Evaluation of Enterprise Green Mine Construction Based on DPSIR Model

Abstract

1. Introduction

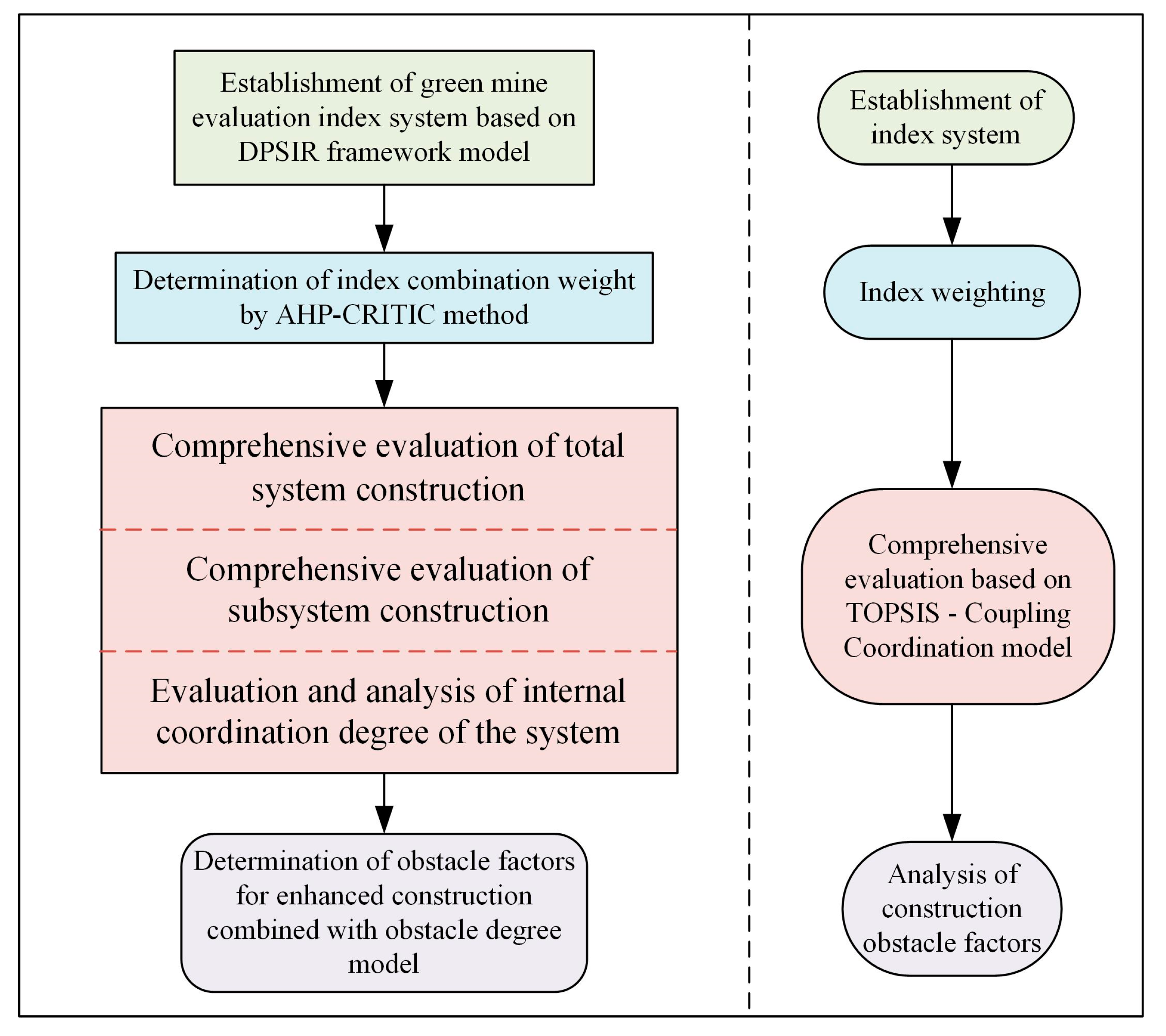

2. Research Design

2.1. Design Principles of the Evaluation Index System

2.2. Evaluation System of Green Mine Construction Based on DPSIR Model

3. Materials and Methods

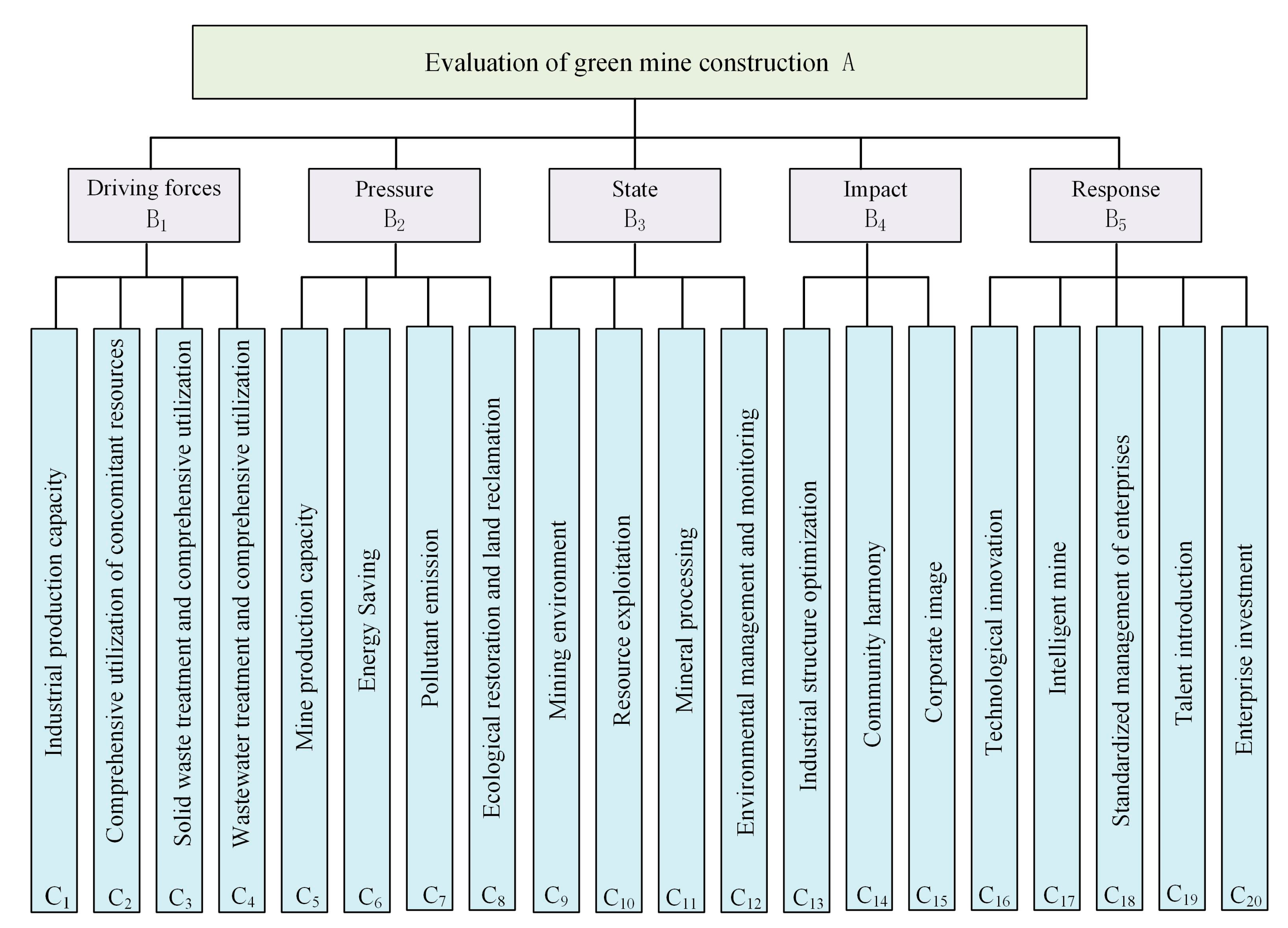

3.1. Index Decomposition Based on DPSIR Framework

3.2. Calculation of Combination Weighting

3.2.1. Determination of Subjective Weight by Analytic Hierarchy Process (AHP)

- (1)

- Establishment of the initial judgment matrix

- (2)

- Normalization of judgment matrix

- (3)

- Calculation of the eigenvalue

- (4)

