Emissions and Exposures Associated with the Use of an Inconel Powder during Directed Energy Deposition Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

2.1. Facility and Process Description

2.2. Powder Characterization

2.3. Particle Emissions

2.4. Personal Exposure

2.5. Data Analysis

2.6. Ethics Approval

3. Results

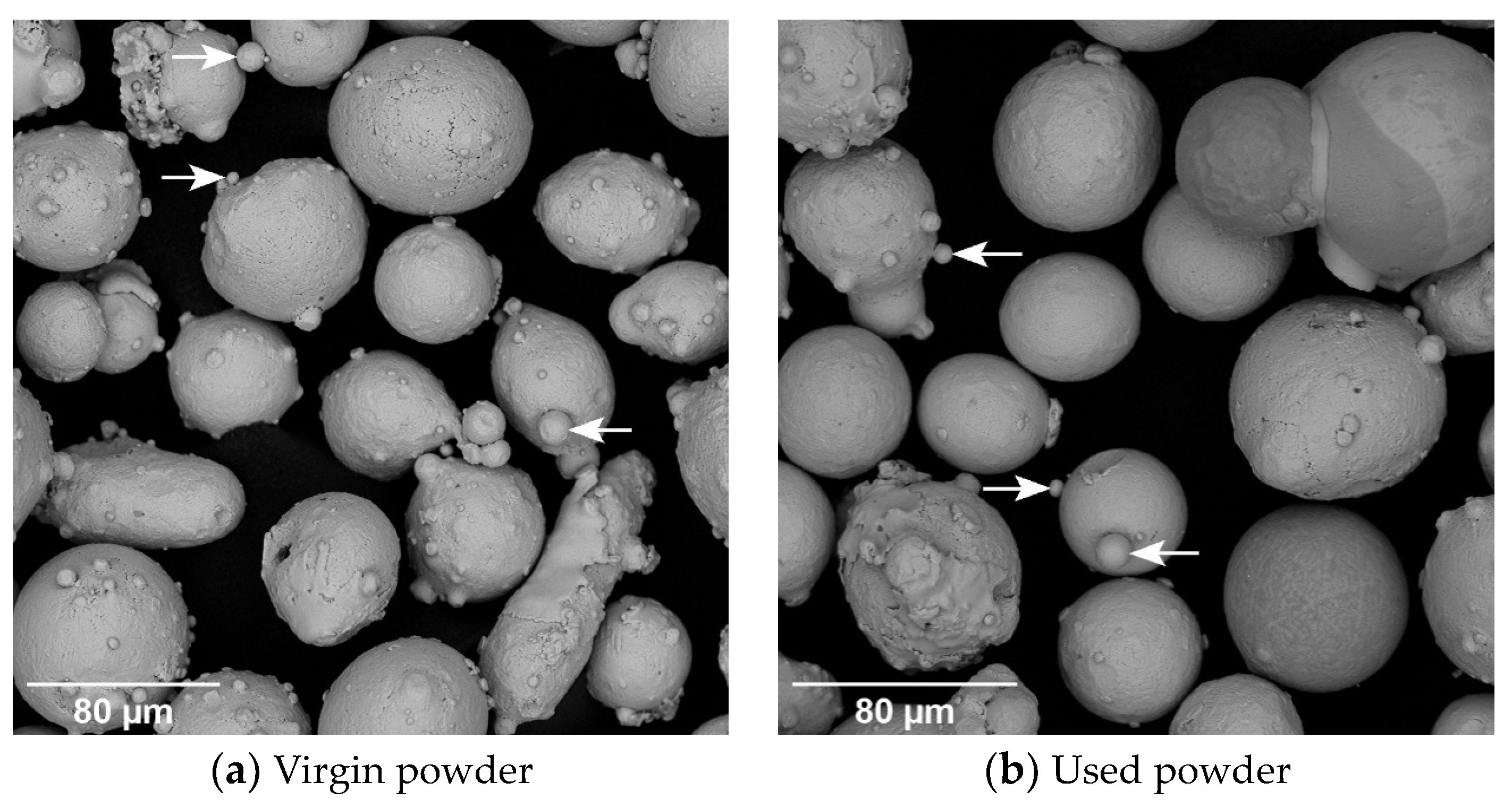

3.1. Powder Characterization

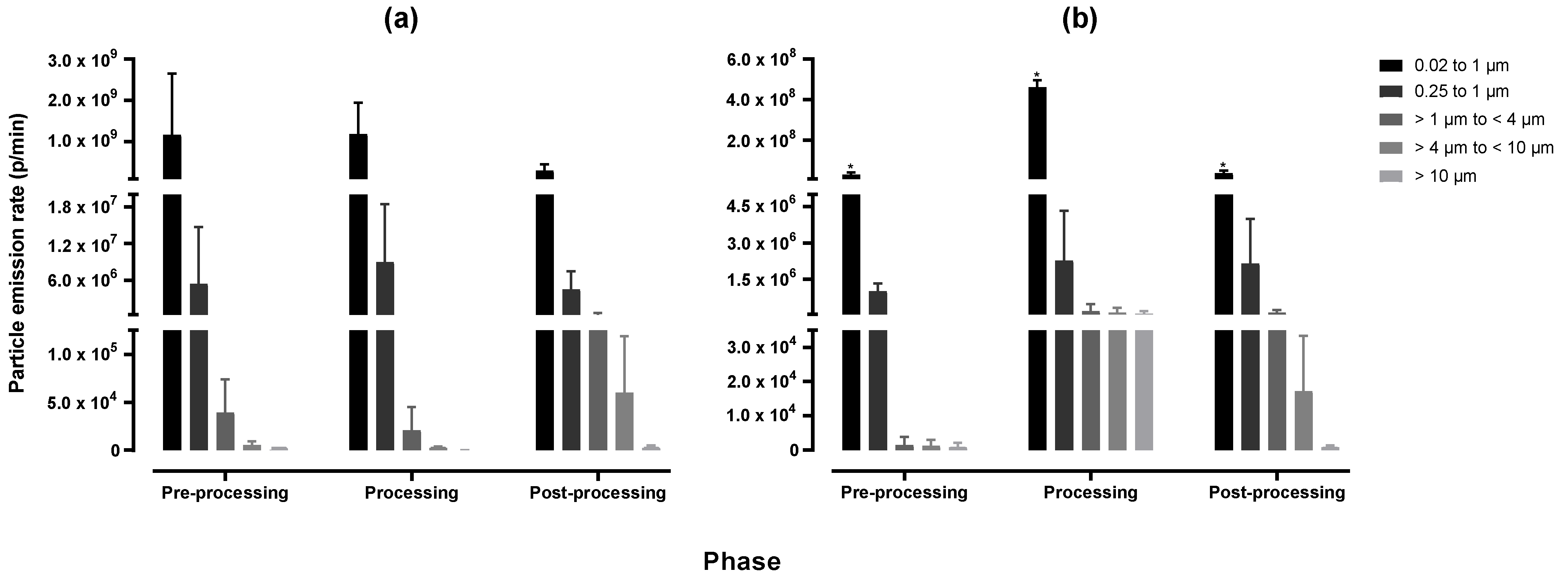

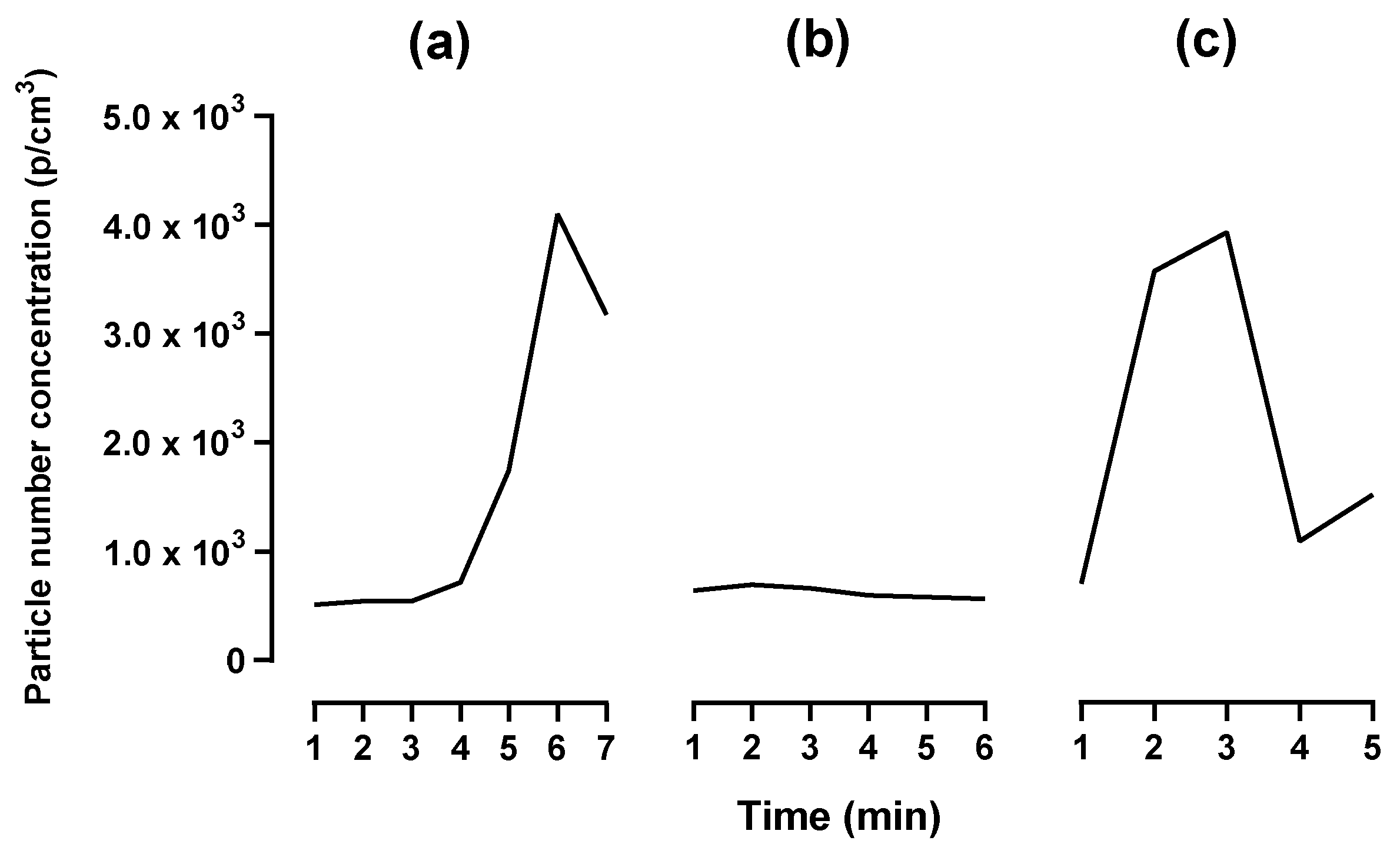

3.2. Particle Emissions

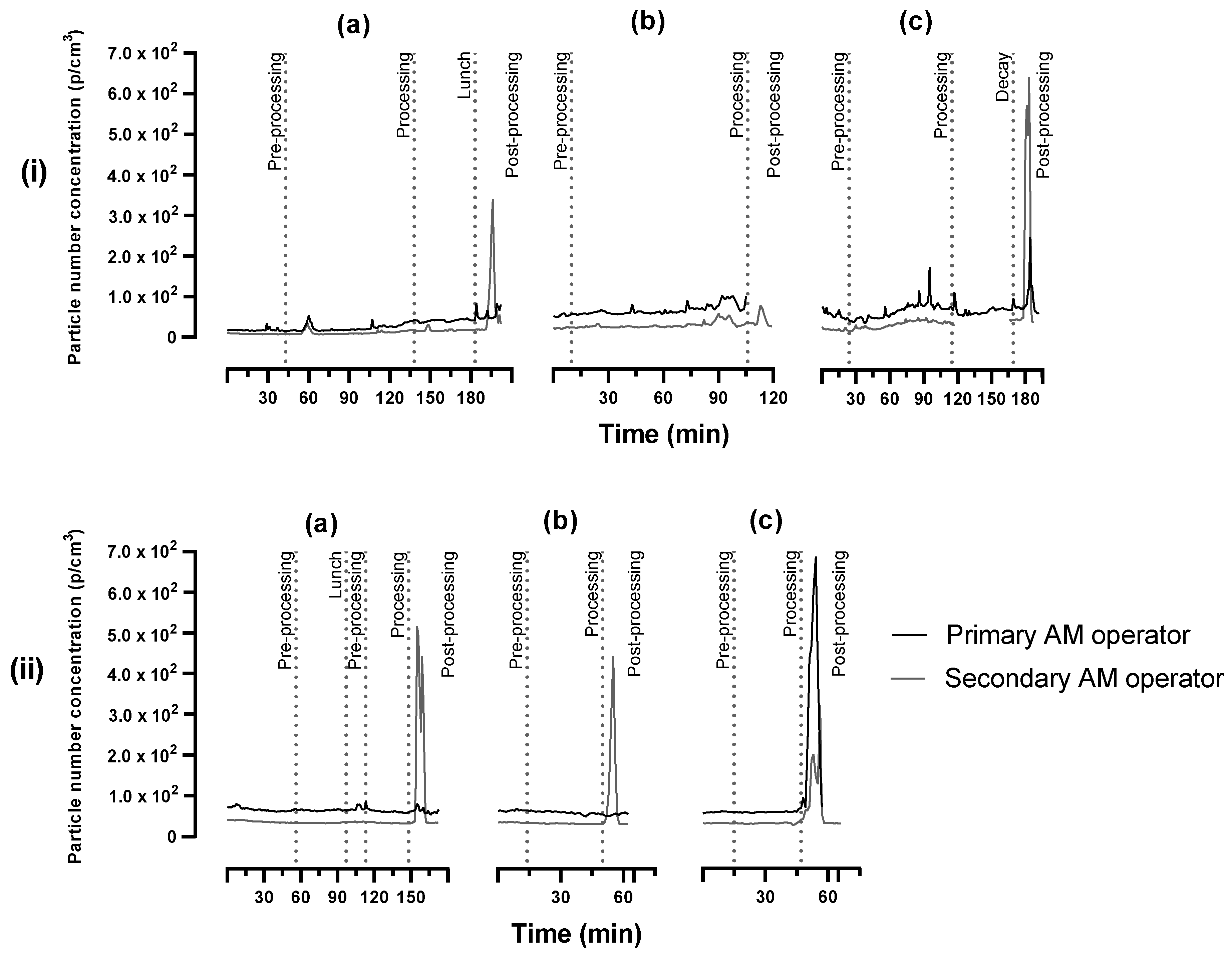

3.3. Personal Exposure

4. Discussion

4.1. Powder Characterization

4.2. Particle Emissions

4.3. Personal Exposure

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bau, S.; Rousset, D.; Payet, R.; Keller, F.-X. Characterizing particle emissions from a direct energy deposition additive manufacturing process and associated occupational exposure to airborne particles. J. Occup. Environ. Hyg. 2020, 17, 59–72. [Google Scholar] [CrossRef] [PubMed]

