°/−10° | |||||

| Other body segments | Extreme positions, uncomfortable | Extreme positions, uncomfortable | - |

| Joint | Movement | Label | Joint | Movement | Label |

|---|---|---|---|---|---|

| Neck | flexion | N1 | Lower back | forward flexion | LB1 |

| extension | N2 | extension | LB2 | ||

| lateral flexion right | N3 | lateral flexion right | LB3 | ||

| lateral flexion left | N4 | lateral flexion left | LB4 | ||

| rotation right | N5 | rotation right | LB5 | ||

| rotation left | N6 | rotation left | LB6 | ||

| Right shoulder | rotation external | RS1 | Left shoulder | rotation external | LS1 |

| rotation internal | RS2 | rotation internal | LS2 | ||

| vertical rotation | RS3 | vertical rotation | LS3 | ||

| horizontal rotation external/ | RS4 | horizontal rotation external | LS4 | ||

| horizontal rotation internal | RS5 | horizontal rotation internal | LS5 | ||

| Right elbow | flexion | RE1 | Left elbow | flexion | LE1 |

| extension | RE2 | extension | LE2 | ||

| rotation external | RE3 | rotation external | LE3 | ||

| rotation internal | RE4 | rotation internal | LE4 |

| Worker | Gender | Age | Weight [kg] | Height [m] | BMI |

|---|---|---|---|---|---|

| Worker 1 | F | 23 | 76 | 1.68 | 26.93 |

| Worker 2 | F | 45 | 52 | 1.68 | 18.42 |

| Worker 3 | F | 45 | 81 | 1.68 | 28.70 |

| Worker 4 | M | 46 | 76 | 1.77 | 24.26 |

| Worker 5 | M | 45 | 86 | 1.85 | 25.13 |

| Results | SK Legislation/Captiv | Captiv/STN EN | SK Legislation/STN EN |

|---|---|---|---|

| t-test | 4.160 | 6.847 | 3.371 |

| p-value | 0.0008 | 0.000005 | 0.0042 |

| Conclusion | H0 rejected | H0 rejected | H0 rejected |

| Area | Worker 1 | Worker 2 | Worker 3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| L vs. C | C vs. S | L vs. S | L vs. C | C vs. S | L vs. S | L vs. C | C vs. S | L vs. S | |

| Green | |||||||||

| p-value | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | 0.004 | 0.080 | <0.001 |

| Conclusion | SD | SD | SD | SD | SD | SD | SD | N | SD |

| Orange | |||||||||

| p-value | 0.016 | 0.007 | 0.659 | <0.001 | 0.006 | 0.672 | 0.014 | 0.362 | 0.401 |

| Conclusion | SD | SD | N | SD | SD | N | SD | N | N |

| Red | |||||||||

| p-value | <0.001 | 0.275 | <0.001 | <0.001 | 0.323 | <0.001 | <0.001 | 0.372 | <0.001 |

| Conclusion | SD | N | SD | SD | N | SD | SD | N | SD |

| Area | Worker 4 | Worker 5 | ||||

|---|---|---|---|---|---|---|

| L vs. C | C vs. S | L vs. S | L vs. C | C vs. S | L vs. S | |

| Green | ||||||

| p-value | 0.060 | <0.001 | <0.001 | 0.001 | 0.002 | <0.001 |

| Conclusion | N | SD | SD | SD | SD | SD |

| Orange | ||||||

| p-value | <0.001 | 0.006 | 0.469 | 0.020 | 0.003 | 0.798 |

| Conclusion | SD | SD | N | SD | SD | N |

| Red | ||||||

| p-value | <0.001 | 0.216 | <0.001 | <0.001 | 0.405 | <0.001 |

| Conclusion | SD | N | SD | SD | N | SD |

| Worker | Percentage Weight of Total Work Activity Workers Spend in Risk Zones in their Job [%] | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Legislation | Captiv | STN EN | |||||||

| Green | Orange | Red | Green | Orange | Red | Green | Orange | Red | |

| Worker 1 | 67.46 | 20.86 | 11.68 | 43.91 | 10.65 | 45.44 | 25.04 | 23.08 | 51.88 |

| Worker 2 | 62.76 | 25.07 | 12.17 | 43.04 | 8.06 | 48.90 | 23.18 | 22.67 | 54.15 |

| Worker 3 | 57.20 | 24.30 | 18.50 | 37.78 | 11.68 | 50.54 | 28.27 | 17.78 | 53.94 |

| Worker 4 | 59.36 | 23.30 | 17.34 | 46.09 | 6.97 | 46.94 | 28.01 | 18.82 | 53.17 |

| Worker 5 | 68.49 | 18.98 | 12.53 | 47.59 | 9.42 | 42.99 | 33.54 | 20.44 | 46.02 |

| Average | 63.05 | 22.50 | 17.92 | 43.68 | 9.36 | 46.96 | 27.61 | 20.56 | 51.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Onofrejova, D.; Andrejiova, M.; Porubcanova, D.; Pacaiova, H.; Sobotova, L. A Case Study of Ergonomic Risk Assessment in Slovakia with Respect to EU Standard. Int. J. Environ. Res. Public Health 2024, 21, 666. https://doi.org/10.3390/ijerph21060666

Onofrejova D, Andrejiova M, Porubcanova D, Pacaiova H, Sobotova L. A Case Study of Ergonomic Risk Assessment in Slovakia with Respect to EU Standard. International Journal of Environmental Research and Public Health. 2024; 21(6):666. https://doi.org/10.3390/ijerph21060666

Chicago/Turabian StyleOnofrejova, Daniela, Miriam Andrejiova, Denisa Porubcanova, Hana Pacaiova, and Lydia Sobotova. 2024. "A Case Study of Ergonomic Risk Assessment in Slovakia with Respect to EU Standard" International Journal of Environmental Research and Public Health 21, no. 6: 666. https://doi.org/10.3390/ijerph21060666

APA StyleOnofrejova, D., Andrejiova, M., Porubcanova, D., Pacaiova, H., & Sobotova, L. (2024). A Case Study of Ergonomic Risk Assessment in Slovakia with Respect to EU Standard. International Journal of Environmental Research and Public Health, 21(6), 666. https://doi.org/10.3390/ijerph21060666