- Consistency test

3.2.2. The Determination of the Objective Weight with the CRITIC Method

3.2.3. Determination of Comprehensive Weight by AHP-CRITIC Method

3.3. Comprehensive Evaluation and Analysis

3.3.1. TOPSIS Model

3.3.2. Calculate the Coupling Co-Scheduling of All Subsystems

3.3.3. Obstacle Function Model

4. Case Study

4.1. Overview of the Gold Mine

4.2. Evaluation of the Green Mine Construction of a Gold Mine

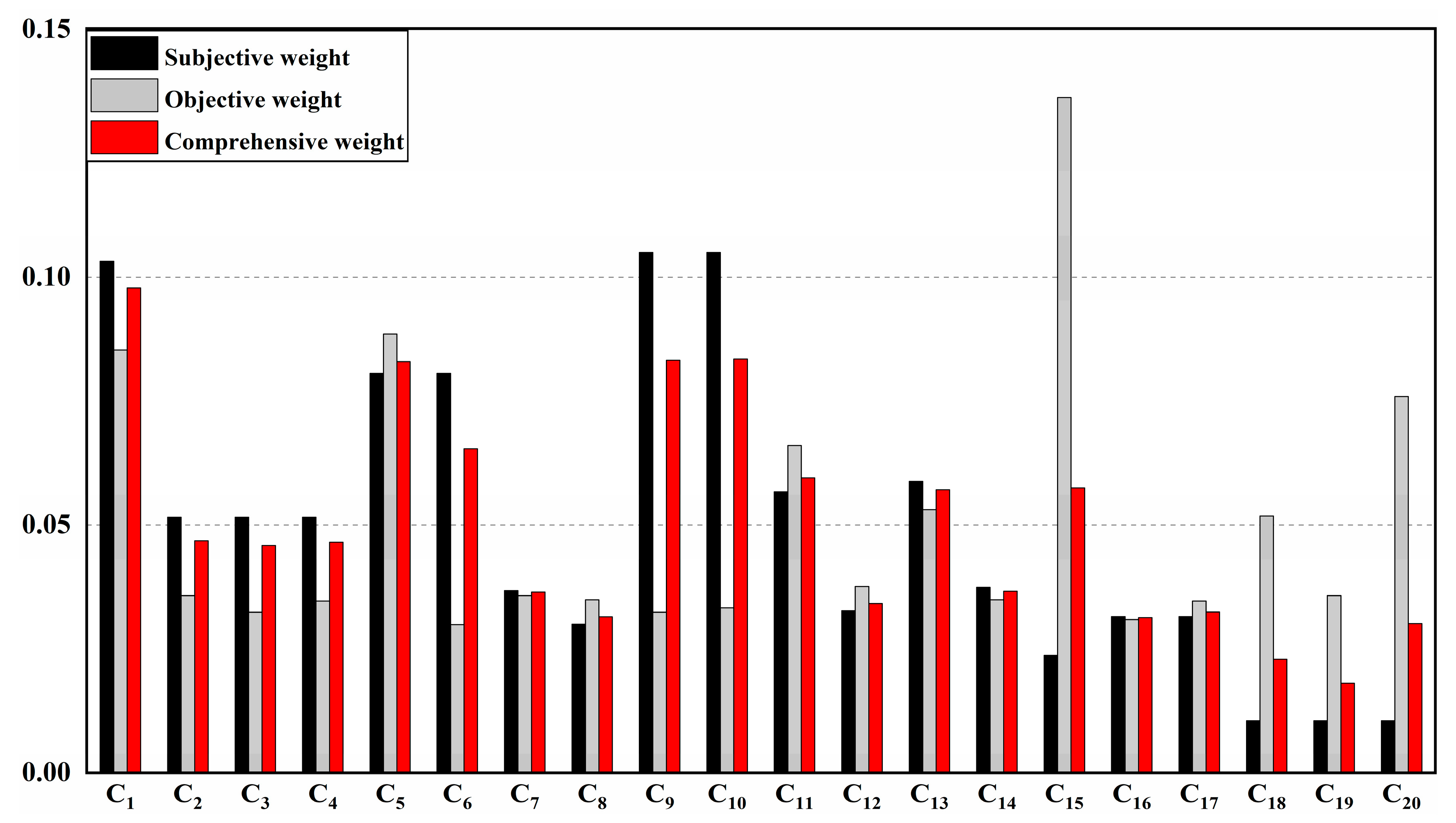

4.2.1. Index Weight Calculation

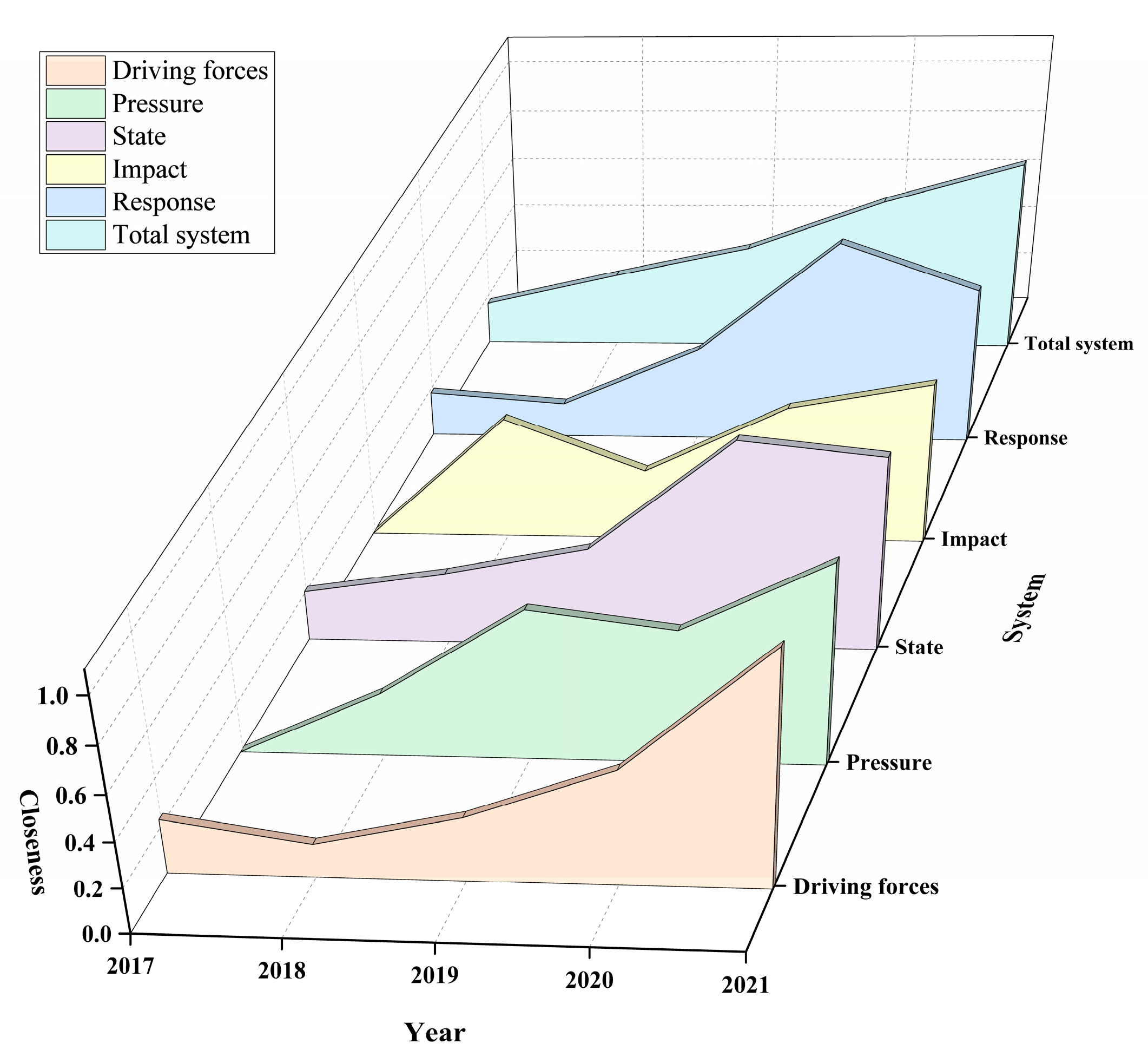

4.2.2. Comprehensive Evaluation and Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Wang, Z. Research on Characteristics and Sustainable Development of Mineral Resources in China. IOP Conf. Ser. Earth Environ. Sci. 2019, 300, 022155. [Google Scholar] [CrossRef]

- Wensheng, W.; Lin, W.; Zefeng, S.; Jiguang, Z. Discussions on the contradiction between development of mineral resources and ecological environment protection in the new era in China. China Min. Mag. 2020, 29, 6–10. [Google Scholar] [CrossRef]

- Jianxing, L. The connotation of green mine and it’s system structure. China Min. Mag. 2014, 23, 51–54. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, G.; Zhou, J.; Pei, D.; Liang, W.; Qiu, J. What Hinders the Promotion of the Green Mining Mode in China? A Game-Theoretical Analysis of Local Government and Metal Mining Companies. Sustainability 2020, 12, 2991. [Google Scholar] [CrossRef]

- Xueqiang, J.; Zhenyu, Z.; Xiaolong, W.; Peng, L. Problems and Suggestions on the Long-term Mechanism of Green Mine in China. China Manganese Ind. 2020, 38, 79–83. [Google Scholar] [CrossRef]

- Xiaogang, Z.; Xuming, Q.; Yonghong, L.; Zhao, H.; Yuzhen, B.; Min, L. Comparison and analysis of national green mine evaluation index and directory in 2019 and 2020. Opencast Min. Technol. 2021, 36, 121–124. [Google Scholar] [CrossRef]