- Dutta, B.; Babu, S.; Jared, B. Science, Technology and Applications of Metals in Additive Manufacturing, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. ISO/ASTM International: Geneva, Switzerland, 2021.

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horizons 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Espach, A.; Gupta, K. Sustainability in Additive Manufacturing—A Review. In Proceedings of the 5th NA International Conference on Industrial Engineering and Operations Management, Detroit, MI, USA, 10–14 August 2020; Available online: http://www.ieomsociety.org/detroit2020/papers/641.pdf (accessed on 12 April 2021).

- Graff, P.; Ståhlbom, B.; Nordenberg, E.; Graichen, A.; Johansson, P.; Karlsson, H. Evaluating Measuring Techniques for Occupational Exposure during Additive Manufacturing of Metals: A Pilot Study. J. Ind. Ecol. 2017, 21, 120–129. [Google Scholar] [CrossRef]

- Kellens, K.; Baumers, M.; Gutowski, T.G.; Flanagan, W.; Lifset, R.; Duflou, J.R. Environmental Dimensions of Additive Manufacturing: Mapping Application Domains and Their Environmental Implications. J. Ind. Ecol. 2017, 21, 49–68. [Google Scholar] [CrossRef]

- Mellin, P.; Jönsson, C.; Åkermo, M.; Fernberg, P.; Nordenberg, E.; Brodin, H.; Strondl, A. Nano-sized by-products from metal 3D printing, composite manufacturing and fabric production. J. Clean. Prod. 2016, 139, 1224–1233. [Google Scholar] [CrossRef]

- Roth, G.A.; Geraci, C.L.; Stefaniak, A.; Murashov, V.; Howard, J. Potential occupational hazards of additive manufacturing. J. Occup. Environ. Hyg. 2019, 16, 321–328. [Google Scholar] [CrossRef]

- Chen, R.; Yin, H.; Cole, I.S.; Shen, S.; Zhou, X.; Wang, Y.; Tang, S. Exposure, assessment and health hazards of particulate matter in metal additive manufacturing: A review. Chemosphere 2020, 259, 127452. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Stefaniak, A.B.; Du Preez, S.; Du Plessis, J.L. Additive Manufacturing for Occupational Hygiene: A Comprehensive Review of Processes, Emissions, & Exposures. J. Toxicol. Environ. Health 2021, 24, 173–222. [Google Scholar] [CrossRef]

- EOS. EOS NickelAlloy IN718 Material Data Sheet; EOS GmbH: Krailling, Germany, 2020; Available online: https://www.eos.info/03_system-related-assets/material-related-contents/metal-materials-and-examples/metal-material-datasheet/nickelalloy-inconel/material_datasheet_eos_nickelalloy_in718_m290_premium_en_web.pdf (accessed on 17 March 2021).

- Praxair S.T. Technology Inc. TruForm. TruFormTM Metal Powders for Additive Manufacturing—TruFormTM 718 Metal Powder; Praxair S.T. Technology Inc.: Indianapolis, IN, USA, 2018; Available online: https://www.i3dmfg.com/wp-content/uploads/2019/01/TruForm-718-Metal-Powders.pdf (accessed on 3 May 2021).