- Shang, D.; Yin, G.; Li, X.; Li, Y.; Jiang, C.; Kang, X.; Liu, C.; Zhang, C. Analysis for Green Mine (phosphate) performance of China: An evaluation index system. Resour. Policy 2015, 46, 71–84. [Google Scholar] [CrossRef]

- Jingjun, H.; Jiashan, N.; Yunfei, S.; Yujun, W.; Gu, Z. Discussion on the Evaluation Index System for Green Mine Construction. Met. Mine 2009, 39, 147–150. [Google Scholar] [CrossRef]

- Xiaoying, L. Evaluation criterion and method of green mine. Resour. Econ. Environ. Prot. 2013, 26. [Google Scholar] [CrossRef]

- Liping, L.; Huali, H.; Jianfen, L. Some Suggestions for Green Mines Construction and Development in China. Nat. Resour. Econ. China 2015, 28, 18–21+25. [Google Scholar] [CrossRef]

- Yingliang, Z.; Ming, Z.X. A Brief Analysis of Green mine Construction. China Non-Met. Miner. Ind. 2019, 2, 63–65. [Google Scholar] [CrossRef]

- Amir, J.; Siamak, K. Analysis of Environmental Costs’ Effect in Green Mining Strategy Using a System Dynamics Approach: A Case Study. Math. Probl. Eng. 2021, 2021, 4893776. [Google Scholar] [CrossRef]

- Xiang, S.; Yinghong, Z.; Li, L.; Shuping, X.; Ling, L. Thoughts on the construction and development of green mine in China in the new era. China Min. Mag. 2020, 29, 59–64. [Google Scholar] [CrossRef]

- Yingxiang, S. A Summary and Reflection on the Research Status of Green Mine Construction in China. Nat. Resour. Econ. China 2020, 33, 35–40+85. [Google Scholar] [CrossRef]

- Xin, G. Analysising on green ecological mine construction in China. China Min. Mag. 2016, 25, 72–74. [Google Scholar] [CrossRef]

- Jinhui, C.; Mithal, J.I.; Aiguo, L.; Chaocheng, Z.; Peixing, J.; Fengjie, L.; Mingyin, L. A hybrid decision model and case study for comprehensive evaluation of green mine construction level. Environ. Dev. Sustain. 2022. [Google Scholar] [CrossRef]

- Dejiang, L.; Hao, W.; Su, H.; Junbo, L.; Hua, P.; Yueqi, W. Multiattribute Evaluation Method for Green Mines Based on Hesitant Fuzzy TOPSIS. Multipurp. Util. Miner. Resour. 2021, 4, 41–49. [Google Scholar] [CrossRef]

- Qiang, F.; Bing, H.; Hanfang, H.; Jingjuan, Z. Effect Appraisal of Standards for Green Mines Based on DEA Method. Stand. Sci. 2017, 8, 43–46. [Google Scholar] [CrossRef]

- Ziling, S.; Junfu, F.; Wenhui, Q.; Xingchen, Y.; Jianguo, W.; Yushi, J. Study on the surface coal mine green mining technology and appraising index system. J. China Coal Soc. 2016, 41, 350–358. [Google Scholar] [CrossRef]

- Liang, W.; Zhao, G.; Luo, S. Sustainability evaluation for phosphorus mines using a hybrid multi-criteria decision making method. Environ. Dev. Sustain. 2021, 23, 12411–12433. [Google Scholar] [CrossRef]

- Shi, L.; Han, L.; Yang, F.; Gao, L. The Evolution of Sustainable Development Theory: Types, Goals, and Research Prospects. Sustainability 2019, 11, 7158. [Google Scholar] [CrossRef]

- Xu, M.; Hu, W.-Q. A research on coordination between economy, society and environment in China: A case study of Jiangsu. J. Clean. Prod. 2020, 258, 120641. [Google Scholar] [CrossRef]

- Jordan, A.; Lenschow, A. Environmental policy integration: A state of the art review. Environ. Policy Gov. 2010, 20, 147–158. [Google Scholar] [CrossRef]

- Heshmati, A. A review of the circular economy and its implementation. Int. J. Green Econ. 2017, 11, 251–288. [Google Scholar] [CrossRef]

- Yizhen, J.; Han, W. Study on Water Resource Carrying Capacity of Zhengzhou City Based on DPSIR Model. Int. J. Environ. Res. Public Health 2023, 20, 1394. [Google Scholar] [CrossRef]

- Junwu, W.; Yipeng, L.; Mingyang, L.; Suikuan, W.; Jiaji, Z.; Han, W. Multi-Phase Environmental Impact Assessment of Marine Ecological Restoration Project Based on DPSIR-Cloud Model. Int. J. Environ. Res. Public Health 2022, 19, 13295. [Google Scholar] [CrossRef]

- Khan, M.; Al-Ghouti, M.A. DPSIR framework and sustainable approaches of brine management from seawater desalination plants in Qatar. J. Clean. Prod. 2021, 319, 128485. [Google Scholar] [CrossRef]

- Kaur, M.; Hewage, K.; Sadiq, R. Investigating the impacts of urban densification on buried water infrastructure through DPSIR framework. J. Clean. Prod. 2020, 259, 120897. [Google Scholar] [CrossRef]

- Singh, A.S.; Eanes, F.R.; Prokopy, L.S. Assessing Conservation Adoption Decision Criteria Using the Analytic Hierarchy Process: Case Studies from Three Midwestern Watersheds. Soc. Nat. Resour. 2018, 31, 503–507. [Google Scholar] [CrossRef]

- Lyu, H.-M.; Zhou, W.-H.; Shen, S.-L.; Zhou, A.-N. Inundation risk assessment of metro system using AHP and TFN-AHP in Shenzhen. Sustain. Cities Soc. 2020, 56, 102103. [Google Scholar] [CrossRef]

- Binghong, P.; Shangru, L.; Zhenjiang, X.; Yang, S.; Xiang, L.; Ruicheng, G. Evaluating Operational Features of Three Unconventional Intersections under Heavy Traffic Based on CRITIC Method. Sustainability 2021, 13, 4098. [Google Scholar] [CrossRef]

- Yiqing, L.; Yanru, L.; Nana, L.; Hua, H. Study on Evaluation Index System of Green Mine Construction Based onHigh Quality Development Perspective. Gold Sci. Technol. 2020, 28, 176–187. [Google Scholar] [CrossRef]

- Yuan, L.; Mingli, W.; Lei, L.; Bowei, Y.; Zhiwei, D.; Qiang, X. Evaluation of the effectiveness of VOC-contaminated soil preparation based on AHP-CRITIC-TOPSIS model. Chemosphere 2021, 271, 129571. [Google Scholar] [CrossRef]

- Jianfei, L.; Songlin, C. Evaluation and Grey Correlational Analysis of Land Use Performancein Fujian Province Based on Entropy- weight TOPSIS Model. J. Fujian Norm. Univ. 2019, 35, 80–87. [Google Scholar] [CrossRef]

- Mei, X.; Jinzhou, W. Comprehensive Evaluation and Obstacle Analysis of Agricultural Circular Development in Hubei Province. J. Yangtze Univ. 2015, 38, 38–43+51. [Google Scholar] [CrossRef]

| Definition | Intensity of Importance |

|---|---|

| Equally important | 1 |

| Moderately important | 3 |

| Strongly more important | 5 |

| Very strongly more important | 7 |

| Extremely more important | 9 |

| Intermediate values between the two adjacent judgments | 2, 4, 6, 8 |

| Matrix Order | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| RI values | 0.00 | 0.00 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 |