- Kracke, A. Superalloys, the most successful alloy system of modern times—Past, present and future. In Proceedings of the 7th International Symposium on Superalloy 718 and Derivatives, Pittsburgh, PA, USA, 10–13 October 2010; Available online: https://www.tms.org/superalloys/10.7449/2010/Superalloys_2010_13_50.pdf (accessed on 24 November 2022).

- Tian, Z.; Zhang, C.; Wang, D.; Liu, W.; Fang, X.; Wellmann, D.; Tian, Y. A Review on Laser Powder Bed Fusion of Inconel 625 Nickel-Based Alloy. Appl. Sci. 2020, 10, 81. [Google Scholar] [CrossRef]

- Van der Walt, S.; Du Preez, S.; Du Plessis, J.L. Particle emissions and respiratory exposure to hazardous chemical substances associated with binder jetting additive manufacturing utilizing poly methyl methacrylate. Hyg. Environ. Health Adv. 2022, 4, 100033. [Google Scholar] [CrossRef]

- Walter, J.; Baumgärtel, A.; Hustedt, M.; Hebisch, R.; Kaierle, S. Inhalation exposure to hazardous substances during powder-bed processes. Procedia CIRP 2018, 74, 295–299. [Google Scholar] [CrossRef]

- Reed, S.; Pisaniello, D.; Benke, G.; Burton, K. Principles of Occupational Health & Hygiene, 2nd ed.; Allen & Unwin: Sydney, Australia, 2013. [Google Scholar]

- ISO 7708:1995; Air Quality—Particle Size Fraction Definitions for Health-Related Sampling. ISO: Geneva, Switzerland, 1995.

- Schoeman, J.J.; Van den Heever, D.J. Occupational Hygiene—The Science, 3rd ed.; Sun Media: Bloemfontein, South Africa, 2018; Volume 1. [Google Scholar]

- Azzougagh, M.N.; Keller, F.-X.; Cabrol, E.; Cici, M.; Pourchez, J. Occupational exposure during metal additive manufacturing: A case study of laser powder bed fusion of aluminum alloy. J. Occup. Environ. Hyg. 2021, 18, 223–236. [Google Scholar] [CrossRef] [PubMed]

- Hann, B.A. Powder Reuse and Its Effects on Laser Based Powder Fusion Additive Manufactured Alloy 718. SAE Int. J. Aerosp. 2016, 9, 209–213. [Google Scholar] [CrossRef]

- Kugler, S.; Nagy, A.; Osán, J.; Péter, L.; Groma, V.; Pollastri, S.; Czitrovszky, A. Characterization of the ultrafine and fine particles formed during laser cladding with the Inconel 718 metal powder by means of X-ray spectroscopic techniques. Spectrochim. Acta B At. Spectrosc. 2021, 177, 106110. [Google Scholar] [CrossRef]

- Ljunggren, S.A.; Ward, L.J.; Graff, P.; Persson, A.; Lind, M.L.; Karlsson, H. Metal additive manufacturing and possible clinical markers for the monitoring of exposure-related health effects. PLoS ONE 2021, 16, e0248601. [Google Scholar] [CrossRef]

- Noskov, A.; Ervik, T.K.; Tsivilskiy, I.; Gilmutdinov, A.; Thomassen, Y. Characterization of ultrafine particles emitted during laser-based additive manufacturing of metal parts. Sci. Rep. 2020, 10, 20989. [Google Scholar] [CrossRef]

- Oddone, E.; Pernetti, R.; Fiorentino, M.L.; Grignani, E.; Tamborini, D.; Alaimo, G.; Imbriani, M. Particle measurements of metal additive manufacturing to assess working occupational exposures: A comparative analysis of selective laser melting, laser metal deposition, and hybrid laser metal deposition. Ind. Health 2022, 60, 371–386. [Google Scholar] [CrossRef]

- International Agency for Research on Cancer (IARC). Monographs on the Evaluation of Carcinogenic Risks to Humans: Cobalt in Hard Metals and Cobalt Sulfate, Gallium Arsenide, Indium Phosphide and Vanadium Pentoxide; IARC: Lyon, France, 2006; Volume 86, Available online: https://publications.iarc.fr/104 (accessed on 24 March 2021).

- International Agency for Research on Cancer (IARC). Monographs on the Evaluation of Carcinogenic Risks to Humans: Arsenic, Metals, Fibres and Dusts; IARC: Lyon, France, 2017; Volume 100C, Available online: http://monographs.iarc.fr/ENG/Monographs/vol100C/ (accessed on 24 March 2021).