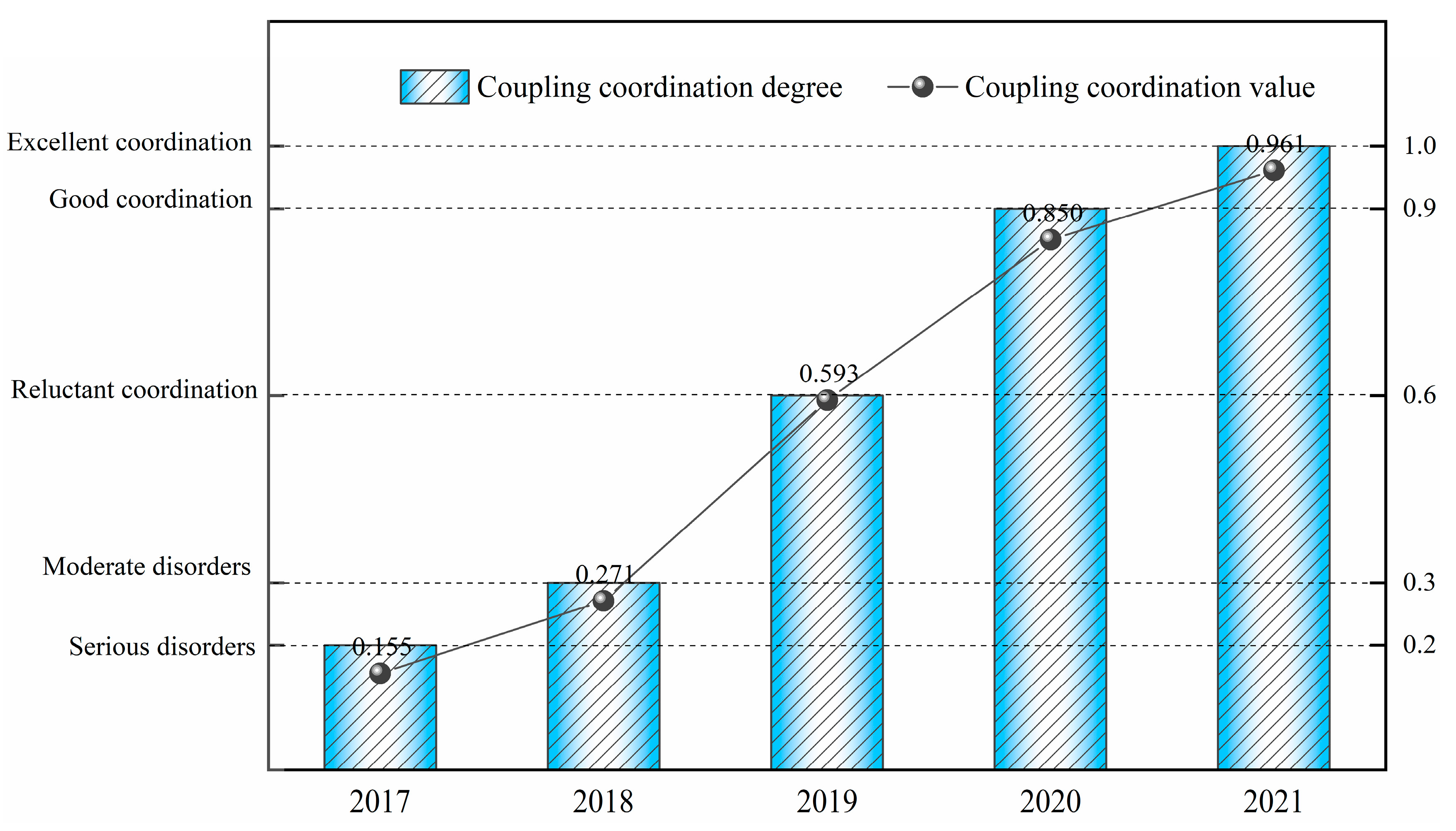

| The Interval of Coupling Co-Ordination Degree D Value | Coordination Level | Coupling Coordination Degree |

|---|---|---|

| (0.0~0.1) | 1 | Extreme disorders |

| (0.1~0.2) | 2 | Serious disorders |

| (0.2~0.3) | 3 | Moderate disorders |

| (0.3~0.4) | 4 | Mild disorders |

| (0.4~0.5) | 5 | Endangered disorders |

| (0.5~0.6) | 6 | Reluctant coordination |

| (0.6~0.7) | 7 | Primary coordination |

| (0.7~0.8) | 8 | Intermediate coordination |

| (0.8~0.9) | 9 | Good coordination |

| (0.9~1.0) | 10 | Excellent coordination |

| Standard Layer | Index Layer | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|---|

| B1 | C1 | 0.4064 | 0.0802 | 0.0107 | 0 | 1 |

| C2 | 0 | 0 | 0.5 | 0.5 | 1 | |

| C3 | 0 | 0.3333 | 0.3333 | 1 | 1 | |

| C4 | 0 | 0 | 0.3333 | 1 | 1 | |

| B2 | C5 | 0 | 0.4704 | 1 | 0.2069 | 0.7293 |

| C6 | 0 | 0.1170 | 0.4362 | 0.9149 | 1 | |

| C7 | 0 | 0 | 0.5 | 0.5 | 1 | |

| C8 | 0 | 0 | 0.5 | 1 | 1 | |

| B3 | C9 | 0 | 0 | 0.2 | 0.8 | 1 |

| C10 | 0 | 0.4484 | 0.7050 | 0.8525 | 1 | |

| C11 | 0.5 | 0 | 0.0250 | 1 | 0.5300 | |

| C12 | 0 | 0.625 | 0.625 | 1 | 1 | |

| B4 | C13 | 0 | 0.3333 | 0.3333 | 1 | 0.3333 |

| C14 | 0 | 0 | 0.5 | 1 | 1 | |

| C15 | 0 | 1 | 0 | 0 | 1 | |

| B5 | C16 | 0 | 0.2857 | 0.5714 | 1 | 1 |

| C17 | 0 | 0 | 0.6667 | 1 | 1 | |

| C18 | 0 | 0.5 | 0.5 | 1 | 1 | |

| C19 | 0 | 0 | 0.5 | 0.5 | 1 | |

| C20 | 0 | 0.0488 | 0.1870 | 1 | 0.0325 |

| Target Layer | The Standard Layer | Comprehensive Weight of First-Level Index | Index Layer | Index Layer Weight | Subjective Weight of AHP | Objective Weight of CRITIC | Comprehensive Weight of Secondary-Level Index |