- Regulations for Hazardous Chemical Agents. 2021 (Notice R: 280). Department of Employment and Labour (DEL), South Africa. Available online: https://www.gov.za/sites/default/files/gcis_document/202103/44348rg11263gon280.pdf (accessed on 19 September 2022).

- Stabile, L.; Scungio, M.; Buonanno, G.; Arpino, F.; Ficco, G. Airborne particle emission of a commercial 3D printer: The effect of filament material and printing temperature. Indoor Air 2017, 27, 398–408. [Google Scholar] [CrossRef]

- Stefaniak, A.B.; Johnson, A.R.; Du Preez, S.; Hamond, D.R.; Wells, J.R.; Ham, J.E.; Du Plessis, J.L. Evaluation of emissions and exposures at workplaces using desktop 3-dimensional printers. J. Chem. Health Saf. 2019, 26, 19–30. [Google Scholar] [CrossRef]

- Batterman, S. Review and Extension of CO2-Based Methods to Determine Ventilation Rates with Application to School Classrooms. Int. J. Environ. Res. Public Health 2017, 14, 145. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Marzouk, T.; Cirligeanu, R.; Malmstrom, H.; Eliav, E.; Ren, Y.-F. Ventilation rate assessment by carbon dioxide levels in dental treatment rooms. J. Dent. Res. 2021, 100, 810–816. [Google Scholar] [CrossRef] [PubMed]

- Praxair S.T. Technology Inc. Powder Solutions; Praxair S.T. Technology Inc.: Indianapolis, IN, USA, 2014; Available online: https://www.praxairsurfacetechnologies.com/-/media/corporate/praxairsurface/us/documents/brochures/powders-solutions-catalog.pdf?la=en (accessed on 1 June 2022).

- BS EN 481:1993; Workplace Atmospheres—Size Fraction Definitions for Measurement of Airborne Particles. CEN: London, UK, 1993.

- Zisook, R.E.; Simmons, B.D.; Vater, M.; Perez, A.; Donovan, E.P.; Paustenbach, D.J.; Cyrs, W.D. Emissions associated with operations of four different additive manufacturing or 3D printing technologies. J. Occup. Environ. Hyg. 2020, 17, 464–479. [Google Scholar] [CrossRef] [PubMed]

| Location Description | Simple Illustration | Activities | Control Measures | |

|---|---|---|---|---|

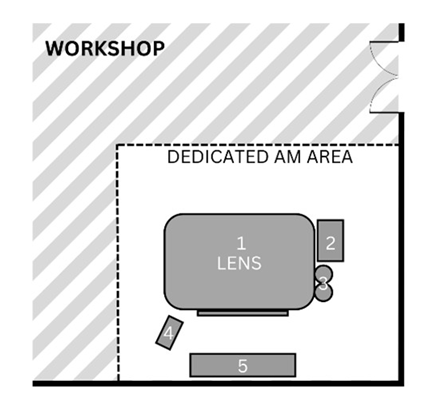

| General workshop Various tasks are performed in this area, which includes AM in a dedicated area. The enclosed LENS machine is situated here. |  |

| Pre-processing AM operators prepare the machine by cleaning and filling the reservoir (2, 3) and setting up machine parameters (4). Processing Automated building of object by LENS machine (1). AM operators complete other tasks, seated at desk (5). | The workshop makes use of natural ventilation through a large door as well as windows. The machine has a safety glass panel through which the process can be monitored, protecting eyes from the laser. Safety notices are displayed around the machine as well as SOPs. Protective clothing and safety shoes were worn by the AM operators (no respirators or gloves were worn when handling the powder). |

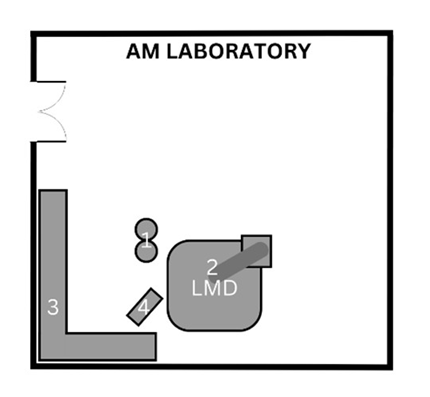

| AM laboratory This laboratory is used solely for AM. The open-table LMD machine, consisting of a table and a robotic arm, is situated here. |  |

| Pre-processing AM operators prepare the machine by cleaning and filling the reservoir (1, 2) and setting up machine parameters (4). Processing Automated building of object by LMD machine (2). AM operators complete other tasks, seated at desk (3). | The AM laboratory makes use of natural ventilation. Safety notices are displayed at the entrance with SOPs next to the machine. Eye protection, protective clothing and safety shoes were worn by the AM operators for the duration of the process while respirators were worn when handling powder (no gloves were worn when handling the powder). |