|---|---|---|---|---|---|---|---|

| A | B1 | 0.2370 | C1 | 0.4768 | 0.1032 | 0.0853 | 0.0978 |

| C2 | 0.1721 | 0.0516 | 0.0358 | 0.0469 | |||

| C3 | 0.1738 | 0.0516 | 0.0324 | 0.0458 | |||

| C4 | 0.1773 | 0.0516 | 0.0347 | 0.0465 | |||

| B2 | 0.2163 | C5 | 0.4389 | 0.0806 | 0.0886 | 0.0830 | |

| C6 | 0.2906 | 0.0806 | 0.0299 | 0.0654 | |||

| C7 | 0.1463 | 0.0368 | 0.0358 | 0.0365 | |||

| C8 | 0.1242 | 0.0300 | 0.0349 | 0.0315 | |||

| B3 | 0.2604 | C9 | 0.3010 | 0.1050 | 0.0324 | 0.0832 | |

| C10 | 0.2937 | 0.1050 | 0.0333 | 0.0835 | |||

| C11 | 0.2968 | 0.0568 | 0.0660 | 0.0595 | |||

| C12 | 0.1085 | 0.0328 | 0.0376 | 0.0342 | |||

| B4 | 0.1512 | C13 | 0.3807 | 0.0588 | 0.0531 | 0.0571 | |

| C14 | 0.1776 | 0.0374 | 0.0349 | 0.0366 | |||

| C15 | 0.4417 | 0.0237 | 0.1363 | 0.0575 | |||

| B5 | 0.1349 | C16 | 0.1642 | 0.0315 | 0.0309 | 0.0313 | |

| C17 | 0.1850 | 0.0315 | 0.0347 | 0.0324 | |||

| C18 | 0.2523 | 0.0105 | 0.0518 | 0.0229 | |||

| C19 | 0.0749 | 0.0105 | 0.0358 | 0.0181 | |||

| C20 | 0.3236 | 0.0105 | 0.0760 | 0.0301 |

| Year | Positive Ideal Solution Distance | Distance of Negative Ideal Solution | Relative Proximity |

|---|---|---|---|

| 2017 | 0.932 | 0.192 | 0.171 |

| 2018 | 0.820 | 0.349 | 0.298 |

| 2019 | 0.671 | 0.487 | 0.416 |

| 2020 | 0.488 | 0.779 | 0.615 |

| 2021 | 0.270 | 0.906 | 0.770 |

| Year | Obstacle Factor 1 | Obstacle Factor 2 | Obstacle Factor 3 | Obstacle Factor 4 |

|---|---|---|---|---|

| 2017 | C10/0.0920 | C9/0.0917 | C5/0.0915 | C6/0.0721 |

| 2018 | C1/0.1148 | C9/0.1061 | C11/0.0759 | C6/0.0734 |

| 2019 | C1/0.1563 | C9/0.1074 | C11/0.0932 | C15/0.0928 |

| 2020 | C1/0.3190 | C5/0.2138 | C15/0.1875 | C2/0.0765 |

| 2021 | C13/0.3246 | C20/0.2479 | C11/0.2373 | C5/0.1901 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, W.; Xue, M.; Wang, Y.; Long, T.; Deng, S.; Deng, B.; Fang, N. Evaluation of Enterprise Green Mine Construction Based on DPSIR Model. Int. J. Environ. Res. Public Health 2023, 20, 4932. https://doi.org/10.3390/ijerph20064932

Yang W, Xue M, Wang Y, Long T, Deng S, Deng B, Fang N. Evaluation of Enterprise Green Mine Construction Based on DPSIR Model. International Journal of Environmental Research and Public Health. 2023; 20(6):4932. https://doi.org/10.3390/ijerph20064932

Chicago/Turabian StyleYang, Wei, Mengge Xue, Yaping Wang, Tao Long, Sha Deng, Bo Deng, and Nan Fang. 2023. "Evaluation of Enterprise Green Mine Construction Based on DPSIR Model" International Journal of Environmental Research and Public Health 20, no. 6: 4932. https://doi.org/10.3390/ijerph20064932

APA StyleYang, W., Xue, M., Wang, Y., Long, T., Deng, S., Deng, B., & Fang, N. (2023). Evaluation of Enterprise Green Mine Construction Based on DPSIR Model. International Journal of Environmental Research and Public Health, 20(6), 4932. https://doi.org/10.3390/ijerph20064932