| Post-processing area The post-processing area has various finishing machinery and workstations that are used for a variety of post-processing tasks, including but not limited to AM. |  |

| Post-processing AM operators sandblast printed object (1). | There is an extraction ventilation system located above the sandblasting station, however, this was not used consistently. The sandblasting station is enclosed. The AM operators wore protective gloves whilst sandblasting. |

| Powder | Elemental Composition (%) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | Co | Cr | Cu | Fe | Mn | Mo | Ni | Nb | Ta | Ti | Si | Zn | |

| Virgin | 0.49 | 0.10 | 20.70 | 0.03 | 18.80 | < 0.01 | 2.87 | 50.20 | 5.36 | 0.06 | 1.01 | 0.07 | 0.20 |

| Used | 0.53 | 0.18 | 20.00 | 0.05 | 18.20 | 0.03 | 3.03 | 50.80 | 5.65 | 0.06 | 1.04 | 0.09 | 0.21 |

| SDS | 0.20–0.80 | 1.00 max | 17.00–21.00 | 0.30 max | 15.00–21.00 | 0.35 max | 2.80–3.30 | 50.00–55.00 | 4.75–5.50 | 4.75–5.50 | 0.65–1.15 | 0.35 max | - |

| Powder | SDS (µm) | Mean Diameter (µm) | Particle Size Distribution (µm) | Particle Shape Analysis | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d [0.1] | d [0.5] | d [0.9] | Circularity | Convexity | Elongation | ||||||||||

| Virgin | ≤45 | 10.96 | ±3.01 | 0.22 | ±0.00 * | 0.25 | ±0.01 | 56.29 | ±4.31 | 0.552 | ±0.019 | 0.949 | ±0.003 | 0.326 | ±0.005 |

| Used | - | 10.31 | ±1.32 | 0.22 | ±0.00 * | 0.25 | ±0.01 | 57.89 | ±4.74 | 0.558 | ±0.014 | 0.950 | ±0.005 | 0.323 | ±0.006 |

| Phase Duration | Particle Size Range | |||||

|---|---|---|---|---|---|---|

| 0.02–1 µm * | 0.25–1 µm | 1–4 µm | 4–10 µm | >10 µm | ||

| Background | Mean | 9.2 × 103 | 3.6 × 102 | 1.3 × 100 | 1.0 × 10−1 | 3.7 × 10−3 |

| SD | 1.7 × 103 | 1.5 × 101 | 8.5 × 10−1 | 5.6 × 10−2 | 2.9 × 10−3 | |

| Max | 1.7 × 104 | 5.2 × 102 | 7.0 × 100 | 4.6 × 10−1 | 1.4 × 10−2 | |

| Pre-processing 25 ± 15.49 min | Mean | 3.1 × 104 | 4.1 × 102 | 1.8 × 100 | 1.8 × 10−1 | 1.0 × 10−2 |

| SD | 9.1 × 103 | 1.9 × 101 | 5.7 × 10−1 | 7.9 × 10−2 | 8.6 × 10−3 | |

| Max | 1.3 × 105 | 5.9 × 102 | 6.0 × 100 | 6.8 × 10−1 | 3.9 × 10−2 | |

| Processing 94 ± 1.25 min | Mean | 3.2 × 104 | 4.9 × 102 | 1.4 × 100 | 1.2 × 10−1 | 6.0 × 10−3 |

| SD | 1.3 × 104 | 1.2 × 102 | 6.8 × 10−1 | 5.9 × 10−2 | 4.2 × 10−3 | |

| Max | 9.7 × 104 | 9.2 × 102 | 6.8 × 100 | 7.9 × 10−1 | 4.4 × 10−2 | |

| Post-processing 9 ± 2.63 min | Mean | 6.4 × 104 | 1.4 × 103 | 8.4 × 101 | 1.3 × 101 | 5.7 × 10−1 |

| SD | 1.0 × 104 | 5.7 × 102 | 4.6 × 101 | 8.4 × 100 | 4.3 × 10−1 | |

| Max | 1.3 × 105 | 3.7 × 103 | 3.3 × 102 | 5.8 × 101 | 3.0 × 100 | |

| Phase Duration | Particle Size Range | |||||

|---|---|---|---|---|---|---|

| 0.02–1 µm * | 0.25–1 µm | 1–4 µm | 4–10 µm | >10 µm | ||

| Background | Mean | 4.7 × 103 | 4.5 × 102 | 1.9 × 100 | 1.5 × 10−1 | 7.1 × 10−3 |

| SD | 4.0 × 102 | 6.0 × 100 | 1.5 × 10−1 | 2.7 × 10−2 | 5.4 × 10−3 | |

| Max | 5.4 × 103 | 4.6 × 102 | 2.1 × 100 | 2.0 × 10−1 | 2.0 × 10−2 | |

| Pre-processing 25 ± 15.49 min | Mean | 7.7 × 103 | 5.5 × 102 | 1.9 × 100 | 3.0 × 10−1 | 1.0 × 10−1 |

| SD | 8.6 × 102 | 8.0 × 101 | 1.5 × 100 | 6.0 × 10−1 | 4.1 × 10−1 | |

| Max | 1.4 × 104 | 1.5 × 103 | 2.0 × 101 | 8.2 × 100 | 5.9 × 100 | |

| Processing 32 ± 0.94 min | Mean | 5.9 × 104 | 7.0 × 102 | 2.3 × 101 | 1.4 × 101 | 8.3 × 100 |

| SD | 2.2 × 104 | 1.5 × 102 | 3.0 × 101 | 2.0 × 101 | 1.2 × 101 | |

| Max | 1.7 × 105 | 1.4 × 103 | 2.2 × 102 | 1.5 × 102 | 1.1 × 102 | |

| Post-processing 9 ± 2.63 min | Mean | 1.3 × 104 | 9.1 × 102 | 2.8 × 101 | 4.0 × 100 | 1.7 × 10−1 |

| SD | 1.3 × 103 | 4.0 × 102 | 3.2 × 101 | 4.0 × 100 | 1.7 × 10−1 | |

| Max | 1.6 × 104 | 2.4 × 103 | 1.6 × 102 | 1.7 × 101 | 9.6 × 10−1 | |

| Metal | TWA (µg/m3) | Inhalable Fraction TWA OEL(µg/m3) | ||||

|---|---|---|---|---|---|---|

| LENS | LMD | |||||

| Al | Aluminium | 0.0021 | ±0.0019 * | 0.0075 | ±0.0075 | - |

| Co | Cobalt | 0.0025 | ±0.0023 * | 0.0009 | ±0.0000 * | 40.0000 |

| Cr | Chromium | 0.0016 | ±0.0013 | 0.0007 | ±0.0001 | 1000.0000 |

| Cr(VI) | Hexavalent chromium | 0.0156 | ±0.0157 * | 0.0002 | ±0.0000 * | 0.4000 |

| Cu | Copper | 0.0019 | ±0.0018 | 0.0011 | ±0.0005 | 2000.0000 |

| Fe | Iron | 0.0221 | ±0.0204 | 0.0066 | ±0.0001 | 10,000.0000 |

| Mn | Manganese | 0.0021 | ±0.0019 * | 0.0007 | ±0.0000 * | - |

| Mo | Molybdenum | 0.0014 | ±0.0011 | 0.0007 | ±0.0000 * | 10,000.0000 |

| Ni | Nickel | 0.0018 | ±0.0016 | 0.0017 | ±0.0007 | 1000.0000 |

| Pb | Lead | 0.0020 | ±0.0019 | 0.0230 | ±0.0315 | 150.0000 |

| Ti | Titanium | 0.0043 | ±0.0051 | 0.0023 | ±0.0000 | 10,000.0000 |

| Zn | Zinc | 0.0041 | ±0.0038 * | 0.0048 | ±0.0042 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

van Ree, M.; du Preez, S.; du Plessis, J.L. Emissions and Exposures Associated with the Use of an Inconel Powder during Directed Energy Deposition Additive Manufacturing. Int. J. Environ. Res. Public Health 2023, 20, 6206. https://doi.org/10.3390/ijerph20136206

van Ree M, du Preez S, du Plessis JL. Emissions and Exposures Associated with the Use of an Inconel Powder during Directed Energy Deposition Additive Manufacturing. International Journal of Environmental Research and Public Health. 2023; 20(13):6206. https://doi.org/10.3390/ijerph20136206

Chicago/Turabian Stylevan Ree, Marelizé, Sonette du Preez, and Johan L. du Plessis. 2023. "Emissions and Exposures Associated with the Use of an Inconel Powder during Directed Energy Deposition Additive Manufacturing" International Journal of Environmental Research and Public Health 20, no. 13: 6206. https://doi.org/10.3390/ijerph20136206

APA Stylevan Ree, M., du Preez, S., & du Plessis, J. L. (2023). Emissions and Exposures Associated with the Use of an Inconel Powder during Directed Energy Deposition Additive Manufacturing. International Journal of Environmental Research and Public Health, 20(13), 6206. https://doi.org/10.3390/ijerph20136206